Page 1

Service Instructions

Important Safety

Information

BEFORE INSTALLING

OR OPERATING THIS

™

3M

Water Activated

Tape Dispenser -

Manual Version

W100

EQUIPMENT

Read, understand, and

follow all safety and

operating instructions.

Spare Parts

It is recommended you

immediately order the

spare parts listed in the

Serial No.

For reference, record dispenser serial number here.

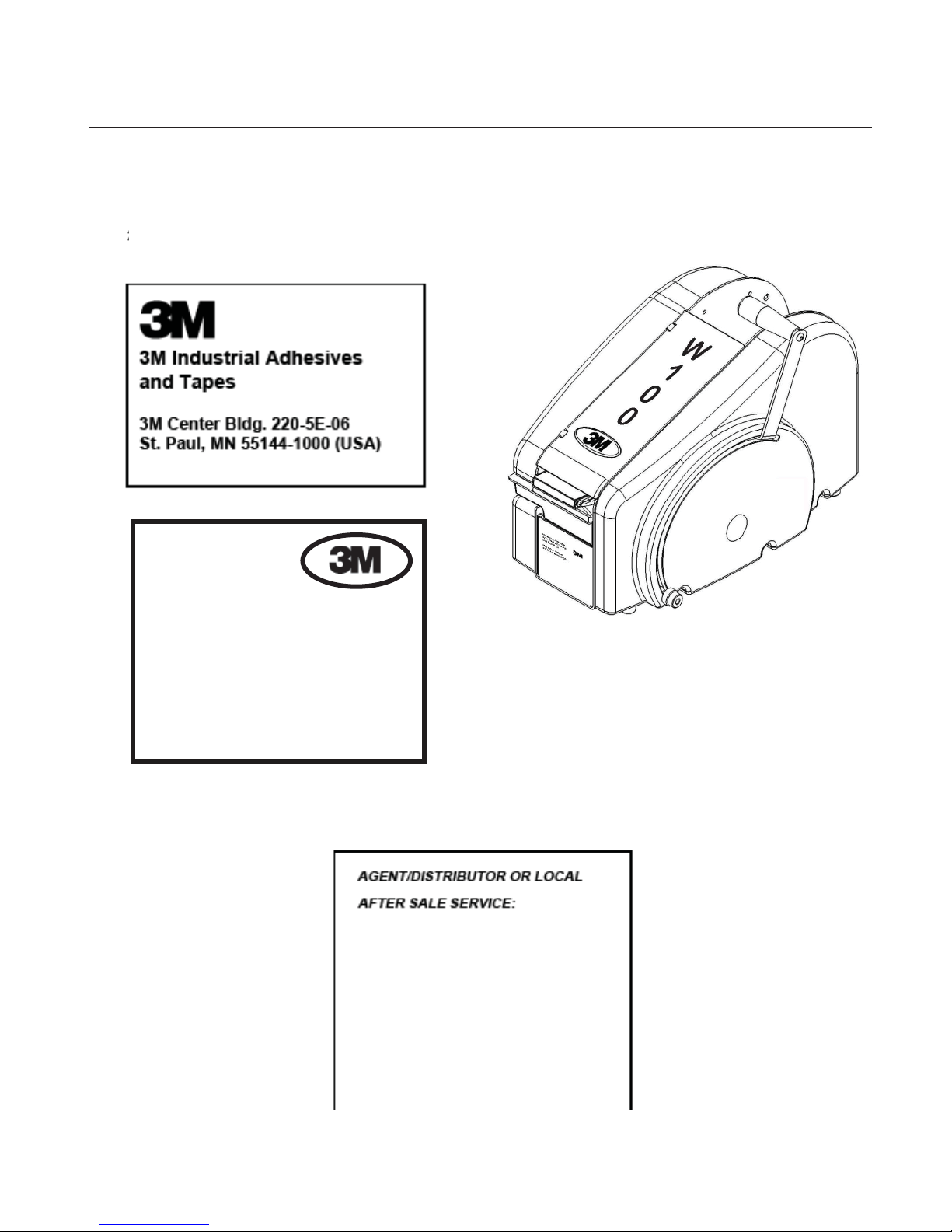

3M Industrial Adhesives and Tapes

3M Center, Building 220-5E-06

St. Paul, MN 55144-1000

"Spare Parts/Service

Information" section.

These parts are expected

to wear through normal

use, and should be kept

on hand to minimize

production delays.

3M™ is a Trademark

of 3M, St. Paul, MN 55144-1000

Printed in U.S.A.

1

© 3M 2011 44-0009-2107-0 (A102011-NA-C)

Page 2

This instruction manual covers safety aspects,

handling and transport, storage, unpacking,

preparation, installation, operation, adjustments,

maintenance, troubleshooting, repair work and

servicing plus parts list of the 3MTM Water Activated

Tape Dispenser (Manual Version), Type 11100.

3M Industrial Adhesives and Tapes

3M Center, Building 220-5E-06

St. Paul, MN 55144-1000

Edition October 2011

Copyright 3M 2011 All rights reserved

The manufacturer reserves the right to change

the product at any time without notice.

i

2

Page 3

Replacement Parts and Service Information

To Our Customers:

®

This is the 3M™ / Scotch

equipment you ordered. It has been set up and tested in the factory with

Scotch® tapes. If technical assistance or replacement parts are needed, call:

Help line:

1-800-328-1390

Spare Parts:

1-800-344-9883

3M Tape Dispenser Parts

241 Venture Drive

Amery, WI 54001-1325:

Included with each dispenser is an Instructions and Parts List manual.

Replacement Parts and Additional Manuals

Order parts by part number, part description, and quantity required.

When ordering parts or additional manuals, include model/dispenser name,

dispenser type, and serial number that are located on the identifi cation plate

(For example: Water Activated Tape Dispenser (manual version) - Type 11100 -

Serial Number 13282).

Identification Plate

MANUAL WATER

ACTIVATED TAPE

DISPENSER

MODEL: W100

SERIAL NUMBER:

3M Industrial Adhesives and Tapes

3M Center, Building 220-5E-06

St. Paul, MN 55144-1000

3M™ is a Trademark of

3M, St. Paul, MN 55144-1000

3

Printed in U.S.A.

ii

Page 4

This Page is Blank

4

Page 5

Replacement Parts And Service Information

To Our Customers:

This is the 3M™ equipment you ordered. It has been set up

and tested in the factory. If any problems occur when operating this equipment and you desire a

service call or phone consultation, call, write, or fax the appropriate number listed below.

Included with each dispenser is an Instructions and Parts List manual.

SERVICE, REPLACEMENT PARTS, AND ADDITIONAL MANUALS

AVAILABLE DIRECT FROM:

Order parts by part number, part description, and quantity required. Also, when ordering parts or

additional manuals, include model/dispenser name, dispenser type, and serial number that are

located on the identifi cation plate.

3M Industrial Adhesives and Tapes

3M Center, Building 220-5E-06

St. Paul, MN 55144-1000

3M™ and Scotch™ are Trademarks of

3M, St. Paul, MN 55144-1000

Printed in U.S.A.

iii

Page 6

This Page is Blank

6

Page 7

TABLE OF CONTENTS - Water Activated Tape Dispenser (manual version) - Type 11100

Instruction Manual

Water Activated Tape Dispenser (manual version) Page

Cover Page

Replacement Parts and Service Information ........................................................................ i - iii

Table of Contents ................................................................................................................. iv - vi

Acronyms and Abbreviations ................................................................................................ vii

1. Introduction

1.1 Manufacturing Specifi cations / Description / Intended Use ........................................ 1

2. General Information

2.1

General Information ..................................................................................................... 3

2.2 Data for Technical Assistance ...................................................................................... 3

2.3 Warranty / Contents ..................................................................................................... 4

3. Safety

3.1 How to read and use the Service Manual .................................................................... 5

3.2.1 Importance of the Manual

3.2.2 Manual Maintenance

3.2.3 Consulting the Manual

3.2.4 How to Update Manual

3.3 Table of Warnings ........................................................................................................ 5

3.4 Operator's Qualitifi cations ............................................................................................ 6

3.5 Number of Operators ................................................................................................... 6

3.6 Safe Use of Dispenser and defi nition of Operator's Qualifi cations ................................. .. 6

3.7 Residual Hazards ........................................................................................................ 6

3.8 Personal Safety Measures ........................................................................................... 6

3.9 Predicatable actions which are incorrect/not allowed .................................................. 6

3.10 Operator Skill Level Descriptions ................................................................................. 7

3.11 Component Locations .................................................................................................. 8

3.12 Warning Labels ............................................................................................................ 9

4. Technical Specifications

4.1 Shipping Weight ........................................................................................................... 10

4.2 Tape ............................................................................................................................. 10

4.3 Dispenser Dimensions ................................................................................................. 10

4.4 Operating Conditions ................................................................................................... 10

5. Shipment and Handling of Packed Dispenser

5.1 Shipment and Handling of Packed Dispenser .............................................................. 11

5.2 Packaging for Overseas Shipment ............................................................................... 11

5.3 Handling and Transportation of Uncrated Dispenser..................................................... 11

5.4 Storage of the Packed or Unpacked Dispenser............................................................. 11

WaterAct-M-S

iv

2011 October

Page 8

This Page is Blank

2

Page 9

TABLE OF CONTENTS (continued)

6. Installation

6.1 Operating Conditions ................................................................................................................ 12

6.2 Space Requirements for Dispenser Operation and Maintenance Work ................................... 12

6.3 Tool Kit needed for Repairs ....................................................................................................... 12

6.4 Dispenser Positioning ................................................................................................................ 12

6.5 Leveling .................................................................................................................................... 13

6.6 Loading Tape ............................................................................................................................. 13 - 14

6.7 Water Bottle Filling ................................................................................................................... 15

6.8

Brush Tank Water Level Adjusting ............................................................................................. 15

6.9 Tape Weight Adjusting .............................................................................................................. 15

7. Theory of Operation

7.1 Operating Instructions .............................................................................................................. 16

8. Safety Devices of the Dispenser

8.1 Safety Measures ...................................................................................................................... 17

8.2 Supplied with the Dispenser .................................................................................................... 17

8.3 Recommended frequency of Inspection and Maintenance Operations..................................... 17

8.4 Inspections to be performed before and after every Maintenance Operation ......................... 17

8.5 Check Effi ciency of Safety Features ........................................................................................ 17

8.6 Cleaning the Water Feed System ............................................................................................ 18

8.7 Cleaning the Cutter Assembly .................................................................................................. 18

8.8 Cleaning the Tape Path ........................................................................................................... 18

8.9 Handle ..................................................................................................................................... 19

8.10 Handle Shaft ............................................................................................................................ 19

8.11 Right Side Cover ....................................................................................................................... 20

8.12 Left Side Cover ........................................................................................................................ 20

8.13 Front Cover .............................................................................................................................. 20

8.14 Water Tank Holder ................................................................................................................... 21

8.15 Cutter Return Spring ................................................................................................................ 21

8.16 Movable Cutter Blade .............................................................................................................. 22

8.17 Fixed Blade .............................................................................................................................. 22

8.18 Cutter Arms .............................................................................................................................. 23

8.19 Pinch Roller ............................................................................................................................. 23

8.20 Top Roller ................................................................................................................................ 24

8.21 Free Spin Roller Shaft ............................................................................................................. 24

8.22 Slide Roller .............................................................................................................................. 24

8.23 Weighted Brush Cover ............................................................................................................. 25

8.24 Brush ....................................................................................................................................... 25

8.25 Tape Channel Plate ................................................................................................................. 26

8.26 Tape Basket / Motor Cover ...................................................................................................... 26

8.27 Tape Guide Assembly .............................................................................................................. 27

8.28 Feed Wheel ............................................................................................................................. 27

8.29 Idler Gear ................................................................................................................................. 27

8.30 Drive Gear with Springs and Clutch Assembly ......................................................................... 28

8.31 Separating/Re-assembling Drive Gear with Springs and Clutch Assembly ............................. 28

8.32 Gear Box / Motor Mount .......................................................................................................... 29

8.33 Ramp ....................................................................................................................................... 29

8.34 List of Maintenance Operations ............................................................................................... 30

8.35 Troubleshooting Guide ............................................................................................................ 31

WaterAct-M-S

(continued on next page)

v

2011 October

Page 10

This Page is Blank

4

Page 11

TABLE OF CONTENTS (continued)

9. Additional Instructions

9.1 Information for Disposal of Dispenser........................................................................................ 32

9.2 Emergency Procedures ........................................................................................................... 32

10. Enclosures / Special Information

10.1 Statement of Conformity ........................................................................................................... 32

10.2 Emissions of Radiation, Gas Vapor, and Dust .......................................................................... 32

10.3 Emission of Hazardous Substances.......................................................................................... 32

10.4 Electric Tests ............................................................................................................................ 32

11. Technical Documentation and Information

11.1 Schematics .............................................................................................................................. 33

11.2 Options and Accessories .......................................................................................................... 34

Replacement Parts and Service Information ................................................................................... 35

Replacement Parts – Illustrations and Parts Lists Information ........................................................ 36

12. Parts Lists and Illustrations

Replacement Parts – Illustrations and Parts Lists ........................................................................... 37 - End of Manual

WaterAct-M-S

5

vi

2011 October

Page 12

ABBREVIATIONS AND ACRONYMS

LIST OF ABBREVIATIONS, ACRONYMS

3M - Trademark of 3M St. Paul, MN 55144-1000

Scotch - Trademark of 3M St. Paul, MN 55144-1000

Drw. - drawing

Ex. - for example

Fig. - exploded view fi gure no. (spare parts)

Figure - Illustration

Max. - maximum

Min. - minimum

Nr. - number

N/A - not applicable

OFF - dispenser not operating

ON - dispenser operating

PLC - Programmable Logic Control

PP - Polypropylene

PTFE - Polytetrafl ourethelene

PU / PU-Foam - Polyurethane Foam

PVC - Poly-vinyl chloride

W - Width

H - Height

L - Length

WaterAct-M-S

vii

2011 October

6

Page 13

1-Instructions

1.1 Description / Intended Use

Congratulations on the purchase of your new water activated gummed tape dispenser (manual versiont). We are

confi dent you will be very pleased with the operation and performance of this durable, quality built dispenser for

many years to come.

The dispenser allows you to dispense gummed tape quietly, quickly, and accurately for a

variety of uses.

3MTM Water Activated Tape Dispenser (manual version), Type 11100

WaterAct-M-S

1

2011 October

Page 14

This Page is Blank

2

2

Page 15

2-GENERAL INFORMATION

2.1 Data Identifying Manufacturer and Dispenser

MANUAL WATER

ACTIVATED TAPE

DISPENSER

MODEL: W100

SERIAL NUMBER:

2.2 Data for Technical Assistance and Service

For Commercial Use Only

WaterAct-M-S

3

2011 October

Page 16

2-GENERAL INFORMATION (continued)

Equipment Warranty and Limited Remedy: THE FOLLOWING WARRANTY IS MADE IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED T O, ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE AND ANY IMPLIED WARRANTY ARISING

OUT OF A COURSE OF DEALING, CUSTOM OR USAGE OF TRADE:

2.2 Warranty

3M sells its 3M™ Water Activated Tape Dispenser, Type 11100 with the following warranties:

1. All 3M™ Water Activated Tape Dispenser parts will be free from defects for ninety (90)

days after delivery.

If any part is defective within this warranty period, your exclusive remedy and 3M’s and seller’s sole obligation shall

be, at 3M’s option, to repair or replace the part. 3M must receive actual notice of any alleged defect within a

reasonable time after it is discovered, but in no event shall 3M have any obligation under this warranty unless it

receives such notice within fi ve (5) business days after the expiration of the warranty period. All notices required

hereunder shall be given to 3M solely through the 3M™ Help line. To be entitled to repair or replacement as provided under this warranty, the part must be returned as directed by 3M to its factory or other authorized service station

designated by 3M. If 3M is unable to repair or replace the part within a reasonable time after receipt thereof, 3M, at

its option, will replace the equipment or refund the purchase price. 3M shall have no obligation to provide or pay for

the labor required to remove any part or equipment or to install the repaired or replacement part or equipment. 3M

shall have no obligation to repair or replace those parts failing due to normal wear, inadequate or improper maintenance, inadequate cleaning, non-lubrication, improper operating environment, improper utilities, operator error or

misuse, alteration or modifi cation, mishandling, lack of reasonable care, or due to any accidental cause.

Limitation of Liability: Except where prohibited by law, 3M and seller will not be liable for any loss or damage arising

from this 3M equipment, whether direct, indirect, special, incidental, or consequential, regardless of the legal theory

asserted, including breach of warranty, breach of contract, negligence, or strict liability.

Contents, Water Activated Tape Dispenser (manual version)

(1) Water Activated Tape Dispenser (manual version), Type 11100

(1) Operator's Manual

®

Scotch

, and 3MTM are Trademarks of 3M, St. Paul, Minnesota 55144-1000

WaterAct-M-S

4

2011 October

Page 17

1-SAFETY

3.1 How to Read and Use the Service Manual

This instruction manual covers safety aspects,

handling and transport, storage, unpacking, preparation, installation, operation, set-up and adjustments,

technical and manufacturing specifi cations, mainte-

nance, troubleshooting, repair work and servicing,

electric diagrams, warranty information, disposal, a

defi nition of symbols, plus a parts list of the 3M Wa-

ter Activated Tape Dispenser (manual version) 3M

Industrial Adhesives and Tapes Division 3M Center,

Bldg. 220-5E-06 St. Paul, MN 55144-1000 (USA) /

Edition October 2011 / Copyright 3M 2011 / All rights

reserved The manufacturer reserves the right to

change the product at any time without notice -

Publication © 3M 2011 44-0009-2107-0.

3.2.1 Importance of the Manual

The manual is an important part of the dispenser; all

information contained herein is intended to enable

the equipment to be maintained in perfect condition

and operated safely. Ensure that the manual is available to all operators of this equipment and is kept

up to date with all subsequent amendments. Should

the equipment be sold or disposed of, please ensure

that the manual is passed on. Electrical and pneumatic diagrams are included in the manual. Equipment using PLC controls and/or electronic components will include relevant schematics or programs in

the enclosure and in addition, the relevant documentation will be delivered separately.

3.2.2 Manual Maintenance

Keep the manual in a clean and dry place near the

dispenser. Do not remove, tear, or rewrite parts of

the manual for any reason. Use the manual without

damaging it. If the manual has been lost or damaged, ask your after sale service for a new copy.

3.2.3 Consulting the Manual

3.2.4 How to Update the Manual in Case of

Modifications to the Dispenser

Modifi cations to the dispenser are subject to manufac-

turer’s internal procedures. The user receives a complete and up-to-date copy of the manual together with

the dispenser. Afterwards the user may receive pages

or parts of the manual which contain amendments or

improvements made after its fi rst publication. The user

must use them to update this manual.

3.3 Table of Warnings

WARNING

• To reduce the risk associated with

mechanical hazards:

− Read, understand, and follow all safety and

operating instructions before operating or

servicing the tape dispenser.

− Allow only properly trained and qualifi ed

personnel to operate and service this

equipment.

CAUTION

• To reduce the risk associated with

sharp blade hazards:

− Keep hands and fi ngers away from

tape cutoff blades. The blades are

extremely sharp.

WARNING

Sharp Blade

The manual is composed of:

- Pages which identify the document and the

dispenser

- Index of the subjects

- Instructions and notes on the dispenser

- Enclosures, drawings and diagrams

- Spare parts (last section)

All pages and diagrams are numbered. The spare

parts lists are identifi ed by the fi gure identifi cation

number. All the notes on safety measures or

possible dangers are identifi ed by the symbol:

WaterAct-M-S

Figure 3-1

WARNING

• To reduce the risk associated with

muscle strain:

− Use proper body mechanics when

working on or moving the dispenser.

2011 October

5

Page 18

3-SAFETY (continued)

3.4 Operator's Qualifications

- Dispenser Operator

- Mechanical Technician

- Manufacturer’s Technician/Specialist

(See Section 3)

3.5 Number of Operators

The operations described below have been analyzed

by the manufacturer; the recommended number of

operators for each operation provides the best and

safest work performance.

WARNING

• To reduce the risk associated with

mechanical hazards:

− Read, understand, and follow all safety and

operating instructions before operating or

servicing the Tape Dispenser.

− Allow only properly trained and qualifi ed

personnel to operate and service this

equipment.

Note: A smaller or greater number of operators

could be unsafe.

3.6 Instructions for a Safe Use of the Dispenser /

Definition of Operator's Qualifications

Only persons who have the skills described in the

skill levels section should be allowed to work on the

dispenser. It is the responsibility of the user to appoint the operators having the appropriate skill level

and the appropriate training for each category of job

(See Section 3).

3.7 Residual Hazards

The Water Activated Tape Dispenser (manual version) incorporates various safety protections which

should never be removed or disabled (notwithstanding the safety precautions conceived by the designers of the dispenser).

3.8 Personal Safety Measures

Safety glasses, safety gloves, safety helmet, safety

shoes, air fi lters, ear muffs - None is required except

when recommended by the user.

3.9 Predictable Actions which are Incorrect and

Not Allowed

- Never work without the safety protections.

- Only authorised personnel should be allowed to

carry out the adjustments, repairs or maintenance

which require operation with reduced safety

protections. During such operations, access to the

dispenser must be restricted. When the work is

fi nished, the safety protections must immediately be

reactivated.

- Do not modify the dispenser or any part of it. The

manufacturer will not be responsible for any

modifi cations.

Follow carefully the installation instructions of this

manual.

WaterAct-M-S

6

2011 October

Page 19

3-SAFETY (continued)

WARNING

• To reduce the risk associated with

mechanical hazards:

− Allow only properly trained and qualifi ed

personnel to operate or service this

equipment

Skill 2: Mechanical Maintenance Technician

This operator is trained to use the dispenser as the

Dispenser OPERATOR and in addition is able to work

with the safety protection disconnected, to check and

adjust mechanical parts, to carry out maintenance operations and repair the dispenser.

3.10 Operator Skill Level Descriptions

Skill 1: Dispenser Operator

This operator is trained to use the dispenser through

any controls, to load and un-load the Dispenser

Tape.

Important: The factory manager should ensure that

the operator has been properly trained on all the

functions of the dispenser before starting work.

Required Operator Skill Levels

Operation

Installation and set up of the

dispenser. N/A for this dispenser (idle)

Replacement of the Dispenser

Tape.

N/A for this dispenser (idle) 1 1

Skill 3: Specialist From the Manufacturer

Skilled operator sent by the manufacturer or its

agent to perform complex repairs or modifi cations,

when agreed with the customer.

State of the

Dispenser

Opera-

tor's

Skill

1 or 2 1

Number

of Op-

erators

Loading, wrapping and

unloading.

Ordinary maintenance. N/A for this dispenser (idle) 2 1

Extraordinary maintenance

(mechanical).

Extraordinary maintenance N/A for this dispenser (idle) 3 1

Extraordinary maintenance

(electrical).

WaterAct-M-S

N/A for this dispenser (idle) 1 1

N/A for this dispenser (idle) 2 1

41

Running with safety protections

disabled.

3a or 4 1

2011 October

7

Page 20

3-SAFETY (continued)

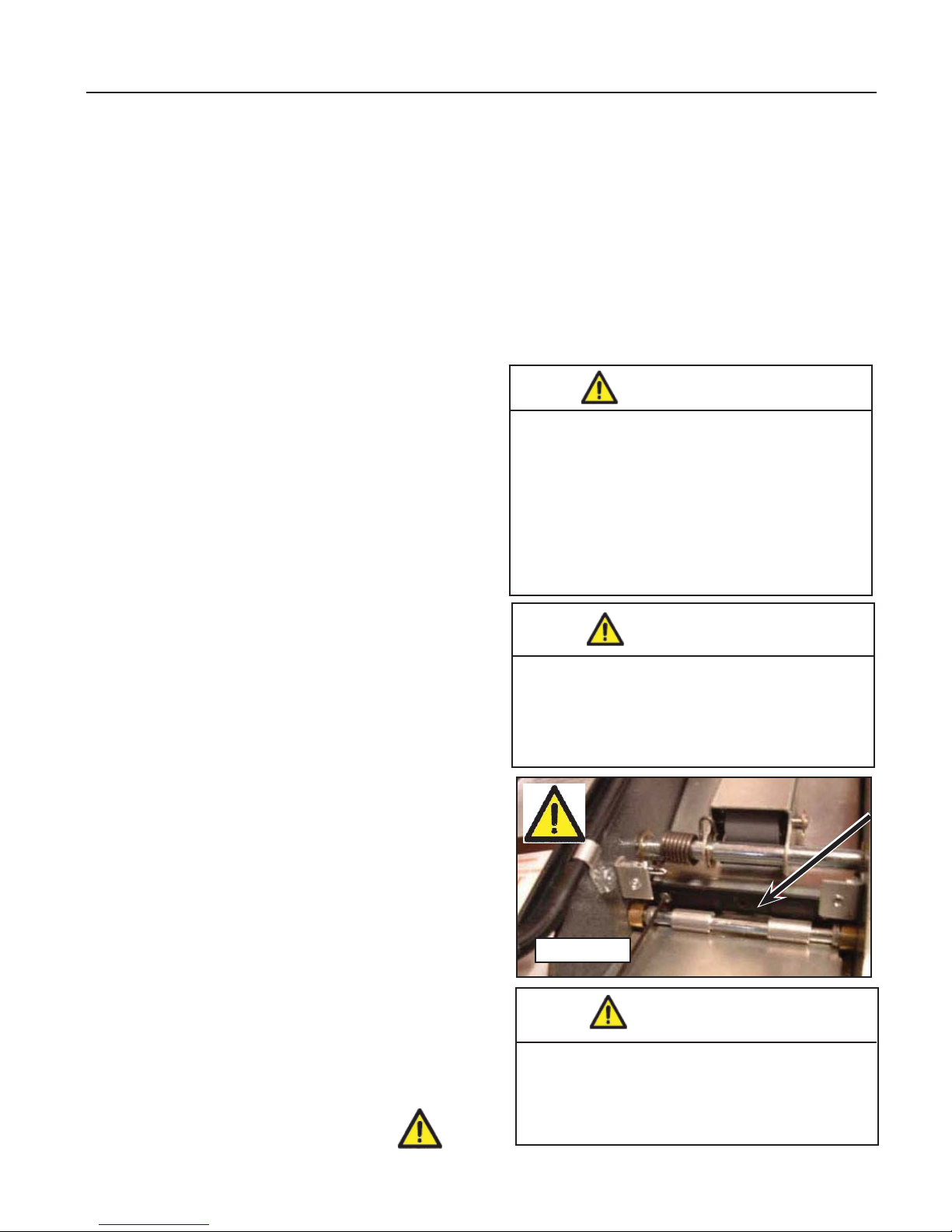

3.11 Component Locations

Refer to Figure 3-2 below to acquaint yourself with the various components and controls of the Tape Dispenser.

Tape Mount

Applicator

Handle

Top

Cover

Water

Tank

Brush

Assembly

Figure 3-2—Water Activated Tape Dispenser Components (manual version)

WaterAct-M-S

8

2011 October

Page 21

3-SAFETY (continued)

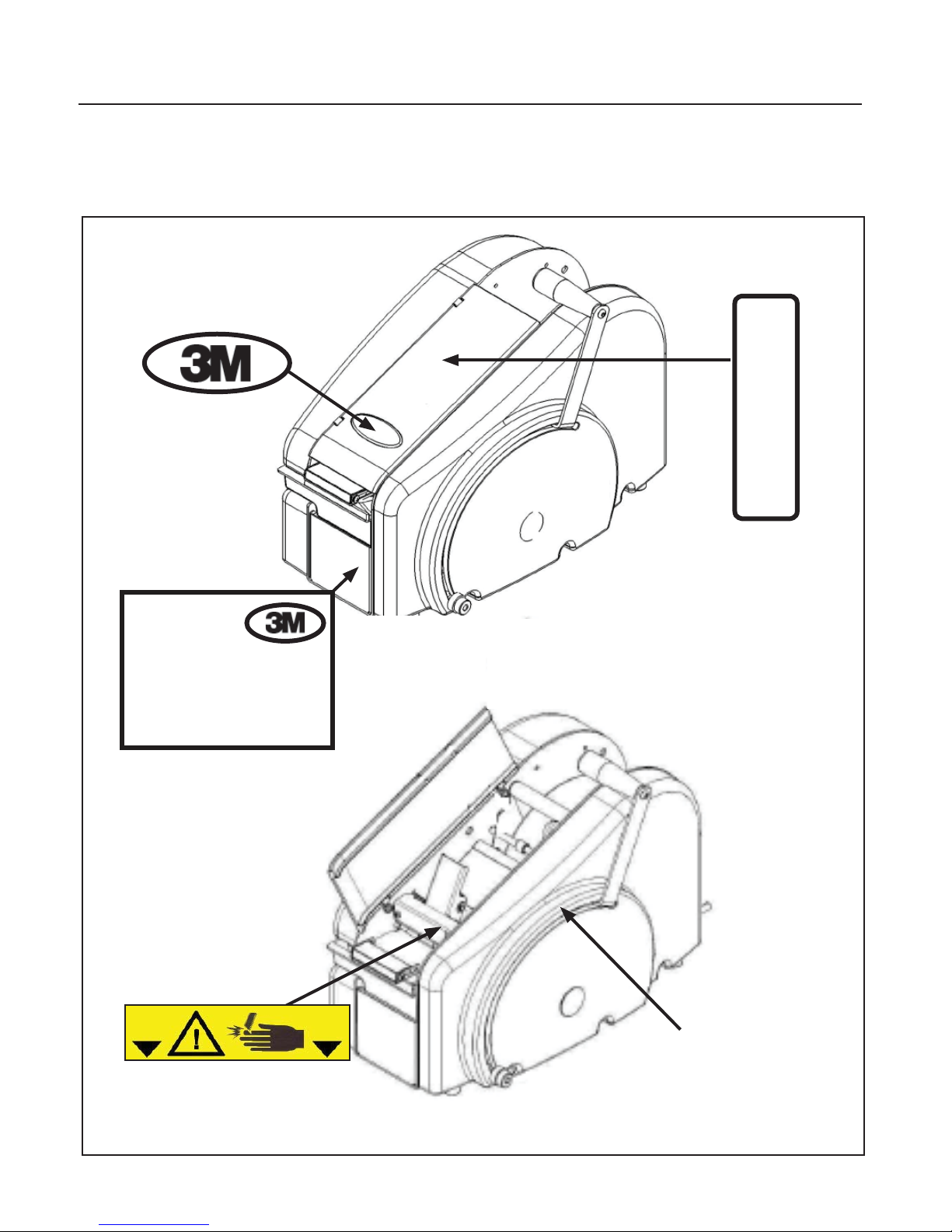

3.12 Safety Warning Labels

If the following safety labels are damaged or destroyed, they must be replaced to ensure operator safety.

Replacement part numbers for individual labels are shown in Figure 3-3.

W

1

78-8137-5487-2

0

0

78-8137-5488-0

MANUAL WATER

ACTIVATED TAPE

DISPENSER

MODEL: W100

SERIAL NUMBER:

78-8137-5483-1

78-8137-5494-8

Label Tape Length

78-8137-5490-6

Figure 3-3—Replacement Labels and 3MTM Part Numbers

WaterAct-M-S

9

2011 October

Page 22

4-SPECIFICATIONS

10.5 in

26.6 cm

13.7 in

34.8 cm

18.9 in

Figure 4-1

48.0 cm

1. Shipping Weight:

Unboxed: 25 pounds (11.3 kg)

Boxed: 31 pounds (14.1 kg)

2. Tape:

Dry gummed tape – paper or reinforced – between 1 to 3 inches (25.4 to 76.2 mm) wide, up to 1000 feet

(304.8 m) long and 9 inches (228.6 mm) max roll diameter

3. Dispenser Dimensions:

(See Figure 4-1)

4. Operating Conditions:

Use in dry, relatively clean environments at 5 oC / 40 oC [40 oF / 105 oF].

Note: Dispenser should not be washed down or subjected to conditions causing moisture condensation on

component

WaterAct-M-S

10

(Specifi cations continued on next page.)

2011 October

Page 23

5-SHIPMENT-HANDLING-STORAGE, TRANSPORT

5.1 Shipment and Handling of Packed Dispenser

The packaging is suitable for travel by land, air and

sea freight.

See Specifi cations.

5.2 Handling and Transportation of Uncrated

Dispenser

Use proper body mechanics when moving the dispenser

(Figure 5-1).

5.3 Storage of the Packed or Unpacked Dispenser

If the dispenser is not used for a long period,

please take the following precautions:

- Store the dispenser in a dry and clean place.

(Never move the dispenser without packaging)

- If the dispenser is unpacked it is necessary to

protect it from dust.

- Do not stack anything over the dispenser.

Figure 5-1

WaterAct-M-S

11

2011 October

Page 24

6-INSTALLATION

6.1 Operating Conditions

See Specifi cations.

6.2 Space Requirements for Dispenser Operation

and Maintenance Work

N/A for this dispenser.

Generally, for ease of operation, allow spacing around

dispenser as needed.

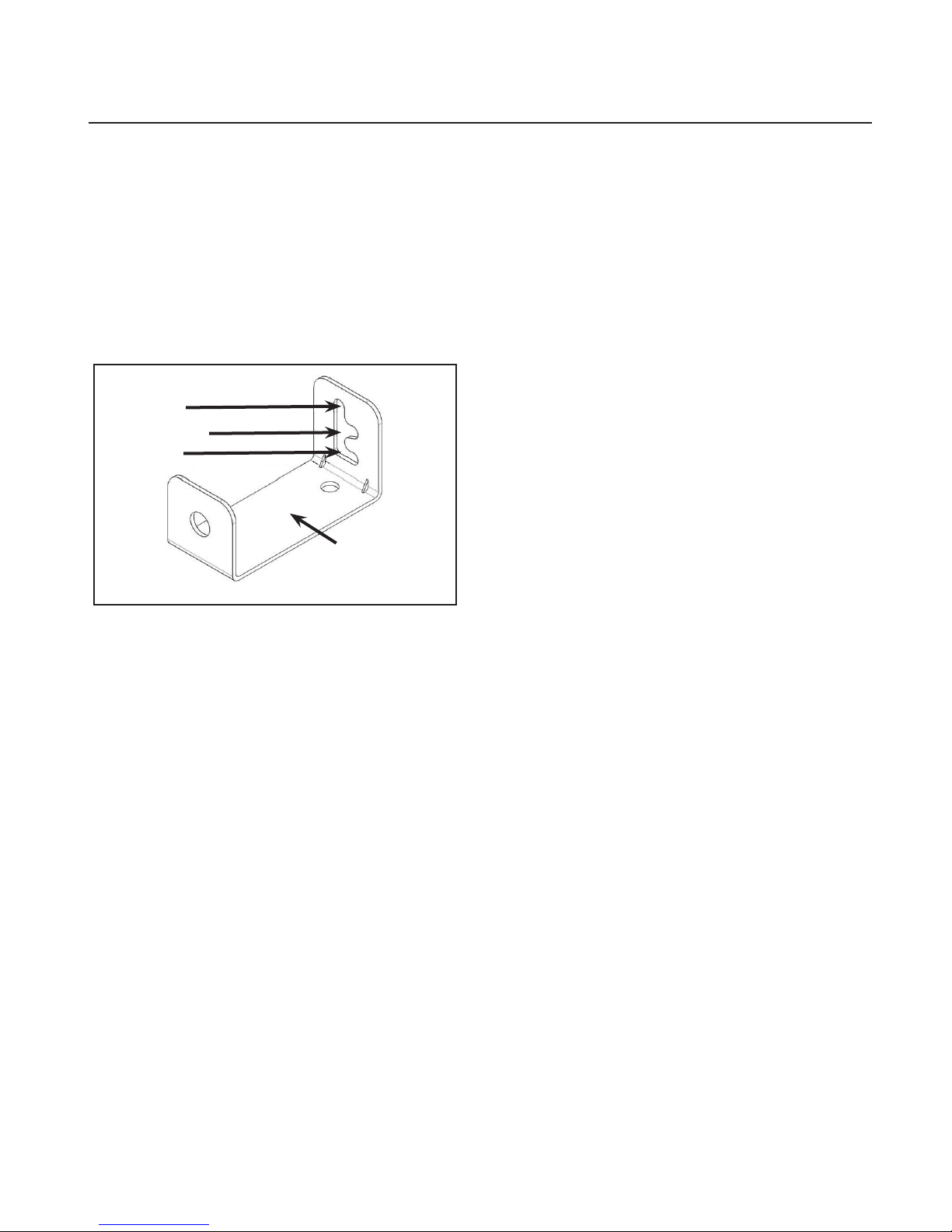

6.3 Tools needed for Repairs (Figure 6-1)

Important! Before attempting repairs, loosen foot

channels (Figure 6-2). Loosening foot

channels allow the chassis to "relax" while

facilitating ease of repairs. Failure to

loosen foot channels may result in diffi culties

with repairs and reassembling dispenser.

WARNING

• To reduce the risk associated with

muscle strain:

− Use appropriate body mechanics when

lifting or repositioning this equipment.

Note: When attempting repairs to sheet metal,

do not overtighten screws.

Below is a list of the tools that are recommended for

disassembly and assembly of dispenser.

Needle nose pliers

Vice grips

3/8” fl at head screw driver

#2 4” Phillips head screw driver

#2 8” Phillips head screw driver

5/16" wrench or socket

3/8” wrench or socket

7/16” wrench or socket

1/2” wrench or socket

15/16" socket

3/32” long hex key

5/64” hex key

1/8” hex key

3/16” hex key

1/4” hex key

Loosen both

Screws on

Bottom of

Chassis

WaterAct-M-S

Figure 6-2

Figure 6-1

6.4 Dispenser Positioning

N/A for this dispenser.

Use proper mechanics in lifting and positioning

dispenser. Place in an elevated and a comfortable

operating position.

WARNING

• To reduce the risk associated with

a mechanical hazard:

− Read, understand, and follow all safety and

operating instructions before operating or

servicing the Tape Dispenser.

12

2011 October

Page 25

6-INSTALLATION (continued)

6.5

Leveling

Set the platform on a fl at surface which allows for even

weight distribution (Figure 6-4).

6.6 Loading Tape (Figures 6-5 and 6-6)

1. Open top cover of dispenser.

2. Using tape guide turnbuckle, adjust width of tape guides

to accommodate the tape.

3. Place tape roll in dispenser.

4. Using tape guide turnbuckle, re-adjust tape guides

leaving an 1/8” clearance on both sides of the tape.

5. Remove pressure plate from dispenser.

6. Feed tape (gummed side down) over top roller, under

tape guide fl aps, and under pinch roller (Figure 6-5).

Note: For Tape that is "gummed side out" (typically used

in Europe), load tape roll opposite as shown while

routing with gummed side (over the top roller).

7. Place pressure plate over tape and release pinch roller.

The pressure plate must be loaded so it touches the

pinch roller shaft and the arrow on the pressure plate

points toward front of dispenser.

8. Close top cover.

WARNING

• To reduce the risk associated with

muscle strain:

− Use appropriate body mechanics when

lifting or repositioning this equipment.

Figure 6-4

Pressure Plate

Top Cover

Tape Guide

Pinch Roller

Top

Roller

Tape Guide

Turnbuckle

Length Scale

WaterAct-M-S

Mechanical Stop

13

Figure 6-5

2011 October

Page 26

6 - INSTALLATION (continued)

Pinch Roller

Shaft

Cutter

Assembly

Pinch

Roller

Pressure

Plate

Top Roller

Tape

(standard threading)

Tape Roll

(1000 ft.)

Tape

(gummed side

facing out)

Water

Bottle

Brackets

Post

Figure 6-6

Water Bottle

Duck Bill Valve

Tape Weight

Brush Tank

WaterAct-M-S

14

Figure 6-7

2011 October

Page 27

6-INSTALLATION (continued)

6.7 Water Bottle Filling (Figures 6-7 and 6-8).

1. Remove water bottle from dispenser.

2. Remove duckbill valve from water bottle.

3. Fill water bottle with clean or distilled water

(Figure 6-7).

4. Place duckbill valve back into water bottle.

5. Place water bottle back on the dispenser.

Check to be sure the post in the brush tank is

inserted through the duckbill valve

(Figure 6-7).

Low

Medium

High

Water Bottle

Bracket

Figure 6-8

6-8 Brush Tank Water Level Adjusting

(Figures 6-7 and 6-8).

1. Loosen the retaining screws on the water bottle

brackets.

2. Move the water bottle brackets to the desired

position to obtain the desired water level in the

brush tank (Both brackets should be at the

same position).

Note: Lightweight tapes would typically be set

at the low position (Figure 6-8).

3. Tighten the retaining screws on the water bottle

brackets.

6-9 Tape Weight Adjusting

(Figure 6-7)

1. Loosen retaining screw.

2. Slide tape weight forward for greater

pressure (this applies more water to tape

and is typically used on heavy weight tapes).

3. Slide tape weight back for less pressure.

(this applies less water to tape and is

typically used on lighter weight tapes).

4. Tighten retaining screw.

WaterAct-M-S

15

2011 October

Page 28

7-OPERATION

7.1 Operating Instructions

Once the dispenser has been properly set up for use, pull the operating handle to the desired length

(indicated on handle scale). Releasing the handle automatically cuts the tape.

Note: The dispenser can be set to accommodate work where a known length will be used.

The dispenser can be set to accommodate work where a known length will be used. A mechanical stop is provided on the side of the dispenser. The mechanical stop can be moved to any desired position by loosening the

knurled nut a half of a turn and sliding the nut up or down within the slot. When placed in the desired position,

re-tighten the knurled nut to set the desired length of tape to be dispensed.

Important: Do NOT remove the knurled nut.

WARNING

• To reduce the risk associated with a mechanical hazard:

− Read, understand, and follow all safety and operating instructions before operating or servicing the

tape dispenser.

WaterAct-M-S

16

2011 October

Page 29

8-MAINTENANCE AND REPAIRS

8.1 Safety Measures (see section 3)

The manually operated Tape Dispenser requires very

little maintenance. It is important to regularly clean the

brush tank and cutter mechanism. Be sure to also

remove any debris from the tape path.

Important! Before attempting repairs, loosen the foot

channels (See Section 6). Loosening foot

channels allow the chassis to "relax" while

facilitating ease of repairs. Failure to

loosen foot channels may result in diffi culties

making repairs and reassembling the dispenser.

8.4 Inspections to be Performed Before and

After Every Maintenance Operation

During the maintenance operation only the operator

responsible for this duty must work on the dispenser.

At the end of every maintenance operation check the

dispenser functions (See Section 8.3).

WARNING

• To reduce the risk associated with

a mechanical hazard:

− Read, understand, and follow all safety and

operating instructions before operating or

servicing the Tape Dispenser.

− Allow only properly trained and qualifi ed

personnel to operate and service this

equipment.

8.2 Supplied with the Dispenser

- Instruction and Spare Parts Manual

8.3 Recommended Frequency of Inspection and Maintenance Operations

Operation Frequency Qualif cation

Inspection safety features Daily 2

Clean the brush, Daily 1

Clean the brush tank Monthly 1

Clean the cutter mechanism As needed 1

Remove debris from the tape path As needed 1

8.5 Check Eff ciency of Safety Features

N/A

WaterAct-M-S

17

2011 October

Page 30

8-MAINTENANCE AND REPAIRS (continued)

8.6 Cleaning the Water Feed System:

1. Clean the brush by soaking it in warm soapy

water. Rinse thoroughly.

2. Clean brush tank, duckbill valve, and water bottle

with warm water.

Tape

Water

Tank

Holder

Cutter

Guard

Cleaning

Pressure

Plate

Channel

Gaps

Weight Tank

Brush Cover

8.7 Cleaning the Cutter Assembly (Figure 8-2)

1. Open top cover.

2. Remove pressure plate.

3. Remove the tape from the tape path.

4. Spray available gaps in front and behind the

cutter guard (use minimal amount of a

non-fl ammable super penetrating lubricant -

WD 40 or Industrial Silicon Spray are

recommended). Wipe off any excess.

Top

Cover

Cutter

Assembly

8.8 Cleaning the Tape Path (Figure 8-1)

1. Press power switch to OFF (I) position and unplug power cord.

2. Open top cover.

3. Remove pressure plate.

4. Remove tape from tape path.

5. Remove cutter guard.

6. To remove debris and adhesive build-up in tape path, use a moist cloth to wipe down all sheet metal

parts (tape channel, pressure plate, weighted brush tank cover, and water tank holder).

7. Using compressed air remove all debris and any visible moisture from tape path.

8. Replace cutter guard.

9. Place tape back into tape path (Refer to Tape Loading - Section 9).

10. Place pressure plate back in dispenser.

11. Close top cover.

WaterAct-M-S

18

Figure 8-1

2011 October

Page 31

8-MAINTENANCE AND REPAIRS (continued)

CAUTION

• To reduce the risk associated with

pinch hazards:

− Keep hands, hair, loose clothing, and

jewelry away from dispenser.

8.9 Handle

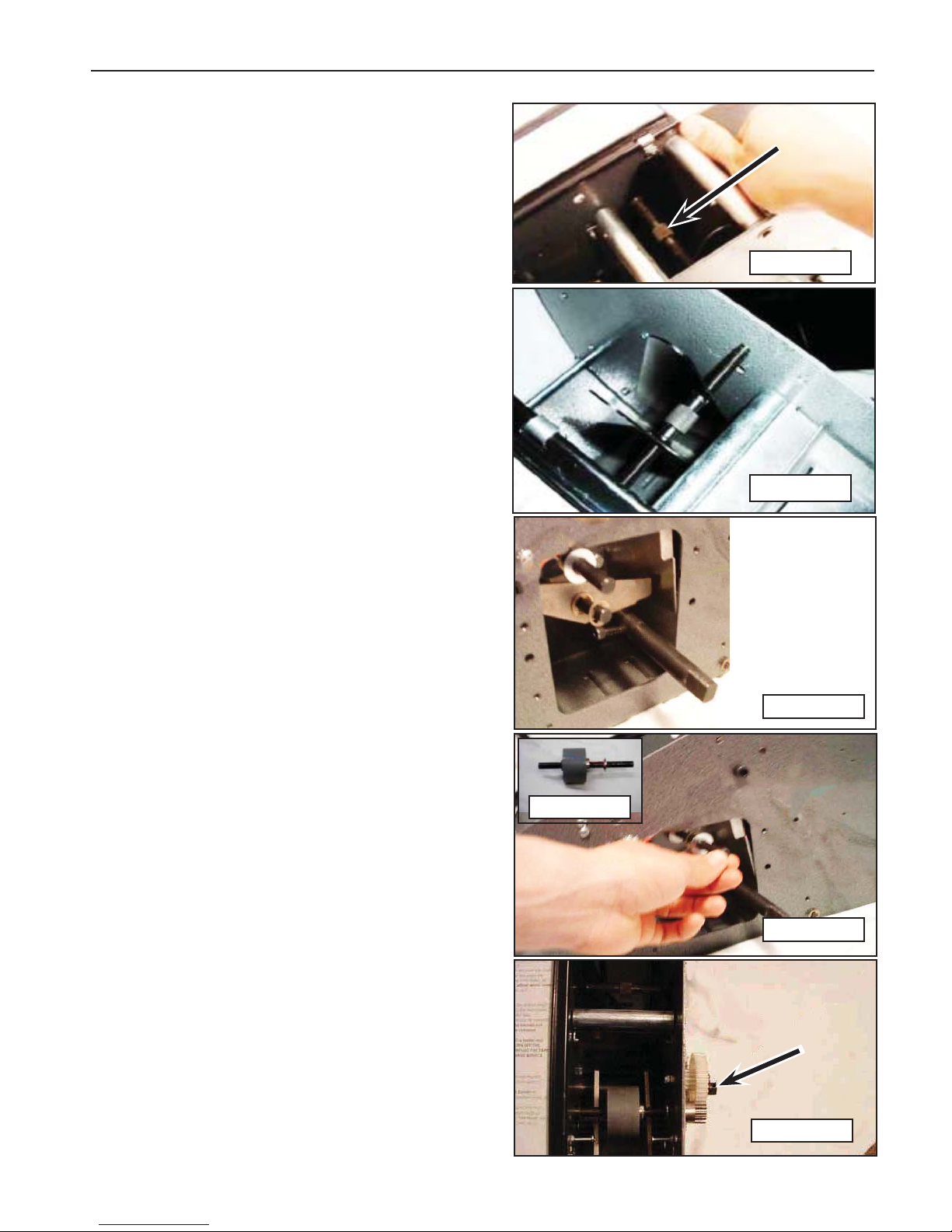

To Remove:

1. Remove handle hole plug (Figure 8-2).

2. Remove 15/16 inch nut.

3. Slide handle OFF handle shaft.

4. Rotate handle forward to about 12 inch

mark on right side cover and pull

handle gently from dispenser (Figure 8-3).

New Part Installation:

Reverse the removal procedure above.

Figure 8-2

Remove

Nut and

Slide handle

off shaft

Rotate Handle

to 12 inch

mark and

remove

Figure 8-3

8.10 Handle Shaft

To Remove:

1. Remove right side cover (See Section 8.11).

2. Remove left side cover (See Section 8.12).

3. Remove pinch roller (See Section 8.19).

4. Remove weighted brush cover

(See Section 8.23).

5. Remove tape channel plate

(See Section 8.25).

6. Remove idler gear (See Section 8.29).

7. Remove drive gear and clutch assembly

(See Section 8.30).

8. Remove cutter arm springs from screws

they are resting upon (Section 8.15).

9. Remove gearbox/motor mount

(Section 8.32).

10. Remove large e-clip from left side of

the handle shaft (Figure 8-4).

11. Remove handle shaft from the chassis and

(if needed) insert a new handle shaft into 1/2"

bearing (Figure 8-5).

Figure 8-4

E-Clip

Figure 8-5

Handle

Shaft

New Part Installation:

Reverse the removal procedure above.

WaterAct-M-S

19

2011 October

Page 32

8-MAINTENANCE AND REPAIRS (continued)

8.11 Right Side Cover

To Remove:

1. Remove the water bottle and duckbill valve.

2. Remove the water tank and brush.

3. Open the top cover (Figure 8-6).

4. Remove the handle hole plug.

5. Remove 15/16 inch nut from the handle shaft.

6. Remove three screws on inside of dispenser

(Figure 8-6).

7. Remove three screws on outside of dispenser

(Figure 8-7).

8. Slide handle to the end of handle shaft.

Slowly remove right side cover / handle.

(Figure 8-8).

9. At this point a new right side cover may

be installed.

New Part Installation:

Reverse the removal procedure above.

8.12 Left Side Cover

To Remove:

1. Remove water bottle and duckbill valve.

2. Remove water tank and brush.

3. Remove three (3) screws along bottom

edge of left side cover (Figure 8-9).

4. Slide left side cover towards bottom of

dispenser, and remove left side cover

(Figure 8-10).

New Part Installation:

Figure 8-6

Figure 8-7

Figure 8-8

Figure 8-9

Remove 3

Screws on

Inside of

Dispenser

Remove 3 Screws on

Outside of Dispenser

Remove-

Screws

Reverse the removal procedure above.

8.13 Front Cover

To Remove:

1. Remove right side cover (See Section 8.11).

2. Remove left side cover (See Section 8.12).

3. Loosen screws of the following parts: coder

bar and dead roller, brush tank holder, and

weighted brush cover shaft (See Section 8.23).

4. Remove four (4) screws from front cover.

5. Remove front cover (Figure 8-11).

6. With one hand pushing chassis slightly apart,

position new front cover.

New Part Installation:

7. Attach the screws to the front cover.

8. Tighten loosened screws (see #3).

Figure 8-10

Figure 8-11

E-Clip

Slide

Down

WaterAct-M-S

20

2011 October

Page 33

8-MAINTENANCE AND REPAIRS (continued)

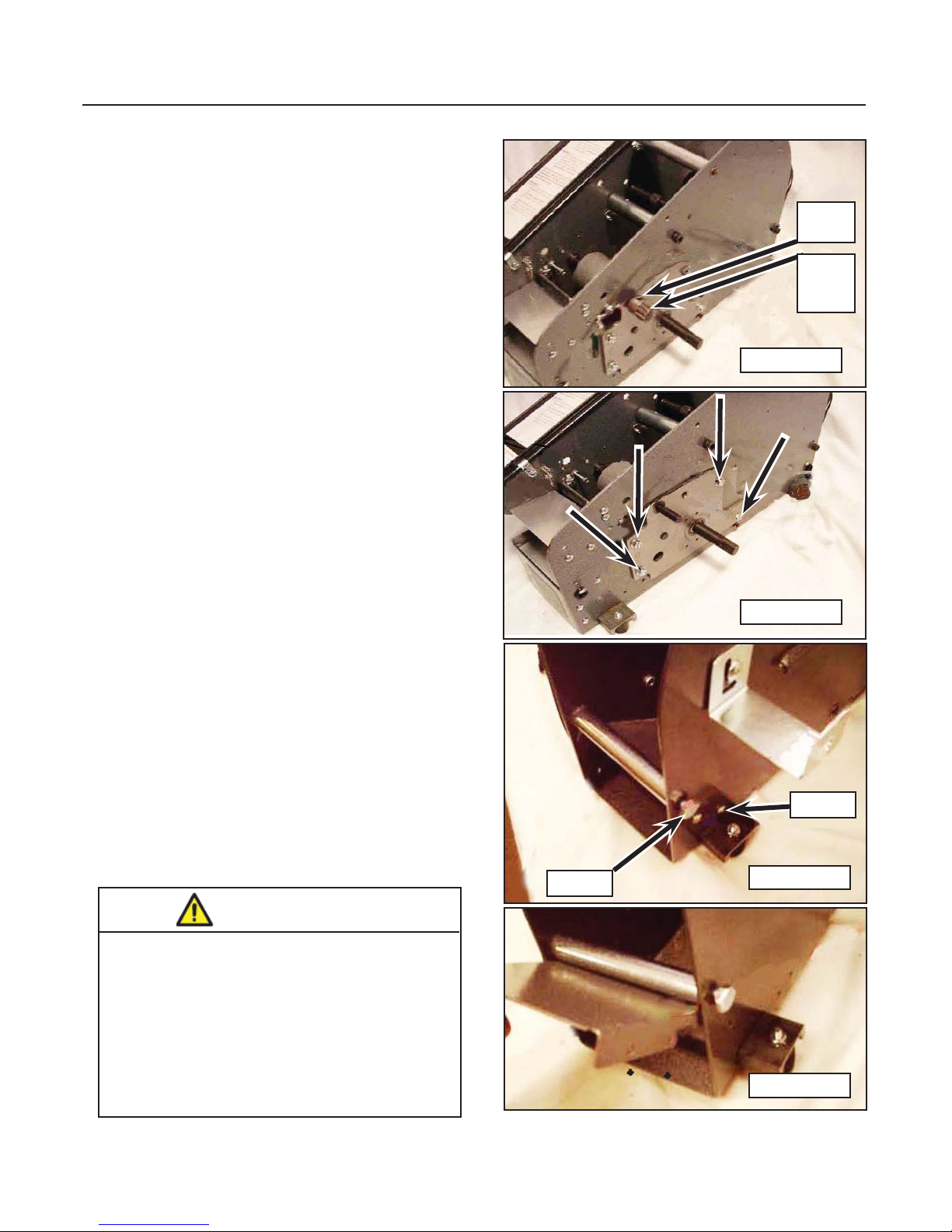

8.14 Water Tank Holder

To Remove:

1. Remove right side cover (See Section 8.11).

2. Remove left side cover (See Section 8.12).

3. Loosen screws in coder bar and dead

roller (Figure 8-12).

4. Remove our (4) screws from front cover.

5. Remove front cover (Figure 8-13).

6. Remove seven (7) screws from water

tank holder.

7. Remove water tank holder (Figure 8-14).

New Part Installation:

Reverse the removal procedure above.

WARNING

• To reduce the risk associated with

mechanical hazards:

− Read, understand, and follow all safety and

operating instructions before operating or

servicing the tape dispenser.

− Allow only properly trained and qualifi ed

personnel to operate and service this

equipment.

Figure 8-12

Figure 8-13

Figure 8-14

Figure 8-15

8.15 Cutter Return Spring

To Remove:

1. Remove right side cover (See Section 8.11).

2. Remove left side cover (See Section 8.12).

3. Remove screws from the front cover and

remove.

4. Attach a pair of vice grips to the cutter return

spring screw (Figure 8-15).

5. While holding the vice grips, remove nut on

inside of dispenser (Figure 8-16).

6. Slowly pull screw from the chassis and

release tension from cutter return

spring (Figure 8-17).

7. Remove cutter slide bolt from the handle

shaft (Figure 8-18).

New Part Installation:

Reverse the removal procedure above.

Figure 8-16

Figure 8-17

Cutter

Slide

Bolt

Figure 8-18

WaterAct-M-S

21

2011 October

Page 34

8-MAINTENANCE AND REPAIRS (continued)

8.16 Movable Cutter Blade

To Remove:

1. Remove Cutter Guard.

2. Remove right side cover (See Section 8.11).

3. Remove cutter guard clips.

4. Loosen set screw to release tension from blade

(Figures 8-19).

5. With one hand pushing down on the handle

(Figures 8-20), remove two (2) remaining

screws and lift moveable cutter blade out of

dispenser.

Important: Place a pencil or screw driver under the

blade so that the it doesn't fall into the dispenser.

6. With one hand holding new moveable cutter

blade, place new blade so two (2) outside screw

holes line up. Screw blade into place.

7. Tighten set screw so that there is a slight bend

in the movable cutter blade.

New Part Installation:

Reverse the removal procedure above.

Figure 8-19

CAUTION

• To reduce the risk associated with

sharp blade hazards:

− Keep hands and fi ngers away from

tape cutoff blades. The blades are

extremely sharp.

8.17 Fixed Blade

To Remove:

1. Loosen screw retaining the fi xed blade stop

and remove stop.

2. Remove fi xed blade retaining screw.

3. Push fi xed blade shoe toward rear of dispenser

(Figures 8-21).

4. Use a magnet, pull fi xed blade from dispenser.

(Figures 8-22).

5. Insert new fi xed blade into chassis.

Important: The blade should be resting on both

sides of the chassis.

Caution: Do not drop any components into the

dispenser.

Figure 8-20

Figure 8-21

7. Release the fi xed blade shoe.

8. Reinstall the fi xed blade retaining screw.

9. Reinstall fi xed blade stop and tighten

retaining screw.

WaterAct-M-S

22

Figure 8-22

2011 October

Page 35

8-MAINTENANCE AND REPAIRS (continued)

8.18 Cutter Arms

To Remove:

1. Remove right side cover (See Section 8.11).

2. Remove left side cover (See Section 8.12).

3. Remove pinch roller (See Section 8.19).

4. Remove weighted brush cover

(See Section 8.23).

5. Remove tape channel plate

(See Section 8.25).

6. Remove water tank holder

(See Section 8.14).

7. Remove cutter arm springs from the screws

they rest on (Figure 8-23).

8. Remove e-clips from cutter arm shaft

(Figure 8-24).

9. Remove cutter arm shaft from chassis

(Figure 8-25).

10. Remove cutter arms.

New Part Installation:

Install new part and reverse the removal

procedure above.

8.19 Pinch Roller

Cutter

Arm Springs

Figure 8-23

Figure 8-24 Figure 8-25

To Remove:

1. Remove water bottle.

2. Remove pressure plate (Figure 8-26).

3. Facing front of dispenser, pull pinch roller spring

tofront and to left of dispenser until spring is no

longer on the pinch roller (Figure 8-27).

4. Release pinch roller spring gently.

5. Remove four (4) 3/8” e-clips from

pinch roller shaft.

Important: Do not let the e-clips fall into dispenser.

6. With one hand holding pinch roller and

pinch roller spring, slide pinch roller shaft to

the left until the pinch roller shaft is no longer

on the chassis (Figure 8-28).

New Part Installation:

1. With left end of the pinch roller spring on

top of the screw and on left side of dispenser,

slide pinch roller shaft into right side of

chassis (Figure 8-29).

Complete the Installation by reversing the

removal procedure above.

Figure 8-26

Figure 8-27

Note: Insert shaft approximately ¼ way in chassis.

WaterAct-M-S

23

Figure 8-28

Figure 8-29

2011 October

Page 36

8-MAINTENANCE AND REPAIRS (continued)

8.20 Top Roller

To Remove:

1. Remove right side cover (See Section 8.11).

2. Remove e-clips from top roller shaft.

3. Remove top roller shaft.

4. Remove top roller tube.

5. Place new top roller into middle of chassis and

hold.

6. Insert new top roller shaft through -

- chassis -

- top roller

- and chassis on other side

(Figure 8-30)

New Part Installation:

Reverse the removal procedure above.

8.21 Free Spin Roller Shaft

To Remove:

1. Remove right side cover (See Section 8.11).

2. Remove left side cover (See Section 8.12).

3. Remove e-clips from free spin roller shaft

(Figure 8-31).

4. Remove free spin roller shaft.

5. Remove free spin roller tube.

New Part Installation:

E-Clip

Top

Roller

Top

Roller

Shaft

E-Clips

Figure 8-30

Figure 8-31

Reverse the removal procedure above.

8.22 Slide Roller

To Remove:

1. Remove right side cover (See Section 8.11).

2. Remove (4) screws holding the sliding

roller plates (Figure 8-32).

3. Remove slide roller assembly (Figure 8-33).

New Part Installation:

Reverse the removal procedure above.

WARNING

• To reduce the risk associated with

mechanical hazards:

− Read, understand, and follow all safety and

operating instructions before operating or

servicing the tape dispenser.

− Allow only properly trained and qualifi ed

personnel to operate and service this

equipment.

Screws

Figure 8-32

Figure 8-33

WaterAct-M-S

24

2011 October

Page 37

8-MAINTENANCE AND REPAIRS (continued)

8.23 Weighted Brush Cover

To Remove:

1. Remove the right side cover

(See Section 8.11).

2. Remove the water bottle.

3. Remove the cutter guard.

4. Remove the screws from the fl apper shaft

(Figure 8-34).

5. Slide the fl apper shaft, weighted brush cover,

tape weight, and bushings from the front

of the dispenser (Figure 8-35).

6. Remove the screw from the tape weight and

remove the tape weight from the weighted

brush cover.

New Part Installation:

Reverse the removal procedure above.

Remove

Screw

Figure 8-34

8.24 Brush

To Remove:

1. Remove Water Bottle.

2. Remove Water Tank.

3. Remove Brush from Water Tank.

4. Place new brush in the tank with bristles

level with work area/fl oor (Figure 8-36).

5. Place tank and brush in water tank holder.

6. Place the water bottle on bottle brackets with

post of water tank inserted into duckbill valve.

New Part Installation:

Reverse the removal procedure above.

CAUTION

• To reduce the risk associated with

pinch hazards:

− Keep hands, hair, loose clothing, and

jewelry away from dispenser.

Figure 8-35

Brush Parallel

WrongRight

Figure 8-36

WaterAct-M-S

25

2011 October

Page 38

8-MAINTENANCE AND REPAIRS (continued)

8.25 Tape Channel Plate

To Remove:

1. Remove right side cover (See Section 8-11).

2. Remove pinch roller (See Section 8-19).

3. Remove weighted brush cover

(See Section 8-23).

4. Loosen dead roller and coder bar screws

(Figure 8-38).

5. Remove pinch roller spring stop (Figure 8-38).

6. Remove two (2) screws attached to tape

channel plate.

7. Pull tape channel plate up allowing tape

channel plate and dead roller to rotate (making

screws underneath accessible - Figure 8-39).

8. Remove two (2) screws connecting tape channel

plate and dead roller (Figure 8-40).

New Part Installation:

1. With the left end of pinch roller spring on

top of screw and left side of the dispenser,

slide the pinch roller shaft into right side of

chassis.

Figure 11-19

Figure 8-37

Tape Channel

Plate

5

5

6

Reverse the removal procedure above.

Note: Insert shaft approximately 1/4 way in chassis.

8.26 Tape Basket / Motor Cover

To Remove:

1. Remove right side cover (See Section 8-11).

2. Remove left side cover (See Section 8-12).

3. Remove pinch roller (See Section 8-19).

4. Remove weighted brush cover

(See Section 8-23).

5. Remove tape channel plate

(See Section 8-25).

6. Remove two (2) screws holding tape basket/

motor cover.

7. Remove tape basket/motor cover by lifting

straight up parallel with angle of tape basket/

motor cover (Figure 8-41).

8. Remove-inspect-and/or install new tape basket

(Figure 8-42).

Figure 8-38 Figure 8-39

Figure 8-40

Figure 8-41

New Part Installation:

Reverse the removal procedure above.

WaterAct-M-S

26

2011 October

Page 39

8-MAINTENANCE AND REPAIRS (continued)

8.27 Tape Guide Assembly

To Remove:

1. Remove right side cover (See Section 8.11).

2. Remove left side cover (See Section 8.12).

3. Remove pressure plate.

4. Loosen screws of these parts: coder bar and

dead roller, the tape basket/motor cover (See

Section 8.16), tape channel plate (See Section

8.25), and weighted brush cover shaft

(See Section 8.23).

5. With tape guides positioned towards middle of

dispenser and one hand spreading chassis

apart, pull turnbuckle to one side of dispenser,

twist turnbuckle slightly and pull assembly out

rear of dispenser (Figures 8-42 and 8-43).

6. With new tape guides set towards middle

of dispenser and slightly twisted, spread the

chassis apart and put both ends of the

turnbuckle into the chassis.

New Part: Reverse the removal procedure above.

Figure 8-42

Figure 8-43

8.28 Feed Wheel

To Remove:

1. Remove right side cover (See Section 8.11).

2. Remove the pinch roller (See Section 8.19).

3. Remove weighted brush cover

(See Section 8.23).

4. Remove tape channel plate

(See Section 8.25).

5. Remove idler gear (See Section 8.29).

6. Remove drive gear and clutch assembly

(See Section 8.30).

7. Remove gearbox/motor mount (Section 8.32).

8. Remove feed wheel shaft and feed wheel from

chassis at a downward angle (Figure 8-44).

9. Attach e-clip and washer to new feed wheel

shaft and insert back into dispenser

(Figures 8-45 and 8-46).

New Part: Reverse the removal procedure above.

8.29 Idler Gear

To Remove:

1. Remove right side cover (See Section 8.11).

2. Remove left side cover (See Section 8.12).

3. Remove weighted brush cover

(See Section 8.23).

4. Remove tape channel plate

(See Section 8.25).

5. Remove bolt from the center of idler gear

(Figure 8-47).

Figure 8-44

Figure 8-45

Figure 8-46

New Part: Reverse the removal procedure above.

WaterAct-M-S

27

Figure 8-47

2011 October

Page 40

8-MAINTENANCE AND REPAIRS (continued)

8.30 Drive Gear with Springs

and Clutch Assembly

To Remove:

1. Remove right side cover (See Section 8.11).

2. Remove pinch roller (See Section 8.19).

3. Remove weighted brush cover

(See Section 8.23).

4. Remove tape channel plate

(See Section 8.25).

5. Remove idler gear (See Section 8.29).

6. Remove drive gear and clutch assembly

(Figure 8-48).

New Part Installation:

Reverse the removal procedure.

Figure 8-48

8.31 Separating/Re-Assembling Drive Gear with

Springs and Clutch Assembly

To Separate:

1. Remove drive gear springs from the clutch

pins (Figure 8-49).

2. Pull drive gear with springs and clutch

assembly apart (Figure 8-50).

To Re-Assemble:

Reverse the separation procedure above.

WARNING

• To reduce the risk associated with

mechanical hazards:

− Read, understand, and follow all safety and

operating instructions before operating or

servicing the tape dispenser.

− Allow only properly trained and qualifi ed

personnel to operate and service this

equipment.

Figure 8-49

WaterAct-M-S

28

Figure 8-50

2011 October

Page 41

8-MAINTENANCE AND REPAIRS (continued)

8.32 Gear Box / Motor Mount

To Remove:

1. Remove right side cover (See Section 8.11).

2. Remove pinch roller (See Section 8.19).

3. Remove weighted brush cover

(See Section 8.23).

4. Remove tape channel plate

(See Section 8.25).

5. Remove idler gear (See Section 8.29).

6. Remove drive gear and clutch assembly

(See Section 8.30).

7. Remove set screw from feed wheel gear

(Figure 8-51).

8. Remove feed wheel gear (Figure 8-51).

9. Remove bolts from gearbox/motor mount.

(Figure 8-52).

10. Remove gearbox/motor mount.

New Part Installation:

Reverse the removal procedure above.

Set

Screw

Feed

Wheel

Gear

Figure 8-51

8.33 Ramp

To Remove:

1. Remove right side cover (See Section 8.11).

2. Remove left side cover (See Section 8.12).

3. Loosen screws on these parts: coder bar and

dead roller - weighted brush cover shaft.

4. Remove four (4) screws holding ramp.

Remove the ramp (Figure 8-53).

5. Attach four (4) screws to new ramp inside

locate thicker end of the ramp toward rear of

dispenser (Figure 8-54).

6. Tighten loosened screws in #4 and reattach left

and right covers.

New Part Installation:

Reverse the removal procedure above.

WARNING

• To reduce the risk associated with

mechanical hazards:

− Read, understand, and follow all safety and

operating instructions before operating or

servicing the tape dispenser.

− Allow only properly trained and qualifi ed

personnel to operate and service this

equipment.

Screw

Figure 8-52

Screws

Figure 8-53

Figure 8-54

WaterAct-M-S

29

2011 October

Page 42

8-MAINTENANCE AND REPAIRS (continued)

8.34 List of the Maintenance Operations

Date: Description of Operation

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

WaterAct-M-S

2011 October

30

Page 43

8-MAINTENANCE (continued)

8.35 Troubleshooting Guide

The Troubleshooting Guide below lists some possible dispenser problems along with their causes and corrections. See Set-up and Maintenance Sections to avoid problems. Issues other than those listed below, call 3M

Technical Service Line for assistance.

PROBLEM CAUSE CORRECTION

PROBLEM CAUSE CORRECTION

Dispenser doesn't feed tape

.

Tape slips at the feed wheel

Cutter doesn’t cut the tape

Handle is hard to pull or

jammed

- Tape path is blocked

- Tape path is dirty

- Tape guides incorrectly set

- Tape incorrectly routed

- Set screw on the feed wheel is loose

- Feed Wheel is dirty

- Feed Wheel set screw loose

- Cutter is dirty/gummed up

- Cutter Blades are worn

- Cutter Blades are dull/worn

- Feed Wheel set screw loose

- Clutch bearings are bad

- Clear all debris from the path of

the tape. Ensure clearance at:

a. the blades

b. feed wheel

- Remove the pressure plate,

remove all debris from the tape

with a damp cloth, and then

replace the pressure plate

- Adjust the tape guide turnbuckle

- Re-route the tape

- Make sure the feed wheel is

in the correct position and then

tighten the feed wheel set screw

- Remove any tape from the

dispenser and wipe the feed

wheel with a damp cloth

- Tighten Feed Wheel set screw

- Clean the Cutter Blades

- Replace the Cutter Blades

(refer to service manual)

- Cutter Blades

(refer to service manual)

- Tighten Feed Wheel set screw

- Replace the clutch.

(refer to service manual)

Tape is jamming or tearing

After cutting, blades do not

return to original position

Tape length is different from

settings

Tape doesn't stick to carton

Tape slips on carton

- Pressure plate is not all the

way to the pinch roll shaft

- Brush is incorrectly installed

- Tape Guides incorrectly set

- Cutter Blades are not clean

- Feed Wheel incorrectly

adjusted

- Water Bottle is empty

- Brush is dirty

- Brush bristles are

worn/missing

- Incorrect pressure on Tape

- Cartons are dirty

- Tape is too wet

- Cartons are dirty

- Place the pressure plate all the

way down to the pinch roll shaft

(make sure the pressure

plate lays fl at)

- Re-install the brush

- Re-adjust the tape guides

- Clean the Cutter Blade

NOTE: Standard Accuracy ± 1/2”

- Clean the feed wheel

- Check to see if the feed wheel

is spinning on it's shaft. If it is

spinning, tighten the set screw

- Fill the Water Bottle

- Clean the Brush

- If brush does not extend above

top of brush tank, replace brush

- Adjust Tape Pressure Weight

- Use clean cartons only

- Adjust water level and/or tape

weight

- Use clean cartons only

WaterAct-M-S

31

2011 October

Page 44

9-ADDITIONAL INSTRUCTIONS 10-ENCLOSURES / SPECIAL INFO.

9.1 Information for Disposal of Dispenser

In order to dispose of dispenser materials, please

comply with the law and environmental directives of

your country.

9.2 Emergency Procedures

IN CASE OF FIRE

Use a fi re extinguisher containing CO2 (Figure 9-1).

DO NOT use Water.

10.1 Statement of Conformity

N/A

10.2 Emissions of Radiation, Gas Vapor, and Dust

Nothing to report

10.3 Emission of Hazardous Substances

Nothing to report

10.4 Electric Tests

N/A

WARNING

Figure 9-1

• To reduce the risk associated with

mechanical hazards:

− Read, understand, and follow all safety and

operating instructions before operating or

servicing the tape dispenser.

− Allow only properly trained and qualifi ed

personnel to operate and service this

equipment.

WaterAct-M-S

32

2011 October

Page 45

11-TECHNICAL DOCUMENTATION AND INFORMATION (continued)

11.1 Schematics - N/A for this dispenser

WaterAct-M-S

33

2011 October

Page 46

11-TECHNICAL DOCUMENTATION AND INFORMATION (continued)

11.2 Options and Accessories

Part Number Option/Accessory

TBA

For information on the options and accessories, contact your 3M

TM

Representative.

WaterAct-M-S

2011 October

34

Page 47

11-TECHNICAL DOCUMENTATION AND INFORMATION (continued)

11.2 Replacement Parts and Service Information

Spare Parts

It is suggested that the following spare parts be ordered and kept on hand:

Qty. Part Number Description

TBA

Label Kit

In the event that any labels are damaged or destroyed, they must be replaced to ensure operator safety. A

label kit is available as a stock item. It contains all the safety labels used on the Water Activated Tape Dispenser

(manual version). Part # TBA.

Replacement Parts Ordering Information and Service

Refer to the fi rst page of this instruction manual "Replacement Parts and Service Information".

WaterAct-M-S

35

2011 October

Page 48

11-TECHNICAL DOCUMENTATION AND INFORMATION (continued)

Replacement Parts – Illustrations and Parts Lists

Water Activated Tape Dispenser (manual version), Type 11100

Frame Assemblies

To Order Parts:

1. Refer to fi rst illustration, Frame Assemblies, for the Figure Number that identifi es a specifi c portion of the

dispenser.

2. Refer to the appropriate Figure or Figures to determine the parts required and the parts reference number.

3. The Parts List that follows each illustration, includes the Reference Number, Part Number and Part

Description for the parts on that illustration.

Note – The complete description has been included for standard fasteners and some commercially

available components. This has been done to allow obtaining these standard parts locally, if desired.

4. Order parts by Part Number, Part Description and Quantity required. Also include dispenser name,

number and type.

5. Refer to the fi rst page of this instruction manual “Replacement Parts and Service Information” for

replacement parts ordering information.

Important – Not all the parts listed are normally stocked items. Some parts or assemblies shown are

available only on special order. Contact 3MTM/Tape Dispenser Parts to confi rm item availability.

WaterAct-M-S

36

2011 October

Page 49

12-Water Activated Tape Dispenser - Parts Lists and Illustrations (manual version)

Machine

Assemblies

Figure 12-1

Top Cover Assembly

Water Bottle

Brush

Brush Tank

Switch

Handle

Figure 12-3

Foot Channel

Tape Guides / Plate

Gear Box / Drive

Motor Cover

Feed Wheel

Handle Shaft

W

1

0

0

MANUAL WATER

ACTIVATED TAPE

DISPENSER

MODEL: W100

SERIAL NUMBER:

Figure 12-2

Front Cover

Ramp

Rollers

Left Side Cover

Cutter Springs

WaterAct-M-S

37

Figure 12-4

Cutter Arms

Cutter Blades

Water Tank Holder

Springs

2011 October

Page 50

Water Activated Tape Dispenser (manual version)

5

3

4

7

12

8

24

18

16

17

1

15

9

19

6

12

Figure 12-1

WaterAct-M-S

23

10

38

11

13

14

2011 October

Page 51

Water Activated Dispenser - Manual Version

Figure 12-1

Ref. No. 3M Part No. Description Original Document Number

12-1-1 78-8137-5509-3 Top Cover

12-1-2 TBA Logo (not shown) RP40310

12-1-3 TBA Nut RP40310 RP40311

12-1-4 TBA Hinge RP40310 RP40311

12-1-5 TBA Screw RP40310 RP40311

12-1-6 78-8137-5502-8 Tank

12-1-7 78-8137-5495-5 Water Bottle

12-1-8 78-8137-5500-2 Duckbill Valve

12-1-9 78-8137-5501-0 Brush

12-1-10 TBA Side Cover RP41301 RP41301-H

12-1-11 TBA Screw RP41301 RP41301-H

12-1-12 TBA Screw RP41301 RP41301-H

12-1-13 78-8137-5505-1 Hole Plug

12-1-14 TBA Stop Assy RP41290 RP41301-H

12-1-15 TBA Handle Arm RP41257

12-1-16 78-8137-5496-3 Handle RP41257

12-1-17 TBA Handle Insert RP41257

12-1-18 TBA Washer RP41257

12-1-19 TBA Screw RP41257

12-1-20 TBA Nut (not listed in original parts list)

12-1-21 TBA Strip (not shown) (not listed in original parts list)

12-1-22 TBA Nut (not shown) (not listed in original parts list)

12-1-23 TBA Screw (not shown) RP41290

WaterAct-M-S

39

2011 October

Page 52

Water Activated Tape Dispenser (manual version)

11

15

16

29

12

1

3

10

13

18

13

21

22

23

17

19

14

2

Figure 12-2

WaterAct-M-S

30

8

24

25

26

27

40

20

2011 October

Page 53

Water Activated Dispenser - Manual Version

Figure 12-2

Ref. No. 3M Part No. Description Original Document Number

12-2-1 TBA Cover RP40315

12-2-2 TBA Screw RP40305 RP40315 RP40325

12-2-3 78-8137-5497-1 Pressure Plate

12-2-4 TBA Tube (not shown) RP40570

12-2-5 TBA Bearing (not shown) RP40570

12-2-6 TBA Shaft (not shown) RP40570

12-2-7 TBA Screw (not shown) RP40570

12-2-8 78-8137-5499-7 Front Water Bottle Bracket

12-2-9 TBA Screw (not shown) RP40570

12-2-10 TBA Roller Tube RP40522

12-2-11 TBA Bearing RP40522

12-2-12 TBA Shaft RP40522

12-2-13 TBA E-Clip RP40522

12-2-14 TBA Side Cover RP40305

12-2-15 78-8137-5498-9 Rear Water Bottle Bracket

12-2-16 TBA Screw RP40404

12-2-17 78-8137-5504-4 Guard

12-2-18 TBA Pin RP40540

12-2-19 TBA Spring RP40540

12-2-20 TBA Shaft RP40540

12-2-21 TBA Holder RP40540

12-2-22 TBA Roll RP40540

12-2-23 TBA E-Clip RP40540

12-2-24 TBA Spring RP41905

12-2-25 TBA Damper RP41905

12-2-26 TBA Screw RP41905

12-2-27 TBA Nut RP41905

12-2-28 TBA S-Hook (not shown) RP41905

12-2-29 TBA Roller RP40580

12-2-30 TBA Screw RP41904

12-2-31 TBA Fixed Blade Stop (not shown) RP40825

WaterAct-M-S

41

2011 October

Page 54

Water Activated Tape Dispenser (manual version)

6

36

10

8

9

28

32

29

33

37

7

13

38

41

14

15

39

12

11

5

40

1

22

43

50

49

48

23

31

30

2

4

3

Figure 12-3

WaterAct-M-S

42 44

34

42

40

35

25

24

26

27

2011 October

Page 55

Water Activated Dispenser - Manual Version

Figure 12-3

Ref. No. 3M Part No. Description Original Document Number

12-3-1 TBA Bar RP40110

12-3-2 TBA Screw RP40110

12-3-3 TBA Rubber Foot RP40115

12-3-4 TBA Screw RP40115

12-3-5 TBA Nut RP40115

12-3-6 TBA Plate RP40515

12-3-7 TBA Screw RP40515 RP40516

12-3-8 TBA Turnbuckle RP40550

12-3-9 TBA Guide RP40550

12-3-10 TBA Guide RP40550

12-3-11 TBA Power Cord Relief RP42956

12-3-12 TBA Plug RP42957

12-3-13 TBA Split Bushing RP42958

12-3-14 TBA Wheel RP40545

12-3-15 TBA Screw RP40545

12-3-16 TBA Tube (not shown) RP40570

12-3-17 TBA Bearing (not shown) RP40570

12-3-18 TBA Shaft (not shown) RP40570

12-3-19 TBA Screw (not shown) RP40570

12-3-20 TBA Bracket (not shown) RP40570

12-3-21 TBA Screw (not shown) RP40570

12-3-22 TBA Gearbox/Motor Frame RP41101

12-3-23 TBA Pin RP41101

12-3-24 TBA Drive Gear RP5065X

12-3-25 TBA Spring RP5065X

12-3-26 TBA Clutch RP5063X

12-3-27 TBA Pin RP5063X

12-3-28 TBA Weighted Tank Cover RP40516

12-3-29 TBA Brass Bushing RP40516

12-3-30 TBA Rod RP40516

12-3-31 78-8137-5503-6 Weight

12-3-32 TBA Screw RP40517

12-3-33 TBA Pin RP40517

12-3-34 TBA Bearing 3/8 RP40231

12-3-35 TBA Bearing 1/2 RP41221

12-3-36 TBA Roller RP40560

12-3-37 TBA Screw RP40560

12-3-38 TBA Shaft RP40230

12-3-39 TBA Shaft RP41220

12-3-40 TBA Screw RP41220

12-3-41 TBA Screw RP41220

12-3-42 TBA E-Clip RP41220

12-3-43 TBA Washer RP16172

12-3-44 TBA Screw (not listed in original parts list)

12-3-45 TBA Screw (not listed in original parts list)

12-3-46 TBA Screw (not listed in original parts list)

12-3-47 TBA Shaft (no original reference number)

12-3-48 TBA Gear (no original reference number)

12-3-49 TBA Gear (no original reference number)

WaterAct-M-S

43

2011 October

Page 56

Water Activated Tape Dispenser (manual version)

8

7

22

23

21

2

12

10

1

16

9

13

15

14

17

18

19

11

2

4

3

6

19

5

Figure 12-4

WaterAct-M-S

44

2011 October

Page 57

Water Activated Dispenser - Manual Version

Figure 12-4

Ref. No. 3M Part No. Description Original Document Number

12-4-1 TBA Steel Plate RP40320

12-4-2 TBA Screw RP40320 RP40715 RP42978

12-4-3 TBA Arm RP41258

12-4-4 TBA Spring RP41258 RP40715

12-4-5 TBA E-Clip RP41258

12-4-6 TBA Shaft RP41258