Page 1

Scotch® Vinyl Electrical Tape 3 5

Data Sheet November 2017

Description

Agency

Approvals & Self

Certifications

Applications

Scotch® Vinyl Electrical Tape 35 is a 7 mil (0,178 mm) polyvinyl chloride (PVC) colorcoding tape. Outstanding electrical and mechanical properties make this tape excellent

for use in phase identification, color coding of motor leads and piping systems, and for

marking safety areas. Scotch

up to 221°F (105°C); applies smoothly and conforms well above 32°F (0°C). This tape is

available in nine fade resistant colors.

UL Listed - UL 510 Standard “Insulating Tape” (product category OANZ), File E129200;

meets UL 510 labeling for “flame-retardant” for vin yl elec t r ic al tape.

C

SA Certification; Standard. C22.2 No. 197-M1983 “PVC Insulating Tape,” File LR

48769.

oHS 2002/95/EC

R

RoHS Compliant 2002/95/EC” means that the product or part (“Product”) does not contain any of the

substances in excess of the maximum concentration values in EU Directive 2002/95/EC, as amended by

Commission Decision 2005/618/EC, unless the substance is in an application that is exempt under RoHS. This

information represents 3M’s knowledge and belief, which may be based in whole or in part on information

provided by third party suppliers to 3M.

Color coding for phase identification, job identification and safety

Insulating electrical wiring

Protecting electrical conductors, motor leads and piping from moisture, alkalis, acids,

corrosion, abrasion and weather

®

Tape 35 operates over a wide range of temperatures –

Installation

Specifications

Apply in half-lapped layers with sufficient tension to conform and produce a uniform

covering. In most applications, this tension will reduce the tape width to approximately

60% of its original width.

On a pigtail splice, wrap the tape beyond the end of the wire and then fold back

er-wrap, leaving a protective cushion to resist cut-through.

ov

Wrap uphill, taping from a smaller diameter to a larger diameter surface. Apply the

tape with no tension on the last wrap to prevent flagging.

Scotch® Tape 35 is based on polyvinyl chloride (PVC) and/or its copolymers and has a

rubber-based, pressure-sensitive adhesive. The tape shall be 7 mils thick, and be UL

Listed and marked per UL Standard 510 as “Flame-Retardant.” The tape shall be

compatible with synthetic cable insulations, jackets and splicing compounds. The tape

will remain stable and will not telescope more than 0.1 inches when maintained at

temperatures below 122°F (50°C).

and

1 of 2

Page 2

Scotch® Vinyl Elec trical Tape 35

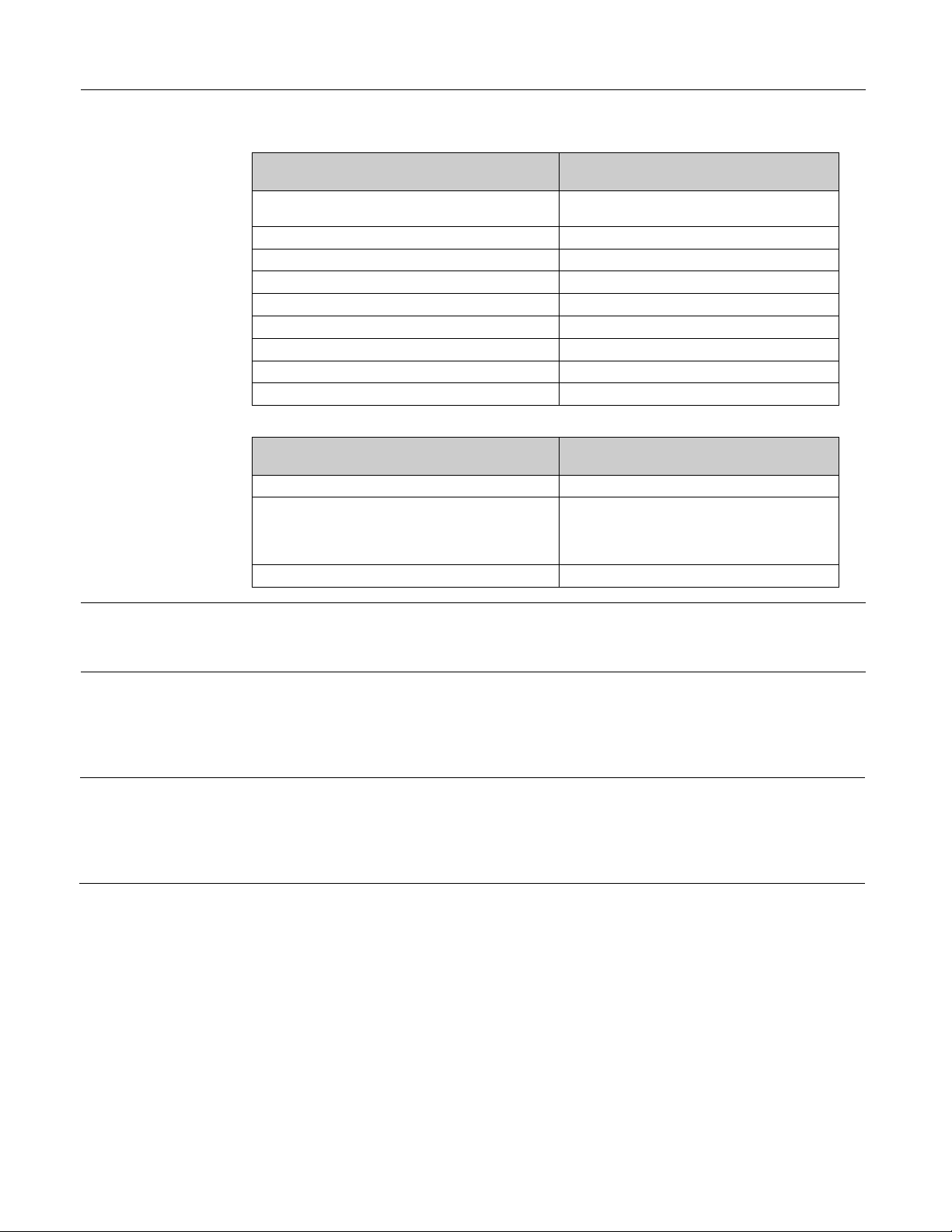

Physical Property

Typical Value

Blue, Brown, Gray, Green, Orange, Red,

Violet, White, Yellow, and Pink

Adhesive

Pressure-sensitive rubber

Thickness

Continuous Operating Temperature (max)

Breaking Strength

17 lb/in (30,3 N/10 mm)

Elongation (% at break)

Adhesion to Steel

20 oz/in (2,2 N/10 mm)

Adhesion to Backing

Flagging

Electrical Property

Typical Value

Voltage Rating (UL 510)

Dielectric Breakdown

Electrical Markets Division

78-8124-4858-3 Rev F

Typical Properties

Not for specifications. Values are typical, not to be considered minimum or maximum.

Properties measured at room temperature 73°F (23°C) unless otherwise stated.

(ASTM D1000, unless noted)

Color(s)

(ASTM D1000, unless noted)

Standard condition

Wet Condition (96 hrs @ 73.4ºF (23ºC)

High Humidity Insulation Resistance

US units (metric)

7 mils (0,178 mm)

221ºF (105ºC)

225%

20 oz/in (2,2 N/10 mm)

0.1 in (2,5 mm)

US units (metric)

600 volts

8,750 volts*

7875 volts

*Note: Dielectric streng th 125 0 V/mi l

6

> 1x 10

megohms

Shelf Life & Storage

Important Notice

Warranty; Limited

Remedy; Limited

Liability

Scotch® Vinyl Electrical Tape 35 has a 5-year shelf life from date of manufacture when

stored in a humidity controlled storage (10°C/50°F to 27°C/80°F and <75% relative

humidity).

All statements, technical information, and recommendations related to 3M’s products are based on information believed to

be reliable, but the accuracy or completeness is not guaranteed. Before using this product, you must evaluate it and

determine if it is suitable for your intended application. You assume all risks and liability associated with such use. Any

statements related to the product, which are not contained in 3M’s current publications, or any contrary statements

contained on your purchase order, shall have no force or effect unless expressly agreed upon, in writing, by an authorized

officer of 3M.

This product will be free from defects in material and manufacture at the time of purchase. 3M MAKES NO OTHER

WARRANTIES INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE. If this product is defective within the warranty period stated above, your

exclusive remedy shall be, at 3M’s option, to replace or repair the 3M product or refund the purchase price of the 3M

product. Except where prohibited by law, 3M will not be liable for any direct, indirect, special, incidental or

consequential loss or damage arising from this 3M product, regardless of the legal theory asserted.

3M and Scotch are trademarks of 3M Company.

Please recycle

© 3M 2017 All rights reserved

2 of 2

Loading...

Loading...