Page 1

March, 2001

3

Technical Bulletin

3MTMVHBTMDurability

Durability of 3M™VHB™Tapes

Summary

This bulletin addresses the long-term durability of VHB™ Acrylic Foam and

Adhesive Transfer Tape products and their ability to perform in certain types of

demanding environments. This will be addressed from a variety of view-points

including chemical composition, resistance to harsh environments, 3M and

independent tests for product durability, and certain applications where VHB™ Tape

products have demonstrated excellent ability to perform in demanding applications.

Test results on moisture resistance, UL durability, accelerated weathering, outdoor

weathering, thermal cycling and fatigue resistance will be discussed.

Composition

3M has been a technological leader in acrylate pressure sensitive adhesive (PSA)

technology for over 35 years. The VHB™ Acrylic Foam and Adhesive Transfer Tapes

represent examples of 3M’s proprietary state-of-the-art in this durable chemistry. The

long-term aging resistance lies in the polymer comprising VHB™ Adhesive Transfer

and Foam Tapes. The chemical bonds that make up the polymer chains consist of

carbon-carbon single bonds that are highly resistant to energy in the form of heat or

ultraviolet light, as well as chemical attack. In less durable foams or adhesives, such

conditions could lead to cleaving of the polymer backbone and thus a weakening of

mechanical properties. In the case of acrylic adhesives and foams, however,

additional crosslinking is chemically favored over chain scission (cleavage). This

means that, rather than undergoing a process of decomposition, the acrylate materials

will tend to build modulus very slightly over extended exposures. This translates to a

stronger, long lasting bond.

Durability Testing

Temperature Exposure

Because of the demanding and diverse applications users have for VHB™ tapes,

durability has always been a key interest in the performance of these products. One of

the first issues for tapes is retention of tack and adhesion after exposure to elevated

temperatures. The VHB™ Adhesive Transfer Tape F-9473PC yielded 92% retention

of peel adhesion after the roll was aged for more than 5 years at 150°F (65°C). The

initial tack and liner release properties were still excellent. The difference in peel

values suggests that a roll of this tape is relatively unaffected by long-term exposure

to elevated temperatures. Bonds made with VHB™ Tapes can tolerate periodic, shortterm exposures to temperatures up to 300°F (150°C) for most Foam Tapes and 500°F

(260°C) for Adhesive Transfer Tapes.

Page 2

Technical Bulletin

3MTMVHBTMTape Durability

Accelerated

Weathering

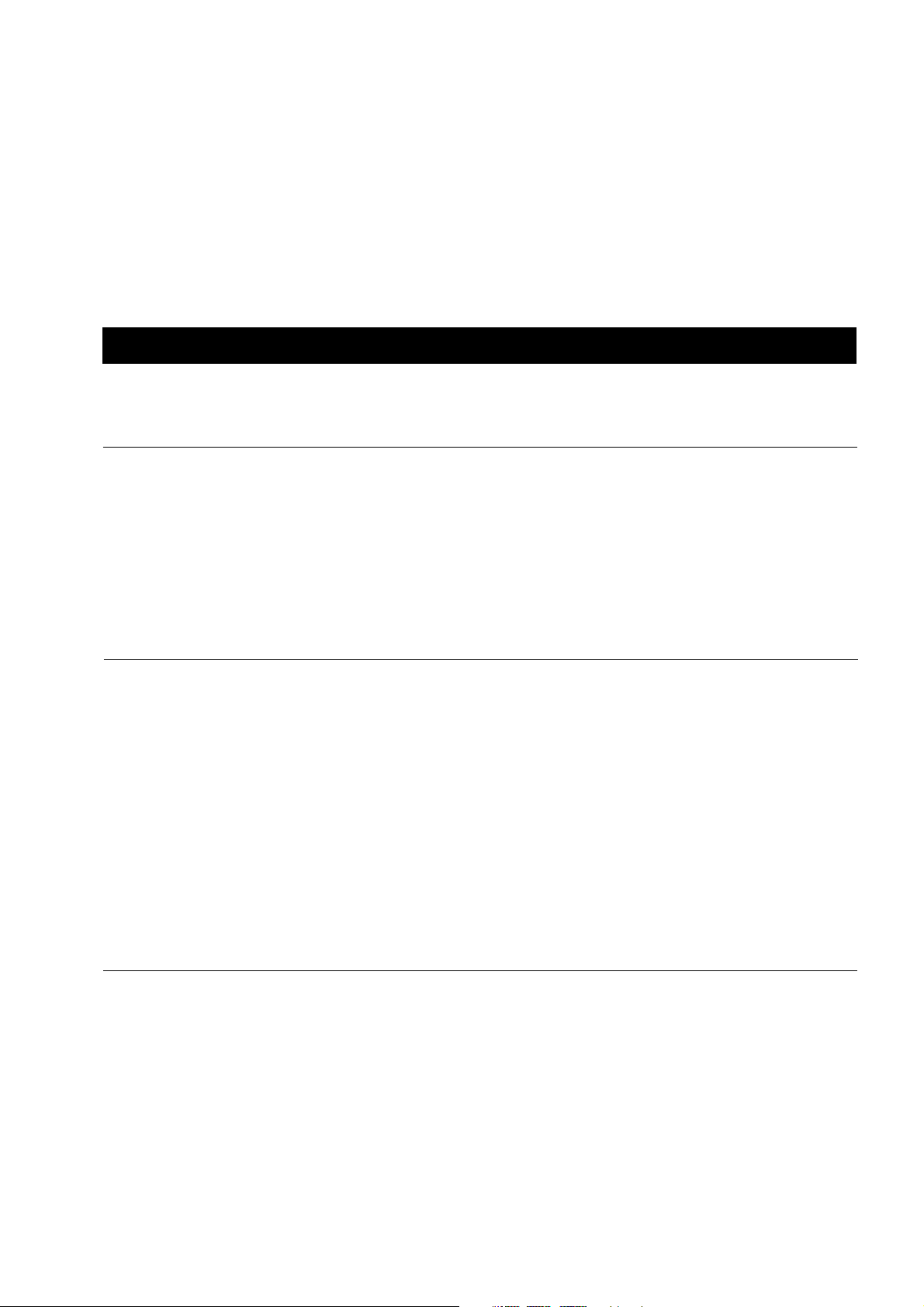

Certain other accelerated aging tests have been conducted in weatherometers which

subject a bond to heat, humidity and concentrated ultraviolet light exposure. These

tests were performed in dynamic shear by making a stainless steel overlap bond with

VHB™ tape 4950 and then subjecting the samples to cycling heat, humidity and

carbon and arc lamp exposure. Small samples provided an increased amount of edge

exposure to UV radiation. Figure 1 indicates that the bond strength does not

deteriorate below its original performance level, even after exposure of 7000 hours in

the weatherometer under these tests.

200

150

100

50

0

0

2000

4000 7000

Figure 1

Weatherometer Testing of 4950 VHB Tape

Hours of Exposure

% Strength Retention

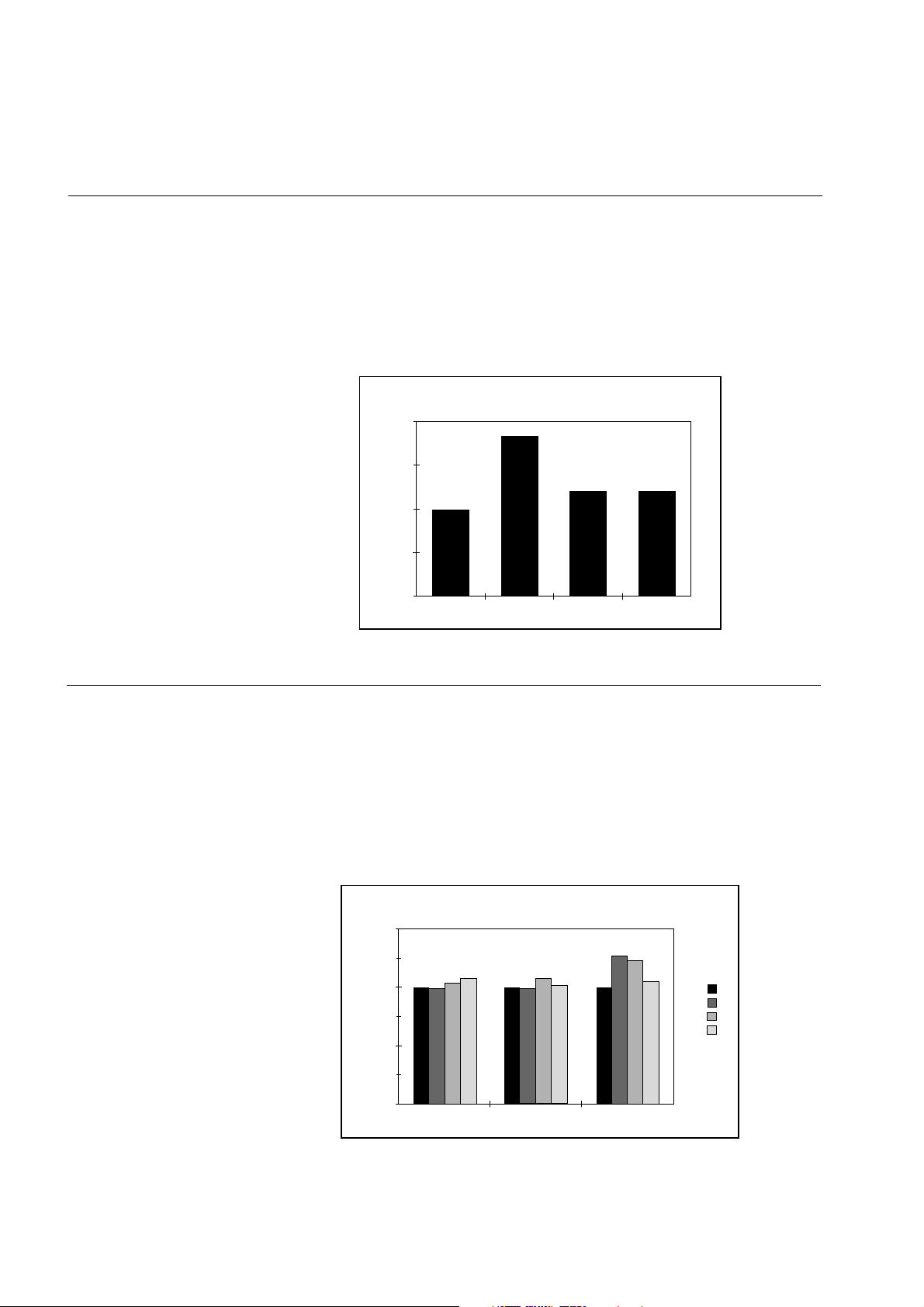

Outdoor Weathering

Outdoor weathering decks in Arizona, Florida and other locations around the world

are also used to collect data on the long-term performance of the VHB™ tape family.

These tests typically demonstrate about 100% bond strength retention in certain

VHB™ Tapes after 2 to 5 years aging cycles in the hot, humid climate of Florida, the

hot, dry and very sunny climate of Arizona and the cold to hot extremes of Minnesota

on bonds to aluminum, glass, PVC and painted metal. Figure 2 shows the constant

performance of VHB™ tapes 4950, 4951 and 4952 after 5 years of outdoor aging in

Minnesota. Similar results have been obtained in 5 year tests conducted in Japan on

the VHB™ tapes.

150

100

50

0

Figure 2

VHB™ Tape (5 Year Outdoor Aging, Minnesota)

% Strength Retention: Tensile

0 Yr

1 Yr

2 Yr

5 Yr

4950

4951

4952

VHB™ Tape

- 2 -

Page 3

Technical Bulletin

3MTMVHBTMTape Durability

UL Listing and

Durability Testing

Both transfer tape and foam representatives of the VHB™ Tape family have UL

746C listings which involve stringent qualification tests and periodic monitoring by

Underwriter’s Laboratories. Qualification for this listing requires high-strength retention

after extended exposure to high temperatures, humidity, cold, and cyclic conditions.

The table below details VHB™ Tapes with the UL 746C listing, and substrate

combinations, as well as the maximum listed temperature for each combination.

Moisture and

Solvent Resistance

Adhesion tests have been performed on VHB™ Tape 4945 bonds of aluminum to

aluminum that were subjected to over 10 years of submersion in 5% salt water and

ordinary tap water. After testing, bright clean aluminum surfaces were observed

underneath the adhesive bond. A combination of adhesive and cohesive failure modes

were observed when the bond was broken which indicated very high performance

levels. Long-term exposure to high humidity or water submersion can have the effect of

making a polymer more resilient and tolerant of high elongation. A subsequent lowering

in peak force is also measured after many days of exposure, usually on the order of

40%. This effect is typical as it parallels the increase in resilience and is the same trend

often seen with structural silicone materials which are also recognized for their

durability. Drying of the VHB™ Tape bond, which occurs in a normal environmental

cycle, will show that this effect is reversible and that the bond will return to the original

dry strength.

After splashes or incidental contact with solvents such as fuels, alcohols, adhesive

removers like MEK, and even weak acids or bases, no affect is measured on the bond

performance. Only after continuous submersion in harsh fuels or solvents is softening

of the adhesive/foam experienced. Note: While VHB™ Tape products may withstand

occasional contact with these types of chemicals, continuous exposure is not

recommended.

110°C

90°C

75°C

Product Families Substrates Temp Rating

VHB™ Foam Tapes

4950, 4930, 4920

Aluminum, Stainless Steel, Galvanized Steel,

Enameled Steel, Glass/Epoxy, Ceramic

PBT

Polycarbonate, ABS, unplasticized PVC

Conformable VHB™

Foam Tapes 4956,

4941, 4936, 4926

Ceramic

Aluminum, Stainless Steel, Galvanized Steel,

Enameled Steel, Polycarbonate, unplasticized

PVC, Glass/Epoxy, PBT

ABS

110°C

90°C

75°C

VHB™ Foam Tape

4945

Phenolic, Aluminum, Galvanized Steel, Alkyd

Enamel

Polyamide (Nylon), Polycarbonate, ABS

Unplasticized PVC

110°C

90°C

75°C

VHB™ Adhesive

Transfer Tapes

F-9473PC,

F-9469PC,

F-9460PC

Stainless, Steel, Glass/Epoxy, Enameled

Steel, Ceramic, Phenolic; Nickel Plated Steel

(9469 only)

ABS, Polycarbonate, Aluminum Galvanized

Steel

Unplasticized PVC

110°C

90°C

75°C

3M™ VHB™ Tapes

UL746C Listings - File MH 17478

Category QOQW2 Component - Polymeric Adhesive Systems, Electrical Equipment

- 3 -

Page 4

Technical Bulletin

3MTMVHBTMTape Durability

15

10

5

0

Figure 3

MIL STD 883 Exposure Tests

VHB™ Tape F-9460 PC: Polyimide to Aluminum

Peel Adhesion (lbs/inch)

Control: 72 hr RT

1000 @ 90°F/90% RH 1000 T. Shock 1000 @ 150°C

*Thermal shock: -50°C to 150°C hourly

Exposure Time (hours) and Condition

Clarity

Since the introduction of the clear VHB™ Acrylic Tapes 4910 and 4905, the

additional issue of long-term clarity and appearance consistency is commonly asked.

Tests have been run for 3000 hours in an accelerated weathering machine which

exposes bonds to high temperatures and intense ultraviolet (UV) light. To measure

clarity, 3 mm float glass plates were bonded together with VHB™ Tape 4910, the

0.040" thick transparent VHB™ Tape. The percent transmittance was monitored

periodically during the exposure cycle, beginning at 88.2% and finishing at 87.3%.

After this long, harsh exposure, only a 1% change in transmittance was observed. In

high humidity environments, however, the VHB™ Tapes 4910 and 4905 may take on

a hazy appearance due to slight absorption of water molecules. Because the same

acrylic polymers are used throughout the VHB™ Tape family, these results suggest

inherent stability of the whole family.

Thermal Shock

The VHB™ Tapes have also performed well in tests, similar to MILSTD 883, which

are commonly used to qualify durable products for the electronics industry. Under

this testing, protocol bonds are subjected to 1000 hours at 150°C, 1000 hours at 85°C

and 85% relative humidity, and 1000 hours of thermal shock which cycles hourly

from -50°C to 150°C. Figure 3 shows the excellent performance of the VHB™

Adhesive Transfer Tape F-9460PC in similar testing which involved bonding

polyimide to aluminum. Typically the bond strength increases with time due to the

high performance PSA’s more complete wet out of the surfaces.

Fatigue

Another durability issue is fatigue resistance. Many types of adhesive tests are run in

a short-term peel, shear or tensile mode where the sample is broken in a matter of a

few seconds. These tests are convenient for quick characterization of the peak force

holding capability, but do not offer any information about a product’s ability to

tolerate vibration or repetitive strains. Because users have used VHB™ Tapes in

many applications which require fatigue resistance, such as trucks or trailers, signs

and building panels, a test has been designed by 3M to characterize this property.

- 4 -

Page 5

Application Examples

of Durability

While positive test results are always encouraging, some of the best examples of

VHB™ Tape’s durability are existing applications in the field. VHB™ Adhesive

Transfer Tapes have been used since the mid 1970’s and VHB™ Acrylic Foam Tapes

have applications dating back to 1980.

One of the oldest and most visible applications for the VHB™ Foam Tapes is on

ambulance bodies. The aluminum panels comprising the body of an ambulance can

be bonded onto the frame with VHB™ Tape. These applications require durability in

harsh conditions on rugged vehicles that are in service for many years.

Another example of durable applications with excellent performance have been

curtain wall constructions such as the Singapore Treasury Building. Here the exterior

panels are stiffened against wind loads by attaching unseen stiffeners to the inner

surface. These bonds must sustain wind loads, daily thermal expansion and

contraction cycles, and elevated temperatures. Similar curtain wall and facade

applications exist around the world. Architectural signs and traffic signs using

VHB™ Tapes have also been standing up to constant weathering, buffering winds,

and occasional storms since the early 1980’s.

Technical Bulletin

3MTMVHBTMTape Durability

10

6

10

5

10

4

10

3

10

2

Figure 4

Dynamic Tension Fatigue VHB™ Tape 4950

Load (PSI)

Cycles to Failure

15

25 35 45 55 65

Fatigue (continued)

In a constant stress machine, tension samples were cyclically loaded over a range of

stresses. The loads were chosen so that bond failures would occur over a broad range

of times. As the load decreases, the specimens will survive more and more cycles and

this trend can be plotted semi-log as in Figure 4. The semi-log plot yields a straight

line which can be used to help predict longer term performance at lower stresses not

practical to measure. Given a product lifetime estimate for cyclic loading, the data can

be extrapolated to estimate the maximum tolerable design stress. For Acrylic Foam

Tapes, this is typically about 20 psi for one million cycles of full reversal loading.

VHB™ Tapes tend to perform well in these types of tests because of their inherent

viscoelasticity. The acrylic foam and adhesive absorb energy and relax stresses

internally, thus helping protect the adhesive bond on the substrate.

- 5 -

Page 6

Technical Bulletin

3MTMVHBTMTape Durability

3

Bonding Systems Division

3M Center, Building 220-7E-01

St. Paul, MN 55144-1000

Printed in U.S.A.

©3M IPC 2000 70-0709-3862-9

Recycled Paper

40% pre-consumer

10% post-consumer

3M warrants for 24 months from the date of sales or delivery, whichever occurs first, that 3M brand VHB™ Tape will

be free of defects in material and manufacture. 3M MAKES NO OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. This Limited Warranty does not cover damage resulting from the use or inability to use

3M brand VHB™ Tape due to misuse, workmanship in application, or application or storage not in accordance with

3M recommended procedures.

Limited

Warranty

Application

Examples of

Durability

(continued)

Another example of VHB™ Tape durability has been generated at the Bendix Automotive

Proving Grounds in Indiana. A full size semi-truck with sleeper cab was constructed with

all exterior panels and doors taped to an underlying frame with VHB™ Tape 4950. After

approximately 300,000 simulated miles on the harsh Durability Track, the VHB™ Tape

bonds remained completely intact. This is particularly impressive in light of the fact that

some mechanically joined and welded parts experienced failures and required repairs for

the test to continue.

One of the most demanding applications for VHB™ Tape has been on aircraft exteriors.

Several commercial aircraft models have incorporated stainless steel anti-chafing strips

bonded to the aluminum wing flaps. These panels help prevent abrasion and chafing

between the flap and underside of the wing during movement of the flaps for take offs,

landings, and in-flight vibration. VHB™ Adhesive Transfer Tape 9473 continues to be a

means for bonding these panels into place. This application has been in use since 1984.

Durability is particularly key in this application since the bond can be subjected to high

skin temperatures in direct sunlight on the ground and -65°F (-54°C) at high altitudes.

In addition, this cycle can be repeated several times per day.

To request additional product information or to arrange for sales assistance, call toll free 1-800-362-3550 or visit

www.3M.com/bonding. Address correspondence to: 3M Bonding Systems Division, 3M Center, Building 220-7E-01,

St. Paul, MN 55144-1000. Our fax number is 651-733-9175. In Canada, phone: 1-800-364-3577. In Puerto Rico,

phone: 1-809-750-3000. In Mexico, phone: 5-728-2180.

For Additional

Information

3M MAKES NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. User is responsible for

determining whether the 3M product is fit for a particular purpose and suitable for user’s method of application.

Please remember that many factors can affect the use and performance of a 3M product in a particular application.

The materials to be bonded with the product, the surface preparation of those materials, the product selected for

use, the conditions in which the product is used, and the time and environmental conditions in which the product is

expected to perform are among the many factors that can affect the use and performance of a 3M product. Given

the variety of factors that can affect the use and performance of a 3M product, some of which are uniquely within

the user’s knowledge and control, it is essential that the user evaluate the 3M product to determine whether it is fit

for a particular purpose and suitable for the user’s method of application.

Important Notice

MSDS: 3M has not prepared a MSDS for these products which are not subject to the MSDS requirements of the

Occupational Safety and Health Administration’s Hazard Communication Standard, 29 C.F.R.1910.1200(b)(6)(v).

When used under reasonable conditions or in accordance with the 3M directions for use, these products should

not present a health and safety hazard. However, use or processing of the products in a manner not in accordance

with the directions for use may affect their performance and present potential health and safety hazards.

TSCA: These products are defined as articles under the Toxic Substances Control Act and therefore, are exempt

from inventory listing requirements.

Recognition/

Certification

If the 3M product is proved to be defective, THE EXCLUSIVE REMEDY, AT 3M’S OPTION, SHALL BE TO

REFUND THE PURCHASE PRICE OF OR TO REPAIR OR REPLACE THE DEFECTIVE 3M PRODUCT. 3M shall

not otherwise be liable for loss or damages, whether direct, indirect, special, incidental, or consequential,

regardless of the legal theory asserted, including, but not limited to, contract, negligence, warranty, or strict liability.

Limitation of

Remedies and

Liability

This Bonding Systems Division product was manufactured under a 3M quality system registered to ISO 9002 standards.

ISO 9002

- 6 -

Loading...

Loading...