Page 1

3

Ultimate FX Full Facepiece Reusable Respirator

Ultimate FX Full Facepiece Reusable Respirator

User Instructions for 3M™ Ultimate FX Full Facepiece FF-401, Small, 3M™ Ultimate FX Full Facepiece FF-402, Medium, 3M™

Ultimate FX Full Facepiece FF-403, Large

IMPORTANT: Before use, the wearer must read and understand these User Instructions. Keep these instructions for reference.

This respirator has dual approval as a United States (US) National Institute for Occupational Safety and Health (NIOSH) full facepiece

respirator and as Brazil Ministry of Labor full face piece respirator.

Specic information is provided where applicable. All other information is common to both standards.

FR

Respirateur à masque complet réutilisable ultra FX

Directives d’utilisation pour respirateur à masque complet ultra FX FF-401 3MMC, petit, respirateur à masque complet ultra FX FF-402

3MMC, moyen, respirateur à masque complet ultra FX FF-403 3MMC, grand

REMARQUE IMPORTANTE : Avant de se servir du produit, l’utilisateur doit lire et comprendre les présentes directives d’utilisation.

Conserver ces directives à titre de référence.

Ce respirateur a une double homologation comme respirateur à masque complet par le National Institute for Occupational Safety and

Health (NIOSH) des États-Unis et comme respirateur à masque complet par le ministère du Travail du Brésil.

Des renseignements spéciques sont fournis le cas échéant. Tous les autres renseignements sont communs aux deux normes.

User Instructions

ES

Respirador reutilizable de pieza facial de cara completa Ultimate FX

Instrucciones para la Pieza facial de cara completa 3M™ Ultimate FX, FF-401, pequeña; Pieza facial de cara completa 3M™ Ultimate

FX, FF-402, mediana; y Pieza facial de cara completa 3M™ Ultimate FX, FF-403, grande.

IMPORTANTE: Antes de usar el producto, el usuario debe leer y entender estas Instrucciones. Conserve estas instrucciones para

referencia futura.

Este respirador cuenta con una aprobación dual como un respirador de pieza facial de cara completa por el Instituto Nacional de

Seguridad y Salud Ocupacional (NIOSH por sus siglas en inglés) de Estados Unidos y por la Secretaría del trabajo de Brasil.

Si aplica, se proporciona información especíca. La demás información es común para ambas normas.

PT

Respirador Reutilizável Peça Facial Inteira FX

Instruções de Uso para 3M™ Peça Facial Inteira FF-401 FX, Pequeno, 3M™ Peça Facial Inteira FF-402 FX, Médio, 3M™ Peça Facial

Inteira FF-403 FX, Grande

IMPORTANTE: Antes de usar, o usuário deve ler e compreender estas Instruções de Uso. Guarde estas instruções para consulta.

Este respirador tem dupla aprovação, como um respirador facial pelo Instituto Nacional para Saúde e Segurança Ocupacional (NIOSH)

dos Estados Unidos (EUA) e como respirador facial pelo Ministério do Trabalho do Brasil.

Informações especícas são fornecidas quando aplicáveis. Todas as outras informações são comuns a ambas as normas.

98-0060-0135-2_6

34-8723-6751-0

Page 2

3

(English)

Ultimate FX Full Facepiece Reusable Respirator

User Instructions

W WARNING

This respirator helps protect against certain airborne contaminants. Misuse may result in sickness or death. For correct use,

consult supervisor and User Instructions or call 3M in U.S.A. at 1-800-243-4630. In Canada, call Technical Service at

1-800-267-4414.

FOREWARD

These User Instructions provide information about facepiece use only. Important information is provided in the User Instructions with each of the air

ltration systems that are used with 3M™ Full Facepiece FF-401, FF-402 and FF-403. Read all User Instructions and warnings before using. Keep

these User Instructions for reference. If you have questions regarding these products contact 3M Technical Service.

In United States:

Internet: www.3M.com/workersafety

Technical Assistance: 1-800-243-4630

Intended Use

The 3M™ Ultimate FX Full Facepiece FF-400 Series Respirators (FF-401, FF-402 and FF-403) are designed to help provide respiratory protection

against certain airborne contaminants when used in accordance with all use instructions and limitations and applicable safety and health regulations.

FF-400 series facepieces meet the requirements of the ANSI Z87.1-2010 standard for face and eye protection. These products provide limited eye

and face protection against ying particles.

Properly selected, used, and maintained respirators help protect against certain contaminants by reducing airborne concentrations

below the Occupational Exposure Limit (OEL). It is essential to follow all instructions and government regulations on the use of this

product, including wearing the complete respirator system during all times of exposure in order for the product to help protect the

wearer. Misuse of respirators may result in overexposure to contaminants and lead to sickness or death. For correct use,

consult supervisor and User Instructions, or contact 3M Technical Service.

In Canada:

Website: www.3M.ca/Safety

Technical Assistance: 1-800-267-4414

W WARNING

List of Warnings and Cautions within these User Instructions

W WARNING

Failure to follow these instructions may reduce respirator performance, expose you to contaminants above the OEL, and may result

in sickness or death.

• To help maintain a good seal between the face and the faceseal, the respirator faceseal must be clear of obstructions at all times. Do

not use with beards or facial hair that prevent direct contact between the face and the respirator faceseal. Do not use with corrective

eyeglasses. If corrective eyeglasses are required, a 3M™ Spectacle Kit must be used inside the respirator.

• Do not clean respirator with solvents. Cleaning with solvents may degrade some respirator components and reduce respirator

effectiveness.

• Inspect all respirator components before each use to ensure proper operating condition.

• Do not alter, misuse, or abuse this respirator.

CAUTION

Failure to properly dispose of spent cartridges, lters, or respirators contaminated by hazardous materials can result in personal exposures as well

as environmental harm. Handling, transportation and disposal of spent cartridges, lters, or respirators must comply with all applicable federal,

state, provincial, and local laws and regulations.

NIOSH Cautions and Limitations for Negative Pressure Usage

The following restrictions may apply. See NIOSH Approval Label. If you are using the FF-400 series facepiece as part of a Supplied Air Respirator

conguration, refer to the User Instructions that accompanies your air control device for information on NIOSH Cautions and Limitations.

A - Not for use in atmospheres containing less than 19.5 percent oxygen.

B - Not for use in atmospheres immediately dangerous to life or health.

C - Do not exceed maximum use concentrations established by regulatory standards.

H - Follow established cartridge and canister change schedules or observe ESLI to ensure that cartridges and canisters are replaced before breakthrough

occurs.

J - Failure to properly use and maintain this product could result in injury or death.

L - Follow the manufacturer’s User’s Instructions for changing cartridges, canister and/or lters.

1

Page 3

(English)

M - All approved respirators shall be selected, tted, used, and maintained in accordance with MSHA, OSHA, and other applicable regulations.

N - Never substitute, modify, add, or omit parts. Use only exact replacement parts in the conguration as specied by the manufacturer.

O - Refer to User’s Instructions, and/or maintenance manuals for information on use and maintenance of these respirators.

S - Special or critical User’s Instructions and/or specic use limitations apply. Refer to User’s Instructions before donning.

S - Special or Critical User’s Instructions

3M™ Organic Vapor Service Life Indicator Cartridges (6001i and 60921i) are equipped with a passive 3M™ End of Service Life Indicator (ESLI). The

indicator must be readily seen when wearing the respirator. If you cannot readily see the ESLI, use a mirror to observe the ESLI; rely on a co-worker

who can see the ESLI; or go to a clean area, remove the respirator and view the ESLI. Do not rely solely on the organic vapor ESLI unless your

employer has determined that it is appropriate for your workplace. See 6001i or 60921i User Instructions for more information, including Special

Instructions regarding the ESLI.

3M™ Mercury Vapor, Organic Vapor and Acid Gas Cartridges (6007 and 60927) must be discarded within 50 hours of use against mercury vapor.

3M™ Particulate Filter P95, Hydrogen Fluoride, with Nuisance Level Acid Gas Relief, 2076HF and 3M™ Particulate Filter P100, Hydrogen Fluoride,

with Nuisance Level Acid Gas Relief, 7093C are recommended for relief against nuisance levels of acid gases or organic vapors. Nuisance level refers

to concentrations not exceeding OSHA PEL or applicable government occupational exposure limits, whichever is lower. Do not use for respiratory

protection against acid gases or organic vapors except hydrogen uoride.

To assemble 3M™ Dual Airline Combination Breathing Tubes with 3M™ Cartridges/Filters, the facepiece inhalation valves must be removed.

If the facepiece is to be used in air-purifying mode (without using the 3M™ Breathing Tubes SA-1600 or SA-2600), the inhalation valves must be

replaced in the facepiece before use.

Respirator Program Management

Occupational use of respirators must be in compliance with applicable health and safety standards. By law U.S. employers must establish a written

respiratory protection program meeting the requirements of the OSHA Respiratory Protection Standard 29 CFR 1910.134 and any applicable OSHA

substance specic standards. In Canada, CSA standard Z94.4 requirements must be met and/or requirements of the applicable jurisdiction, as

appropriate. In Brazil, follow the Respiratory Protection Program of the Ministry of Labor.

For additional information on this standard contact OSHA at www.OSHA.gov. Consult an industrial hygienist or call 3M Technical Service with

questions concerning applicability of these products to your job requirements.

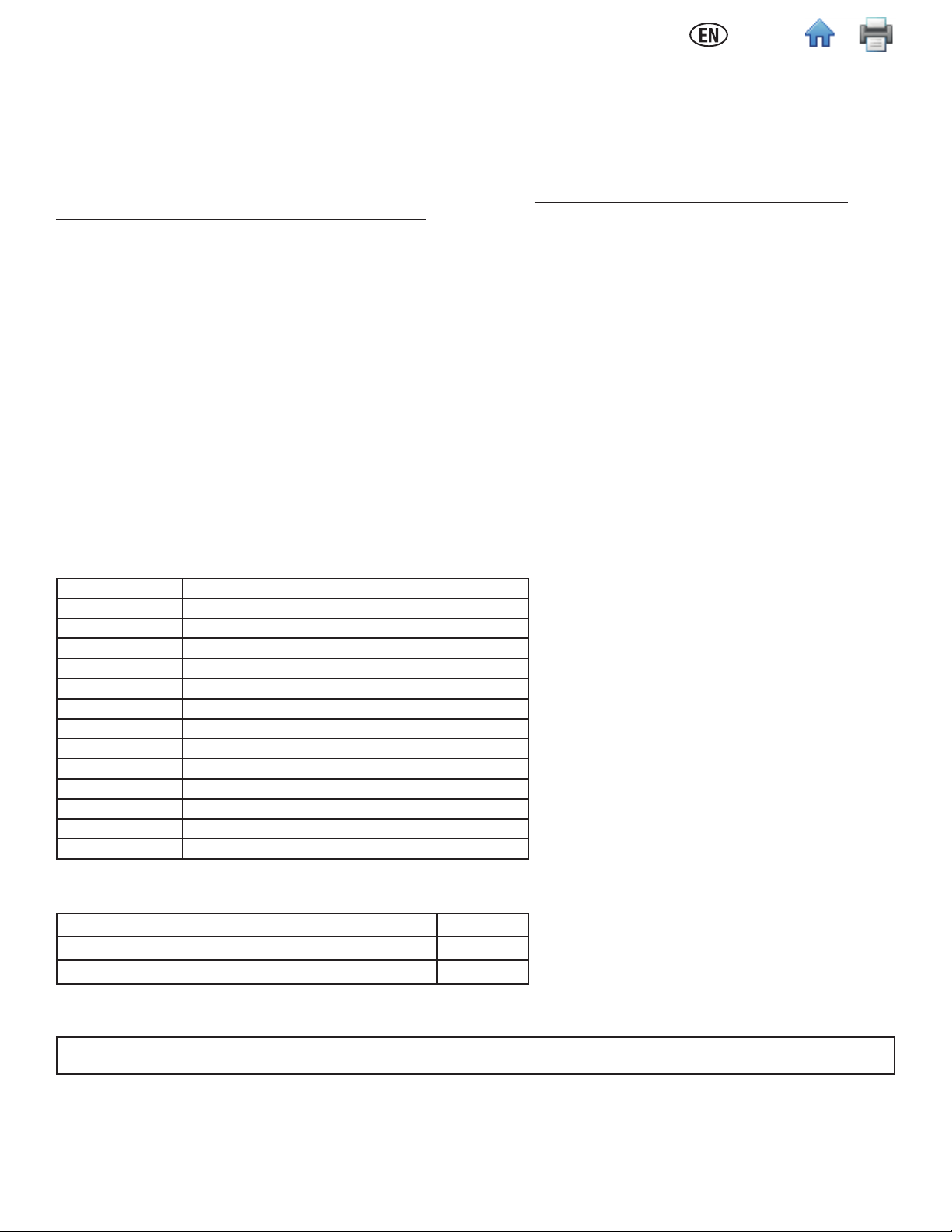

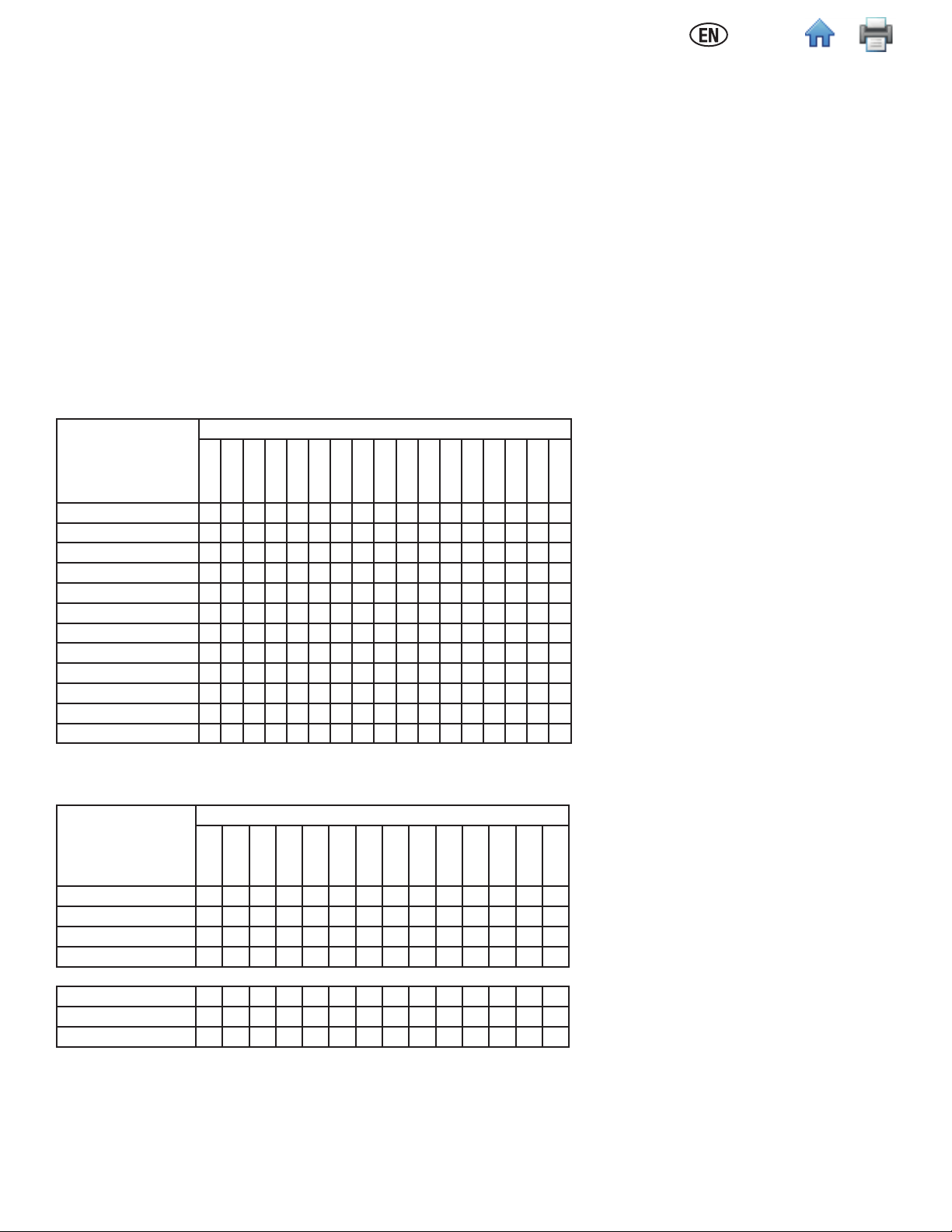

Table 1: Major Sections of OSHA 29 CFR 1910.134

Section Description

A Permissible Practice

B Denitions

C Respiratory Protection Devices

D Selection of Respirators

E Medical Evaluations

F Fit Testing

G Use of Respirators

H Maintenance and Care of Respirators

I Breathing Air Quality and Use

J Identication of Cartridges, Filters, and Canisters

K Training and Information

L Program Evaluation

M Recordkeeping

Assigned Protection Factors

Table 2: Assigned Protection Factors

Type of Respirator APF

Full Facepiece Negative Pressure Air Purifying Respirator 10/50

Full Facepiece Supplied Air Respirator (SAR) Continuous Flow 1000

1

The respirator wearer must be t tested using a quantitative t test method in order to use an assigned protection factor greater than 10 when used

as a negative pressure air purifying respirator.

In Brazil, according to the Respiratory Protection Program of the Ministry of Labor, do not use quantitatively t tested full facepiece respirators when

concentrations of contaminants are greater than 100 times the permissible exposure limit in air-purifying mode.

1

2

Page 4

(English)

OPERATING INSTRUCTIONS

Unpacking

Inspect the package contents for shipping damage and ensure all components are present (Refer to Fig. 27). The product should be inspected before

each use following the procedures in the “Inspection” section of this User Instruction.

Assembly

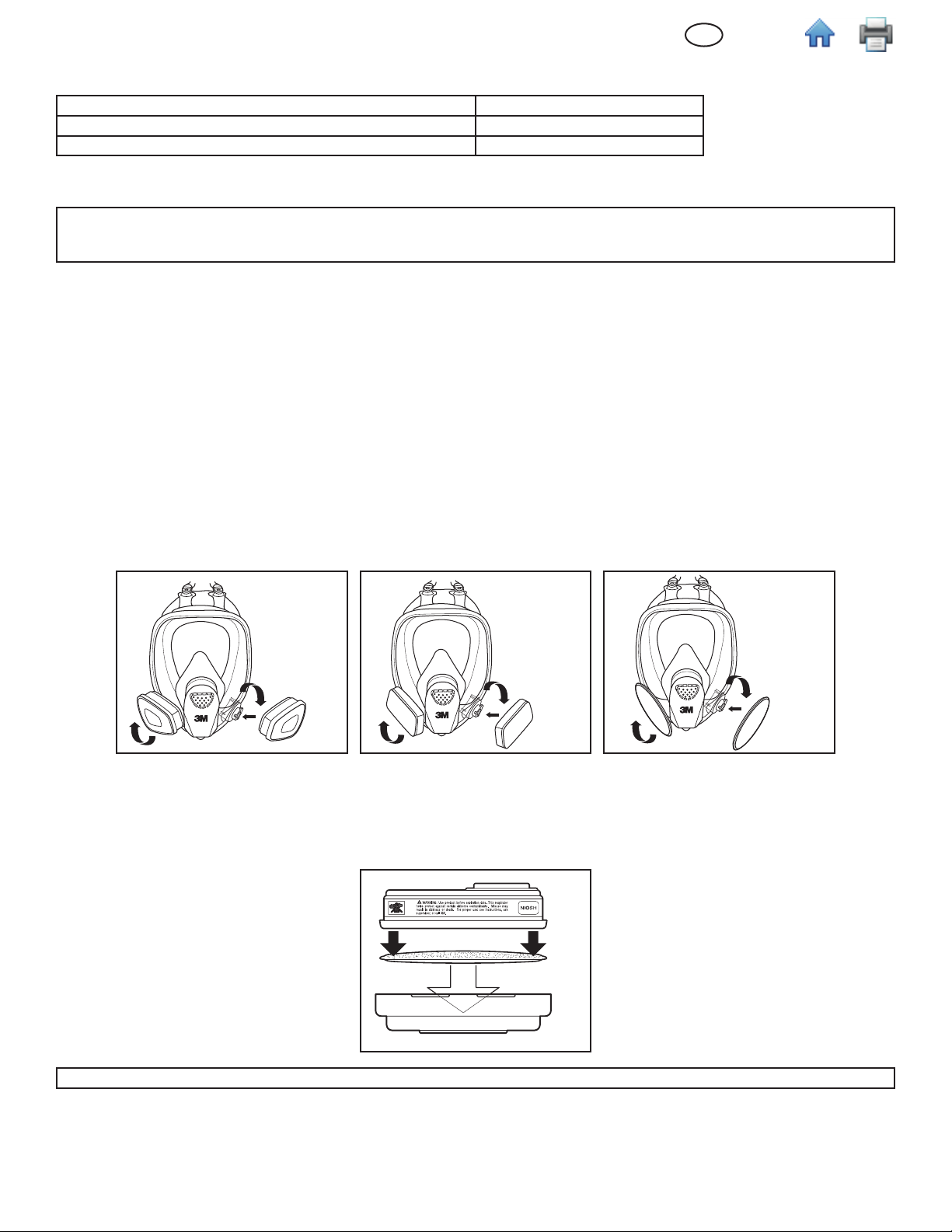

3M™ Cartridge 6000 Series, Filter 7093, and Cartridge/Filter 7093C Assembly (Fig. 1, 2)

1. Align the cartridge or lter notch with the small solid bayonet lug on facepiece and push together.

2. Turn cartridge or lter clockwise until it is rmly seated and cannot be further turned (about 1/4 turn).

3. Repeat with second cartridge or lter.

3M™ Filter 2000 Series (Fig. 3)

1. Align opening of lter with lter attachment on facepiece and push together.

2. Turn lter clockwise until it is rmly seated and cannot be further turned.

3. Repeat for second lter.

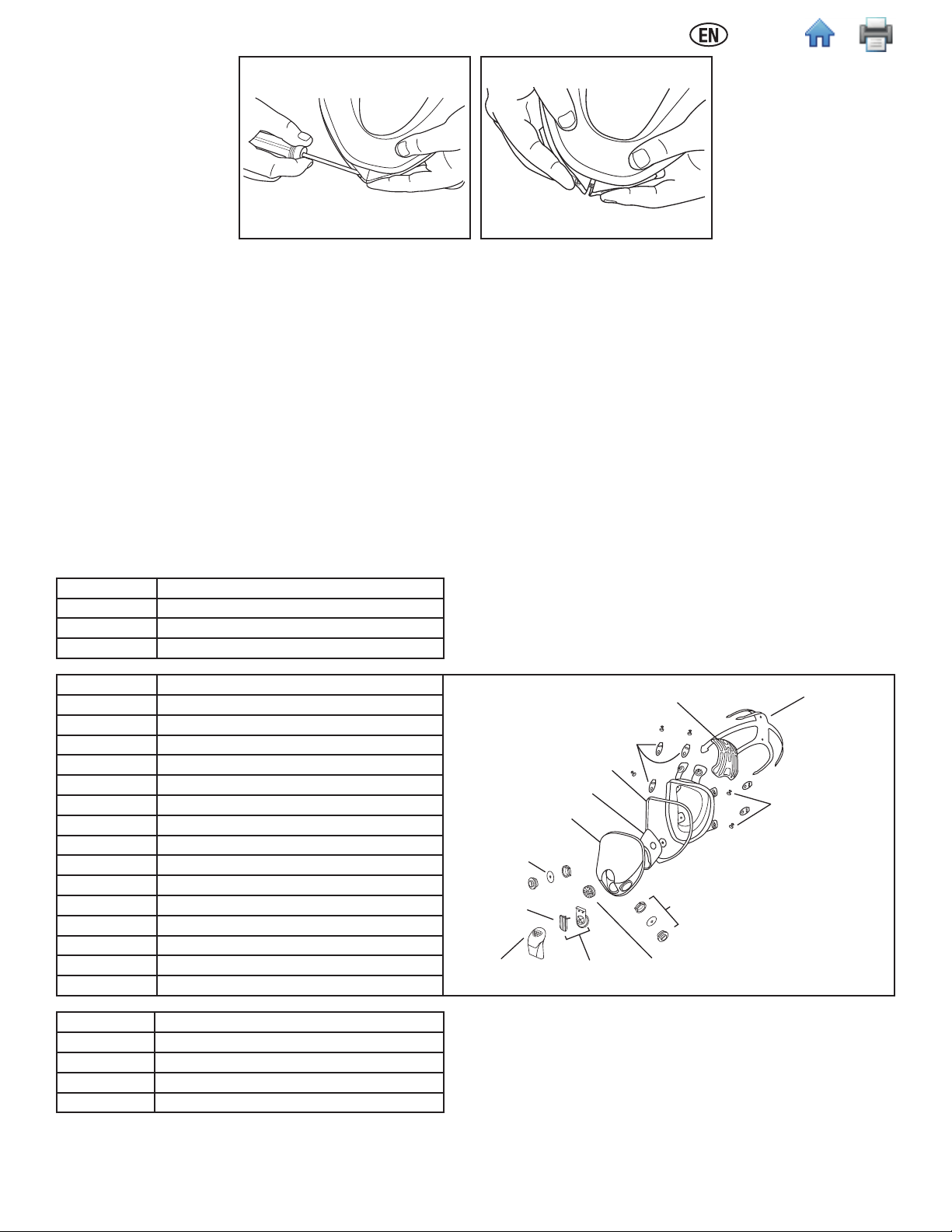

Fig. 1 Fig. 2 Fig. 3

3M™ Filters 5N11 and 5P71

1. Place lter into 3M™ Retainer 501 so printed side of lter faces the cartridge.

2. Press cartridge into lter retainer. It should snap securely into lter retainer. When correctly installed, lter should completely cover face of cartridge

(Fig. 4).

3. To replace lter, remove retainer by lifting on tab.

Fig. 4

In Brazil, the 3M™ Filter 5935BR can be used with the 3M™ Filter Retainer 501 on the 3M™ Full Facepiece FF-400 Series.

3M™ Adapter Assembly 502

1. Align adapter over cartridge. Engage front snap by squeezing front of cartridge and adapter together, placing thumbs of both hands over top of

adapter and ngers along bottom sides of cartridge (Fig. 5).

2. Engage back snap by squeezing back side of cartridge and adapter together using the same hand positions. An audible click should be heard as each

snap is engaged (Fig. 6).

3. Place lter onto the lter holder so that lter comes into even contact with gasket. Twist clockwise a quarter turn until it is rmly seated and lter

cannot be turned further. Repeat for second lter.

3

Page 5

(English)

Fig. 5 Fig. 6

IMPORTANT: The 3M™ Adapter Assembly 502, once installed on a 3M™ Cartridge 6000 Series, is not to be removed or reused. Removal or

reuse may result in leakage, overexposure, sickness or death.

3M™ Filter Adapter 603 and Filters 5N11 and 5P71

1. Align notch on edge of 603 adapter with facepiece mark as shown (Fig. 7).

2. Turn adapter 1/4 turn clockwise to stop. To remove adapter, turn 1/4 turn counterclockwise (Fig. 8).

3. Place lter into 501 retainer with lter printing facing towards the 603 adapter. Snap together and ensure the lter seal is free from creases or gaps

(Fig. 9).

1

1

2

Fig. 7

2

Fig. 8

Fig. 9

In Brazil, the 3M™ Filter 5935BR can be used with the 603 Filter Adaptor and the 501 Filter Retainer on the 3MTM Full Facepiece, FF-400 Series.

3M™ Dual Airline Respirator Assembly

User must follow Dual Airline Supplied Air Respirator User Instructions provided with the 3M™ Dual Airline Supplied Air Respirators.

Assembly of Dual Airline Breathing Tubes

1. Hold the facepiece in front of you so that the 3M logo is facing you. Align the two branches of the breathing tube over the two bayonet mounts on

facepiece (Fig. 10). For 3M™ Breathing Tubes SA-1500 or SA-1600, make sure that 3M logo on breathing tube and on facepiece are both facing

towards you. For 3M™ Breathing Tubes SA-2500 or SA-2600, make sure that the 3M logo on breathing tube is facing in opposite direction to 3M logo

on facepiece.

2. Twist each branch of breathing tube clockwise a quarter turn until it is rmly seated in the bayonet and cannot be turned further (Fig. 11 and 12). Do

not forcibly overturn as the bayonet could be damaged. SA-1500/SA-2500 shown.

3. Attach airline to approved air regulators per pressure schedules in dual airline, supplied air respirators User Instructions.

Fig. 10 Fig. 11 Fig. 12

Assembly of 3M™ Combination Dual Airline Breathing Tubes with Cartridges and/or Filters

The SA-1600 (front-mounted) and SA-2600 (back-mounted) versions of the 3M™ Dual Airline Breathing Tubes allow use of selected,

NIOSH-approved 3M™ Cartridge 6000 Series and 3M™ Filter 2000 Series. For the listing of approved cartridges and lters, reference the NIOSH

Approval Label included with 3M™ Dual Airline Adapter kits.

1. Attach SA-1600 or SA-2600 breathing tubes to facepiece per the procedures outlined previously. The procedure is identical to the SA-1500 and

SA-2500 models.

2. Make a selection of cartridges and/or lters that meets your respiratory protection requirements, and attach to the outer bayonets of SA-1600 or

SA-2600 breathing tubes.

4

Page 6

(English)

3. Don facepiece per procedures outlined in “Donning Respirator” section of instructions.

4. After being properly t tested, perform a positive and negative pressure user seal check each time the respirator is donned per procedures outlined in

“User Seal Check” section of instructions.

If you cannot achieve a proper t, DO NOT enter contaminated area. See your supervisor.

To assemble 3M™ Dual Airline Combination Breathing Tubes with 3M™ Cartridges/Filters, the facepiece inhalation valves must be removed.

IMPORTANT: If the facepiece is to be used in air-purifying mode (without using the SA-1600 or SA-2600 breathing tubes), the inhalation valves must

be replaced in the facepiece before use.

Using the 3M™ Combination Dual Airline Breathing Tubes without Cartridges and/or Filters

To use the Combination Dual Airline Breathing Tubes (SA-1600 and SA-2600) without cartridges or lters, attach a 3M™ Bayonet Cap 6880 to each

outer bayonet mount on the dual airline breathing tube. When used as a Type C, continuous ow supplied air full facepiece respirator, the Assigned

Protection Factor is 1000 times the PEL or other occupational exposure limit.

FITTING INSTRUCTIONS

W WARNING

Failure to follow these instructions may reduce respirator performance, expose you to contaminants above the OEL, and may result

in sickness or death.

• To help maintain a good seal between the face and the faceseal, the respirator faceseal must be clear of obstructions at all times. Do

not use with beards or facial hair that prevent direct contact between the face and the respirator faceseal. Do not use with corrective

eyeglasses. If corrective eyeglasses are required, a 3M™ Spectacle Kit must be used inside the respirator.

These instructions MUST be followed each time respirator is worn.

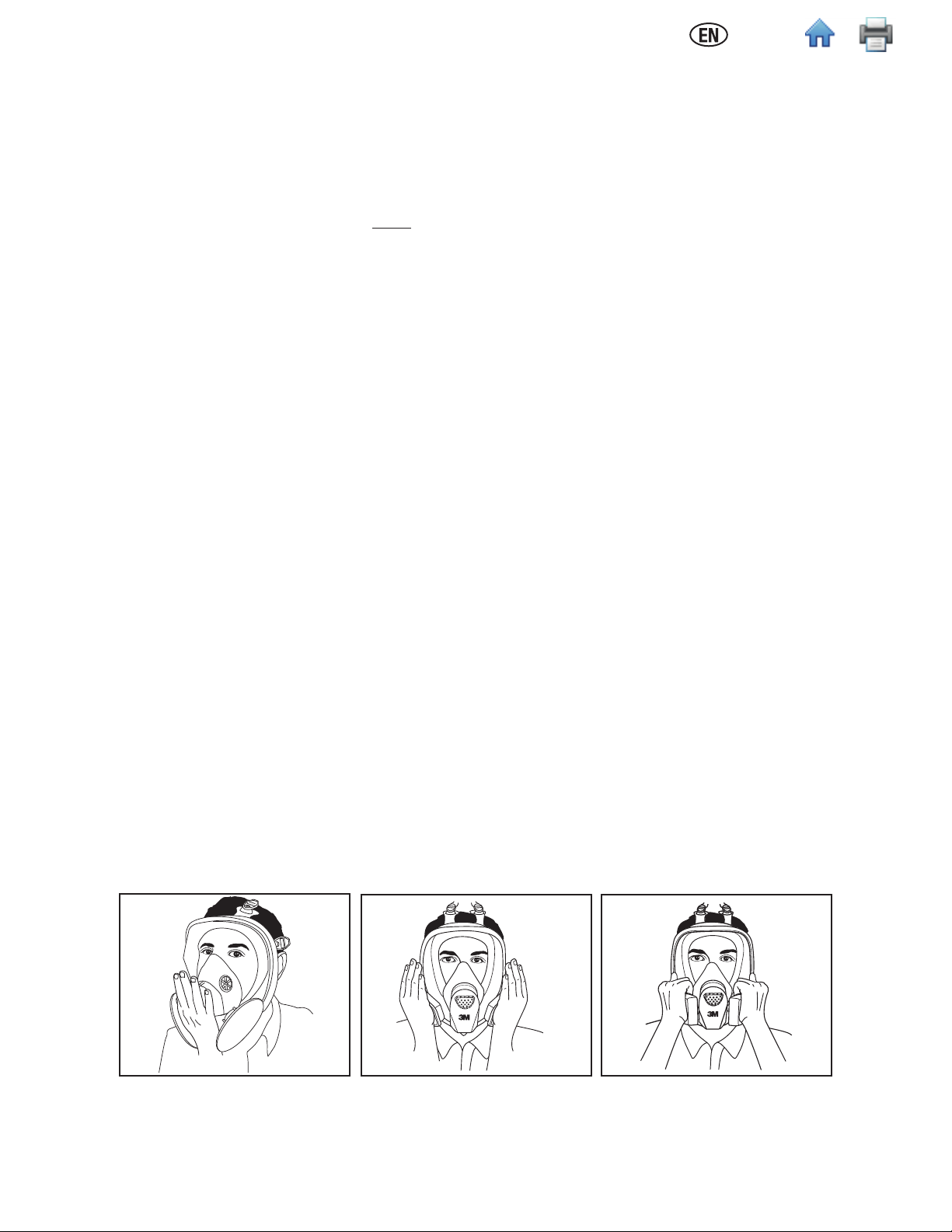

Donning Respirator

NOTE: Two key factors in effective donning are placing the nose in the nose cup initially to center the respirator on the face and to tighten

the straps twice following steps 4, 5, 6, rst to snug the respirator then repeating steps 4, 5, 6 a second time to secure the facepiece seal.

Care must be taken to not over tighten bottom straps on the rst turn.

1. Fully loosen all six headstraps.

2. Hold the front of the facepiece with one hand and the straps/comfort cradle away from the facepiece with the other hand, creating an opening for the

head. Pull the respirator assembly down over the head and face through the opening. Place the nose in the nose cup and chin in the chin cup area

then press the facepiece rmly and evenly against the face (Fig. 13).

3. Pull head harness to back of head (Fig. 13).

NOTE: Repeat the sequence of steps 4-6 twice, once to snug the straps and take up slack and a second time to secure and seal the respirator

facepiece to the face.

4. Tighten the bottom straps one at a time. Be careful to tighten both sides equally (Fig. 14).

5. Tighten the middle straps one at a time. Be careful to tighten both sides equally.

6. Tighten the top straps one at a time. Be careful to tighten both sides equally.

7. Recheck all straps to ensure that they are tight and evenly tensioned so that the head harness is centered on the back of your head. Ensure that the

straps and tabs lay at against your head.

If possible, have a partner verify that you have donned your respirator properly. Perform a user seal check as described in these User Instructions.

Fig. 13

Fig. 14

Initial Selection of Small, Medium or Large Facepieces

More than one facepiece size may need to be donned before you determine the best size for your face.

After donning verify the following.

1. Nothing (e.g. hair, jewelry, etc.) comes between the face and the sealing surface of the respirator. Facial hair or sideburns may have to be trimmed.

2. Bottom straps and middle straps do not cut into ears.

3. Eyes are looking between center and top 1/3 of the lens.

4. Respirator does not press so tightly against face that eyes are partly closed.

5. Bottom of the mask assembly does not cut into throat.

5

Page 7

(English)

6. No visible gaps between the face seal and the face.

7. Skin in front of ear is not wrinkled.

8. Nosecup does not obscure vision.

9. Ensure that other safety equipment does not interfere with buckles or t of respirator.

If any of these criteria are not met, it is possible that the respirator may not t you adequately. Selecting a different size facepiece may provide you

with a more adequate t. More than one facepiece size may need to be donned before you determine the best size for your face. A t test can conrm

adequate t. If you have further questions, see your supervisor.

User Seal Checks

Always check the seal of the respirator on your face before entering a contaminated area according to the instructions provided below for your

specic respirator conguration. The positive pressure seal check is the primary and preferred method for verication of a good seal for all cartridge

and lter congurations. The positive pressure seal check is the only method for this respirator with Filters 2000 Series. The negative pressure user

seal check can also be done for additional verication of a good seal for this respirator with Cartridges 6000 Series and Filters 7093/7093C. Be

careful not to disturb the respirator seal by pressing too forcefully during negative pressure seal checks.

IMPORTANT: If you cannot achieve a proper seal, DO NOT enter the contaminated area. See your supervisor. Before assigning any respirator

to be worn in a contaminated area, a qualitative or quantitative t test MUST be performed per OSHA Standard 1910.134, CSA Standard

Z94.4 or Brazil Respiratory Protection Program of the Ministry of Labor.

Positive Pressure User Seal Check for all approved congurations and required for Filters 2000

Series

1. Remove the exhalation valve cover by depressing bottom of cover with thumb and sliding cover up, parallel with lens.

2. Place the palm of your hand over the exhalation valve and exhale gently (Fig. 15). Care must be taken to ensure a good seal of the exhalation valve. To

do this, cover the entire face of the blue valve with the base of the palm.

3. If the facepiece bulges slightly and no air leaks are detected between the face and the facepiece, a proper seal has been obtained.

4. If faceseal air leakage is detected, reposition the respirator on your face and/or readjust the tension of the straps to eliminate leakage and

recheck seal.

5. Replace exhalation valve cover by placing open end at top of exhalation valve assembly, guide tabs underneath valve cover assembly and slide

downward until the valve cover snaps in place.

If faceseal air leakage is detected, reposition the respirator on your face and/or readjust the tension of the straps to eliminate the leakage and recheck

seal. Care must be taken when performing the positive pressure seal check not to exhale too hard. The aim is to check the seal, not disturb the seal

between the mask and the face.

Negative Pressure User Seal Check with Cartridges 6000 Series

1. Place palms of hands to cover face of cartridge or open area of 3M™ Filter Retainer 501and inhale gently. If you feel the facepiece collapse slightly

and pull closer to your face with no leaks between the face and facepiece, a proper seal has been obtained (Fig. 16).

2. If faceseal air leakage is detected, reposition the respirator on your face and/or readjust the tension of the straps to eliminate leakage and

recheckseal.

Be careful not to disturb the respirator seal by pressing too forcefully during negative pressure seal checks.

NOTE: Use of lter retainer 501 may aid respirator wearer in conducting a negative pressure user seal check.

Negative Pressure User Seal Check with Filters 7093/7093C

1. Using hands squeeze or press lter covers toward facepiece and inhale gently. If you feel the facepiece collapse slightly and pull closer to your face

with no leaks between the face and facepiece a proper seal has been obtained (Fig. 17).

2. If faceseal air leakage is detected, reposition the respirator on your face and/or readjust the tension of the straps to eliminate the leakage and recheck

seal.

Be careful not to disturb the respirator seal by pressing too forcefully during negative pressure seal checks.

Fig. 15

Fig. 16

Fig. 17

Negative Pressure User Seal Check with Dual Airline

1. Disconnect airline hose from air control valve.

2. With breathing tube still connected to the air control valve inhale gently. If you feel facepiece collapse slightly and pull closer to your face with no leaks

between the face and facepiece, a proper seal has been obtained.

6

Page 8

(English)

3. For combination dual airline where cartridges or lters are attached perform user seal check as described above under the appropriate cartridge or

lter that is being used.

4. If faceseal air leakage is detected, reposition the respirator on your face and/or readjust the tension of the straps to eliminate the leakage and recheck

seal.

IMPORTANT: If you cannot achieve a proper seal, DO NOT enter the contaminated area. See your supervisor. Before assigning any

respirator to be worn in a contaminated area, a qualitative or quantitative t test MUST be performed per OSHA Standard 1910.134, or CSA

StandardZ94.4.

RESPIRATOR REMOVAL

1. Fully loosen all six head straps by lifting up on buckles.

2. Remove respirator by pulling straps over head.

FIT TESTING

The effectiveness of a respirator will be reduced if it is not tted properly. Therefore, either qualitative or quantitative t testing must be conducted

prior to the respirator being used. Fit testing is a U.S. Occupational Safety and Health Administration (OSHA), a Canadian CSA and a Brazilian

BMOL requirement. Respirators should also be t tested while wearing any personal protective equipment (PPE) the wearer may use in their work

environment that may affect the t of the respirator (e.g. hoods, hardhats, hearing protectors, etc.). For further information concerning t testing,

contact 3M Technical Service.

Quantitative Fit Testing

Quantitative Fit Testing (QNFT) can be conducted using a 3M™ Fit Test Adapter 601 and P100 lters such as the 3M™ Particulate Filters 2091

or 7093.

Qualitative Fit Testing

Qualitative Fit Testing (QLFT) with the 3M™ Qualitative Fit Test Apparatus FT-10 or FT-30 can be conducted using any of the NIOSH approved

particulate lters.

Entering and Exiting a Contaminated Area

• Airborne contaminants which can be dangerous to your health include those that are so small you may not be able to see or smell them.

• Always conduct a user seal check before entering a contaminated area.

• Leave the contaminated area immediately if any of the following conditions occur:

• Any part of the respirator becomes damaged,

• Breathing becomes difcult,

• You feel dizzy or your vision is impaired,

• You taste or smell contaminants,

• Your face, eyes, nose or mouth become(s) irritated,

• You suspect that the concentrations of contaminants may have reached levels at which this respirator may no longer provide adequate

protection.

• Do not wear this respirator in areas where:

• Atmospheres are oxygen decient,

• Contaminant concentrations are unknown,

• Contaminant concentrations are Immediately Dangerous to Life or Health (IDLH),

• Contaminant concentrations exceed the Maximum Use Concentration (MUC) determined using the Assigned Protection Factor (APF) for the

specic respirator system or the APF mandated by specic government standards, whichever is lower.

INSPECTION, CLEANING, AND STORAGE

W WARNING

Failure to follow these instructions may reduce respirator performance, expose you to contaminants above the OEL, and may

result in sickness or death.

• Do not clean respirator with solvents. Cleaning with solvents may degrade some respirator components and reduce respirator

effectiveness.

• Inspect all respirator components before each use to ensure proper operating condition.

Inspection Procedure

This respirator must be inspected before each use to ensure that it is in good operating condition. Any damaged or defective parts must be replaced

before use. Do not enter a contaminated area with damaged or defective parts. The following inspection procedure is recommended.

1. Check facepiece for cracks, tears and dirt. Be certain facepiece, especially faceseal area, is not distorted.

2. Examine inhalation valves for signs of distortion, cracking or tearing.

3. Make sure that head straps are intact and have good elasticity.

4. Examine all plastic parts for signs of cracking or fatiguing. Ensure bayonet gaskets are in good condition.

5. Remove exhalation valve cover and examine exhalation valve and valve seat for signs of dirt, distortion, cracking or tearing. Replace exhalation valve

cover.

6. Inspect lens for any damage that may impair respirator performance or vision.

7

Page 9

(English)

Cleaning and Storage

Cleaning is recommended after each use.

1. Remove cartridges, lters and/or breathing tubes, and nose cup. The exhalation valve cover, exhalation valve assembly, speaking diaphragm, bayonet

assembly, lens and faceseal can also be disassembled if necessary.

2. Clean facepiece (excluding lters and cartridges), by immersing in warm cleaning solution, water temperature not to exceed 120°F (49°C), and scrub

with soft brush until clean. Add neutral detergent if necessary. Do not use cleaners containing lanolin or other oils.

3. Disinfect facepiece by soaking in a solution of quaternary ammonia disinfectant or sodium hypochloride (1oz. [30 mL] household bleach in 2gallons

[7.5 L] of water), or other disinfectant.

4. Rinse in fresh, warm water and air dry in non-contaminated atmosphere. Do not replace nose cup until facepiece is completely dry.

5. Respirator components must be inspected prior to each use. A respirator with any damaged or deteriorated components should be repaired or

discarded.

6. The cleaned respirator should be stored away from contaminated areas when not in use.

SPECIFICATIONS

Contact 3M Technical Service for technical specications (e.g. weight, materials of construction, etc). This product contains no components made

from natural rubber latex.

Cartridge and Filter Selection and Approvals

Before using any of these products, the user must read the specic “Use For”, “Use Limitations and Warning” information in the User Instructions and

product documentation or call 3M Technical Service. Do not exceed maximum use concentrations established by local regulatory agencies.

3M™ 6000 Series Cartridges

NIOSH Approvals

Certain Organic Vapors X X X X X X X X X X X X X

Chlorine X X X X X X X X X

Hydrogen Chloride X X X X X X X

Sulfur Dioxide X X X X X X X X X

Chlorine Dioxide X X X X

Hydrogen Sulde X X X X X X X X X

Hydrogen Fluoride X X X X X

Formaldehyde X X X X

Ammonia X X X X

Methylamine X X X X

Mercury Vapor X X

Particulate Filter P100 X X X X X X X X X

** 3M Recommended for use against methylbromide or radioiodine up to 5ppm with daily cartridge replacement.

NOTE: Not NIOSH approved for use against methylbromide or radioiodine.

NIOSH Approvals

P100 X X X X X X X X

P95 X X X X

N95 X X

HF X X

6001

2071

6001i

6002

2078**

6003

6004

2076 HF

2091

6005

6006

3M™ Filters

2096

2097**

6007

2291

60921

60921i

2296

60922

2297**

5N11

60923

60924

5P71

60925

60926

7093

60927

7093C

60928**

5935BR

Nuisance level relief*

Acid gases X X X X X

Organic Vapors X X X X

* 3M recommended for relief against nuisance levels of acid gas or organic vapors. Nuisance level refers to concentrations not exceeding OSHA PEL

or applicable exposure limits, whichever is lower. Do not use for respiratory protection against acid gas/organic vapors.

** 3M recommended for ozone protection up to 10 times the OSHA PEL or applicable government occupational exposure limits, whichever is lower.

NOTE: Not NIOSH approved for use against ozone.

8

Page 10

(English)

In Brazil, the 5935BR lter is approved as a NIOSH N95 lter and a BMOL P3 lter.

3M™ Filter Adapters and Retainers

Number Description

501 Filter Retainer for use with Cartridge 6000 Series and Filters 5N11 and 5P71

502 Filter Adapter for use with Cartridge 6000 Series and Filters 2000 and 7093/7093C

603 Filter Adapter for use with Filters 5N11 and 5P71

In Brazil, the 3M™ Filter 5935BR can be used with the Filter Adaptor 603 and the Filter Retainer 501 on the 3M™ Full Facepiece, FF-400 Series.

Service Life of Chemical Cartridges and Particulate Filters

CAUTION

Failure to properly dispose of spent cartridges, lters, or respirators contaminated by hazardous materials can result in personal exposures as well

as environmental harm. Handling, transportation and disposal of spent cartridges, lters, or respirators must comply with all applicable federal,

state, provincial, and local laws and regulations.

Time Use Limitations

1. Cartridges and lters must be used before expiration date on packaging.

2. Particle lters must be replaced if they become damaged, soiled or if an increase in breathing resistance occurs. N-series lters should not be used

in environments containing oils. R-series lters may be limited to 8 hours of continuous or intermittent use if oil aerosols are present. In environments

containing only oil aerosols, P-series lters should be replaced after 40 hours of use or 30 days, whichever is rst.

3. Service life of gas/vapor cartridges will depend upon activity of wearer (breathing rate); specic contaminant and concentration; and environmental

conditions such as humidity, pressure, and temperature. Cartridges must be replaced in accordance with an end of service life indicator, established

change schedule or earlier if smell, taste or irritation from contaminants is detected. Please see 3M Service Life Software at

www.3M.com/sls.

4. The 6007 and 60927 mercury vapor cartridges must be discarded within 50 hours of use against mercury vapor; or according to organic vapor,

chlorine, hydrogen sulde or sulfur dioxide service life, or when odors of vapors or gases become noticeable, whichever occurs rst. Mercury vapor

has no odor.

REPLACEMENT PARTS INSTRUCTIONS

3M™ Ultimate FX Full Facepiece Assembly FF-400

The facepiece assembly consists of the head harness assembly, nose cup assembly, speaking diaphragm assembly, exhalation valve assembly, lens

assembly, faceseal (small, medium or large), frame assembly (frame, nut and screw), bayonet assemblies and exhalation valve cover. To disassemble

lens assembly from faceseal, remove the Phillips screw from frame, pull the frame away from the faceseal and remove faceseal from lens assembly.

Valve Cover Replacement

1. Remove valve cover by depressing bottom of cover with thumb and sliding cover up, parallel with lens (Fig. 18).

2. Replace valve cover by placing open end at top of exhalation valve assembly, guide tabs underneath valve cover assembly and slide downward until

the valve cover snaps in place.

Fig. 18

Exhalation Valve Assembly Replacement

1. Remove valve cover by depressing bottom of cover with thumb and sliding cover up, parallel with lens (Fig. 18).

2. Remove exhalation valve assembly by turning counter clockwise 1/4 turn (Fig. 19).

3. Replace exhalation valve assembly by aligning lugs with exhalation valve assembly opening in lens and turning clockwise 1/4 turn until rm stop.

4. Replace valve cover assembly.

9

Page 11

(English)

Fig. 19

Exhalation Valve Replacement

1. Remove valve cover by depressing bottom of cover with thumb and sliding cover up, parallel with lens (Fig. 18).

2. Remove exhalation valve assembly by turning counter clockwise 1/4 turn (Fig. 19).

3. Grasp valve and pull each valve stem out from valve seat.

4. Inspect valve seat making certain it is clean and in good condition.

5. Place new exhalation valve replacement over the exhalation port by inserting stems and pulling through from the opposite side until they are both

snapped in place. Push laterally on valve stems to ensure they are properly seated.

6. Replace exhalation valve assembly.

7. Replace valve cover.

NOTE: Conduct a negative pressure user seal check to ensure exhalation valve is functioning properly.

Nose Cup Assembly Replacement

The nose cup assembly consists of a nose cup and inhalation valves. It is designed to install directly to the lens and comfortably t over the respirator

wearer’s mouth and nose to aid in purging exhaled breath and prevent lens fogging.

1. Remove the nose cup assembly by grasping the nose cup below the inhalation valve and gently pulling up and away from lens assembly (Fig. 20).

2. To replace, position nose cup assembly onto lens assembly by aligning hard plastic ring on nose cup with lens assembly and pressing rmly on center

tabs until bottom nose cup tabs snap in place (Fig. 21).

3. Press down on top of nose cup ring until tabs snap in place.

Fig. 20 Fig. 21

Speaking Diaphragm Assembly Replacement

1. Remove the nose cup assembly by grasping the nose cup below the inhalation valve and gently pulling up and away from lens assembly (Fig. 20).

2. Remove valve cover by depressing bottom of cover with thumb and sliding cover up, parallel with lens (Fig. 18).

3. Remove exhalation valve assembly by turning counter clockwise 1/4 turn.

4. Remove speaking diaphragm assembly by turning counter clockwise 1/4 turn (Fig. 22).

5. Replace speaking diaphragm assembly by aligning speaking diaphragm lugs with speaking diaphragm opening in lens assembly.

6. Turn clockwise 1/4 turn until rm stop.

7. Replace exhalation valve assembly.

8. Replace valve cover assembly.

9. Replace nose cup assembly (Fig. 21).

Fig. 22

10

Page 12

(English)

Bayonet Assembly Replacement

The bayonet assembly consists of the bayonet ring, bayonet, and inhalation gasket.

1. Remove the nose cup assembly by grasping the nose cup below the inhalation valve and gently pulling up and away from lens assembly (Fig. 20).

2. Remove bayonet ring by rotating counter clockwise 1/4 turn (Fig. 23).

3. Remove bayonet from lens assembly (Fig. 24).

4. Align key on new bayonet with slot on lens assembly and hold rmly in place.

5. Align lugs on ring with slots on bayonets and rotate clockwise 1/4 turn until rm stop.

6. Replace nose cup assembly (Fig. 21).

Fig. 23 Fig. 24

Inhalation Valve Replacement

Inhalation valves are located on bayonet assemblies at the facepiece inhalation ports and inside the nose cup inhalation ports. These valves should be

inspected before each respirator use and replaced whenever valves become damaged or lost.

1. Remove existing valve(s) by grasping valve and pulling valve stem out from valve seat.

2. Install new valve(s) onto valve seat(s) by pushing through valve stem seat(s). Be certain valve stem(s) is fully engaged through valve seat(s), lays at,

and moves freely (spins).

Head Harness Assembly Replacement

1. Remove existing head harness by unsnapping each buckle from the buttons (Fig. 25).

2. Pull the end tabs of the head harness, at an angle, out through the buckles. Note the orientation of the head harness tabs and buckles for

re-assembly.

3. Place the head harness down on a at surface with the 3M logo facing up (Fig. 26).

4. Thread the end tabs of the head harness through the buckles and pull each through until the end tab is completely through the buckle.

5. Place the facepiece lens down on a at surface and lay the new head harness and buckle assembly over the facepiece. The head harness should be

assembled with the 3M logo facing up.

6. Snap each buckle into corresponding button, ensuring that straps are not twisted.

Fig. 25 Fig. 26

Lens Frame Assembly Replacement

The lens frame assembly consists of a lens frame, nut, and screw.

1. Remove the Phillips screw from frame. Pull the frame away from the faceseal (Fig. 27).

2. Position new frame, aligning marks top and bottom. Install and securely tighten screw. Make certain alignment marks are properly aligned top and

bottom with all components (Fig. 28).

11

Page 13

(English)

Fig. 27 Fig. 28

Lens Assembly Replacement

The lens assembly consists of a hard-coated polycarbonate lens.

1. Remove the nose cup assembly by grasping the nose cup below the inhalation valve and gently pulling up and away from lens assembly (Fig. 20).

2. Remove the valve cover by depressing bottom of cover with thumb and sliding cover up, parallel with lens (Fig. 18).

3. Remove exhalation valve assembly by turning counter-clockwise 1/4 turn and withdrawing from lens center port (Fig. 19).

4. Remove speaking diaphragm by turning counter clockwise 1/4 turn (Fig. 22).

5. Remove bayonet assemblies by rotating bayonet rings counter clockwise 1/4 turn (Fig. 23) and removing bayonets from the lens assembly (Fig.24).

6. Remove the Phillips screw from frame. Pull the frame away from the faceseal (Fig. 27).

7. Remove faceseal from lens.

8. Place new lens and faceseal together aligning marks at top and bottom. Position frame, again aligning marks top and bottom. Install and securely

tighten screw. Make certain alignment marks are properly aligned top and bottom with all components (Fig.28).

9. Install speaking diaphragm.

10. Install exhalation valve assembly.

11. Replace exhalation valve cover.

12. Replace bayonet assemblies.

13. Replace nose cup assembly (Fig. 21).

3M™ Ultimate FX Full Facepiece FF-400 Replacement Parts and Accessories

Number Description

FF-401 Small

FF-402 Medium

FF-403 Large

Number Description

FF-400-01 Head Harness Buckle

FF-400-02 Head Harness Button

FF-400-03 Lens Assembly

FF-400-04 Head Harness

FF-400-05 Frame Assembly w/ Screw

FF-400-06 Comfort Cradle

FF-400-07 Exhalation Valve Assembly

FF-400-08 Bayonet Assembly Inhalation Valve

FF-400-09 Exhalation Valve Cover (Standard)

FF-400-10 Exhalation Valve Cover (Solid)

FF-400-11 Nose Cup Assembly

FF-400-13 Speaking Diaphragm Assembly

FF-400-20 Spectacle Kit

7582 Inhalation Valve

7583 or 6583 3M™ Cool Flow™ Exhalation Valve

FF-400-03

7582

7583

6583

FF-400-09

FF-400-10

FF-400-05

FF-400-11

3

FF-400-07

FF-400-06

FF-400-01

FF-400-08

FF-400-13

FF-400-04

FF-400-02

Fig. 29

Number Description

FF-400-15 Lens Cover

FF-400-17 Semi-Permanent Lens Cover

504 Respirator Cleaning Wipes

601 Quantitative Fit Test Adapter

12

Page 14

(English)

For Compliance in Brazil NOTE:

1. In Brazil, according to the Respiratory Protection Program of the Ministry of Labor, do not use quantitatively t tested full facepiece respirators when

concentrations of contaminants are greater than 100 times the permissible exposure limit in air-purifying mode.

2. Do not use in decient or enriched oxygen atmospheres.

3. Storage, Transportation and Care: store in a clean and dry place and away from contaminants and extreme temperature and humidity.

4. The components of this respirator are made of materials which are not expected to cause adverse health effects.

5. It is necessary to have special care to use this product in explosives atmospheres.

6. In Brazil do not use powered air-purifying respirators if airow is less than 120 lpm for tight tting facepieces or 170 lpm for hoods and/or helmets.

Product Manufacturing Date

The parts of the product show markings that bring information of manufacturing date, and its reading is described as in the example below:

Date Code = 12th month 2019 (12/19)

12

11 1

10

9

8

7

FOR MORE INFORMATION

In United States, contact:

Website: www.3M.com/workersafety

Technical Assistance: 1-800-243-4630

For other 3M products:

1-800-3M-HELPS or 1-651-737-6501

1 9

6

2

3

4

5

13

98-0060-0135-2_6

34-8723-6751-0

Page 15

3

FR

(Français)

Respirateur à masque complet réutilisable ultra FX

Directives d’utilisation

W MISE EN GARDE

Ce respirateur protège contre certains contaminants en suspension dans l’air. Une mauvaise utilisation peut provoquer des

problèmes de santé ou la mort. Pour tout renseignement sur l’utilisation adéquate de ce produit, consulter son superviseur, lire

les directives d’utilisation ou communiquer avec 3M, aux États-Unis, au 1 800 243-4630. Au Canada, communiquer avec le Service

technique au 1 800 267-4414.

AVANT

Ces directives d’utilisation fournissent uniquement des renseignements relatifs à l’utilisation des masques. Des renseignements importants sont

inclus dans les directives d’utilisation de chaque système de ltration d’air utilisé avec les masques complets FF-401, FF-402 et FF-403 3MMC. Lire

toute les directives d’utilisation et les mises en garde avant d’utiliser ce produit. Conserver ces directives d’utilisation à titre de référence. Pour toute

question sur ces produits, communiquer avec le Service technique de 3M.

États-Unis :

Internet : www.3M.com/workersafety

Service technique : 1 800 243-4630

Usage prévu

Les Respirateurs à masque complet ultra FX 3MMC de Série FF-400 (FF-401, FF-402 et FF-403) sont conçus pour offrir une protection respiratoire

contre certains contaminants en suspension dans l’air lorsqu’on les utilise conformément à toutes les directives et restrictions d’utilisation,

ainsi qu’aux règlements applicables en matière de santé et de sécurité. Les masques de Série FF-400 répondent aux exigences de la norme

Z87.1-2010 de l’ANSI en matière de protection des yeux et du visage. Ces produits offrent une protection limitée des yeux et du visage contre la

projection departicules.

Canada :

Site Web : www.3M.ca/Safety

Assistance technique : 1 800 267-4414

W MISE EN GARDE

Les respirateurs qui sont bien choisis, utilisés et entretenus aident à protéger contre certains contaminants en réduisant les

concentrations de contaminants en suspension dans l’air sous la limite d’exposition permise en milieu de travail. Il est essentiel

de suivre toutes les directives d’utilisation et les réglementations gouvernementales portant sur l’utilisation de ce produit, ce qui

comprend le port du système de protection respiratoire complet pendant tout le temps d’exposition an que le produit puisse aider

à protéger l’utilisateur. Une mauvaise utilisation des respirateurs peut résulter en une surexposition de l’utilisateur aux

contaminants et causer des problèmes de santé ou la mort. Pour tout renseignement sur l'utilisation adéquate de ce produit,

consulter son superviseur, lire les directives d'utilisation ou communiquer avec le Service technique de 3M.

Liste des mises en garde et des avertissements énoncés dans les présentes directives d’utilisation

W MISE EN GARDE

Tout manquement à ces directives peut réduire le rendement du respirateur, vous surexposer à des contaminants au-dessus de la

limite d’exposition permise en milieu de travail et peut causer des problèmes de santé ou la mort.

• Pour aider à maintenir une bonne étanchéité entre le visage et la membrane d’étanchéité faciale, la membrane d’étanchéité faciale

doit être exempte de toute obstruction en tout temps. Ne pas utiliser si l’on porte la barbe ou des poils susceptibles d’empêcher un

contact direct entre le visage et la membrane d’étanchéité faciale. Ne pas utiliser avec des lunettes de correction de la vue. Si l’on

doit porter des lunettes, utiliser la trousse pour lunettes 3MMC à l’intérieur du respirateur.

• Ne pas nettoyer le respirateur à l’aide de solvants. Le nettoyage du respirateur avec des solvants peut endommager certains de ses

composants et en réduire l’efcacité.

• Inspecter tous les composants du respirateur avant chaque utilisation an de s’assurer qu’il est en bon état de fonctionnement.

• Ne pas modier ni utiliser le respirateur de façon abusive ou incorrecte.

AVERTISSEMENT

Le fait de ne pas mettre convenablement au rebut les cartouches, les ltres et les respirateurs usés et contaminés par des substances dangereuses

peut entraîner une exposition personnelle et des dommages environnementaux. La manipulation, le transport et la mise au rebut des cartouches,

des ltres et des respirateurs usés doivent être conformes aux lois fédérales, provinciales et municipales applicables.

1

Page 16

FR

(Français)

Avertissements et restrictions du NIOSH pour une utilisation par pression négative

Les restrictions suivantes peuvent s’appliquer. Consulter l’étiquette d’homologation du NIOSH. Lorsqu’on utilise le masque FF-400 comme

composante d’une conguration de respirateur à adduction d’air, consulter les directives d’utilisation qui accompagnent le dispositif de ltration d’air

pour obtenir des renseignements sur les avertissements et les restrictions du NIOSH.

A - Ne pas utiliser lorsque la concentration ambiante en oxygène est inférieure à 19,5%.

B - Ne pas utiliser si l’atmosphère présente un danger immédiat pour la vie ou la santé.

C - Ne pas utiliser en présence de concentrations supérieures au taux établi par la réglementation.

H - Se conformer aux horaires de changement établis des cartouches et boîtiers ltrants ou tenir compte de l’indicateur de n de durée utile (IFDU) pour

s’assurer de remplacer la cartouche et les boîtiers ltrants avant la n de leur durée de protection.

J - L’utilisation et l’entretien inadéquats de ce produit peuvent provoquer des blessures ou la mort.

L - Pour le changement des cartouches, des boîtiers ltrants et/ou des ltres, suivre les directives d’utilisation du fabricant.

M - Tous les respirateurs homologués doivent être sélectionnés, ajustés, portés et entretenus conformément aux règlements de la MSHA, de l’OSHA et à

tout autre règlement en vigueur.

N - Ne jamais substituer ou modier ce produit ni lui ajouter ou lui enlever des pièces. N’utiliser que les pièces de rechange exactes indiquées par le

fabricant.

O - Consulter les directives d’utilisation et/ou les manuels d’entretien pour obtenir des renseignements sur l’utilisation et l’entretien de ces respirateurs.

S - Des directives d’utilisation spéciales ou d’importance capitale et/ou des restrictions d’utilisation spéciques s’appliquent. Consulter les directives

d’utilisation avant de porter ce produit.

S - Directives d’utilisation spéciales ou d’importance capitale

Les Cartouches contre les vapeurs organiques 3MMC (6001i et 60921i) sont dotées d’un Indicateur de n de durée utile 3MMC (IFDU) passif.

L’indicateur doit être facilement visible par celui qui porte le respirateur. Si on ne peut pas voir facilement l’IFDU, utiliser un miroir pour l’observer

ou se er à un collègue qui peut le voir, ou aller dans un endroit propre, retirer le respirateur et observer l’IFDU. Ne pas se er uniquement à l’IFDU

de la cartouche contre les vapeurs organiques à moins que l’employeur ait déterminé qu’il convient au milieu de travail. Consulter les Directives

d’utilisation des cartouches 6001i ou 60921i pour obtenir de plus amples renseignements, y compris des directives spéciales concernant l’IFDU.

Les Cartouches contre les vapeurs de mercure, les vapeurs organiques et les gaz acides 3MMC (6007 et 60927) doivent être mises au rebut après 50

heures d’utilisation contre les vapeurs de mercure.

Le Filtre P95 contre les particules, le uorure d’hydrogène avec protection contre les concentrations nuisibles de gaz acides 2076HF 3MMC et le Filtre

P100 contre les particules, le uorure d’hydrogène avec protection contre les concentrations nuisibles de gaz acides 7093C 3MMC sont recommandés

pour la protection contre les concentrations nuisibles de gaz acides ou de vapeurs organiques. Par concentrations nuisibles, on entend les concentrations

inférieures à la limite d’exposition admissible de l’OSHA ou à la limite d’exposition en milieu de travail établie par le gouvernement, selon la valeur la

moins élevée. Ne pas utiliser pour la protection respiratoire contre les gaz acides ou les vapeurs organiques, sauf le uorure d’hydrogène.

Avant d’effectuer le montage des ltres et cartouches 3MMC sur les tuyaux de respiration combinés à deux arrivées d’air 3MMC, retirer le masque et

les soupapes d’inhalation.

Remettre les soupapes d’inhalation dans le masque avant chaque utilisation si on utilise le masque en mode d’épuration d’air (sans tuyau de

respiration SA-1600 ou SA-2600 3MMC).

Programme de gestion du respirateur

L’utilisation professionnelle des respirateurs doit être conforme avec les normes de santé et de sécurité applicables. Selon la loi, les employeurs

américains doivent établir un programme de protection respiratoire écrit qui satisfaits aux exigences de la norme de protection respiratoire 29 CFR

1910.134 de l’OSHA et toute norme de l’OSHA applicable à une substance spécique. Au Canada, se conformer à la normeZ94.4 de la CSA et/ou aux

exigences de l’autorité compétente, tel qu’approprié. Au Brésil, suivre le programme de protection respiratoire du ministère du Travail.

Pour tout renseignement supplémentaire sur cette norme, communiquer avec l’OSHA à l’adresse www.OSHA.gov. Consulter un hygiéniste industriel

ou appeler le Service technique de 3M pour toute question concernant l’application de ces produits aux exigences de votre travail.

Tableau 1 : Sections principales de la norme 29 CFR 1910.134 de l’OSHA

Section Description

A Pratique admissible

B Dénitions

C Appareils de protection respiratoire

D Sélection des respirateurs

E Évaluations médicales

F Essai d’ajustement

G Utilisation des respirateurs

H Maintenance et entretien des respirateurs

I Qualité de l’air respirable et utilisation

J Identication des cartouches, ltres et contenants

K Formation et informations

L Évaluation du programme

M Tenue des dossiers

2

Page 17

FR

(Français)

Facteurs de protection caractéristiques

Tableau2 : Facteurs de protection caractéristiques

Type de respirateur Facteur de protection assigné

Respirateur à épuration d’air à pression négative avec masque complet 10/50

Respirateur à adduction d’air à débit continu avec masque complet 1000

1

L’utilisateur du respirateur doit subir un essai d’ajustement réalisé à l’aide d’une méthode d’essai d’ajustement quantitatif an d’obtenir un facteur

de protection assigné supérieur à 10 lorsqu’utilisé comme respirateur d’épuration d’air à pression négative.

Au Brésil, conformément au programme de protection respiratoire du ministère du Travail, ne pas utiliser de respirateurs à masque complet qui ont

subi un essai d'ajustement quantitatif si les concentrations de contaminants sont supérieures à 100 fois la limite d'exposition admissible en mode

d'épuration d'air.

1

DIRECTIVES D’OPÉRATION

Déballage

Inspecter le contenu de l’emballage pour vérier s’il a été endommagé pendant l’expédition et s’assurer que tous les composants sont présents

(consulter la Fig. 27). Le produit doit être inspecté avant chaque utilisation conformément aux procédures décrites dans la section « Inspection » de

ces directives d’utilisation.

Assemblage

Cartouche 3MMC de série 6000, ltre 7093 et ensemble cartouche/ltre 7093C 3MMC (Fig. 1, 2)

1. Aligner l’encoche de la cartouche ou du ltre avec la patte rigide du raccord du dispositif de verrouillage du masque et les enclencher en poussant.

2. Tourner le ltre dans le sens des aiguilles d’une montre jusqu’à ce qu’il soit bien inséré et qu’il arrête de tourner (environ 1/4 de tour).

3. Répéter avec le second ltre ou la seconde cartouche.

Filtre 3MMC de série 2000 (Fig. 3)

1. Aligner l’ouverture du ltre avec le dispositif de xation de ltre situé sur le masque et les enclencher en poussant.

2. Faire tourner le ltre dans le sens des aiguilles d’une montre jusqu’à ce qu’il soit immobilisé et ne puisse tourner davantage.

3. Suivre les mêmes directives pour le second ltre.

Fig. 1 Fig. 2 Fig. 3

Filtres 5N11 et 5P71 3M

1. Placer le ltre dans le dispositif de retenue501 3MMC, côté imprimé face à la cartouche.

2. Enfoncer la cartouche dans le dispositif de retenue de ltre. S’assurer qu’elle est parfaitement insérée dans le dispositif de retenue. Lorsqu’il est

parfaitement inséré, le ltre couvre entièrement la surface de la cartouche (Fig.4).

3. Pour replacer le ltre, retirer le dispositif de retenue en soulevant la languette.

MC

Fig. 4

Au Brésil, le ltre 5935BR 3MMC peut être utilisé sur le dispositif de retenu 501 3MMC sur le masque complet 3MMC de série FF-400.

3

Page 18

FR

(Français)

Montage de l’adaptateur 502 3M

MC

1. Aligner l’adaptateur sur la cartouche. Enclencher l’encoche avant dans la cartouche en comprimant ensemble l’avant de la cartouche et l’adaptateur.

Pour ce faire, placer les pouces sur la partie supérieure de l’adaptateur et les doigts le long de la partie inférieure de la cartouche (Fig.5).

2. Enfoncer l’encoche arrière de la même façon, en plaçant les pouces et les doigts de la même manière. Un déclic se fait entendre lorsque chaque

languette est enclenchée (Fig. 6).

3. Insérer le ltre dans le dispositif de retenue de ltre de manière qu’il soit en contact uniforme avec le joint d’étanchéité. Faire tourner le ltre de

un quart de tour dans le sens des aiguilles d’une montre jusqu’à ce qu’il soit bien inséré et qu’il ne puisse tourner davantage. Suivre les mêmes

directives pour le second ltre.

Fig. 5 Fig. 6

REMARQUE IMPORTANTE : L’ensemble adaptateur 502 3MMC, une fois installé sur une cartouche 3MMC de série6000, ne doit pas être enlevé

ni réutilisé. Le retirer ou le réutiliser peut entraîner des fuites, une surexposition, des problèmes de santé ou la mort.

Adaptateur pour ltres 603 et ltres 5N11 ou 5P71 3MMC

1. Aligner l’encoche sur le bord de l’adaptateur 603 avec la marque du masque comme l’indique l’illustration (Fig. 7).

2. Tourner l’adaptateur d’un quart de tour dans le sens des aiguilles d’une montre. Pour retirer l’adaptateur, tourner d’un quart de tour dans le sens

contraire des aiguilles d’une montre (Fig. 8).

3. Placer le ltre dans le dispositif de retenue 501 en s’assurant que le côté imprimé soit face à l’adaptateur 603. Les enclencher ensemble et s’assurer

que le joint du ltre est exempt de plis ou de vides (Fig. 9).

1

1

2

Fig. 7

2

Fig. 8

Fig. 9

Au Brésil, le Filtre 5935BR 3MMC est homologué par le NIOSH et le ministère du Travail du Brésil en tant que ltre N95 et en tant que ltre P3,

respectivement. Il peut être utilisé avec l'adaptateur pour ltre 603 et le dispositif de retenue du ltre 501 sur le Respirateur à demi-masque 3MMC

de Série 6000.

Montage du respirateur à deux arrivées d’air 3M

MC

L’utilisateur doit suivre les directives d’utilisation fournies avec les respirateurs à deux arrivées d’air 3MMC.

Montage des tuyaux de respiration à deux arrivées d’air

1. Tenir le masque, logo 3M face à soi. Aligner les deux extrémités du tuyau de respiration avec les deux supports à baïonnette situés sur le masque (Fig.

10). Pour les tuyaux de respiration SA-1500 ou SA-1600 3MMC, s’assurer que le logo 3M qui se trouve sur le tuyau de respiration et sur le masque

soient tous deux face à soi. Pour les tuyaux de respiration SA-2500 et SA-2600 3MMC s’assurer que le logo 3M situé sur le tuyau de respiration soit

opposé au logo 3M situé sur le masque.

2. Tourner d’un quart de tour les deux extrémités du tuyau de respiration dans le sens des aiguilles d’une montre jusqu’à ce qu’elles s’enclenchent

fermement dans les raccords de verrouillage et ne puissent plus tourner (Fig. 11 et 12). Ne pas trop tourner, car cela risque d’endommager le

dispositif de verrouillage. Tuyaux de respiration SA-1500/SA-2500 illustrés.

3. Relier le tuyau d’air comprimé aux dispositifs de régulation d’air homologués, en se conformant aux pressions énoncées dans les directives

d’utilisation des systèmes à adduction d’air à deux arrivées d’air.

4

Page 19

FR

(Français)

Fig. 10 Fig. 11 Fig. 12

Montage des tuyaux de respiration combinés à deux arrivées d’air 3MMC avec cartouches et/ou

ltres

Les tuyaux de respiration à deux arrivées d’airSA-1600 (monté à l’avant) et SA-2600 (monté à l’arrière) 3MMC permettent l’utilisation de certaines

cartouches 3MMC de série6000 et de certains ltres 3MMC de série2000 homologués par le NIOSH. Pour obtenir la liste des cartouches et des ltres

homologués, consulter l’étiquette d’homologation du NIOSH comprise dans les trousses d’adaptateur à deux arrivées d’air 3MMC.

1. Relier le tuyau de respiration SA-1600 ou SA-2600 au masque, conformément aux directives énoncées précédemment. Ce sont les mêmes directives

que pour les modèles SA-1500 et SA-2500.

2. Choisir les cartouches et/ou les ltres convenant aux besoins en matière de protection respiratoire et les xer aux dispositifs de verrouillage externes

du tuyau de respirationSA-1600 ou SA-2600.

3. Porter le masque selon les directives indiquées à la section « Mise en place du respirateur ».

4. Une fois le respirateur correctement ajusté, effectuer les vérications de l’ajustement par pression positive et négative avant chaque utilisation,

conformément aux directives indiquées à la section « Vérifcation de l’ajustement ».

Si l’on ne peut obtenir un ajustement parfaitement étanche, ne pas pénétrer dans la zone contaminée. Consulter son superviseur.

Avant d’effectuer le montage des ltres et cartouches 3MMC sur les tuyaux de respiration combinés à deux arrivées d’air 3MMC, retirer le masque et

les soupapes d’inhalation.

REMARQUE IMPORTANTE : Replacer les soupapes d’inhalation dans le masque avant chaque utilisation si on utilise le masque en mode d’épuration

d’air (sans tuyau de respirationSA-1600 ou SA-2600).

Utilisation des tuyaux de respiration combinés à deux arrivées d’air 3MMC sans cartouches ni ltres

Pour utiliser les tuyaux de respiration SA-1600 et SA-2600 combinés à deux arrivées d’air sans les cartouches ou les ltres, xer un Capuchon

à baïonnette 6880 3MMC à chacun des supports de baïonnette extérieurs sur le tuyau de respiration à deux arrivées d’air. Lorsque le masque

complet est utilisé comme respirateur à adduction d’air à débit continu de type C, son facteur de protection caractéristique est de 1000 fois la limite

d’exposition admissible ou une autre limite d’exposition en milieu de travail.

DIRECTIVES D’AJUSTEMENT

W MISE EN GARDE

Tout manquement à ces directives peut réduire le rendement du respirateur, vous surexposer à des contaminants au-dessus de la

limite d’exposition permise en milieu de travail et peut causer des problèmes de santé ou la mort.

• Pour aider à maintenir une bonne étanchéité entre le visage et la membrane d’étanchéité faciale, la membrane d’étanchéité faciale

doit être exempte de toute obstruction en tout temps. Ne pas utiliser si l’on porte la barbe ou des poils susceptibles d’empêcher un

contact direct entre le visage et la membrane d’étanchéité faciale. Ne pas utiliser avec des lunettes de correction de la vue. Si l’on

doit porter des lunettes, utiliser la trousse pour lunettes 3MMC à l’intérieur du respirateur.

On DOIT suivre ces directives chaque fois que l’on utilise le respirateur.

Mise en place du respirateur

REMARQUE : Deux facteurs sont essentiels pour la mise en place du respirateur. Ils consistent à placer, au début, le nez dans la coquille

nasale pour centrer le respirateur sur le visage et de serrer les courroies deux fois en suivant les étapes 4, 5 et 6, en premier pour ajuste le

respirateur, puis de répéter les étapes 4, 5 et 6 une seconde fois pour sécuriser la membrane d’étanchéité faciale. Il faut faire attention de

ne pas trop serrer les courroies inférieures la première fois.

1. Desserrer complètement les six courroies de tête.

2. Tenir l’avant du masque avec une main et les courroies éloignées du masque avec l’autre main an de créer une ouverture pour la tête. Pousser

l’ensemble respirateur vers le bas au-dessus de la tête et du visage, à travers l’ouverture. Placer le nez dans la coquille nasale et le menton dans la

mentonnière puis appuyer le masque de façon ferme et uniforme contre le visage (Fig. 13).

3. Tirer le harnais à l’arrière de la tête (Fig. 13).

REMARQUE : Répéter les étapes 4 à 6 deux fois, une fois pour serrer les courroies et éliminer le jeu et une deuxième fois pour sécuriser et sceller le

masque du respirateur sur le visage.

4. Serrer les courroies inférieures du respirateur, une à la fois. S’assurer de serrer les deux côtés de façon égale (Fig. 14).

5

Page 20

FR

(Français)

5. Serrer les courroies du milieu du respirateur, une à la fois. S’assurer de serrer les deux côtés de façon égale.

6. Serrer les courroies supérieures du respirateur, une à la fois. S’assurer de serrer les deux côtés de façon égale.

7. Vérier à nouveau toutes les courroies pour s’assurer qu’elles sont bien serrées et qu’elles ont la même tension de façon à ce que le harnais de tête

soit centré au dos de la tête. S’assurer que les courroies et les languettes sont disposées à plat sur la tête.

Dans la mesure du possible, demander à une autre personne de vérier si le respirateur a été mis en place correctement. Vérier l’ajustement comme

décrit dans ces directives d’utilisation.

Fig. 13

Fig. 14

Sélection initiale du masque – petit, moyen ou grand

Essayer plus d’une taille de masque avant de déterminer celui qui est le plus confortable sur le visage.

Après la mise en place, procéder aux vérications ci-dessous.

1. Rien (p. ex., pilosité, bijoux) ne doit s’interposer entre la surface de scellement du masque et le visage. Il est possible qu’on doive tailler la barbe ou les

favoris.

2. Les courroies inférieures et intermédiaires ne doivent pas passer par-dessus les oreilles.

3. Les yeux doivent être situés entre le centre et le tiers supérieur des lentilles.

4. Le respirateur ne doit pas être serré au point d’empêcher d’ouvrir complètement les yeux.

5. Le bas de l’ensemble masque ne doit pas trop serrer la gorge.

6. Aucun espace ne doit être visible entre la membrane d’étanchéité faciale et le visage.

7. La peau devant l’oreille ne doit pas plisser.

8. La coquille nasale ne doit pas nuire pas à la vision.

9. S’assurer qu’aucun autre équipement de protection n’interfère avec les boucles ou l’ajustement du respirateur.

Tout manquement à ces critères signie peut-être que le respirateur n’est pas adéquatement ajusté. Il est possible qu’une autre taille de masque soit

plus adéquate. Essayer plus d’une taille de masque avant de déterminer celui qui est le plus confortable sur le visage. Un essai d’ajustement peut

conrmer que l’ajustement est adéquat. Pour toute question, consulter son superviseur.

Vérication de l’ajustement par l’utilisateur

Toujours vérier l’ajustement du respirateur sur son visage avant d’entrer dans une zone contaminée conformément aux directives fournies

ci-dessus pour la conguration spécique à son respirateur. La vérication de l’ajustement par pression positive est la méthode à privilégier pour la

vérication d’un bon ajustement pour toutes les congurations de ltre et cartouche. La vérication de l’ajustement par pression positive est la seule

méthode pour ce respirateur avec les ltres de la série 2000. La vérication de l’ajustement par pression négative peut être également être effectuée

pour vérier une fois de plus le bon ajustement de ce respirateur avec les cartouches de série 6000 et les ltres 7093/7093C. Faire attention de ne

pas modier l’ajustement du respirateur en appuyant trop fort pendant les vérications d’ajustement par pression négative.

REMARQUE IMPORTANTE : Si l’on ne peut obtenir un ajustement parfaitement étanche, NE PAS pénétrer dans la zone contaminée.

Consulter son superviseur. Effectuer un essai d’ajustement quantitatif ou qualitatif avant de choisir quel respirateur porter dans une zone

contaminée, conformément à la norme 1910.134 de l’OSHA, à la norme Z94.4 de la CSA ou au programme de protection respiratoire du

ministère du Travail au Brésil.

Vérication de l’ajustement de l’utilisateur par pression positive pour toutes les congurations

approuvées et requise pour les ltres de série 2000

1. Retirer le couvercle de la soupape d’exhalation en appuyant sur le bas du couvercle avec le pouce et en le faisant glisser, parallèlement avec la

lentille.

2. Placer la paume de la main sur la soupape d’exhalation et expirer doucement (Fig. 15). Prendre bien soin de s’assurer du bon ajustement de la

soupape d’exhalation. Pour ce faire, la face complète de la soupape bleue avec la base de la paume.

3. Si le masque gone légèrement et que l’on ne détecte aucune fuite d’air entre le visage et le masque, l’ajustement est bon.

4. Si l’on détecte une fuite d’air, replacer le respirateur sur le visage et/ou rajuster la tension des courroies an d’éliminer les fuites et vérier de nouveau

l’ajustement.

5. Replacer le couvercle de la soupape d’exhalation en plaçant l’extrémité ouverte au haut de l’ensemble de soupape d’exhalation, en orientant les

languettes sous l’ensemble de soupape d’exhalation et en glissant vers le bas jusqu’à ce que le couvercle de la soupape s’enclenche en place.

Si l’on détecte une fuite d’air, replacer le respirateur sur le visage et/ou rajuster la tension des courroies an d’éliminer les fuites, puis vérier de

nouveau l’ajustement. Faire attention de ne pas exhaler trop fort lorsqu’on effectue la vérication d’ajustement par pression positive. L’objectif est de

vérier l’ajustement sans modier l’ajustement entre le masque et le visage.

6

Page 21

FR

(Français)

Vérication de l’ajustement par pression négative avec les cartouches de série6000

1. Placer les paumes de la main sur la surface de la cartouche ou sur la région ouverte du dispositif de retenue de ltre501 3MMC et inhaler doucement.

Si le masque s’affaisse légèrement, qu’il se resserre sur le visage et que l’on ne détecte aucune fuite d’air entre le visage et le masque, l’ajustement

est bon (Fig. 16).

2. Si l’on détecte une fuite d’air, replacer le respirateur sur le visage et/ou rajuster la tension des courroies an d’éliminer les fuites et vérier de nouveau

l’ajustement.

Faire attention de ne pas modier l’ajustement du respirateur en appuyant trop fort pendant les vérications d’ajustement par pression négative.

REMARQUE : L’utilisation du dispositif de retenue de ltre501 3MMC peut faciliter l’exécution de l’essai d’ajustement par pression négative.

Vérication de l’ajustement par pression négative avec les ltres7093/7093C

1. Appuyer ou exercer une pression avec les mains sur les couvercles de ltre en direction du masque et inhaler doucement. Si le masque s’affaisse

légèrement, qu’il se resserre sur le visage et que l’on ne détecte aucune fuite d’air entre le visage et le masque, l’ajustement est bon (Fig. 17).

2. Si l’on détecte une fuite d’air, replacer le respirateur sur le visage et/ou rajuster la tension des courroies an d’éliminer les fuites, puis vérier de

nouveau l’ajustement.

Faire attention de ne pas modier l’ajustement du respirateur en appuyant trop fort pendant les vérications d’ajustement par pression négative.

Fig. 15

Fig. 16

Fig. 17

Vérication de l’ajustement par pression négative pour les respirateurs à deux arrivées d’air

1. Débrancher le tuyau d’air comprimé de la soupape de régulation d’air.

2. Avec le tuyau de respiration toujours raccordé à la soupape de régulation d’air, inhaler doucement. Si le masque s’affaisse légèrement, qu’il se

resserre sur le visage et que l’on ne détecte aucune fuite d’air entre le visage et le masque, l’ajustement est bon.

3. Pour les systèmes combinés à deux arrivées d’air munis de cartouches ou de ltres, effectuer une vérication de l’ajustement conformément aux

directives ci-dessus en fonction de la cartouche ou du ltre approprié utilisé.

4. Si l’on détecte une fuite d’air, replacer le respirateur sur le visage et/ou rajuster la tension des courroies an d’éliminer les fuites, puis vérier de

nouveau l’ajustement.

REMARQUE IMPORTANTE : Si l’on ne peut obtenir un ajustement parfaitement étanche, NE PAS pénétrer dans la zone contaminée. Consulter

son superviseur. Avant de porter un respirateur dans une zone contaminée, on DOIT procéder à un essai d’ajustement qualitatif ou

quantitatif conformément à la norme 1910.134 de l’OSHA ou Z94.4 de la CSA.

RETRAIT DU RESPIRATEUR

1. Desserrer complètement les six courroies de tête en tirant vers le haut sur les boucles.

2. Retirer le respirateur en faisant passer les courroies par-dessus la tête.

ESSAI D’AJUSTEMENT

Un mauvais ajustement du respirateur en diminue l’efcacité. C’est pourquoi on doit effectuer un essai d’ajustement quantitatif ou qualitatif avant

d’utiliser le respirateur. L’essai d’ajustement est une exigence de l’Occupational Safety and Health Administration (OSHA) aux États-Unis, de

la CSA au Canada et du ministère du Travail du Brésil. Les respirateurs doivent être soumis à un essai d’ajustement avec le matériel de protection

individuelle qu’on prévoit porter dans son milieu de travail et qui pourrait affecter l’ajustement du respirateur (p. ex., cagoules, casques durs,

dispositifs de protection de l’ouïe, etc.). Pour obtenir de plus amples renseignements au sujet des essais d’ajustement, communiquer avec le Service

technique de 3M.

Essai d’ajustement quantitatif

On peut faire l’essai d’ajustement quantitatif à l’aide d’un adaptateur pour essai d’ajustement 601 3MMC et de ltres P100 comme les ltres 2091 ou

7093 3MMC contre les particules.

Essai d’ajustement qualitatif

On peut réaliser l’essai d’ajustement qualitatif à l’aide des appareils d’essai d’ajustement qualitatif FT-10 ou FT-30 3MMCet de tout ltre contre les

particules homologué par le NIOSH.

7

Page 22

FR

(Français)

Entrer dans une zone contaminée et en sortir

• Les contaminants en suspension dans l’air qui peuvent être dangereux pour la santé englobent ceux qui sont tellement petit que vous pourriez ne pas

être en mesure de les voir ou de les sentir.

• Toujours effectuer un essai d’ajustement avant d’entrer dans une zone contaminée.

• Quitter immédiatement la zone contaminée si l’une ou l’autre des conditions ci-dessous survient :

• Une partie du respirateur est endommagée.

• La respiration devient difcile.

• On éprouve des étourdissements ou des problèmes de vision.

• On décèle un goût ou une odeur de contaminants.

• On ressent une irritation au visage, aux yeux, au nez ou à la bouche.

• On pense que la concentration des contaminants a atteint un niveau tel que le respirateur ne fournit plus une protection adéquate.

• Ne pas porter ce respirateur en présence des conditions ci-dessous :

• Atmosphères décientes en oxygène.

• Atmosphères où les concentrations des contaminants sont inconnues.

• Atmosphères où les concentrations des contaminants présentent un danger immédiat pour la vie ou la santé (DIVS).

• Les concentrations de contaminants qui dépassent la concentration maximale d’utilisation, telle que déterminée en utilisant le facteur de

protection caractéristique du système de protection respiratoire ou le facteur de protection caractéristique exigé par les normes spéciques du

gouvernement, selon la valeur la moins élevée.

INSPECTION, NETTOYAGE ET ENTREPOSAGE

W MISE EN GARDE