Page 1

S c o t c h l ok™UD W2

D rop Wi re Co n n e c t o r

The 3M brand Scotchlok

™

UDW2 Connector is the

easiest drop wire connector

to install.

The UDW2 is a full pair, moistureresistant drop wire connector designed

to accommodate 16 - 19 AWG

(1.3 mm - 0.9 mm) copper or coppercoated steel conductors in strain relief

areas. Its precrimp feature helps hold

the drop wires in place until the

connector is crimped and the splice is

complete. Molded from a black UV

resistant plastic, the UDW2 does not

require taping.

The Scotchlok UDW2 Connector

is ideal for use on Alpha Duct GT-7,

Alpha Tel, F-Drop and C-Drop wire

accommodating a maximum

insulation of 0.175” x 0.180” (4.45

mm x 4.57 mm) and a minimum of

0.100” x 0.100” (2.54 mm x 2.54 mm).

When used in mid-span applications

or where tensile load is greater than 50

pounds, additional strain relief should

be provided using wire clamps.

For best results, use with Scotchlok

E-9B or E-9BM Crimping Tools.

UDW2 Connectors are available in

bags of 25 connectors.

Page 2

1.0 General

The 3M brand Scotchlok™UDW2

Drop Wire Connector is a full pair

moisture-resistant drop wire connector

especially designed for 16 - 19 AWG

(1.3 mm - 0.9 mm) copper or copperclad steel conductors with insulation

diameters up to .175” (4.4 mm) O.D.

2.0 Accessories Required

• Scotchlok E-9B or E-9BM

Crimping Tool

• Double Headed Drop Wire Clamps

(if used mid-span)

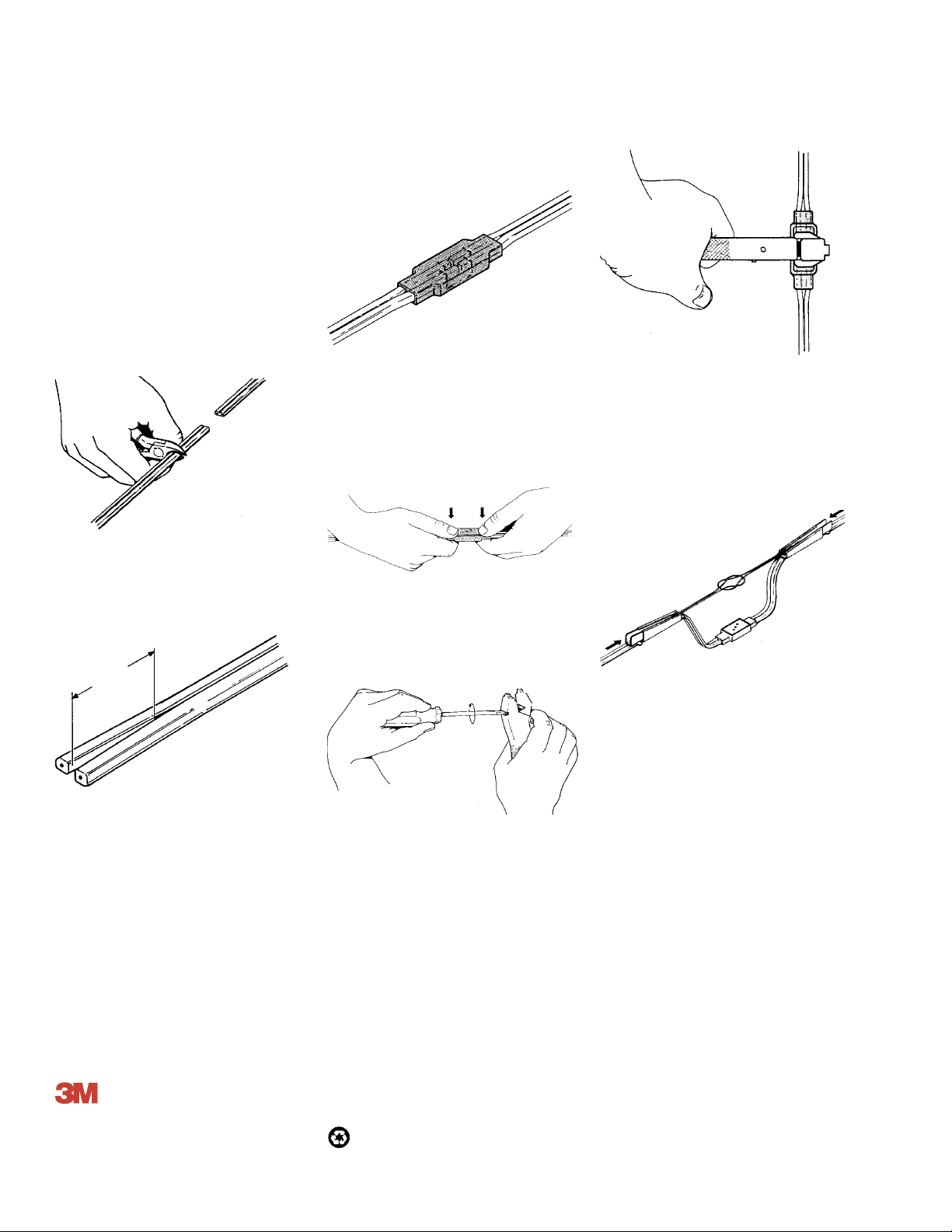

3.03 Line up ribs of drop wires so that

tip and ring are not reversed at

the splice. Slide one of the drop

wires into the connector.

Holding connector and drop

wire, insert the other drop wire.

Make sure both drop wires are

inserted all the way.

3.06 Once the tool is adjusted

properly, position connector all

the way back in the jaws. Fully

crimp the connector so that the

cap is flush with the body.

3.0 Drop Wire Preparation

3.01 Flush cut the two ends to be

spliced.

76654

3.02 Slit drop wire approximately

1 1/4” (32 mm) with a drop wire

splitter.

Note: On “C Type” drop wire, remove

the outer jacket.

76655

76656

3.04 Important: Press both thumbs

down equally on the connector

cap. You will hear a “crunch.”

This means the connector is

pre-crimped. (This will help

hold the drop wires in place

until the connector is crimped).

Pre-Crimp

766557

3.05 Adjust the E-9B Crimping Tool

to thin-thin configuration or the

E-9BM Crimping Tool to thickthin configuration on the

adjustable jaws of the tool.

76659

76660

3.07 When connector is used midspan, provide additional strain

relief by using two drop wire

clamps. Make sure that the

clamps are locked onto the drop

wires by tapping the clamps to

set the teeth.

76662

Packing: 25/bag, 4 bags/cs.,

1.1 kg (2.5 lbs.)/cs.

Shipping Unit: 100 connectors

Important N o t i c e

All statements, technical information, and

recommendations related to Seller’s products are

based on information believed to be reliable, but

the accuracy or completeness thereof is not

guaranteed. Before utilizing the product, the user

should determine the suitability of the product for

its intended use. The user assumes all risks and

liability whatsoever in connection with such use.

Telecom Systems Division

6801 River Place Blvd.

Austin, TX 78726-9000

800/426 8688

Any statements or recommendations of the Seller

which are not contained in the Seller’s current

publications shall have no force or effect unless

contained in an agreement signed by an

authorized officer of Seller. The statements

contained herein are made in lieu of all

warranties, express or implied, including but not

limited to the implied warranties of merchantability

and fitness for a particular purpose which

warranties are hereby expressly disclaimed.

Printed on 50% recycled paper

with 10% post consumer.

SELLER SHALL NOT BE LIABLE TO THE USER

OR ANY OTHER PERSON UNDER ANY LEGAL

THEORY, INCLUDING BUT NOT LIMITED TO

NEGLIGENCE OR STRICT LIABILITY, FOR ANY

INJURY OR FOR ANY DIRECT OR

CONSEQUENTIAL DAMAGES SUSTAINED OR

INCURRED BY REASON OF THE USE OF ANY

OF THE SELLER’S PRODUCTS THAT WERE

DEFECTIVE.

Printed in USA.

© 3M 1994 80-6107-5732-2

Loading...

Loading...