Page 1

INSTR4089 1006

™

Owner’s Manual

This manual is for the installation, operation, and maintenance of the

ScaleGard™ PLUS 2

Water Treatment Systems

STM150

TSR150

Installer please leave manual with end user.

Page 2

SAFETY INFORMATION

CAUTION

WARNING

Read, understand, and follow all safety information contained in these instructions prior to

installation and use of the CUNO Foodservice STM150/TSR150 ScaleGard™ PLUS 2 Water

Treatment Systems. Retain these instructions for future reference.

Intended use:

The CUNO Foodservice STM150/TSR150 ScaleGard PLUS 2 water treatment systems are intended for use in

fi ltering and scale reductions for water used in coffee and espresso equipment, steam kettles and tables, combis,

electric and gas steamers, misters or other similar equipment, and have not been evaluated for other uses. The

system is typically installed near where treated water is desired, and must be installed as specifi ed in the instal-

lation instructions.

EXPLANATION OF SIGNAL WORD CONSEQUENCES

Indicates a potentially hazardous situation, which, if not avoided, could

result in death or serious injury and/or property damage.

Indicates a potentially hazardous situation, which, if not avoided, may

result in property damage.

WARNING

To reduce the risk associated with ingestion of contaminants due to use with water that is microbiologically unsafe or of unknown quality:

• Do not use with water that is microbiologically unsafe or of unknown quality without adequate disin-

fection before or after the system.

T o reduce the risk associated with hazardous voltage due to damage of the transformer/power supply:

• Do not use the ScaleGard system if the transformer/power supply is damaged — contact qualifi ed

service personnel for repair.

T o reduce the risk associated with hazardous voltage due to an installer drilling through existing

electric wiring or water pipes in the area of installation:

• Do not install near electric wiring or piping which may be in path of a drilling tool when selecting the

position to mount the fi lter bracket.

T o reduce the risk associated with back strain due to the heavy weight of the system:

• Follow safe lifting procedures.

CAUTION

To reduce the risk associated with property damage due to water leakage:

• Read and follow Use Instructions before installation and use of this system.

• Install on cold water lines only.

• Installation must comply with existing state or local plumbing codes;

• Do not use a torch or other high temperature sources near fi lter system or cartridges;

• Protect from freezing. Drain fi lter when room temperature drops below 40°F (4.4°C);

• Do not install on systems where line pressures above 65 psi (448 kPa) may occur. Line water pres-

sure in excess of 65 psi will require installation of a pressure regulator prior to the unit;

• Shut off inlet water supply and depressurize system as shown in manual when changing cartridges or

servicing;

• The fi lter must be installed with the inlet and outlet ports as labeled. Make sure not to reverse connections;

• Do not install near water pipes which will be in path of a drilling tool when selecting the position to mount

the bracket;

• Mount the system in such a position as to prevent it from being struck by other items used in the area

of installation.

IMPORTANT NOTES

• Allow minimum of 3” (7.62 cm) clear space under [the assembly] to facilitate cartridge changes;

• All components should be accessible and have at least 6” (15 cm) of clearance on all sides of the

system to facilitate servicing.

Page 3

Contents

Installation Requirements

Space Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Feedwater Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Electrical Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Water Production Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installation Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Operating Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Additional Plumbing Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation Procedure

Positioning Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Wall Mounting the Filter System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Feedwater Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Drain Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Automatic Bypass Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Storage Tank Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Point of Use Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Start-Up Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Routine Maintenance

De-pressurization Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Sediment Prefilter Cartridge Replacement. . . . . . . . . . . . . . . . . . . . . . . . 7

Chlorine Filter Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

TDS Reduction Filter Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Hardness Filter Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Ion Media Filter Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Restarting and Purging the RO System. . . . . . . . . . . . . . . . . . . . . . . . . . 8

‘Push-In’ Tubing Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Electrical Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installation Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

System Parts List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Page 4

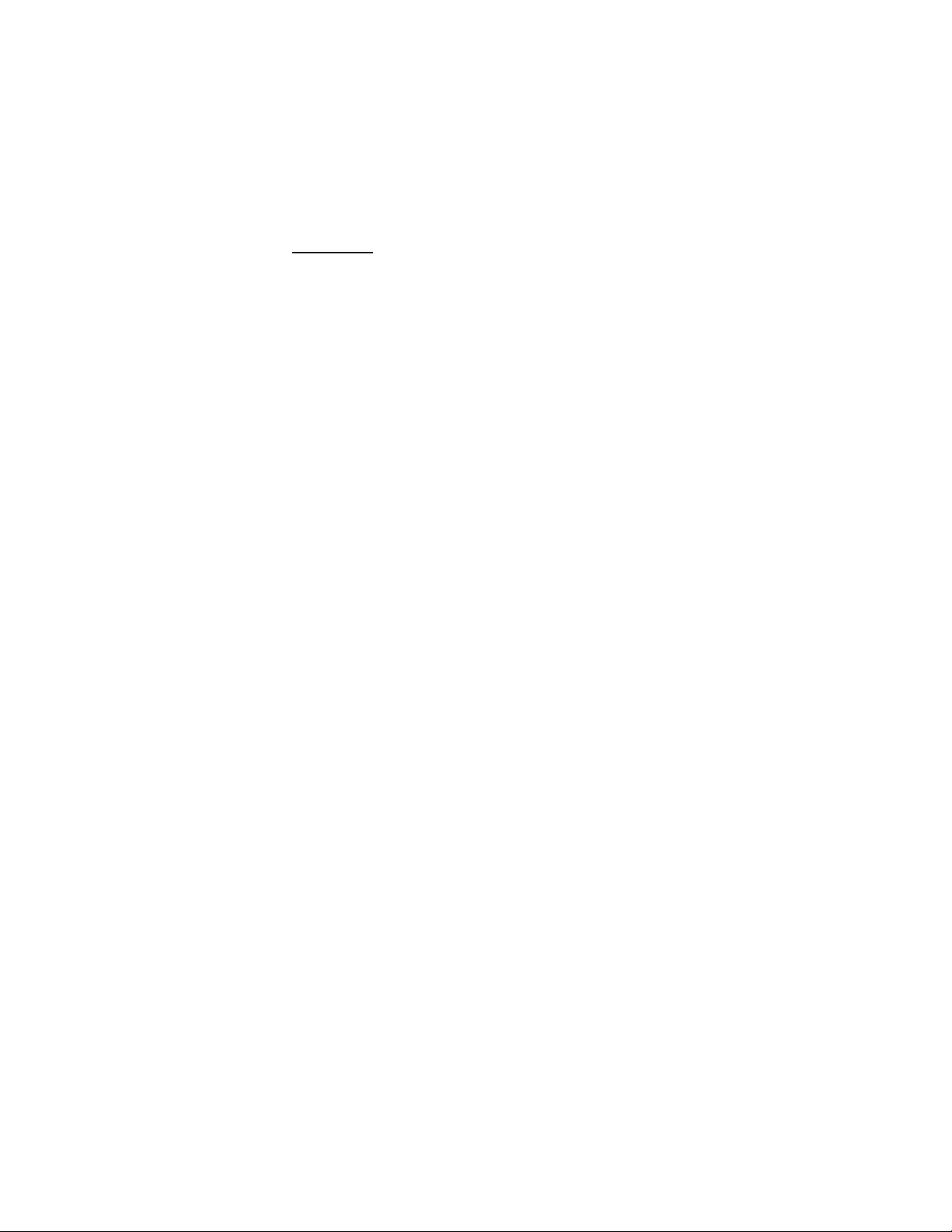

Space

Requirement

11”

(27.9 cm)

7 3/4”

(19.7 cm)

16 11/16”

(42.4 cm)

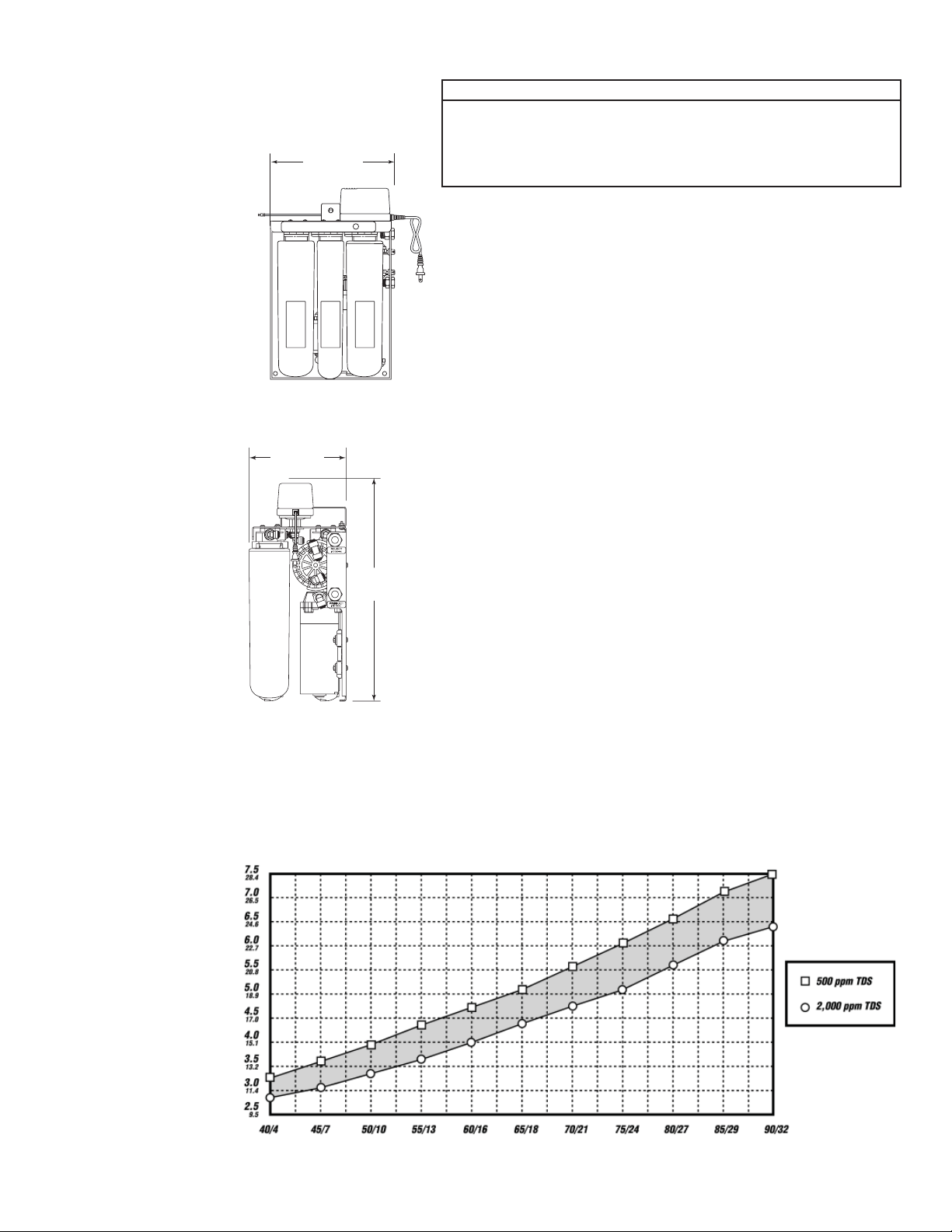

ScaleGard Plus 2 - Estimated Water Production

Important: Installation Requirements

CAUTION

To reduce the risk associated with property damage due to water

leakage:

• Installation must comply with existing state or local plumbing codes;

• Read and follow Use Instructions before installation and use of this

system.

Congratulations on your purchase of the CUNO Foodservice ScaleGard

PLUS 2 water treatment system. The ScaleGard PLUS 2 systems utilize

some of the world’s most advanced scale and corrosion control technologies in a compact, highly efficient package.

The ScaleGard PLUS 2 system is designed for food service equipment

with low water draw such as steam kettles and tables, combis, electric

and gas steamers, misters or other applications, where water consumption does not exceed 6 gph (22.7 lph) continuous. See estimated water

production chart below.

The ScaleGard PLUS 2 STM150 is recommended where a minimal

TDS level is required for proper equipment operation. The ScaleGard

PLUS 2 TSR150 is recommended for applications where zero hardness

is required such as proofing ovens, flash steamers, injection steamers

and misters.

Before beginning the installation, take a few minutes to familiarize yourself with the system by reviewing the entire installation, operating and

maintenance manual. It is also important to review the criteria below

to make sure that the requirements have been or will be met when the

installation is complete. Be sure to confirm that the feedwater falls within

the limits shown below. If you’re not sure if this has been done, check

with your distributor before installing the system. This is important

because failures caused by water related problems are not covered

under the system warranty.

Installation must comply with state and local plumbing requirements.

Feedwater Parameters:

Feed TDS . . . . . . . . . . . . . . . .Up to 2000 ppm (mg/L)

Hardness* . . . . . . . . . . . . . . . .< 10 grains (171 mg/L)

Iron (Fe) . . . . . . . . . . . . . . . . . .< 0.1 mg/L

Hydrogen Sulfide . . . . . . . . . . .none allowable

Feed pH . . . . . . . . . . . . . . . . . .4-11

Free chlorine . . . . . . . . . . . . . .< 2 mg/L

Manganese(Mn) . . . . . . . . . . .< 0.05 mg/L

Turbidity . . . . . . . . . . . . . . . . . .< 5 NTU

* Note: For waters over 10 grain hard, a CUNO water softener is recommended

for pretreatment. Consult CUNO technical services for correct sizing.

Electrical Requirements:

Confirm that transformer is compatible with available electrical power

supply.

™

Water Production (Gallons Per Hour/Liters Per Hour)

Feedwater Temperature (°F/°C)

3

Page 5

ScaleGard™ PLUS 2 Installation Schematic

telnI

y l p p

u S

retaW

e v l a V

Additional

Plumbing

Connections

(not supplied)

• Manual Bypass:

A manual bypass loop is

recommended to facilitate

proper service of the filter

system.

• Drain Line:

A drain line is recommended to depressurize the

system during cartridge

changeout, for sanitizing

the system, and for draining the tank. Note: 10, 20,

and 40 gallon (38, 76, 151

liter) tanks are capable of

draining water in excess

of 13 gpm (49 lpm). Drain

connection must be sized

accordingly.

Service Shut

V d i o n e l o S s s a p y B

m e t s y S O R

0 5 1 M T S

s u l P v e B

s m e t s y S R S T

O R " 8 / 3

n i a r D

. y s s A e v l a

s s a p y B l a u n a M

) l a n o i t p O (

e n i L r e t a W

k n a T O R

k n a T l a u n a M

e v l a V

n/Sample ValveiarD knaT

Off Valve

(Optional)

e v l a V k c e h C

If your water analysis indicates that any of these parameters are not in

range, additional pretreatment or higher frequency of maintenance may

be required. Contact your distributor for assistance. The presence of

silica or flocculants (e.g. alum or cationic polymers) in the feedwater

can cause membrane fouling and may require special chemical pretreatment or periodic membrane cleaning.

Operating Parameters:

Typical TDS Cartridge Rejection .....>95%

Feed Temperature ...........................40-100°F (4-38°C)

Feed Pressure .................................20-65 psi (138-448 kPa)*

Production .......................................... Chart on page 3 shows output in

gallons per hour at varying water

temperatures. Actual output may

vary according to feedwater

conditions and membrane variations.

Note: For water temperature below 50°F (10°C) water can be

preheated to improve production rate.

ec i v r e S o T

• Pressure Gauge:

A pressure gauge in the

product water line is recommended to determine

the system’s performance

and when the system is

de-pressurized.

CAUTION

*To reduce the risk associated with property damage due to water

leakage:

• Do not install on systems where line pressures above 65 psi (448

kPa) may occur. Line water pressure in excess of 65 psi will require installation of a pressure regulator prior to the unit.

4

Page 6

Installation Procedure

CAUTION

To reduce the risk associated with property damage due to water leakage:

• Installation must comply with existing state or local plumbing codes;

• Read and follow Use Instructions before installation and use of this system.

Positioning Equipment

Prior to installing the ScaleGard™ PLUS 2 system, review the installation schematic (page 4) and carefully

plan the installation location for all system components. Obtain all additional hardware for plumbing connections. This will help provide proper positioning and improve serviceability during routine maintenance.

1. Position the storage tank in desired location. (See storage tank installation procedure, page 6.)

2. The ScaleGard PLUS 2 system should be installed within 15 ft (4.6 m) of the storage tank.

3. The ScaleGard PLUS 2 system must be installed within 6 ft (1.8 m) of an electrical outlet. The bypass

solenoid valve should be installed within 6 ft. (1.8 m) of the storage tank.

4. All components should be accessible and have at least 6 inches (15 cm) of clearance on all sides of

ScaleGard PLUS 2 system to facilitate servicing.

5. Access to feedwater and drain connection are also required.

Wall Mounting the Filter System

The filter system weighs approximately 30 lbs. (13.6 kg) and must be mounted securely to a rigid surface.

There are two additional mounting holes on both sides of the booster pump at the bottom of the bracket if

needed. System must be installed vertically.

1. Determine the desired mounting location and using the supplied template, mark mounting hole locations.

2. Install the three mounting screws in the marked locations, leaving about an 1/8” (3.2 mm) from the wall.

3. Remove the cartridges from the filter system by turning to the left 1/4 turn and pull down to remove.

4. Lift the filter system and align the keyhole slots over the mounting screws. Tighten the screws, securing the

filter system to the wall. Note: You may have to slide the permeate pump to the left to fully expose the

right mounting hole.

5. Install the cartridges. Note: Mate the head

icon letter with the cartridge icon letter

(S, C, M, T or H). The TDS filter (M) has

a John Guest® fitting for reject water.

Attach reject tubing to the fitting (as

shown in drawing below).

6. Mount the transformer to the bracket with

screws provided to the top right side of the

bracket.

Feedwater Connection

The feedwater supply line is 3/8” O.D. tubing

and should not exceed 20 ft (6.1 m) from the

main feedwater connection to the filter system.

For longer distances, 1/2” pipe or larger should

be brought to within 20 ft (6.1 m) of the system.

Important: Connect to an adequate water

supply having a minimum 20 psi (138 kPa) and

maximum 65 psi (448 kPa) pressure at the inlet

of the filter system.

To reduce the risk associated with property

damage due to water leakage:

• Do not install on systems where line pressures

above 65 psi (448 kPa) may occur. Line water

pressure in excess of 65 psi will require installation of a pressure regulator prior to the unit.

1. Connect a shut-off valve to main water line.

Under no circumstances should a needle

valve or self piercing valve be used.

2. Run a 3/8” O.D. line from the feedwater

connection at the main water line to the water

inlet on the filter system. Inlet connection is a

3/8” John Guest fitting.

CAUTION

TDS Filter M

(RO Module)

5

Reject

Tu be

Plug

IMPORTANT: Remove white

plug from module and insert

black tube as shown. Insert

RO module into fi lter head

and rotate 1/4 turn until it

stops. The label should face

the front.

Permeate

Pump

Transformer

Connection

Page 7

The water pressure in

the tank will increase as

the tank fills with water.

When the pressure in the

tank reaches approximately 80 psi (552 kPa)

the filter system shuts off.

When water is drawn from

the tank and the pressure

drops to approximately 60

psi (414 kPa), the filter

system will automatically turn on.

Drain Connection

Important: An approved air gap should exist between the filter system

drain lines and the drain opening to meet local plumbing codes.

1. Run a minimum 3/8” O.D. tube from the reject port to the drain.

2. The 3/8” O.D. reject tubing line may be run up to 10 ft (3 m) from the

filter system to the drain. Care must be taken not to crimp or block the

reject tubing line.

Automatic Bypass Valve

The auto-bypass valve has 3/8” MNPT inlet and outlet ports and a 6’ (183

cm) power cord that plugs into the filter system. This auto-bypass valve

should be installed between the incoming unfiltered water line to the filter

system and the water line to service after check valve. (Refer to page 4.)

If the tank pressure drops

to 40 psi (276 kPa) the

auto-bypass solenoid valve

will open allowing unfiltered

water to flow to service

until tank pressure reaches

approximately 60 psi (414

kPa). When the filter system is in auto-bypass the

red light on the front of

the bracket will come on.

NOTE: TSR150-2/2A/2B

Bypass at 20psi (138

kPa) to 40 psi (276 kPa).

IMPORTANT!

The use of metallic piping

materials for high quality

water is not recommended because the water is

aggressive due to low TDS

and pH. Plastic tubing and

pipe are most suitable.

Solvent bonded plastic pipe

should be assembled carefully to avoid excessive glue

inside the pipe. Piping of

any type should be flushed

thoroughly before use. Be

sure piping conforms to

local plumbing codes.

Storage Tank Installation

Note: Storage tanks are purchased separately. Consult the CUNO®

Foodservice Price List for applicable sizes and part numbers.

1. Follow installation instructions provided with tank.

2. Check the air pressure in the tank at the valve in the top of the tank.

With the tank empty, the pressure should be 20 psi (137.9 kPa).

Adjust the air pressure as required.

3. Place the tank in the desired location. It should be placed in an area

where it will not be bumped or jarred.

4. Connect fitting and minimum 3/8” O.D. tubing to product port of the unit.

5. Run tubing from the other side of the TEE to the check valve and

on to point of use connection and bypass line. Refer to Installation

Schematic on page 4.

6. Open the ball valve on the tank by turning the handle until it is parallel

with the body of the valve.

Storage Tank Diameter Height Pipe Connection

2.5 gal. (9.5 lit.) 9 1/16" (23 cm) 14 1/8" (35.9 cm) 1/4" (0.6 cm)

5 gal. (19 lit.) 15 3/8" (39.1 cm) 17 3/8" (44.1 cm) 3/4" (1.9 cm)

10 gal. (38 lit.) 16" (40.6 cm) 32 1/2" (82.6 cm) 1" (2.5 cm)

20 gal. (76 lit.) 16" (40.6 cm) 57 1/2" (146.1 cm) 1" (2.5 cm)

40 gal. (151 lit.) 24" (61 cm) 56 1/2" (143.5 cm) 1 1/4" (3.2 cm)

Point-of-Use Connections

Distance from Storage

Tank to Point of Use

up to 5 ft (0-1.5 m) 1/2" O.D. (1.3 cm) 3/8" (1 cm) Schedule 40 PVC

5-20 ft (1.5-6.1 m) 3/4" O.D. (1.9 cm) 1/2" (1.3 cm) Schedule 40 PVC

20-40 ft. (6.1-12.2 m) N/R 1/2" (1.3 cm) Schedule 40 PVC

40-60 ft. (12.2-18.3 m) N/R 3/4" (1.9 cm) Schedule 40 PVC

Note: The above table is appropriate for point of use applications that require flow

rates up to 5 gpm (18.9 lpm).

Select the tubing or pipe size that will help provide adequate flow and pressure to the

point of use (i.e. Longer runs require larger tubing).

The type of tubing or pipe used must conform to local plumbing codes. Tubing or pipe

used for drinking water applications must be NSF listed or made of FDA compliant

materials.

Recommended Minimum

Tubing Size

Recommended Minimum

Plastic Pipe Size

6

Page 8

Start-Up Procedure

1. Check air pressure in the storage tank, Refer to Storage Tank Installation. (page 6)

2. Close all water valves (5) in the system. (page 4)

3. Open water supply valve at the connection to the main water feed and the inlet water valve at the

unit. If manual bypass is installed it should be in the filter position.

4. Plug in transformer.

5. Plug bypass solenoid into the filter system.

6. Open the drain/sample valve. This will purge the air from the system. When you see a steady

stream of water close the drain/sample valve.

7. Open the ball valve on the storage tank.

8. Inspect all connections, fittings in the system for leaks, repair as necessary.

9. Allow storage tank to fill with RO water. NOTE: see chart for required times to fill storage tanks.

10. Open valve in water line to service and flush feed lines to each point of use.

11. System is now ready to use.

Tank Capacity

2.5 gal. (9.5 lit.) 0.4 - 0.5 hour

5 gal. (19 lit.) 0.9 - 1.1 hours

10 gal. (38 lit.) 1.8 - 2.1 hours

20 gal. (76 lit.) 3.6 - 4.2 hours

40 gal. (151 lit.) 7.2 - 8.4 hours

@ 70°F (21°C) Water Temperature

Time Required

To Fill Tank

Routine Maintenance

CAUTION

To reduce the risk associated with property damage due to water leakage:

• Installation must comply with existing state or local plumbing codes;

• Read and follow Use Instructions before installation and use of this system.

De-pressurization Procedure

1. Turn off the inlet water valve.

2. Close the tank ball valve.

3. Open the drain line valve.

4. Wait for 30 seconds, then unplug the transformer. System is now de-pressurized.

Caution: Tank will still be under pressure.

Sediment Filter (S)

Replacement Procedure [6-12 months]

1. De-pressurize the system as instructed above.

2. Locate the sediment filter. To remove the sediment filter, turn to the left 1/4 turn. Pull down to remove

and discard it.

3. Insert the new filter by aligning the tabs with the filter head. Push up to insert and turn to the right

1/4 turn.

Chlorine Reduction Filter (C)

Replacement Procedure [6-12 months]

1. De-pressurize the system as instructed above.

2. Locate the chlorine reduction filter. To remove the chlorine reduction filter, turn to the left 1/4 turn.

Pull down to remove and discard it.

3. Insert the new filter by aligning the tabs with the filter head. Push up to insert and turn to the right

1/4 turn.

7

Page 9

TDS Reduction Filter (M)

Replacement Procedure [annually]

1. De-pressurize the system as instructed above.

2. Locate the TDS reduction filter. To remove the TDS reduction filter, turn to the left 1/4 turn. Pull down

to remove.

3. Disconnect reject tubing by pushing in the white collet on plastic fitting to release the tubing (see page

9). Discard the used cartridge.

4. Remove the plug from the plastic fitting on the new cartridge and connect the reject tubing.

5. Insert the new filter by aligning the tabs with the filter head. Push up to insert and turn to the right 1/4 turn.

Note: The first full tank of water filtered after the filter is replaced should be discarded.

See start-up procedure, page 7.

Hardness Reduction Filter (H)

(ScaleGard™ PLUS 2 TSR150) Replacement Procedure [6-12 months]

1. De-pressurize the system as instructed above.

2. Locate the hardness reduction filter. To remove the hardness reduction filter, turn to the left 1/4 turn.

Pull down to remove and discard it.

3. Insert the new filter by aligning the tabs with the filter head. Push up to insert and turn to the right 1/4 turn.

Note: The first full tank of water filtered after the filter is replaced should be discarded.

See start-up procedure, page 7.

TDS Adjustment Filter (T)

(ScaleGard PLUS 2 STM150) Replacement Procedure [6 months]

1. De-pressurize the system as instructed above.

2. Locate the TDS adjustment filter. To remove the TDS adjustment filter, turn to the left 1/4 turn. Pull

down to remove and discard it.

3. Insert the new filter by aligning the tabs with the filter head. Push up to insert and turn to the right 1/4 turn.

Note: The first full tank of water filtered after the filter is replaced should be discarded.

See start-up procedure, page 7.

Restarting and Purging the RO System

1. Turn on inlet water valve.

2. Make sure the tank ball valve is closed.

3. Open the drain/sample valve

4. Plug in the transformer and wait for a steady stream of water to come from the drain/sample valve.

This will purge the air from the system.

5. Close the drain/sample valve and wait for pump to shut off (this will pressurize system). Check for leaks.

6. Open tank ball valve.

7. Plug in bypass solenoid valve.

8

Page 10

‘Push-In’ Tubing Connector

(John Guest® Fitting)

This product is outfitted with user friendly “Push

In” connectors. Proper use of the connectors is

shown in the diagrams. It is most important that

the tubing selected for use with these connectors

be of high quality, exact size and roundness, and

with no surface nicks or scratches. If it is necessary to cut the tubing, use a plastic tubing cutter

or sharp razor knife. Make a clean square cut.

Should a leak occur at a ‘Push In’ connector, the

cause is usually defective tubing.

To fix leaks:

• Relieve pressure.

• Release tubing.

• Cut off at least 3/8” (9.5 mm) from end.

• Reattach tubing.

• Confirm connection is leak free.

To Attach Tubing

1

Tube

Grey Collet

Push tubing straight in as far as it will go.

To Release Tubing

1

2

Tubing is secured in.

2

Push in grey collet to release tubing.

Pull tubing straight out.

ScaleGard™ PLUS 2 Electrical Wiring Diagram

Bypass Pressure Switch

(Red Terminals)

Tank Pressure Switch

(Blue Terminal)

Bypass

Light

Solenoid

Automatic

Bypass

Solenoid

Fuse

Holder

Booster Pump

Transformer

Installation Components for ScaleGard™ PLUS 2 Systems*

• 1 pc of 3/8” Cross • 1 pc of 1/4” x 3/8” Male Connector

• 1 pc of 3/8” x 1/4” Reducer Bushing • 1 pc of 1/4” NPT 0-160 pressure gauge

• 6 pcs of 1/2” x 3/8” Male Connector • 1 pc of 3/8” Female Pipe Tee

• 1 pc of 3/8” Female Ball Valve • 1 pc of 3/8”x1” Reducer Bushing

• 3/8” Nipple • 3/8” Tubing

• 1/2” Tubing (optional) • Cutter or sharp razor knife.

* Not Provided With System

9

Page 11

ScaleGard™ PLUS 2 System Part List

Item # Description STM150 TSR150-2

1 Sediment Filter (S) 55997-01 55997-01

2 Chlorine Reduction Filter (C) 55995-01 55995-01

3 TDS Reduction Filter (M) 55987-07 55987-07

4 Ion Media Filter (T) 55998-01 -

4 Hardness Reduction Filter (H) - 55996-01

5 Permeate Pump 89-1331202 89-1331202

6 Pump / Fuse Assembly 53-41401 53-41401

7 Solenoid Valve 60-1213201 60-1213201

8 Brine Flow Control 53-52001 53-52001

9 Bypass Solenoid Valve Assembly (60 Hz) 50-025 50-025

9 Bypass Solenoid Valve Assembly (50 Hz) 50-026 50-026

10 Transformer (115V/60 Hz) 25-63031 25-63031

10 Transformer (230V/50 Hz) 25-63032 25-63032

10 Transformer (100V/50 Hz) 25-63030 25-63030

Not Shown Tank Switch (blue plug) 25-15505 25-15505

Not Shown Bypass Switch (red plug) 25-15503 25-15502

Not Shown Fuse, 2 Amp, 3AGC-250V 25-61225 25-61225

10

9

TSR150-4

55997-01

55995-01

55987-07

-

55996-01

89-1331202

53-41401

60-1213201

53-52001

50-025

50-026

25-63031

25-63032

25-63030

25-15505

25-15503

25-61225

8

5

7

4

3

2

1

Front View Front View without Front Cartridges

10

6

Page 12

Limited Two Year Warranty

CUNO Incorporated warrants the original purchaser-consumer of its Product that is free of defects in materials and

workmanship. Any defect, malfunction, or other failure of the

Product to conform to this warranty will be remedied by CUNO

in the manner provided below.

This Warranty, together with any warranties implied by law,

shall be limited to a duration of two (2) years from the original

date of purchase by the consumer.

This Warranty does not apply to defects that result from

abuse, misuse, alteration or damage not caused by CUNO.

IMPORTANT: To file a claim under this warranty you must

complete and mail the Warranty Registration Card supplied with

this product to CUNO at the address below within ten (10) days

of original purchase date.

THIS WARRANTY DOES NOT COVER, AND IS INTENDED

TO EXCLUDE ANY LIABILITY ON THE PART OF CUNO,

WHETHER UNDER THIS WARRANTY OR UNDER ANY

WARRANTY IMPLIED BY LAW, FOR ANY INDIRECT OR

CONSEQUENTIAL DAMAGES FOR BREACH HEREOF OR

THEREOF.

Note: Some states prohibit limitations on the duration of

implied warranties and on the exclusion of indirect or consequential damages; and so the limitation on implied warranties

and on incidental and consequential damages may not be applicable to you.

RESPONSIBILITY OF CUNO

CUNO’s responsibility under this warranty shall be to repair

at its expense, at no charge to the original purchaser-consumer,

any product that is actually defective, malfunctioning, or otherwise in violation of this warranty. If CUNO for any reason

cannot repair a Product covered hereby within two (2) weeks

after receipt of the original purchaser-consumer’s notification

of a Warranty claim, then CUNO’s responsibility shall be, at its

option, either to replace the defective Product with a compa-

rable new unit at no charge to the consumer or to refund the full

purchase price. CUNO’s obligations of repair, replacement, or

refund are conditioned upon return of the defective Product to

CUNO.

If any Product covered hereby is actually defective within the

terms of this Warranty, then CUNO will bear all the reasonable

and proper shipping and mailing charges actually incurred in the

consumer’s return of the Product set forth herein. If the Product

proves not to be defective within the terms of this Warranty, then

all costs and expenses in connection with the processing of the

consumer’s claim hereunder shall be borne by the consumer.

RESPONSIBILITY OF THE CONSUMER

The original purchaser-consumer’s sole responsibility in the

instance of a warranty claim shall be to notify CUNO of the

defect, malfunction, or other manner in which the terms of this

Warranty are violated. You may secure performance of obligations hereunder by (in writing):

1. Identifying the Product involved (by model or serial number

or other sufficient description that will allow CUNO to determine

which product is defective).

2. Specifying where, when, and from whom the Product was

purchased.

3. Describing the nature of the defect, malfunction, or other

violation of this Warranty.

4. Sending such notification together with the defective Product

and $5.00 check or money order to cover postage and handling

to:

CUNO Incorporated,

400 Research Parkway, Meriden, Connecticut 06450, USA

THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS,

AND YOU MAY ALSO HAVE OTHER RIGHTS, WHICH VARY

FROM STATE TO STATE

CUNO and ScaleGard are trademarks of 3M Company used under license.

John Guest is a trademark of John Guest International Limited.

© 2007 3M Company. All rights reserved.

a 3M company

CUNO Incorporated

400 Research Parkway

Meriden, CT 06450, USA

Toll Free: 1-888-218-CUNO

Worldwide: 203-237-5541

Fax: 203-238-8701

www.cunofoodservice.com • www.cuno.com

Loading...

Loading...