Page 1

TR-800 Series/Série/Serie/Série

Versao

TM/MC

Powered Air Purifying Respirator (PAPR) Assembly

User Instructions for 3M™ Versao™ Powered Air Purifying Respirator TR-800 Belt

Mounted Assemblies

Ensemble respirateur d’épuration d’air propulsé

Directives d’utilisation pour les ensembles respirateurs d’épuration d’air propulsé montés

à la ceinture TR-800 VersaoMC 3MMC

Ensamble de Respirador Puricador de Aire Forzado (PAPR)

Instrucciones para Respirador Puricador de Aire Forzado 3M™ Versao™ TR-800,

montado en cinturón

Instalação do Respirador Puricador de Ar Motorizado

(PAPR)

Instruções de Uso para o Respirador Puricador de Ar Motorizado Versao™ da 3M™

da Série TR-800

IMPORTANT: Before use, the wearer must read and understand these User Instructions. Keep these User

Instructions for reference.

IMPORTANT : Avant de se servir du produit, l’utilisateur doit lire et comprendre les présentes directives

d’utilisation. Conserver ces directives d’utilisation à titre de référence.

IMPORTANTE: Antes de usar el producto, el usuario debe leer y entender estas Instrucciones. Conserve estas

Instrucciones para referencia futura.

IMPORTANTE: Antes de usar, o usuário deve ler e compreender este Instruções de Uso. Guarde este Instruções

de Uso para consulta.

Page 2

Page 3

This product is part of a system that helps reduce exposures to certain airborne contaminants. Before use, the

wearer must read and understand these User Instructions. Follow all local regulations. In the U.S., a written

respiratory protection program must be implemented meeting all the requirements of 29CFR1910.134,

including training, t testing and medical evaluation. In Canada, CSA standard Z94.4 requirements must

be met and/or requirements of the applicable jurisdiction, as appropriate. Misuse may result in injury,

sickness or death. For correct use, consult supervisor and User Instructions, or call 3M Technical Service in

USA at 1-800-243-4630 and in Canada at 1-800-267-4414.

!!!IMPORTANT READ FIRST!!!

• Battery packs should be charged immediately and fully upon receipt.

• Read and understand the contents of these User Instructions prior to use, including all warnings and advisories.

• This system is for professional occupational use only.

• The lter loading indicator is for particulate only. It does not convey any information about gas and vapor service life.

• The 3M™ Versao™ Powered Air Purifying Respirator TR-800 System has been tested and classied by UL for

intrinsic safety. Exia Division 1:

IS Class I, II, III; Division 1(Includes Division 2); Groups C, D, E, F, G; T4

Ex ia I Ma

Class I, Zone 0, AEx ia IIB; T4 / Class I, Zone 0, Ex ia IIB; T4

Zone 20, AEx ia IIIC; T135°C / Zone 20, Ex ia IIIC; T135°C

-20°C ≤ Ta ≤ 55°C

CONTENTS

FOREWORD .......................................................................................................................... 1

Contact Information .......................................................................................................... 1

System Description ........................................................................................................... 1

LIST OF WARNINGS AND CAUTIONS WITHIN THESE USER INSTRUCTIONS .............................. 1

LIMITATIONS OF USE ............................................................................................................. 2

RESPIRATOR PROGRAM MANAGEMENT ................................................................................2

APPROVALS, CAUTIONS & LIMITATIONS ................................................................................. 3

UNPACKING & BATTERY CHARGING ....................................................................................... 4

COMPONENT DESCRIPTION & ASSEMBLY ............................................................................. 5

BATTERY PACK CHARGING & INSTALLATION .......................................................................... 8

BELTS AND BACKPACK .......................................................................................................... 8

BREATHING TUBE ................................................................................................................ 10

HEADGEAR .......................................................................................................................... 11

OPERATING INSTRUCTIONS ................................................................................................. 11

INSPECTION ........................................................................................................................ 12

ENTERING AND EXITING THE CONTAMINATED AREA ............................................................ 14

CLEANING, STORAGE AND DISPOSAL .................................................................................. 14

TECHNICAL SPECIFICATIONS ...............................................................................................16

TROUBLESHOOTING ............................................................................................................ 17

TR-800 FILTER AND CARTRIDGE OPTIONS WITH COVERS ................................................... 17

IMPORTANT NOTICE ............................................................................................................ 17

WARRANTY ..................................................................................................................... 17

LIMITATION OF LIABILITY ..................................................................................................... 17

FCC COMPLIANCE ............................................................................................................... 17

SYSTEM INTRINSIC SAFETY APPROVAL INFORMATION......................................................... 18

⚠ WARNING

Page 4

FOREWORD

Read and understand all instructions and warnings before use. Keep these User Instructions for reference. If you have

questions regarding these products contact 3M Technical Service. Check www.3m.com/workersafety for potential updates to

these User Instructions.

Contact Information

In United States:

Website: www.3m.com/workersafety

Technical Service: 1-800-243-4630

In Canada:

Website: www.3M.ca/Safety

Technical Service: 1-800-267-4414

System Description

The 3M™ Versao™ Powered Air Purifying Respirator (PAPR) TR-800 Assemblies are part of the 3M™ Versao™ Family of

respiratory protection products. The TR-800 PAPR assemblies are designed to be used with the 3M headgear listed on the

approval label to form a complete National Institute of Occupational Safety and Health (NIOSH) approved respiratory system.

When used in accordance with its NIOSH approval, TR-800 PAPR assemblies help provide respiratory protection against

certain gases, vapors and particulates. 3M™ Versao™ systems and components are for professional occupational use

only. When fully assembled, the TR-800 is an intrinsically safe system for the following: Exia Division 1: IS Class I, II,

III; Division 1 (Includes Division 2); Groups C, D, E, F, G; T4, Ex ia I Ma, Class I, Zone 0, AEx ia IIB; T4 / Class I, Zone 0,

Ex ia IIB; T4, Zone 20, AEx ia IIIC; T135°C / Zone 20, Ex ia IIIC; T135°C, -20°C ≤ Ta ≤ 55°C.

See the “NIOSH Approval” section in these User Instructions for additional information regarding approvals.

The TR-800 belt mounted PAPR assemblies consist of a motor/blower unit, high efciency (HE) particulate lter or

combination chemical cartridge/HE lter, lithium-ion battery pack, and waist belt. The motor/blower unit draws ambient

air through its lter/cartridge and supplies ltered air to the headgear via a breathing tube. For ease of use and training,

most user interface points are colored yellow or blue. The blower provides three user selectable airow settings. It is

equipped with automatic ow control; the motor airow is regulated during operation to compensate for the charge state

of the battery, the increasing level of airow resistance caused by particle lter loading, and changes in air density due to

changes in elevation and air temperature. Should the airow fall below the minimum design ow rate, an audible alarm will

activate and the lter loading LED on the blower unit will ash red to warn the user to immediately leave the contaminated

environment. Similarly, an audible and visual low battery alarm will activate when the battery pack has approximately 10-15

minutes of charge remaining to warn the user to leave the contaminated area.

Multiple cartridges are available for specic chemicals, grouping of chemicals, and chemical families. The effective use

time (service life) of the cartridge will vary depending on your specic environment. Under the Occupational Safety and

Health Administration (OSHA) Respiratory Protection Standard (U.S. 29 CFR 1910.134), it is the employer’s responsibility to

ensure adequate worker protection including selecting the appropriate lter/cartridge for this PAPR system, and ensuring

the cartridge is used within its service life. 3M provides free software to aid in lter/cartridge selection and service life

calculations available at www.3m.com/workersafety.

LIST OF WARNINGS AND CAUTIONS WITHIN THESE USER INSTRUCTIONS

1. This product is part of a system that helps reduce exposures to certain airborne contaminants. Before use, the wearer

must read and understand these User Instructions. Follow all local regulations. In the U.S., a written respiratory

protection program must be implemented meeting all the requirements of 29CFR1910.134, including training, t

testing and medical evaluation. In Canada, CSA standard Z94.4 requirements must be met and/or requirements

of the applicable jurisdiction, as appropriate. Misuse may result in injury, sickness or death. For correct use,

consult supervisor and User Instructions, or call 3M Technical Service in USA at 1-800-243-4630 and in Canada at

1-800-267-4414.

2. The 3M™ Battery Pack TR-830 is intrinsically safe only when mated with a TR-800 Powered Air Purifying Respirator.

To reduce the risk of ignition of a ammable or explosive atmosphere, batteries must be changed only in a

location known to be non-hazardous. Never bring this battery alone into an area which is potentially ammable or

explosive. Doing so may result in serious injury or death.

3. The battery chargers for this system are not intrinsically safe. The TR-830 battery pack must not be charged in

an area which is potentially ammable or explosive. Doing so may result in serious injury or death.

4. Always correctly use and maintain the lithium-ion battery packs. Failure to do so may cause re or explosion or

could adversely affect respirator performance and result in injury, sickness, or death.

a. Do not charge batteries with unapproved chargers, in enclosed cabinets without ventilation, in hazardous locations,

or near sources of high heat.

b. Do not immerse without the battery storage and cleaning cover installed.

c. Do not use, charge, or store batteries outside the recommended temperature limits.

d. Charge in an area free of combustible material and readily monitored, and outside of the classied intrinsically

safe area.

5. To reduce the risks associated with re and explosion which, if not avoided, could result in serious injury or

death: Do not use or bring non-intrinsically safe electrical components (e.g. auto-darkening lters) in areas

where intrinsically safe equipment is required.

⚠ WARNING

1

Page 5

6. Always observe all Hazardous Locations regulations and requirements that apply to your work environment.

⚠ WARNING

7. Always correctly use and maintain the lter/cartridge assembly. Failure to do so may reduce respirator

performance, overexpose you to contaminants, and may result in sickness or death.

a. Inspect lter/cartridge and inner circular sealing gasket before each installation. Replace lter/cartridge if damaged

or if the circular gasket is damaged or missing.

b. Always properly install the lter/cartridge into the blower unit.

c. Keep inner circular sealing gasket clean.

d. Never attempt to clean lter/cartridge by knocking or blowing out accumulated material. Doing so will damage the

lter media.

e. Use of the spark arrestor is mandatory for welding and all situations where the 3M™ Versao™ Powered Air

Purifying Respirator TR-800 may be exposed to sparks, molten metal or other hot particulates. Failure to use the

spark arrestor when needed may allow the lter to catch re, or be damaged and allow contaminants to enter the

respirator and may result in injury, sickness or death.

f. Store the lter/cartridge as described in these User Instructions within the recommended storage temperature

conditions and observe lter expiration dates.

g. The lter loading indicator is for particulate loading levels only. It does not provide any information about

gas and vapor service life. Attempting to use the lter loading indicator for gases and vapors may result in

sickness or death.

8. Failure to follow these User Instructions may reduce respirator performance, overexpose you to contaminants,

and may result in injury, sickness, or death.

a. Do not use with parts or accessories other than those manufactured by 3M as described in these User Instructions

or on the NIOSH approval label for this respirator.

b. The 3M™ Versao™ Powered Air Purifying Respirator TR-800 Assembly is one component of an approved

respiratory protection system. Always read and follow all User Instructions supplied with your 3M headgear and

other system components in order to ensure correct system operation.

c. Do not turn off the motor/blower, remove the facepiece or headgear, or reach your hand into the headgear while

inside the contaminated area. This could allow contaminants to enter the respirator and may result in sickness or

death.

9. Dispose of lithium-ion battery packs according to local environmental regulations. Do not dispose of in standard waste

bins, in a re or send for incineration. Failure to properly dispose of battery packs may lead to environmental

contamination, re or explosion and may result in serious injury or death.

10. To reduce exposure to hazardous voltage:

a. Do not attempt to service the chargers. There are no user-serviceable parts inside.

b. Do not substitute, modify or add parts to the chargers.

c. Inspect the chargers and power cords before use. Replace if any parts are damaged.

d. Do not use the chargers outdoors or in wet environments.

LIMITATIONS OF USE

Do not wear this respirator system to enter areas where:

• Atmospheres are oxygen decient.

• Contaminant concentrations are unknown.

• Contaminant concentrations are Immediately Dangerous to Life or Health (IDLH).

• Contaminant concentrations exceed the maximum use concentration (MUC) determined using the Assigned Protection

Factor (APF) for the specic respirator system or the APF mandated by specic government standards, whichever is

lower.

• The hazardous locations are outside of those tested and classied for intrinsic safety by Underwriters Laboratory.

Immediately exit the contaminated area if any of the 3M™ Versao™ Powered Air Purifying Respirator TR-800 alarms

activate.

Refer to the User Instructions provided with the applicable headgear and the additional cautions and limitations under the

“NIOSH Cautions and Limitations” in these User Instructions.

The recommended operating temperature range is 23°F to 131°F (-5°C to 55°C).

The recommended operating altitude range is -328 feet (-100 meters) to 16404 feet (5000 meters). For use in elevations

outside this range, contact 3M Technical Service.

Before use in environments subject to high magnetic elds, contact 3M Technical Service.

RESPIRATOR PROGRAM MANAGEMENT

Occupational use of respirators must be in compliance with applicable health and safety standards. By United States

regulation, employers must establish a written respirator protection program meeting the requirements of the Occupational

Safety and Health Administration (OSHA) Respiratory Protection standard 29 CFR 1910.134 and any applicable OSHA

substance specic standards. For additional information on this standard contact OSHA at www.OSHA.gov. In Canada, CSA

standard Z94.4 requirements and/or requirements of the applicable jurisdiction must be met as appropriate. The major

sections of 29 CFR 1910.134 are listed here for convenience. Consult an industrial hygienist or call 3M Technical Service

with questions concerning applicability of these products to your job requirements.

2

Page 6

Major Sections of OSHA 29 CFR 1910.134

Section Description

A Permissible Practice

B Denitions

C Respiratory Protection Program

D Selection of Respirators

E Medical Evaluation

F Fit Testing

G Use of Respirators

H Maintenance and Care of Respirators

I Breathing Air Quality and Use

J Identication of Cartridges, Filters, and Canisters

K Training and Information

L Program Evaluation

M Recordkeeping

APPROVALS, CAUTIONS & LIMITATIONS

NIOSH approval

The 3M™ Versao™ Powered Air Purifying Respirator TR-800 Assembly is one component of a NIOSH approved

respiratory system. Refer to these User Instructions and/or the NIOSH Approval Label provided with the TR-800 for a listing

of components and optional accessories that can be used to assemble a complete NIOSH approved respirator system or

contact 3M Technical Service.

NIOSH Cautions and Limitations

A – Not for use in atmospheres containing less than 19.5 percent oxygen.

B – Not for use in atmospheres immediately dangerous to life or health.

C – Do not exceed maximum use concentrations established by regulatory standards.

F – Do not use powered air-purifying respirators if airow is less than four cfm (115 lpm) for tight tting facepieces or six

cfm (170 lpm) for hoods and/or helmets.

H – Follow established cartridge and canister change schedules or observe ESLI to ensure that cartridge and canisters are

replaced before breakthrough occurs.

J – Failure to properly use and maintain this product could result in injury or death.

L – Follow the manufacturer’s User’s Instructions for changing cartridges, canister and/or lters.

M – All approved respirators shall be selected, tted, used, and maintained in accordance with MSHA, OSHA, and other

applicable regulations.

N – Never substitute, modify, add, or omit parts. Use only exact replacement parts in the conguration as specied by the

manufacturer.

O – Refer to User’s Instructions, and/or maintenance manuals for information on use and maintenance of these respirators.

P – NIOSH does not evaluate respirators for use as surgical masks.

System Intrinsic Safety Approval Information

The 3M™ Versao™ Powered Air Purifying Respirator TR-800 Motor/Blower, with the 3M™ Battery Pack TR-830 attached,

has been tested and classied for intrinsic safety in Hazardous Locations (Exia) by Underwriters Laboratory (UL) for the

following:

Exia Division 1:

IS Class I, II, III; Division 1 (Includes Division 2); Groups C, D, E, F, G; T4

Ex ia I Ma

Class I, Zone 0, AEx ia IIB; T4 / Class I, Zone 0, Ex ia IIB; T4

Zone 20, AEx ia IIIC; T135°C / Zone 20, Ex ia IIIC; T135°C

-20°C ≤ Ta ≤ 55°C

NOTE: Review warnings 1, 2, 3, 4 and 5 in next section related to intrinsic safety for this system.

UNPACKING & BATTERY CHARGING

Unpacking

Inspect the package contents for shipping damage and ensure all components are present. Package contents will vary

depending on components or kit ordered. The product should be inspected before each use following the procedures in the

“Inspection” section of these User Instructions.

3

Page 7

1. The 3M™ Battery Pack TR-830 is intrinsically safe only when mated with a TR-800 Powered Air Purifying Respirator.

To reduce the risk of ignition of a ammable or explosive atmosphere, batteries must be changed only in a

location known to be non-hazardous. Never bring this battery alone into an area which is potentially ammable or

explosive. Doing so may result in serious injury or death.

2. The battery chargers for this system are not intrinsically safe. The TR-830 battery pack must not be charged in

an area which is potentially ammable or explosive. Doing so may result in serious injury or death.

3. Always correctly use and maintain the Lithium-ion battery packs. Failure to do so may cause re or explosion or

could adversely affect respirator performance and result in injury, sickness or death.

a. Do not charge batteries with unapproved chargers, in enclosed cabinets without ventilation, in hazardous locations,

or near sources of high heat.

b. Do not immerse without the battery storage and cleaning cover installed.

c. Do not use, charge, or store batteries outside the recommended temperature limits.

d. Charge in an area free of combustible material and readily monitored, and outside of the classied intrinsically

safe area.

4. To reduce the risks associated with re and explosion which, if not avoided, could result in serious injury or

death: Do not use or bring non-intrinsically safe electrical components (e.g. auto-darkening lters) in areas

where intrinsically safe equipment is required.

5. Always observe all Hazardous Locations regulations and requirements that apply to your work environment.

Battery Charger Setup

⚠ WARNING

There are two battery charging options for 3M™ Versao™ Powered Air Purifying Respirator TR-800 Batteries. The 3M™

Battery TR-641N kit includes (1) 3M™ Charger Cradle TR-640 and (1) 3M™ Power Supply TR-941N. The 3M™ 4-Station

Battery Charger Kit TR-644N includes (1) 3M™ 4-Station Battery Charger Base/Power Supply TR-944N, and (4) 3M™

Charger Cradles TR-640. Refer to the chargers and battery packs for the 3M™ Versao™ Powered Air Purifying Respirator

TR-800 Assemblies User Instructions for additional information on proper battery pack use and maintenance.

NOTE: Immediately charge battery packs upon receipt and after each use.

Refer to TR-800 chargers and battery packs User Instructions for additional information on proper battery pack use, charging

and maintenance. The run times for the TR-800 will vary for each conguration and is dependent on headgear,

lter/cartridge, selected airow, lter loading, battery selected, battery condition, and environmental conditions.

The battery packs do not require a learn cycle to calibrate or re-calibrate the battery pack charge indicator. However, it may

take up to three complete charge/discharge cycles for the battery to reach its maximum capacity and claimed run times.

Charge the battery pack

1. Inspect battery pack. If cracks or damage are noted do not charge the battery pack. Properly dispose of the battery

pack and replace.

2. Place chargers in a cool, well-ventilated location free of particulates or other airborne contamination.

Optimal temperature range: 68°F to 77°F (20°C to 25°C).

Charging range: 32°F to 104°F (0°C to 40°C). Do not charge outside of this range.

3. Charging cradle setup:

• 3M™ Single Station Battery Charger TR-641N: Insert the DC supply cord from the 3M™ Power Supply TR-941N into

the cradle. (Fig. 1a). Plug the power cord into an AC power source (100-240V), such as a wall outlet.

• 3M™ 4-Station Battery Charger TR-944N: Insert the 3M™ Battery Charger TR-640 into one of the charging ports on

the TR-944N and slide back to lock into place. (Fig. 1b). (NOTE: the TR-941N power cord is not used with the TR-640,

when the 4-station charger is used.) Insert the DC supply cord supplied with the kit into the 4-station base. Plug the

power cord into an AC power source (100-240V), such as a wall outlet. You may charge any combination of up to four

3M™ Battery Packs simultaneously.

NOTE: The 3M™ Battery Charger TR-640 and 3M™ 4-Station Battery Charger TR-944N do not use the same power supply.

Use only the power supply supplied with your charger kit.

2

1

1

2

1

Fig. 1a Fig. 1b Fig. 2

4. Battery charging: Ensure the gold electrical contacts on the battery and charger are clean, dry, and free of debris. Insert

the battery pack into the 3M™ Battery Charger Cradle TR-640 by sliding the back end of the battery pack in rst. Set

front end down into place (Fig. 2), charging will begin.

5. Removal:

• Lift up on battery pack to remove from cradle.

4

Page 8

• The 3M™ Battery Charger TR-640 can remain attached to the 3M™ 4-Station Battery Charger TR-944N if desired.

To release the cradle from base, press down on the oval release tab on the base, slide cradle forward and lift out. Be

careful not to pinch ngers as the cradle slides forward.

COMPONENT DESCRIPTION & ASSEMBLY

The 3M™ Versao™ Powered Air Purifying Respirator TR-800 System has multiple component options and optional

accessories. At a minimum, each NIOSH approved conguration of this PAPR system should include approved headgear

or facepiece, breathing tube, motor/blower, lter/cartridge, battery, and a belt or backpack. Common accessories include

prelter/spark arrestor and lter cover. Refer to the supplied User Instructions for each of these components for additional

information prior to use.

High Efciency (HE) Particulate Filter, Chemical Cartridge/Filter, Prelter, Spark Arrestor and

Filter Covers

Always correctly use and maintain the lter/cartridge assembly. Failure to do so may reduce respirator performance,

overexpose you to contaminants, and may result in sickness or death.

a. Inspect lter/cartridge and inner circular sealing gasket before each installation. Replace lter/cartridge if damaged

or if the circular gasket is damaged or missing.

b. Always properly install the lter/cartridge into the blower unit.

c. Keep inner circular sealing gasket clean.

d. Never attempt to clean lters by knocking or blowing out accumulated material. Doing so will damage the lter media.

e. Use of the spark arrestor is mandatory for welding and all situations where the 3M™ Versao™ Powered Air

Purifying Respirator TR-800 may be exposed to sparks, molten metal or other hot particulates. Failure to use the

spark arrestor when needed may allow the lter to catch re, or be damaged and allow contaminants to enter the

respirator and may result in injury, sickness or death.

f. Store the lter as described in these User Instructions within the recommended storage temperature conditions

and observe lter expiration dates.

g. The lter loading indicator is for particulate loading levels only. It does not provide any information about gas and

vapor service life. Attempting to use the lter loading indicator for gases and vapors may result in sickness or death.

The 3M™ Versao™ Powered Air Purifying Respirator TR-800 can be used with either a high efciency (HE) lter or

combination chemical cartridge/HE lter. The available lter and lter/cartridge options can be found at

www.3m.com/workersafety or in the TR-800 Components, Accessories and Replacement Parts guide.

Particulate Filter Loading

The 3M™ Versao™ Powered Air Purifying Respirator TR-800 Motor/Blower has a combination HE lter loading/low airow

indicator (Fig. 12-5). This indicator is for particulate loading only; it does not apply to the service life of the carbon

in the chemical cartridge for the combination HE lter/gas and vapor cartridges. With a new HE only lter, all LEDs

on the indicator will light green. For certain combination HE lter/gas and vapor cartridges the inherent pressure drop, even

on a new cartridge/lter, may prevent the top LED on the lter loading indicator from being lit. As the HE lter becomes

loaded, the LEDs will begin to turn off. User must immediately leave the work area and the lter should be changed when the

audible alarm or a red LED activates or when the chemical cartridge service life is exceeded- whichever comes rst. See the

“Operating Instructions” section of these User Instructions for further information on the HE lter/low airow alarm.

Gas and Vapor Cartridge Service Life

The effective use time (service life) of a chemical cartridge (gas and vapor cartridge) will vary depending on your specic

environment. The user must determine a service life period based on their specic work conditions. The 3M™ Service Life

Software (www.3m.com/workersafety) may be able to assist user in this calculation.

Prelter/Spark Arrestor

Use of the foam prelter (3M™ Prelter TR-6600) and metal mesh spark arrestor/prelter (3M™ Spark Arrestor TR-662)

is optional in many situations. They can be used individually or in combination. Both act by helping to block larger particles

from reaching the main lter, and if changed (TR-6600) or cleaned (TR-662) frequently may help to extend the useable life of

the main lter. The spark arrestor may be cleaned by rinsing it under water. NOTE: Use of the spark arrestor is mandatory

for welding and all situations where the 3M™ Versao™ Powered Air Purifying Respirator TR-800 may be exposed

to sparks, molten metal or other hot particulates. Failure to use the spark arrestor when needed may allow the lter

to catch re, or be damaged and allow contaminants to enter the respirator and may result in injury, sickness or

death. The foam prelter and the metal mesh spark arrestor must be used with a lter cover.

⚠ WARNING

Filter Covers

Filter covers are available for each size of lter. Use of lter covers are highly recommended. Filter covers help protect the

lter body and lter media from damage from external forces. The lter cover must be in place if operating the PAPR in a

decon shower or while being subject to liquid spray. The lter cover helps the PAPR resist water spray directed towards the

wearer, such as if going through a decon shower. The lter cover is required when using a prelter or spark arrestor prelter.

Install and remove HE lter, lter/cartridge, prelter, spark arrestor and cover

Install and remove the lter/cartridge in non-hazardous locations only.

1. Inspect the lter/cartridge to be installed:

• Filter/cartridge is intact with no tears, cracks, distortion or other damage.

• The inner circular gasket is present and intact with no tears, cuts or distortions. Wipe the lter seal with a clean cloth

5

Page 9

if necessary. Dispose of and replace lter/cartridge if damage is noted or suspected. NOTE: The 3M™ Versao™

Powered Air Purifying Respirator TR-600/TR-800 Filter/Cartridge Assemblies have both an inner circular gasket

(Fig.3-6) and outer rectangular barrier (Fig. 3-5). The inner gasket is the primary seal between the lter and blower.

The outer barrier acts to keep dirt and debris from behind the lter.

2. To install the lter/cartridge:

• Conrm the TR-800 is powered off. Do not install or replace lter/cartridges while the motor/blower is running.

Option 1: Using the lter/cartridge with prelter/spark arrestor and lter cover.

Fig. 4 (Recommended for most applications).

NOTE: Use the specied lter cover for the lter/cartridge. See “Specications” section for correct pairing.

• Hold the lter cover so it faces down (Fig. 4-1).

• (If required) insert the metal mesh spark arrestor/prelter into the cover, ensuring the cutouts are aligned properly

(Fig.4-2).

• (If required) insert the foam prelter, ensuring the cutouts are aligned properly (Fig. 4-3).

• Insert the lter/cartridge into the lter cover ensuring the bottom latching tab snaps into place (Fig. 4-4). The

lter/cartridge label must be visible in the cover window (Fig. 13).

• Place the hinge side of the lter/cartridge into the motor/blower (Fig. 5-1) and snap latch side into the lter latch

(Fig.5-2).

• Gently tug on lter/cartridge to ensure proper attachment at both sides.

Option 2: Using the lter/cartridge without the lter cover.

(May typically be used in applications when lter/cartridges are changed very frequently to reduce potential for

cross-contamination.)

NOTE: Using the lter/cartridge without the lter cover leaves it more susceptible to damage from external forces and

liquid spray.

• Place the hinge side of the lter/cartridge into the motor/blower hinge (Fig. 5-1) and snap latch side into the lter

latch (Fig. 5-2).

• Gently tug on lter/cartridge to ensure proper attachment at both sides.

1

2

3

4

5

6

1. Filter cover

2. Spark arrestor/prelter

3. Prelter

4. Filter/cartridge

5. Outer barrier

6. Inner gasket

Fig. 3

6

Page 10

Fig. 4-1

Fig. 4-2

Fig. 4-3

Fig. 4 – Installing lter cover, spark arrestor, and prelter

Fig. 5-1 Fig. 5-2

Fig. 5 – Latching the lter/cartridge

3. Removal of the lter/cartridge and cover (in non-hazardous locations only):

• Turn the unit off. Do not remove or replace lter/cartridge while the motor/blower running.

• Hold the unit downwards so the back (belt side) faces you and the lter and cover face down on a at surface (Fig. 6)

to help minimize the potential for contamination of the motor/blower inlet.

• Press the yellow lter latch on the left side (Fig. 6). The latch requires two ngers to engage. Pull the lter/cartridge

out and away from the motor/blower.

Fig. 4-4

Fig. 6 – Filter/Cartridge removal

• Remove the lter/cartridge cover. Hold the lter/cartridge upside down. Pull out on the blue tab at the bottom of the

lter cover to unlatch it from the lter/cartridge. Pull the cover down and away from the lter/cartridge.

7

Page 11

BATTERY PACK CHARGING & INSTALLATION

Battery Pack Charge Status

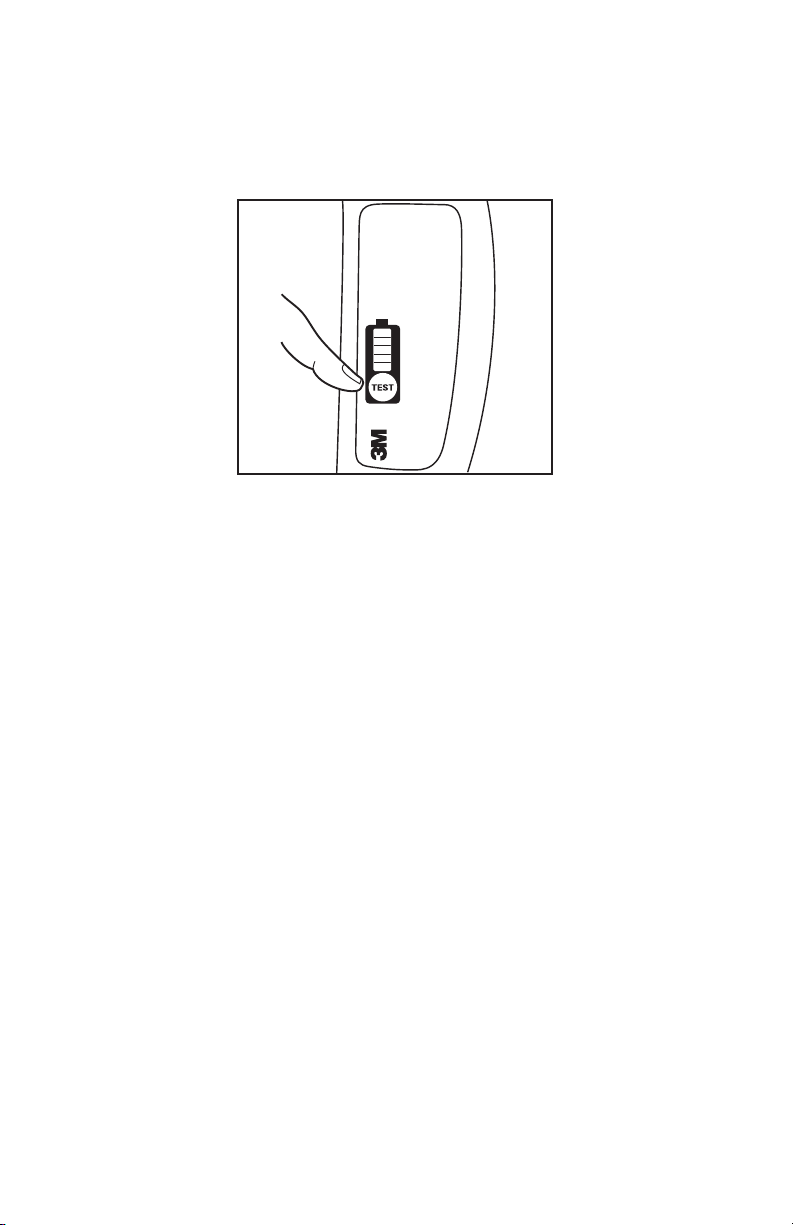

Battery pack charge status is indicated by pressing the indicator button on the top of the battery (Fig. 7). Number of bars

illuminated indicates approximate battery pack charge capacity (5 bars: 80-100%; 1 bar: less than 20%) based on original

battery capacity.

NOTE: As the battery pack ages, it will normally lose capacity. An older battery pack, or one that has been exposed to

temperature extremes, may show less than 5 bars after completing a charge cycle (i.e. after a full charge as indicated by the

battery charger, only 4 bars light indicating 60-80% of original capacity is available).

Fig. 7 – Battery charge status check

Installation and Removal of 3M™ Versao™ Powered Air Purifying Respirator TR-830

Battery Packs

NOTE: Only 3M™ Battery Pack TR-830 can be used with the 3M™ Versao™ Powered Air Purifying Respirator TR-800

Motor/Blower. Attempts to use any other battery pack will void the NIOSH approval, system warranty, will not provide

respiratory protection, and may damage the PAPR. 3M™ Versao™ Battery Pack TR-830 will not function on other

PAPR systems.

To install a charged battery pack, hold the unit so the lter cover faces you.

1. Inspect the hinge and fastener on the battery pack and ensure it is clean and undamaged.

2. Inspect the molding surrounding the electrical connection pins. It must be in place and intact.

3. Ensure the gold electrical contacts on the battery and pin area of the motor/blower are clean and free of debris.

4. Hook the hinge end of the battery pack into its holder on the bottom of the unit.

5. Push the fastener side of the battery pack into the motor/blower and fasten with a 3/32 inch hex head tool. Do not

overtighten.

6. Grasp the battery pack and gently pull to conrm pack is locked into place.

To remove the battery pack, turn the unit upside down so the battery bottom faces you.

1. Insert a 3/32 inch hex head tool into the fastener side and unscrew until it releases.

2. Lift the battery out.

NOTE: The fastener can be removed for deep cleaning by pressing up on the thread side of the fastener.

BELTS AND BACKPACK

The 3M™ Versao™ Powered Air Purifying Respirator TR-800 is approved for use with either a belt or backpack.

Belts

The TR-800 is approved for use with two premium belt options:

• The 3M™ Heavy Duty Belt TR-626 features a durable surface and leather straps.

• The 3M™ Easy Clean Belt TR-627 features a smooth deconable surface and urethane straps.

Select the belt appropriate for the work conditions.

8

Page 12

To install the belt:

1. With a lter/cartridge and lter cover installed, place the motor/blower face down on a table with outlet facing away

from you.

2. Place the 4 keyholes (Fig. 8-2) of the belt onto the 4 T-bars (Fig. 8-1) on the back of the motor/blower (Fig. 8-3).

3. Push down on the belt between the top and bottom keyholes on each side using your thumbs (Fig. 8-4).

4. Slide the belt up (Fig. 8-5) until the belt snaps over the belt locking tabs on the bottom of the motor/blower (Fig. 8-6).

5. Gently tug on belt to ensure it is securely attached to the motor/blower unit.

6. Position the motor/blower. Typical use is to rest it in the small of the back. Tighten belt for a snug comfortable t. A belt

extender is available if additional length is needed.

7. Secure excess belt length into the belt keeper. Excess belt length may be carefully trimmed if it will not be needed.

To remove the belt from the motor/blower, lift the lower, center portion of the belt over the locking edges and slide the belt down.

Fig. 8-1

Fig. 8-3

Fig. 8-5

Fig. 8-2

Fig. 8-4

Fig. 8-6

Fig. 8 – Installing belt

9

Page 13

Backpack

The 3M™ Backpack BPK-01 with the 3M™ Backpack Adapter TR- 655 may be used in place of the belt (Fig. 9). Refer to the

BPK-01 and TR-655 User Instructions for more information.

Fig. 9 – 3M™ Backpack BPK-01

BREATHING TUBE

The 3M™ Versao™ Powered Air Purifying Respirator TR-800 PAPR is approved for use with 3M™ Versao™ Breathing

Tubes. Select an approved breathing tube that is appropriate for the work conditions.

1. Insert the end of the breathing tube with the bayonet tting (two small prongs) into the parallel slots in the air outlet of

the motor/blower (Fig. 10).

2. Twist the breathing tube 1/4 turn to the right to lock it into place.

3. Refer to the User Instructions for the headgear to be used for procedures to connect the breathing tube to the headgear.

4. Removal: Turn the motor/blower upside down so that the outlet faces down (Fig. 11) to help minimize the potential for

contamination of the outlet.

Fig. 10 – Installing breathing tube

Fig. 11 – Removing breathing tube

10

Page 14

HEADGEAR

The 3M™ Versao™ Powered Air Purifying Respirator TR-800 is approved for use with many 3M™ Headgear options.

Refer to the headgear User Instructions for information on attaching and donning the headgear to be used, and to determine

assigned protection factor (APF) for the complete respiratory protection system. Consult 3M Technical Data Bulletin #175 for

additional information on APFs and supporting test data.

OPERATING INSTRUCTIONS

Power 3M™ Versao™ Powered Air Purifying Respirator TR-800 on

• Press and hold the smaller, yellow power button (Fig. 12-1) for 1 second. The unit will turn on and perform a

self-diagnostic. The ow level, lter loading and battery charge indictors will blink, and the auditory alarm will sound.

Battery indicator (Fig. 12-4) will show current charge status of the battery pack. Filter indicator will show remaining

capacity of the lter (Fig. 12-5). Continuous blinking and/or sounding of any alarm indicates a fault condition

that must be corrected prior to use of the respirator system. If auditory alarm or visual indicators do not

activate at start-up, do not use system. Remove from service and see your supervisor.

Select airow

• There are three user selectable airow settings- standard, medium, and high ow. The motor/blower will start at

the standard ow setting. Pressing and holding the larger yellow ow control button (Fig. 12-2) for 1 second will

cycle the motor/blower to the next of three ow settings. One beep and ow LED on the ow setting indicator (Fig.

12-3) indicates standard ow, two beeps and two ow LEDs indicate medium ow, three beeps and three ow LEDs

indicate high ow. Pressing the ow control button once more cycles back to the standard ow setting.

Power 3M™ Versao™ Powered Air Purifying Respirator TR-800 off

• Press and hold yellow power button for 2 seconds (Fig. 12-1).

2

3

1

Fig. 12 – Motor/blower User Interface

5

4

6

TR-800

1. On/Off button

2. Flow control button

3. Airow setting indicator

4. Battery charge status level/

alarm indicator

5. Filter loading/alarm indicator

6. Tight-tting mode indicator

(future option)

Display Sleep Mode

To conserve battery power, the display will go into ‘sleep mode’ after 30 seconds from the last button press. The ow speed

indicator will periodically blink with the current ow setting (Fig. 12-3). To wake up the display, momentarily press any

display button.

Battery Charge Status Indicator and Low Battery Alarm

The battery level/alarm indicator (Fig. 12-4) displays the remaining battery charge status. This charge status indicator

mirrors the charge status indicator on the battery. The number of bars illuminated indicates approximate battery pack

charge status remaining: 5 bars = 80-100%, 4 bars = 60-80%, 3 bars = 40-60%, 2 bars = 20-40%, 1 bar = < 20%, 1 bar

ashing = < 10%. The charge status indicator is based on the original charge capacity. It does not recalibrate as the battery

ages, and the number of bars illuminated with a fully charged battery will decrease as the battery naturally loses capacity.

This is a safety feature so that throughout the life of the battery the number of charge status bars lit consistently indicates

approximate run time remaining (with a given system setup and lter loading). When the low battery alarm sounds, users

must immediately exit the hazardous area and replace the battery in an area where intrinsically safe equipment is

not required. Never bring the TR-830 battery alone into an area which is potentially ammable or explosive. Doing so may

result in serious injury or death.

Filter Load Indicator and Low Flow Alarm

The lter loading indicator (Fig. 12-5) monitors the pressure drop in the system. Increase loading of contaminants on the

lter is indicated by the progressive extinguishing of LEDs in the lter loading indicator. As the pressure drop increases the

motor/blower fan speed increases to compensate. When the fan is no longer able to compensate and provide adequate

airow the motor/blower will alarm. A low ow alarm is indicated by the bottom LED of the lter loading indicator ashing

RED. When the low ow alarm sounds, users must immediately exit the hazardous area and replace the

lter/cartridge and/or the prelter/spark arrestor in an area where intrinsically safe equipment is not required.

Step Down Feature

To conserve battery power when in the medium or high airow setting, the motor/blower will automatically step down to the

next lower airow setting when the lter loading reaches approximately 90% or the battery run time remaining is less than

4 hours. This can be over-ridden by the user by pressing the ow control button to move the airow back to the desired ow.

The low battery alarm and low ow alarm will always operate as described above, when either alarm sounds, users

must immediately exit the hazardous area and replace in an area where intrinsically safe equipment is not required.

11

Page 15

INSPECTION

Failure to follow these User Instructions may reduce respirator performance, overexpose you to contaminants,

and may result in injury, sickness, or death.

a. Do not use with parts or accessories other than those manufactured by 3M as described in these User Instructions

or on the NIOSH Approval Label for this respirator.

b. The 3M™ Versao™ Powered Air Purifying Respirator TR-800 Assembly is one component of an approved

respiratory protection system. Always read and follow all User Instructions supplied with your 3M™ Headgear and

other system components in order to ensure correct system operation.

c. Do not turn off the motor/blower, remove the facepiece or headgear, or reach your hand into the headgear while inside

the contaminated area. This could allow contaminants to enter the respirator and may result in sickness or death.

Before each entry into a contaminated area, the following inspection must be performed to help ensure proper function of

the respirator system. Respirator systems are intended to help reduce exposures to certain contaminants and should always

be handled with care and fully inspected prior to use. Refer to the specic assembly subsection of these User Instructions for

proper assembly procedures.

1. PAPR system:

Closely inspect the entire PAPR system including the motor/blower, cover, lter/cartridge, breathing tube, battery, belt,

headgear. Pay particular attention to component connection points for wear or damage. If parts are missing or damaged,

replace them only with 3M™ Versao™ Powered Air Purifying Respirator TR-800 Replacement Parts before proceeding.

2. Filter/cartridge:

• Closely inspect lter/cartridge plastic housing including the corners and latches, outer rectangular barrier, and inner

circular lter seal gasket for cracks, tears, cuts, distortion, indentations or debris. Replace lter/cartridge if damaged.

If the lter/cartridge has been mishandled or dropped, re-inspect fully. If you have any questions, contact 3M

Technical Service for guidance.

• Ensure the lter/cartridge is properly installed in the PAPR unit.

• If the lter cover is used, the lter/cartridge label must be visible in the lter cover window (Fig. 13).

• If sparks or other hot particles are present, the spark arrestor with lter cover must be in place in front of the

lter/cartridge and prelter (if used). Failure to use the spark arrestor when needed may allow the lter to catch re,

or be damaged and allow contaminants to enter the respirator.

⚠ WARNING

Fig. 13 – 3M™ Versao™ Powered Air Purifying Respirator TR-800 with lter/cartridge label visible

3. Battery pack: Conrm that the battery pack is fully charged or charge is sufcient for duration of the work period. Ensure

plastic surrounding electrical contact pins are intact. The battery pack must be connected to the motor/blower. Gently tug

on the battery to ensure secure connection.

4. Breathing tube: Examine the entire breathing tube for tears, holes or cracks. Bend the tube to verify that it is exible.

Ensure the gaskets located at both ends of the breathing tube (i.e. headgear and air source connections) are present and

not damaged. The breathing tube should t securely into the air source connection.

5. Headgear: Follow the User Instructions supplied with your 3M headgear to ensure correct system operation.

6. Airow check:

The TR-800 is pre-calibrated to ensure required airow. However, the 3M™ Airow Indicator TR-971 must be used to

verify minimum required airow is attained prior to each day’s use. The TR-800 compensates for changes in air density,

which is affected by elevation and air temperature. During use, if you suspect the TR-800 is not delivering a minimum

of 6 cfm (170 lpm), exit the contaminated area, see your supervisor, and recheck the airow with the 3M™ Airow

Indicator TR-971. The airow is checked with your current lter installed.

• Ensure oat ball in the TR-971 moves freely in the tube and the gasket at the bottom end of the tube is in place.

• Insert the TR-971 into the outlet of the TR-800 motor/blower unit. If the breathing tube is in place, it must be

removed to allow the airow indictor to be inserted (Fig. 14-1).

• Turn the motor/blower unit on by pressing and holding the power button for 1 second. Run the 3M™ Versao™

Powered Air Purifying Respirator TR-800 for up to 1 minute to allow the airow to stabilize.

12

Page 16

• With the airow indicator in a vertical position, ensure that the bottom of the oating ball rests at, or above, the

minimum ow mark for the ‘letter’ representing your ‘Zone’ (Fig. 14-2). Airow indicator must be in the vertical

position for an accurate reading.

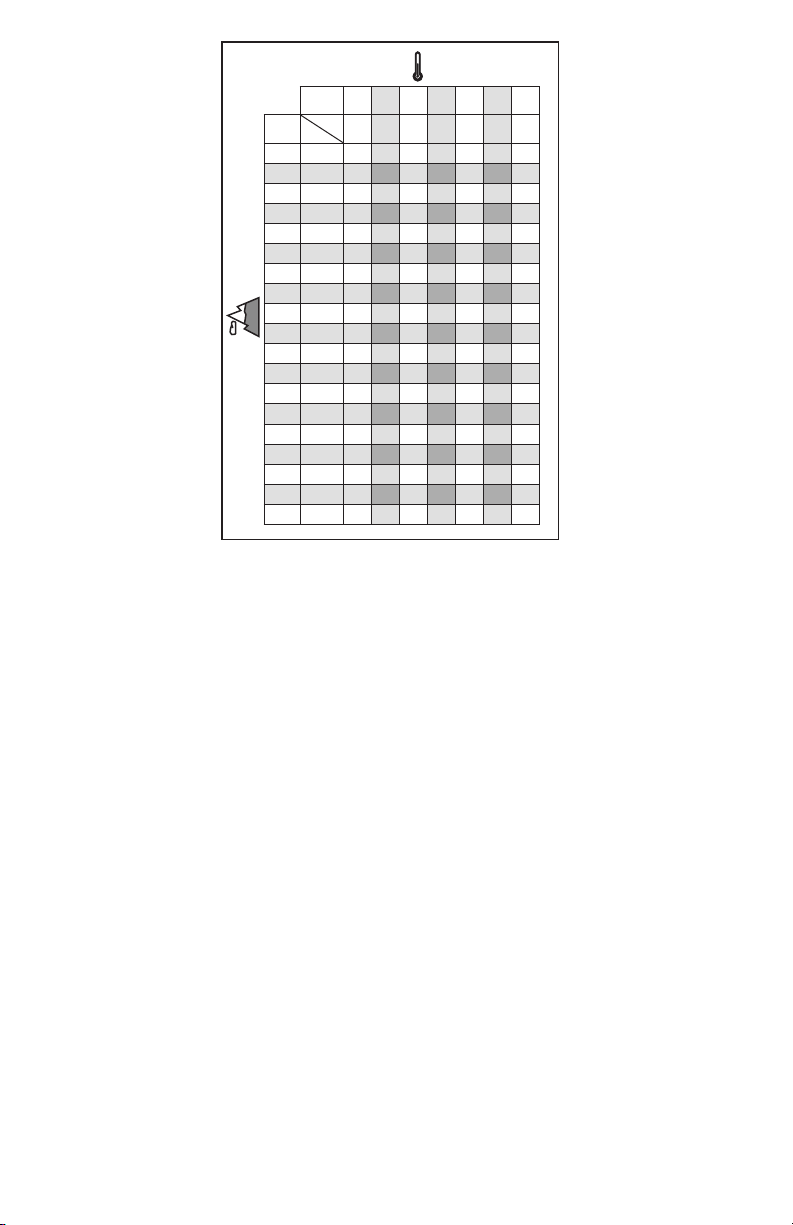

The airow indicator is graduated into different ‘zones’ based on air density, which is based on elevation and ambient

temperature. To determine your zone, determine the elevation and temperature for the environment where you are

conducting the airow check. See your supervisor if you are not certain of these values. Find the zone where your

elevation and temperature intersect on the chart supplied with the airow indicator (Chart 1).

Fig. 14-1 – Attaching airow indicator Fig. 14-2 – Checking airow

°C -10 01020304050

°F

m1432506886 104 122

ft

-305 -1000 ABCDEFG

00BCDEFGH

305 1000 CD EFGH I

610 2000 DE FGHIJ

915 3000 EFGH IJK

1219 4000 FGHIJKL

1524 5000 GH IJKLM

1829 6000 HI JKLMN

2134 7000 IJKLMNO

2439 8000 JKLMNOP

2744 9000 KLMNOPQ

3048 10000 LMN OPQR

3353 11000 MN OPQRS

3658 12000 N OPQRST

3963 13000 OPQRSTU

4268 14000 PQRSTUV

4573 15000 QRSTUVW

4877 16000 RSTUVWX

5182 17000 STU VWX Y

Chart 1 – Determining airow indicator zone based on elevation and temperature. Recommended use temperature

range: 23°F to 131°F (-5°C to 55°C). Recommended elevation: -328 feet to 16404 feet (-100 meters to 5000 meters).

Contact 3M Technical Service if intended use may be outside of these ranges.

NOTE: If the airow indicator ball fails to rise at or above the minimum ow level, do not use the motor/blower unit. Refer to

the 3M™ Versao™ Powered Air Purifying Respirator TR-800 “Troubleshooting” guide or contact 3M Technical Service.

7. Low ow alarm check: Check the low airow alarm by simulating a low airow condition. With the motor/blower on:

• Remove the airow indicator and tightly cover the outlet of the motor/blower with the palm of your hand. The motor

should automatically speed up, attempting to compensate for the low airow condition.

13

Page 17

• Continue to press your palm tightly against the end of the outlet, making a tight seal. In less than approx. 30 seconds,

the unit will sound an audible alarm, and the bottom bar on the lter loading/low ow indicator will ash red.

(Fig.12-5).

• Remove your hand from the end of the breathing tube. In less than approx. 30 seconds, the audible alarm and the

ashing red LED should both stop when the motor returns to the selected speed.

NOTE: If the low airow alarm fails to sound, do not use the unit. Contact 3M Technical Service.

ENTERING AND EXITING THE CONTAMINATED AREA

Prior to entering the contaminated area, complete the inspection procedures listed in these User Instructions and ensure the

selected PAPR setup is appropriate protection for the given airborne contaminant and concentration.

1. Turn the motor/blower on.

2. Check both the airow with the airow indicator and low ow alarms. NOTE: High environmental noise levels or use of

hearing protection may interfere with the user’s ability to hear audible alarms. Heavy clothing or tasks with high vibration

levels may interfere with sensing the vibratory alarm. User may need to check for the visual alarms more frequently in

high noise, or high vibration environments.

3. Don the 3M™ Versao™ Powered Air Purifying Respirator TR-800 Assembly and Headgear. Enter the work area.

4. Leave the contaminated area immediately if any of the following conditions occur:

a. Any part of the system becomes damaged.

b. Airow into the respirator decreases or stops.

c. The low airow or low battery alarms trigger. In the event an audible or visual alarm trigger, the user should

immediately leave the contaminated area.

d. Breathing becomes difcult.

e. You feel dizzy or your vision is impaired.

f. You taste or smell contaminants.

g. Your face, eyes, nose or mouth become(s) irritated.

h. You suspect that the concentration of contaminants may have reached levels at which this respirator may no longer

provide adequate protection.

5. Do not remove the respirator or reach your hand into the headgear in areas where the air is contaminated.

6. Follow your facility’s specic exiting and decontamination procedures for turning off the motor/blower and removing the

respirator system.

CLEANING, STORAGE AND DISPOSAL

The 3M™ Versao™ Powered Air Purifying Respirator TR-800 Assembly should be cleaned and inspected after each use

and prior to storage.

Cleaning

While system is together and still running, conduct a general wipe down/removal of dust and debris with a soft

brush or soft cloth prior to disassembly. Remainder of cleaning steps should be conducted outside of the hazardous area

with the blower turned off. Inspect all parts for damage or other signs of excessive wear. Replace all damaged parts prior to

storage or next use.

1. Motor/blower:

• Clean the outer surfaces of the TR-800 assembly and battery pack (still attached) with a soft cloth dampened in a

solution of water and mild, pH neutral detergent. Do not use solvents or abrasive cleaners. Do not attempt to clean

the interior of the motor/blower with compressed air or vacuum. Do not attempt to clean the battery connection

pins on the blower or the blower/charger connection pads on the battery- these are coated and direct

cleaning with moist cloths or wipes should be avoided.

• If additional cleaning is required, remove the lter/cartridge and breathing tube. To minimize material falling onto the

motor/blower, remove the breathing tube (Fig. 11) and lter/cartridge (Fig. 6) while it is facing downward. Remove

the battery. Attach the air inlet and air outlet cleaning and storage plugs (3M™ Cleaning and Storage Kit TR-653)

into the TR-800 (see Fig. 15). The TR-800 can now be rinsed under running water, immersed, or put in a respirator

washer for further cleaning. Water temperature should not exceed 122°F (50°C). The plug gaskets should be

inspected for damage and wear prior to each use. Worn or damaged gaskets must be replaced. Washing the TR-800

while using damaged plug gaskets may cause damage to the TR-800 and void the warranty. Blowers which have

been dropped or damaged should not be immersed or put into a respirator washer due to potential water ingress.

Gaskets should be replaced every 30 uses or yearly, whichever comes rst, to minimize use of worn gaskets.

14

Page 18

1

2

2

2

1

2

1

1

Fig. 15 – Attaching motor/blower cleaning and storage covers

2. Battery:

• While still on the blower, wipe the housing of the battery pack with a soft cloth dipped in mild cleaning solution. Then

wipe with a soft cloth dipped in clean water. Wipe dry.

• Remove battery and wipe down top of battery pack, if needed, with a soft dry cloth. Avoid contact with the

blower/charger connection pads; if they become damp, allow to dry before reinstalling on blower or charger.

• If needed, the battery strap included with the 3M™ Cleaning and Storage Kit TR-653 can be used to protect the pads

during cleaning. With the strap in place, the TR-830 battery can now be rinsed under running water, immersed, or

put in a respirator washer for further cleaning.

3. Breathing tube:

• Detach breathing tube with unit upside down (Fig. 11).

• Clean the connection sites on the breathing tube with the water and detergent solution. The breathing tube can be

immersed in water for cleaning if required. The inside of the tube must be completely dried prior to use or storage.

• Air dry, or dry by connecting to the motor/blower unit and use it to force air through the tube until dry. Orient tube to

prevent water from running into blower.

• Optional plastic breathing tube covers (BT-922) may also be used to facilitate cleaning.

4. Belt:

• Remove the belt from the motor/blower by lifting the bottom of the belt over the belt locking tabs and sliding the

belt down. The 3M™ Easy Clean Belt TR-627 is made of a non-porous and closed-cell material and can be wiped

down or submersed in a soapy water solution. The 3M™ High Durability Belt TR-626 is made of leather leads

with a rubber hip belt.

• The leather leads can be cleaned with a leather cleaner. The hip belt can be cleaned with a soapy water solution.

Wipe or rinse all belts thoroughly and dry completely before next use.

5. Filter/cartridge:

• Remove the lter cover and inspect the lter/cartridge (and prelter/spark arrestor if used). Replace lter/cartridge if

excessively dirty, wet or damaged.

• Do not attempt to clean the inside of the lter/cartridge housing or the lter/cartridge media itself. Do not clean with

compressed or pressurized air. Doing so will damage the media. The exterior of the lter/cartridge can be gently

wiped down with a dry or damp cloth to remove excess dirt and debris.

• The prelter (3M™ Prelter TR-6600) cannot be cleaned. Replace if excessively dirty or damaged.

• The spark arrestor (3M™ Spark Arrestor TR-662) can be cleaned using a water and detergent solution. Completely

dry the spark arrestor with a clean cloth or air dry. If the spark arrestor cannot be cleaned or is damaged, replace

with a new spark arrestor.

NOTE: To minimize material falling onto the motor/blower, remove the lter/cartridge while it is facing downward (Fig. 6).

Storage

Clean the system prior to storing. Store in a clean/dry environment not exposed to contaminant dusts, gasses or vapors.

Filters/cartridges may be stored attached to the blower. Do not hang blower or headtop by the breathing tube, or hang the

blower from the headtop. The system must be fully inspected prior to next use. For prolonged storage, the motor must be run

for 5 minutes annually to ensure proper lubrication and operation.

See “Specications” section of this User Instructions for information on suggested storage temperatures. Humidity and

ambient contaminants may diffuse into chemical cartridges once they are removed from their original packaging, which may

reduce service life. Storing chemical cartridges in a clean airtight container, attached to or removed from the blower body,

may help maintain remaining service life. For additional information on cartridge reuse, refer to 3M Technical Data Bulletin

#142- Reuse of Organic Vapor Chemical Cartridges.

Battery Pack Maintenance and Storage

Battery packs should be charged prior to storage. Battery pack charge depletes slowly during storage; battery packs must

not be allowed to fully discharge during extended storage. For short-term storage, the battery pack may be left attached

to the motor/blower. For long-term storage, the battery pack should be removed from the motor/blower. Refer to the 3M™

Versao™ Powered Air Purifying Respirator TR-800 Chargers and Battery Packs User Instructions for specic maintenance

and storage recommendations.

3M™ Battery Pack TR-830 can provide approximately 750 full charge/discharge cycle equivalents while maintaining 80% of

its original capacity, when used under recommended conditions and during its rst year of service. Normal use of the battery

and natural aging of battery cells will gradually decrease the battery’s available capacity. For additional information on

15

Page 19

battery use and optimization see the Versao™ TR-830 Chargers and Battery Packs User Instructions and 3M Technical Data

Bulletin #223 3M™ Versao™ PAPR Battery Maintenance.

Do not store battery packs where temperatures may exceed 122°F (50°C).

Disposal

⚠ WARNING

Dispose of lithium-ion battery packs according to local environmental regulations. Do not dispose of in standard waste

bins, in a re or send for incineration. Failure to properly dispose of battery packs may lead to environmental

contamination, re or explosion and may result in serious injury or death.

In the United States and Canada, 3M participates in the Call2Recycle program which provides for 3M™ PAPR Batteries to be

dropped off (free of charge) at participating recycling collection sites. Please dispose of batteries according to federal, state,

provincial and local regulations. Contact the Call2Recycle Hotline at 1-877-273-2925 or go to their website,

www.call2recycle.org, for drop off site locations.

Used lter/cartridges should be disposed of based on the contaminants collected on it and according to local environmental

regulations.

The motor/blower and charger contain electronic components. Dispose of according to local and government regulations.

TECHNICAL SPECIFICATIONS

Consult the 3M™ Versao™ Powered Air Purifying Respirator TR-800 Technical Specications sheet for additional

specications.

Airow Approx. 6.7 cfm (190 lpm): Standard ow

Intrinsic Safety

Weight:

TR-800 motor/blower- no battery pack

Standard battery pack- TR-830

High durability belt- TR-626

Easy clean belt- TR-627

Operating temperature

Operating altitude/elevation range

Storage conditions:

Relative humidity

Temperature (daily storage)

Temperature (extended storage)

Optimal temp for battery packs to maintain existing

charge while stored off charger

Battery charging*

* Based on the internal temperature of the battery

Shelf life from date of manufacture when stored in original

packaging and recommended storage conditions:

1. Motor/blower

2. Battery pack

3. Filters and cartridges

Approx. 7.2 cfm (205 lpm): Medium ow

Approx. 7.8 cfm (220 lpm): High ow

Exia Division 1: IS Class I, II, III; Division 1

(Includes Division 2); Groups C, D, E, F, G; T4

Ex ia I Ma

Class I, Zone 0, AEx ia IIB; T4

Class I, Zone 0, Ex ia IIB; T4

Zone 20, AEx ia IIIC; T135°C

Zone 20, Ex ia IIIC; T135°C

-20°C ≤ Ta ≤ 55°C

Approx. 1.5 lbs (675 grams)

Approx. 1.5 lbs (663 grams)

Approx. 0.9 lbs (425 grams)

Approx. 0.6 lbs (270 grams)

23°F to 131°F (-5°C to 55°C)

-328 feet to 16404 feet (-100 meters to 5000 meters)

< 90%

-22°F to 122°F (-30°C to 50°C)

40°F to 95°F (4°C to 35°C)

59°F (15°C)

Range: 32°F to 104°F (0°C to 40°C)

Optimal: 68°F to 77°F (20°C to 25°C)

1. 5 years*

2. 6 months

3. 5 years

*Run for 5 minutes/year

California Energy Commission Compliant

16

Page 20

TROUBLESHOOTING

To reduce exposure to hazardous voltage:

a. Do not attempt to service the chargers. There are no user-serviceable parts inside.

b. Do not substitute, modify or add parts to the chargers.

c. Inspect the chargers and power cords before use. Replace if any parts are damaged.

d. Do not use the chargers outdoors or in wet environments.

There are no user-serviceable parts inside the 3M™ Versao™ Powered Air Purifying Respirator TR-800 PAPR

Assembly. The motor/blower unit should not be opened to attempt repairs. Consult the TR-800 “Troubleshooting”

guide or contact 3M Technical Service to help identify additional possible causes and corrective actions for other

problems you may experience.

⚠ WARNING

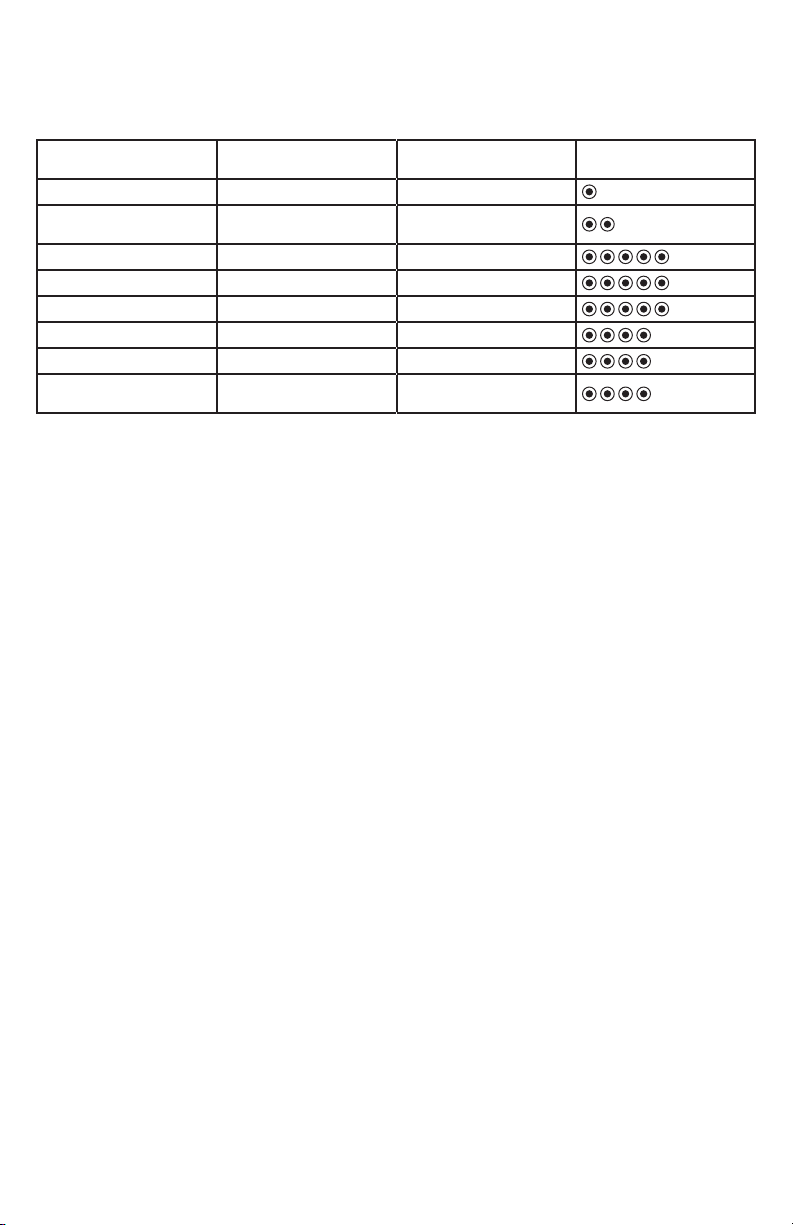

TR-800 FILTER AND CARTRIDGE OPTIONS WITH COVERS

Protection Catalog # Associated Cover Size Cover Size Icon

HE TR-6710N-5 & TR-6710N-40 TR-6700FC

HE/HF/Nuisance OV TR-6820N TR-6800FC

HE/OV TR-6510N TR-6500FC

HE/OV/AG/HF TR-6530N TR-6500FC

HE/Multi-gas TR-6590N TR-6500FC

HE/AG TR-6320N TR-6300FC

HE/Formaldehyde TR-6350N TR-6300FC

HE/Ammonia/Methylamine TR-6360N TR-6300FC

IMPORTANT NOTICE

WARRANTY

3M warrants that 3M™ Versao™ Powered Air Purifying Respirator TR-800 (PAPR) and all 3M™ Versao™ PAPR and

Supplied Air Respirator (SAR) Systems, and their component parts will be free from defective materials and workmanship

at the time of purchase and will cover the parts listed below for the time periods indicated, provided they are maintained

and used in accordance with the product’s User Instructions and/or recommendations. The only 3M obligation under this

Warranty will be, at 3M’s option, to repair or replace without charge any defective parts of the 3M™ Versao™ Respirator

Product returned to 3M in accordance with the instructions below and found by 3M to have been defective at the time of

purchase or during the warranty period as applicable. This Warranty does not apply to any parts that have been misused,

altered or had repair attempted, or have been subjected to abuse, accidental or otherwise. The Warranty does not apply

to expendable consumables, accessories, or fabric components such as but not limited to: lters/cartridges, face seals,

shrouds, hoods and head covers, and visors.

Warranty time periods for specied parts:

- PAPR Blower Unit, excluding consumables: 1 year from date of purchase.

- Batteries: 750 full cycle equivalents or 1 year from date of purchase, whichever occurs sooner.

- Battery chargers, SAR Valves, SAR Panels, excluding consumables, and Respiratory Faceshields, Hard Hats, and

Helmets, excluding consumables: 1 year from date of purchase.

- CO monitors: 2 years from date of purchase.

EXCLUSIONS TO WARRANTY: THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY IMPLIED WARRANTY OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR OTHER WARRANTY OF QUALITY, EXCEPT OF TITLE AND

AGAINST PATENT INFRINGEMENT.

LIMITATION OF LIABILITY

Except as provided above, 3M shall not be liable or responsible for any loss or damage, whether direct, indirect, incidental,

special or consequential, arising out of sale, use or misuse of 3M™ Versao™ Products, or the user’s inability to use such

products. THE REMEDIES SET FORTH HEREIN ARE EXCLUSIVE.

FCC COMPLIANCE

NOTE: Because the motor/blower and battery charger of this TR-800 PAPR Assembly may produce radio frequency energy,

3M is providing the following information pursuant to FCC regulations.

FCC Compliance

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) this device may

not cause harmful interference, and (2) this device must accept any interference received, including interference that may

cause undesired operation.

17

Page 21

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of

the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment

is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at user’s own expense.

Industry Canada

CAN ICES-3(A) / NMB-3(A)

SYSTEM INTRINSIC SAFETY APPROVAL INFORMATION

The 3M™ Versao™ Powered Air Purifying Respirator TR-800 Motor/Blower, with the 3M™ Battery Pack TR-830 attached,

has been tested and classied for intrinsic safety in Hazardous Locations (Exia) by Underwriters Laboratory (UL) for the

following:

Exia Division 1:

IS Class I, II, III; Division 1 (Includes Division 2); Groups C, D, E, F, G; T4

Ex ia I Ma

Class I, Zone 0, AEx ia IIB; T4 / Class I, Zone 0, Ex ia IIB; T4

Zone 20, AEx ia IIIC; T135°C / Zone 20, Ex ia IIIC; T135°C

-20°C ≤ Ta ≤ 55°C

Approval Standards:

UL 913, 8th edition

UL 60079-0, 6th Edition, 2013

UL 60079-11, 6th Edition, 2013

CAN/CSA-C22.2 NO. 60079-0:15

CAN/CSA-C22.2 NO. 60079-11:14

Explanation of device markings containing safety information

Symbol/Statement Description

To reduce the risk of injury,

user must read instruction manual

Warning

60°C

Li-ion

Um: 14 Vdc Charge; 5.5 Vdc Communication Battery maximum input voltages

Warning: To reduce the risk of a hazardous or

ammable atmosphere, batteries must be changed only in

a location known to be non-hazardous. Correctly use and

maintain battery. Misuse may result in sickness, injury or

death. See User Instructions for proper use.

Maximum ambient temperature 60°C/140°F

Rechargeable Lithium-ion battery

Do not remove or replace battery in hazardous location

Do not throw battery in trash.

Dispose of product as directed by local regulations.

Do not throw electronic waste in trash.

Dispose of product as directed by local regulations.

Battery safety warning statement

18

Page 22

1. The 3M™ Battery Pack TR-830 is intrinsically safe only when mated with a TR-800 Powered Air Purifying Respirator.

⚠ WARNING

To reduce the risk of ignition of a ammable or explosive atmosphere, batteries must be changed only in a

location known to be non-hazardous. Never bring this battery alone into an area which is potentially ammable or

explosive. Doing so may result in serious injury or death.

2. The battery chargers for this system are not intrinsically safe. The TR-830 battery pack must not be charged in

an area which is potentially ammable or explosive. Doing so may result in serious injury or death.

3. Always correctly use and maintain the lithium-ion battery packs. Failure to do so may cause re or explosion or

could adversely affect respirator performance and result in injury, sickness, or death.

a. Do not charge batteries with unapproved chargers, in enclosed cabinets without ventilation, in hazardous locations,

or near sources of high heat.

b. Do not immerse without the battery storage and cleaning cover installed.

c. Do not use, charge, or store batteries outside the recommended temperature limits.

d. Charge in an area free of combustible material and readily monitored, and outside of the classied intrinsically

safe area.

FOR MORE INFORMATION

In United States, contact:

Website: www.3m.com/workersafety

Technical Assistance: 1-800-243-4630

For other 3M products:

1-800-3M-HELPS or 1-651-737-6501

RENSEIGNEMENTS SUPPLÉMENTAIRES

Aux États-Unis:

Site web: www.3m.com/workersafety

Assistance technique: 1800243-4630

Autres produits 3M :

1800364-3577 ou 1651737-6501

PARA MAYORES INFORMES

En Estados Unidos:

Sitio Web: www.3m.com/workersafety

Soporte técnico: 1-800-243-4630

Para otros productos 3M:

1-800-3M-HELPS o 1-651-737-6501

PARA MAIS INFORMAÇÕES

Nos Estados Unidos, entre em contato com:

Website: www.3m.com/workersafety

Assistência Técnica: 1-800-243-4630

Para outros produtos 3M:

1-800-3M-HELPS ou 1-651-737-6501

POUR OBTENIR DE PLUS AMPLES RENSEIGNEMENTS/

FOR MORE INFORMATION

Au Canada, communiquer avec/In Canada, contact :

Site web : www.3M.ca/Safety

Assistance technique/Technical Assistance :

1 800 267-4414

Centre communication-client/Customer Care Center :

1 800 364-3577

19

Page 23

Ce produit fait partie d'un système qui réduit l'exposition à certains contaminants en suspension dans l'air.

Avant de se servir du produit, l'utilisateur doit lire et comprendre les présentes directives d'utilisation. Suivre

tous les règlements locaux. Aux États-Unis, un programme de protection respiratoire écrit, conforme au

règlement 29 CFR 1910.134, en matière de formation, d'essai d'ajustement et d'évaluation médicale doit

être mis sur pied. Au Canada, se conformer à la norme Z94.4 de la CSA et/ou aux exigences de l'autorité

compétente de sa région, le cas échéant. Une mauvaise utilisation peut provoquer des blessures, des

problèmes de santé ou la mort. Pour tout renseignement sur l'utilisation adéquate de ce produit, consulter

son superviseur, lire les directives d'utilisation ou communiquer avec le Service technique de 3M aux É.-U. au

1 800 243-4630 et au Canada au 1 800 267-4414.

!!!IMPORTANT, À LIRE EN PRIORITÉ!!!

• Charger complètement les blocs-piles neufs immédiatement après les avoir reçus.

• Lire et comprendre les présentes directives d’utilisation avant l’utilisation, y compris les mises en garde et les avis.

• Ce système est réservé à une utilisation professionnelle en milieu de travail.

• L’indicateur d’encrassement du ltre n’est utile que pour les particules. Il ne donne aucun renseignement quant à la

durée utile contre les gaz et les vapeurs.

• Le respirateur d’épuration d’air propulsé VersaoMC 3MMC de sérieTR-800 a été soumis à des essais et porte

l’homologation UL en matière de sécurité intrinsèque. Exia, division 1 :

Intrinsèquement sécuritaire classe I, II et III; division 1 (comprend la division 2), groupes C, D, E, F, G; T4

Ex ia I Ma

Classe I, zone 0, AEx ia IIB, T4 / classe I, zone 0, Ex ia IIB; T4

Zone 20, AEx ia IIIC; T135°C / zone 20, Ex ia IIIC; T135°C

-20°C ≤ Ta ≤ 55°C

TABLE DES MATIÈRES

AVANT-PROPOS .................................................................................................................. 21

Coordonnées .................................................................................................................. 21

Description du système .................................................................................................. 21

LISTE DES MISES EN GARDE ET DES AVERTISSEMENTS ÉNONCÉS DANS

LES PRÉSENTES DIRECTIVES D’UTILISATION ....................................................................... 21

RESTRICTIONS D’UTILISATION ............................................................................................22

GESTION DES PROGRAMMES DE PROTECTION RESPIRATOIRE ............................................ 23

APPROBATIONS, RESTRICTIONS ET LIMITES D’UTILISATION ................................................ 23

DÉBALLAGE ET CHARGE DE LA PILE .................................................................................... 24

DESCRIPTION ET ASSEMBLAGE DES COMPOSANTS ............................................................ 25

INSTALLATION ET CHARGE DU BLOC-PILES ......................................................................... 28

CEINTURES ET ENSEMBLE HARNAIS ................................................................................... 29

TUYAU DE RESPIRATION ...................................................................................................... 31

PIÈCE FACIALE .................................................................................................................... 31

MODE D’EMPLOI ................................................................................................................. 31

INSPECTION ........................................................................................................................ 33

ENTRÉE ET SORTIE DE LA ZONE CONTAMINÉE .................................................................... 35

NETTOYAGE, ENTREPOSAGE ET MISE AU REBUT .................................................................36

CARACTÉRISTIQUES TECHNIQUES ....................................................................................... 38

DÉPANNAGE ....................................................................................................................... 38

CHOIX DE FILTRES ET DE CARTOUCHES AVEC COUVERCLES

POUR LE RESPIRATEUR TR-800 .......................................................................................... 39

AVIS IMPORTANT ................................................................................................................ 39

GARANTIE ....................................................................................................................... 39

LIMITE DE RESPONSABILITÉ ............................................................................................... 39