Transportation Safety Division

3M™ Stamark™ Pavement

Marking Tape Series 270 ES

Product Bulletin 270 ES

June 2020

Replaces Product Bulletin 270 ES Dated May 2011

1 Description

3M™ Stamark™ Pavement Marking Tape Series 270 ES (“Tape”) is a retroreflective patterned polymer pavement

marking that can be used as an inlay marking on new asphalt or as an overlay marking on asphalt and concrete

pavement surfaces in good condition.

The Tape offers “Extended Season” applications due to an improved pressure sensitive adhesive (PSA) package on

the bottom surface.

The Tape does not require 3M Stamark Surface Preparation Adhesive P-50 (“P-50”) or 3M Stamark Low VOC

Surface Preparation Adhesive SPA60 (“SPA60”) prior to application, if applied during the application season as

outlined in the 3M Climate Guide for 3M Stamark Pavement Marking Tapes

Series A270 ES: No liner. Used for lane lines, edge lines, channelizing lines, gore markings, stop bars, and

crosswalks.

.

Series L270 ES: With liner. Used to cut symbols and legends.

Series SMS-L270 ES: With liner. Precut symbols and legends.

2 3M™ Stamark™ Pavement Marking Tape Series 270 ES June 2020

1.1 Product Features

o Durable, conformable to pavement and retroreflective

o Embedded net provides increased tear resistance

o Pressure sensitive adhesive (PSA) on bottom surface

o No surface preparation adhesive required when applied within standard tape application season as by

o the 3M Climate Guide

o Can be applied early and late season, down to 40 °F (4 °C) with use of 3M Stamark Surface Preparation

Adhesive P-50 or 3MTM Stamark Low VOC Surface Preparation Adhesive SPA60

o Retroreflective layer of glass beads bonded in a highly durable polyurethane topcoat

o Manufactured without the use of heavy metals, lead chromate pigments or other similar, lead containing

chemicals

o Nominal total thickness of 0.090 in. (2.3 mm)

oWhite: 270 ES

o Yellow: 271 ES

2 Specifications

2.1 Retroreflectivity

Table 1 presents minimum initial coefficient of retroreflected luminance (RL) values for tape when measured in

accordance with ASTM D4061 and ASTM 4505. R

footcandle [(mcd • ft

-2

) • fc-1].

values are expressed in millicandelas per square foot per

L

Table 1. Minimum R

Entrance Angle

Observation Angle

Coefficient of Retroreflected

Luminance [mcd/m

a. An Entrance Angle of 88.76° and an Observation Angle of 1.05° are used

to simulate the viewing geometry of a driver at a distance of 30 meters.

a

values for white and yellow Tape.

L

White (270 ES) Yellow (271 ES)

88.76° 88.76°

a

2

/lux]

1.05° 1.05°

300 250

2.2 Color

The daytime and nighttime colors of Tape conform to ASTM D6628, the Standard Specification for Color of

Pavement Marking Materials.

2.3 Skid Resistance

The patterned, retroreflective, pliant polymer surfaces of Tape shall provide average initial skid resistance

values of 45 BPN or more when tested according to ASTM E303, subject to the following modification:

o Skid resistance is calculated as the average of two measurements taken at an angle of 45° from one

another.

2.4 Patchability

Snow removal equipment and heavy traffic may cause wear and damage to Tape. Such damaged areas can be

repaired using patches made of Tape. Remove damaged Tape and replace it according to the instructions

presented in the “Overlay Applications” section of 3M Information Folder 5.7

.

3 3M™ Stamark™ Pavement Marking Tape Series 270 ES June 2020

3 Application

Install Tape according to the instructions presented in 3M Information Folder 5.7.

All applications should be installed using the instructions in the appropriate section of 3M Information Folder 270

ES. Surface preparation adhesive is not needed when applying the tape during the application season outlined in

the 3M Climate Guide for 3M Stamark Pavement Marking Tapes. The tape can be applied down to 40 °F (4 °C)

ambient temperature outside the dates outlined in the Climate Guide for Stamark pavement marking tapes with the

use of P-50 or SPA60. For long line applications, the P-50 or SPA60 surface preparation adhesive should be

applied with a 3M Adhesive Spray Applicator PS-14. For transverse markings, the surface preparation adhesive

should be applied using a solvent resistant 3/8 inch nap paint roller.

Road lanes are typically exposed to different levels of traffic shear exposure. Road lanes that are exposed to a high

frequency of high shear turning, especially by trucks and other large vehicles, require use of SPA60 or P50 for

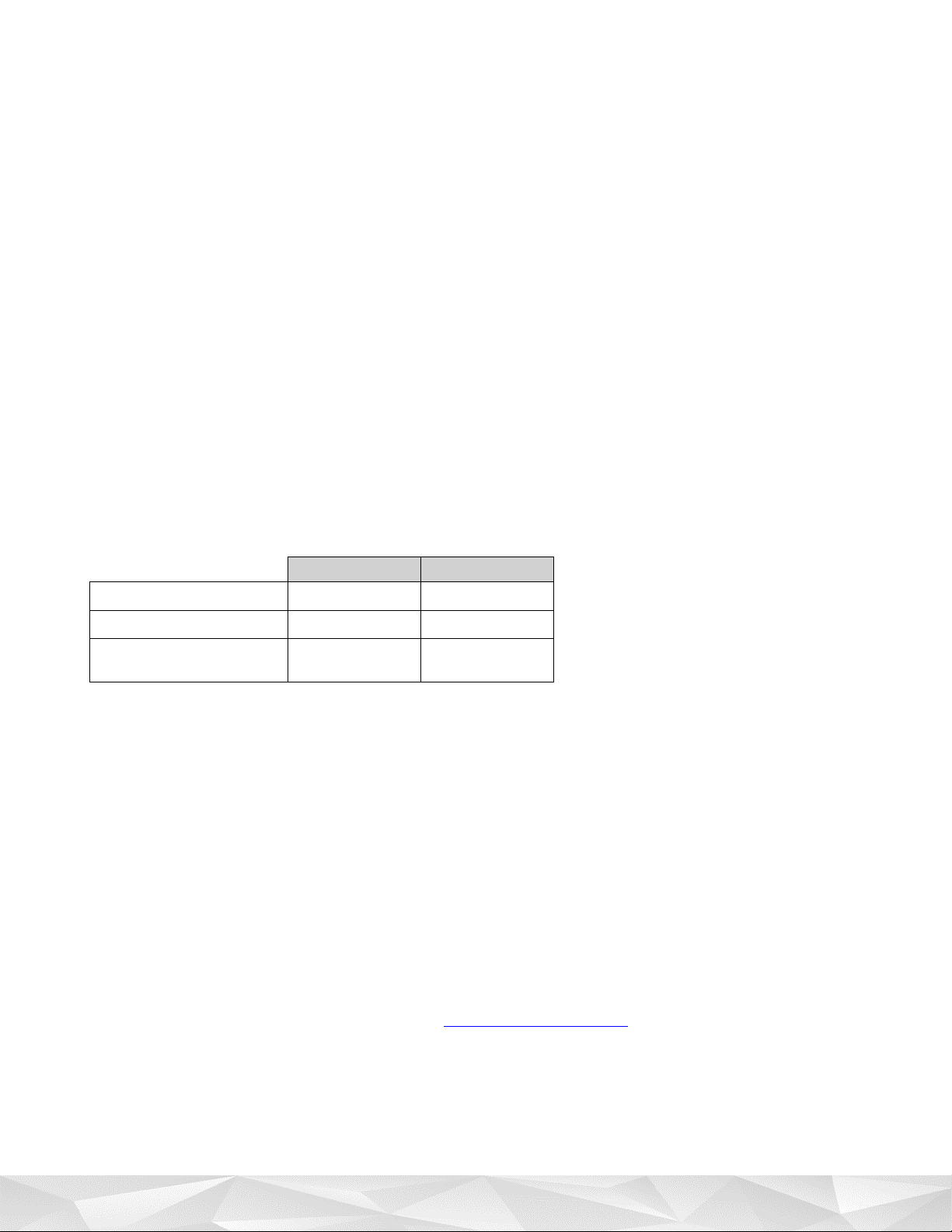

application of Stamark pavement marking tapes. The following table summarized the product and surface

preparation adhesive application recommendations by shear condition:

Contact 3M Technical Service at 1800-553-1380 for questions.

Table 2.

Shear Level Product and Adhesive Recommendation

Very High Shear

High Shear

Pounds per 100 sq ft

Low Shear

Within the Climate Guide Recommendations

Stamark Tape Use SPA60

Stamark Tape “A” and “L” Series

Use SPA60

Stamark Tape “A” and “L” Series

Use P50 or SPA60

Stamark Tape “A” and “L” Series

4 Durability

The Tape is weather resistant and provides excellent retroreflectivity and color retention. The Tape is a highly

effective lane marking material and will show no appreciable fading, lifting, shrinkage, or chipping for the duration

of the warranty period, when applied according to the 3M requirements described in the 3M product literature.

The Tape’s durability depends on several environmental and traffic conditions, including, but not limited to, snow

removal practices, method of application, and pavement and atmospheric conditions at the time of application.

Damage will be caused by heavy trucks, excessive encroachment (crossover) on high ADT roadways, narrow lane

width, unpaved shoulders, snow removal and ice control techniques. It is recommended that the customer

thoroughly evaluate Tape under the conditions present at the installation location prior to large-scale

implementation.While experience has shown that, properly applied, these materials are highly effective traffic

control devices, 3M makes no generalized performance claims.

5Storage

Store indoors, in a cool, dry area. Use within one year of receipt.

6 Health and Safety Information

Read all health hazard, precautionary, and first aid statements found in the Safety Data Sheets (SDS) and Article

Information Sheets for important health, safety, and environmental information. To obtain SDSs and Article

Information Sheets for 3M products, go to 3M.com/SDS, contact 3M by mail, or for urgent requests

call 1-800-364-3577.

4 3M™ Stamark™ Pavement Marking Tape Series 270 ES June 2020

7 Basic Product Warranty

3M warrants to the purchaser that the Tape will be free of defects in materials and manufacture at the time of

shipment and meet the specifications stated in this product bulletin (“Basic Warranty”). If Tape is proven not to

have met the Basic Warranty on its shipment date, then a buyer's exclusive remedy, and 3M's sole obligation, at

3M's option, will be refund or replacement of the Tape.

8 Other Product Information

Always confirm that you have the most current version of the applicable product bulletin, information folder, or

other product information from 3M’s Website at http://www.3M.com/roadsafety

.

9 Literature References

3M IF 5.2 Highway Tape Applicator (HTA)

3M IF 5.7

3M IF 5.8

3M IF 5.17

3M IF 5.18

3M IF 5.21

3M™ Stamark™ Tapes Pavement Surface Preparation and Application Techniques

3M™ Stamark™ Pre-Cut Symbols and Legends Application

3M™ Stamark™ Surface Preparation Adhesive P-50 Instructions for use with 3M™ Stamark™

Pavement Marking Tapes

Application Guidelines for Pavement Markings in Grooved Pavement Surfaces

3M™ Stamark™ Low VOC Surface Preparation Adhesive SPA60 Spray Application Instructions

for Bulk Liquid for Longitudinal Pavement Marking Tapes

ASTM Test Methods are available from ASTM International, West Conshohocken, PA.

For Information or Assistance

Call:

In Canada

1

Interne

1-800-553-1380

Call:

-800-3M HELPS (1-800-364-3577)

t:

http://www.3M.com/roadsafety

3M, Science. Applied to Life., and Stamark are trademarks of 3M. Used under license in Canada.

All other trademarks are the property of their respective owners.

3M assumes no responsibility for any injury, loss, or damage arising out of the use of a product that is not of our

manufacture. Where reference is made in literature to a commercially available product, made by another

manufacturer, it shall be the user’s responsibility to ascertain the precautionary measures for its use outlined by

the manufacturer.

Important Notice

All statements, technical information and recommendations contained herein are based on tests we believe to be

reliable at the time of this publication, but the accuracy or completeness thereof is not guaranteed, and the

following is made in lieu of all warranties, or conditions express or implied. Seller's and manufacturer's only

obligation shall be to replace such quantity of the product proved to be defective. Neither seller nor manufacturer

shall be liable for any injury, loss or damage, direct, indirect, special, or consequential, arising out of the use of or

the inability to use the product. Before using, user shall determine the suitability of the product for his/her

intended use, and user assumes all risk and liability whatsoever in connection therewith. Statements or

recommendations not contained herein shall have no force or effect unless in an agreement signed by officers of

seller and manufacturer.

Transportation Safety Division

3M Center, Building 0225-04-N-14

St. Paul, MN 55144-1000 USA

Phone 1-800-553-1380

Web 3M.com/roadsafety

Please recycle. Printed in USA © 3M 2020.

All rights reserved. Electronic Only

Loading...

Loading...