Page 1

a 3M company

®

™

3M

SS Series

Cartridge Filter Housings

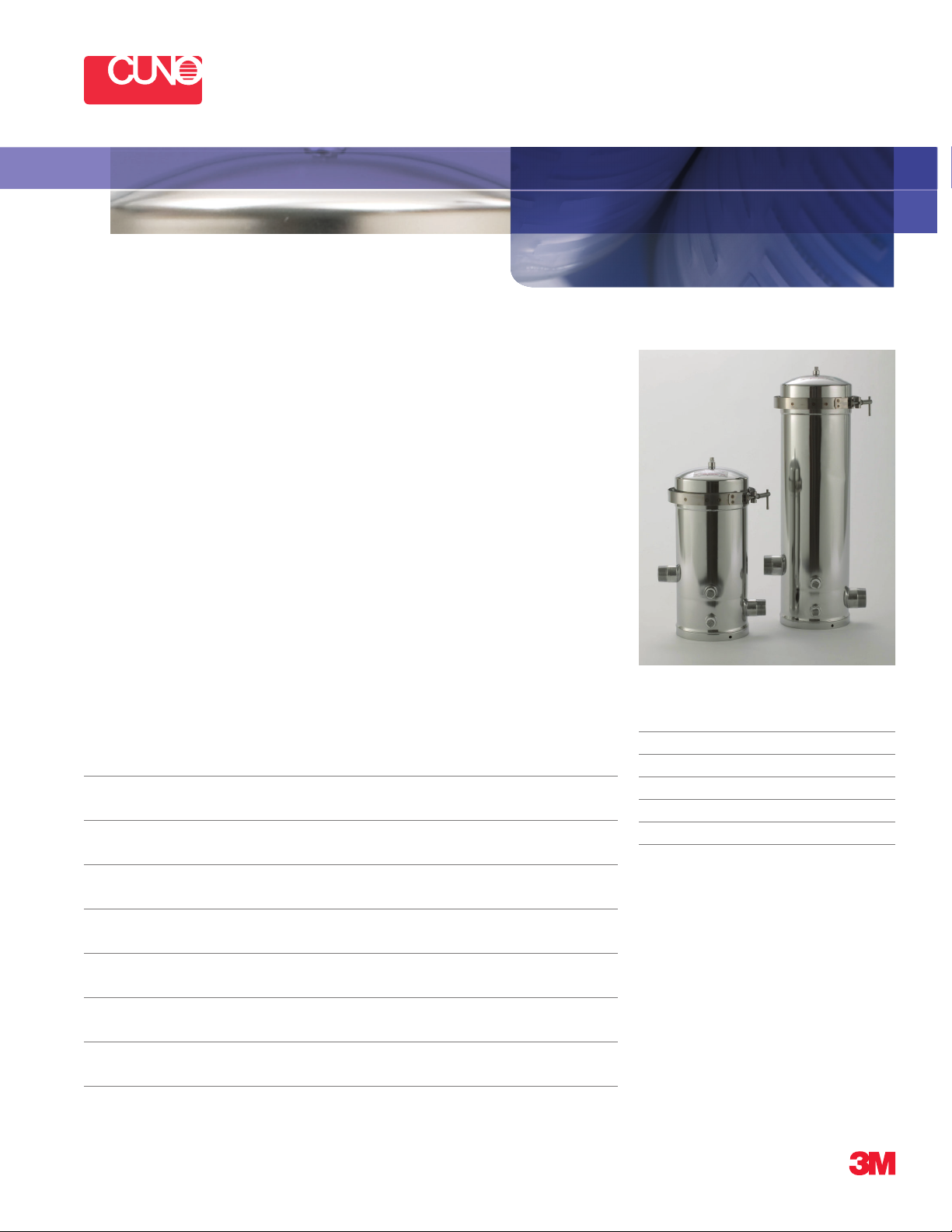

3M™ Model SS Series Cartridge Filter Housings, constructed of durable 316L stainless

steel, meet general-purpose industrial and commercial filtration needs. All wetted welded

surfaces are stainless steel. External surfaces of these filter housings are electro-polished

for a consistent, easy care finish.

The filter housings are available in a variety of sizes to accommodate from 4 to 88 filter

cartridges (Single length equivalents) with lengths to 40 inches (see Ordering Guide). The

housing has a maximum allowable working pressure of up to 150 psig (10.3 bar) at 250°F

(121°C), see Table 1.

Specifi cations

Table 1 gives standard model specifications for Model SS Series cartridge filter housings.

Note that maximum allowable working pressure and temperature is the rating for the

housing only. Actual housing maximum operating temperature depends on temperature and

chemical capability of the filter cartridge and gasket used in the housing.

Cartridge Requirements

Model SS Series filter housings accept both single and multiple length filter cartridges.

Table 2 lists the number of filter cartridges for each model housing.

Features & Benefi ts

316L stainless steel construction.

■

Provides excellent corrosion protection for rugged, long-lasting service.

Accepts varying length cartridges.

■

Allows use of 9 ¾" and 10" modular cartridges for greater fl exibility.

Shouldered seal plates.

■

Solid fi t into cartridge core enables positive seal and prevents bypass.

V-Band Clamp and Swing Bolt designs.

■

Optimizes cartridge change-out.

Removable cartridge posts.

■

Easy cleaning reduces maintenance.

Housing drains located on dirty and clean chambers.

■

Allows full drainage of chambers for optimized fi lter change-out.

Air Vent.

■

Allows venting before start-up and draining for more effi cient fi lter operation.

Pedestal cup fi tting.

■

Allows for use of both DOE or SOE cartridges.

Applications

Chemicals & Petrochemicals

Food & Beverage

Healthcare

Industrial Processes

Paint & Coatings

Industrial Water Treatment

Page 2

Double

Open-end

Cartridge

Single

Open-end

Cartridge

with

Locating Spear

Flow Rates

Table 3 lists the maximum water flow rates in gallons per minute (GPM) for each model

filter housing.

Use the data in Table 3 only as a guide in establishing the max imum housing

flow capacity; do not use it for filter sizing. Once a flow rate for a selected cartridge is known, use Table 3 to check whether the housing’s flow rate falls within

the recommended guidelines.

When sizing a filter, the amount of contaminant load needs to be considered in

addition to the flow rate and desired pressure drop. Low initial pressure drop

enhances filter cartridge life.

Cartridge Seal Assemblies

The SS24, SS36, SS48, SS66, and SS88 housings include spring seal assemblies

(Picture 1) that permit the use of filter cartridges with single length equivalents of

9 3/4 to 10 inches.

SS4 through SS20 models use pressure plate assemblies while SS24 through SS88 models

use pressure plate with individual spring and seal assemblies.

Standard housings are configured to accept double open end style cartridges. To adapt the

housing to accept single open end, double o-ring cartridges with locating spear, remove

the housing cartridge posts and the spring & seal assembles. Replace the standard pressure

plate with the SOE pressure plate (order separately).

Picture 1: Spring Seal Assembly

Table 3: Maximum Housing Flow Rate

Housing Water (GPM/LPM)

SS4, SS8, SS12 65/246

SS5, SS10, SS15, SS20 105 /397

SS24, SS36, SS48 230/871

SS66, SS88 400/1,514

Standard Model Dimensions

To find a selected dimension, refer to Table 4 to locate the model in the left column and the

selected dimension symbol (A-D) in the top row. These dimensions can be used for rough

plumbing. For critical installations, request a certified drawing.

Table 1: Standard Model Specifi cations

Operating Data SS Models - 316L Stainless Steel

Max. Allowable Working

Pressure @ Temperature*

Flow Rate (GPM) See Table 3

Connection Sizes See Ordering Guide

Vent & Drain Connections

Cartridge Sizes 9 ¾ "-10" modular cartridges, 1-, 2-, 3-, or 4-high configurations

Standard Cover Gasket Nitrile

Options Cover gasket is available in EPR, Fluorocarbon or Silicone

*Models SS24, SS 36, SS48, S S66, SS88 maximum allowable work ing pressure @ temperature is 150 psi @ 212°F (10.3 bar @ 100°C)

Table 2: Cartridge Requirements

Housing Model Single Length (9 ¾ 9 7/8, or 10") Cartridge Capacity

SS4 4

SS8 8

SS12 12

SS5 5

SS10 10

SS15 15

SS20 20

SS24 24

SS36 36

SS48 48

SS66 66

SS88 88

150 psi @ 250°F (10.3 bar @ 121°C)

SS4 - SS20 Housings – ¼ " NPT Vent, ¾ " NPT Drains

SS24 - SS88 Housings – ½ ” NPT Vent, 1” NPT Drains

Page 3

Figure 1: SS Series Configurations

Models SS4, SS5, SS8, SS10, SS12, SS15, & SS20 Models SS24, SS36, & SS48 Models SS66 & SS88

Inlet Outlet

D

Inlet

A*

Outlet

A

B

Inlet Outlet

D

A

B

B*

C*

C

Table 4: Standard Model Dimensions

Housing Model

A*

(in / mm)

SS4 19 ½ / 495.3

SS8 29 ½ / 749.3 46 / 1168.4 24 / 10.9 34 / 15.4

SS12 39 ½ / 1003.3 66 / 1676.4 28 / 12.7 39 / 17.7

SS5 19 ½ / 495.3

SS10 29 ½ / 749.3 46 / 1168.4 25 / 11.3 35 / 15.9

SS15 39 ½ / 1003.3 66 / 1676.4 29 / 13.1 40 / 18.1

SS20 49 ½ / 1257.3 86 / 2184.4 33 / 15.0 45 / 20.4

SS24 48 1/8 /1222.4

SS36 58 / 1473.2 82 / 2082.8 170 / 77 195 / 88.5

SS48 67

13

/16 / 1722.4 102 / 2590.8 187 / 85 215 / 97.5

SS66 67 / 1701.8

SS88 76 ¾ / 1949.5 102 / 2590.8 324 / 147 375 / 170.1

*Add ¾ " for leg installation on S S4 - SS20 housings

B*

(in / mm)

C*

(in / mm)

D

(in / mm)

6 ¾ /171.4 2 7/8 / 73 12 / 304.8

6 ¾ / 171.4 2

7

/8 / 73 12 / 304.8

27 9/16 / 700 13 25/32 / 350 19 11/16 / 500

27 9/16 / 700 13 25/32 / 350 25 5/8 / 650

Cartridge Removal

Clearance (in / mm)

Housing Weight

(lbs / kg)

Approx. Shipping Weight

26 / 660.4 19 / 8.6 29 / 13.1

26 / 660.4 20 / 9.0 30 / 13.6

62 / 1574.8 152 / 69 175 / 79.4

82 / 2082.8 269 / 122 320 / 145.1

C

(lbs / kg)

Page 4

Model SS Series Ordering Guide

CUNO SS Series Housing

Model (316L SS) Connection Type Catalog Number

SS4 EPE-316L 1 ½ " NPT (Male per ASME B1.20.1) 4808713

SS8 EPE-316L 2" NPT (Male per ASME B1.20.1) 4808714

SS12 EPE-316L 2" NPT (Male per ASME B1.20.1) 4808715

SS5 EPE-316L 1 ½ " NPT (Male per ASME B1.20.1) 4808813

SS10 EPE-316L 2" NPT (Male per ASME B1.20.1) 4808814

SS15 EPE-316L 2" NPT (Male per ASME B1.20.1) 4808815

SS20 EPE-316L 2" NPT (Male per ASME B1.20.1) 4808816

SS24 EPE-316L 3" 150# RF FLG (A NSI B16.5) 4808907

SS36 EPE-316L 3" 150# RF FLG (A NSI B16.5) 4808908

SS48 EPE-316L 3" 150# RF FLG (A NSI B16.5) 4808909

SS66 EPE-316L 4" 150# RF FLG (ANSI B16.5) 4809005

SS88 EPE-316L 4" 150# RF FLG (ANSI B16.5) 4809006

Gasket Ordering Guide

Housing Model Nitrile EPR Fluorocarbon Silicone

SS4, SS5, SS8, SS10, SS12, SS15, and SS20 3792031 3756437 3756434 3756440

SS24, SS36, and SS48 3756455 3756456 3756457 3756458

SS66 and SS88 3756459 3756460 3756461 3756462

Supplied with Nitrile vessel gasket. Ethylene Propylene Rubber (EPR); Fluorocarbon or Silicone.

Optional Kit for Single Open End Cartridge Use

Kit Part Number Fits Housing Model

9885501 SS4 - SS12

9885502 SS5 - SS20

9885504 SS24

9885505 SS36

9885506 SS48

9885509 SS66

9885510 SS88

All units supplied with center rods, posts, pressure plates, spring

and seal assemblies for double opened ended (DOE) st yle

cartridges. To conver t units to use single open ended (SOE) st yle

cartridges, order the appropriate optional kit.

Important Notice

CUNO MAK ES NO WARRA NTIES, E XPR ESS OR IMPL IED, INCLU DING, B UT NOT LIMI TED TO, A NY IM PLIED WARRAN TY OF MERCHA NTABILITY OR F ITN ESS FOR A PART ICU LA R PURPOSE. Since

a variety of factors can affect the use and performance of a CUNO

product in a particular application, some of which are uniquely within

the user’s knowledge and control, user is responsible for determining

whether or not the CUNO product is fi t for a particular purpose and

suitable for user’s method of application.

Warrant y

Seller war rants its e quipment again st defects i n workmans hip and mater i a l f o r a p e r i o d o f 1 2 m o n t h s f r o m d a t e o f s h i p m e n t f r o m t h e f a c t o r y u n d e r

normal use a nd service and ot herwise when suc h equipment is used in

accordance with instructions furnished by Seller and for purposes disclo sed in w ritin g at the t ime of p urcha se, if a ny. Any u nauth orized alteration of modifi cation of the equipment by Buyer will void this warranty.

Seller’s liability under this warranty shall be limited to the replacement

or repair, F.O.B., point of manufacture, of any defective equipment or

part which, having been returned to the factory, transpor tation charges

prepaid, has been inspected and determined by Seller to be defective.

THIS WARRANTY IS IN LIEU OF ANY OTHER WARRANTY, EITHER

EXPRESSED OR IMPLIED, AS TO DESCRIPTION, QUALITY, MERCHA NTABILI TY, FITNE SS FOR ANY PARTICUL AR PURPOSE OR USE,

OR AN Y OTHE R MATT ER. Under no circumstances shall Seller be liable to Buyer or any third party for any loss of profi ts or other direct or

indirect costs, expenses, losses or consequential damages arising out

of or as a result of any defects in or failure of its products or any part

or parts thereof or arising out of or as a result of parts or components

incorporated in Seller’s equipment but not supplied by the Seller.

®

a 3M company

CUNO Incorporated

400 Research Parkway

Meriden, CT 06450

U.S.A.

(800) 243-6894

(203) 237-5541

Fax (230) 630-4530

www.CUNO.com

Your Local CUNO Distributor:

CUNO is a trademark of 3M Company

used under license.

3M is a trademark of 3M Company.

© 3M 2008. All rights reserved.

70-0202-2106-8

LITHSSS1.1108

Loading...

Loading...