Page 1

ANSI Z359.4 - 2013

ROLLGLISSTM

Rescue-Positioning Device

USER INSTRUCTIONS

5902114 REv. F

© 3M 2021

Page 2

2

A

B

C

D

E

F

G

H

H

K

M

3 4

A B C

J

A. B. C. D.

E. F. G.

2

Page 3

5 6

FC

1

W

B

A

7 8

2

C

A

A

B

B

3

Page 4

9 10

11 12

A

4

Page 5

13 14

A

B

15

5

Page 6

SAFETY INFORMATION

EN

Please read, understand, and follow all safety information contained in these instructions, prior to the use of this product. FAILURE TO DO SO

COULD RESULT IN SERIOUS INJURY OR DEATH.

These instructions must be provided to the user of the equipment. Retain these instructions for future reference.

Intended Use:

This product is used as part of a complete Fall Protection system.

Use in any other application including, but not limited to, material handling, recreational or sports-related activities, or other activities not described in these

instructions, is not approved by 3M and could result in serious injury or death.

This product is only to be used by trained users in workplace applications.

! WARNING

This product is used as part of a complete Fall Protection system. All users must be fully trained in the safe installation and operation of their complete Fall

Protection system. Misuse of this product could result in serious injury or death. For proper selection, operation, installation, maintenance, and service,

refer to all instruction manuals and manufacturer recommendations. For more information, see your supervisor or contact 3M Technical Services.

• To reduce the risks associated with working with a Rescue Device which, if not avoided, could result in serious injury or death:

- Inspect the product before each use and after any fall event, in accordance with the procedures dened in these instructions.

- If inspection reveals an unsafe or defective condition, remove the product from service immediately and clearly tag it “DO NOT USE”. Destroy or

repair the product as required by these instructions.

- Any product that has been subject to fall arrest or impact force must be immediately removed from service. Destroy or repair the product as

required by these instructions.

- Ensure that Fall Protection systems assembled from components made by different manufacturers are compatible and meet the requirements of

applicable Fall Protection regulations, standards, or requirements. Always consult a Competent or Qualied Person before using these systems.

- Always maintain 100% tie-off.

- Ensure the lifeline is kept free from all hazards, including, but not limited to: entanglement with users, other workers, moving machinery, other

surrounding objects, or impact from overhead objects that could fall onto the lifeline or users.

- Use appropriate edge protection when the lifeline may contact sharp edges or abrasive surfaces.

- Do not twist, tie, knot, or allow slack in the lifeline.

- Do not touch parts of the system exposed to friction during or after a descent; these parts become hot and may cause burns.

- Follow all manufacturer recommendations when connecting a lifeline.

- Always follow your workplace rescue plan when performing rescue operations.

- Do not use this product unless you have received technical rescue training.

- Use caution when installing, using, or moving the product as moving parts may create pinch points.

- Always record descents as specied by these instructions and remove product from service as necessary in accordance with listed usage limits.

- The operator must always maintain control of the hand wheel while the system is under load.

- Always maintain control of the connecting device and descend at a controlled rate.

• To reduce the risks associated with working at height which, if not avoided, could result in serious injury or death:

- Your health and physical condition must allow you to safely work at height and to withstand all forces associated with a fall arrest event. Consult

your doctor if you have questions regarding your ability to use this equipment.

- Never exceed allowable capacity of your Fall Protection equipment.

- Never exceed the maximum free fall distance specied for your Fall Protection equipment.

- Do not use any Fall Protection equipment that fails inspection, or if you have concerns about the use or suitability of the equipment. Contact 3M

Technical Services with any questions.

- Some subsystem and component combinations may interfere with the operation of this equipment. Only use compatible connections. Contact 3M

Technical Services before using this equipment in combination with components or subsystems other than those described in these instructions.

- Use extra precautions when working around moving machinery, electrical hazards, extreme temperatures, chemical hazards, explosive or toxic

gases, sharp edges, abrasive surfaces, or below overhead materials that could fall onto you or your Fall Protection equipment.

- Ensure use of your product is rated for the hazards present in your work environment.

- Ensure there is sufcient fall clearance when working at height.

- Never modify or alter your Fall Protection equipment. Only 3M, or persons authorized in writing by 3M, may make repairs to 3M equipment.

- Before using Fall Protection equipment, ensure a written rescue plan is in place to provide prompt rescue if a fall incident occurs.

- If a fall incident occurs, immediately seek medical attention for the fallen worker.

- Only use a Full Body Harness for Fall Arrest applications. Do not use a body belt.

- Minimize swing falls by working as directly below the anchorage point as possible.

- A secondary Fall Protection system must be used when training with this product. Trainees must not be exposed to an unintended fall hazard.

- Always wear appropriate Personal Protective Equipment when installing, using, or inspecting the product.

- Never work below a suspended load or worker.

FORM NO: 5908259 REV: B

6

Page 7

Prior to installation and use of this equipment, record the product identication information from the ID label in the

;

Inspection and Maintenance Log (Table 2) at the back of this manual.

The user must read and follow the manufacturer’s instructions for each component of the complete system.

;

PRODUCT DESCRIPTION:

Figure 1 illustrates the 3M™ DBI-SALA® Rollgliss™ Rescue-Positioning Device. DBI-SALA rescue and positioning devices are

designed to be components of a rescue-positioning system. This equipment is used for applications where personnel need to be

raised or lowered over a vertical distance.

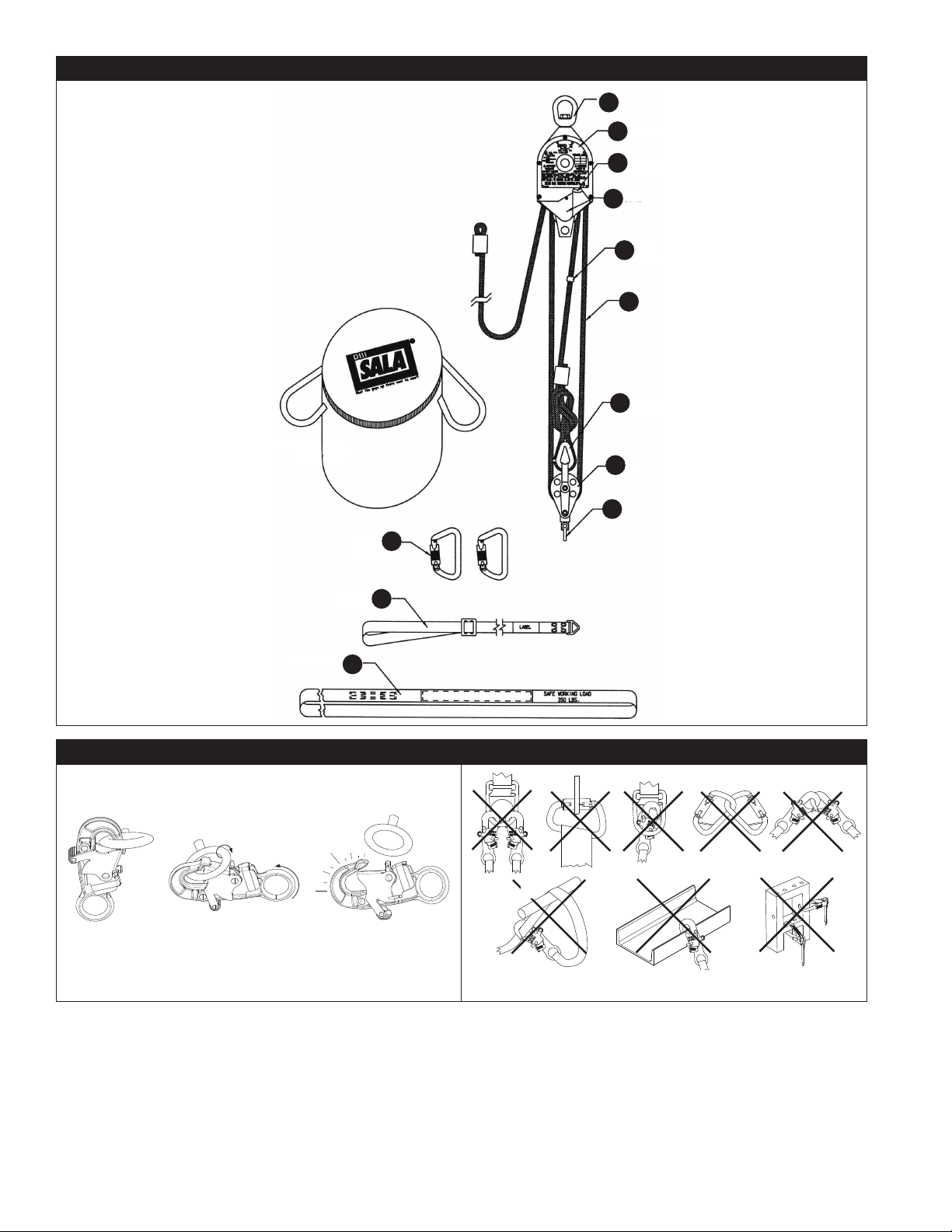

Figure 2 illustrates components of the Device. See Table 1 for Component Specications.

Table 1 – Specications

System Specications:

Capacity:

A maximum of one user can connect to a single Rescue-Positioning Device for rescue or

;

personnel riding applications. In emergency situations, a maximum of two users is allow with a

maximum capacity of 620 lb. (281.2 kg). See below.

Number of

Users

1 310 lb. (140 kg)

2 620 lb. (280 kg)

Lifting Ratio 3:1 - Models 3600000-3601410

4:1 - Models 3602000-3603560

Locking Speed 3 ft./second

Anchorage Strength: Anchorages selected for rescue or personnel riding systems shall have a strength capable of

Service Temperature Do not use where air temperatures exceed 300° F (145°C) or where the rope may come into contact

Anchorage Connector

Breaking Strength:

Standards: The Rescue-Positioning Device has been tested in accordance with the standards identied on the

sustaining static loads applied in the directions permitted by the Rescue Positioning Device of at

least 3,100 lbf (13.8 kN).

When more than one Rescue Positioning Device is attached to an anchorage, the strengths stated

above must be multiplied by the number of devices attached to the anchorage.

with material that is above 250° F (120°C).

5,000 lbf (22.2 kN)

front cover of these instructions.

Total Weight

(including tools, clothing, etc.)

7

Page 8

Component Specications:

Figure 2

Reference

A

B

C

D

E

F

G

H

J

K

L

M

N

P

Component Specications

Swivel Material: Aluminum/Steel

Labels

Indicator Flag

Housing Material: Aluminum

Override Ferrule Material: Stainless steel

Rope

9502091

Teardrop Thimble

Pulley

Carabiner

2000523

Rescue Sling

Connection Sling

3620001

Anchorage Strap

Rope Gripping Handle

9503008 - Optional (Right hand)

9503037 - Optional (Left Hand)

Rescue Cradle

3610000 - Optional

Table 1 – Specications

Material: Plastic

Width: 1/2 in. (1.27 cm)

Material: Kernmantle rope lifeline, braided polyester cover with nylon

lament core

Diameter: 3/8 in. (9.5 mm)

Calculating rope length:

(3:1): Multiply working travel length by 4 and add 10 ft. (3 m) for total.

(4:1): Multiply working travel length by 5 and add 10 ft. (3 m) for total.

Tensile Strength: 5,600 lbf (25 kN)

Material: Plastic

Width: 1/2 in. (1.27 cm)

Material: Zinc plated

Tensile Strength: 5,000 lbf (22 kN)

Material: Wide polyester web construction, drop forged alloy steel

hardware

Width: 1.75 in. (4.4 cm)

Material: Wide latex treated polyester web

Width: 1 in. (2.54 cm)

Length: 3 ft. (0.9 m)

Tensile Strength: 9,800 lbf. (43.6 kN)

Material: Polyester Webbing

Tensile Strength: 9,800 lbf (43.6 kN)

Material: Aluminum body, stainless steel pivots and springs, tempered

steel cam, insulated grip

Weight: 0.43 lb. (0.19 kg)

Material: Treated canvas with polyester web

Capacity: 350 lb. (160 kg)

8

Page 9

1.0 PRODUCT APPLICATION

1.1 PURPOSE: The Rescue-Positioning Device is designed to be a component of a rescue-positioning system. The device is

intended to lower one or two people simultaneously from an elevated height to a lower level in a positioning operation or

rescue situation.

1.2 STANDARDS: Your device conforms to the national or regional standard(s) identied on the front cover of these

instructions. If this product is resold outside the original country of destination, the re-seller must provide these

instructions in the language of the country in which the product will be used.

1.3 SUPERVISION: Use of this equipment must be supervised by a Competent Person¹.

1.4 TRAINING: This equipment must be installed and used by persons trained in its correct application. These instructions are to be used

as part of an employee training program as required by national, regional, or local standards. It is the responsibility of the users and

installers of this equipment to ensure they are familiar with these instructions, trained in the correct care and use of this equipment,

and are aware of the operating characteristics, application limitations, and consequences of improper use of this equipment.

1.5 RESCUE PLAN: When using this equipment and connecting subsystem(s), the employer must have a written rescue plan

and the means to implement and communicate that plan to users², authorized persons³, and rescuers4. A trained, on-site

rescue team is recommended. Team members should be provided with the equipment and techniques necessary to perform a

successful rescue. Training should be provided on a periodic basis to ensure rescuer prociency. Rescuers should be provided

with these instructions.

1.6 AFTER A FALL: If the device is subjected to the forces of arresting a fall, it must be removed from service immediately,

clearly tag it “DO NOT USE”, and then either destroyed or forwarded to 3M for replacement or repair.

2.0 SYSTEM REQUIREMENTS

2.1 CAPACITY: The user capacity of a complete Fall Protection system is limited by its lowest rated maximum capacity component.

For example, if your connecting subsystem has a capacity that is less than your harness, you must comply with the capacity

requirements of your connecting subsystem. See the manufacturer instructions for each component of your system for capacity

requirements.

2.2 DESCENT PATH AND LANDING AREA CLEARANCE: The planned descent path must be unobstructed. The landing

area must be clear of obstructions to permit safe landing of the user. Failure to provide an unobstructed descent path and

landing area may result in serious injury. Maintain a minimum distance of 1 ft. (31 cm) away from any vertical surface to

ensure safe descent.

2.3 ENVIRONMENTAL HAZARDS: Use of this equipment in areas with environmental hazards may require additional

precautions to prevent injury to the user or damage to the equipment. Hazards may include, but are not limited to: heat,

chemicals, corrosive environments, high voltage power lines, explosive or toxic gases, moving machinery, sharp edges, or

overhead materials that may fall and contact the user or device. Contact 3M Technical Services for further clarication.

2.4 SHARP EDGES: Avoid using this equipment where system components will be in contact with, or scrape against, sharp

edges and abrasive surfaces. All sharp edges and abrasive surfaces must be covered with protective material when

contact is unavoidable.

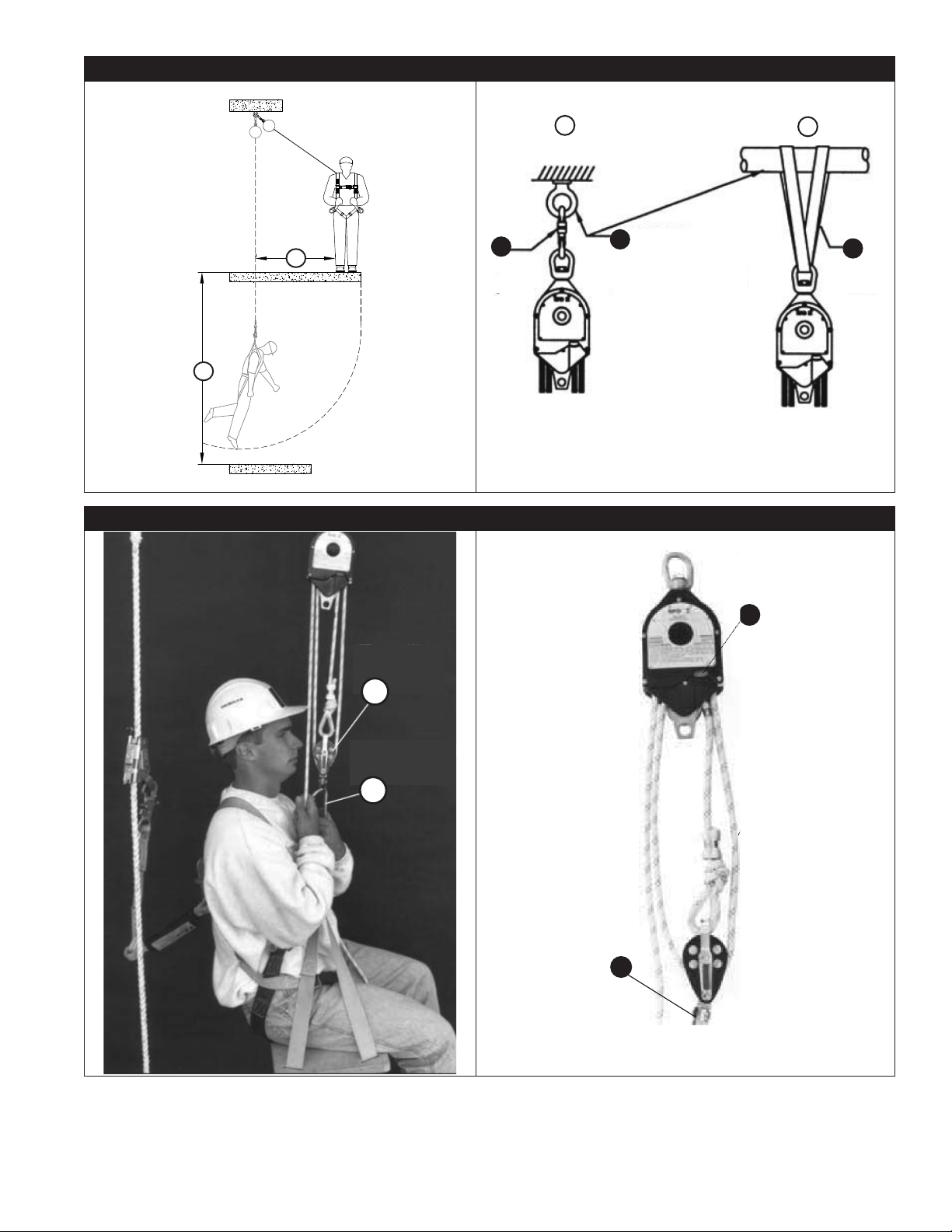

2.5 SWING FALLS: Swing Falls occur when the anchorage point is not directly above the point where a fall occurs (see Figure

5). The force of striking an object in a swing fall may cause serious injury or death. Do not permit a swing fall if injury

could occur. Minimize swing falls by working as directly below the anchorage point as possible. The required Fall Clearance

(FC) of the user increases as User Work Radius (W) increases, since the total fall distance will be greater than if the user

had fallen directly below the anchorage point.

2.6 COMPONENT COMPATIBILITY: 3M equipment is designed for use with 3M approved components and subsystems

only. Substitutions or replacements made with non-approved components or subsystems may jeopardize compatibility of

equipment and may affect the safety and reliability of the complete system.

2.7 CONNECTOR COMPATIBILITY: Connectors are compatible with connecting elements when the size and shape of either

component does not cause the connector to inadvertently open, regardless of orientation. Connectors must comply with

applicable standards. Connectors must be fully closed and locked during use. 3M Connectors (snap hooks and carabiners)

are designed to be used only as specied in each instruction manual. Ensure connectors are compatible with the

system components to which they are connected. Do not use equipment that is non-compatible. Use of non-compatible

components may cause the connector to unintentionally disengage (see Figure 3). If the connecting element to which a

connector attaches is undersized or irregular in shape, a situation could occur where the connecting element applies a

force to the gate of the connector (A). This force could then cause the gate to open (B), disengaging the connector from

the connecting element (C).

1 Competent Person: One who is capable of identifying existing and predictable hazards in the surroundings or working conditions which are

unsanitary, hazardous, or dangerous to employees, and who has authorization to take prompt corrective measures to eliminate them.

2 User: A person who performs activities while protected by a Fall Protection system.

3 Authorized Person: A person assigned by the employer to perform duties at a location where the person will be exposed to a fall hazard

4 Rescuer: A person using the Rescue system to perform an assisted rescue.

9

Page 10

2.8 MAKING CONNECTIONS: All connections must be compatible in size, shape, and strength. See Figure 4 for examples of

inappropriate connections. Do not attach snap hooks and carabiners:

A. To a D-ring to which another connector is attached.

B. In a manner that would result in a load on the gate. Large-throat snap hooks should not be connected to standard-

size D-Rings or other connecting elements, unless the snap hook has a gate strength of 3,600 lbf (16 kN) or greater.

C. In a false engagement, where size or shape of the connector or connecting element is not compatible and, without

visual conrmation, would seem to be fully engaged.

D. To each other.

E. Directly to webbing or rope lanyard or tie-back material, unless the instruction manuals for both the lanyard and

connector specically allow such a connection.

F. To any object whose size or shape does not allow the connector to fully close and lock, or that could cause connector

roll-out.

G. In a manner that does not allow the connector to align properly while under load.

10

Page 11

3.0 INSTALLATION

Installation of the Device must be supervised by a Qualied Person1. The installation must be certied by a

;

Competent Person as meeting the criteria for a Certied Anchorage, or that it is capable of supporting the potential

forces that could be encountered during a fall.

3.1 PLANNING: Plan your Device and how it will be used before starting your work. Account for all factors that may affect

your safety before, during, and after a fall. Consider all requirements, limitations, and specications dened in Section 2

and Table 1.

3.2 INSTALLING THE RESCUE-POSITIONING DEVICE: The anchorage point for the Rescue-Positioning Device must be

capable of supporting a 2,500 lb. minimum static load in the direction of operational pull. The anchor may be a tripod,

building structure, or other suitable anchoring point. The unit may be attached in the following manner:

• Through the top loop in the Rescue-Positioning Device housing using the connection hook. The hook

(A) can be connected directly to the anchor point (B) or to the connection sling which has been attached to the

anchorage via a straight loop, choker, or basket loop. See Figure 6.1.

• Through the top loop in the Rescue-Positioning Device housing using the connection sling. Use a choker or

basket loop to connect the sling to the Rescue-Positioning Device. Attachment can be made directly through the top

loop in the Rescue-Positioning Device housing using the connection sling provided. Use a choker or basket loop to

connect the sling to the Rescue-Positioning Device. See Figure 6.2.

• Rig the Rescue-Positioning Device system directly above the intended working area. If the Rescue-

Positioning Device is not rigged directly overhead, a swing fall situation could occur. Swing falls occur when a worker

swings and strikes an immovable object. See Figure 5.

• After attaching the Rescue-Positioning Device onto the proper anchorage over the working area, attach the travelling

pulley (A) to the personnel support device using a self-locking carabiner (B). See Figure 7.

An independent fall protection system is required by law (OSHA) when using this system during normal work

;

positioning operations. Do not connect fall protection equipment directly to the Rescue-Positioning Device system.

Fall protection systems must be connected to an independent anchor with a minimum tensile strength of 5,000 lbf

(22 kN), measured in direction of possible fall.

4.0 USE

4.1 BEFORE EACH USE: Verify that your work area and Fall Arrest System meet all criteria dened in Section 2 and that

a formal Rescue Plan is in place. Inspect the Rescue-Positioning Device per the ‘User’ inspection points dened on the

“Inspection and Maintenance Log” (Table 2). If inspection reveals an unsafe or defective condition, do not use the device.

Remove the device from service and destroy, or contact 3M regarding replacement or repair.

4.2 BODY SUPPORT: When using the Rescue-Positioning Device, it is recommended that a work-seat or boatswain’s chair be

used. A full body harness should also be worn for connection to the independent Fall Protection system. The D-ring on the

back between the shoulders (dorsal D-ring) should be used to connect the personal fall protection system.

Do not use a body belt with this equipment. Body belts do not support your entire body, which may result in

;

serious injury.

4.3 ANCHORAGE: Anchorage connections shall be stabilized to prevent unwanted movement or disengagement of the Rescue

System from the anchorage. Verify the system connection by pretensioning the system before applying the intended load.

Anchorage connectors must not be attached to anchorages where such attachment would reduce the anchorage system

strength below the anchorage specifcations in Table 1.

Anchorage requirements vary with the fall protection application. The mounting structure on which the equipment is placed

must meet the Anchorage specications dened in Table 1. A suitable anchorage connector shall be used for rigging the

connection of lanyards and lifelines to structural members. A lanyard shall not be connected back onto itself for use as an

anchorage connector unless designed for this purpose.

Anchorages used in fall arrest applications must conform to ANSI Z359.2. When an anchorage is used for both fall

;

arrest and rescue applications, the greater load requirements shall apply.

4.4 FALL CLEARANCE: Should the operator release the line while in the free mode, there must be sufcient clearance in the area

below to avoid hitting an obstruction or a lower level. Fall clearance is the measure of distance between a user and the next

obstruction below them. Before use of this product, the user should determine how much Fall Clearance is necessary to prevent

them from striking an obstruction should they fall. With the anchorage located directly overhead, it is recommended that a

minimum of 2 ft. (0.6 m) of clearance be maintained between the work level and the nearest obstruction in the fall path.

4.4 APPLICATIONS: The Device may be used in the following methods:

A. Positioning: In this application, the Rescue-Positioning Device is used as part of a complete positioning and personnel

riding system. Such systems typically include a full body harness, boatswain’s chair or work-seat, independent personal

fall protection system, and the Rescue-Positioning Device.

B. Rescue: In this application, the Rescue-Positioning Device is used as part of a complete rescue system. Such systems

typically include a full body harness or rescue sling, anchorage connector (i.e. carabiner, etc.) and the Rescue-Positioning

Device.

11

Page 12

When using this equipment for personnel, federal law (OSHA) requires a secondary or back-up Fall Protection

;

system be used. The back-up or secondary fall protection system is not required in applications where the RescuePositioning Device is only used to retrieve personnel (i.e. emergency rescue operations).

4.5 OPERATION OF THE RESCUE-POSITIONING DEVICE:

A. Before securing the Rescue-Positioning Device system, operate the unit so the silver indicator ag (A) is showing and

the unit is in a locked position. Pull down the connector (B) to ensure the device is locked. See Figure 8.

B. Connect yourself or other worker to the personnel support device. If the rescue sling is used, slip it over the shoulders.

Position the rescue sling below the arms and move the adjuster buckle to tighten. See Figure 9. If a work-seat, accident

cradle (3610000), or other support device is used, follow the instructions for that equipment.

C. To raise, pull on the free end of the rope with a smooth hand-over-hand action or use the optional rope gripping

handle. To lock it in position, raise until the silver indicator ag is showing. Gradually release the rope. See Figure 10.

D. To lower, grasp the free rope and raise it slightly until the orange indicator ag appears. This will occur approximately

every two inches (5 cm) of personnel travel. When the orange indicator appears, lowering may begin. Lower by using a

hand-over-hand action or the optional gripping handle. To position, raise slightly until the indicator ag is showing silver.

The unit will now be locked in position. Always maintain safe speeds when raising or lowering. See Figure 10.

An optional rope gripping handle (9503008 right hand, 9503037 left hand) may be used to aid in raising or lowering

operations. To operate, pull back on the spring loaded jaw and insert the rope. Raise or lower as required. To reposition,

release the jaw and move it to the desired location. Release the jaw to lock it in place. See Figure 10. An optional method

to aid in lowering yourself can be used; the free rope end can be passed through a D-ring and/or connecting hook and

then controlled easily by hand. Raising or lowering may be done by the user or an assistant.

If rope tension eases during lowering, the person being lowered may have reached a work level or obstruction.

;

Do not continue operation without communicating with the person being lowered. Always maintain tension on the

personnel line. Slack line could cause a free fall situation.

Do not use the Rescue-Positioning Device for lifting or lowering more than one person per trip.

;

Operate the device by manual power only. Do not use power winches or other similar devices to operate this

;

system.

4.6 AFTER A RESCUE: The Rescue-Positioning Device must be removed from service following use in a rescue event. The

Rescue-Positioning Device should then be destroyed or sent to an authorized service center for inspection and repair.

4.7 USE WITH A HORIZONTAL SYSTEM: In applications where the Rescue-Positioning Device is used in conjunction with

a horizontal system, compatibility between the Rescue-Positioning Device and horizontal system components must be

achieved. Horizontal systems must be designed and installed under the supervision of a qualied person.

5.0 INSPECTION

Inspection criteria must be set by the user or manufacturer and cannot be less than what is specied in these

;

intstructions.

5.1 INSPECTION FREQUENCY:

additionally, by a Competent Person other than the user monthly and annually. Extreme working conditions (harsh

environment, prolonged use, etc.) may require increasing the frequency of inspections. Annual servicing shall include, but

not be limited to, an intensive inspection and cleaning of all internal and external components. Failure to provide proper

service may considerably shorten product life and could endanger performance. A record of annual service dates can

be found on the face label of the Rescue-Positioning Device. Inspection procedures are described in the “Inspection and

Maintenance Log” (Table 2). Results of each User and Competent Person inspection should be recorded on copies of the

“Inspection and Maintenance Log”.

5.2 DEFECTS: If inspection reveals an unsafe or defective condition, remove the Rescue-Positioning Device from service

immediately and tag it “DO NOT USE”. Do not attempt to repair the device. Only 3M or parties authorized in writing by 3M

may make repairs to this equipment.

5.3 PRODUCT LIFE: The functional life of the Rescue-Positioning Device is determined by work conditions and maintenance.

As long as the product passes inspection criteria, it may remain in service.

The Rescue-Positioning Device shall be inspected by the user before each use and,

6.0 MAINTENANCE, SERVICING, STORAGE

6.1 CLEANING: Periodically clean the exterior of the device with water and mild detergent. Position the device so excess

water will drain out. Clean labels as required.

• Rope: Clean rope with water and mild detergent. Rinse and thoroughly air dry. Do not force dry with heat.

Immediately wash the entire rope assembly if it has been exposed to acidic vapors.

If the rope comes in contact with liquid or solid acids, remove it from service and wash it with a water and mild

;

detergent solution. Do not return the system to service without it rst being inspected by a qualied inspector.

Acids in contact with rope for extended periods of time can weaken the rope without visible evidence of damage.

Only a qualied inspector can determine rope status.

12

Page 13

6.2 SERVICE: Only 3M or parties authorized in writing by 3M may make repairs to this equipment. If the Rescue-Positioning

Device has been subject to fall force or inspection reveals an unsafe or defective conditions, remove the system from

service and destroy. Rope replacement, as well as additional maintenance and servicing procedures, must be completed

by a factory authorized service center.

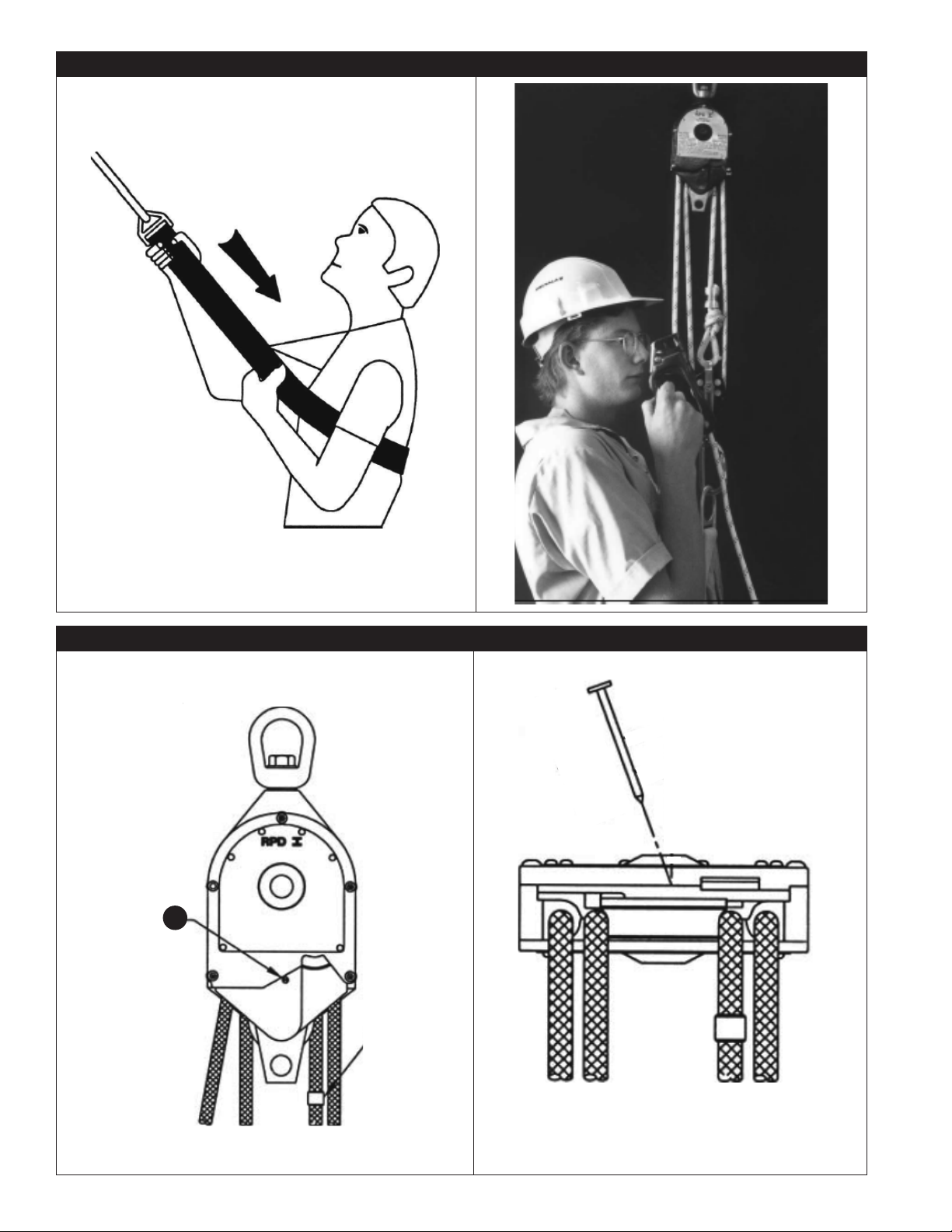

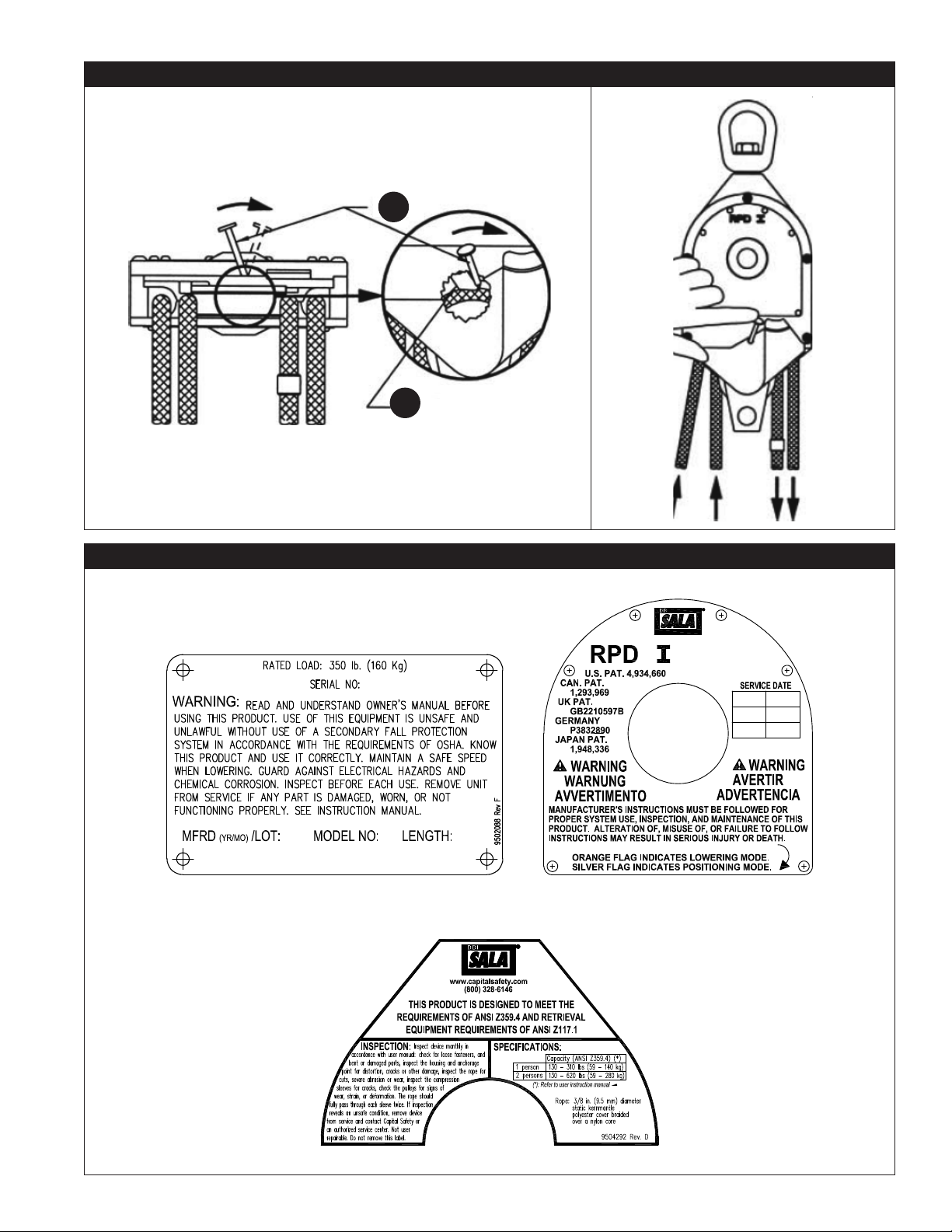

6.4 EMERGENCY RELEASE OF JAMMED ROPE: If the load has been raised very close to the Rescue-Positioning Device unit,

it may not appear possible to reach the lowering mode (orange indicator). However, an override system consisting of an

override ferrule and lever (see steps 1 & 3) is provided to release the brake. To override the brake, continue raising the

load and then lower it. Repeat as required until lowering mode is reached. If this does not work, remove the load and use

the procedure below:

Step 1: Remove the load and the screw or plug (A). See Figure 11.

Step 2: Insert a nail or similar object at an angle into the screw hole. The nail should be 2 in. (2.54 cm) long with 1/8

in. (.32 cm) diameter. See Figure 12.

Step 3: Tip the nail (A) as shown to activate the brake over-ride lever. The brake override lever (B) is located internally

on the side opposite the nail. The override lever may be partially visible through the screw hole. Some force

may be required to move the override lever. See Figure 13.

Step 4: While maintaining pressure on the nail, pull down on the line as shown. Pull out enough line to easily allow the

lowering mode to be reached. Replace the screw or plug. See Figure 14.

6.3 STORAGE AND TRANSPORT: Store and transport the Rescue Positioning Device in a cool, dry, clean environment out of

direct sunlight. Avoid areas where chemical vapors may exist. Thoroughly inspect the device after extended storage.

6.4 CHEMICAL HAZARDS: Solutions containing acids, alkali or other caustic chemicals, particularly at elevated

temperatures, may damage the Rescue-Positioning Device. When working with such chemicals, frequent inspection of

the Rescue-Positioning Device must be completed. Contact 3M if doubt exists concerning use of this equipment around

chemical hazards.

6.5 HEAT: The Rescue-Positioning Device is not intended for use in environments where incendiary sparking could cause an

explosion or re. Use of this equipment is prohibited where there the rope could come in contact with power lines, live

cables, etc. See Table 1 for maximum service temperature.

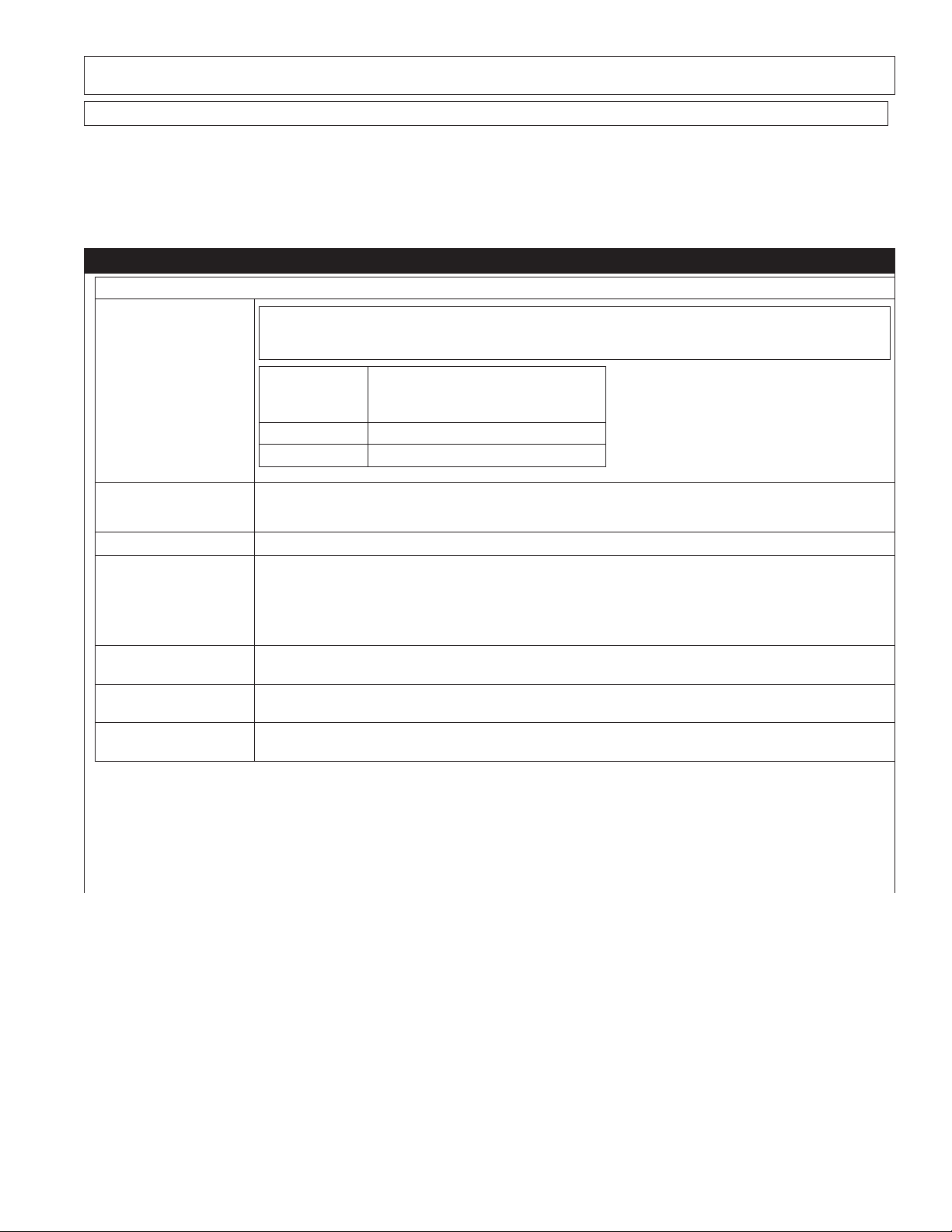

7.0 LABELS

Figure 15 illustrates labels present on the Device. Figure 2 (B) shows where the labels are located. Labels must be replaced if

they are not present and fully legible.

13

Page 14

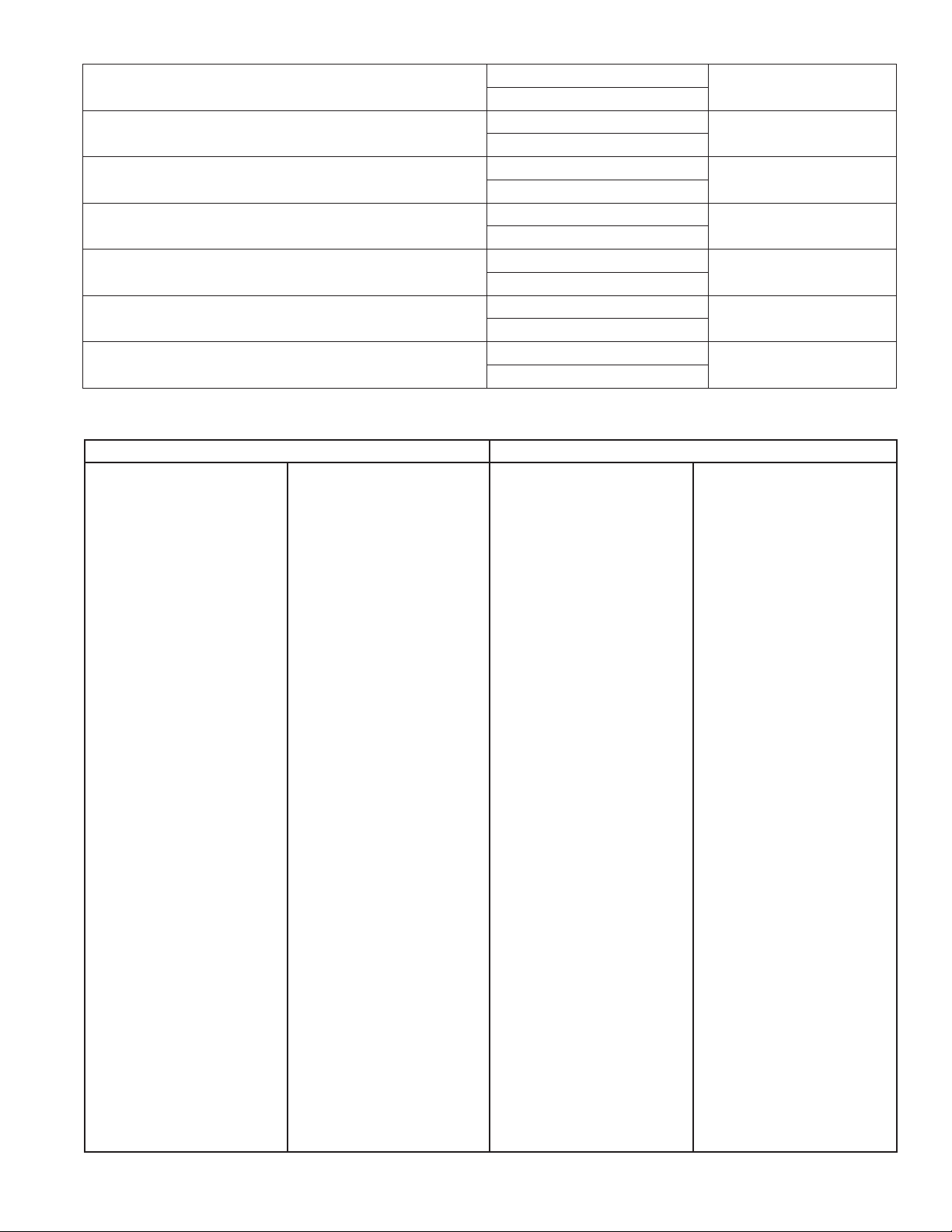

Table 2 – Inspection and Maintenance Log

Inspection Date: Inspected By:

Component: Inspection: (See Section 5 for Inspection Frequency) User Competent

Person

Rescue-Positioning

Device

(Figure 2)

Labels

(Figure 15)

Fall Arrest System and

Other Equipment

Inspect hardware for cracks, sharp edges, deformation, corrosion,

chemical attack, excessive heating, alternation, or excessive wear. Inspect

loose fasteners and bent or damaged parts.

Inspect the housing for distortion, cracks or other damage. Ensure the

anchorage point is not damaged or distorted in any way (the RPD has a

swiveling anchorage point).

Inspect the rope for fraying, unsplicing, unlaying, kinking, knotting,

roping, broken or pulled stiches, excessive elongation, excessive soiling,

abrasion, alteration, needed or excessive lubrication, excessive aging or

wear. Check for contact with acids or other chemicals.

Inspect the compression sleeves on both ends of the rope. The rope

should fully pass through each sleeve twice. Ensure the compression

sleeve is not cracked.

Check the pulleys for any sign of wear or strain. Check for distortion in the

connecting loops.

Do not disassemble the Rescue-Positioning Device block. It is not user

serviceable. See section 6.

Inspect the entire unit for signs of corrosion.

With the unit properly mounted from a sturdy structure, test the overspeed protection system:

1. Position the travelling pulley approximately 4 ft. (1.2 m) below the

Rescue-Positioning block.

2. Position the system so the orange indicator ag can be seen

and is to the side nearest you.

3. With the right hand, grasp the rope exiting the right side of the RescuePositioning Device. Grip it near the bottom of the housing.

4. With the left hand, lightly restrain the free end of the rope.

5. Pull down sharply with the right hand to engage the over-speed

brake. The unit should lock up. If the brake fails to engage, immediately

remove the unit from service.

Operate the system in both directions. Keep a moderate back pressure on

the rope.

A. The indicator ag should cycle between the locking mode (silver)

and the lowering mode (orange) as the system is being raised.

B. The orange ag should be visible when the system is in lowering mode.

C. The silver ag should be visible when the system is in a locking

(positioning) mode.

Ensure that all labels are present and fully legible.

Additional Fall Arrest System equipment (harness, SRD, etc.) that are used

with the Rescue-Positioning Device should be installed and inspected per

the manufacturer’s instructions.

Serial Number(s): Date Purchased:

Model Number(s): Date of First Use:

Corrective Action/Maintenance: Approved By: Next inspection due:

Date:

Corrective Action/Maintenance: Approved By: Next inspection due:

Date:

Corrective Action/Maintenance: Approved By: Next inspection due:

Date:

Corrective Action/Maintenance: Approved By: Next inspection due:

Date:

Corrective Action/Maintenance: Approved By: Next inspection due:

Date:

14

Page 15

Corrective Action/Maintenance: Approved By: Next inspection due:

Date:

Corrective Action/Maintenance: Approved By: Next inspection due:

Date:

Corrective Action/Maintenance: Approved By: Next inspection due:

Date:

Corrective Action/Maintenance: Approved By: Next inspection due:

Date:

Corrective Action/Maintenance: Approved By: Next inspection due:

Date:

Corrective Action/Maintenance: Approved By: Next inspection due:

Date:

Corrective Action/Maintenance: Approved By: Next inspection due:

Date:

Model numbers:

3:1 4:1

3600000

3600001

3600002

3600008

3600009

3600010

3600012

3600015

3600016

3600018

3600019

3600020

3600022

3600023

3600025

3600026

3600029

3600030

3600032

3600035

3600039

3600040

3600041

3600043

3600045

3600050

3600050F

3600055

3600057

3600060

3600065

3600068

3600070

3600072

3600075

3600080

3600085

3600090

3600094

3600098

3600099

3600100

3600100F

3600110

3600115

3600120

3600120F

3600123

3600125

3600130

3600140

3600140F

3600150

3600160

3600165

3600170

3600170F

3600175

3600180

3600190

3600200

3600210

3600230

3600250

3600264

3600265

3600275

3600280

3600290

3600300

3600312

3600330

3600350

3600400

3600410

3600450

3600500

3600501

3600503

3600504

3600505

3600506

3600507

3600508

3600509

3602000

3602006

3602008

3602010

3602012

3602013

3602014

3602015

3602016

3602017

3602018

3602020

3602021

3602022

3602023

3602024

3602025

3602026

3602027

3602028

3602029

3602030

3602031

3602032

3602033

3602034

3602035

3602037

3602038

3602040

3602042

3602045

3602048

3602049

3602050

3602051

3602052

3602055

3602058

3602060

3602063

3602051

3602052

3602055

3602058

3602060

3602063

3602064

3602065

3602066

3602282

3602300

3602310

3602325

3602340

3602358

3602068

3602070

3602074

3602075

3602078

3602080

3602082

3602085

3602087

3602090

3602093

3602098

3602099

3602100

3602101

3602102

3602108

3602110

3602112

3602118

3602120

3602125

3602128

3602130

3602132

3602135

3602138

3602140

3602150

3602151

3602160

3602165

3602170

3602172

3602175

3602180

3602190

3602200

3602210

3602215

3602228

3602240

3602250

3602260

3602275

3602280

15

Page 16

USA

3833 SALA Way

Red Wing, MN 55066-5005

Toll Free: 800.328.6146

Phone: 651.388.8282

Fax: 651.388.5065

3Mfallprotection@mmm.com

Brazil

Rodovia Anhanguera, km 110

Sumaré

CEP: 13181-900

Brasil

Phone: 0800-013-2333

falecoma3m@mmm.com

Mexico

Av. Santa Fe No. 190

Col. Santa Fe, Ciudad de Mexico

CP 01219, Mexico

Phone: 01 800 120 3636

3msaludocupacional@mmm.com

GLOBAL PRODUCT WARRANTY, LIMITED REMEDY

AND LIMITATION OF LIABILITY

WARRANTY: THE FOLLOWING IS MADE IN LIEU OF ALL WARRANTIES OR CONDITIONS, EXPRESS

OR IMPLIED, INCLUDING THE IMPLIED WARRANTIES OR CONDITIONS OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE.

Unless otherwise provided by local laws, 3M fall protection products are warranted against factory

defects in workmanship and materials for a period of one year from the date of installation or fi rst use

by the original owner.

LIMITED REMEDY: Upon written notice to 3M, 3M will repair or replace any product determined by

3M to have a factory defect in workmanship or materials. 3M reserves the right to require product be

returned to its facility for evaluation of warranty claims. This warranty does not cover product damage

due to wear, abuse, misuse, damage in transit, failure to maintain the product or other damage beyond

3M’s control. 3M will be the sole judge of product condition and warranty options.

This warranty applies only to the original purchaser and is the only warranty applicable to 3M’s fall

protection products. Please contact 3M’s customer service department in your region for assistance.

LIMITATION OF LIABILITY: TO THE EXTENT PERMITTED BY LOCAL LAWS, 3M IS NOT LIABLE

FOR ANY INDIRECT, INCIDENTAL, SPECIAL OR CONSEQUENTIAL DAMAGES INCLUDING, BUT NOT

LIMITED TO LOSS OF PROFITS, IN ANY WAY RELATED TO THE PRODUCTS REGARDLESS OF THE

LEGAL THEORY ASSERTED.

– SP

WEBSITE:

3M.com/FallProtection

Canada

600 Edwards Blvd, Unit #2

Mississauga, ON L5T 2V7

Phone: 905.795.9333

Toll-Free: 800.387.7484

Fax: 888.387.7484

3Mfallprotection-ca@mmm.com

EME A (Europe, Middle East, Africa)

EMEA Headquarters:

Le Broc Center

Z.I. 1re Avenue - BP15

06511 Carros Le Broc Cedex

France

Phone: + 33 04 97 10 00 10

Fax: + 33 04 93 08 79 70

informationfallprotection@mmm.com

Australia & New Zealand

137 McCredie Road

Guildford

Sydney, NSW, 2161

Australia

Toll-Free : 1800 245 002 (AUS)

Toll-Free : 0800 212 505 (NZ)

3msafetyaucs@mmm.com

ISO

9001

FM534873

Asia

Singapore:

1 Yishun Avenue 7

Singapore 768923

Phone: +65-6450 8888

Fax: +65-6552 2113

TotalFallProtection@mmm.com

China:

38/F, Maxdo Center, 8 Xing Yi Rd

Shanghai 200336, P R China

Phone: +86 21 62753535

Fax: +86 21 52906521

3MFallProtecton-CN@mmm.com

Korea:

3M Koread Ltd

20F, 82, Uisadang-daero,

Yeongdeungpo-gu, Seoul

Phone: +82-80-033-4114

Fax: +82-2-3771-4271

TotalFallProtection@mmm.com

Japan:

3M Japan Ltd

6-7-29, Kitashinagawa, Shinagawa-ku, Tokyo

Phone: +81-570-011-321

Fax: +81-3-6409-5818

psd.jp@mmm.com

EU DECLARATION OF CONFORMITY:

3M.com/FallProtection/DOC

Loading...

Loading...