Page 1

Transportation Safety Division

3M™ Reflective License Plate

Sheeting Recommended

Manufacturing Procedures

Information Folder 9.8

February 2021

Replaces Information Folder 9.8 Dated March 2020

1 Description

3M Reflective License Plate Sheeting Series 3750, 4770, 4780, 4790, 6700, 6750, and 9250 are durable, allweather sheetings designed for use in the fabrication of multi-year retroreflective license plates. They are used to

produce attractive license plates which function 24 hours a day to enhance nighttime safety and the legibility of

the vehicle identification system. The backsides of these sheetings are pre-coated with a pressure sensitive

adhesive, protected by a removable liner, for application to license plate substrates. Plates can be embossed and

roll coated with either transparent or opaque roll coating inks, or dry roll coating foils. Plates made with digitally

printed variable plate message sheeting need no roll coating.

2 Substrates

Metal cleanliness, pretreatment, and surface temperature are the most important factors for ensuring good

adhesion of the sheeting to the metal substrate. For instructions on checking metal cleanliness, see Section 4.1,

Quality Checklist: Metal Cleaning.

After metal straightening, aluminum entering the sheeting laminator should be in the temperature range of

105 ± 10 °F for optimal adhesion.

A minimum temperature of 70 °F is recommended.

Page 2

2 3M™ Reflective License Plate Sheeting Recommended Manufacturing Procedures February 2021

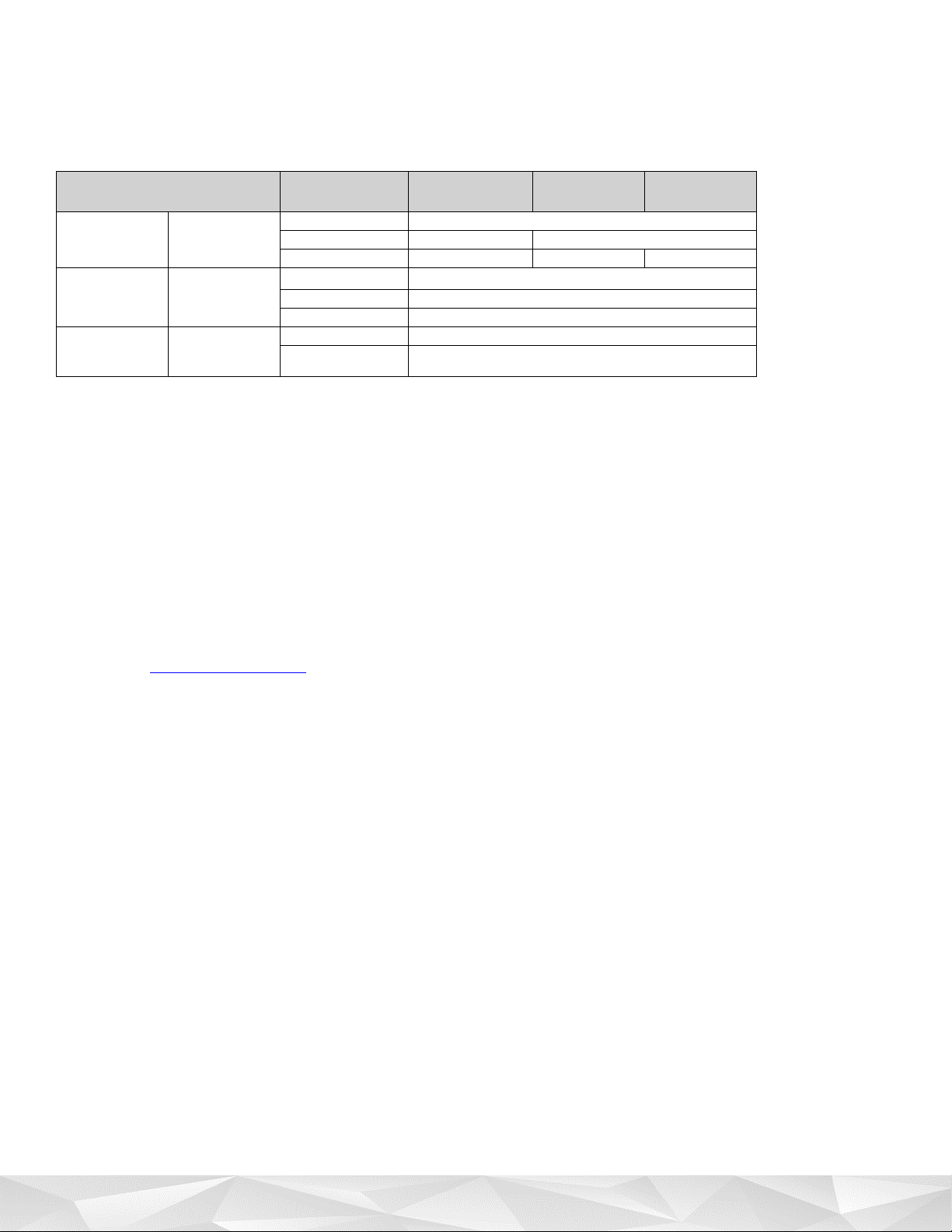

Table 1 presents the desired characteristics of recommended aluminum stock materials.

Table 1. Typical aluminum stock characteristics

Material Property

Alloy 3105

Al coil base Base metal

Front surface Pretreatment

Pretreatment

Back surface

a. 3M has experimented extensively with license plate pretreatments and concluded:

License plate manufacturers should consult with their aluminum stock supplier to discuss best options.

or polyester

washcoat

Aluminum pretreated with Bonderite 1455SF is no longer recommended for use.

Aluminum pretreated with Bonderite M-CR 1430C is recommended as a suitable replacement.

Temper H-18 or H-28 H-12 or H-22

Gauge (in.) 0.022 0.027 0.032

Formulation

Powdery residue None

Appearance No change in coating pattern

Powdery residue None

Appearance No change in coating pattern

DLP

(non-embossed)

Chemically treated or conversion coated

DLP &

Embossed

Embossed

a

3 Procedure

3.1 Retroreflective Sheeting Application

Applicator operators must maintain proper side to side alignment of the sheeting on the metal by adjusting the

steering on the 3M Squeeze Roll Applicator (16 inches) as needed.

For graphic printed sheeting, the 16 inch squeeze roll applicator adjustment must be set and monitored to

maintain the correct repeat pattern measurement on the sheeting after it is applied to the metal substrate. On

3M applicators, this adjustment is set by the thumb-wheel switches on the applicator electronic control panel

(refer to Information Folder 9.4

).

3.2 Cut Blanks

Cut blanks must be stored on edge after being removed from the blanking press. Avoid packing blanks too

tightly to minimize sticking of blanks and scuffing or scraping of sheeting.

The cut blanks must be stored for a minimum of 48 hours prior to embossing to allow the sheeting to reach

maximum adhesion to the metal substrate. Check the adhesion of the sheeting to the metal after the 48 hour

rest period (see Section 4.2 Quality Checklist: metal cleaning).

The surface of the license plate sheeting scratches easily. Care must be taken when handling cut blanks to

prevent the sheeting surfaces from getting scratched.

Blanking dies must be kept sharpened as any burrs on the bolt holes or along the edges of the plate can

scratch the surface of the sheeting.

3.3 Embossing

Embossing height must be uniform and maintained at a height sufficient to avoid smudging the background

during roll coating.

1 Satisfactory embossing heights are usually in the range of 0.070–0.080 inches (1.8–2.0 mm). 2 If registration characters and fixed copy cannot be maintained at a uniform height, registration

characters may be slightly higher, however, the difference between the registration character and

fixed copy heights should not exceed 0.003 inches (0.076 mm).

Dies causing scuffing and cutting should be removed from production, polished, adjusted, and/or repaired

before being put back into use.

Page 3

3 3M™ Reflective License Plate Sheeting Recommended Manufacturing Procedures February 2021

Check all new die setups for roll coating quality before beginning any volume production.

Cover the tops of racks of embossed plates to prevent accumulation of dust and other foreign matter.

License plate blanks must be handled with care during the embossing operation to prevent scratching their

sheeting surfaces.

3.4 Roll Coat and Oven Drying Operations

The roll coat color should be applied to match the shade established by the appropriate state agency.

1 Mount sample plates on or near roll coaters for operator reference. See Section 4.3, Quality Checklist:

Color Shade.

2 Match the color shade by adjusting the doctor roll on the roll coater (refer to roll coater operator's

manual).

Roll coat ink can be thinned as necessary according to the manufacturer's recommendations.

1 Colors may be pre-thinned using up to 10% by weight of the recommended thinner. 2 Additional thinning on the rolls using a pistol oiler or spray may be necessary to keep the ink from

drying on the rolls during equipment shutdowns or other production delays.

Roll coat ink smudges on background areas of plates must be removed prior to drying.

o Smudges, or all of the wet coating, may be wiped off with a cloth saturated in a solvent recommended in

the appropriate roll coat product bulletin. Wiped off plates must be completely dry before being recoated.

Dry roll coat foils.

o Dry roll coat foils are applied to clean, embossed plates using high quality roll-on dry roll coat machines

capable of providing adequate heat and pressure. It is recommended that adhesion between dry roll coat

foil and license plate sheeting be tested each time a new roll of foil is loaded onto the machine.

Consistent oven temperature and dwell time must be maintained to provide thorough curing of roll coat inks.

o The hardness of the dried roll coat, when applied to the bare metal backside of the plate, must be

sufficient to resist rupture of the coating by a “B” hardness pencil. See Section 4.4, Quality Checklist:

Hardness Test.

License plates must be allowed to cool down to room temperature prior to being stacked and packaged.

4 Quality Checklist

4.1 Metal Cleaning

Test and record the cleanliness of the metal substrate using the Water Break Test.

1 Pour water onto the surface of the substrate. 2 The water should not bead up, but rather flow out to form a uniform film on the surface (see Figure 1). 3 Following the water break test, be sure to wipe the water off of the substrate before laminating the

retroreflective sheeting.

Figure 1. Water break test: the image on the left illustrates a failure, the image on the right, a pass.

Page 4

4 3M™ Reflective License Plate Sheeting Recommended Manufacturing Procedures February 2021

4.2 Sheeting Adhesion

Test the sheeting adhesion on a scrap blank 48 hours after application of sheeting.

1 Starting at the rounded corner of a scrap blank, peel the sheeting away from the metal substrate with

your fingernail.

2 Peel sheeting away until you have enough to hold with your fingers.

3 Hold the sheeting and pull it away from the substrate using uniform tension.

4 It should be difficult to impossible to peel the sheeting, including its adhesive, in one piece from the

aluminum. 5 In case of a failure, recheck cleanliness of aluminum stock.

4.3 Color Shade

Compare the color shade on the roller coated plates with a target color shade sample and record lighter, equal

to, or darker on a sample plate or sheeting.

If necessary, adjust roll clearances on the roll coater to achieve the correct color shade match.

4.4 Hardness Test

Test and record the hardness of the dried roll coat ink applied to the back of the license plate.

Emboss a blank upside down so the embossed alpha/numeric characters are on the backside of the blank.

With a set of graded drawing pencils consecutively rated for hardness B, HB, F, and H:

1 Press the lead into the surface at a 45° angle. Apply sufficient pressure in a forward direction to

crumble the lead or penetrate the ink film, but not enough to break the main piece of lead.

2 Results shall be reported as the range of hardness of consecutive pencils, the softer of which

crumbles, and the harder of which penetrates the ink film. Example: Pencil B-HB.

3 Ink coatings showing pencil hardnesses of B-HB or harder are needed for best reflectorized license

plate durability and performance.

5 Environmental, Health, and Safety

Read all health hazard, precautionary, and first aid statements found in the Safety Data Sheets (SDS) and Article

Information Sheets for important health, safety, and environmental information. Consult local regulations and

authorities for possible restrictions. To obtain SDSs and Article Information Sheets for 3M products, go to

3M.com/SDS

, contact 3M by mail, or for urgent requests call 1-800-364-3577.

6 Other Product Information

Always confirm that you have the most current version of the applicable product bulletin, information folder, or

other product information from 3M’s Website at 3M.com/VehicleRegistration

.

7 Literature Reference

Before starting any job, be sure you have the most current Product and Instruction Bulletins.

3M IF 9.4

3M PB 3750/3750P

3M PB 4770E/T

3M PB 4780E/T

3M PB 4790

3M PB 4800/4900

3M PB 4850/4950

3M PB 6700

3M PB 6750

3M PB 9250E/T

3M PB HSF 100/200

and DRF 300/400 3M™ Dry Roller Coat Foil Series HSF 100/200 and DRF 300/400

3M™ Squeeze Roll Applicator (16 inch)

3M™ Reflective License Plate Sheeting Series 3750

3M™ Preclear Reflective License Plate Sheeting Series 4770E/4770T

3M™ Preclear Reflective License Plate Sheeting Series 4780E/4780T

3M™ Preclear Reflective License Plate Sheeting Series 4790

3M™ Roll Coat Inks Series 4800/4900

3M™ Roll Coat Inks Series 4850/4950

3M™ High Definition Reflective License Plate Sheeting Series 6700

3M™ High Definition Reflective License Plate Sheeting Series 6750 With Removable

Top Liner

3M™ Digital License Plate Reflective License Plate Sheeting Series 9250E/9250T

Page 5

For Information or Assistance

Call:

In Canada

1

Interne

1-800-553-1380

Call:

-800-3M HELPS (1-800-364-3577)

t:

http://www.3M.com/roadsafety

3M, and Science. Applied to Life. are trademarks of 3M. Used under license in Canada.

3M assumes no responsibility for any injury, loss, or damage arising out of the use of a product that is not of our

manufacture. Where reference is made in literature to a commercially available product, made by another

manufacturer, it shall be the user’s responsibility to ascertain the precautionary measures for its use outlined by

the manufacturer.

Important Notice

All statements, technical information and recommendations contained herein are based on tests we believe to be

reliable at the time of this publication, but the accuracy or completeness thereof is not guaranteed, and the

following is made in lieu of all warranties, or conditions express or implied. Seller's and manufacturer's only

obligation shall be to replace such quantity of the product proved to be defective. Neither seller nor manufacturer

shall be liable for any injury, loss or damage, direct, special or consequential, arising out of the use of or the

inability to use the product. Before using, user shall determine the suitability of the product for his/her intended

use, and user assumes all risk and liability whatsoever in connection therewith. Statements or recommendations

not contained herein shall have no force or effect unless in an agreement signed by officers of seller and

manufacturer.

Transportation Safety Division

3M Center, Building 0225-04-N-14

St. Paul, MN 55144-1000 USA

Phone 1-800-553-1380

Web 3M.com/roadsafety

Please recycle. Printed in USA © 3M 2021.

All rights reserved. Electronic Only

Loading...

Loading...