Page 1

®

LifeASSURE BW

Membrane Filters for Bottled Water Service

LifeASSURE BW BLA100 filters have been

tested and certified by NSF International to

Standard 53. This standard was developed

in conjunction with the bottled water industry

to certify filter performance in removing

Cryptosporidium

meets EPA and CDC recommendations.

LifeASSURE BW filters are an effective

means of providing microbiological control in

water without the need for ozone. Ozone

can generate unwanted disinfection by-prod

ucts, such as bromate, leading the EPA to

introduce regulations restricting the level of

bromate in drinking water to <10 mg/L (10

ppb). The International Bottled Water Asso

ciation (IBWA) recommends membrane

filtration as an option in providing microbio

logical control, without the use of ozone, as

part of a “multi-barrier” approach to water

safety.

Fluid Purification

and

Giardia

cysts and

®

-

-

-

LifeASSURE®BW membrane filter cartridges

are used as final filters in bottled water and

other beverage grade water requiring high retention of

Cryptosporidium,Giardia

,

heterotrophic plate count (HPC) bacteria, and

other microorganisms. Encompassing two

leading edge technologies, FlexN™ membrane

manufacture and MaxMedia™ pleating con

struction, the LifeASSURE BW series of filters

offers an unmatched combination of exception

ally high microorganism retention and long

service life.

Features Benefits

+

Multi-zone, FlexN Nylon membrane

+

Exceptionally high HPC microorganism retention

+

Extended service life

+

No disinfection by-products

NSF International

NSF International is a widely respected independent certification organization and the

accepted authority in evaluating filter claims

related to water and public health. Only

products tested and certified by NSF are allowed to carry their mark. LifeASSURE BW

BLA100 has been tested and certified by

NSF to Standard 53

for reduction of

cysts. This inde

pendent certification

assures the rigor,

reproducibility and

impartiality that the

bottled water indus

try has come to

expect from NSF.

-

Tested and certified by NSF

International against ANSI/NSF

Standard 53 for the reduction of

-

Cysts and material requirements only

+

MaxMedia construction providing high

membrane surface area

+

ANSI/NSF Std. 53 certified and listed

+

100% integrity tested in manufacturing

and testable by the user

+

Fast per-cartridge flow rates

+

Smaller filter housing assemblies required

+

Reliable cyst reduction as certified by the only

accredited testing body for cyst reduction

+

Ensures proper installation and operation

Page 2

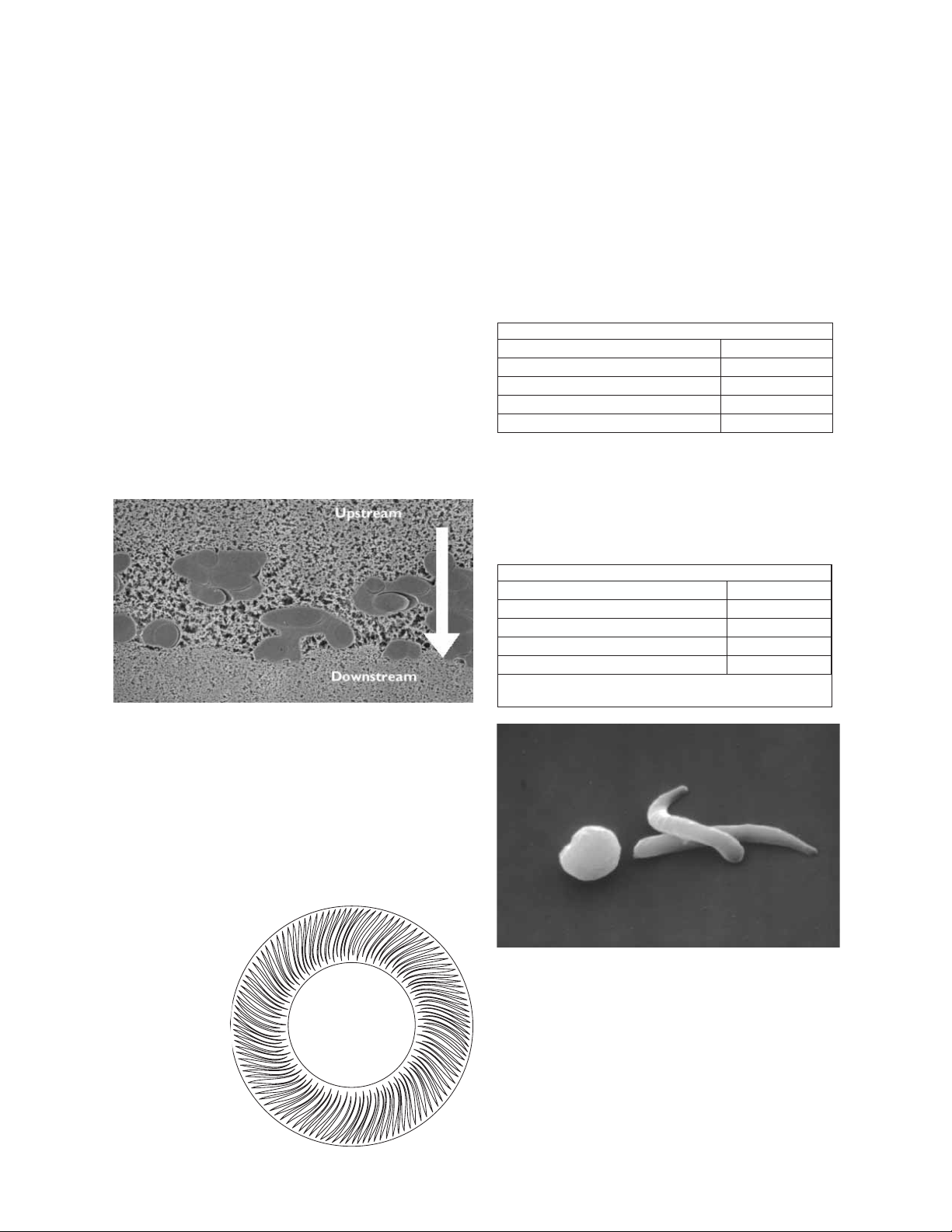

FlexN™ Membrane

LifeASSURE BW membrane filters incorporate

CUNO’s advanced FlexN membrane technol

ogy*. It allows unmatched flexibility in creating

a multi-zone membrane that offers the maxi

mum in contaminant holding capacity while

providing very high per-cartridge flow rates.

The cross-section SEM photograph shows that

a single layer of LifeASSURE BW membrane

consists of an “open” zone on the upstream

side of the membrane and a “tighter” zone on

the downstream side. In effect, the open zone

acts are a prefilter by capturing larger particles

and microorganisms while the tighter zone re

tains smaller microorganisms. This multi-zone

structure eliminates the need for a dual layer

membrane or thick, fibrous filter media com

monly used in other filter cartridges. The

result? LifeASSURE BW filters provide more

membrane surface area per cartridge, faster

cartridge flow rates and longer service life.

-

-

-

-

Microorganism Reduction

Microorganism control is a critical parameter

in preparation of quality bottled or beverage

grade water. LifeASSURE BW membrane

filters consistently exhibit a greater reduction

of microorganisms than competitive filters. In

tests conduced with

fluorescens

(a typical heterotrophic plate

count, or HPC, organism) LifeASSURE BW

BLA100 grade filters exhibited retention far

exceeding that of similarly rated filters (Table

1.).

Table 1.

Filter Average LRV*

CUNO LifeASSURE BW BLA100

Osmonics Flowtrex™ GF

Whatman VTEC

Pall AbsoLife™

Even in tests with

(considered one of the smallest bacteria)

LifeASSURE BLA020 and BLA045 grade fil

ters exhibited log reduction values (LRV)

significantly higher than similarly rated filters

(Table 2.)

Pseudomonas

6.5

0.8

1.5

0.1

Brevundimonas diminuta

,

-

SEM Photograph Showing LifeASSURE BW Membrane

Cross-Section

MaxMedia™ Construction

LifeASSURE cartridge filters also feature

CUNO’s innovative MaxMedia construction for

extended service life. This design technology

maximizes the useful surface area of the filter

while maintaining proper flow paths between

media pleats. By employing as much as 50%

more effective surface

area than competitive

filters, the

LifeASSURE

BW filter pro

vides lower

pressure

drops, longer

service life

and lower

overall filtra

tion costs.

-

-

Table 2.

Filter Average LRV

CUNO LifeASSURE BW BLA020

Millipore Milligard

CUNO LifeASSURE BW BLA045

Millipore Milligard CWSC

* LRV =log10 number of organisms in/number of

organisms out.

Scanning Electron Micrograph (SEM) of

®

CWSS

. Magnification: 8,400X.

parvum

7.3

4.5

3.5

2.6

Cryptosporidium

Optimized Service Life

As the data in Chart 1 and Tables 1 & 2

demonstrate, LifeASSURE BW cartridges

are designed to provide both enhanced ser

vice life without sacrificing effluent quality or

microorganism retention. A laboratory study

was conducted to measure the relative ser

vice life of filters marketed as cyst reducing

-

-

Page 3

using a model contaminant (kaolin clay and an

bso

e

(

)

hydrous sodium pyrophosphate at 10 ppm) to

induce plugging. Filters were tested side by

side at a constant flow rate of 3 GPM. Filter

service life was measured until a terminal dif

-

ferential pressure of 20 psid was observed.

100

90

80

70

60

50

40

30

Percent Throughput

20

10

0

CUNO

LifeASSURE BW

Chart 1. - Throughput Comparison

Whatman

VTEC

Osmonics

Flotrex

Pall

A

Lif

As the data show, LifeASSURE BW filters

lasted 56% longer than the nearest competitor,

and nearly four times longer than the competitor with the least throughput.

Cartridge Flow Rates

0.15

2

1.5

1

0.5

BLA020

BLA045

BLA065

BLA100

0.10

0.05

-

Installation Integrity Test

LifeASSURE BW membrane filters are 100%

integrity tested manufacturing. An in situ in

stallation integrity test, a non-destructive

measurement of a filter’s ability to function as

intended, can be performed by the user upon

installation. Conducting an installation integ

rity test assures the user that the filter is

installed and sealed correctly in the filter

housing and is ready for service. For installa

tion integrity test procedures and values,

please consult CUNO document LITTDCO3.

Cartridge Component Material of Construction

Cage, core, end-caps,

and media support

layers

Membrane FlexN Nylon 66

Adapter support ring Polysulfone

Quality system ISO 9001 certified

Regulatory Standards

Cartridge Dimensions Dimension

Filtration surface area 11 ft

Outside diameter 2 ¾” (7 cm) nominal

Length

Operating Parameters Specification

Maximum operating

temperature

Maximum differential

pressure

bar

Hot water sanitation 30 min @180°F (80°C)

Steam sterilization 30 min @250°F (121°C)

Chemical

cleaning/sanitizing

Installation integrity test

Polypropylene

FDA CFR21 listed materials of

construction

USP Class VI tested

NSF Standard 53 certified

(BLA100)

2

(1 m2)

Nominal 10, 20, 30 & 40 inches

(25, 51, 76, and 102cm)

180°F(80°C)

Forward: 80 psid (5.5 bar) @

75°(25°C)

25 psid (1.7 bar) @

180°F(80°C)

Reverse: 50 psid (3.4 bar) @

75°(25°C)

Caustic solutions: consult

literature: LITTDBA2

Peracetic acid based solutions:

consult literature: LITTDBA2CL

Consult CUNO for appropriate

values for specific filter

housings in field use.

-

-

-

Differential Pressure (psid)

0

2468100

Flow Rate (gpm)

0

10

5

20 30

15

25

35

Flow Rate (lpm)

Graph 1. - LifeASSURE BW Flow Rates

Differential Pressure

Flowtrex is a trademark of Osmonics,Inc., VTEC is a trade

mark of Whatman, PLC., and AbsoLife is a trademark of Pall

Corp.

-

Page 4

LifeASSURE®BW ANSI/NSF Standard 53 Certified Configuration Ordering Guide

Cartridge

Grade

BLA 100 - 1.0 micron

Removal

Rating

Configuration

B - Pleated

MaxMedia™

Configuration

Length

Inches

01 - 10”

02 - 20”

03 - 30”

04 - 40”

B - 226 O-ring & Spear (Code 7)

C - 222 O-ring & Spear (Code 8)

F - 222 O-ring & Flat Cap (Code 3)

J - 226 O-ring & Flat Cap

LifeASSURE®BW Filter Cartridge Ordering Guide

Cartridge

Grade

BLA

Removal

Rating

020 - 0.20 micron

045 - 0.45 micron

065 - 0.65 micron

080 - 0.80 micron

Configuration

B - Pleated

MaxMedia™

Configuration

Length

Inches

01 - 10”

02 - 20”

03 - 30”

04 - 40”

B - 226 O-ring & Spear (Code 7) A - Silicone

C - 222 O-ring & Spear (Code 8) B - Fluorocarbon

D - Double open end (10” Length) C - EPR

E - Double open end (9 ¾” Length) D - Nitrile

F - 222 O-ring & Flat Cap (Code 3) H - Clear Silicone*

J - 226 O-ring & Flat Cap

Your local CUNO distributor is:

End-modification

End-modification

Gasket/O-ring

Material

D - Nitrile

Gasket/O-ring

Material

* O-Ring Only.

Seller warrants its equipment against defects in workmanship and ma

terial for a period of 12 months from date of shipment from the factory

under normal use and service and otherwise when such equipment is

used in accordance with instructions furnished by Seller and f

poses disclosed in writing at the time of purchase, if any.

Any unauthori

Buyer will void this warranty. Seller’s liability under this warranty shall

be limited to the replacement or repair, F.O.B. point of manufacture,

of any defective equipment or part which, having been returned to the

factory, transportation charges prepaid, has been inspected and de

zed alteration or modification of the equipment by

or pur

Service Worldwide

Visit us at www.cuno.com

CUNO Pacific Pty Ltd

140 Sunnyholt Road

Blacktown, NSW 2148

Rua Amf Do Brasil 251

18120 Mairinque-Sp

Australia

CUNO Latina Ltda

Brazil

Wihl-Th-Römheld-Str.32

19 Avenue de la Sablière

BP 81 - 94372 Sucy en Brie Cedex

CUNO GmbH

55130 Mainz

Germany

CUNO Europe SA

ZI

de la Sablière

France

20032 Cormano (Mi)

Hodogaya Station

1-7 Iwai-cho, Hodagaya-ku

Yokohama 240 Japan

WARRANTY

termined by the Seller to be defective. THIS WARRANTY IS IN LIEU

OF ANY OTHER WARRANTY, EITHER EXPRESSED OR IMPLIED,

AS TO DESCRIPTION, QUALITY, MERCHANTABILITY, FITNESS

FOR ANY PARTICULAR PURPOSE OR USE, OR ANY OTHER

-

MATTER. Under no circumstances shall Seller be liable to Buyer or

any third party for any loss of profits or other direct or indirect costs,

expenses, losses or consequential damages arising out of or as a re

sult of any defects in or failure of its products or any part or parts

thereof or arising out of or as a result of parts or components incorpo

-

rated in Seller’s equipment but not supplied by the Seller.

CUNO Srl

Via Zara, 38

Italy

CUNO K.K.

Building 6F

An IBWA Bottler (Supplier) Member

CUNO Filtration Asia Pte Ltd

18 Tuas Link 1 (3 Floor)

21 Woking Business Park

Woking, Surrey GU215JY

rd

Singapore 638597

CUNO Ltd

Albert Drive

United Kingdom

-

-

Fluid Purification

CunoIncorporated

400 Research Parkway

Meriden, CT 06450, U.S.A.

Tele:(800) 243-6894

(203) 237-5541

Fax:(203) 238-8977

Ó CUNO INCORPORATED, 2002 - ALL RIGHTS RESERVED LITLABW1NSF.1110p

Loading...

Loading...