Page 1

3M Purification Inc.

LifeASSURE™ BNA045 & BNA065 Series

Filter Cartridges for Beverage Microbiological Stability

Page 2

-1-

Page 3

LifeASSURE™ BNA Series Filter Cartridges

Filter Cartridges for Beverage Microbiological Stability

Controlling the spoilage microorganism population prior to bottling is critical for many beverage processors. Eliminating these

microorganisms, while keeping other beverage properties unchanged, is of vital importance. Of equal importance, however, is attaining

long on-stream filter cartridge service life and driving down operating costs associated with filtration.

3M Purification Inc. has solved this demanding problem with the creation of the LifeASSURE™ BNA

series of filter cartridges. LifeASSURE BNA filter cartridges encompass leading-edge technologies that

not only provide the highest degree of microorganism control, but do so in an extremely durable and

long-lasting design.

LifeASSURE BNA filter cartridges employ a highly-asymmetric polyether sulfone (PES) membrane

that delivers excellent spoilage microorganism retention while greatly minimizing any organoleptic

interference. This highly durable membrane/cartridge design withstands repeated exposure to hot

water sanitation and steam sterilization as well as common chemical cleaning and sanitizing agents.

Complementing this high-performance membrane are 3M Purification Inc.’s Advanced Pleat

Technology (APT) design and an upstream and downstream support design. All three work in

concert to provide an increased flow rate at a lower pressure drop, resulting in smaller

filter cartridge assemblies with extended service life and a lower overall operational

costs.

Features Benefits

Highly asymmetric PES membrane

High spoilage organism retention

Advanced Pleat Technology (APT)

Novel upstream/downstream supports

Broad chemical compatibility Stable with most cleaning and sanitation regimes

Meets requirements for food contact

Longer service life than competitive filter cartridges

Lower operating costs than competitive filter cartridges

Reliable microbiological control

Performance matched to industry standards

Increased accessible surface area

Longer service life than competitive filter cartridges

Lower operating costs than competitive filter cartridges

Increased flow per cartridge

Reduced housing costs

Complies with requirements of the Pure Food, Drug and

Cosmetic Act for food contact

ADVANCED TECHNOLOGIES

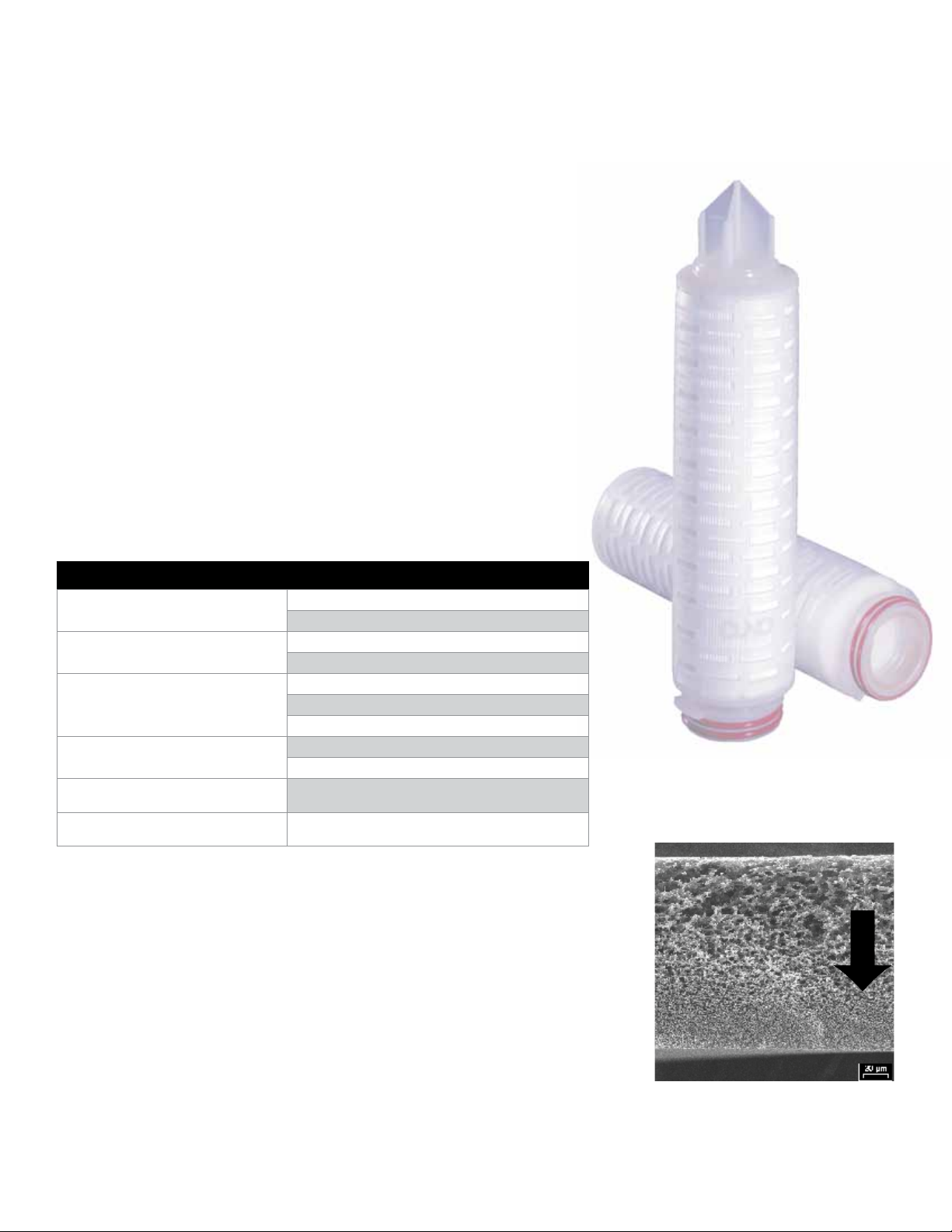

Highly Asymmetric PES Membrane

LifeASSURE BNA filter cartridges incorporate a novel PES membrane with a high degree of

asymmetry (Figure 1). When viewed in cross-section, the membrane contains larger pores on

the upstream surface that gradually taper to smaller pores towards the downstream surface.

Compared to conventional membranes with a symmetric pore structure, this structure provides

greater contaminant capacity, since it presents greater open spaces (void volume) in which

to retain these contaminants. This increase in capacity leads directly to longer service life. In

addition, the asymmetric structure provides less resistance to flow, resulting in a lower pressure

drop when compared at a constant flow rate to competitive filter cartridges, allowing a user to

employ fewer LifeASSURE BNA filter cartridges for any given flow rate.

FLOW

Figure 1. LifeASSURE BNA SEM

-1-

Page 4

Figure 2.

Advanced Pleat Technology

Advanced Pleat Technology (APT)

LifeASSURE™ BNA filter cartridges feature Advanced Pleat Technology (APT) design for extended

service life. This design technology maximizes the useful surface area of the filter cartridge while

maintaining open flow paths between the media pleats (refer to Figure 2). By employing the APT

design, the LifeASSURE BNA filter cartridge provides lower pressure drops, longer service life, and

lower overall operational costs than competitive filter cartridges.

Flow Distribution

Layer

Downstream Support

Layer

PES Media

Upstream Support

Layer

Novel Upstream/Downstream Support Design

LifeASSURE BNA filter cartridges employ a design that results in higher beverage flow versus

pressure drop compared to competitive filter cartridges. This unique 3M Purification Inc.

development combines the high flowing PES membrane with special support layers upstream and

downstream of the membrane. When combined with the previously mentioned Advanced Pleat

Figure 3.

LifeASSURE BNA Support Design

Technology, this feature greatly increases flow per filter cartridge, and results in lower overall

operational costs than competitive filter cartridges.

ADVANCED PERFORMANCE

Extended Service Life

In the majority of beverage applications, the final membrane filter cartridge is used in a continuous (as opposed to a batch) operation. Its

service life is measured either by the volume filtered, or the number of days in service, before becoming permanently blocked. Filter

cartridges that provide longer service life not only reduce direct operational costs, but also reduce indirect filter cartridge costs as well

(filter cartridge change-out/installation labor, downtime between change-outs, filter cartridge flushing, etc.). The LifeASSURE BNA filter

cartridge’s unique combination of highly asymmetric PES membrane, Advanced Pleat Technology design, and novel upstream/downstream

support design, all work together to maximize the volume of beverage that can be processed. Chart 1 depicts the service life performance of

the LifeASSURE BNA filter cartridge compared to various competitive filter cartridges. A surrogate solution was employed to mimic beverage

plugging characteristics at an increased rate.

As the chart demonstrates, the LifeASSURE BNA filter cartridge’s unique design provided more than twice the throughput of the nearest

competitor, greatly reducing overall filtration costs.

100

90

80

70

60

50

40

30

Relative Service Life (%)

20

10

0

3M Purification

LifeASSURE

BNA

Competitive

PES 1

Competitive

PES 2

Competitive

PVDF

Chart 1. Comparative Service Life

-2-

Page 5

Reliable Microbiological Control

(

(

The primary purpose of a membrane filter cartridge in beverage processing is to effectively control spoilage microorganisms. LifeASSURE™

BNA 0.45 micron and 0.65 micron rated filter cartridges provide superior retention of common spoilage microorganisms, even at challenge

concentrations that far exceed those experienced by most beverage producers (typically 1,000,000 to 10,000,000 cells per cm2 of membrane

area).

LifeASSURE BNA Microorganism Typical Log Reduction Value (LRV)

BNA045

BNA045

BNA045

BNA045

BNA065

BNA065

Serratia marcescens

Oenococcus oeni

Lactobacillus brevis

Dekkera intermedia

Lactobacillus brevis

Dekkera intermedia

8

9

10

9

7

9

Log Reduction Values are calculated using the following formula:

LRV = log

total number of organisms entering the filter cartridge

10

total number of organisms exiting the filter cartridge

For additional information, consult the LifeASSURE BNA Technical Support Guide, 70-0201-8839-0.

Fast Flow Rates at Low Pressure Drops

3M Purification Inc. has combined three key technological advances to provide the fastest flow rate per unit of pressure drop. These three

technologies, a highly asymmetric microporous membrane, Advanced Pleat Technology (APT) design, and an upstream and downstream

support design, afford users with faster process flow rates using fewer filter cartridges.

Consider the following example:

Initial clean pressure drop (water) for a 30” filter cartridge flowing at 20 gpm (76 lpm)

3M Purification Inc. LifeASSURE BNA045 0.75 psid (52 mbar)

Pall OenoPure “GB” * 1.92 psid (132 mbar)

Millipore Vitipore® II * 7.5 psid (517 mbar)

Sartorius Vinosart PS * 2.5 psid (172 mbar)

* Data from published product literature

-3-

10” Filter Cartridge Flow Rates

2.0

1.5

1.0

0.5

Differential Pressure (psid)

0

0

0

5

25

BNA045

10

Flow (gpm)

Flow (lpm)

15

50

BNA065

20

75

25

120

100

80

60

40

20

Differential Pressure (mbar)

30

100

Page 6

As the example illustrates, LifeASSURE™ BNA filter cartridges have a considerably lower pressure drop at a given flow rate when compared

to competitive filter cartridges. Since filter cartridge change-out is usually tied to a terminal differential pressure drop (typically between 20

and 35 psid), employing filter cartridges that exhibit a lower initial pressure drop can result in longer filter cartridge service life.

Alternatively, when determining the number of filter cartridges needed in a new system to provide a desired flow rate at a given pressure

drop, faster flowing filter cartridges will result in smaller, more economical systems.

Consider the following example:

Number of 10” filter cartridges† needed to provide a 20 gpm flow with a clean pressure drop of 1 psid (76 lpm flow at 69 mbar)

3M Purification Inc. LifeASSURE BNA045 2

Pall OenoPure “GB” 5

Millipore Vitipore II 24

Sartorius Vinosart PS 5

†

rounded to nearest 10” filter cartridge length.

As the example above illustrates, the nearest competitor requires more than twice as many filter cartridge elements to provide the same flow

rate and pressure drop.

Durable Design

The LifeASSURE BNA filter membrane and filter cartridge design innovations result in a highly durable filter cartridge, capable of secure

operation through numerous cycles of hot water sanitation, steam sterilization, and chemical based cleaning and sanitation.

LifeASSURE™ BNA Filter Cartridge Construction

LifeASSURE BNA filter cartridges are constructed of single-layer, highly asymmetric, polyethersulfone (PES) microporous membrane pleated

with polypropylene upstream and downstream support materials. The outer

cage, inner core and reinforced end-cap adapters are made of polypropylene.

Multiple length filter cartridges, with industry standard connection styles, are

produced to fit the most widely used housing designs and system sizes. No

resin or binder compounds are added. All materials used in manufacturing are

traceable and are approved for direct food contact. Materials of construction

meet the requirements of the USP Biological Reactivity Test for Plastics, Class

VI - 121 0C. Filter cartridges are manufactured under an ISO 9001:2008

certified quality system using the most advanced thermoplastic welding

techniques to ensure filter cartridge integrity. LifeASSURE BNA filter cartridges

are 100% integrity tested after manufacture to ensure quality.

Materials of Construction

Membrane Polyether sulfone

Reinforced

End Cap

Adapter

Various O-Ring

Materials

PES

Membrane

Support

Layers

Flow

Distribution

Layer

Support layers Polypropylene

Outer Cage, Inner Core, End Caps Polypropylene

Adaptor Polypropylene with polysulfone reinforcing ring

O-rings Various

Inner Core

& Outer Cage

-4-

Page 7

Nominal Filter Cartridge Dimensions

Operating Parameters

Effective Filtration Area

(EFA)

Filter Cartridge

Diameter

Filter Cartridge

Lengths

10” (254 mm), 20” (508 mm), 30”

(762 mm), 40” (1016 mm)

2

8.5 ft

(0.79 m2)

2.75” (70 mm)

Integrity Testing Parameters

The Integrity Test is a non-destructive test that

can be performed by the user to ensure the filter

cartridge is installed correctly and ready for operation.

LifeASSURE™ BNA filter cartridges can be Integrity

Tested either manually, or with the automated

CUNOCheck™ 2 tester, by one of three methods:

the Forward Flow Test, the Bubble Point Test, or the

Pressure Hold Test.

Forward Flow Test Pressure 22 psi (1.52 bar) 15 psi (1.03 bar)

Max. Diffusion (10” element) ≤ 35 cc/min ≤ 25 cc/min

Recommended Flow Rate

(10” element)

Max. Differential Pressure

(Forward)

Max. Differential Pressure

(Reverse)

Max. Hot Water Sanitation

Temperature

Max. Steam Sterilization T

emperature

NaOH cleaning duration (conc.

1M @ 65°C)

Peracetic acid sanitation

(conc. 1 % @ 21°C)

``

BNA045 (0.45 µm) BNA065 (0.65 µm)

Beer 1-2 gpm (3.8 – 7.6 lpm)

Wine 2 – 3 gpm (7.6 – 11.4 lpm)

Maximum

80 psid @ 77°F (5.5 bar @ 25°C)

35 psid @ 194°F (2.4 bar @90°C)

50 psid @ 77°F (3.44 bar @ 25°C)A

194°F (90°C) - 150, 30 minute cycles

275°F (135°C) - 75 cycles, 30 minute cycles

100 hours

100 hours

9 gpm per psid

( 34 lpm per 68.9 mbar)

Minimum Bubble Point ≥ 24 psi (1.65 bar) ≥ 17 psi (1.17 bar)

Pressure Hold Test Consult 3M Purification Inc. Consult 3M Purification Inc.

For additional information regarding filter cartridge wetting and integrity testing, please refer to Technical Brief LITTDBAPESINT.

Automated Integrity Testing - CUNOCheck™ 2

A full range of non-destructive integrity tests can be easily and automatically performed with the CUNOCheck 2 integrity test instrument. The

CUNOCheck 2 and MiniCheck integrity test instruments provide fast, reliable and accurate automated integrity testing of LifeASSURE™ BNA

cartridges. For more information, see 3M Purification Inc. document 70-0201-8692-3.

Prefiltration Selections

Many bottling applications employ a prefilter and final filter cartridge in series to achieve maximum performance and economy. Prefilter

cartridges are used to help protect and extend the life of more expensive final filter cartridges. 3M Purification Inc. offers two premium

prefilter cartridge choices: Zeta Plus™ H Series depth filter cartridges and LifeASSURE™ BLA series membrane filter cartridges. Zeta

Plus™ MH series dual zone H Series filter cartridges (Literature 70-0201-8864-8) have long been used in clarifying fine wine in both cellar

operation and in-line to the bottler. Customers preferring cylindrical prefilter cartridges can select from 3M Purification Inc.’s LifeASSURE BLA

series prefilter cartridge family (Literature 70-0201-8712-9). Containing a dual-zone membrane, LifeASSURE BLA Series filter cartridges are

designed to deliver excellent throughputs with high flow rates, while providing the ultimate in final membrane protection.

3M Purification Inc. Filter Cartridge Housings

A specialized range of filter cartridge housings is available to meet the needs of the food & beverage industry. The housings provide easy

access for filter cartridge change-out and ensure that LifeASSURE™ BNA filter cartridges are sealed securely to eliminate the possibility

of fluid bypass. All housings are constructed using 316L stainless steel to maximize corrosion resistance. Internal surfaces of the housings

are polished to 20 micro-inch Ra to limit microbial adhesion and provide easy cleaning. 3M Purification Inc. also offers custom-design, fully

automated filtration skids and mobile units. These units can incorporate membrane housings, prefilter housings, SIP and CIP systems along

with all necessary piping, valves, monitoring devices and computer controls for reliable, hands-free operation.

-5-

Page 8

P

3M Purification Inc. Scientific Applications Support Services (SASS)

The cornerstone of 3M Purification Inc.’s philosophy is service to customers, not only in product quality and prompt service, but also in

problem solving, application support and in the sharing of scientific information. 3M Purification Inc.’s Scientific Applications Support Services

group is a market-oriented group of scientists and engineers who work closely with customers to solve difficult separations problems and

aid in the selection of the most effective and economical filtration systems. SASS provides a vital link between 3M Purification Inc. and users

of 3M Purification Inc. filter cartridge systems. SASS can carry out projects on-site, or in 3M Purification Inc.’s extensive state-of-the-art

laboratory facilities. 3M Purification Inc.’s considerable experience with countless beverage installations provides the knowledge and insight

to resolve problems promptly and efficiently in a cost-effective manner.

LifeASSURE™ BNA Filter Cartridge Ordering Guide

Catalog

Number

BNA

Important Notice:

The test results described in this literature are accurate to the best of our knowledge. A variety of factors, however, can affect the performance of 3M Purification Inc. product(s) in a particular application,

some of which are uniquely within your knowledge and control. INFORMATION IS SUPPLIED UPON THE CONDITION THAT THE PERSONS RECEIVING THE SAME WILL MAKE THEIR OWN DETERMINA-

TION AS TO ITS SUITABILITY FOR THEIR USE. IN NO EVENT WILL 3M PURIFICATION INC. BE RESPONSIBLE FOR DAMAGES OF ANY NATURE WHATSOEVER RESULTING FROM THE USE OF OR

RELIANCE UPON INFORMATION.

It is your responsibility to determine if additional testing or information is required and if the 3M Purification Inc. product is fit for a particular purpose and suitable in your specific application.

3M PURIFICATION INC. MAKES NO REPRESENTATIONS OR WARRANTIES, EITHER EXPRESS OR IMPLIED INCLUDING WITHOUT LIMITATION ANY WARRANTIES OF MERCHANTABILITY, FITNESS

FOR A PARTICULAR PURPOSE OR OF ANY OTHER NATURE HEREUNDER WITH RESPECT TO INFORMATION OR THE PRODUCT TO WHICH INFORMATION REFERS.

Limitation of Liability:

3M Purification Inc. will not be liable for any loss or damage arising from this 3M Purification product, whether direct, indirect, special, incidental, or consequential, regardless of the legal theory asserted,

including warranty, contract, negligence or strict liability. Some states and countries do not allow the exclusion of limitation of incidental or consequential damages, so the above limitation or exclusion may

not apply to you.

Rating Configuration Length End Modification

045 - 0.45 µm

065 - 0.65 µm

F - APT Pleat

01 - 10”

02 - 20”

03 - 30”

04 - 40”

B - 226 O-rings bayonet lock with & spear

C - 222 O-rings & spear

F - 222 O-rings & flat cap

J - 226 O-rings bayonet lock with flat cap

T - 222 with spear (Sartorius code 28, not

available with support ring)

O-Ring/Gasket

Material

A - Silicone

B - Fluorocarbon

C - EPR

D - Nitrile

3M Purification Inc.

400 Research Parkway

Meriden, CT 06450

U.S.A.

(800) 243-6894

(203) 237-5541

Fax (230) 630-4530

www.3Mpurification.com

3M is a trademark of 3M Company.

LifeASSURE, Zeta Plus, and CunoCheck are trademarks of 3M used under license.

All other trademarks are the property of their respective owners.

© 2010 3M Company. All rights reserved.

70-0201-8878-8

Rev 1110

-6-

Loading...

Loading...