Page 1

Betapure

™

BK Series Absolute Rated Filter Cartridge

ltration systems include clarifying lters, pre-lters, nal lters,

stainless steel housings and engineered skid-mounted systems

designed and sized for specic applications.

Absolute Betapure™ BK Series

Absolute Betapure BK series removal ratings are determined

for the entire cartridge life using a new lter performance test

developed by 3M Purication that complies with the general

procedure outlined in ASTM 975. A copy of 3M Purication’s

Technical Report summarizing absolute rating of Betapure

BK series cartridges and the test methodology is available by

requesting 3M Purication literature number LITTDMPC2.795.

3M Purication denes Absolute Rating as “ the particle size (x)

providing an initial Beta Ratio (βx) = 1000.” At this Beta Ratio the

removal efciency is equal to 99.9%. Beta Ratio (βx) is dened by

the following equation:

Betapure™ BK

Series Filters

ßx =

Betapure™ BK Series Filters – The Clear Solution

3M Purication Inc. continues an 80 year tradition of innovative

cost effective solutions to challenging industrial ltration

applications with Betapure™ BK series. Betapure BK series is a

truly absolute rated, rigid (non-compressible) resin bonded lter

cartridge.

Consistent quality and performance at absolute ratings from 5 to

70 m make Betapure BK series the clear choice in the confusing

world of indistinguishable “me-too” cartridge lters.

Consistent Performance

Absolute rated rigid structure Betapure BK series provides

consistent performance. Unlike many competitors, Betapure BK

series does not unload or lose ltration efciency throughout its

usable life!

Significant Life Advantage

Betapure BK series’s rigid graded-porosity grooved structure

provides a signicant life advantage over the competition!

3M Purication provides quality solutions worldwide for

the most challenging ltration applications. 3M Purication

Cumulative Number of Particles Larger than x in the Influent Challenge

Cumulative Number of Particles Larger than x in the Effluent

Betapure BK series lters achieve a minimum Betax (βx) value of

1000 at the specied ratings seen in Table 1.

Betapure™ BK Series Features & Benefits

Absoltue rated cartridge filters from 5 - 70 microns

Absolute filtration efficiency at the specified reduction rating

Consistent production yields with absolute contaminant retention

Rigid resin bonded structure

No by-pass or unloading at high differential pressure

Consistent product quality throughout the filter's life

Grooved surface with true graded-porosity internal structure

Significantly longer life

Cost effective filtration with optimized yields

300 °F high temperature option

Choice of temperature compatible options

Inventory one product for many applications

No metal or plastic cores

Easy disposal, suitable for incineration or shredding

Disposal cost reduction

Available with polypropylene or polyester end modifications

Retrofit any industrial housing

Usuable in existing filter housings

1

Page 2

Table 1. – Betapure™ BK Series Absolute Ratings

Grade Designation ßx = 1000 (x = Absolute Micron Rating)

Z8 050 5

Z8 070 7

Z8 100 10

Z8 140 14

Z8 150 15

Z8 200 20

Z8 300 30

Z8 400 40

Z8 500 50

Z8 700 70

High Temperature Betapure™ BK Series

Standard Betapure™ BK series provides consistent performance at temperatures to 250 °F (121 °C) and differential pressures to 70 psid

(4.8 bar). High temperature (HT) Betapure BK series extends the temperature rating to 300 °F (149 °C) for those non-aqueous processes

that require service under extreme conditions.

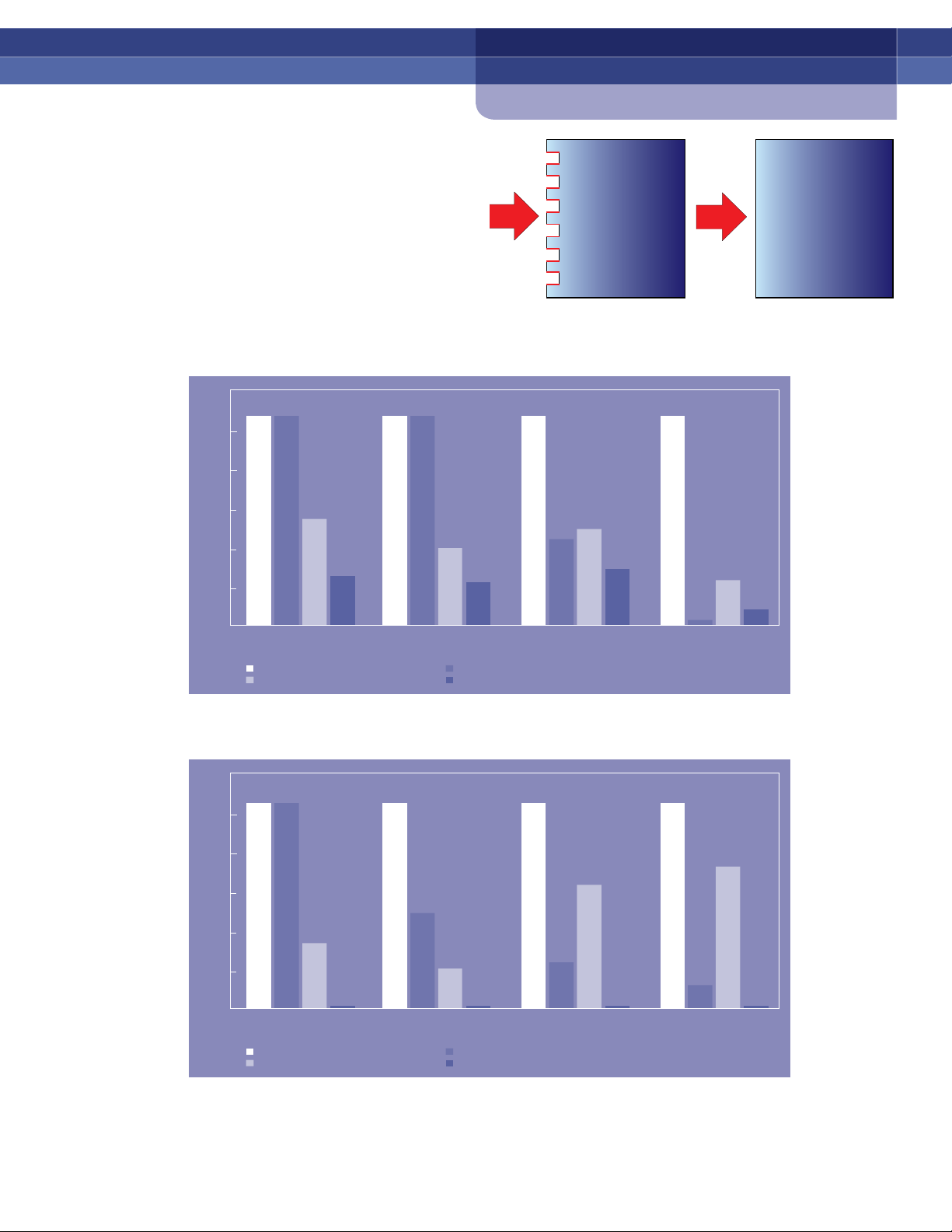

Betapure™ BK Series – Consistent Performance

The initial Beta Ratio for all grades of Betapure BK series lter cartridges is equal to or greater than 1000, and each cartridge performs

at or above this initial value throughout its usable (all the way to plugging) life! This denes Betapure BK series’ absolute ltration

performance. The Beta Ratio vs. Differential Pressure Graphs 1 and 2 illustrate how competitive lters do not achieve the consistent

performance of Betapure BK series. Filters that show a decrease in Beta Ratio as the differential pressure increases are exhibiting

either unloading of previously held contaminants or a loss of ltration efciency. This inconsistent performance results in a reduction in

nished product quality, product yield, and an increase in total ltration cost.

As illustrated in Graphs 1 and 2, the performance of melt-blown polypropylene (Competitor P) degrades rapidly after a small (0.5 psi)

increase in differential pressure, indicating contaminant unloading and a loss of ltration efciency typical of a compressible structure.

In Graph 1, the generic cotton wound, Competitor C, exhibits erratic performance caused by media movement under increasing

pressure, and, in Graph 2, it exhibits minimal ability to retain contaminant throughout the test. In Graph 1, melt-blown Competitor O

never approaches a Beta Ratio of 1000, and it shows a decreasing Beta Ratio at high differential pressure. Resin bonded Competitor

F, as shown in Graph 2, exhibits very low Beta Ratios at low differential pressures indicating poor performance. Above 1.0 psid, the

contaminant builds a cake which accounts for the subsequent increase in Beta Ratio. Betapure BK series exhibits consistent Beta Ratios

at all differential pressures.

Rigid Graded-Porosity Betapure™ BK Series

Betapure BK series lter cartridges are manufactured using an exclusive process

that achieves a true “graded-porosity” ber structure with a clean and smooth inside

diameter. Each ber is locked in this arrangement by a thermosetting resin binder to

create a rigid structure, eliminating the need for a metal or plastic center core. Larger

particles are trapped in the outer area and ner particles towards the inner area.

Figure 1 illustrates how in a graded-porosity structure the overall effect is to classify

and retain particles by size as they progress through the cartridge.

FLUID

GRADED-POROSITY

STRUCTURE

Figure 1. – Betapure™ BK Series GradedPorosity Structure

FLUID

2

Page 3

High Surface Area Betapure™ BK Series

Betapure™ BK series cartridges also feature an optimized

groove pattern that increases the surface area by over 65%

when compared to smooth cylindrical cartridges (see Figure 2).

The grooved surface prevents premature blinding of the outer

surface by large particles and allows full utilization of the depth

structure. Maximum surface area with a true graded-porosity

structure means that Betapure BK series can provide 3 times or

greater service life than competitive lter cartridges.

Graph 1. - Beta Ratio Comparison Of Filter Cartridges Rated At 20 Microns

1200

1000

800

600

Betapure™ BK Series Filters

GROOVED

SURFACE

FLOW

INCREASE IN

SURFACE AREA

Figure 2. – Surface Area Comparison

FLOW

UNGROOVED

SURFACE

Beta Ratio

400

200

0

Initial 0.5 1

Betapure™ BK Series - Rigid Res in Bonded Compet itor P - Mel t-Blown Propylene

Compet itor O - Mel t-Blown Polypro pylene Competitor C - Co tton Wound

Differential Pressure

Graph 2. - Beta Ratio Comparison Of Filter Cartridges Rated At 70 Microns

1200

1000

800

600

Beta Ratio

400

200

10

™

Betapure

BK Serie s at or above

1000 throughout service life

Note:

0

Initial 0.5 1

Betapure™ BK Series - Rigid Res in Bonded Compet itor P - Mel t-Blown Propylene

Compet itor F - Gen eric Resin Bonded Compet itor C - Cotton Wou nd

Differential Pressure

3

10

™

Betapure

BK Serie s at or above

1000 throughout service life

Note:

Page 4

Betapure™ BK Series Product Specifications

Absolute Rating

(µm)

5 Z8050

7 Z8070

10 Z8100

14 Z8140

15 Z8150

20 Z8200

30 Z8300

40 Z8400

50 Z8500

70 Z8700

Standard Temperature

High Temperature

Maximum Operating Temperature

Maximum Differential Pressure 70 psid (4.8 bar) @ 68 °F (20 °C)

Recommended Change-out Dif-

ferential Pressure

Inside Diameter 1 1/16" (26.9 mm)

Outside Diameter 2 19/32" (65.9 mm)

Cartridge Length 9 3/4" through 40" (248 - 1016 mm)

Grade Fiber Resin

Acrylic/Glass/Cellulose

Phenolic

Acrylic/Cellulose

Cartridge End Modifications

Polypropylene bonding with polypropylene

end modifications

Thermoset epoxy bonding with polyester

end modifications

Operating Parameters

Standard – 250 °F (121 °C)

With polyethylene gasket – 200 °F (93 °C)

With polypropylene end modifications – 180

°F (82 °C)

High Temperature Option – 300 °F (149 °C)

with or without polyester end modifications,

non-aqueous applications

35 psid (2.4 bar)

Dimensions

Betapure™ BK Series Applications

Betapure™ BK series provides consistent reproducible ltration

performance and longer life while meeting or exceeding

quality specications in a wide variety of industrial processing

applications. Betapure BK series is particularly well suited for

high viscosity uids, high temperature processes, and differential

pressures to 70 psid (4.8 bar).

• Petroleum Products - gas, oils, gasoline, kerosene, lube oil,

fuel oil, waxes

• Chemical/Petrochemical - acids, bases, organic solvents,

catalysts, monomers, polymers, glycols

• W a t e r - p r o c e s s w a t e r , p r o d u c e d w a t e r , b o i l e r f e e d ,

demineralized feed, pre-reverse osmosis system, waste

water

• General Industrial - paint, varnish, lacquer, inks, coatings,

e m u l s i o n s , m a g n e t i c m e d i a , r e s i n s , d e t e r g e n t s , a d h e s i v e s ,

machine tool coolants, cutting oils, parts washers

• Brines and aqueous salt solutions

Betapure™ BK Series Flow Rates

Table 2. – Betapure™ BK Series Flow Rates

Grade

Z8 050 5 0.75 13. 6 3 11.4

Z8 070 7 0.33 5.98 3 11.4

Z8 100 10 0.20 3.64 4 15 .1

Z8 140 14 0.16 2.89 4 15.1

Z8 150 15 0.27 4.88 4 15.1

Z8 200 20 0 .13 2.34 5 18.9

Z8 300 30 0.08 1.44 5 18.9

Z8 400 40 0.06 1.10 6 22.7

Z8 500 50 0.05 0.89 7 26.5

Z8 700 70 0.03 0.55 7 26.5

1

Specific aqueous pressure drop at ambient temperature for a single equivalent 10"

cartridge . For multiple cartridge lengths, divide total flow by the number of single length

equivalents.

2

Optimal efficiency and life is achieved at aqueous flow rates less than the maximum flow

indicated.

Absolute

Rating (µm)

Specific Pressure Drop

Per 10" Cartridge1

psi/gpm mbar/lpm gpm lpm

Recommended Maxi-

mum Aqueous Flow

Rate2 Per 10" Cartridge

4

Page 5

Betapure™ BK Series Filters

Table 2 provides ow information for Betapure™ BK series

lters in aqueous uids.

For liquids other than water, multiply the specic pressure

drop value (in column 3) by the viscosity in centipoise. The

specic pressure drop values may be effectively used when

three of the four variables (Viscosity, Flow, Differential

Pressure, and Cartridge Grade) are set.

Betapure™ BK Series Chemical Compatibility

Table 3 shows Betapure BK series’s wide range of chemical

compatibility. Betapure BK series exhibits excellent

resistance to petroleum products, organic solvents, water,

acids, brines and aqueous salt solutions. Betapure BK

series is not recommended for strong acids or bases at

temperatures over 100 °F (38 °C).

Table 3. – Chemical Compatibility

Fluid

Category Example

Gasoline R

Kerosene R

Petroleum

Organic Solvents

Amines (DEA, MDEA, MEA) 20% - 50%

Water

Organic Acids

Hydrochloric (Muriatic ) Acid 5% R

Inorganic Acids

Brines and Aqueous

Salt Solutions

Weak Alkalis

Fatty Acids – Oils

Oxidizers Hydrogen Peroxide 90% R

R = Generally Recommended up to 250 °F (121 °C) unless otherwise noted. N = Not

Recommended L = Likely Compatible, test before use.

Diesel Fuel R

Lube Oil R

Fuel Oil R

Waxes R

MEK R

Benzene R

Toluene R

Xylene R

Alcohols R

Glycols R

Dimethyl Formamide (DMF) N

up to 160 °F (71 °C)

Process - to 212 °F R

Produced - to 212 °F R

Boiler Feed - to 212 °F R

Demineralizer Feed - to 212 °F R

Potable Water N

WFI N

Acetic (100%) R

Tannic 10% R

Sulfuric 50% R

Sulfurous 5-10% R

Nitric R

Sodium Chloride R

Sodium Sulfate R

Sodium Nitrate R

Aluminum Hydroxide R

Ferric Hydroxide R

Magnesium Hydroxide R

Detergents R

Mineral Oil R

Industrial Vegetable Oils R

Silicone Oils R

Rating

L

5

Page 6

Betapure™ BK Series Ordering Guide

Ca r tridge Type Length* Grade Surface Packaging**

BK - Betapure™

Series

* Lengths are multiples of either 9 3/4" or 10". ** All 39" and 40" cartridges poly bagged. ***Required for grades Z8050 through Z8140

09 - 9 ¾" Z8050 G – Grooved 1 – Standard Shrink Wrap S – Standard C - 222 O-ring & A - Silicone

10 - 10 " Z8070 U – Ungrooved 2 – Bulk Pack H – High Temp. Spear B - Fluorocarbon

19 - 19½" Z 8100 F - 222 O-ring & C - EPR

20 - 20" Z 8140 Flat Cap D - Nitrile

29 - 29¼ Z8150 K - 222 O-ring, G - Volara Gasket***

30 - 30" Z8200 Retaining Clip & N - None

39 - 39" Z8300 Flat Cap Y - Nylon Flat Gasket

40 - 40" Z8400 N - None

Z8500 P - Polypropylene

Z8700 Core Extender

Temper atur e

Option

Notes on End Modification Ordering

Double Open-End (DOE) Cartridges

DOE without end modication or gasket: N - N

DOE with at gasket: N - G

End Modification Gasket/O-ring

S - SS Core

Extender

Single Open-End (SOE) O-ring Style End Modifications

C - Code 8 style end modication (222) double o-ring connector with locating spear for use with standard plug-in style housing

diaphragms and positioning plates.

F - Code 3 style end modication (222) double o-ring connector with at cap for use with standard plug-in style housing.

K - 222 style o-ring connector with one o-ring and retaining clip for use with the 7PC housing

Core Extenders - For proper alignment and cartridge centering in competitive housings

P - Polypropylene extender for applications where compatible

S - Stainless Steel extender for chemical compatibility and for high temperatures > 180 °F (82 °C)

6

Page 7

Betapure™ BK Series Filters

Important Notice

The information described in this literature is accurate to the best of our knowledge. A variety of factors, however, can affect the performance of the Product(s) in a particular

application, some of which are uniquely within your knowledge and control. INFORMATION IS SUPPLIED UPON THE CONDITION THAT THE PERSONS RECEIVING THE

SAME WILL MAKE THEIR OWN DETERMINATION AS TO ITS SUITABILIT Y FOR THEIR USE. IN NO EVENT WILL 3M PURIFICATION INC. BE RESPONSIBLE FOR DAMAGES

OF ANY NATURE WHATSOEVER RESULTING FROM THE USE OF OR RELIANCE UPON INFORMATION.

It is your responsibility to determine if additional testing or information is required and if this product is fi t for a particular purpose and suitable in your specifi c application.

3M PURIFICATION INC. MAKES NO REPRESENTATIONS OR WARRANTIES, EITHER EXPRESS OR IMPLIED INCLUDING WITHOUT LIMITATION ANY WARRANTIES OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR OF ANY OTHER NATURE HEREUNDER WITH RESPECT TO INFORMATION OR THE PRODUCT TO WHICH

INFORMATION REFERS.

Limitation of Liability

3M Purifi cation Inc. will not be liable for any loss or damage arising from the use of the Product(s), whether direct, indirect, special, incidental, or consequential, regardless of

the legal theory asserted, including warranty, contract, negligence or strict liability. Some states do not allow the exclusion or limitation of incidental or consequential damages,

so the above limitation may not apply to you.

Your Local Distributor:

3M Purifi cation Inc.

400 Research Parkway

Meriden, CT 06450

U.S.A.

Phone (800) 243-6894

(20 3) 2 37-5 541

Fax (203) 630-4530

www.3Mpurifi cation.com

Betapure is a trademark of 3M Company used under license.

Please recycle. Printed in U.S.A.

3M is a trademark of 3M Company.

© 3M 2011. All rights reserved.

70-0201-8688-1 REV 1111b

Loading...

Loading...