Page 1

Betapure™

NT-T Series

The Next Generation in Depth Filter Technology

Betapure™ NT-T Series filter cartridges are 3M Purification Inc.’s latest advance in

depth filtration technology. The all polypropylene filter is constructed using a design

that utilizes flow enhancing filter media and an innovative flow pattern. The result is an

absolute-rated filter with vastly superior on-stream life that provides more cost effective

filtration than conventional melt-blown filter technologies. Betapure NT-T Series filter

cartridges - the new leader in filtration performance.

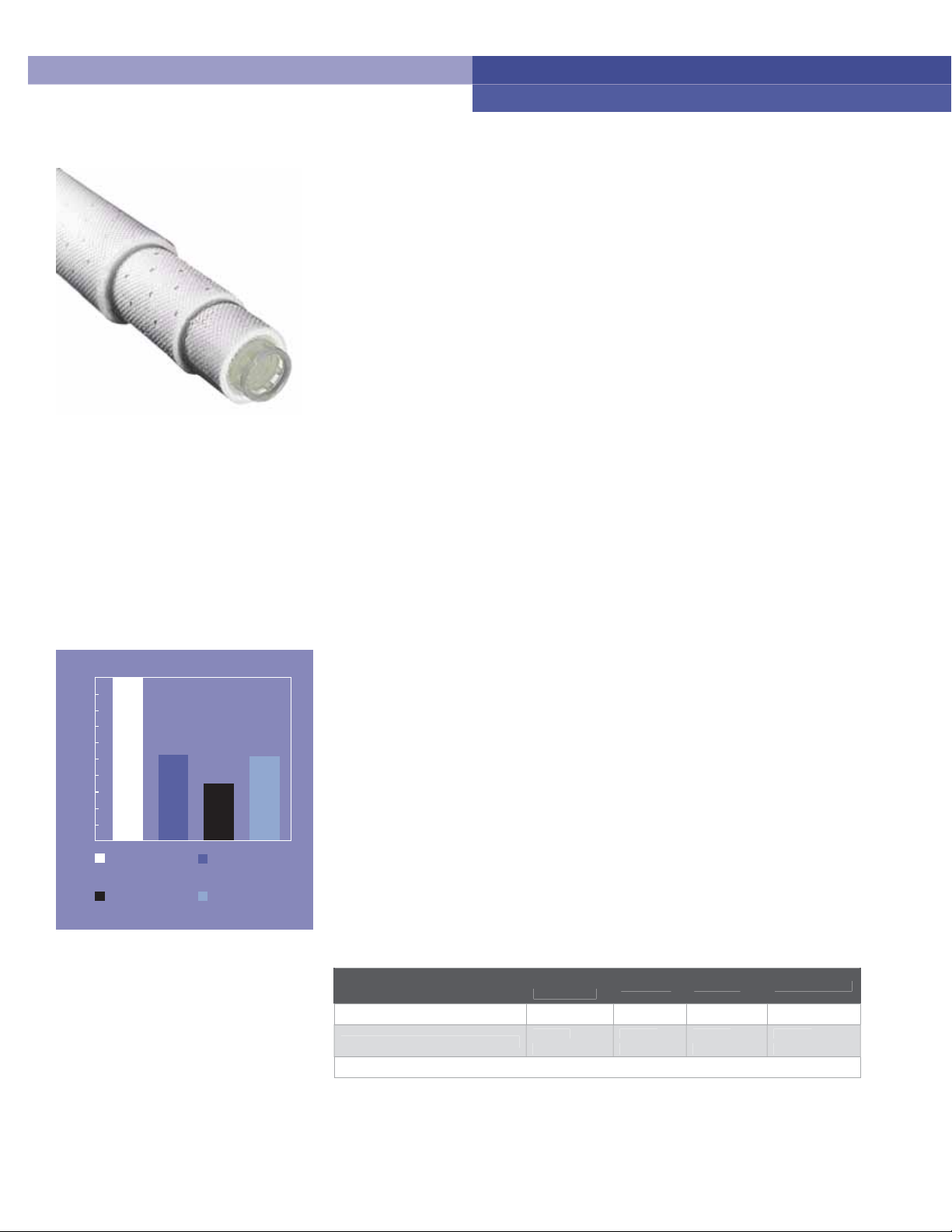

Betapure NT-T Series Filter Construction

3M Purification Inc. designed the Betapure NT -T Series cartridge to provide significantly

superior service life while maintaining a consistent filtration efficiency . Betapure NT-T

Series filters achieve this through an innovative cartridge design that allows uniform

distribution of fluid flow and contaminant throughout the entire depth of the cartridge.

Betapure NT-T Series filter construction combines a polypropylene media with fluid distribution netting to form multiple layers. Critically positioned media flow channels allow

greater movement of fluid from layer to layer. Three distinct media sections, made from

multiple media/netting layers, are combined to form the filter cartridge.

Figure 1: Betapure NT-T Series Media Sections. Note that the actual fi lter sections contain multiple layers of media.

Features & Benefi ts

Superior Service Life.

■

As much as 3 times greater dirt holding capacity than competitive fi lters.

All polypropylene depth fi lter cartridges.

■

Allow for broad chemical and temperature compatibility.

Ratings from 0.5 to 70 micron.

■

Suit a wide range of applications.

Absolute-Rated Performance.

■

Allows for consistent fi ltration quality.

Exhibits Superior Particle Retention Under Increasing Differential Pressure.

Filter Cartridges

Applications

Chemical and Acids, bleach (sodium hypo-

Hydrocarbon chlorite), polyethylene & poly-

Processing propylene manufacture, amine

sweetening & water fl ood

Food & Beverage Bottled water particulate & tur-

bidity reduction, reverse osmo sis membrane & spray nozzle

protection, diatomaceous earth

or carbon fi ne trap & beverage

blending, rinsing & wash water

Fine Chemical Pre-RO fi ltration of high silt

and Electronics density index incoming water,

copper sulfate plating bath

fi ltration in printed circuit board

construction and color screen

fi ltration for CRT production

Coating Film & paper coatings, photo

graphic fi lm, lens coatings &

can coatings, high quality

paints & ink

Industrial Machine tool lubrication, chemi cals, detergents, and waste

water, textiles, plating baths,

pulp & paper, process water &

ground water remediation

Page 2

m

B

Series

s

Pa

e

Pa

s

Osmonics Sele

d

3.1

1.0

1.8

0.8

c

37 / 30

*

g.

The outer and middle sections contain multiple layers of interleaved filter media and

fluid distribution netting. Within each media layer a portion of the fluid travels through

the media while the balance of the fluid is delivered directly to the next distribution

layer through the flow channels. The fluid distribution netting provides longitudinal and

latitudinal flow paths to evenly distribute fluid flow across the surface of each successive

media layer.

The Difference is Performance

Flow channels appear in the outer and middle sections of the filter matrix, as seen in the

cartridge cut-away. The size, number, and location of the flow channels combined with

the fluid distribution netting ensure that a uniform amount of contaminant is distributed

to each layer within these two sections, while maintaining a consistent flow.

Cut-away of the Betapure NT-T Series fi lter cartridge

showing the three sections of media layers and core

Graph 1: Betapure NT-T Series filters deliver

longer service life

Service Life C omparison of 20 μm Filter Cartridges

100

90

80

70

60

50

40

30

20

Percent of Betapure NT-T Series Life

10

0

Betapure

NT-T Series

Competitor B

Gradient Pore Structure

Melt-Blown with Core

Competitor A

Gradient Pore Structure

Melt-Blown with Core

Competitor C

Graded Density Structure

Melt-Blown, Coreless

The number of media flow channels decrease from the outer to middle sections to ensure

even contaminant loading throughout the entire filter matrix. Extensive laboratory testing has demonstrated that 3M Purification Inc. has developed the optimal filter cartridge

design.

The inner section, supported by a rigid polypropylene core and equal to approximately

one third of the filter’s depth, contains no flow channels and is the final qualifying section

ensuring absolute rated performance.

The even distribution of contaminated fluid throughout the depth of the cartridge is the

key to the Betapure NT-T Series filter’ s exceptionally long service life, low pressure

drops, and increased cost effectiveness.

The Result

Superior Filter Service L if e

Extensive testing has demonstrated that competitive filters of equivalent removal ratings

subjected to the same contaminant load plug more quickly than Betapure NT-T Series

filters. The result is significantly shorter service life, and unpredictable filtration efficiencies. Betapure NT -T Series filters provide a service life improvement of up to 3 times

greater than competitive products. (Graph 1 )

Lower Pr essur e Drop

The design and construction of the Betapure NT-T Series cartridge allows for significantly lower pressure drops compared to equivalently rated polypropylene depth filters.

Based on published data, a Betapure NT-T Series filter system with a given flow would

use up to 75% few er cartridges than Osmonics Selex, 68% fewer than Pall® Profile , an d

42% fewer than Pall® Nexis. T o underscore the Betapure NT-T Series filter cost benefit,

use the example in T able 1 as a guideline.

Table 1: Comparison of 5 Micron* Filters in a 110 GPM Syste

Flow (gpm) / 10” cartridge @ 1 psi

Number of filters for a 110 gpm flow rate

Based on the manufacturers published ratin

etapure NT-T

Filter

12 / 30”

artridges

ll Profil

cartridges

ll Nexi

”

21 / 30”

cartridges

43 / 30”

cartridges

x

2

Page 3

For the same initial cartridge differential pressure, a 1 10 gpm system using Betapure

gs

n

)

T

*

01T0202T0303T0505T100

10

020T30030T40040

T50050T70070

d

NT-T Series filters require significantly fewer cartridges. This results in lower capital

investment for the filter housing and fewer cartridges to purchase.

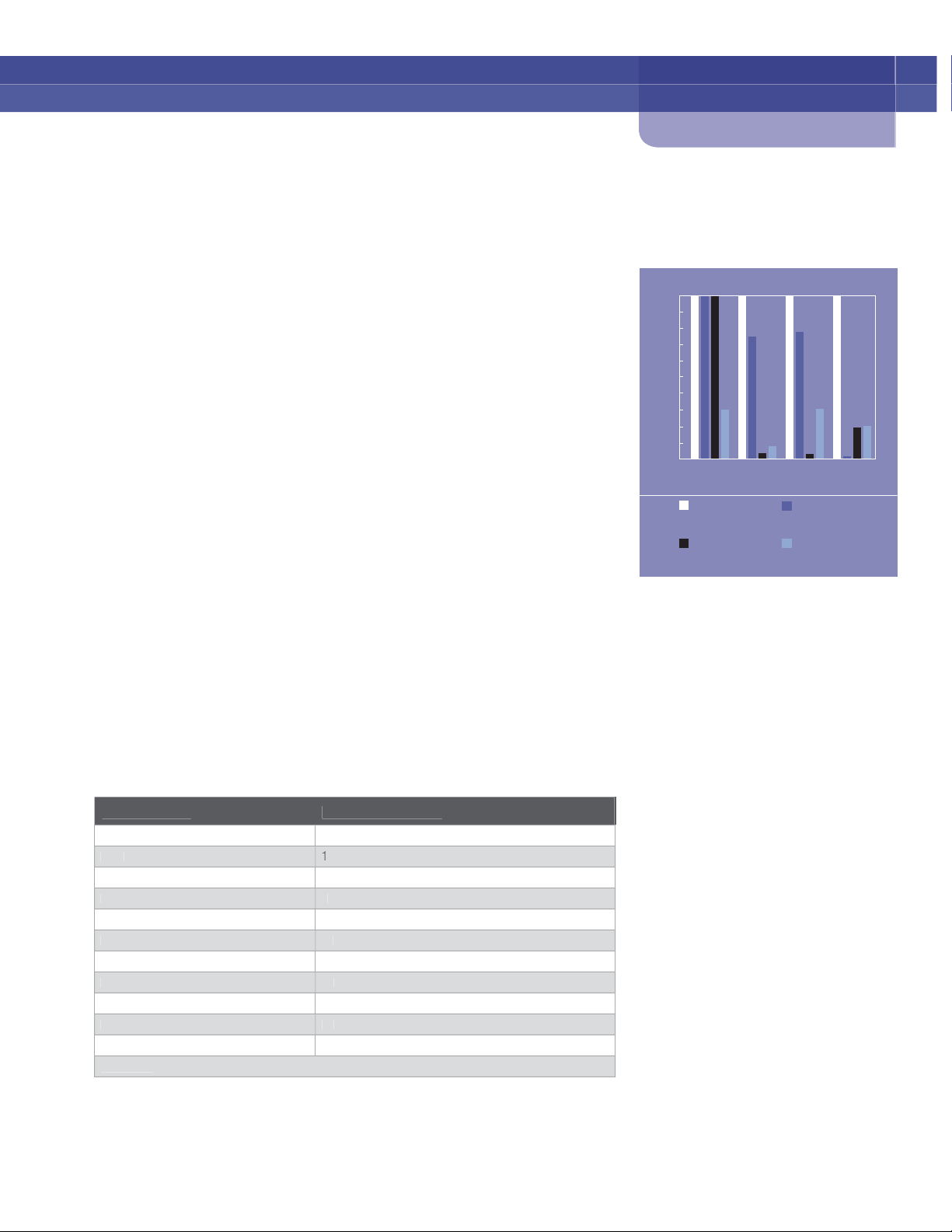

The Confi dence of Consistency

Betapure™ NT-T Series filters utilize advanced design and construction to achieve a

level of filtration consistency unattainable by competitive filters. Combined with an

exceptionally long service life, the Betapure NT-T Series filter’s consistent performance,

as illustrated by comparative Beta-Ratio vs. Differential Pressure (Graph 2), provides

predictable results throughout the filters’ usable life. Filters A, B, and C show a degradation in the Beta-Ratio as psid increases. These filters exhibit a pattern of either

unloading previously held particles or a loss of filtration efficiency. The result of this

inconsistent performance is a reduction in finished product quality, product yield, and

an increase in total filtration cost.

Absolute Betapure NT-T Series

Consistent filtration performance, time after time, from start to finish - the goal of every

filter user, the solution provided by Betapure NT-T Series filters. Absolute removal

ratings for Betapure NT-T Series filters are determined using a filter performance test

developed by 3M Purification Inc. to comply with the general procedures outlines in

ASTM STP 97 5. 3M Purification Inc. defines absolute rating as the particle size (x)

providing an initial Beta Ratio (Bx) = 1000. At this Beta Ratio, the removal efficiency

is equal to 99.9%. Betapure NT -T Series filter ratings are specified in Table 2.

Betapure™

NT-T Series

Graph 2: Beta Ratios demonstrate the

Betapure NT-T Series filter’s ability to

perform consistently throughout its life

Beta Ratio Comparison of 20μm Filter Cartridges

1000

900

800

700

600

500

400

300

200

Beta Ratio

100

0

Betapure

NT-T Series

Competitor B

Gradient Pore Structure

Melt-Blown with Core

0.5 1 10Initial

Differential Pressure (psid)

Filter Cartridges

Competitor A

Gradient Pore Structure

Melt-Blown with Core

Competitor C

Graded Density Structure

Melt-Blown, Coreless

Your Benefi t - Total Filtration Cost Reduction

The Betapure NT-T Series filter’s performance and superior life advantage allows direct

cost savings by reducing the number of filters used. In addition, the resulting reduction

in filter change-out frequency decreases direct labor and filter disposal costs. Betapure

NT-T Series filter cartridges - providing performance and value.

Table 2: Betapure NT-T Series Filter Ratin

Grade Designatio

005 0.5

T01

T20

* extrapolate

Absolute Rating (Micron

3

Page 4

Betapure NT-T Series Filter Applications

Betapure NT-T Series’ construction provides benefits to customers in a wide range of enduse filtration applications. High quality filtration along with total filtration cost reductions are very attractive benefits to customers in diverse industries.

Chemical and Hydrocarbon Pr ocessing

Cost reduction is the most critical issue in the production of high quality chemicals,

petrochemicals, and in hydrocarbon processing. Using Betapure NT -T Series filters in

demanding applications that require absolute-rated performance provides long service life,

the consistency demanded to attain quality standards, and a total Filtration Cost reduction.

Applications include:

• Acids, bleach (sodium hypochlorite)

• Polyethy lene and polypropylene manufacture

• Amine sweetening and waterflood

Food & Beverage Applications

Increased consumer emphasis on product quality, as well as increased government

regulation, are driving today’s food & beverage industry to ever-finer levels of filtration.

Betapure NT-T Series filter cartridges meet this challenge throughout their entire service

life. Typical applications include:

• Bottled water particulate and turbidity reduction

• Reverse osmosis membrane and spray nozzle protection

• Diatomaceous earth or carbon fine trap

• Beverage blending, rinsing and wash water

Fine Chemical and Electronics

Betapure NT-T Series filters with their filter matrix are ideally suited for electronics applications where heavy contaminant loading is present and efficient long lasting filtration

is required. The combination of all-polypropylene construction and the media provide the

perfect filtration device for use in wafer manufacturing and semiconductor device fabrication. Applications include:

• Pre-RO filtration of high silt density index incoming water

• Copper sulfate plating bath filtration in printed circuit board construction

• Color screen filtration for CRT production

Coating

Betapure NT -T Series filter cartridges are well suited for the filtration of high solid

coatings where they provide superior life while selectively removing the large undesired

particles from the coating and allowing the smaller desired particles to pass. Betapure

NT-T Series applications include:

• Film & paper coatings

• Photographic film

• Lens coatings

• Can coatings, high quality paints & ink

Industrial

Betapure NT-T Series filter cartridges are ideal for higher dirt loads because of the

flow characteristics and long service life that provide reduced overall filtration costs.

Betapure NT -T Series cartridges are used in a broad range of general industrial applications that include:

• Machine tool lubrication, chemicals, detergents, and waste water

• T extiles, plating baths

• Pulp & paper

4

• Process water & ground water remediation

Page 5

3M Purifi cation Inc. Filter Housings

3M Purification Inc. manufactures a wide range of filter housings. Housings that accommodate from a single filter element, to many hundreds, available in a broad choice of

materials, and a flexibility of design ensure that 3M Purification Inc. has a filter housing

to suit your needs.

ES Series Filter Housing

The ES Series filter housing is a durable high volume filter housing constructed from

3 16L stainless or carbon steel. With a cartridge capacity from 12 to 480 equivalent

lengths, the ES filter can accommodate a wide range of flow requirements. For more

information, ask your local 3M Purification Inc. distributor for brochure 70-0201-8711-1.

CTG Ser ies F ilt er Housing

The CTG Series Filter design provides a totally enclosed system using separate pressure

vessel and filter pack to isolate process fluid from the housing. This system virtually

eliminates the costs involved with filter change-out while protecting the environment and

operator from exposure to the process fluid. For more information, ask your local 3M

Purification Inc. distributor for brochure 70-0201-8693- 1.

DC & SD Filter Housings

DC and SS filter housings offer a cost effective alternative for low vo lume filtration.

Constructed from reliable 304L stainless steel (Model DC) or 3 16L stainless steel

(Model SS), systems are available for a wide range of flow rates and applications. For

more information ask for literature 70-0201-8757-4 and 70-0202-2106-8.

Betapure™

NT-T Series

Filter Cartridges

5

Page 6

s

Grade

)

S

s

ps

T

0.5

4.5

81.9

T01012.54

T02020.8

5.9

T03030.44

8.0

T05050.325.9

T100100.14

2.5T20020

0.065

1

T300300.05

0.91

T40040

0.0420.76

T500500.029

0.52

T700700.025

0.45

g

p

Table 2: Betapure NT-T Series Filter Specification

s

*

e

Sili

EPR, Nitril

PTFE

d

fluorocarbon, and Polyethylene

,yy

fluorocarbon, and Polyethylene

,yy

O

s

e

C)

C)

C)

C)

C)

C

3/32

” no

al

Outside

1/2

” no

al

L

h

9

3

/

4

19

1/2

1/4

s

Materials of Construction

Filter Media, Netting, Core, End Connector Polypropylen

Gaskets & O-ring Options (see ordering guide)

cone, Fluorocarbon,

e,

encapsulate

perating Condition

Maximum Operating Temperatur

Maximum Differential Pressure

Recommended Change-Out Differential Pressure35 psid at 86°F (2.4 bar at 30°

180°F (82°

50 psid at 86°F (3.4 bar at 30°

30 psid at 131°F (2.0 bar at 55°

15 psid at 180°F (1.0 bar at 82°

artridge Dimensions

Inside Diameter 1

Diameter2

engt

* All materials are FDA compliant per CFR 21

min

min

5,

, 10,

, 20, 29

30, 39, and 40 inche

Flow Rates

Detailed information for calculating flows for water and fluids with other viscosities is located in the following table. Use the formula in conjunction with the values from columns

3 or 4 in the table. The specific pressure drop values may be effectively used when three

of the four variables (viscosity, flow, differential pressure, and cartridge grade) are set.

Chemical Compatibility

Table 3: Betapure NT-T Series Flow Rate

Absolute Rating (μm

005

* Specific aqueous pressure drop at ambient temperature for a single length equivalent (10”) cartridge. For multiple

cartrid

e lengths, divide the total flow by the number of equivalent lengths. For liquids other than water, multiply the

s

ecific pressure drop value provided in the table by the viscosity in centipoise.

Clean

psi (mbar)

Δ p

Total System gpm [lpm]

(

=

Number of Equivalent Single Length Cartridges in Housing

(

pecific Pressure Drop per 10” Cartridge

psid/gpm/cp

71

Viscosity in Cp

) (

) (

mbar/lpm/c

5.5

.2

Value From Table

)

)

6

Page 7

The 100% polypropylene construction provides excellent chemical compatibility

in many demanding process fluid applications. Compatibility is influenced by

process operating conditions: in critical applications, cartridges should be tested

under actual conditions to ensure correct selection.

Scientifi c Application Support Services (SASS)

Providing the key to customer collaboration, the global 3M Purification Inc.

SASS organization is a team of multi-disciplinary scientists and engineers that

provide the vital link between 3M Purification Inc.’s filtration knowledge base

and customer needs. With complete access to 3M Purification Inc. technology

and its research and development, members of the SASS group provide on-site

bench-scale tests and assist with customer scale-up to the full manufacturing

process. When processing requirements are encountered, SASS is expertly

equipped to identify filtration solutions using either the broad array of existing

3M Purification Inc. filter products or by working with 3M Purification Inc.

R&D to design a custom solution for the application.

Service Worldwide

3M Purification Inc. is a U.S. based multinational company with distribution

and manufacturing sites worldwide. Global manufacturing sites together with

trained stocking distributors and state-of-the-art laboratory facilities bring quality solutions to challenging filtration applications.

Betapure™

NT-T Series

Filter Cartridges

A Global, Diversifi ed Technology Company

3M is fundamentally a science-based company. As a member of the 3M family,

we create imaginative solutions, and we are a leading filtration provider in a

wide range of markets, from the coarsest industrial filtration to the finest DNA

separation. We provide the trusted solutions that our customers demand and expect. Our success is built on our ability to apply our technologies and expertise

to an endless array of real-world customer needs. Virtually anywhere you go,

3M Purification Inc. technologies are at work – making life easier and better for

people around the world.

7

Page 8

Betapure™ NT-T Series Ordering Guide

Cartridge Type

NT - Betapure NT-T Series

✝

Requires N end modification for use in CT101 (PN 44860) only.

* Applies to D, N, and P end modifications only.

** For use with 1ZMP housing.

Length

(inches)

06✝ - 5

09 - 9 3/

4

10 - 10

19 - 19 1/

20 - 20

29 - 29 1/4*

30 - 30

39 - 39*

40 - 40

2

Grade

Code Rating

(μm)

T005 0.5

T010 1

T020 2

T030 3

T050 5

T100 10

T200 20

T300 30

T40 0 40

T500 50

T700 70

F

B

C

D

M

N

P

&

Y

Q

Packaging

Option

S - Standard

R

Support Ring

Option

For End Modifi cation

D, N, P, Q, & R

0 - None

For End Modifi cation

B, C, F, M, & Y

1 - Polysulfone

2 - Stainless Steel

0 - None

End Modifi cation (see

illustration below)

B - 226 O-Ring with Spear

C - 222 O-Ring with Spear

D - DOE with Polypropylene

End Caps

F - 222 O-Ring with Flat Cap

M - 222 O-Ring with Flat Cap**

N - Unmodifi ed DOE

P - Polypropylene Core Extender

Q - SOE, End Cap without Spring

R - SOE, End Cap with Spring

Y - Single O-Ring

(40” length only)

Gasket/O-ring Material

For End Modifi cation B, C, D,

F, M, Q, R & Y

A - Silicone

B - Fluorocarbon

C - EPR

D - Nitrile

K - PTFE encapsulated

fl uorocarbon.

For End Modifi cation N, P,

Q & R

G -Polyethylene

This Betapure NT-T Series filter is tested and certified

by WQA against NSF/ANSI Standard 61 for material

requirements only.*

*For O-Ring “K” please consult factory.

Cold Water Only

Install this product in accordance with the instructions

provided by the housing manufacturer. This product

has a minimum flow rate requirement of 6.6 gallons

per day (25L per day).

Important Notice

3M Purifi cation Inc. MAKES NO WA RRANTIES, EXPRESS OR IMPLIED, INCLUDING , BUT N OT LIMITED TO, ANY IMPLIED WARR ANTY OF MERCHA NTABILIT Y OR FITNES S FOR A PARTICULAR PUR POSE .

Since a var iety of factors can af fect the use and performance of a 3M Purifi cation Inc. product in a particular application, some of which are uniquely within the user’s knowledge and control, user is

responsible for determining whet her or not t he product is fi t for a par ticular purpose and suitable for user’s method of application.

Limited Warranty

3M Purifi cation Inc. warr ants it this product to be free from defects in material and workmanship during normal use for a period of one (1) year from t he date of shipment from the f actor y. If the

Product(s) is (are) defective within this warranty period, your exclusive remedy and 3M Purifi cation Inc.’s sold obligations shall be, at 3 M Purifi cation Inc.’s option, to replace or repair the Product(s)

or refund the original purchase price of the Product(s) This warran ty does not apply to failures that result from abuse, misuse, alternation or damage not caused by 3 M Purifi cation Inc. or failure to properly follow installation and use instruc tions.

Limitation of Liability

3M Purifi cation Inc. will not be liable for any loss or damage arising from the use of the Product(s), whether direct, indirect, special, incidental, or consequential, regardless of the legal theory asser ted,

including warranty, contract, negligence or strict liability. Some states do not allow the exclusion or limit ation of incidental or consequen tial damages, so the above limitation may not apply to you.

This warranty gives you specifi c legal rights and you may have other rights which vary from state to state, or country to country.

Your Local 3M Purifi cation Inc. Distributor:

3M Purification Inc.

400 Research Parkway

Meriden, CT 06450

U.S.A.

(800) 243-6894

(203) 237-5541

Fax (230) 630-4530

www.3Mpurifi cation.com

Betapure is a trademark of 3M Company used under license.

3M is a trademark of 3M Company.

Pall is a trademark of Pall Corporation.

Osmonics is a trademark of GE Osmonics, Inc.

© 2010 3M Company. All rights reserved.

70-0201-8720-2

LITCPN1.1110pt

Loading...

Loading...