Page 1

a 3M company

®

Betafi ne™

XL Series

Absolute-Rated Pleated Poylpropylene Filter Cartridges

The Betafine XL filter represents a major advance in pleated filter technology . Building

on CUNO’s history of filter design innovation, this absolute-rated, 100% polypropylene,

pleated cartridge features an Advanced Pleat Technology (APT) that increases the usable

filtration surface area while maintaining standard industrial cartridge dimensions. The

result is a filter cartridge that dramatically enhances service life.

Advanced Pleat Technology

The service life of a pleated cartridge is often dictated by the accessible surface area.

Conventional pleated filters may offer a large gross surface area, but when the media is

packed too tightly into the cartridge, only part of the surface area is usable resulting in

both flow restrictions and limited contaminant holding capacity. The “blind” or unusable

area commonly occurs near the inside diameter (see figures below) where the pleats are

packed most tightly. The Betafine XL cartridge is manufactured using a staggered pleat

configuration that, when combined with a novel support material, provides more open

space between the pleats.

The APT staggered pleats with increased open area allow for greater contaminant loading

between pleats at the inside diameter, while the reduced length pleats take advantage of

existing open space closer to the cartridge’s outside diameter. The result is a fully used

surface area that provides superior service life.

Betafi ne XL Advanced Pleat Technology utilizes a

confi guration designed to increase the accessible

surface area for signifi cantly greater fi lter media use.

Conventional pleat designs, with full-depth densely

packed pleats, fi ll the upstream pleat surface with

contaminant that quickly constrict fl ow at the pleat’s

inside diameter.

Features & Benefi ts

Reduced Total Filtration Costs

■

Fewer cartridges used, reduced cartridge change-out frequency, reduced downtime and product

waste, and reduced labor and disposal costs.

Predictable fi ltration performance

■

Reduced quality checks, reduced product rejects and rework, and increased productivity and plant

capacity

Applications

Betafi ne XL fi lters are ideal for a wide array

of applications. Contact your local distributor with your specifi c applications. A more

detailed listing of applications is on page 6.

Paint & Coatings

Industrial

Pharmaceutical, Biological, and Bioprocessing

Electronics

Food & Beverage

Chemical and Petrochemical Processes

Page 2

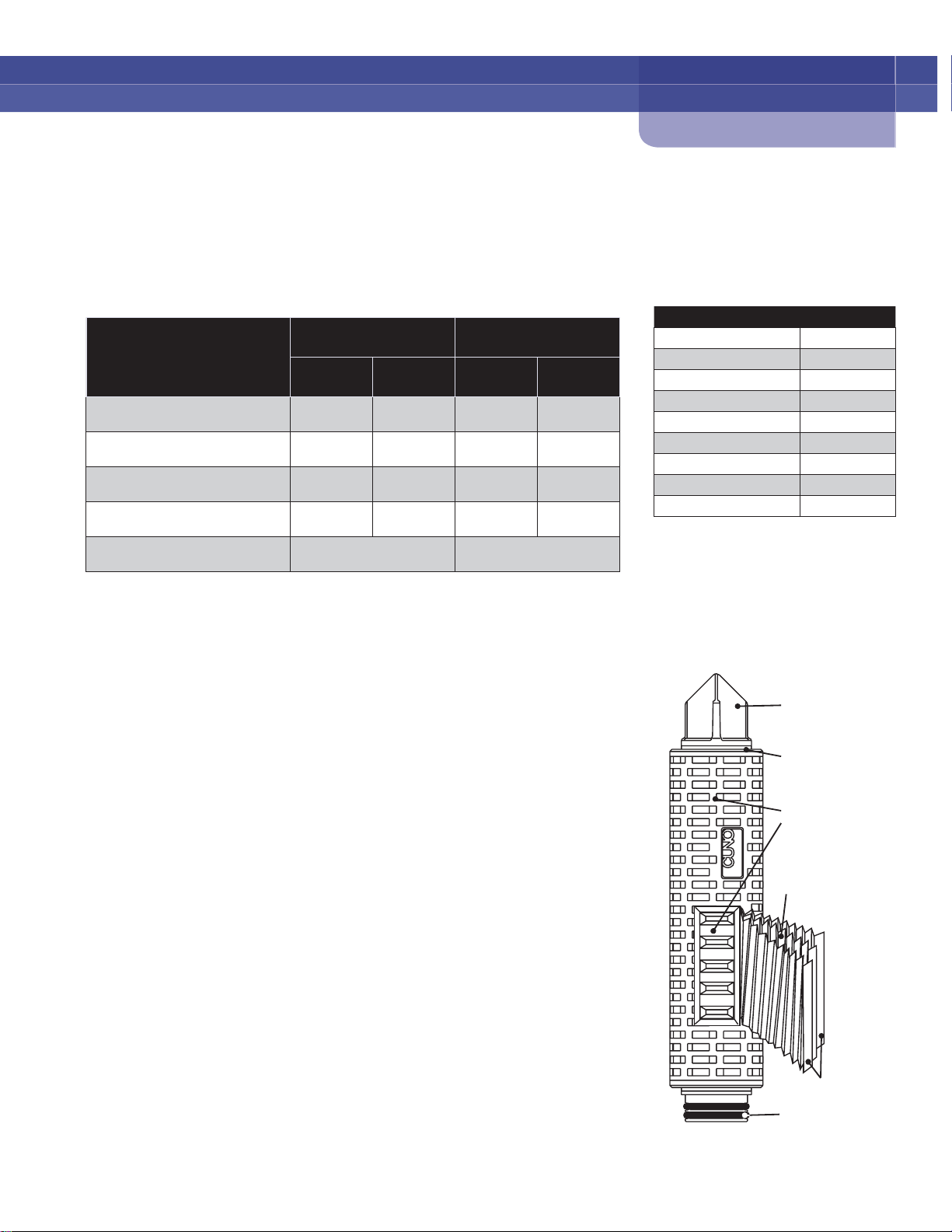

Superior Service Life

Extensive testing has demonstrated that the Betafine XL filter provides service life

superior to competitive pleated filters of equivalent removal ratings when subjected to the

same contaminant load. The result of using filters with significantly longer service life is

substantially reduced filtration costs. Betafine XL filters provide a service life improvement of up to 4.4 times greater than competitive products! (Graph 1 )

Graph 1 — Betafine XL filters provide significantly enhanced service life when compared to

conventional pleated filters of like published removal ratings.

Service Life Comparison by Rating (Microns)

100

75

50

25

Percent of Betafine XL Life

0

XL A B C

0.5 Micron

100

75

50

25

Percent of Betafine XL Life

0

100

75

50

25

Percent of Betafine XL Life

0

Grade Not Available

XL A B C XL A B C

2.5 Micron

XL A B C

10 Micron

100

75

50

25

Percent of Betafine XL Life

0

XL A B C

1 Micron

100

75

50

25

Percent of Betafine XL Life

0

5 Micron

CUNO Betafine XL

Competitor A

Varied Fiber Diameter

Competitor B

Combination Polypropylene

Melt-Blown and Polyester

Spun-Bound

Competitor C

Constructed with

Polysulfone or

Polypropylene Media

Superior on-line service life provides significant total filtration cost reductions. From

fewer filter cartridges used to a reduction in labor costs by decresing filter change-out frequency, Betafine XL filters provide the ultimate in cost effective pleated filter technology.

2

Page 3

The Impact of Service Life on Total Filtration Costs

The service life of a filter has a direct impact on total annual filtration costs. To illustrate

how great an impact can occur, the follo wing example is provided. The example is based

on a model system with a flow rate of 250 gpm using 18 (30” long ) filter cartridges with a

change-out frequency of one week.

A Filter with 50% of Betafine

Process Requirements*

Estimated filter usage

(annual, based on $75 per cartridge U.S.)

Required labor

(1 hour per filter change-out at $40/hr U.S.)

Estimated disposal

(56 cartridges per drum at $50/drum U.S.)

Process downtime 52 hours ? 26 hours ?

Total Annual Filtration Cost $73,130 $36,590

XL Filter Service Life

Units

936 $70,200 468 $35,100

52 hours $2,080 26 hours $1,040

17 drums $850 9 drums $450

Estimated

Cost

Betafine XL Filter Cartridge

Units

Estimated

Cost

Betafi ne™ XL

Filter Cartridges

Absolute-Rated Pleated Poylpropylene Filter Cartridges

Betafine XL Absolute Filter Ratings

CUNO Designation Rating (micron)

002 0.2

005 0.5

010 1

025 2.5

050 5

100 10

200 20

400 40

700 70

* These estimates are based on conditions as noted. Your savings will vary depending on your actual costs.

Absolute Ratings

The assurance of predictable and reproducible contaminant removal can best be provided

by the use of absolute-rated filters. Betafine XL filters are absolute rated to Beta 1000

(99.9% efficiency at its rating) and are available in 9 distinct ratings from 0.2 micron to 70

micron. This provides a complete choice of ratings to meet the exacting filtration requirements for the most critical applications.

Filter Cartridge Construction

Betafine XL filters, constructed of 1 00% polypropylene, provide excellent chemical

and thermal compatibility. The filter media is constructed from continuous micro-fibers

that are precisely controlled to provide a uniform matrix and consistent effluent quality.

Betafine XL filter incorporates a polypropylene support upstream and downstream of

the media to provide optimum flow characteristics and long service life. The all-polypropylene cartridge components are thermally bonded — no resin or binder compounds are

used. All materials used in the manufacture of Betafine XL filters are FDA CRF Title 2 1

listed for direct food contact. Available in 9 distinct micron ratings and integral lengths

3

from 9

ing designs, Betafine XL cartridges are ideal for a wide variety of applications.

/4 to 40 inches with a wide selection of end treatments to fit common filter hous-

Optional End

Treatments

Polypropylene

End Cap Adapter

Polypropylene

Outer Cage

&

Inner Core

100%

Polypropylene

Media

Polypropylene

Media Support

Optional

Gasket Materials

3

Page 4

Chemical Compatibility

The 100% polypropylene construction provides excellent chemical compatibility in

many demanding process fluid applications. Listed in the following table are commonly

requested compatibilities. Compatibility for specific fluids may vary and is influenced

by operating conditions. Consult your local CUNO distributor or the factory for more

information.

Chemical Temperature Chemical Temperature

Acetic Acid 20% 175°F (80°C) Nitric Acid 20% 100°F (38°C)

Ammonia 10% 140°F (60°C) Potassium Hydroxide 140°F (60°C)

Bleach 5.5% 70°F (21°C) Sodium Carbonate 100°F (38°C)

Ethylene Glycol 140°F (60°C) Sodium Hydroxide 70% 140°F (60°C)

Alkanolamines 140°F (60°C) Sulfuric Acid 20% 140°F (60°C)

Hydrogen Peroxide 100°F (38°C) Sulfuric Acid 70% 100°F (38°C)

Methyl Ethyl Ketone 70°F (21°C) Urea 140°F (60°C)

Mineral Oil 70°F (21°C)

CUNO Filter Housings

CUNO manufactures a wide range of filter housings. Housings that accommodate from

a single filter element, to many hundreds, are available in a broad choice of materials. A

flexibility of design ensures that CUNO has a filter housing to suit your needs. The housings provide easy access for filter change-out and the greatest assurance that Betafine XL

filter cartridges are seated securely, thus eliminating the possibility of fluid bypass.

ES Series Filter Housing

The ES Series filter housing is a durable high flow filter housing constructed from 31 6L

stainless or carbon steel. With a cartridge capacity from 12 to 480 equivalent lengths, the

ES filter housing can accommodate a wide range of flow requirements. For more information, ask your local CUNO distributor for brochure LITCHSES 1.

CTG-Klean Filter Housing

The CTG-Klean Filter Housing design provides a totally enclosed system using a filter

pack to isolate process fluid from the housing. This system reduces the costs involved

with filter change-out while protecting the environment and operator from exposure to

the process fluid. For more information, ask your local CUNO distributor for brochure

LITCCK001 .

DC & SD Filter Housings

DC and SD filter housings offer a cost effective alternative for lo w vo lume filtration. Constructed from reliable 304L stainless steel (Model DC) or 316L stainless steel (Model SD),

systems are available for a wide range of flow rates and applications. For more information, ask for literature LITHSDC1 and LITHSSD1 . For other style housings, contact your

local CUNO Distributor.

4

Page 5

Scientifi c Application Support Services (SASS)

Dedicated technical support teams comprised of CUNO scientists and engineers are

available to provide application specific recommendations for the most effective and

economical filtration system. In addition to comprehensive testing and analysis conducted

at CUNO’s advanced laboratories, the SASS staff frequently performs on-site testing at

customer’s facilities. Contact your CUNO representative for additional information.

Flow Characteristics and Sizing Options

Flow vs. differential pressure for water is depicted in the following graphs for each Betafine XL grade. A typical filter system is often sized for an initial differential pressure of

0.5 to 1 psi (0. 04 to 0.07 bar ) . Low flow rates further extend the life of the filter system.

Chart 1

14

13

12

11

10

9

8

7

6

5

4

3

Differential Pressure (PSID)

2

1

0

0123456789

Water Flow Rate (GPM/10”cartridge)

XL 002

XL 005

XL 010

10

Betafi ne™ XL

Filter Cartridges

Absolute-Rated Pleated Poylpropylene Filter Cartridges

Chart 2

1.5

1.4

1.3

1.2

1.1

0.9

1.0

0.8

0.7

0.6

0.5

0.4

0.3

0.2

Differential Pressure (PSID)

0.1

0

0123456789

Water Flow Rate (GPM/10”cartridge)

XL 025 & X L 050

XL 100 & XL 200

XL 400 & XL 700

10

Reduced cartridge change-out frequency

For a given process flow rate, the increased accessible surface area decreases filter cartridge change-out frequency by 30 to 50 percent or more depending on the application.

Reduced fi lter housing costs

For new applications, the low pressure drops of the Betafine XL filter allow smaller or

fewer housings to be required. Fewer filter cartridges and smaller housings ensure lower

capital and operating costs, year after year!

5

Page 6

Betafi ne XL Applications

Betafine XL filters are ideal for a wide array of applications. Contact your local distributor for

assistance with your specific applications.

Paint and Coatings Applications

Betafine XL filter cartridges are well suited for the filtration of raw materials as well as final

product. Betafine XL filter applications include:

• Film & paper coatings

• Photographic film

• Lens coatings & magnetic media

• Can coatings, high quality paints, & ink

Industrial Applications

Betafine XL filter cartridges are ideal for reducing overall filtration costs in a broad range of

indus trial a p p licatio ns , in c l u din g :

• Machine tool lubrication, detergents, process and waste water

• Plating baths and chemicals

• Pulp & paper, and textiles

Pharmaceutical, Biological, and Bioprocessing

Betafine XL filter cartridges are ideal for clarification and prefiltration. The Betafine XL filter’ s

polypropylene media and materials of construction meet industry standards. Betafine XL cartridges can be used in a broad range of aqueous based applications including:

• High-Purity Pharmaceutical Water Systems, Solvent & F ermentation Feed Streams

• Reagents & Buffers, Bulk Pharmaceutical Chemicals & Intermediates

• Air Prefiltration

• T o iletries and Cosmetics, Orals & T opi cals

Electronic Applications

Betafine XL filters meet the needs of many electronics and electronic component filtration applications by delivering high flow rates, broad process compatibility, and easy installation in a

variety of systems.

• CD and DVD media

• Printed circuit boards

• Video displays

• DI water

Food & Beverage Applications

Increased consumer emphasis on product quality, as we ll as increased government regulation,

are driving today’s food & beverage industry to ever-finer levels of filtration. Betafine XL filter

cartridges meet this challenge throughout the entire service life. Typical applications include:

• Bottled water particulate and turbidity reduction

• Reverse osmosis membrane and spray nozzle protection

• Diatomaceous earth or carbon fines trap

• Beverage blending, rinsing, or wash water

6

Page 7

Betafi ne™ XL

n

M

ls

Media

Pl

M

t

Pol

s

Pol

s

S

O

s

M

e

1

Ma

essure

Ma

essure

B

Diamete

2

)

N

h

t

F

Filter Cartridges

Chemical and Petrochemical Processing

Betafine XL is ideally suited for demanding filtration applications within Chemical and Petrochemical

production processes.

• Clarification of high purity chemicals, organic and inorganic chemical intermediates, and

various acids and bases

• Production of petrochemicals from feed-stocks and intermediates, solvents, polymer solutions

• Process water for quench and flushing

Betafine XL Cartridge Specificatio

ateria

eated Polypropylene

edia Suppor

Core, Outer Cage, End Cap

Gasket & O-Ring Option

ypropylene

ypropylene

ilicone, Fluorocarbon, EPR, PTFE Encapsulated O-Ring, Polyethylene, Nitrile

perating Condition

aximum Operating Temperatur

ximum Forward Pr

ximum Reverse Pr

etafi ne XL Cartridges can be autoclaved, steamed in place or hot water sanitized. (For cartridges with 222 or 226 o-ring end styles, order option with reinforcing ring.)

Cartridge Dimensions

r

ominal Lengt

Regulatory Status

CFR Complian

Differential 60 psi at 77°F (4 bar at 25°C)

Differential 40 psi at 77°F (2.6 bar at 25°C)

75°F (80°C)

.62 inches (6.6 cm

9 ¾ , 10, 19 ½ , 20, 29 ¼ , 30, 39, 40 inches

ilter components are FDAS listed for food contact per CFR 21, Parts 170-199

This Betafi ne XL series fi lter is tested and certifi ed by WQA against

NSF/ANSI Standard 61 for material requirements only*.

* For gasket /o-rings G, H, K, & L, please consult factory.

Cold Water Only

Install this product in accordance with the instructions provided by the

housing manufacturer.

7

Page 8

Betafi ne XL Series Ordering Guide

Cartridge

XL

Betafi ne XL

B

Length

Material

Rating

End Style Gasket/O-Ring

Code In. Code Micron

09* 9 3/4

10 10 005 0.5 B2 226 O-ring & Spear Stainless Steel Ring B Fluorocarbon

19* 19 1/2 010 1 C0 222 O-ring & Spear No Reinforcing Ring C EPR

20 20 025 2.5 C1 222 O-ring & Spear Polysulfone Ring D Nitrile

20* 29 1/4 050 5 C2 222 O-ring & Spear Stainless Steel Ring G Polyethylene (end styles D, P, Q & R only)

30 30 100 10 D Double Open End (DOE) H Clear Silicone O-Ring

39* 39 200 20 F0 222 O-ring & Flat Cap No Reinforcing Ring K PTFE Encapsulated fl uorocarbon O-Ring

40 40 400 40

C

D

Polypropylene

F

PP

P

002 0.2 B1 226 O-ring & Spear Polysulfone Ring A Silicone

F1 222 O-ring & Flat Cap Polysulfone Ring L PTFE Encapsulted Silicone O-Ring

700 70 F2 222 O-ring & Flat Cap Stainless Steel Ring

P DOE with Polypropylene Core Extender

Q Single Open End (SOE)**

R Single Open End (SOE) with stainless steel

spring

RQ

U 222 O-ring & Flat Cap No Reinforcing Ring (One

high only, shorter cartridge retrofi ts Mykrolis

/ Millipore™ Code 0)

™

* Not available in B, C, F, Q, R and U end styles.

** Can be used a replacement cartridge with R end style.

Important Notice

CUNO MAK ES NO WARRA NTIES, E XPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY I MPLIED WARRA NTY OF MERCHA NTABILITY OR FITNESS FOR A PART ICULAR PURPOSE. Since a variety of factors

can affect the use and performance of a CUNO product in a particular application, some of which are uniquely within the user’s knowledge and control, user is responsible for determining whether or not the CUNO product

is fi t for a particular purpose and suitable for user’s method of application.

Warrant y

Seller warrants its equipment against defects in workmanship and material for a period of 12 months from date of shipment from the factor y under normal use and ser vice and otherwise when such equipment is used in

ac cord ance wit h ins truc tio ns fu rnis hed b y Sel ler a nd fo r pur pose s dis clo sed i n wri ting at th e tim e of pu rcha se, i f any. Any unautho rized alteration of modifi c ation of the equipment by Buyer will v oid this warranty. Seller’s liab ility

under this wa rranty shall be limit ed to the replacement o r repair, F.O.B., poin t of manufacture, of any d efective equipmen t or part whic h, hav ing be en re turne d to t he fac tory, tran spor tat ion ch arge s prep aid, h as be en ins pect ed

and determined by Seller to be defective. THIS WARRANTY IS IN LIEU OF ANY OTHER WARRANTY, EITHER EXPRESSED OR IMPLIED, AS TO DESCRIPTION, QUALITY, MERCHANTABILITY, FITNESS FOR ANY PARTICULAR

PUR POSE OR US E, OR ANY OT HER MATT ER. Under no circ umstances shall Se ller be liable to Buyer or any t hird party for any l oss of profi ts or other direc t or in direc t cos ts, ex penses, losses or consequential damages arising

out of or as a result of any defects in or failure of its products or any par t or parts thereof or arising out of or as a result of parts or components incorporated in Seller’s equipment but not supplied by the Seller.

Your Local CUNO Distributor:

®

a 3M company

CUNO Incorporated

400 Research Parkway

Meriden, CT 06450

U.S.A.

(800) 243-6894

(203) 237-5541

Fax (230) 630-4530

www.CUNO.com

CUNO and Betafi ne are trademarks

of 3M Company used under license.

3M is a trademark of 3M Company.

Mykrolisis is a trademark of Entegris, Inc.

Millipore is a trademark of Millipore Corporation.

Water Quality Association is a trademark of Water

Quality Association.

© 2009 3M Company. All rights reserved.

70-0201-8686-5

LITCBFXL.1110

Loading...

Loading...