Page 1

9100 FX

3M Occupational Health and

Environmental Safety Division

3M Center, Building 0235-02-W-70

St. Paul, MN 55144-1000

Printed in USA

© 3M 2011. All rights reserved.

3M and Speedglas are trademarks of 3M Company, used under license in Canada

Kevlar is a trademark of E.I. du Pont de Nemours and Company.

3M Occupational Health

and Environmental Safety Division

3M Canada Company

P.O. Box 5757 London, Ontario N6A 4T1

Printed in USA

© 3M 2011. All rights reserved.

3M and Speedglas are trademarks of 3M Company, used under license in Canada

Kevlar is a trademark of E.I. du Pont de Nemours and Company.

Division des produits d’hygiène

industrielle et de sécurité

environnementale de 3M

Compagnie 3M Canada

C.P. 5757

London (Ontario) N6A 4T1

Imprimé au Canada.

© 3M, 2011. Tous droits réservés.

3M et Speedglas sont des marques de commerce de 3M, utilisées sous licence au Canada.

Kevlar est une marque déposée d’E.I. duPont de Nemours and Company.

3M México S.A. de C.V.

Av. Santa Fe No. 190

Col. Santa Fe, Del. Álvaro Obregón

México D.F. 01210

Impreso en EUA.

© 3M 2011. Todos los derechos reservados.

3M y Speedglas son marcas comerciales de 3M Company, usadas bajo licencia en Canadá.

Kevlar es una marca comercial de E.I. du Pont de Nemours and Company.

Welding Helmet User Instructions

Directives d’utilisation pour le masque pour soudeurs

Instrucciones de la Careta para soldadura

IMPORTANT: Before use, the wearer must read and understand these User Instructions. Keep these User

Instructions for reference.

IMPORTANT : Avant de se servir du produit, l’utilisateur doit lire et comprendre les présentes directives

d’utilisation. Conserver ces directives d’utilisation à titre de référence.

IMPORTANTE: Antes de usar el producto, el usuario debe leer y entender estas Instrucciones. Conserve estas

Instrucciones para referencia futura.

98-0060-0194-9/1

34-8706-8887-5

Page 2

Table of Contents

System Description ............................................................................................................................... 1

Warnings and Cautions ......................................................................................................................... 1

Limitations of Use ................................................................................................................................. 2

Specifi cations ....................................................................................................................................... 2

Operating Instructions ........................................................................................................................... 4

Helmet Adjustment ...................................................................................................................... 4

ADF Function ............................................................................................................................... 9

System Components and Replacement Parts ...................................................................................... 13

System Inspection and Maintenance ................................................................................................... 16

Cleaning and Storage .......................................................................................................................... 23

Disposal.............................................................................................................................................. 23

Warranty ..............................................................................................................................................23

For More Information ...........................................................................................................................23

Page 3

SYSTEM DESCRIPTION

These User Instructions are applicable to the 3M™ Speedglas™ Welding Helmet, 9100 FX. The 3M Speedglas

Welding Helmet, 9100 FX with auto-darkening fi lter (ADF), is designed to help protect the wearer’s eyes from

harmful radiation including visible light, ultra-violet radiation (UV) and infrared radiation (IR) resulting from

certain arc, plasma and gas welding/cutting processes when used in accordance with these User Instructions.

Three sensors on the front of the auto-darkening fi lters (ADFs) react independently at the moment the welding

arc is struck and cause the fi lter to darken. The ADF switches back to the light shade after the welding arc

has stopped. Two lithium batteries are used as the power source. Protection from ultra-violet radiation (UV)

and infrared radiation (IR) is continuous, whether the ADF is in the light or the dark state due to the protective

purple lens coating known as a bandpass fi lter. In the event of battery or electronic failure, the welder remains

protected against UV and IR radiation equivalent to the darkest shade setting (shade 13).

These welding helmets offer a clear wideview polycarbonate lens that is ideal for precision weld preparation

under a variety of lighting conditions. The clear lens meets ANSI Z87.1-2010 and CSA Z94.3 requirements

for high impact eye and face protection and provides limited protection against certain fl ying particles. To use

the clear lens, the user simply lifts up the spring-mounted welding shield, which holds the auto-darkening

welding fi lter (ADF) securely in a raised position for weld preparation. The spring-mounted welding shield

must be returned to the down position prior to welding.

LISTING OF WARNINGS WITHIN THESE USER INSTRUCTIONS

W WARNING

• Do not use any welding product without appropriate training. For proper use, see supervisor or User

Instructions or call 3M in U.S.A.1-800-243-4630. In Canada, call Technical Service at 1-800-267-4414.

• The 3M Speedglas Welding Helmet, 9100 FX has passed the requirements of the ANSI Z87.1-2010 and

CSA Z94.3 for ignition resistance. However, under certain circumstances, these products may support

a fl ame. Users must evaluate hazards in the workplace and take appropriate precautions for those

hazards. 3M does not recommend the use of these products in areas where contact with an open

fl ame is possible. Improper use may result in injury or death.

• Always wear ANSI Z87.1 compliant safety spectacles in addition to any welding headgear. Failure

to do so may result in permanent eye injury and vision loss. In Canada, users should follow CSA

Z94.3 and/or the eyewear requirements of the authority having jurisdiction in their region.

• Never modify or alter this welding helmet. Repair or replace parts only with approved 3M components.

Utilizing components other than those supplied by 3M may adversely affect the performance of the

welding helmet and may result in serious injury or death.

• This headgear must not be painted or cleaned with solvents. Any decals applied to the headgear must

be compatible with the surface material and known not to affect adversely the characteristics of the

materials used in the headgear. Decals may affect the fl ammability characteristics of this headgear.

• Any headgear subjected to severe impact should be replaced.

• The SideWindows should be covered with the cover plates in situations when other welders are

working beside you and in situations where refl ected light can pass through the SideWindows.

W WARNING

• Should the 3M™ Speedglas™ Auto Darkening Filter (ADF) fail to switch to dark mode upon striking an

arc, stop welding immediately and inspect the ADF as described in these User Instructions. Continued

use of an ADF that fails to switch to the dark state may result in permanent eye injury and vision

loss. If the problem cannot be identifi ed and corrected, do not use the ADF; contact your supervisor,

distributor or 3M for assistance.

• Carefully inspect the complete 3M Speedglas 9100 Welding Filter before each use. Cracked, pitted

or scratched fi lter glass or protection plates reduce vision and can seriously impair protection. All

damaged components should be replaced immediately. Remove any protective fi lm from the visor.

• The 3M Speedglas Welding Helmet, 9100 FX is not designed for heavy duty overhead welding/cutting

operations due to the risk of burns from falling molten metal. Use of this product for these applications

may result in serious injury or death.

• The 3M Speedglas Welding Helmet, 9100 FX (used with 3M Speedglas Series 9100 ADFs) are not

suitable for laser welding or welding processes that require shade 14 or higher fi lters. Use of this

product for these applications may result in permanent eye injury and vision loss.

• Only operate the ADF at temperatures between 23°F (–5°C) and 131°F (+55°C). If used outside of

this range, the fi lter may not perform as designed and may result in permanent eye injury and

vision loss.

CAUTION:

Dispose of equipment that has reached its in tended service life in accordance with local regulations.

LIMITATIONS OF USE

Important Use Limitations:

• These products do not provide any protection from respiratory hazards that may result from welding

processes or from other sources. 3M Speedglas Helmet 9100 FX Series may be worn in conjunction with

certain respirator models. For more information about respiratory protection for welders, contact 3M

Technical Service at 1-800-243-4630. In Canada, call Technical Service at 1-800-267-4414.

Note: The 3M Speedglas Welding Helmet, 9100 FX contains no component made from natural rubber

latex.

SPECIFICATIONS

Eye and face protection Meets ANSI Z87.1-2010, high impact

requirements and CSA Z94.3

Head top impact None- does not offer head top impact protection

Operating Temperatures 23°F to 131°F (-5°C to 55°C)

1 2

Page 4

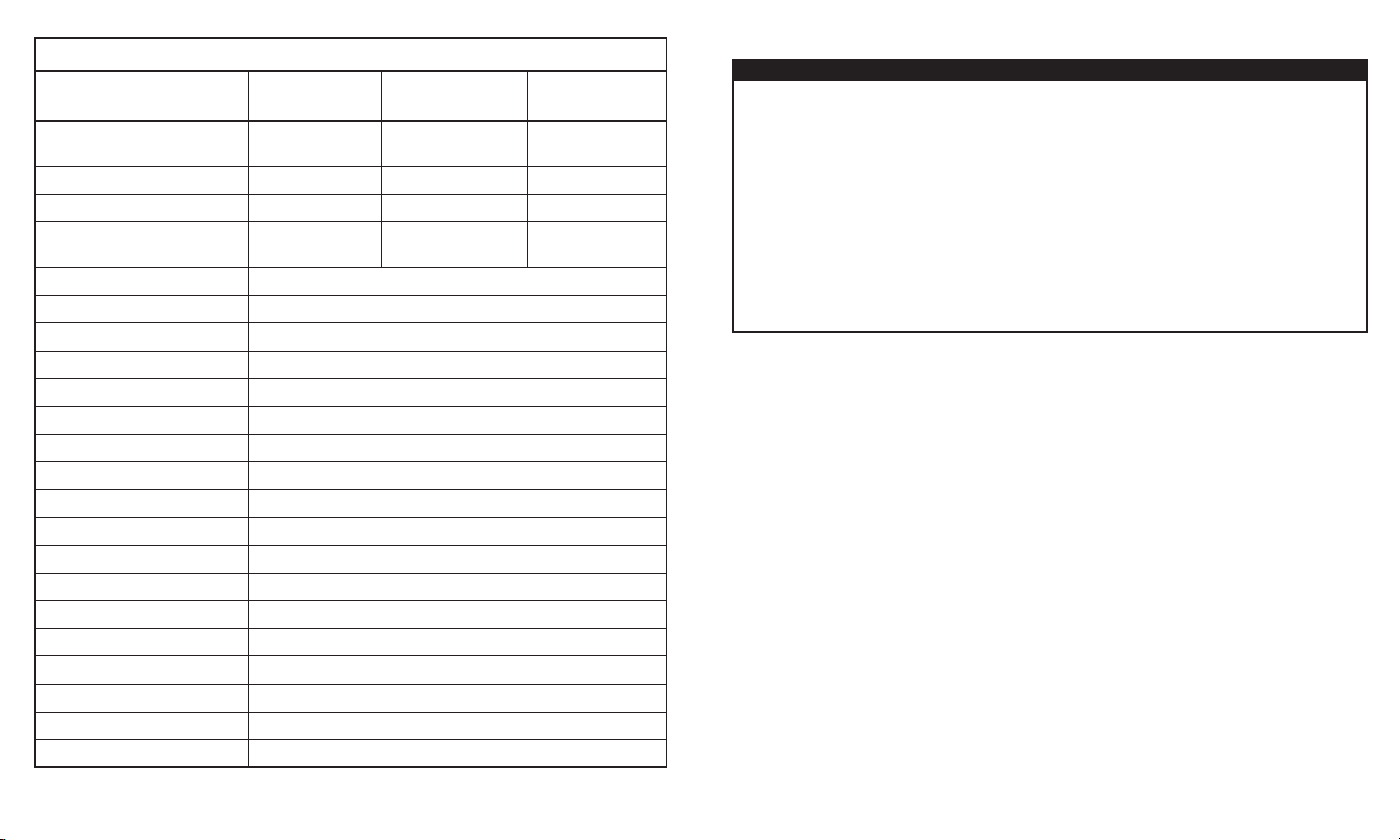

Table 1. Specifi cations for 3M™ Speedglas™ Welding Helmets

Technical Data

Viewing Area

Battery Life (2 x CR-2032) (min.) 2,800 hours 2,500 hours 2,000 hours

Solar Assist Yes Yes No

9100 FX Weight Comp. Assy w/

SideWindows (approx.) 19.1oz (550g) 19. 8 oz (560g) 20.6 oz (585g)

Dark Shades Shades 5, 8, 9, 10, 11, 12, 13

Light State Shade 3

Switching Speed < 0.1 ms (+23°C)

Special Modes Grind, Tack, Lock-in

Sensitivity Modes 5 levels

TIG Rating > 1 Amp

Number of Sensors 3 (2 eye-level, 1 center)

Delay (Recovery) Adjustable 40 - 1300 ms

Temperature Range 23°F to 131°F (-5°C to 55°C)

Standards Compliance ANSI Z87.1-2010 & CSA Z94.3-2007

Warranty 2 Years

Head sizes 6 ¼ to 8 inch (50-64 cm)

Shield PPA

Silver Front and ADF Housing Nylon

Headband Nylon, PP, PE, TPE

SideWindows Polycarbonate

Protection Plates Polycarbonate

Flame Resistant Fabric 75% Cotton, 25% Kevlar® synthetic fi ber

9100 FX-V

Welding Helmet

1.8 x 3.7 in

(45 x 93 mm)

9100 FX-X

Welding Helmet

2.1 x 4.2 in

(54 x 107 mm)

9100 FX-XX

Welding Helmet

2.8 x 4.2 in

(72 x 107 mm)

OPERATING INSTRUCTIONS

W WARNING

The 3M™ Speedglas™ Welding Helmet, 9100 FX has passed the requirements of the ANSI Z87.1-2010

and CSA Z94.3 for ignition resistance. However, under certain circumstances, these products may support

a fl ame. Users must evaluate hazards in the workplace and take appropriate precautions for those hazards.

3M does not recommend the use of these products in areas where contact with an open fl ame is possible.

Improper use may result in injury or death.

The SideWindows should be covered with the cover plates in situations when other welders are working

beside you and in situations where refl ected light can pass through the SideWindows.

The 3M Speedglas Welding Helmet, 9100 FX is not designed for heavy duty overhead welding/cutting

operations due to the risk of burns from falling molten metal. Use of this product for these applications

may result in serious injury or death.

Always wear ANSI Z87.1 compliant safety spectacles in addition to any welding headgear. Failure to do so

may result in permanent eye injury and vision loss. In Canada, users should follow CSA Z94.3 and/or

the eyewear requirements of the authority having jurisdiction in their region.

Unpacking

Inspect the package contents for shipping damage and ensure all components are present. The product

should be inspected before each use following the procedures in the Inspection section of these User

Instructions.

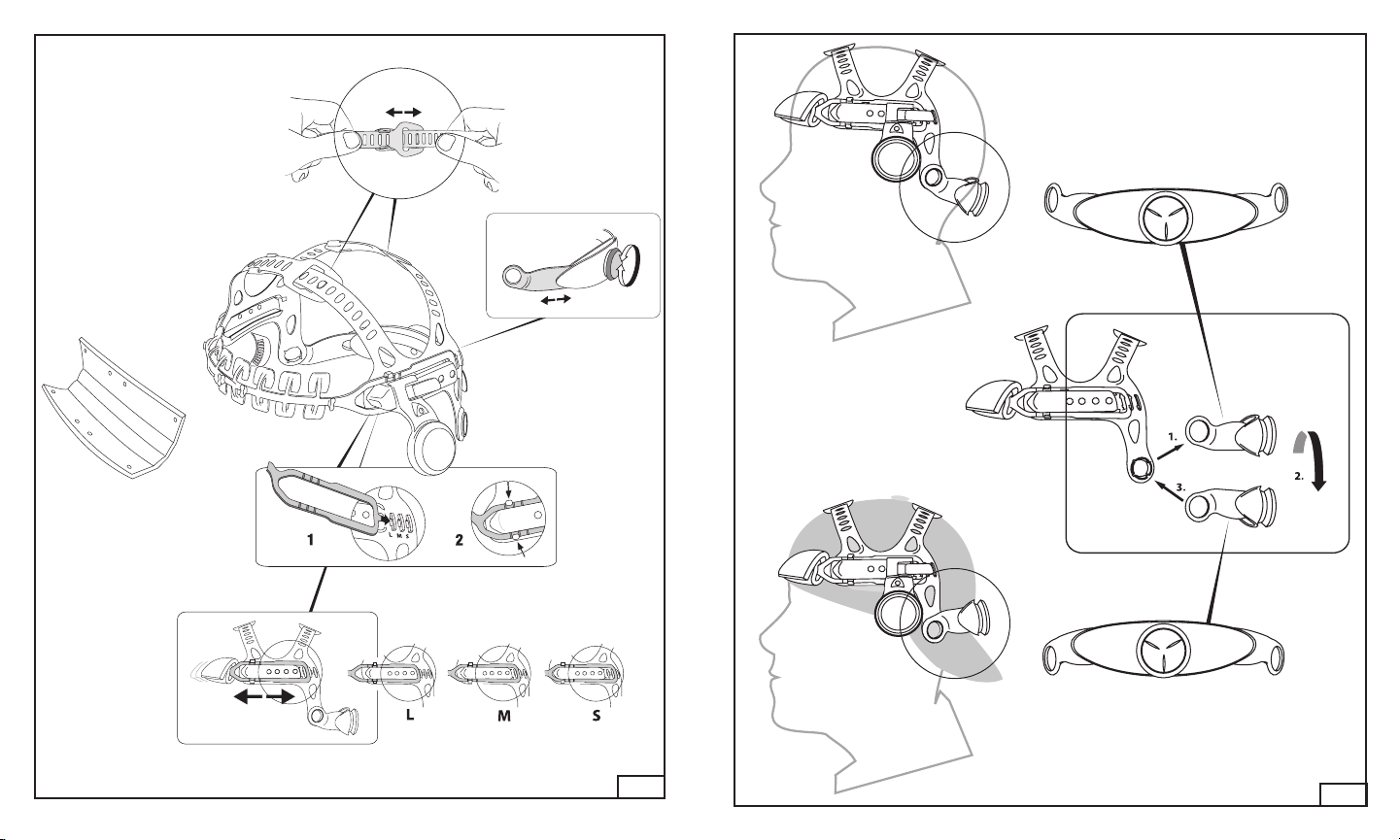

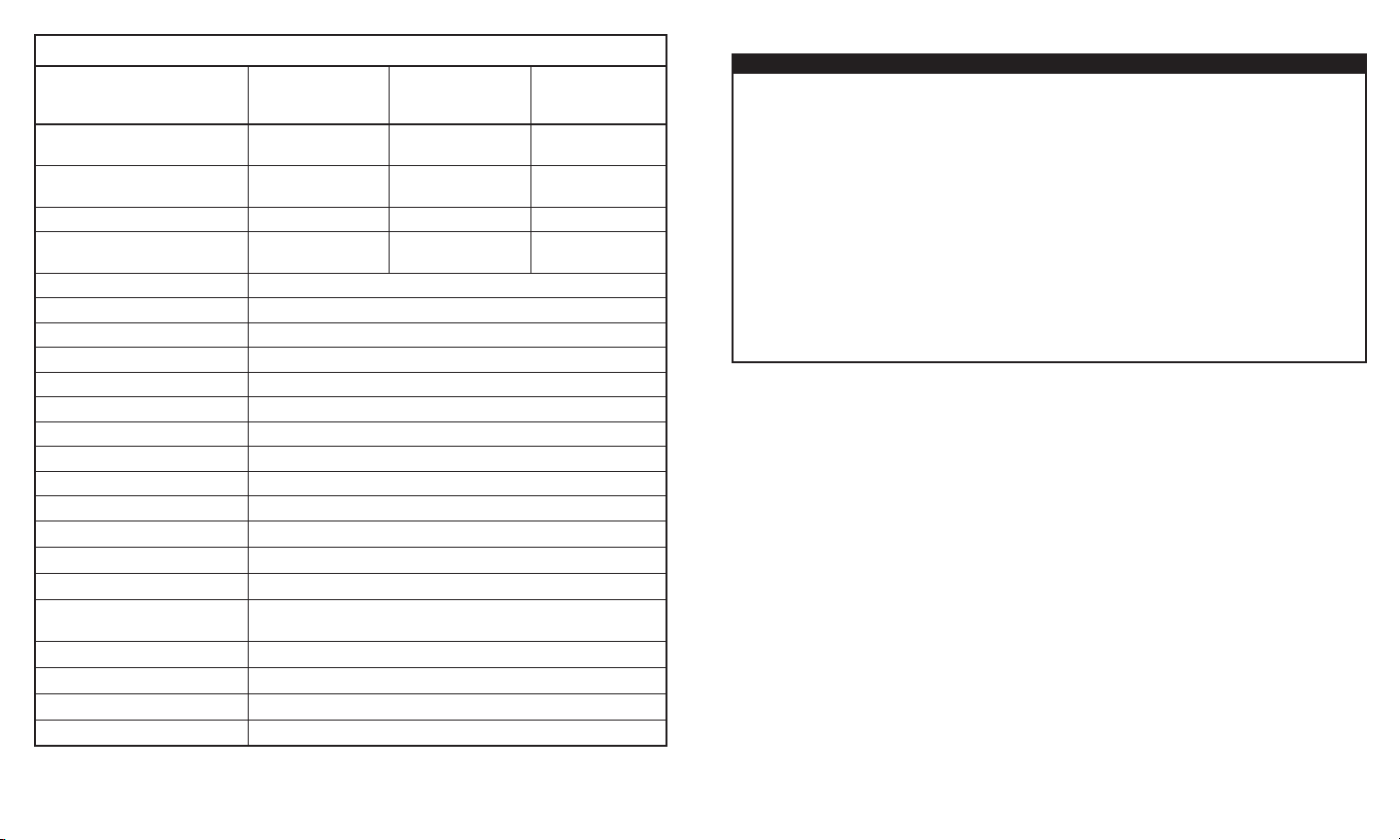

Helmet Adjustment

Note: The following adjustments should be made to help ensure that the 3M Speedglas Welding

Helmet, 9100 FX is properly adjusted and fi tted prior to use.

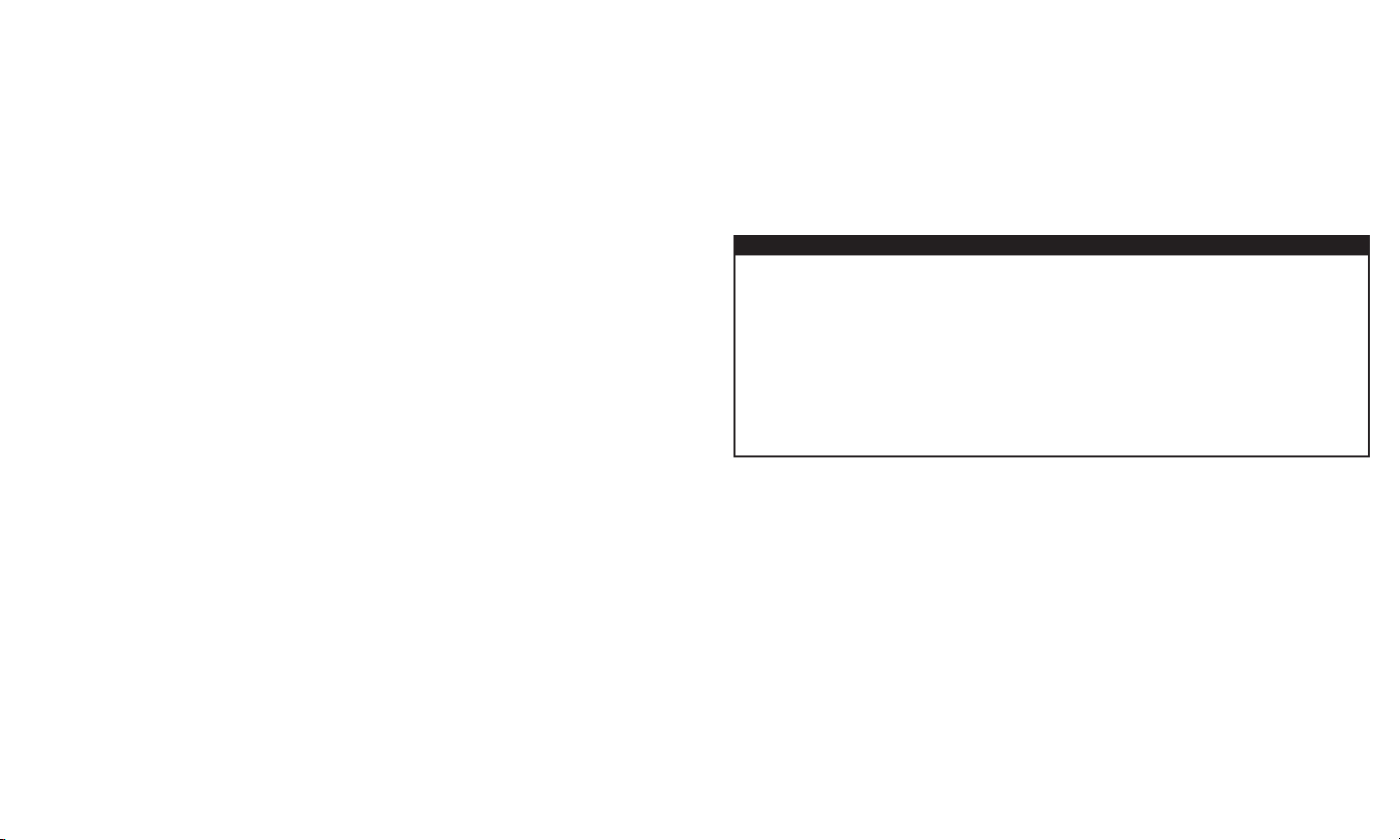

1) Place the 3M Speedglas Welding Helmet, 9100 FX on the head and tighten the ratchet on the back

of the headgear (Fig.1) until a comfortable, but secure fi t is achieved. If a comfortable fi t can not be

achieved using the ratchet alone, use the coarse adjustment of the front headband where the L, M, and

S adjustment are as shown in the bottom of Fig. 1. L refers to a larger head circumference, M is for a

medium head circumference and S is for a smaller head circumference. Adjust the course adjustment

based on head circumference, and then replace the helmet on the head and tighten the ratchet to achieve

a comfortable but secure fi t. For additional adjustment, the ratchet may also be turned 180 degrees to

achieve a slightly different fi t based on position as shown in Fig. 2.

2) The two top, crown straps should be adjusted to assure that the weight of the helmet is distributed and

carried evenly on the top of the head. With the helmet on, and the ratchet tightened, check to make sure

that both crown straps are adjusted so that there is no excess space or gaps between the top of the head,

and the crown straps. At times, the back crown strap may be too large and cause a gap, but this is not

an appropriate manner for wearing the helmet. If there is an excessive gap, adjust the crown straps by

sliding and tightening as shown in Fig. 1. If there is no gap, but the helmet feels as though it is too high

on the head, loosen the crown straps until a comfortable height is achieved.

3 4

Page 5

Fig. 1

5 6

Fig. 2

Page 6

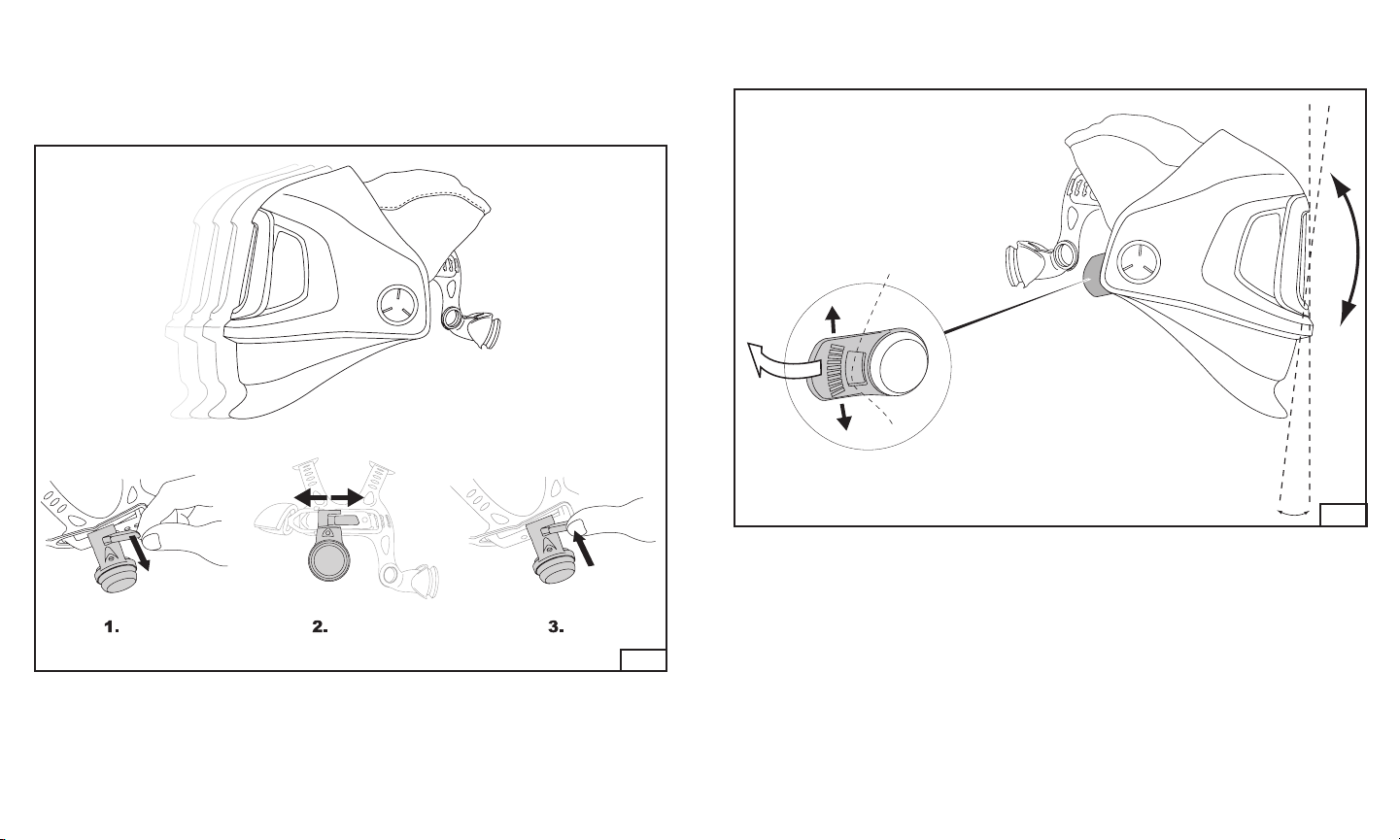

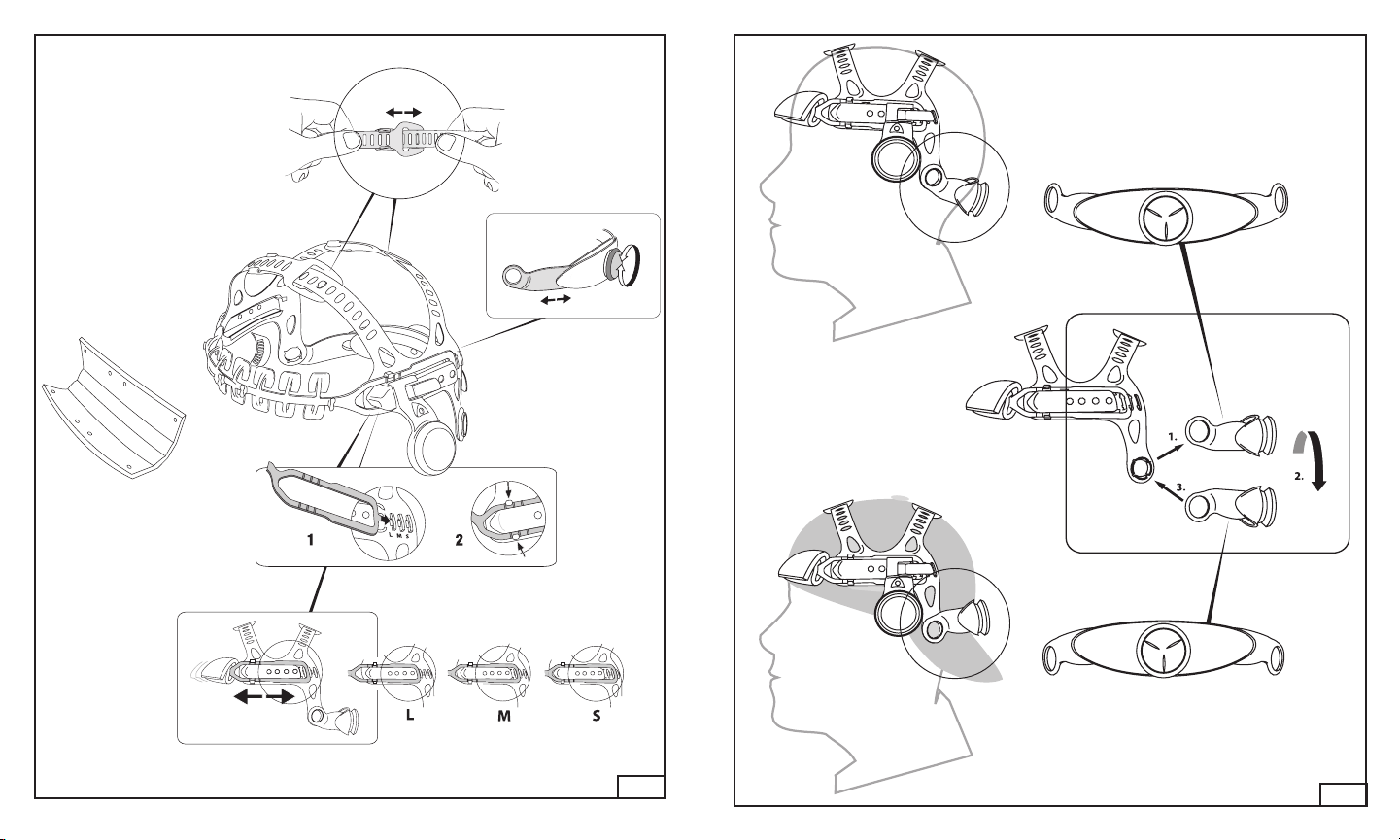

3) Next, the front-to-back, or fore/aft position of the helmet, should be adjusted so that the helmet is a

comfortable distance from your face, but not touching your nose or face. The front-to-back adjustment

can be achieved by moving the slide adjustments in the headgear which also moves the helmet back

and forth as shown in Fig. 3. It is a good idea to make sure that the settings on both sides of the slide

adjustment are at the same position to help with balance and overall comfort.

4) With the helmet on the head, adjust the vertical viewing angle as shown in Fig. 4 to optimize the viewing

area and position of the helmet relative to the workplace application.

Fig. 4

Fig. 3

7 8

Page 7

ADF Function

W WARNING

Should the 3M™ Speedglas™ Auto Darkening Filter (ADF) fail to switch to dark mode upon striking an arc,

stop welding immediately and inspect the ADF as described in these User Instructions. Continued use of

an ADF that fails to switch to the dark state may result in permanent eye injury and vision loss. If the

problem cannot be identifi ed and corrected, do not use the ADF; contact your supervisor, distributor or 3M

for assistance.

The 3M Speedglas Welding Helmet, 9100 FX (used with 3M Speedglas Series 9100 ADF) is not suitable

for laser welding or welding processes that require shade 14 or higher fi lters. Use of this product for these

applications may result in permanent eye injury and vision loss.

Only operate the ADF at temperatures between 23°F (–5°C) and 131°F (+55°C). If used outside of this

range, the fi lter may not perform as designed and may result in permanent eye injury and vision loss.

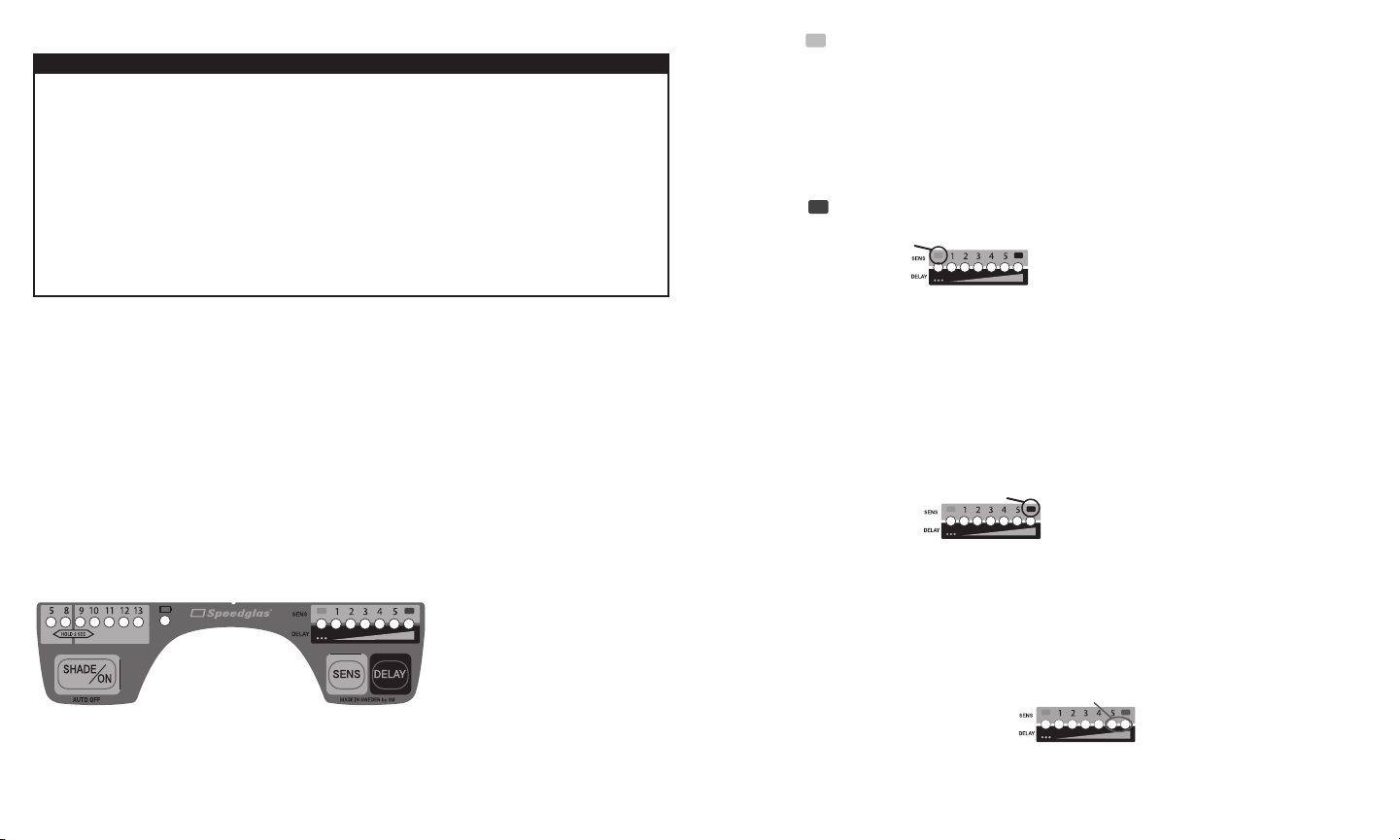

On/Off

To activate the ADF, press the SHADE/ON button. The ADF automatically turns OFF after 1 hour of inactivity.

The ADF has three photo sensors that react independently and cause the fi lter to darken when a welding arc

is struck. The ADF may not turn dark if the sensors are blocked or the welding arc is totally shielded. Flashing

light sources (e.g. safety strobe lights) can trigger the ADF making it fl ash when no welding is occurring. This

interference can occur from long distances and/or from refl ected light. Welding areas must be shielded from

such interference.

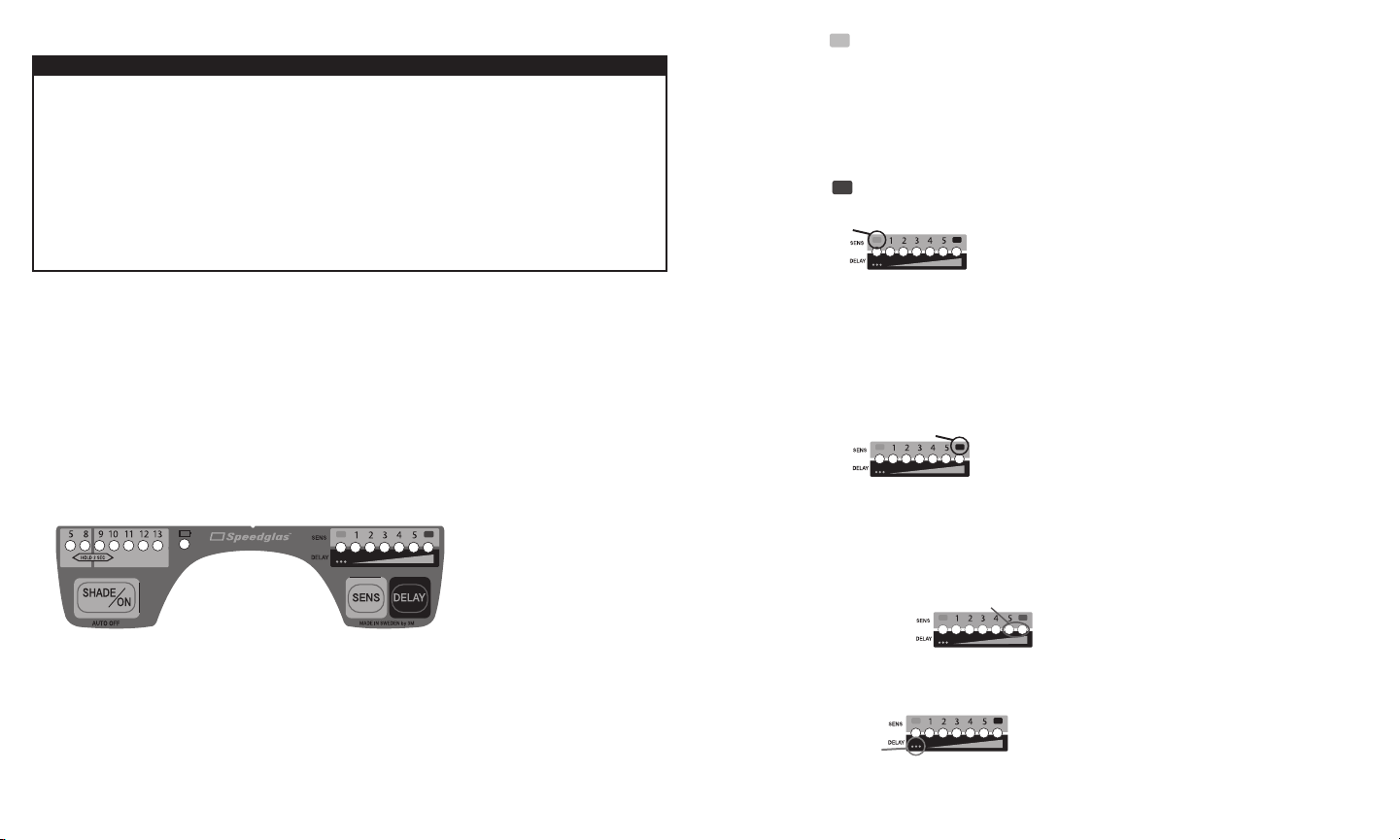

Shade

Seven different shade settings are available, split into two groups, 5, 8 and 9-13. In order to see the current

shade setting, momentarily press the SHADE/ON button. To change shade, press the SHADE/ON button

repeatedly. Move the fl ashing LED to the desired shade. To shift between the two shade groups (shade 5, 8)

and (shade 9-13); hold the SHADE/ON button down for 2 seconds. In all welding processes the arc should only

be viewed with the recommended dark shade (Table 2).

Position Light-State Lock (Grinding Mode) – switching function is disabled, remains in

constant shade 3.

Position 1 Least sensitive setting. Used if there is interference from other welders’ arcs in

the vicinity.

Position 2 Default setting. Used for most types of welding, indoors and outdoors.

Position 3 For welding with stable welding arcs (e.g., TIG welding).

Position 4 For low current TIG welding or inverter-type welding machines.

Position 5 For TIG welding where part of the arc is obscured from view.

Position Dark-State Lock – switching function is disabled, remains in selected dark

shade.

Light-State Lock

This setting is intended for grinding or other non-welding activities. When the ADF is locked in the light state

(shade 3) the LED under the symbol will fl ash every 8 seconds to alert the user. The ADF must be changed to

an appropriate SENS setting before arc welding or it will remain in the light-state lock mode. When the ADF

turns off (after 1 hour inactivity), it will automatically return to the default sensitivity setting 2.

Position 1-5

If the fi lter does not darken during welding as desired, increase the sensitivity until the ADF switches reliably.

Should the sensitivity be set too high, the fi lter may remain in the dark state after welding is complete due

to ambient light. In this case, adjust the sensitivity downward to a setting where the ADF both darkens and

lightens appropriately.

Dark-State Lock

This setting locks the ADF in the selected dark shade. If the ADF turns off (after 1 hour inactivity), it will

automatically return to the default sensitivity setting 2.

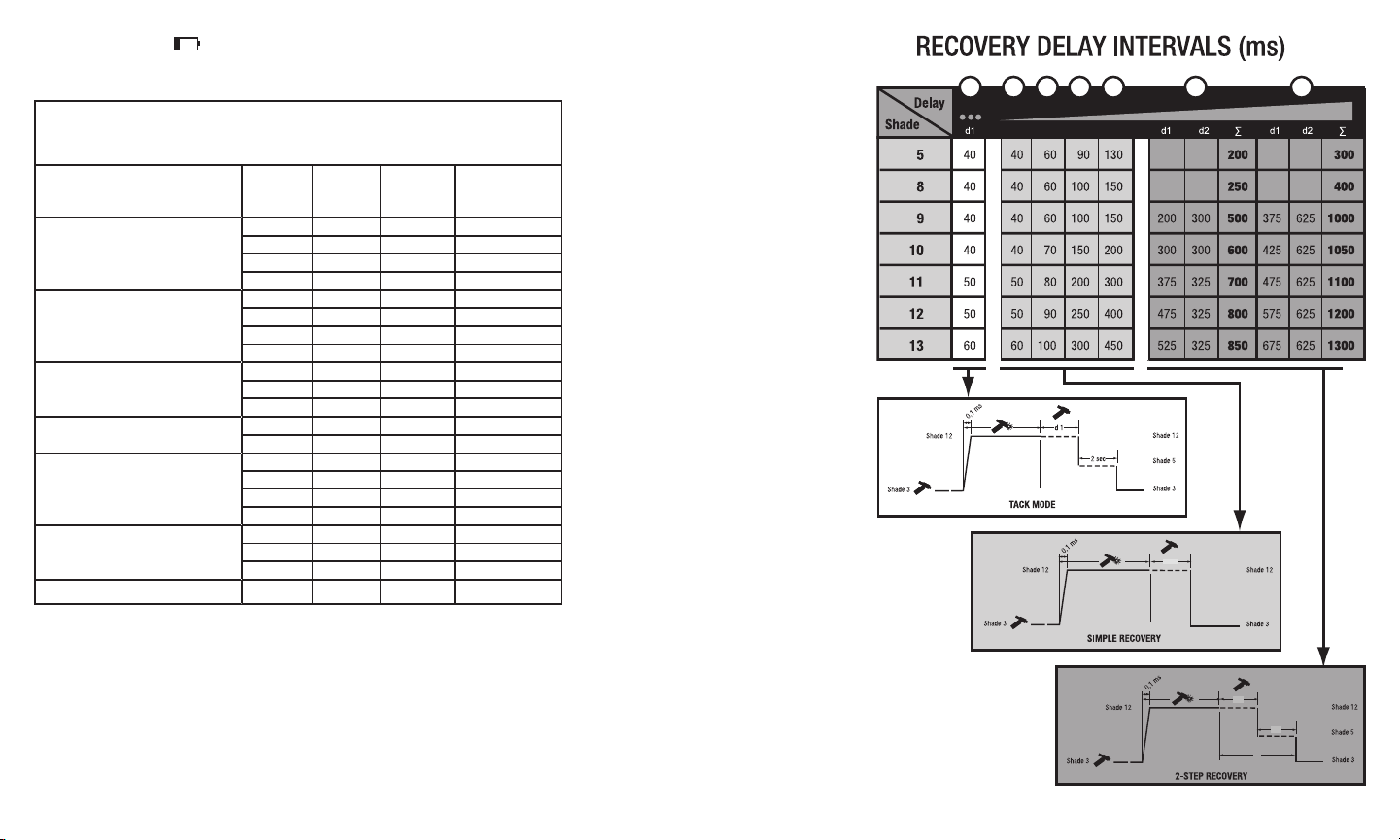

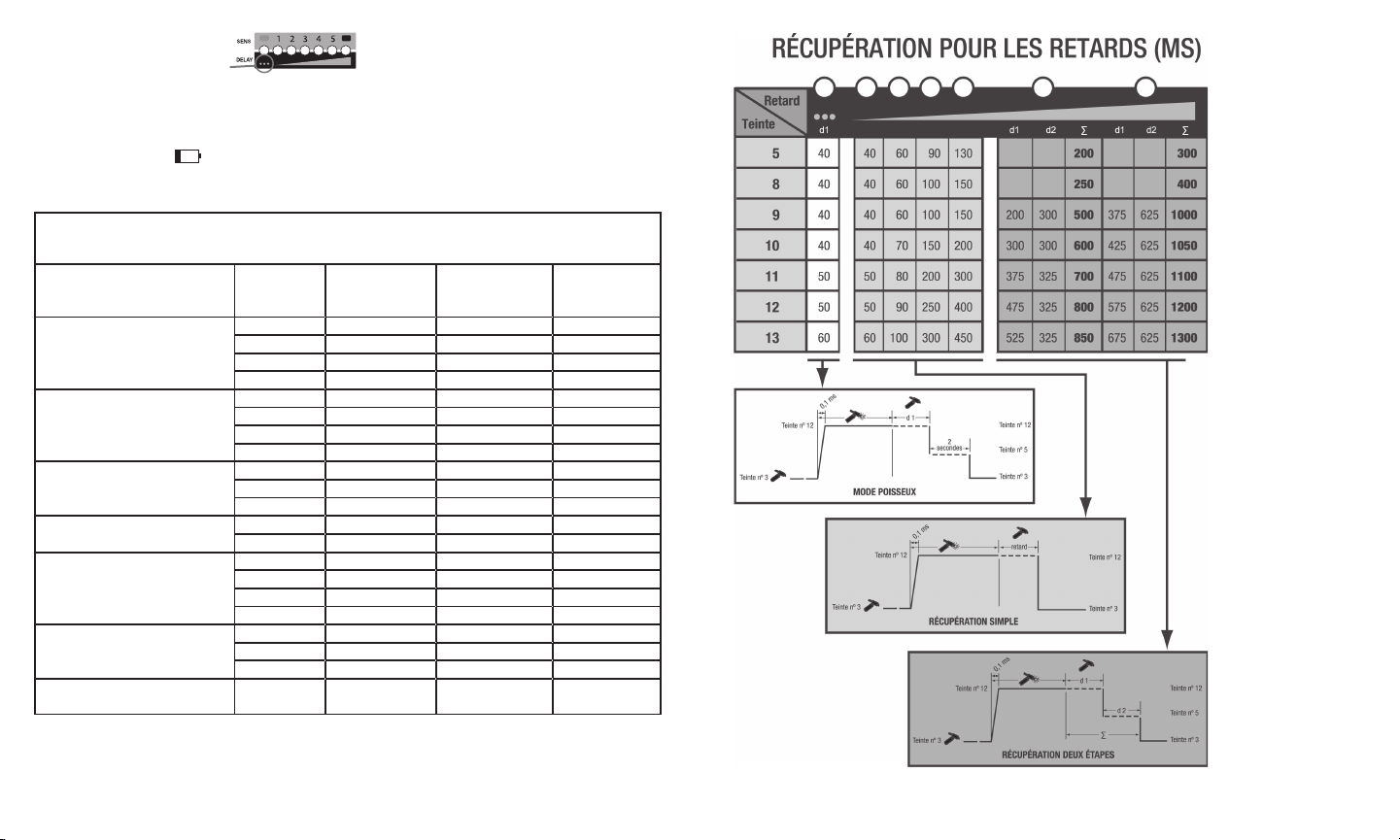

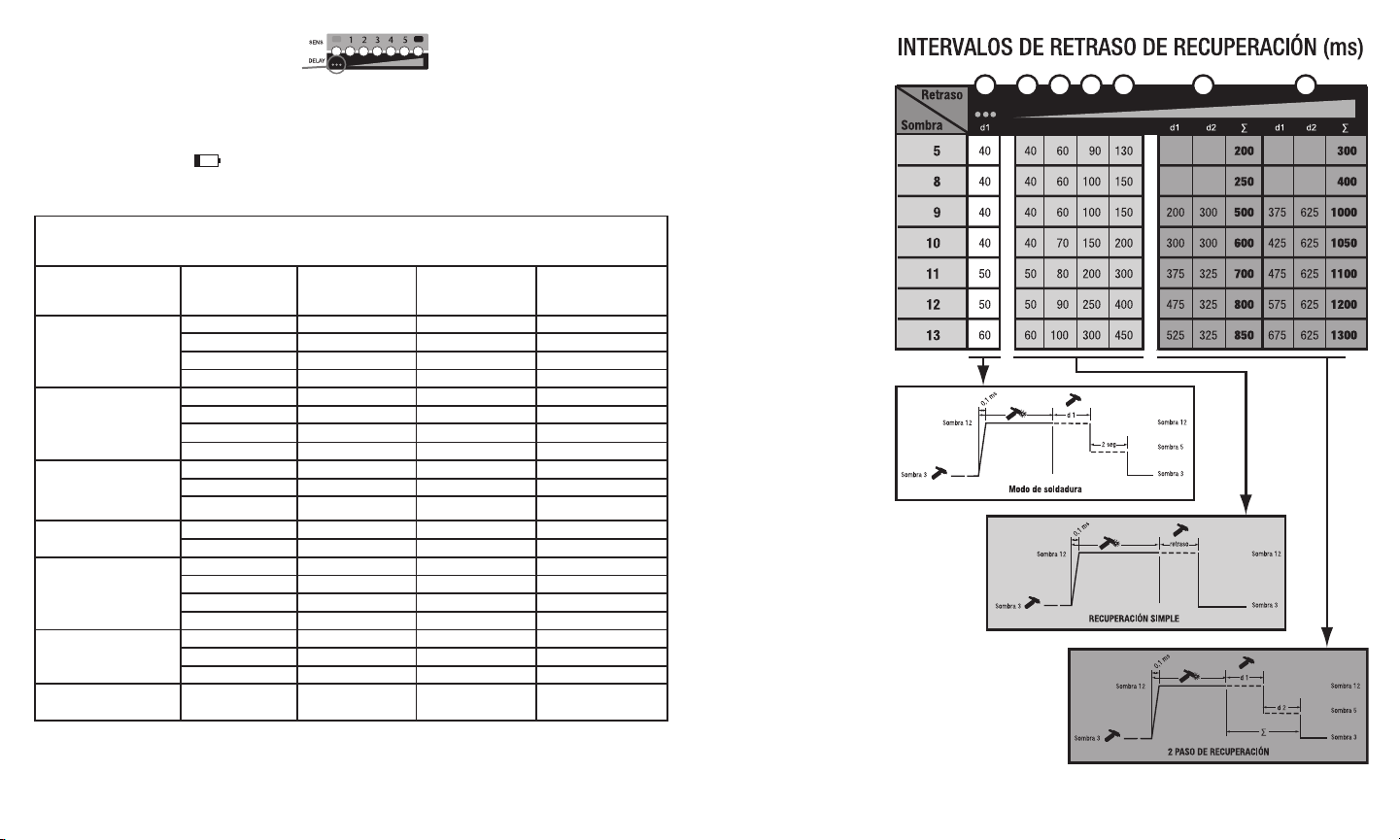

Delay

The delay function allows the user to manually increase or decrease the recovery delay time (from dark to

light) according to the requirements of the welding process. The recovery time intervals are also automatically

extended as the shade increases. The time intervals are listed in milliseconds in Table 3. Although the Delay

and Sensitivity functions share the same LED display, they are separate adjustments.

Sensitivity Selection

The programming and sensitivity of the photo detector system can be adjusted to accommodate a variety

of welding processes and workplace conditions. To change the sensitivity setting, press the SENS button

repeatedly until the LED shows the desired setting.

9 10

2-Step Recovery

The two longest delay settings include an intermediate stage in the recovery. As the arc

extinguishes, the fi lter will briefl y recover to shade 5 and then to shade 3. The time intervals for

each stage are listed as d1 and d2 in Table 3.

Tack Mode

This setting may help reduce eye fatigue resulting from the eye frequently adjusting to differing

light levels during rapid tack welding. As the arc extinguishes, the fi lter will recover to shade 5. If

another arc is not struck within 2 seconds the fi lter will return to the normal light state (shade 3).

Page 8

Low Battery Indicator

The batteries should be replaced when the low battery indicator fl ashes or LEDs do not fl ash when the

buttons are pressed.

Table 2. Recommended Guide for Shade Numbers

(Adapted from ANSI Z49.1-2003)

Operation

Electrode

diameter

inches

Arc

current,

amps

Minimum

Protective

Shade

Recommended

Shade

Number

Shielded metal arc < 3 < 60 7 ---

3-5 60-160 8 10

5-8 160-250 10 12

> 8 250-550 11 14

Gas-metal-arc welding < 60 7 ---

60-160 10 11

160-250 10 12

250-500 10 14

Gas-tungsten-arc < 50 8 10

50-150 8 12

150-500 10 14

Air-carbon-arc cutting

< 500 10 12

500-1000 11 14

Plasma-arc welding

< 20 6 6-8

20-100 8 10

100-400 10 12

400-800 11 14

Plasma-arc cutting < 300 8 9

300-400 9 12

400-800 10 14

Carbon arc welding

14

delay

Table 3

11 12

d 1

d 1

d 2

d 2

∑

Page 9

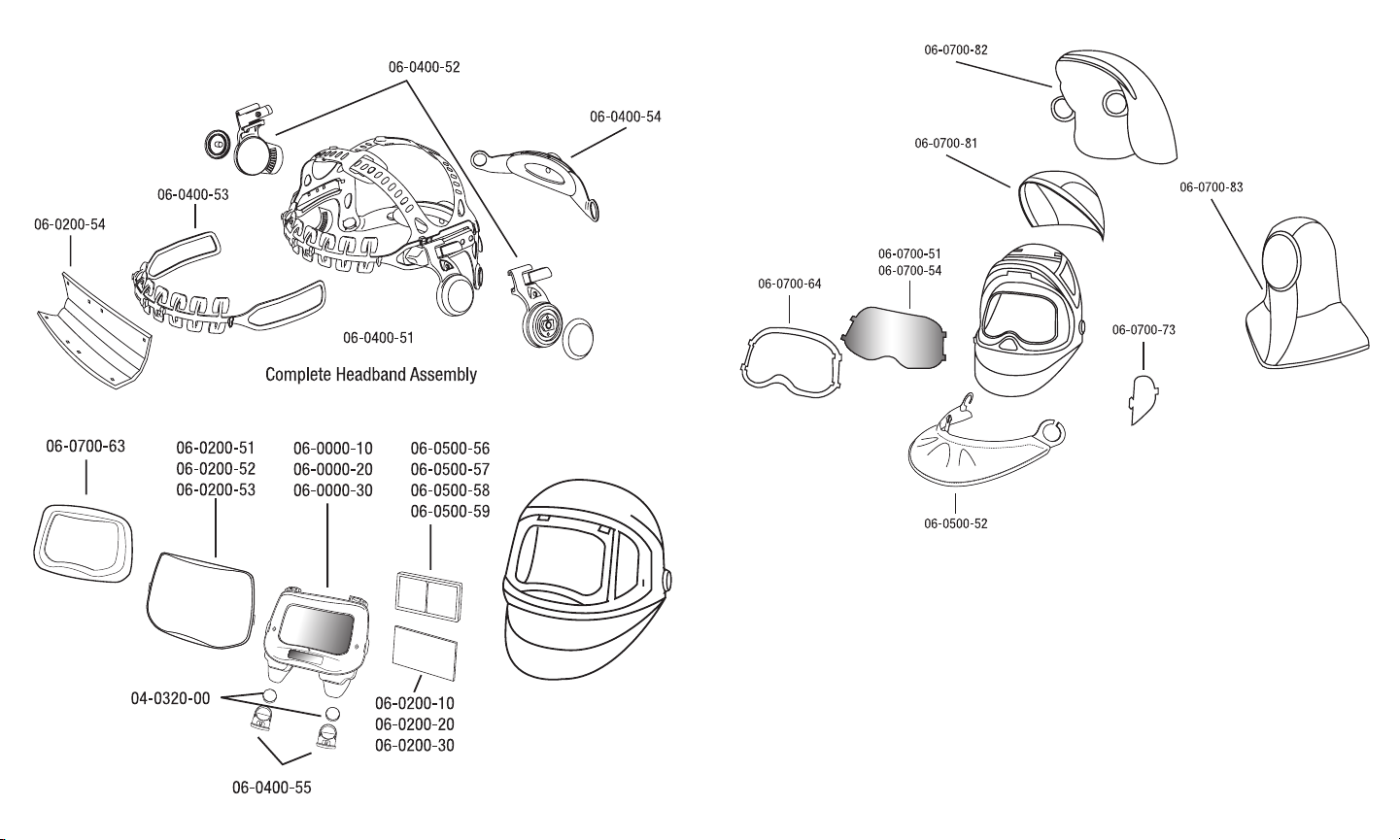

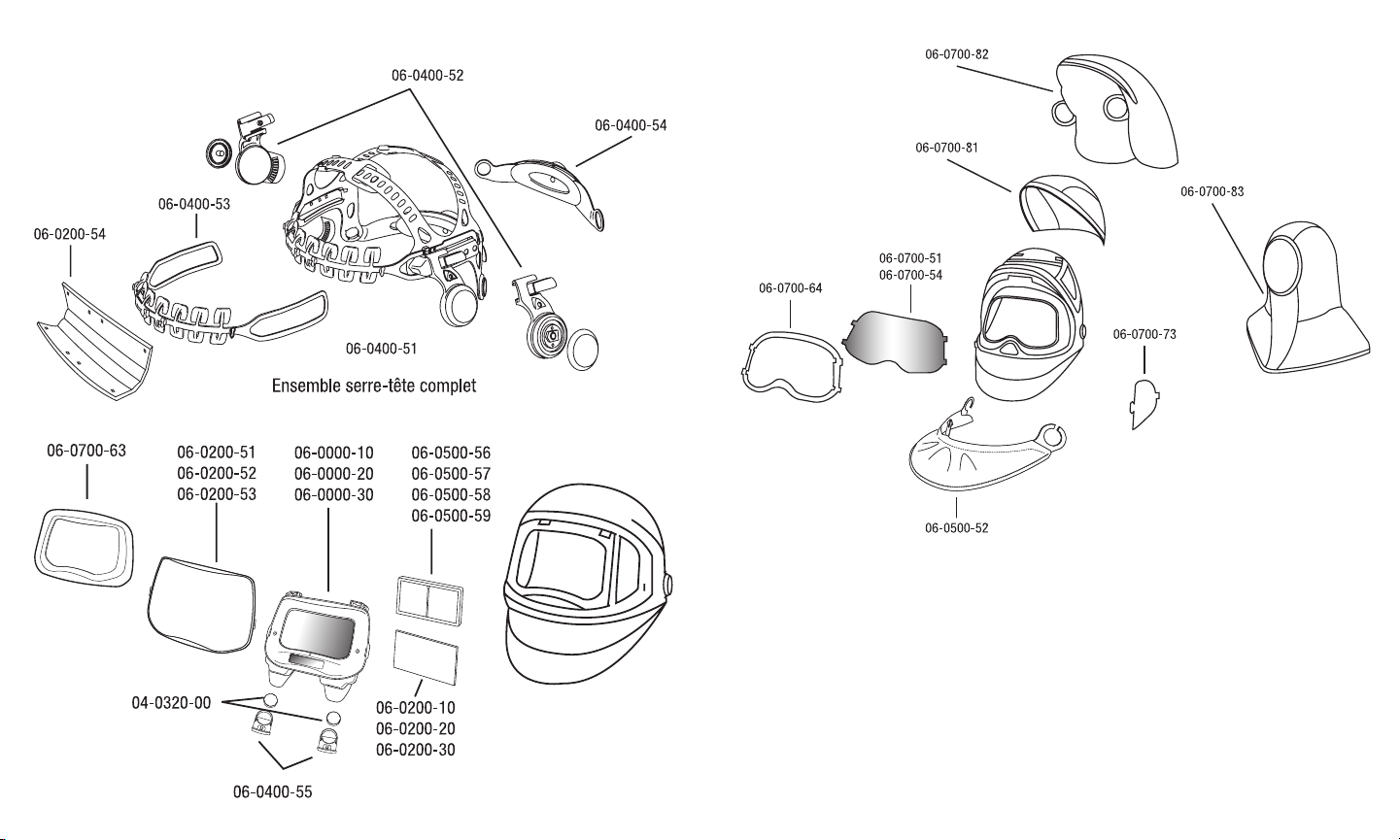

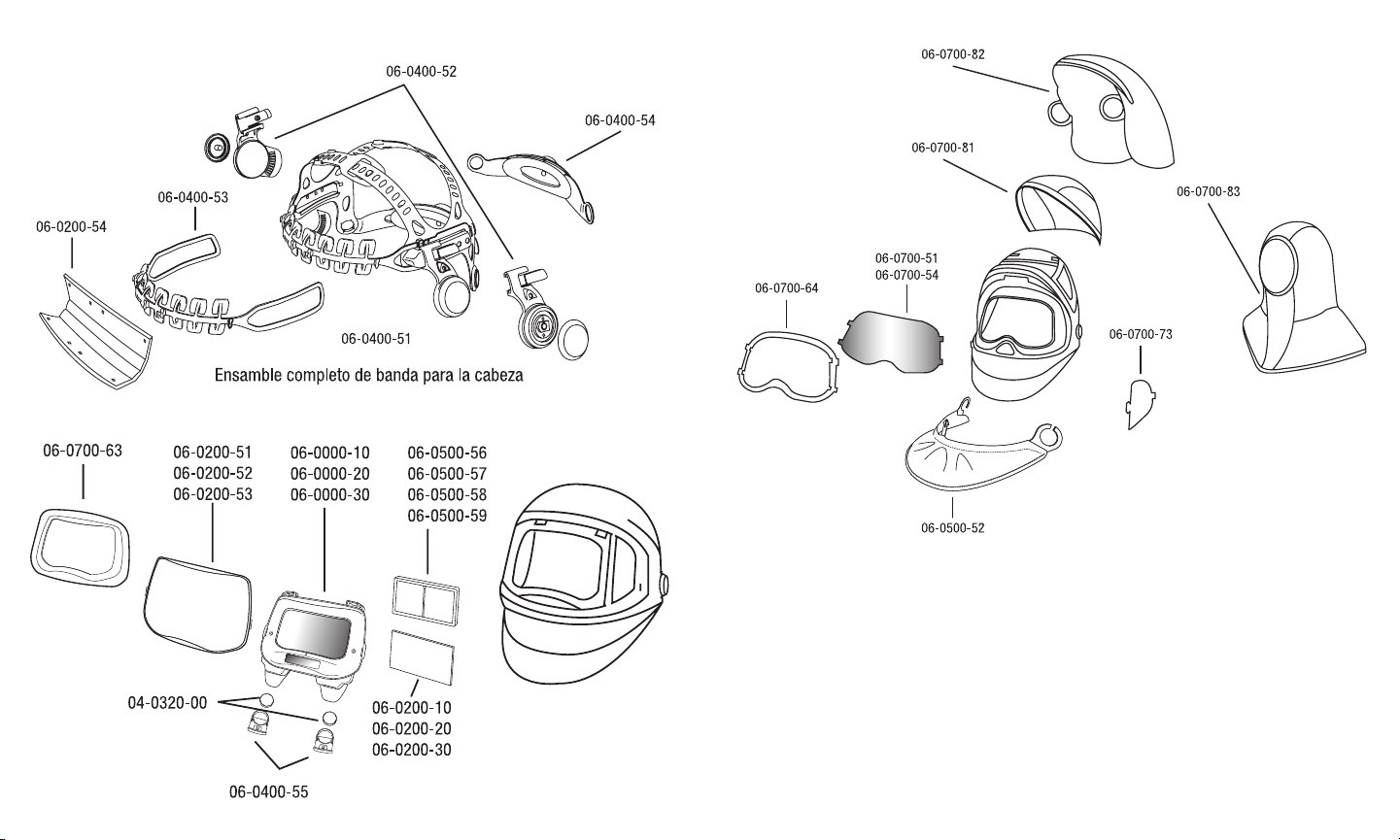

3M™ SPEEDGLAS™ SYSTEM COMPONENTS AND REPLACEMENT PARTS

13 14

Page 10

3M™ Speedglas™ Complete Helmet Assemblies

06-0600-10SW Welding Helmet 9100 FX SideWindows with ADF 9100V

06-0600-20SW Welding Helmet 9100 FX SideWindows with ADF 9100X

06-0600-30SW Welding Helmet 9100 FX SideWindows with ADF 9100XX

3M™ Speedglas™ Replacement Parts and Accessories

04-0320-00 Batteries (CR-2032)

06-0000-10 ADF 9100V

06-0000-20 ADF 9100X

06-0000-30 ADF 9100XX

06-0200-10 Inside Protection Plate 9100V (5 pack)

06-0200-20 Inside Protection Plate 9100X (5 pack)

06-0200-30 Inside Protection Plate 9100XX (5 pack)

06-0201-10 Starter Kit 9100V (5 Outside & 2 Inside Protection Plates, 1 sweatband)

06-0201-20 Starter Kit 9100X (5 Outside & 2 Inside Protection Plates, 1 sweatband)

06-0201-30 Starter Kit 9100XX (5 Outside & 2 Inside Protection Plates, 1 sweatband)

06-0200-51 Outside Protection Plate 9100, Standard

06-0200-52 Outside Protection Plate 9100, Scratch Resistant

06-0200-53 Outside Protection Plate 9100, High Temperature

06-0200-54 Sweatband 9100

06-0400-51 Headband Assembly 9100 Complete (headgear)

06-0400-52 Pivot Mechanism 9100 (Left & Right)

06-0400-53 Headband 9100 Front Part

06-0400-54 Headband 9100 Back Part (ratchet adjuster)

06-0400-55 Battery Holder 9100

06-0500-51 Head Protector 9100, Tecaweld

06-0500-52 Ear and Neck Protector 9100, Tecaweld

06-0500-54 Welding Beanie Hat, (no visor)

06-0500-55 Welding Cap with Visor

06-0500-56 Magnifi cation Plate 1.5X

06-0500-57 Magnifi cation Plate 2.0X

06-0500-58 Magnifi cation Plate 2.5X

06-0500-59 Magnifi cation Plate 3.0X

06-0500-60 Cloth Storage Bag

06-0500-61 Branded Toolbox Decal

15 16

06-0700-51 Wideview Clear Grinding Visor, Standard

06-0700-54 Wideview Clear Grinding Visor, Anti-Fog

06-0700-63 Chrome Front Panel, 9100 FX

06-0700-64 Wideview Clear Grinding Visor Frame, 9100 FX

06-0700-73 SideWindow Covers, 9100 FX

06-0700-81 Standard Headcover, 9100 FX

06-0700-82 Extended Headcover (Head and Neck), 9100 FX

06-0700-83 Full Hood, Black

SYSTEM INSPECTION AND MAINTENANCE

W WARNING

Never modify or alter this welding helmet. Repair or replace parts only with approved 3M components.

Utilizing components other than those supplied by 3M may adversely affect the performance of the welding

helmet and may result in serious injury or death.

This headgear must not be painted or cleaned with solvents. Any decals applied to the headgear must be

compatible with the surface material and known not to affect adversely the characteristics of the materials

used in the headgear. Decals may affect the fl ammability characteristics of this headgear.

Carefully inspect the complete 3M™ Speedglas™ Welding Filter, 9100 before each use. Cracked, pitted or

scratched fi lter glass or protection plates reduce vision and can seriously impair protection. All damaged

components should be replaced immediately. Remove any protective fi lm from the visor.

Any headgear subjected to severe impact should be replaced.

Inspect the welding helmet and headgear for any worn or damaged parts. Replace any worn or damaged

parts utilizing those components listed in the replacement parts and accessories list contained in this User

Instruction.

To check for proper ADF operation, hold the ADF within a few inches of a fl uorescent light bulb and observe

the ADF switch to the selected dark state. Depending on the light source, it may be necessary to temporarily

increase the sensitivity setting. Optionally, the ADF can be triggered by pointing any electronic device remote

control (e.g. television) at the ADF sensors and by pushing the “On” button.

Note: If the ADF does not function as described in these User Instructions, do not use and immediately contact

your supervisor or 3M representative.

Page 11

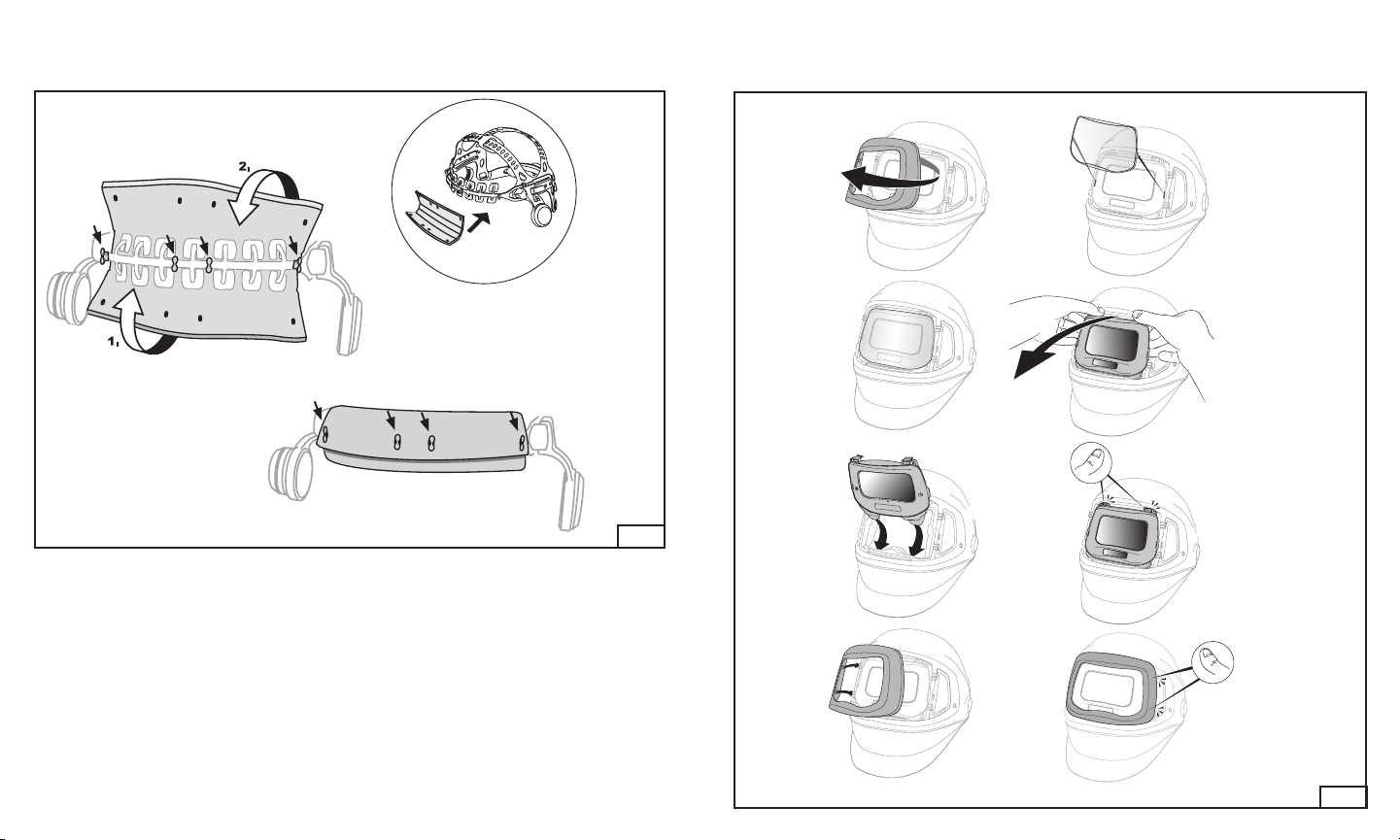

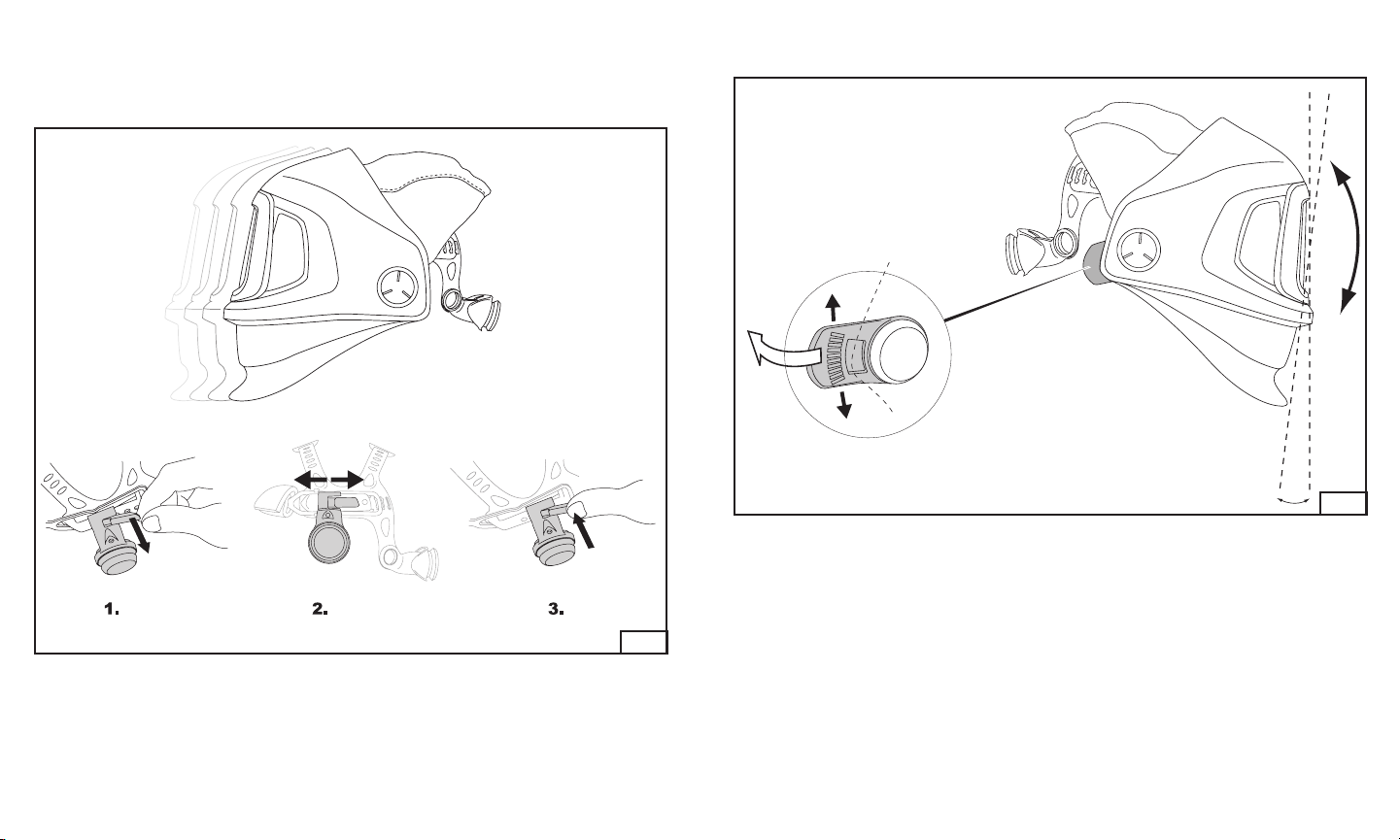

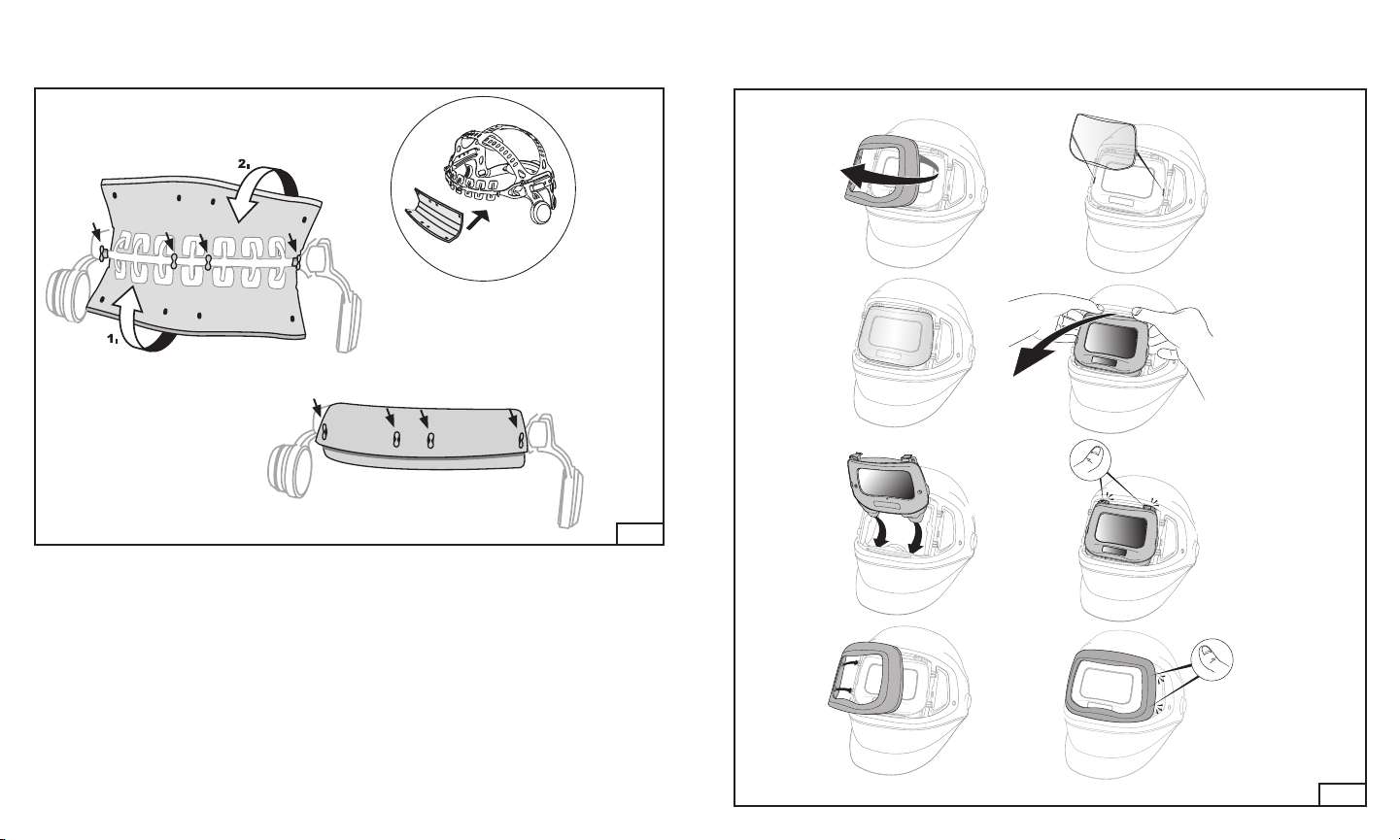

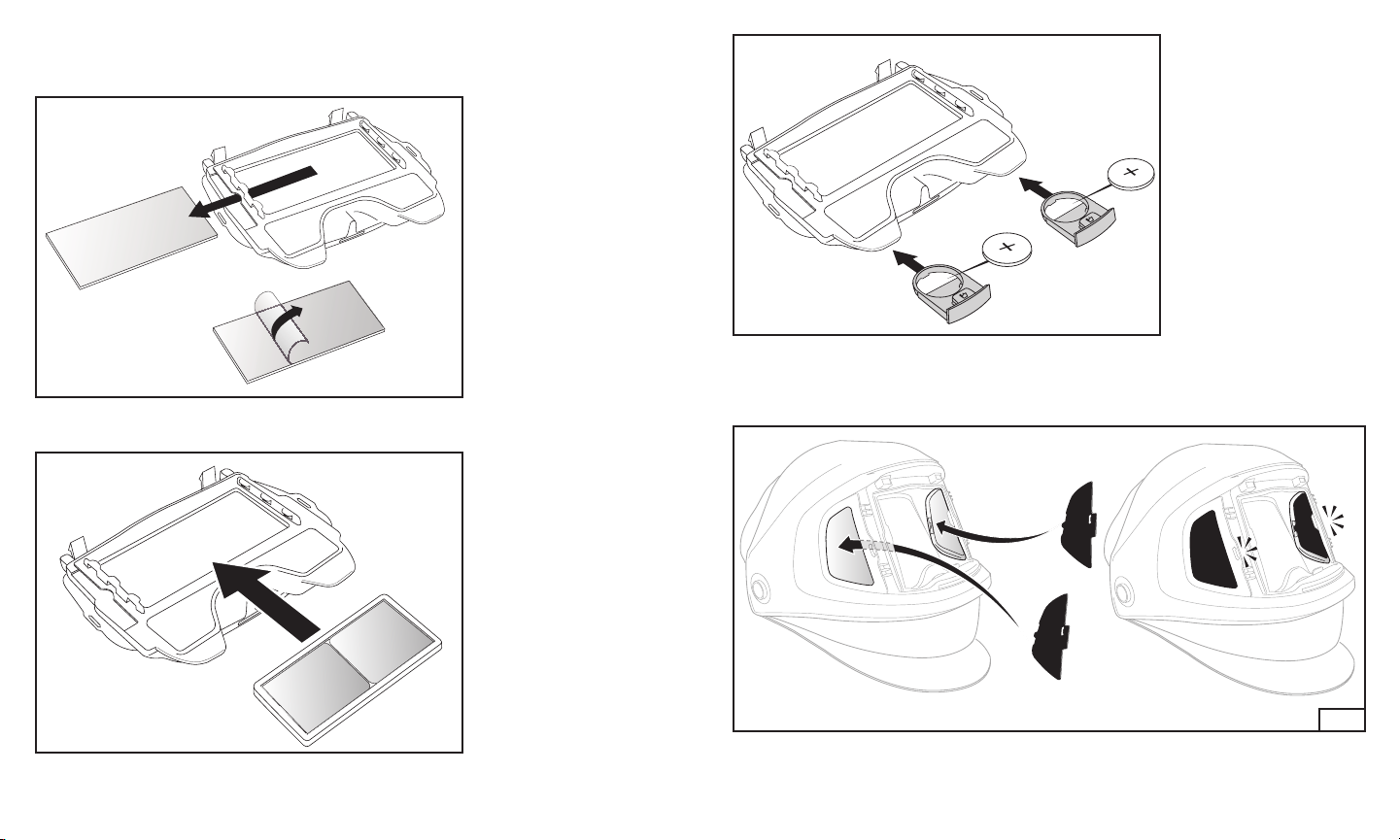

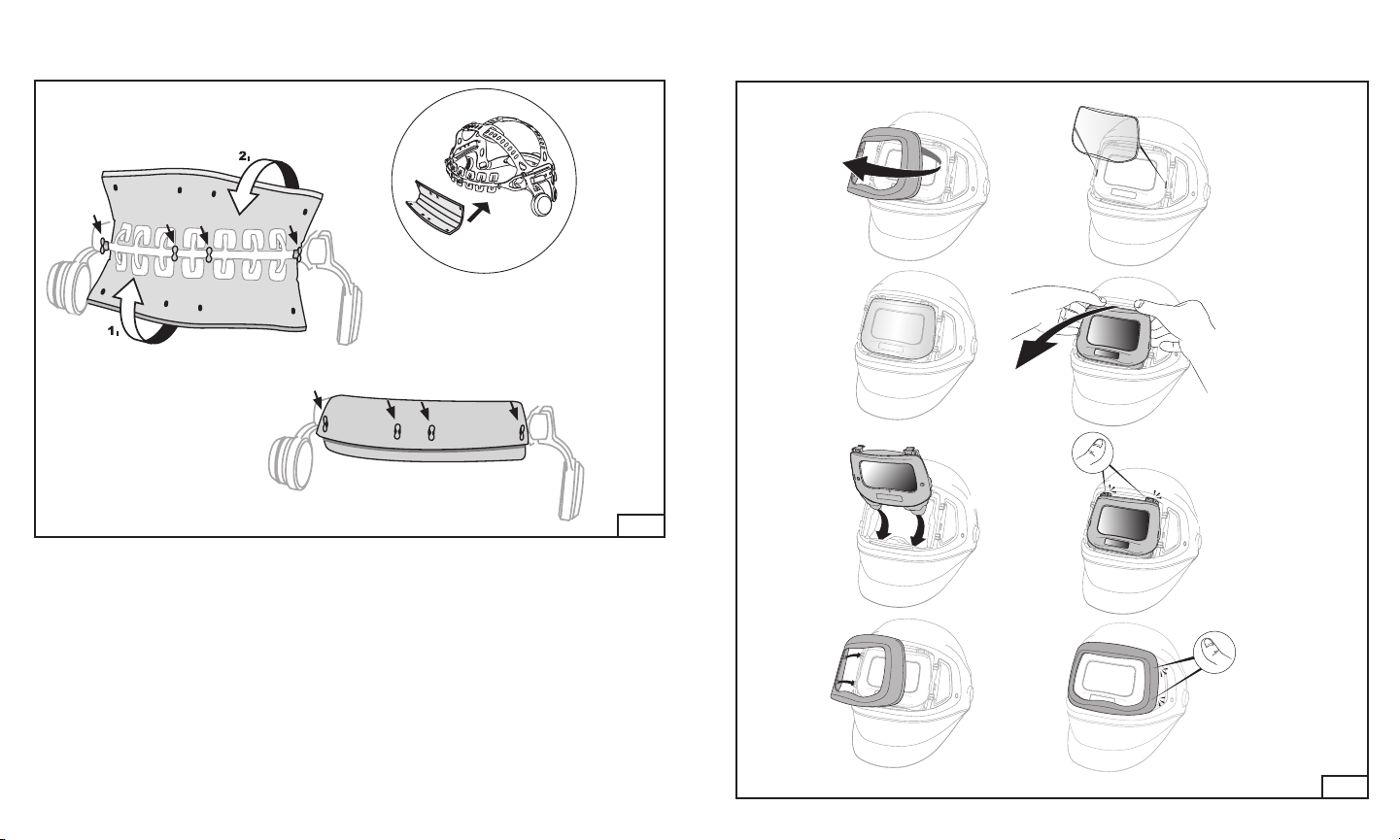

Sweatpad Replacement

See Fig. 5.

Silver Frame, Outer Protection Plate, and ADF Removal and Replacement

See Fig. 6.

12

3

Fig. 5

5

78

17 18

4

6

Fig. 6

Page 12

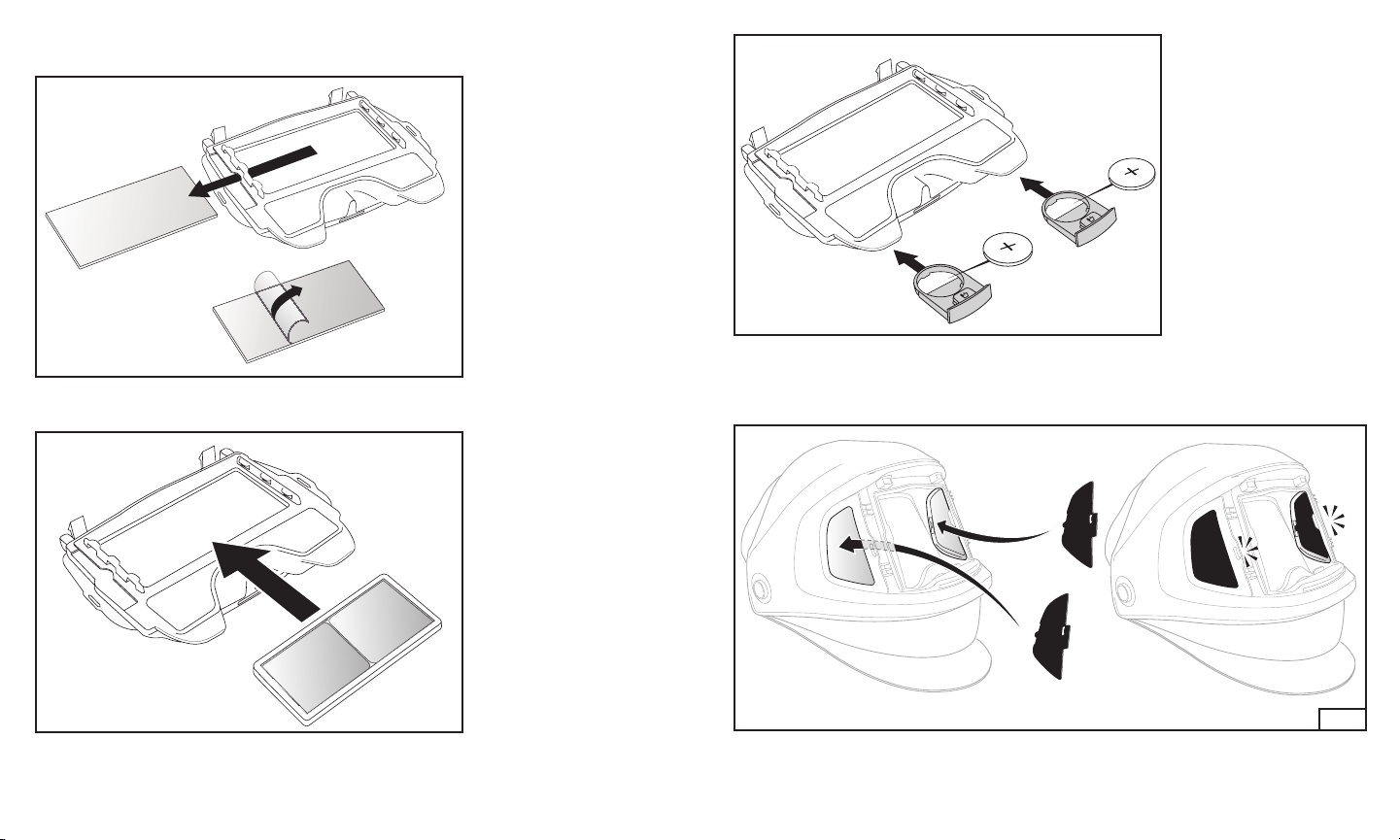

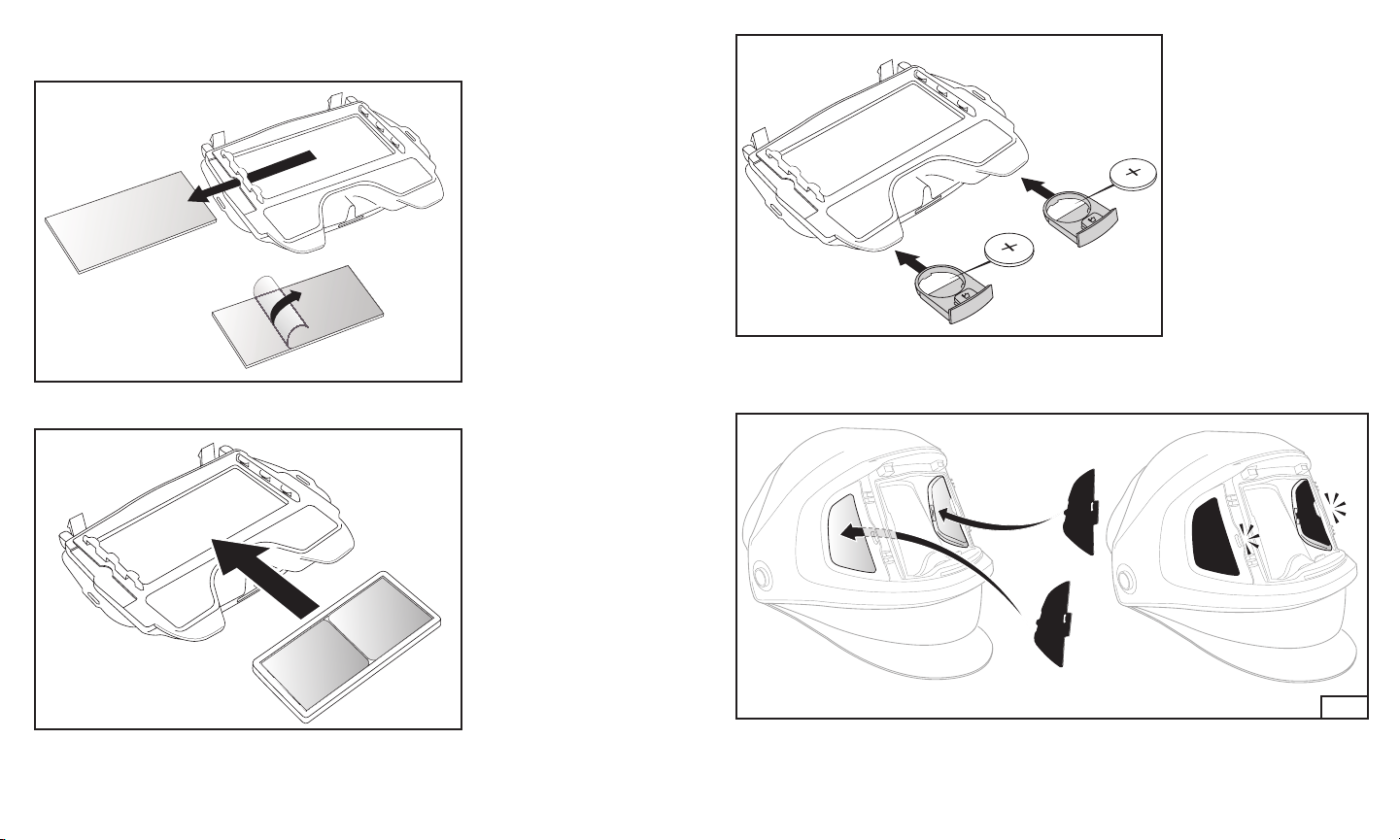

Inside Protection Plate, Batteries Replacement and Magnifying Lens Installation

See Figs. 7 through 9.

Fig. 7 Inside Protection Plate

Fig. 9 Battery

Installation of SideWindow Coverplates

See Fig. 10.

Fig. 8 Magnifi cation Plate

Fig. 10

19 20

Page 13

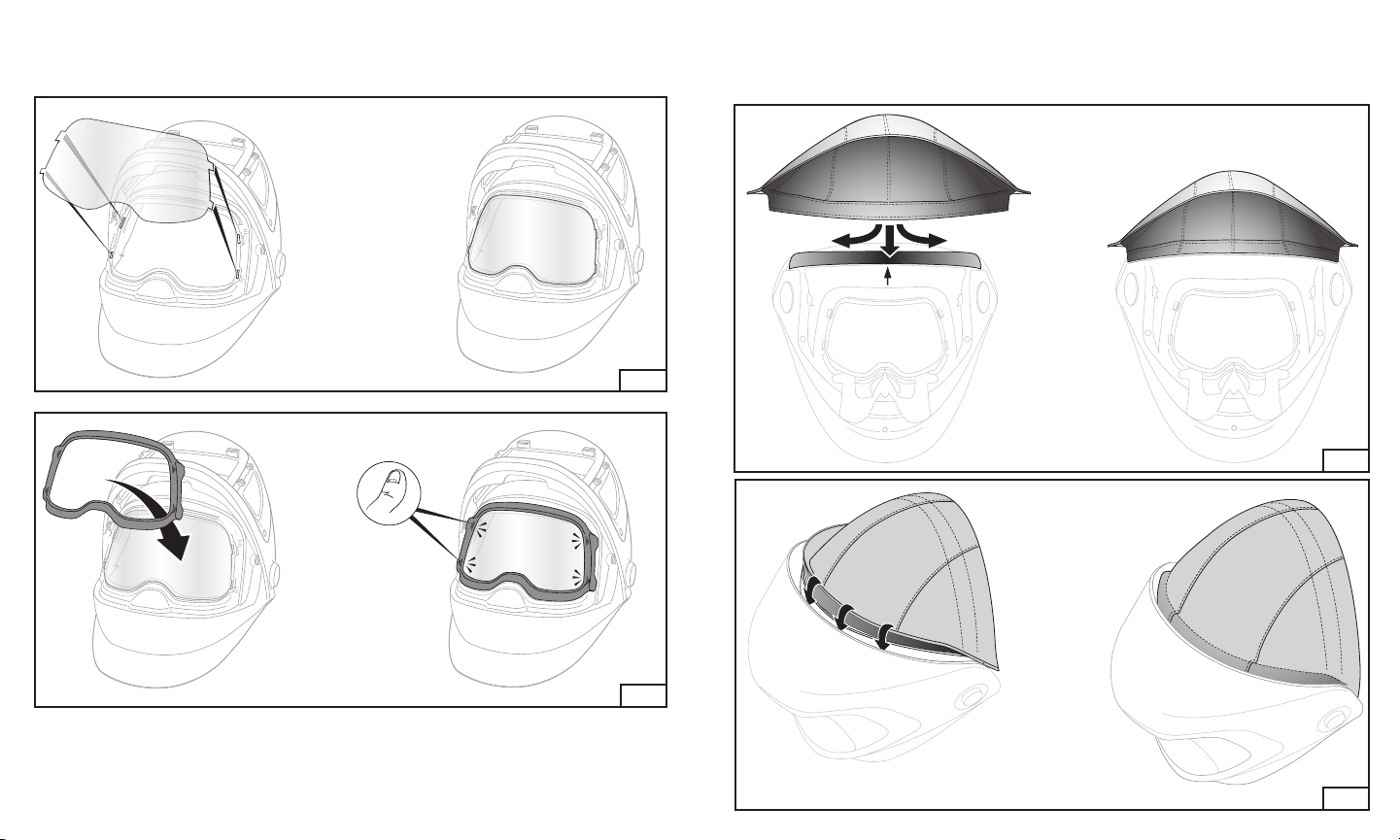

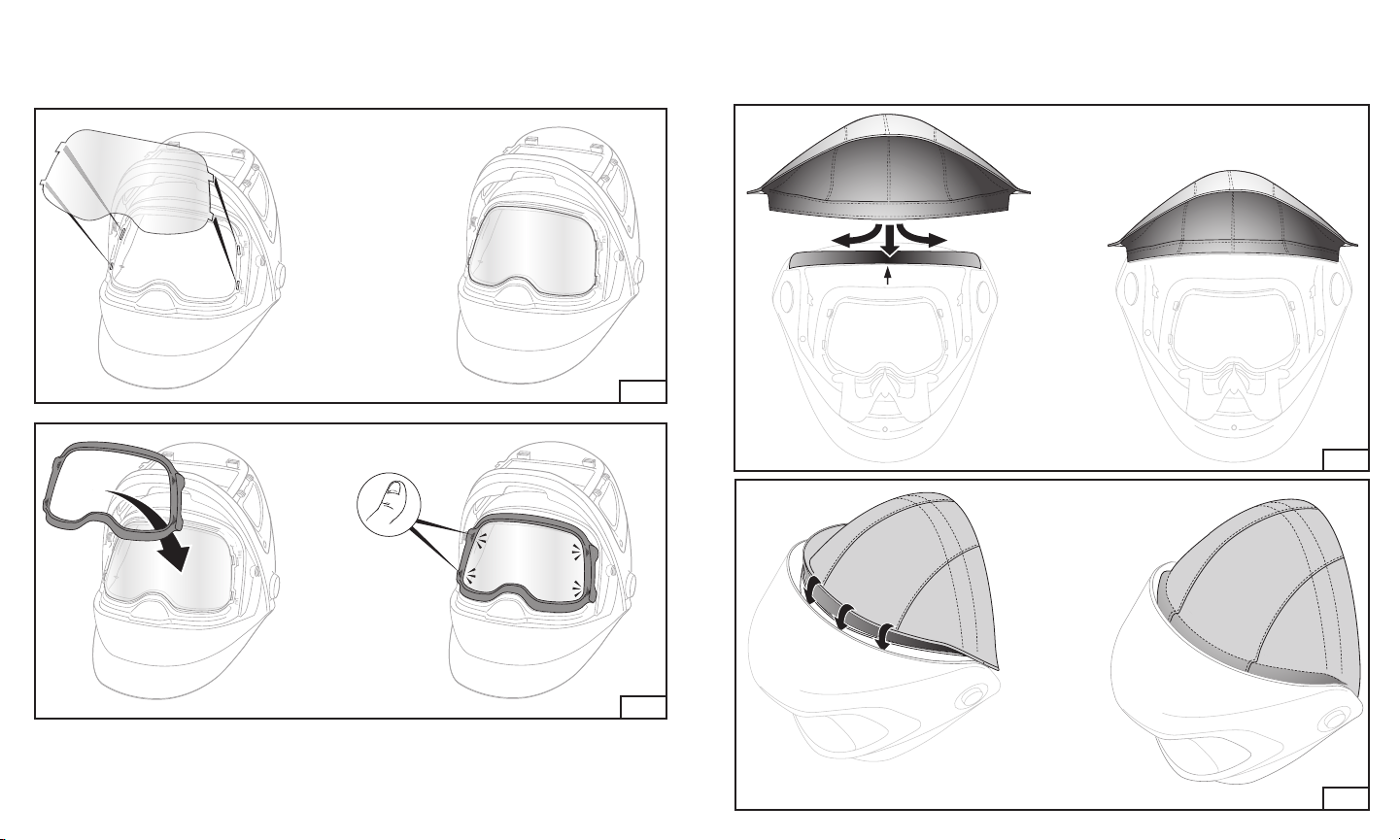

Clear Grinding Visor Replacement

Remove black grinding visor frame by gently lifting on the 4 tabs. Remove and replace the clear grinding visor

and replace the black grinding visor frame (Figs. 11 & 12).

Fig. 11

Top Extended Coverage Installation

Align hook and loop fasteners as shown (Figs. 13 & 14). If the extended coverage is the large version, secure

fastening loops between the inside of the helmet and the pivot mechanism location of the headgear.

Fig. 13

Fig. 12

21 22

Fig. 14

Page 14

CLEANING AND STORAGE

W WARNING

This headgear must not be painted or cleaned with solvents. Any decals applied to the headgear must be

compatible with the surface material and known not to affect adversely the characteristics of the materials

used in the headgear.

Clean the welding helmet with mild soap and lukewarm water. Do not use solvents. Clean the ADF with a

clean, lint-free tissue or cloth. Do not immerse ADFs in water or spray directly with liquids. Store equipment in

a clean, dry and dust-free environment at room temperature.

DISPOSAL

Dispose of equipment that has reached its intended service life in accordance with local regulations.

WARRANTY

WARRANTY: In the event any 3M OH&ESD product is found to be defective in material, workmanship, or not

in conformation with any express warranty for a specifi c purpose, 3M’s only obligation and your exclusive

remedy shall be, at 3M’s option, to repair, replace or refund the purchase price of such parts or products

upon timely notifi cation thereof and substantiation that the product has been stored, maintained and used in

accordance with 3M’s written instructions.

EXCLUSIONS TO WARRANTY: THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY EXPRESS OR IMPLIED

WARRANTY OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR OTHER WARRANTY OF QUALITY,

EXCEPT OF TITLE AND AGAINST PATENT INFRINGEMENT.

LIMITATION OF LIABILITY: Except as provided above, 3M shall not be liable or responsible for any loss or

damage, whether direct, indirect, incidental, special or consequential, arising out of sale, use or misuse of

3M OH&ESD products, or the user’s inability to use such products. THE REMEDIES SET FORTH HEREIN ARE

EXCLUSIVE.

FOR MORE INFORMATION

In United States, contact:

Internet: www.3M.com/OccSafety

Technical Assistance: 1-800-243-4630

For other 3M products:

1-800-3M-HELPS or 1-651-737-6501

Table des matières

Description du système .......................................................................................................................25

Mises en garde et avertissements .......................................................................................................25

Restrictions d’utilisation ....................................................................................................................... 26

Spécifi cations ......................................................................................................................................26

Mode d’emploi .....................................................................................................................................28

Ajustement du masque ...............................................................................................................28

Fonctionnement du fi ltre à lentille photosensible ........................................................................33

Composants du système et pièces de rechange ................................................................................... 37

Entretien et inspection du système ......................................................................................................40

Nettoyage et entretien .........................................................................................................................47

Mise au rebut ......................................................................................................................................47

Garantie ...............................................................................................................................................47

Pour obtenir de plus amples renseignements/For more information .....................................................47

23 24

Page 15

DESCRIPTION DU SYSTÈME

Les présentes directives d’utilisation s’appliquent au masque pour soudeurs 9100 FX Speedglas™ 3M™

Lorsqu’on l’utilise selon les présentes directives d’utilisation, le masque pour soudeurs 9100 FX Speedglas

3M avec fi ltre à lentille photosensible vise à protéger les yeux contre les rayonnements nocifs, notamment la

lumière visible, les ultraviolets et les infrarouges émis par certains procédés de soudage à l’arc, au plasma et

méthodes de soudage ou de coupage au gaz. Trois capteurs situés à l’avant du fi ltre à lentille photosensible

réagissent séparément à l’apparition de l’arc de soudage et déclenchent l’obscurcissement du fi ltre. Le fi ltre

redevient pâle une fois l’arc de soudage disparu. Deux piles au lithium alimentent le fi ltre. La protection contre

les rayons ultraviolets (UV) et infrarouges (IR) est continue, que le fi ltre à lentille photosensible soit pâle ou

foncé, en raison du revêtement protecteur violet de la lentille appelé fi ltre passe-bande. En cas de défaillance

des piles ou des composants électroniques, le soudeur demeure protégé contre les rayonnements UV et IR par

la teinte la plus foncée (teinte 13).

Ces masques pour soudeurs sont munis d’une grande lentille en polycarbonate transparente idéale pour

la préparation des soudures sous une variété d’éclairages. La lentille transparente est conforme aux

normes Z87.1-2010 de l’ANSI et Z94.3 de la CSA en matière de protection des yeux et du visage contre les

chocs violents et fournit une protection limitée contre la projection de certaines particules. Pour voir à travers

la lentille transparente, l’utilisateur doit simplement relever l’écran pour soudeurs monté sur ressorts qui

retient fermement le fi ltre à lentille photosensible en position relevée pendant la préparation de la soudure.

Abaisser l’écran pour soudeurs monté sur ressorts avant de procéder au soudage.

MISES EN GARDE ÉNONCÉES DANS LES PRÉSENTES DIRECTIVES D’UTILISATION

W MISE EN GARDE

• Ne pas utiliser de produit pour le soudage sans avoir reçu la formation nécessaire. Pour tout

renseignement sur l’utilisation adéquate de ce produit, consulter son superviseur, lire les directives

d’utilisation ou communiquer, au Canada, avec le Service technique de 3M au 1 800 267-4414.

• Le masque pour soudeurs 9100 FX Speedglas 3M respecte les exigences des normes Z87.1-2010 de

l’ANSI et Z94.3 de la CSA en matière d’infl ammabilité.

• Cependant, dans certains cas, ces produits peuvent continuer à brûler. L’utilisateur doit évaluer les

dangers présents dans son milieu de travail et prendre les mesures nécessaires pour y faire face. 3M

ne recommande pas l’utilisation de ces produits s’ils sont susceptibles d’entrer en contact avec une

fl amme nue. Une mauvaise utilisation peut provoquer des blessures ou la mort.

• Toujours porter des lunettes de protection conformes à la norme Z87.1 de l’ANSI en plus d’une

pièce faciale pour soudeurs. Tout manquement à ces directives peut provoquer des blessures

oculaires permanentes et une perte de vision. Au Canada, se conformer à la norme Z94.3 de la

CSA et/ou aux exigences de l’autorité compétente de sa région en matière de lunettes de protection.

• Ne jamais modifi er ce masque pour soudeurs. Réparer ou remplacer les pièces uniquement avec

des composants approuvés par 3M. L’utilisation de composants autres que ceux fournis par 3M peut

réduire le rendement du masque pour soudeurs et provoquer des blessures graves ou la mort.

• Ne pas peindre la pièce faciale ou la nettoyer à l’aide de solvants. Tout décalque appliqué sur la pièce

faciale doit être compatible avec la surface et ne doit pas affecter les caractéristiques des matériaux

de la pièce faciale. Les décalques peuvent modifi er les caractéristiques d’infl ammabilité de cette

pièce faciale.

• Remplacer toute pièce faciale ayant subi un choc violent.

25 26

W MISE EN GARDE

• Couvrir les lentilles latérales avec des protecteurs lorsque d’autres soudeurs travaillent à proximité et

lorsque la lumière réfl échie peut passer par ces lentilles.

• Si le fi ltre à lentille photosensible Speedglas™ 3M™ ne s’obscurcit pas à l’apparition de l’arc

de soudage, cesser immédiatement de souder et inspecter le fi ltre conformément aux directives

d’utilisation. L’utilisation d’un fi ltre à lentille photosensible qui ne s’obscurcit pas peut provoquer

des blessures oculaires permanentes et une perte de vision. Ne pas utiliser un tel fi ltre s’il est

impossible de trouver la cause du problème et de le corriger; communiquer avec son superviseur, son

distributeur ou avec 3M pour obtenir de l’aide.

• Inspecter soigneusement tout le fi ltre pour soudeurs 9100 Speedglas 3M avant chaque utilisation. Un

fi ltre ou des plaques de protection fi ssurés, piqués ou égratignés peuvent réduire la visibilité et réduire

considérablement la protection. Remplacer immédiatement tous les composants endommagés. Enlever

la pellicule protectrice de la visière.

• Le masque pour soudeurs 9100 FX Speedglas 3M n’est pas conçu pour de gros travaux de soudage

ou de coupage au-dessus de la tête en raison des risques de brûlures causés par la chute de métal en

fusion. L’utilisation de ce produit à ces fi ns peut provoquer des blessures graves ou la mort.

• Le masque pour soudeurs 9100 FX Speedglas 3M (utilisé avec un fi ltre à lentille photosensible

Speedglas™ 3M™ de série 9100) n’est pas conçu pour le soudage au laser ni pour les méthodes de

soudage qui exigent une teinte 14 ou des fi ltres plus foncés. L’utilisation de ce produit à ces fi ns peut

provoquer des blessures oculaires permanentes et une perte de vision.

• N’utiliser le fi ltre à lentille photosensible qu’à des températures comprises entre -5 et 55°C (23 et

131°F). À défaut de quoi, le fi ltre peut ne pas fonctionner comme prévu et il y a alors risque de

blessures oculaires permanentes et une perte de vision.

AVERTISSEMENT :

Mettre au rebut le matériel qui a atteint la durée utile prévue, conformément aux règlements locaux.

RESTRICTIONS D’UTILISATION

Restrictions d’utilisation importantes

• Ces produits ne protègent pas contre les dangers respiratoires provenant de procédés de soudage ou

d’autres sources. On peut porter un masque Speedglas 3M de série 9100 FX avec certains modèles de

respirateurs. Pour obtenir de plus amples renseignements sur la protection respiratoire pour soudeurs,

communiquer, au Canada, avec le Service technique de 3M au 1 800 267-4414.

Remarque : Le masque pour soudeurs 9100 FX Speedglas 3M ne contient aucun composant en latex

de caoutchouc naturel.

SPÉCIFICATIONS

Protection oculaire et faciale Conforme aux normes Z87.1-2010 de l’ANSI et

Chocs sur le dessus de la tête N’offre pas de protection contre les chocs sur le

Températures d’utilisation -5 à 55°C (23 à 131°F)

Z94.3 de la CSA relatives à la résistance aux

chocs haute vélocité

dessus de la tête.

Page 16

Tableau 1. Spécifi cations des masques pour soudeurs Speedglas™ 3M™

Données techniques

Fenêtre

Masque pour

soudeurs

9100 FX-V

45 x 93 mm

(1,8 x 3,7 po)

Masque pour

soudeurs

9100 FX-X

54 x 107 mm

(2,1 x 4,2 po)

Masque pour

soudeurs

9100 FX-XX

72 x 107 mm

(2,8 x 4,2 po)

Durée utile des piles (2 x CR-2032)

(min.) 2 800 heures 2 500 heures 2 000 heures

Panneau solaire Oui Oui Non

Ensemble 9100 FX avec lentille

latérales, poids comparé (approx.) 19,1 oz (550 g) 19,8 oz (560 g) 20,6 oz (585 g)

Teintes foncées Teintes 5, 8, 9, 10, 11, 12 et 13

Teinte pâle Teinte 3

Vitesse de changement de teinte < 0,1 ms (+23°C)

Modes spéciaux Meulage, soudage par point et verrouillage

Niveaux de sensibilité 5 niveaux

Intensité TIG > 1 A

Nombre de capteurs 3 (2 au niveau des yeux, 1 au centre)

Délai de retour à la teinte pâle Réglable de 40 à 1 300 ms

Plage de températures -5 à 55°C (23 à 131°F)

Conformité aux normes Norme Z87.1-2010 de l’ANSI, norme Z94.3-2007 de la CSA

Garantie 2 ans

Tours de tête 50 à 64 cm (6 1/4 à 8 po)

Écran Polyphtalamide

Panneau avant et boîtier de fi ltre

argentés Nylon

Serre-tête Nylon, polypropylène, polyéthylène et élastomères thermoplastiques

Lentilles latérales SideWindows Polycarbonate

Plaques de protection Polycarbonate

Tissu ignifuge 75% coton, 25% fi bre synthétique Kevlar

®

27 28

MODE D’EMPLOI

W MISE EN GARDE

Le masque pour soudeurs 9100 FX Speedglas™ 3M™ respecte les exigences des normes Z87.1-2010 de

l’ANSI et Z94.3 de la CSA en matière d’infl ammabilité. Cependant, dans certains cas, ces produits peuvent

continuer à brûler. L’utilisateur doit évaluer les dangers présents dans son milieu de travail et prendre

les mesures nécessaires pour y faire face. 3M ne recommande pas l’utilisation de ces produits s’ils sont

susceptibles d’entrer en contact avec une fl amme nue. Une mauvaise utilisation peut provoquer des

blessures ou la mort.

Couvrir les lentilles latérales avec des panneaux lorsque d’autres soudeurs travaillent à proximité et

lorsque la lumière réfl échie peut passer par ces lentilles.

Le masque pour soudeurs 9100 FX Speedglas 3M n’est pas conçu pour de gros travaux de soudage ou de

coupage au-dessus de la tête en raison des risques de brûlures causés par la chute de métal en fusion.

L’utilisation de ce produit à ces fi ns peut provoquer des blessures graves ou la mort.

Toujours porter des lunettes de protection conformes à la norme Z87.1 de l’ANSI en plus d’une pièce

faciale pour soudeurs. Tout manquement à ces directives peut provoquer des blessures oculaires

permanentes et une perte de vision. Au Canada, se conformer à la norme Z94.3 de la CSA et/ou aux

exigences de l’autorité compétente de sa région en matière de lunettes de protection.

Déballage

Inspecter le contenu de l’emballage pour s’assurer qu’aucun dommage n’est survenu pendant l’expédition

et qu’il ne manque aucun composant. Inspecter le produit avant chaque utilisation en suivant la procédure

décrite dans la section Inspection des présentes directives d’utilisation.

Ajustement du masque

Remarque : Effectuer les ajustements ci-dessous pour s’assurer que le masque pour soudeurs

9100 FX Speedglas 3M est bien ajusté avant de l’utiliser.

1) Placer le masque pour soudeurs 9100 FX Speedglas 3M sur la tête et serrer avec le bouton à cliquet

situé à l’arrière de la pièce faciale (Fig. 1) pour obtenir un ajustement confortable et sécuritaire. S’il est

impossible d’obtenir un ajustement confortable uniquement avec le bouton, utiliser l’ajustement grossier

L, M et S situé à l’avant du serre-tête comme l’indique le bas de la Fig. 1. L signifi e un grand tour de tête;

M, un tour de tête moyen et S, un petit tour de tête. Régler en fonction du tour de tête, puis remettre le

masque sur la tête et serrer avec le bouton à cliquet pour obtenir un ajustement confortable et sécuritaire.

Pour un réglage supplémentaire, tourner le bouton à cliquet de 180 degrés pour un ajustement

légèrement différent en fonction de la position comme le montre la Fig. 2.

2) Régler les deux sangles d’amortissement supérieures de manière à répartir également et à équilibrer

le poids du masque sur le dessus de la tête. Avec le masque en place sur la tête et le bouton à cliquet

serré, ajuster les deux sangles d’amortissement de sorte qu’il n’y ait aucun espace ou écart excessif ces

dernières et le dessus de la tête. Parfois, la sangle d’amortissement arrière peut s’avérer trop grande et

créer du jeu, mais ce n’est pas ainsi qu’il faut porter le masque. S’il se crée un jeu excessif, régler les

sangles d’amortissement en les faisant glisser et en les serrant comme l’indique la Fig. 1. S’il n’y a pas

de jeu, mais que l’on sent que le masque est trop haut sur la tête, agrandir les sangles d’amortissement

pour obtenir une hauteur confortable.

Page 17

Fig. 1

29 30

Fig. 2

Page 18

3) Ensuite, ajuster la position avant-arrière du masque, de sorte qu’il soit à une distance confortable du

visage, sans qu’il touche le nez ou le visage. On règle la position avant-arrière en déplaçant les dispositifs

de réglage latéraux dans la pièce faciale qui permettent de déplacer le masque vers l’avant ou l’arrière

comme le montre la Fig. 3. Il est conseillé de s’assurer que les réglages latéraux soient à la même

position de chaque côté pour obtenir un port équilibré et pour le confort général.

4) Avec le masque en place sur la tête, régler l’angle de vision vertical comme l’illustre la Fig. 4, de manière

à optimiser le champ de vision et la position du masque par rapport au travail à effectuer.

Fig. 4

Fig. 3

31 32

Page 19

Fonctionnement du fi ltre à lentille photosensible

W MISE EN GARDE

Si le fi ltre à lentille photosensible Speedglas™ 3M™ ne s’obscurcit pas à l’apparition de l’arc de

soudage, cesser immédiatement de souder et inspecter le fi ltre conformément aux directives d’utilisation.

L’utilisation d’un fi ltre à lentille photosensible qui ne s’obscurcit pas peut provoquer des blessures

oculaires permanentes et une perte de vision. Ne pas utiliser un tel fi ltre s’il est impossible de trouver

la cause du problème et de le corriger; communiquer avec son superviseur, son distributeur ou avec 3M

pour obtenir de l’aide. Le masque pour soudeurs 9100 FX Speedglas 3M (utilisé avec un fi ltre à lentille

photosensible Speedglas 3M de série 9100) n’est pas conçu pour le soudage au laser ni pour les méthodes

de soudage qui exigent une teinte 14 ou des fi ltres plus foncés. L’utilisation de ce produit à ces fi ns peut

provoquer des blessures oculaires permanentes et la cécité.

N’utiliser le fi ltre à lentille photosensible qu’à des températures comprises entre -5 et 55°C (23 et 131°F).

À défaut de quoi, le fi ltre peut ne pas fonctionner comme prévu et il y a alors et provoquer des blessures

oculaires permanentes et une perte de vision.

Marche/arrêt

Pour activer le fi ltre à lentille photosensible, appuyer sur le bouton « SHADE/ON » (teinte/marche). Le fi ltre

se DÉSACTIVE automatiquement après 1 heure d’inactivité. Le fi ltre comporte trois capteurs optiques qui

réagissent séparément et déclenchent l’obscurcissement du fi ltre à l’apparition d’un arc de soudage. Le fi ltre

peut ne pas s’obscurcir si les capteurs sont obstrués ou lorsque l’arc de soudage est complètement protégé.

Les sources lumineuses intermittentes (p. ex., lampes stroboscopiques de sécurité) peuvent activer le fi ltre,

le faisant clignoter alors qu’il n’y a aucun procédé de soudage en cours. Cette interférence peut se produire

de loin et/ou par lumière réfl échie. Les environnements de soudage doivent être bien protégés de telles

interférences.

Teinte

Il y sept réglages de teintes, répartis en deux groupes : teintes 5 et 8 et teintes 9 à 13. Pour connaître le

réglage de teinte en cours, appuyer un moment sur le bouton SHADE/ON. Pour changer de teinte, appuyer

à répétition sur le bouton SHADE/ON. Déplacer la DEL clignotante à la teinte recherchée. Pour changer

de groupe de teintes (teintes 5 et 8) et (teintes 9 à 13); maintenir le bouton SHADE/ON enfoncé pendant

2 secondes. Dans tous les procédés de soudage, on doit regarder l’arc seulement avec la teinte foncée

recommandée (tableau 2).

Position Verrouillage sur teinte pâle (mode meulage) – fonction commutation désactivée,

demeure constamment en teinte 3.

Position 1 Réglage le moins sensible. Utilisé si les arcs d’autres soudeurs à proximité créent

de l’interférence.

Position 2 Réglage par défaut. Utilisé pour la plupart des types de soudages à l’intérieur et à

l’extérieur.

Position 3 Pour le soudage à l’arc stable (p. ex., soudage TIG).

Position 4 Pour le soudage TIG à faible intensité ou les machines à souder à onduleur.

Position 5 Pour le soudage TIG où une partie de l’arc n’est pas visible.

Position Verrouillage sur teinte foncée – fonction commutation désactivée, demeure

constamment en teinte foncée.

Verrouillage sur teinte pâle

Réglage destiné au meulage ou à d’autres activités hormis le soudage. Lorsque le fi ltre à lentille

photosensible est verrouillé sur la teinte pâle (teinte 3), la DEL sous le symbole correspondant clignote toutes

les 8 secondes pour le signaler à l’utilisateur. Le fi ltre à lentille photosensible doit être réglé à une sensibilité

appropriée avant de commencer le soudage à l’arc, sinon il demeurera verrouillé à la teinte pâle. Lorsque le

fi ltre à lentille photosensible se désactive (après 1 heure d’inactivité), il revient automatiquement au réglage

de sensibilité 2 par défaut.

Positions 1 à 5

Si le fi ltre ne s’obscurcit pas comme prévu pendant le soudage, accroître la sensibilité jusqu’à ce que le fi ltre

passe à la teinte adéquate de manière fi able. Si la sensibilité est trop élevée, le fi ltre peut conserver la teinte

foncée après le soudage en raison de la lumière ambiante. Dans ce cas, réduire la sensibilité de manière que

le fi ltre passe correctement à une teinte foncée ou pâle.

Verrouillage sur teinte foncée

Réglage qui verrouille le fi ltre à lentille photosensible sur la teinte foncée sélectionnée. Lorsque le fi ltre à

lentille photosensible se désactive (après 1 heure d’inactivité), il revient automatiquement au réglage de

sensibilité 2 par défaut.

Délai

La fonction de délai permet d’augmenter ou de diminuer le délai de retour à la teinte pâle en fonction des

exigences du procédé de soudage. Les intervalles de temps de retour s’accroissent automatiquement avec

l’accroissement de la teinte. Le tableau 3 présente ces intervalles en millisecondes. Même si les fonctions de

délai et de sensibilité partagent une même DEL, il s’agit de réglages distincts.

Sélection de la sensibilité

La programmation et la sensibilité du détecteur optique peuvent être réglées en fonction d’une variété de

procédés de soudage et de conditions régnant dans le milieu de travail. Pour modifi er le réglage de la sensibilité,

appuyer à répétition sur le bouton SENS (sensibilité) jusqu’à ce que la DEL indique la sensibilité voulue.

33 34

Retour à la teinte pâle en 2 étapes

Dans le passage à la teinte pâle, les deux plus longs réglages comprennent une phase

intermédiaire. Lorsque l’arc s’éteint, le fi ltre revient brièvement à la teinte 5, puis à la teinte 3. Les

intervalles pour chaque phase correspondent à d1 et d2 dans le tableau 3.

Page 20

Soudage par points

Ce réglage peut aider à réduire la fatigue oculaire occasionnée par l’accommodement constant de

l’œil à différents niveaux d’éclairage durant le soudage par points rapide. Lorsque l’arc s’éteint, le

fi ltre revient à la teinte 5. Si un autre arc ne s’allume pas dans les 2 secondes suivantes, le fi ltre

revient à la teinte 3 normale.

Voyant de piles faibles

Remplacer les piles lorsque l’indicateur de piles faibles clignote ou lorsque les DEL ne clignotent pas quand

on appuie sur les boutons.

Tableau 2. Guide recommandé pour les numéros de teinte

(adapté de la norme Z49.1-2003 de l’ANSI)

Diamètre de

Procédé de soudage

Soudage à l’arc avec électrode

enrobée

Soudage à l’arc avec fi l électrode < 60 7 ---

Soudage à l’électrode de

tungstène

Coupage à l’arc au charbon

avec jet d’air comprimé

Soudage au plasma < 20 6 6 à 8

Découpage au plasma < 300 8 9

Soudage à l’arc avec électrode

de carbone

l’électrode,

po

< 3 < 60 7 --3 à 5 60 à 160 8 10

5 à 8 160 à 250 10 12

> 8 250 à 550 11 14

60 à 160 10 11

160 à 250 10 12

250 à 500 10 14

< 50 8 10

50 à 150 8 12

< 500 10 12

500 à 1 000 11 14

20 à 100 8 10

100 à 400 10 12

400 à 800 11 14

300 à 400 9 12

400 à 800 10 14

14

Intensité de

l’arc, ampères

150 à 500 10 14

Teinte de

protection

minimale

N° de teinte

recommandé

Tableau 3

35 36

Page 21

COMPOSANTS ET PIÈCES DE RECHANGE DU SYSTÈME SPEEDGLAS™ 3M™

37 38

Ensemble masque complet Speedglas™ 3M™

06-0600-10SW Masque pour soudeurs 9100 FX avec lentilles latérales SideWindows et fi ltre à

lentille photosensible 9100V

06-0600-20SW Masque pour soudeurs 9100 FX avec lentilles latérales SideWindows et fi ltre à

lentille photosensible 9100X

06-0600-30SW Masque pour soudeurs 9100 FX avec lentilles latérales SideWindows et fi ltre à

lentille photosensible 9100XX

Pièces de rechange et accessoires Speedglas™ 3M™

04-0320-00 Piles (CR-2032)

06-0000-10 Filtre à lentille photosensible 9100V

06-0000-20 Filtre à lentille photosensible 9100X

06-0000-30 Filtre à lentille photosensible 9100XX

Page 22

06-0200-10 Plaque de protection intérieure 9100V (5/paquet)

06-0200-20 Plaque de protection intérieure 9100X (5/paquet)

06-0200-30 Plaque de protection intérieure 9100XX (5/paquet)

06-0201-10 Trousse de lancement 9100V (contient 5 plaques de protection extérieures,

2 plaques de protection intérieures et un bandeau antisudation)

06-0201-20 Trousse de lancement 9100X (contient 5 plaques de protection extérieures,

2 plaques de protection intérieures et un bandeau antisudation)

06-0201-30 Trousse de lancement 9100XX (contient 5 plaques de protection extérieures,

2 plaques de protection intérieures et un bandeau antisudation)

06-0200-51 Plaque de protection extérieure ordinaire 9100

06-0200-52 Plaque de protection extérieure antiégratignures 9100

06-0200-53 Plaque de protection extérieure thermorésistante 9100

06-0200-54 Bandeau antisudation 9100

06-0400-51 Ensemble serre-tête 9100 complet (pièce faciale)

06-0400-52 Mécanisme à pivot 9100 (gauche et droite)

06-0400-53 Partie avant du serre-tête 9100

06-0400-54 Partie arrière du serre-tête 9100 (mécanisme d’ajustement à cliquet)

06-0400-55 Porte-piles 9100

06-0500-51 Protecteur de tête 9100, Tecaweld

06-0500-52 Protecteur pour les oreilles et le cou 9100, Tecaweld

06-0500-54 Calotte pour soudeurs (sans visière)

06-0500-55 Casque pour soudeurs avec visière

06-0500-56 Plaque de grossissement 1,5X

06-0500-57 Plaque de grossissement 2,0X

06-0500-58 Plaque de grossissement 2,5X

06-0500-59 Plaque de grossissement 3,0X

06-0500-60 Sac de rangement pour vêtements

06-0500-61 Décalque de marque pour coffre à outils

INSPECTION ET ENTRETIEN DU SYSTÈME

W MISE EN GARDE

Ne jamais modifi er ce masque pour soudeurs. Réparer ou remplacer les pièces uniquement avec des

composants approuvés par 3M. L’utilisation de composants autres que ceux fournis par 3M peut réduire

le rendement du masque pour soudeurs et provoquer des blessures graves ou la mort. Ne pas peindre

la pièce faciale ou la nettoyer à l’aide de solvants. Tout décalque appliqué sur la pièce faciale doit être

compatible avec la surface et ne doit pas affecter les caractéristiques des matériaux de la pièce faciale.

Les décalques peuvent modifi er les caractéristiques d’infl ammabilité de cette pièce faciale.

Inspecter soigneusement tout le fi ltre pour soudeurs 9100 Speedglas™ 3M™ avant chaque utilisation.

Un fi ltre ou des plaques de protection fi ssurés, piqués ou égratignés peuvent réduire la visibilité et affaiblir

considérablement la protection. Remplacer immédiatement tous les composants endommagés. Enlever la

pellicule protectrice de la visière.

Remplacer toute pièce faciale ayant subi un choc violent.

Vérifi er si des pièces du masque pour soudeurs et de la pièce faciale sont usées ou endommagées. Remplacer

toute pièce usée ou endommagée comprenant des composants énumérés dans la liste des pièces de rechange

et des accessoires mentionnée dans les présentes directives d’utilisation.

Vérifi cation du bon fonctionnement du fi ltre à lentille photosensible : Tenir le fi ltre à quelques pouces d’une

lampe fl uorescente et observer le fi ltre passer à la teinte foncée sélectionnée. Selon la source de lumière, il peut

être nécessaire d’augmenter temporairement le niveau de sensibilité. Au choix, le fi ltre à lentille photosensible

peut être déclenché en pointant une télécommande (p. ex., de téléviseur) sur les capteurs du fi ltre et en

appuyant sur le bouton « On » (marche).

Remarque : Si le fi ltre à lentille photosensible ne réagit pas comme il est indiqué dans les présentes directives

d’utilisation, ne pas l’utiliser et communiquer immédiatement avec son superviseur ou son représentant de 3M.

06-0700-51 Visière à grande visibilité pour meulage, standard

06-0700-54 Visière à grande visibilité pour meulage, antibuée

06-0700-63 Panneau avant 9100 FX, chrome

06-0700-64 Cadre de visière à grande visibilité 9100 FX pour meulage

06-0700-73 Protecteurs de lentilles latérales 9100 FX

06-0700-81 Pièce faciale 9100 FX standard

06-0700-82 Pièce faciale 9100 FX allongée (tête et cou)

06-0700-83 Cagoule complète, noire

39 40

Page 23

Remplacement du bandeau antisudation

Voir la Fig. 5.

Retrait et installation du cadre argent, de la plaque de protection extérieure et du fi ltre à lentille

photosensible

Voir la Fig. 6.

12

3

Fig. 5

5

78

41 42

4

6

Fig. 6

Page 24

Installation de la plaque de protection intérieure, remplacement des piles et installation de la lentille

de grossissement

Voir les Figs. 7 à 9.

Fig. 7. Plaque de protection intérieure

Fig. 9. Pile

Installation des protecteurs pour lentilles latérales

Voir la Fig. 10.

Fig. 8. Lentille de grossissement

Fig. 10

43 44

Page 25

Remplacement de la visière transparente pour meulage

Retirer le cadre noir de la visière pour meulage en soulevant doucement les quatre languettes. Retirer et

remplacer la visière transparente pour meulage et remettre le cadre en place (Fig. 11 et 12).

Installation du protecteur surdimensionné supérieur

Aligner les attaches à boucles et à crochets conformément à ce qui est illustré (Fig. 13 et 14). Si le protecteur

surdimensionné est de grande taille, fi xer les boucles d’attache entre l’intérieur du masque et l’emplacement

du mécanisme à pivot de la pièce faciale.

Fig. 11

Fig. 13

Fig. 12

45 46

Fig. 14

Page 26

NETTOYAGE ET ENTREPOSAGE

W MISE EN GARDE

Ne pas peindre la pièce faciale ou la nettoyer à l’aide de solvants. Tout décalque appliqué sur la pièce

faciale doit être compatible avec la surface et ne doit pas affecter les caractéristiques des matériaux de la

pièce faciale.

Nettoyer le masque pour soudeurs à l’eau tiède et au savon doux. Ne pas utiliser de solvants. Nettoyer le fi ltre

à lentille photosensible avec un essuie-tout ou un chiffon propre et sans charpie. Ne pas plonger les fi ltres à

lentille photosensible dans l’eau ni les asperger directement de liquide. Entreposer le matériel à température

ambiante dans un endroit propre, sec et exempt de poussière.

MISE AU REBUT

Mettre au rebut le matériel qui a atteint la durée utile prévue, conformément aux règlements locaux.

GARANTIE

GARANTIE : Si un produit de la Division des produits d’hygiène industrielle et de sécurité environnementale

de 3M présente un défaut de matériau ou de fabrication, ou s’il n’est pas conforme à toute garantie explicite

d’adaptation à un usage particulier, la seule obligation de 3M, qui constitue votre seul recours, est, au gré de

3M, de réparer ou de remplacer toute pièce ou tout produit défectueux, ou d’en rembourser le prix d’achat, à

condition que l’utilisateur avise 3M en temps opportun et pourvu qu’il présente une preuve que le produit a

été entreposé, entretenu et utilisé conformément aux directives écrites de 3M.

RESTRICTIONS DE GARANTIE : LA PRÉSENTE GARANTIE EST EXCLUSIVE ET TIENT LIEU DE TOUTE GARANTIE

OU CONDITION EXPLICITE OU IMPLICITE DE QUALITÉ MARCHANDE ET D’ADAPTATION À UN USAGE

PARTICULIER OU DE TOUTE AUTRE GARANTIE OU CONDITION DE QUALITÉ, À L’EXCEPTION DES GARANTIES

RELATIVES AUX TITRES DE PROPRIÉTÉ ET À LA CONTREFAÇON DE BREVETS

LIMITE DE RESPONSABILITÉ : À l’exception de ce qui précède, 3M ne saurait être tenue responsable des

pertes ou dommages directs, indirects, spéciaux, fortuits ou conséquents résultant de la vente, de l’utilisation

ou de la mauvaise utilisation des produits de la Division des produits d’hygiène industrielle et de sécurité

environnementale de 3M, ou de l’incapacité de l’utilisateur à s’en servir. LES RECOURS ÉNONCÉS AUX

PRÉSENTES SONT EXCLUSIFS.

POUR OBTENIR DE PLUS AMPLES RENSEIGNEMENTS/

FOR MORE INFORMATION

Au Canada, communiquer avec/In Canada, contact :

Internet : www.3M.ca/Safety

Assistance technique/Technical Assistance :

1 800 267-4414

Centre communication-client/Customer Care Center : 1 800 364-3577

Contenido

Descripción del sistema ....................................................................................................................... 49

Advertencias y precauciones................................................................................................................49

Limitaciones de uso ............................................................................................................................. 50

Especifi caciones ..................................................................................................................................50

Instrucciones de operación ..................................................................................................................52

Ajuste de la careta ...................................................................................................................... 52

Función del ADF ......................................................................................................................... 57

Componentes del sistema y partes de repuesto ...................................................................................61

Inspección y Mantenimiento Del Sistema .............................................................................................64

Limpieza y almacenamiento.................................................................................................................71

Eliminación .......................................................................................................................................... 71

Limitación de responsabilidades .......................................................................................................... 71

Para obtener más información ............................................................................................................. 71

47 48

Page 27

DESCRIPCIÓN DEL SISTEMA

Estas Instrucciones aplican para la Careta para soldadura 3M™ Speedglas™ 9100 FX. Las Caretas para

soldadura Speedglas 3M 9100 FX con lente auto-oscurecente (ADF por sus siglas en inglés) están diseñadas

para ayudar a proteger los ojos del usuario contra radiación dañina, como luz visible, radiación ultravioleta

(UV) y radiación infrarroja (IR), ocasionadas por ciertos proceso de soldadura por arco, plasma y gas, cuando

se utilizan de acuerdo con estas Instrucciones. Los tres sensores ubicados al frente de los lentes autooscurecentes (ADFs) se activan independientemente al momento de iniciar el proceso de soldadura por

arco, lo que hace que el lente se oscurezca. El ADF regresa a la sombra clara tan pronto termina el arco de

soldadura. Como fuente de energía se usan dos baterías de litio. Debido al recubrimiento morado del lente,

conocido como fi ltro, la protección contra radiación ultravioleta (UV) e infrarroja (IT) es continua, ya sea que

el ADF esté en el estado de sombra clara u oscura. En caso de que haya una falla de batería o electrónica, el

soldador sigue protegido contra la radiación UV e IR de acuerdo con la sombra más oscura (sombra 13).

Estas caretas para soldadura ofrecen un lente transparente de policarbonato con campo de visión amplio,

ideal para precisión de soldadura bajo una variedad de condiciones de luz. El lente transparente cumple con

los requerimientos de las normas ANSI Z87.1-2010 y CSA Z94.3 para protección ocular y facial contra alto

impacto y ofrece protección limitada contra ciertas partículas en el aire. Para usar el lente transparente, el

usuario sólo levanta el protector para soldadura montado con resorte, que sostiene el lente auto-oscurecente

para soldadura (ADF) y lo fi ja en la posición superior para la preparación de soldadura. Antes de iniciar el

trabajo de soldadura debe bajar de nuevo el protector para soldadura montado.

LISTA DE ADVERTENCIAS Y PRECAUCIONES DENTRO DE ESTAS INSTRUCCIONES

W ADVERTENCIA

• No use ningún producto para soldadura sin contar con la capacitación adecuada. Para su uso

adecuado consulte a su supervisor, lea las Instrucciones, o llame a 3M en EUA al 1-800-243-4630. En

Canadá llame al Servicio Técnico al 1-800-267-4414. En México llame al 01-800-712-0646.

• La Careta para soldadura 3M Speedglas 9100 FX cumple con los requerimientos de las normas ANSI

Z87.1-2010 y CSA Z94.3 para infl amabilidad. El usuario debe evaluar los riesgos en el lugar de trabajo

y tomar las medidas precautorias necesarias para estos. 3M no sugiere el uso de estos productos en

áreas donde es posible el contacto con fl ama abierta. El uso inadecuado puede ocasionar lesiones

o incluso la muerte.

• Siempre use gafas de seguridad que cumplan con la norma ANSI Z87.1- junto con cualquier careta

para soldadura. No hacerlo puede ocasionar lesiones permanentes en los ojos y pérdida de la

vista. En Canadá debe cumplir con la norma CSA Z94.3 y/o los requerimientos para protección ocular

de la autoridad correspondiente en la región.

• Nunca modifi que ni altere esta careta para soldadura. Sólo repare o remplace las partes con

componentes 3M aprobados. El uso de componentes distintos a los suministrados por 3M puede

afectar el funcionamiento de la careta para soldadura y ocasionar enfermedad o incluso la muerte.

• Esta careta no se debe pintar ni limpiar con solventes. Cualquier calcomanía aplicada a la careta

debe ser compatible con el material de la superfi cie y no afectar las características de los materiales

utilizados en la careta. Es probable que las calcomanías afecten las características de infl amabilidad

de esta careta.

• Debe reemplazar cualquier careta sujeta a impacto severo.

49 50

W ADVERTENCIA

• Debe cubrir las ventanas laterales con micas protectoras en situaciones donde otros soldadores estén

trabajando en un lugar cercano y en situaciones donde la luz refl ejada pueda pasar a través de las

ventanas.

• Si el Lente auto-oscurecente 3M™ Speedglas™ no cambia a modo oscuro al momento de iniciar

el proceso de soldadura por arco, de inmediato debe detener la operación y revisar el ADF como se

indica en estas Instrucciones. El uso continuo de un ADF que falla en el cambio a modo oscuro puede

resultar en lesiones permanentes de los ojos y pérdida de la vista. Si no puede identifi car ni

corregir el problema, no use el ADF; contacte a su supervisor o a 3M para solicitar ayuda.

• Antes de cada uso, revise cuidadosamente el Filtro 3M Speedglas 9100. Las los lentes o las micas

protectoras agrietadas, pinchadas o rayadas pueden comprometer la protección y reducir la visión.

Debe de reemplazar de inmediato todos los componentes dañados. Retire la película protectora del

visor.

• La Careta para soldadura 3M Speedglas 9100 FX no está diseñada para operaciones de soldadura/

corte aéreas de uso rudo, debido al riesgo de quemaduras proveniente del metal fundido. Usar este

producto para estas aplicaciones puede ocasionar lesiones graves o incluso la muerte.

• La Careta para soldadura 3M Speedglas 9100 FX – usada con ADFs 3M Speedglas Serie 9100- no son

adecuadas para soldadura con láser o procesos de soldadura que requieren lentes con sombra 14 o

superior. El uso de este producto para estas aplicaciones puede ocasionar lesiones permanentes en

los ojos y pérdida de la vista.

• Sólo use el ADF en temperaturas entre –5°C (23ºF) y +55ºC (131ºF). Usado sa fuera de este rango, es

posible que el desempeño del lente desempeño no sea el óptimo, lo que puede ocasionar lesiones

permanentes en los ojos y pérdida de la vista.

PRECAUCIÓN:

Deseche el equipo que ha alcanzado el total de su vida útil de acuerdo con las regulaciones locales.

LIMITACIONES DE USO

Limitaciones importantes:

• Estos productos no ofrecen ninguna protección contra riesgos respiratorios ocasionados por procesos

de soldadura u otras fuentes. La Careta para soldadura 3M Speedglas 9100 FX puede usarse junto con

ciertos modelos de respiradores. Para mayores informes sobre protección respiratoria para soldadores,

contacte al Servicio Técnico 3M en EUA al 1800-243-4630; en Canadá al 1-800-267-4414; en México al

01-800-712-0646, o contacte a 3M en su país.

Nota: La Careta para soldadura 3M Speedglas 9100 FX no incluye componentes de látex de hule

natural.

ESPECIFICACIONES

Protección ocular y facial Cumple con ANSI Z87.1-2010, requerimientos de

alto impacto y CAS Z94.3

Impacto en cabeza Ninguno – No ofrece protección contra impacto

en cabeza

Temperaturas de operación -5ºC a 55ºC (23ºF a 131ºF)

Page 28

Tabla 1. Especifi caciones de Caretas para soldadura 3M™ Speedglas™

Careta para

Datos técnicos

Área de visión

Vida de la batería (2 x CR-2032)

(min.) 2,800 horas 2,500 horas 2,000 horas

Soporte solar Sí Sí No

Peso total 9100 FX Ensamble c/

ventanas laterales (aprox.) 550 g (19.1 oz) 560 g (19.8 oz) 585 g (20.6 oz)

Sombras oscuras Sombras 5, 8, 9, 10, 11, 12, 13

Estado claro Sombra 3

Velocidad de cambio de sombra < 0.1 ms (+23°C)

Modos especiales Lijado, unión, seguro

Modos de sensibilidad 5 niveles

Rango TIG > 1 Amp

Número de sensores 3 (2 nivel del ojo, 1 central)

Retardo (recuperación) Ajustable 40 – 1300 ms

Rango de temperatura -5ºC a 55ºC (23ºF a 131ºF)

Cumplimiento de normas ANSI Z87.1-2010 & CSA Z94.3-2007

Garantía 2 años

Tamaños de cabeza 50-64 cm (6-8 pulgs)

Visor PPA

Frente plata y caja ADF Nylon

Banda para la cabeza Nylon, PP, PE, TPE

Ventanas laterales Policarbonato

Micas protectoras Policarbonato

Tela resistente a la fl ama 75% algodón, tela sintética 25% Kevlar®

soldadura 9100

FX-V

1.8 x 3.7 pulg

(45 x 93 mm)

Careta para

soldadura 9100

FX-X

2.1 x 4.2 pulg

(54 x 107 mm)

Careta para

soldadura 9100

FX-XX

2.8 x 4.2 pulg

(72 x 107 mm)

INSTRUCCIONES DE OPERACIÓN

W ADVERTENCIA

La Careta para soldadura 3M™ Speedglas™ 9100 FX cumple con los requerimientos de las normas ANSI

Z87.1-2010 y CSA Z94.3 para infl amabilidad. El usuario debe evaluar los riesgos en el lugar de trabajo y

tomar las medidas precautorias necesarias para estos. 3M no sugiere el uso de estos productos en áreas

donde es posible el contacto con fl ama abierta. El uso inadecuado puede ocasionar lesiones o incluso

la muerte.

Debe cubrir las ventanas laterales con micas protectoras en situaciones donde otros soldadores estén

trabajando en un lugar cercano y en situaciones donde la luz refl ejada pueda pasar a través de las

ventanas.

La Careta para soldadura 3M Speedglas 9100 FX no está diseñada para operaciones de soldadura/corte

aéreas de uso rudo, debido al riesgo de quemaduras proveniente del metal fundido. Usar este producto

para estas aplicaciones puede ocasionar lesiones graves o incluso la muerte.

Siempre use gafas de seguridad que cumplan con la norma ANSI Z87.1- junto con cualquier careta para

soldadura. No hacerlo puede ocasionar lesiones permanentes en los ojos y pérdida de la vista.

En Canadá debe cumplir con la norma CSA Z94.3 y/o los requerimientos para protección ocular de la

autoridad correspondiente en la región.

Desempacado

Revise si el contenido del empaque tiene algún daño por transporte y asegúrese que estén todos los

componentes. Antes de cada uso debe revisar el producto de acuerdo con los procedimientos señalados en la

sección de Inspección de estas Instrucciones.

Ajuste de careta

Nota: Para asegurarse que la Careta para soldadura 3M Speedglas 9100 FX esté bien ajustada antes

de su uso debe realizar los siguientes ajustes.

1) Coloque la Careta para soldadura 3M Speedglas 9100 FX en la cabeza y apriete la matraca en la parte

posterior de la careta (Fig. 1) hasta que logre un ajuste seguro y cómodo. Si no puede lograr un ajuste

cómodo con la matraca, use el ajuste en la banda para la cabeza frontal donde el ajuste L, M y S están

mostrados en el fondo de la Fig. 1. L se refi ere a una circunferencia de cabeza más grande, M es para

una mediana y S para una circunferencia pequeña. Arregle el ajuste con base en la circunferencia de la

cabeza y luego vuelva a colocar la careta en la cabeza y apriete la matraca para lograr un ajuste fi jo y

cómodo. Para un ajuste adicional también debe girar la matraca 180 grados para lograr un ajuste un poco

diferente con base en la posición como se muestra en la Fig. 2.

2) Las dos bandas superiores de la coronilla deben ajustarse para asegurar que el peso de la careta quede

distribuido uniformemente sobre la cabeza. Con la careta puesta y la matraca apretada, asegúrese que

ambas bandas en la coronilla están ajustadas de modo que no haya espacios entre la parte superior de

la cabeza y las bandas para la coronilla. A veces, la banda para la coronilla posterior es muy larga y dejar

un espacio, pero no es una forma adecuad de usar la careta. Si hay un espacio grande, ajuste las bandas

para la coronilla al deslizar y apretar como se muestra en la Fig. 1. Si no hay ningún espacio, pero siente

que la careta queda muy arriba de la cabeza, afl oje las bandas de la coronilla hasta que logre la altura

deseada.

51 52

Page 29

Fig. 1

53 54

Fig. 2

Page 30

3) Después, debe ajustar la posición del frente hacia atrás, de modo que la careta quede a una distancia

cómoda desde la cara, pero que no toque la nariz o la cara. El ajuste de frente hacia atrás puede lograrse

al mover los ajustes del riel en la careta, que también mueve la careta de adelante hacia afuera, como se

muestra en la Fig. 3. Asegúrese que los accesorios en ambos lados del riel de ajuste estén en la misma

posición para ayudar al balance y comodidad total.

4) Con la careta puesta en la cabeza, ajuste el ángulo de visión vertical como se muestra en la Fig. 4 para

optimizar el área de visión y la posición de la careta relativa a la aplicación del lugar de trabajo.

Fig. 4

Fig. 3

55 56

Page 31

Función del ADF

W ADVERTENCIA

Si el Lente auto-oscurecente 3M™ Speedglas™ no cambia a modo oscuro al momento de iniciar el

proceso de soldadura por arco, de inmediato debe detener la operación y revisar el ADF como se indica en

estas Instrucciones. El uso continuo de un ADF que falla en el cambio a modo oscuro puede resultar en

lesiones permanentes de los ojos y pérdida de la vista. Si no puede identifi car ni corregir el problema,

no use el ADF; contacte a su supervisor o a 3M para solicitar ayuda. La Careta para soldadura 3M

Speedglas 9100 FX – usada con ADF 3M Speedglas Serie 9100 - no es adecuada para soldadura con láser

o procesos de soldadura que requieren lentes con sombra 14 o superior. El uso de este producto para estas

aplicaciones puede ocasionar lesiones permanentes en los ojos y pérdida de la vista.

Sólo use el ADF en temperaturas entre –5°C (23ºF) y +55ºC (131ºF). Usado fuera de este rango, es posible

que el desempeño del lente desempeño no sea el óptimo, lo que puede ocasionar lesiones permanentes

en los ojos y pérdida de la vista.

Encendido/apagado

Para activar el ADF presione el botón SHADE/ON (SOMBRA/ENCENDIDO). El ADF se apaga automáticamente

después de una hora de inactividad. El ADF cuenta con tres fotosensores que reaccionan de forma

independiente y hacen que el fi ltro se oscurezca cuando se inicia el arco de soldadura. Es posible que el

ADF no se encienda si los sensores están bloqueados o el arco de soldadura está totalmente protegido. Las

fuentes de luz centellante, como las lámparas estroboscópicas, pueden activar el ADF incluso cuando no haya

un proceso de soldadura. Esta interferencia puede ocurrir desde distancias grandes y/o de luz refl ejada. Las

áreas de soldadura deben estar protegidas de esta interferencia.

Sombra

Se encuentran disponibles siete sombras diferentes, divididas en dos grupos: 5, 8 y 9-13. Para ver la

programación actual de sombra, presione por un momento el botón SHADE/ON. Para cambiar la sombra,

presione repetidas veces el botón SHADE/ON. Mueva el LED centellando hasta la sombra deseada. Para

cambiar entre los dos grupos de sombra (sombra 5,8) y (sombra 9-13); presione el botón SHADE/ON por 2

segundos. En todo proceso de soldadura el arco sólo debe verse con la sombra sugerida (Tabla 2).

Selección de sensibilidad

La programación y sensibilidad del sistema detector de luz puede ajustarse para acomodar una variedad de

procesos de soldadura y condiciones del lugar de trabajo. Para cambiar la programación de sensibilidad, pulse

el botón de SENS varias veces hasta que el LED indique la programación deseada.

57 58

Posición Seguro: estado de luz (modo de lijado) – La función de cambio está deshabilitada,

permanece en sombra 3 constante.

Posición 1 Programación menos sensible. Usada si hay interferencia desde otros arcos de

soldadura en los alrededores.