Page 1

Advanced Systems

Tester

900AST Series

Coaxial Wire Testing

Technical Tip

December 2005

78-8135-6156-6-A

Page 2

3M™ Advanced Systems Tester 900AST Series

Setup for Use

Battery Requirement

The battery holder holds six “AA” standard alkaline

batteries and should be installed prior to using the

unit. Please see the 900AST tester manual or DVD

for battery installation instructions. Always initiate a

self-calibration after installing new batteries.

The battery symbol in the upper right-hand corner

of the display gives an indication of the approximate

battery capacity. Each bar represents one-quarter of

the full capacity.

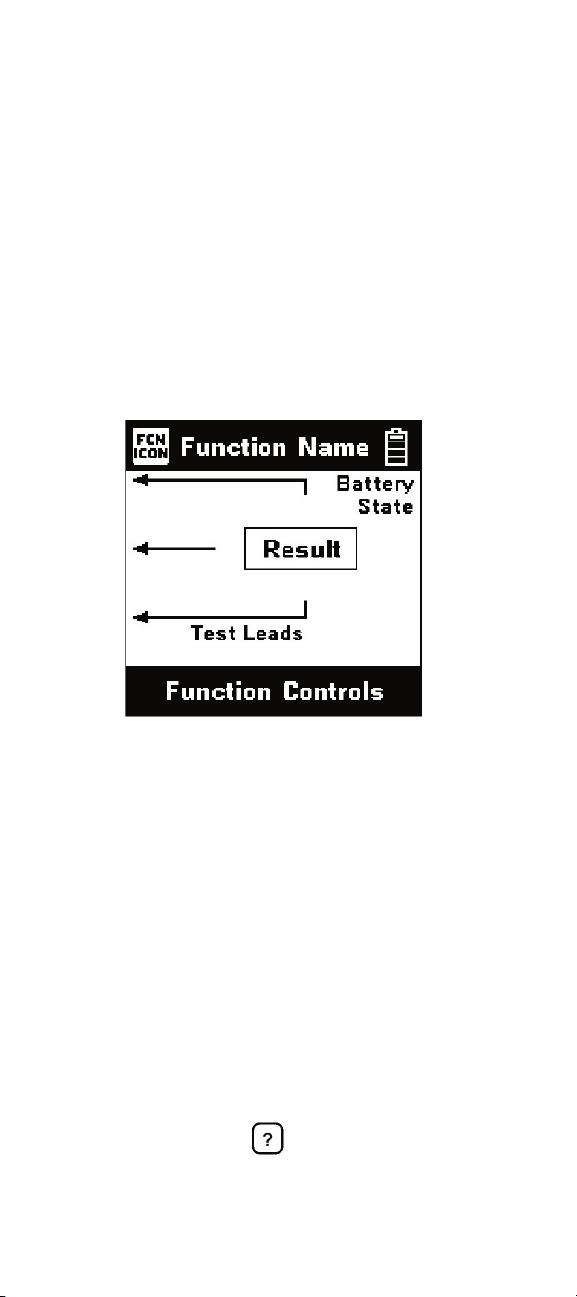

Front Panel

Test Leads

The test lead icons are shown on each of the

measurement screens and appear after a function or

test is selected. Each lead points to a color dot on

the front label that corresponds to the actual test lead

and test jack to be used. This on screen display is the

connection diagram for the selected test. The active

control keys are displayed on the bottom of the

screen and act as a guide through setup and testing.

For TDR applications using the special coaxial TDR

test lead(s), the test lead icons indicate which test

jacks (also denoted by colors) to use.

Operational Help

For operational information, refer to the 900AST

tester manual or “Help”

900AST tester keypad. For technical service,

warranty or repair questions, call 800 426 8688 (US

and Canada) or contact your local 3M representative.

control key on the

2

Page 3

3M™ Advanced Systems Tester 900AST Series

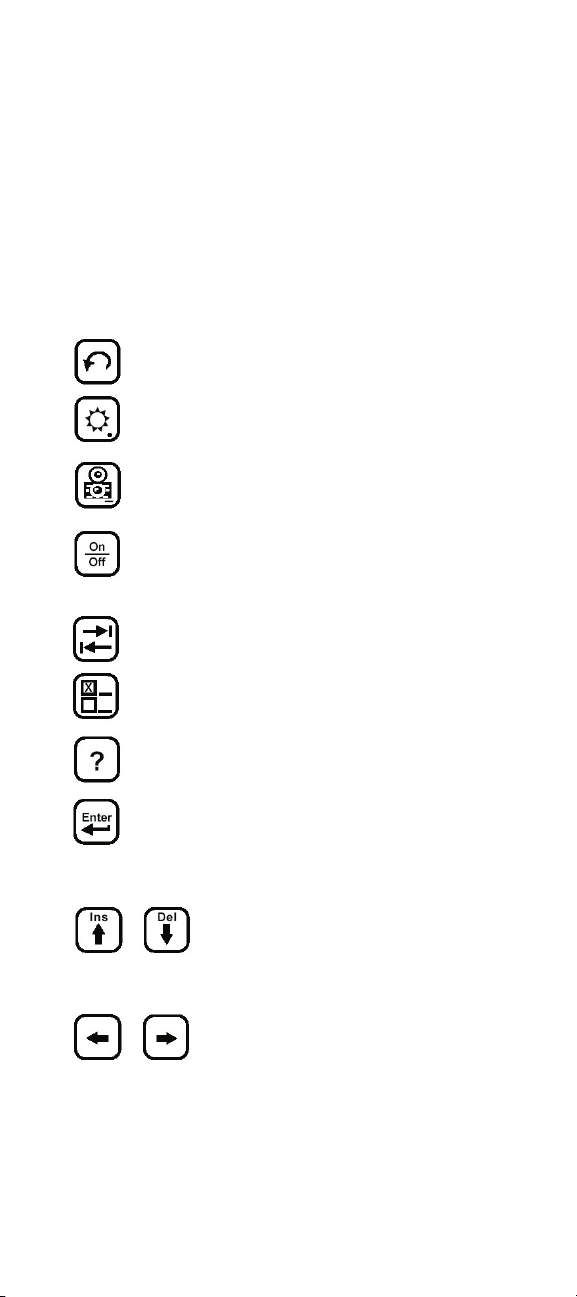

Keypad

The 900AST tester keypad has twelve yellow and

red “Control Keys” and nine blue “Function Keys”.

Additional blue keys on the keypad are reserved for

future expansion and have no designation or current

function.

Control Keys

Use the red and yellow keys to control and setup the

900AST tester and its functions.

Use the [Return] key to return to a previous

step in a function.

Use the [Contrast] key to adjust the contrast

or to turn the backlight on or off.

Use the [Save] key for storing TDR traces.

Use the [On/Off] key to turn the 900AST

power on or off (also see “Power Down

Timeout”).

Use the [Tab] key to select between

different options.

Use the [Setup] key to change the setup of a

function.

Use the [Help] key to get context sensitive

help with any screen or function.

Use the [Enter] key to accept changes or

move to the next step in a function. To

insert a space to the left of the cursor press

enter.

Use the [Up] and [Down] keys to

scroll to different menu options

or insert/delete characters when

editing.

Use the [Left] and [Right] keys to

select different options or move the

TDR cursor

3

Page 4

3M™ Advanced Systems Tester 900AST Series

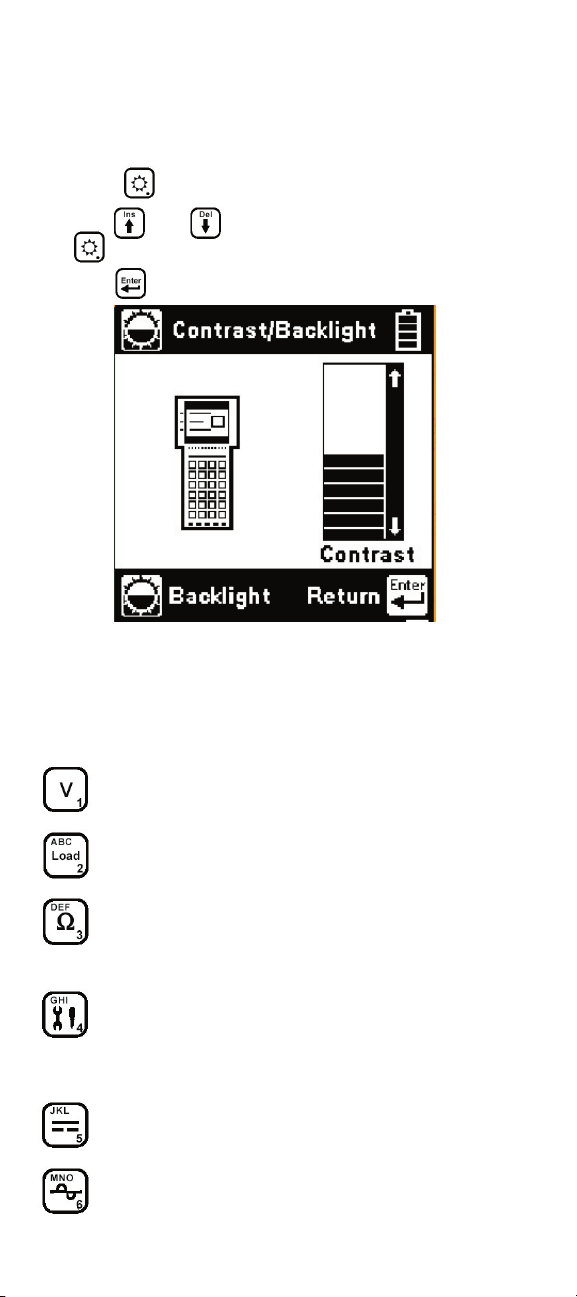

Contrast and Backlighting

Note: Use of backlight decreases available battery

capacity.

Press the

Use the

the key again to turn the backlight on or off.

Use the

key to display the contrast screen.

and

keys to adjust the contrast. Press

key to return to previous screen.

Function Keys

Use the blue keys to select the different tests in the

900AST tester. The blue keys become number or

letter keys when editing.

Use the [Voltage] key to measure DC or AC

voltage.

Use the [Load] key to measure the current

through a simulated load lamp.

Use the [Resistance] key to measure

resistance and access the ‘Soak Test’ and

‘Contact Resistance’ functions.

Use the [Toolbox] key to access: Self

Calibration, Stored Results, Special

Resistance, and the Ohms to Distance

Calculator

Use the [Capacitance] key to measure the

capacitance of a component or circuit.

Use the [Tone] key to send interrupted tone

for circuit identification.

4

Page 5

3M™ Advanced Systems Tester 900AST Series

Use the [RFL] key to find the distance to a

resistance fault between two conductors or a

conductor and ground.

This key is used for editing only.

Use the [TDR] key to activate the Time

Domain Reflectometer.

Use the [Auto] key to activate automatic

TDR trace analysis.

CAUTION

The 900AST tester is a tool for troubleshooting wiring

problems. It is not designed for troubleshooting electronic

circuits or instrumentation. The ohms, soak, contact

resistance, special resistance and RFL functions

generate a current limited (< 1 mA) 80V stimulus.

TDR and Auto TDR functions generate high-energy

electromagnetic pulses. Unexpected measurement

results and/or damage are possible if applied to

electronic circuits.

Circuit testing should be performed by personnel trained

in electrical safety practices and in accordance with

applicable safety standards.

Connecting to Coaxial Wires for Testing

Ensure that electrical power has been removed and

components disconnected from the wiring to be

tested before beginning wiring tests.

Note: For best operation, use the special coaxial

TDR test leads supplied with your 900AST

tester to perform coaxial wire TDR

measurements.

The TDR test cable has a standard male BNC

connector on the end. Plug the opposite end of the

TDR test leads plug into the Red/Black and/or Blue/

Yellow test jacks on the 900AST tester (one or more

cables may be used depending on the desired TDR

mode.)

Connect the end of the TDR test cable to the coaxial

wire to be tested. Use a BNC adapter (if needed) to

connect to the coaxial circuit under test.

5

Page 6

3M™ Advanced Systems Tester 900AST Series

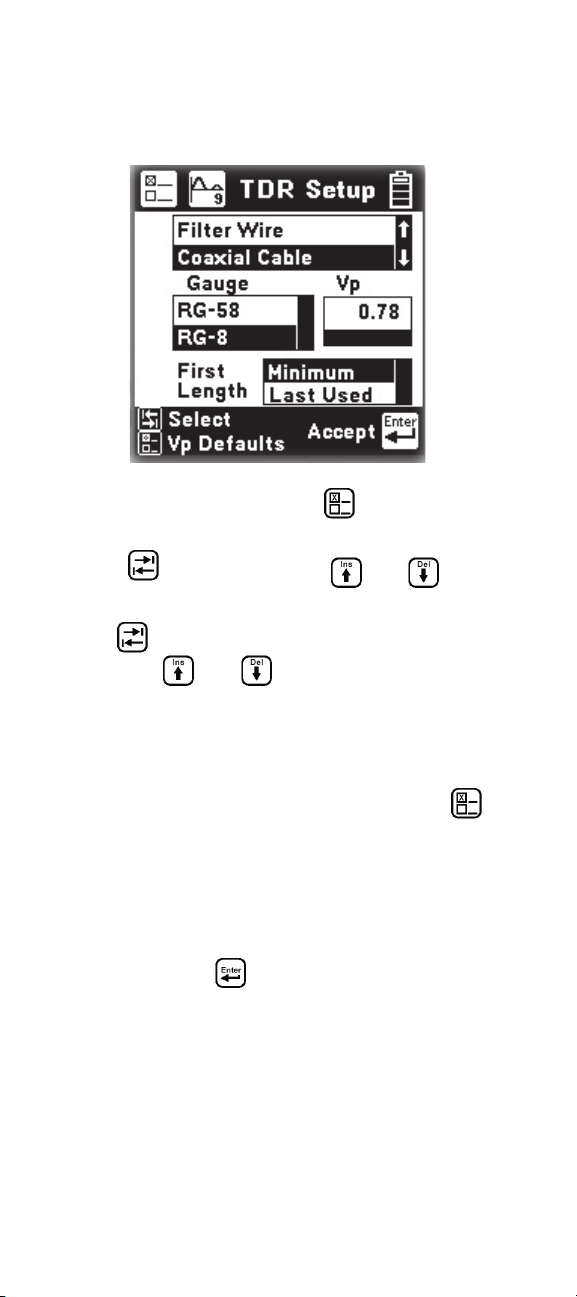

TDR Setup

The TDR features a setup function that allows you to

select the type of Coaxial wire to be tested.

From the TDR Menu, press the Setup key to

enter the TDR Setup.

Press the select key and the and arrow

keys to highlight coaxial cable for wire type.

Use the

box. Use the

select key to move to the wire gauge

and keys to highlight the type

of coaxial cable to be tested and select ‘minimum

possible’ or ‘last used’ initial measurement length

setting.

Note: The 900AST tester maintains modified Vp

settings in internal memory. Press the

key in the TDR Setup screen to restore

original default Vp settings for all wire types.

Use the blue numeric keys changes the velocity

factor for the selected coaxial wire type or use the

default setting.

Press the enter key

to accept changes and

proceed.

6

Page 7

3M™ Advanced Systems Tester 900AST Series

TDR Test Modes

Press the or keys to move to the desired

mode.

Press the key to accept the highlighted mode

and start the measurement.

Single Trace

Use the TDR Single Trace mode to test a single

coaxial wire or circuit.

7

Page 8

3M™ Advanced Systems Tester 900AST Series

Dual Trace

Dual Trace is used to compare two coaxial circuits at

the same time (usually a faulted and a good circuit).

Connect the TDR test leads to the (Red and Black

jacks) and connect the second TDR test lead set

(Blue and Yellow jacks) to the reference circuit.

This mode is valuable when testing a system with

multiple coaxial wires serving the same system.

Memory

Memory mode is used to compare a circuit under

test to a stored trace in memory. The first screen in

memory mode will show a list of the ID numbers for

all stored TDR traces. Use the

highlight the desired stored result.

and keys to

Press the key to select the highlighted result and

display the stored results list for that ID number by

type (TDR), date and time.

You can delete individual stored results by pressing

the key.

8

Page 9

3M™ Advanced Systems Tester 900AST Series

Use the and keys to highlight the desired

stored result. Press the

key to display the stored

trace on the bottom of the TDR screen and the

“live” trace on the top. You may move the cursor by

using the

and keys.

The control settings for the stored trace can be

viewed by pressing the

or keys but the

settings cannot be changed.

The TDR Memory function includes a Difference

(‘Diff’) control, accessible from the memory screen

by pressing the

Control OFF. Use the

key. The default is Difference

and arrow key to turn

the Difference Control ON. Diff combines the live

trace with the stored trace to show the difference in

the two readings.

Peak

Use the TDR Peak mode to capture events that

may be intermittent. The ‘live’ trace is displayed

continuously. As a new maximum or minimum trace

is detected, it will replace the previous one on the

display.

If the circuit being tested is stable (no intermittent

faults), then the minimum, maximum and “live”

traces should appear as a single trace.

Note: If any of the control values are changed, the

peak histories will be erased and new values

will begin to display.

9

Page 10

3M™ Advanced Systems Tester 900AST Series

Length allows you to set the distance (or span) from

the left side of the screen to the right side. The left

side of the screen is at the end of the BNC test lead

and the right side is the farthest distance that can be

displayed with the selected length

Use the or keys to move forward or

backward through the TDR controls. Use the

and keys to change the parameters for the

control selected.

Available controls are Length, Filter, VP, Pulse, and

Gain. Individual controls and their parameters are

described in the 900AST Series Instruction Manual.

Move Cursor

Note: The 900AST tester automatically compensates

for the length of the special TDR test leads.

Zero distance is at the end of the test lead

BNC male connector.

Always place the cursor to the left side of an event

to mark its location. Use the

and arrow

keys to move the cursor across the screen. The

distance from the 900AST tester to the cursor is

always shown in the center of the distance bar. The

left side of the screen is at the end of the test leads,

and the right side is the farthest distance that can be

displayed with the selected length.

TDR Save for Coaxial Wiring Comparison

Approximately 200 TDR screenshots can be saved.

You can save only the active “Single Trace” TDR

screen.

Select the TDR control parameters so the screen

displays the trace as desired.

10

Page 11

3M™ Advanced Systems Tester 900AST Series

Press the key.

The 900AST tester will display the Save Results

screen as follows:

Use the blue keys to enter an alphanumeric ID. The

ID may have up to twelve digits. Whether a number

or letter is entered depends on how many times the

key is pressed. As an example, if the Ohms key is

pressed once, the number “3” will be displayed. If

the same key is pressed twice, the letter “d” will be

displayed.

Use the

arrow to position the cursor under the

first space and enter the first character, and then

use the

arrow to move the cursor under the next

space.

Insert the next character and use the

cursor

again to position the cursor to the next position.

Continue entering numbers or letters in this manner

until all have been entered.

Use to insert a space to the left of the cursor.

To delete a character, press the

key.

Use to add a ‘dash’ in a record name.

Once the ID has been entered, press the

key to

save the current TDR trace information.

Event Recognition

Events are the “dips” and “peaks” seen on the screen

caused by faults or changes (such as an open circuit

or short) on the conductor or pair. Connectors

11

Page 12

3M™ Advanced Systems Tester 900AST Series

generally cause small upward peaks due to a change

in impedance. To determine if an upward event is an

impedance change or a main event fault you may go

to the other end of the coaxial cable and disconnect

it. Next, take a jumper and short the inner conductor

to the outer shield. If you see a large downward

deflection in the trace the small peak is impedance

change. Conversely, if you can’t see the short or

downward deflection you have an open circuit in the

cable.

Target Contact

The first peak or dip on the screen is usually the

“target contact” which occurs at the point where

the 900AST tester connects to the circuit under test.

Since impedances of the different types of coaxial

conductors vary significantly, the initial event caused

by the 100-ohm TDR launch circuit contacting

the target can usually be ignored. Remember that

distance zero (0”) begins at the end of the test leads

for the TDR function. Should the dip after the initial

peak move significantly below the line you may have

a short at the shield termination point on the end

of the cable. Move to the other end of the coaxial

conductor and connect the tester leaving the first end

open. The end of the trace should produce an upward

deflection at the end of the cable. A downward

deflection may indicate a short.

Open Circuit

Any open circuit will show up as a peak on the

screen. A complete open will be the tallest peak you

will see. You cannot see events past a complete open.

12

Page 13

3M™ Advanced Systems Tester 900AST Series

Short Circuit

A short circuit (or zero-Ohm resistance fault) will

show up as the lowest dip on the screen. You cannot

see events past a short circuit

Branch Circuit

The beginning of the branch circuit will look like

a small dip and the end of the branch will look like

an open (upward peak). Use the 900AST tester

Resistance function to measure the resistance of

the conductors. If the resistance is high, you may

suspect a branch circuit.

Resistance Faults on Coaxial Cable

A resistance fault will show as a dip on screen. The

lower the value of resistance (or the closer to a zeroohm short), the lower the dip. Use the resistance

function to check the coaxial cable for a resistive

fault. Use the Soak test function to determine if the

resistive fault is caused by moisture, corrosion or if

it is purely resistive.

Soak Test

Use the Soak Test function to continuously measure

the insulation resistance of a coaxial conductor inner

conductor to shield.

13

Page 14

3M™ Advanced Systems Tester 900AST Series

Connect the 900AST test leads to the coaxial

conductor under test.

Press the

key to access the Soak test from the

Resistance screen.

Use the

key to save the active resistance to the

“Snap Shot” area.

Rising resistance in the active box typically indicates

moisture while falling resistance indicates corrosion.

Auto TDR for Coaxial Fault Detection

Use the Auto TDR function to have the 900AST

tester analyze and interpret a TDR coaxial cable

trace.

The Auto TDR function imports the coaxial

configuration selected in the TDR function using the

Setup key.

14

Page 15

3M™ Advanced Systems Tester 900AST Series

To change the coaxial configuration go to the TDR

function and press the Setup key.

Use the

and keys and the Blue numeric

keys to enter the length of cable to analyze. Enter a

length longer than the cable being tested but as close

as possible to the total length of the cable.

When the correct information is displayed on the

Auto TDR screen, press the

key to start the

analysis. The 900AST performs tests to determine

if the cable is shorted, open circuited, or has a

resistance fault.

Note: Auto TDR operates from a captured trace.

The trace is not ‘live’ as in the standard TDR

mode.

Auto TDR Resistive Faults

Note: Resistance faults are very difficult to detect

using TDR techniques. If a resistance fault

is detected, the 900AST tester prompts you

to consider using the RFL (Resistance Fault

Locate) function as shown below.

Auto TDR Trace Analysis

If the Auto TDR detects an open circuit, the cursor

is positioned at the location of the open circuit and

OPEN is displayed below the trace. If the Auto

TDR detects a short circuit or low resistance fault,

the cursor is positioned at the location of the short

circuit and SHORT is displayed below the trace.

15

Page 16

3M™ Advanced Systems Tester 900AST Series

In this case the low impedance anomaly at 24

inches is detected but not classified. The Auto TDR

displays ‘????’ below the trace.

Restoring the Aircraft After Testing/

Troubleshooting

Disconnect the 900AST TDR test cable from the

aircraft wiring. Also, remove any adapters (if

used). Ensure the other end of the coaxial cable is

reconnected. Reinstall the line replaceable unit or

component that was removed to accomplish testing

or troubleshooting and perform all applicable

maintenance manual procedures and operational

checks.

Care and Maintenance

Please see the 900AST Series Instruction Manual for

care and maintenance information.

16

Page 17

3M™ Advanced Systems Tester 900AST Series

This is the EU symbol for equipment that is covered

under the Waste from Electrical and Electronic

Equipment (WEEE) directive per CENELEC

Specification 5041. It indicates that certain products

should not be discarded in the trash, but rather

should be recycled. This applies to all electronic

pluggable and battery powered products.

3M is a trademark of 3M Company.

Important Notice

All statements, technical information, and recommendations

related to 3M’s products are based on information believed to

be reliable, but the accuracy or completeness is not guaranteed.

Before using this product, you must evaluate it and determine if

it is suitable for your intended application. You assume all risks

and liability associated with such use. Any statements related to

the product which are not contained in 3M’s current publications,

or any contrary statements contained on your purchase order

shall have no force or effect unless expressly agreed upon, in

writing, by an authorized officer of 3M.

Warranty; Limited Remedy; Limited Liability.

This product will be free from defects in material and manu

facture for a period of one (1) year from the time of purchase. 3M MAKES NO OTHER WARRANTIES INCLUDING,

BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE. If this product is defective within the warranty period

stated above, your exclusive remedy shall be, at 3M’s option, to

replace or repair the 3M product or refund the purchase price of

the 3M product. Except where prohibited by law, 3M will not

be liable for any indirect, special, incidental or consequential loss or damage arising from this 3M product, regardless

of the legal theory asserted.

-

Aerospace and Aircraft Maintenance Division

Transportation Business

3M Center, Building 220-9W-14

St. Paul, MN 55144-1000

1-800-364-3577 or 651-737-6501

www.3M.com/aerospace

17

78-8135-6156-6-A

© 3M 2005

Loading...

Loading...