Page 1

Transportation Safety Division

3M™ Piezo Inkjet Series 8900UV

Ink

Product Bulletin Series 8900UV November 2020

Replaces PB 8900UV Dated August 2020

1 Description

3M™ Piezo Inkjet Series 8900UV Ink is designed as part of 3M's system of matched components for application

with Durst 163TS and EFI H1625-RS Wide Format Inkjet Printers onto 3M™ Advanced Flexible Engineer Grade

Reflective Sheeting Series 7300, 3M™ High Intensity Prismatic Digital Sheeting Series 3930DS, and 3M™ Diamond

Grade™ DG

3

Prismatic Digital Sheeting Series 4000DS. These UV curable inks are durable, transparent, weather-

resistant, and have excellent color retention when used in combination with the appropriate recommended 3M

system of matched components.

The ink is available in the following colors.

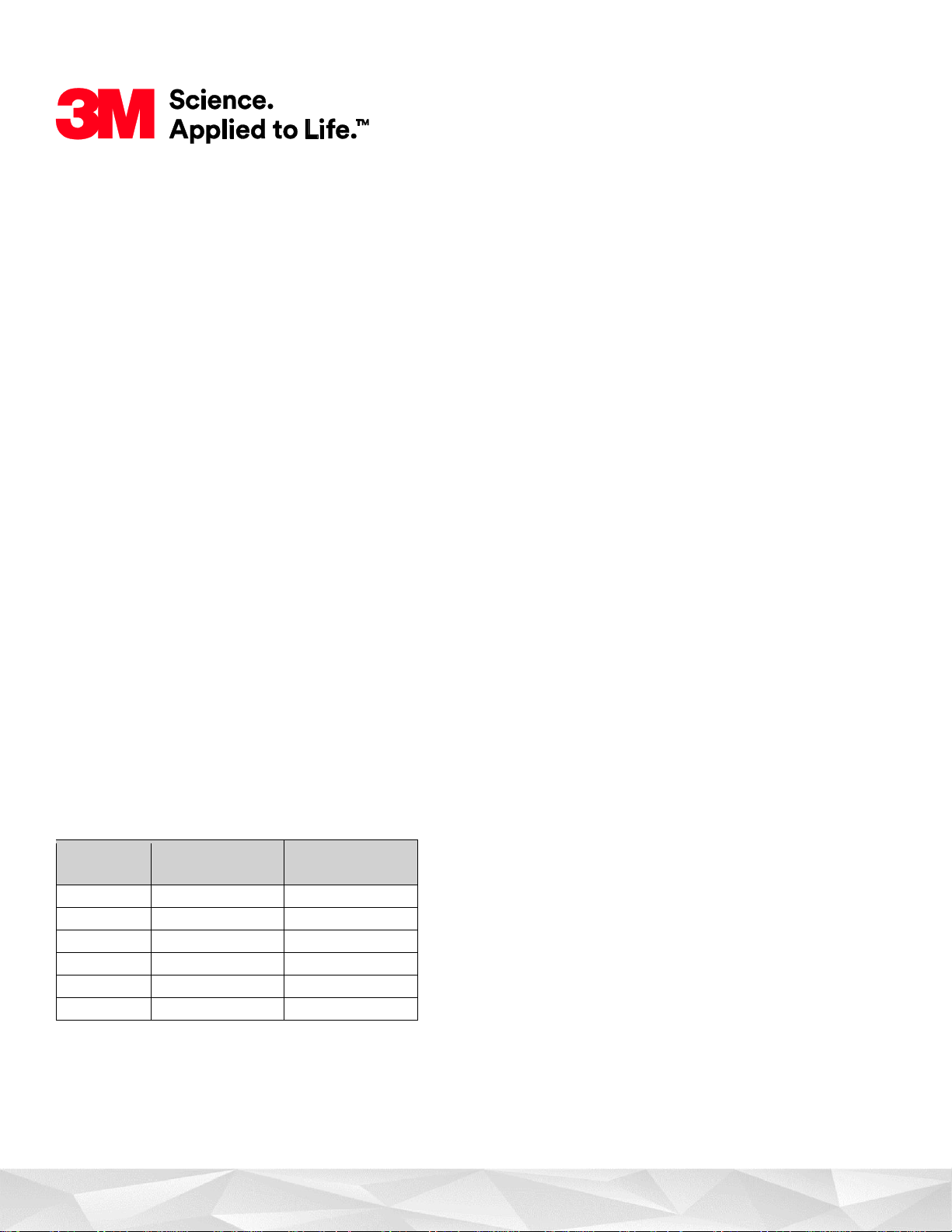

Table 1. Product codes by color for EFI and Durst printers.

Ink Color

EFI H1625-RS

Product Code

Durst 163TS

Product Code

Blue

8903UV v2

8953UV v2

Black

8905UV

8955UV

Red

8922UV

8972UV

Yellow

8924UV

8964UV

Magenta

8915UV

8965UV

Cyan

8916UV

8966UV

Page 2

2 3M™ Piezo Inkjet Series 8900UV Ink March 2020

2 ASTM Compliance

When 3M recommended settings are used, traffic colors yellow, red, blue, green, and brown printed with 3M

Piezo Inkjet Series 8900UV Inks onto 3M™ Advanced Flexible Engineer Grade Reflective Sheeting Series 7300 and

laminated with 1170 clear overlaminate, are expected to meet the daytime color, nighttime color, and daytime

luminance factor requirements stated in ASTM D4956, Tables 11, 13, and 2, respectively, and have not less than

70% of the coefficients of retroreflection (RA) stated in ASTM D4956 Table 1 (Type I).

When 3M recommended settings are used, traffic colors yellow, red, blue, green, brown, purple, and orange,

printed with 3M Piezo Inkjet Series 8900UV Inks onto 3M High Intensity Prismatic Digital Sheeting 3930DS and

laminated with 1170 clear overlaminate, are expected to meet the daytime color, nighttime color, and daytime

luminance factor requirements stated in ASTM D4956, Tables 11, 13, and 2, respectively, and have not less than

70% of the coefficients of retroreflection (RA) stated in ASTM D4956 Table 5 (Type IV).

When 3M recommended settings are used, traffic colors yellow, red, blue, green, brown, purple, and orange,

printed with Piezo Inkjet Series 8900UV Inks onto 3M Diamond Grade DG3 Prismatic Digital Sheeting 4090DS and

laminated with 1170 clear overlaminate, are expected to meet the daytime color, nighttime color, and daytime

luminance factor requirements stated in ASTM D4956, Tables 11, 13, and 2, respectively, and have not less than

70% of the RA values stated in ASTM D4956 Table 10 (Type XI).

When 3M recommended settings are used, black, printed on 3M™ Advanced Flexible Engineer Grade Reflective

Sheeting Series 7300, 3M High Intensity Prismatic Digital Sheeting Series 3930DS, or 3M Diamond Grade DG3

Prismatic Digital Sheeting Series 4000DS and laminated with 1170 clear overlaminate, will appear opaque.

3 Durability

3M reflective sheeting durability depends upon substrate selection and preparation, compliance with

recommended application procedures, geographic area, exposure conditions, and maintenance. Maximum

durabilities can be expected in applications subject to vertical exposures on stationary objects when processed

and applied to properly prepared aluminum according to 3M recommendations provided in Information Folder

1.7. The user must determine the suitability of any nonmetallic sign backing for its intended use. Applications to

unprimed, excessively rough, or non-weather-resistant surfaces and exposure to severe or unusual conditions

can shorten the lifetime of 3M sheeting. Signs in mountainous areas that are covered by snow for prolonged

periods may also have reduced durabilities. Atmospheric conditions in certain geographic areas may result in

reduced durability.

Important Notice: This product bulletin provides technical information only. The user must determine the

suitability of the product for its required or intended use, and the user assumes all risk and liability whatsoever

in connection herewith.

4 Disclaimer

With the exception of 3M branded products, 3M does not represent that any printer or printer accessory

recommended in 3M literature will meet customer requirements, any federal, state, or local regulations, or any

applicable safety standards. Such determination is the responsibility of the printer owner. For a buyer's

convenience, 3M may provide engineering or technical information, recommendations, certifications, and other

information or materials relating to other company's products (“Other Information”), but 3M does not warrant

Other Information, including but not limited to its accuracy or completeness.

Page 3

3 3M™ Piezo Inkjet Series 8900UV Ink March 2020

5 Printing Guidelines

Please follow the recommendations below for best results.

5.1 Selecting, Preparing & Using 3M Retroreflective Sheeting

Do not use damaged rolls of sheeting, as this can result in head strikes and printer damage. Condition the

sheeting, ink and overlaminate for at least 24 hours in the same environment as the printer before using.

5.2 Printing Recommendations for Traffic Signage

Printer set-up is critical to achieving good image quality and ensuring proper sheeting processing. Please

follow the printer setting recommendations provided by the printer manufacturer during printer

installation, as they are required as part of 3M's system of matched components for the production of traffic

signs.

5.3 Operation and Maintenance Procedures

Printer maintenance is very important in the production of high quality signs and graphics. Follow all

operation and maintenance procedures recommended in the printer's user manual.

5.4 Application of Overlaminate

To avoid silvering artifacts (trapped air between the ink layer and overlaminate), the lamination process

should be conducted using a laminator that meets the following performance considerations:

1 Roll to roll laminator

2 Minimum 48" wide, Maximum 65" wide

3 Top nip roll heated to 150 °F

4 Prefer pneumatically controlled nip

5 Rubber covered nip rolls capable of a minimum nip pressure of 7 pounds per lineal inch

6 Speed variable from 0-10 feet per minute

7 One unwind shaft for printed sheeting

8 One unwind shaft for overlaminate

9 One rewind shaft for finished product

10 One rewind shaft for overlaminate liner

6 Shelf Life and Storage

Use inks within one year of date of manufacture. Leave the ink in the original packaging during both storage and

use to prevent exposure to light. Light can cause the UV ink to cure prematurely and damage the printer. Store at

temperatures between 32 and 80 °F.

7 Environmental, Health, and Safety

Read all health hazard, precautionary, and first aid statements found in the safety data sheet (SDS), article

information sheet, and/or product label of chemicals prior to handling or use. Consult local regulations and

authorities for possible restrictions. Visit us at www.3M.com/US and select SDS Search to obtain current safety

data sheets, contact 3M by mail, or, for urgent requests, call 1-800-364-3577.

When using any equipment, always follow the manufacturers' instructions for safe operation.

Page 4

4 3M™ Piezo Inkjet Series 8900UV Ink March 2020

8 Warranty Information

8.1 3M Basic Product Warranty

3M Piezo Inkjet Series 8900UV Ink (“Product”) is warranted (“Basic Warranty”) to be free of defects in

materials and manufacture at the time of shipment and to meet the specifications stated in this product

bulletin. If the Product is proven not to have met the Basic Warranty on its shipment date, then a buyer's

exclusive remedy, and 3M's sole obligation, at 3M's option, will be refund or replacement of the Product.

8.2 3M MCS™ Warranty, MCS Warranty for Traffic, and Limited Remedy

For the MCS Warranty, MCS Warranty for Traffic, and limited remedies applicable to the Product, refer to the

3M Digitally-Imaged Sign Warranty Bulletin.

8.3 Warranty Disclaimer

THE 3M WARRANTY IS MADE IN LIEU OF ALL OTHER WARRANTIES OR CONDITIONS, EXPRESS OR

IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY OR CONDITION OF

MERCHANTABILITY, OR FITNESS FOR A PARTICULAR PURPOSE, OR ANY IMPLIED WARRANTY ARISING OUT

OF A COURSE OF DEALING OR OF PERFORMANCE, CUSTOM, OR USAGE OF TRADE.

8.4 Limitation of Liability

Except for the exclusive remedy stated above, and except where prohibited by law, 3M will not be liable for

any loss or damage arising from signs or any 3M product, whether direct, indirect, special, incidental, or

consequential damages (including but not limited to lost profits, business, or revenue in any way),

regardless of the legal theory asserted including warranty, contract, negligence, or strict liability.

9 Other Product Information

Always confirm that you have the most current version of the applicable product bulletin, information folder, or

other product information from 3M’s Website at http://www.3M.com/roadsafety.

10 Literature References

3M IF 1.7

Sign Base Surface Preparation

3M IF 1.11

Sign Maintenance Management

3M IF 1.19

Digital Imaging with Durst 163TS Printers on 3M™ Reflective Sheeting

3M IF 1.20

Digital Imaging with EFI H1625 RS Printer on 3M™ Reflective Sheeting

3M PB 1170

3M™ ElectroCut™ Film Series 1170

3M PB 7300

3M™ Advanced Flexible Engineer Grade Reflective Sheeting Series 7300

3M PB 3930DS

3M™ High Intensity Prismatic Reflective Digital Sheeting Series 3930DS

3M PB 4000DS

3M™ Diamond Grade™ DG3 Prismatic Reflective Digital Sheeting Series 4000DS

ASTM Test Methods are available from ASTM International, West Conshohocken, PA.

Page 5

For Information or Assistance

Call: 1-800-553-1380 In

Canada Call:

1-800-3M HELPS (1-800-364-3577)

Internet: http://www.3M.com/roadsafety

3M, Science. Applied to Life., Diamond Grade, MCS, and ElectroCut are trademarks of 3M. Used under license in Canada. All

other trademarks are the property of their respective owners.

3M assumes no responsibility for any injury, loss, or damage arising out of the use of a product that is not of

our manufacture. Where reference is made in literature to a commercially available product, made by another

manufacturer, it shall be the user’s responsibility to ascertain the precautionary measures for its use outlined

by the manufacturer.

Important Notice

All statements, technical information and recommendations contained herein are based on tests we believe to

be reliable at the time of this publication, but the accuracy or completeness thereof is not guaranteed, and the

following is made in lieu of all warranties, or conditions express or implied. Seller's and manufacturer's only

obligation shall be to replace such quantity of the product proved to be defective. Neither seller nor

manufacturer shall be liable for any injury, loss or damage, direct, indirect, special, or consequential, arising

out of the use of or the inability to use the product. Before using, user shall determine the suitability of the

product for his/her intended use, and user assumes all risk and liability whatsoever in connection therewith.

Statements or recommendations not contained herein shall have no force or effect unless in an agreement

signed by officers of seller and manufacturer.

Transportation Safety Division

3M Center, Building 0225-04-N-14

St. Paul, MN 55144-1000 USA

Phone 1-800-553-1380

Web 3M.com/roadsafety

Please recycle. Printed in USA © 3M 2020.

All rights reserved. Electronic Only

Loading...

Loading...