Page 1

5419 Low Static Polyimide Film Tape

Product Data Sheet

Updated : March 1996

Supersedes : November 1993

Product Description

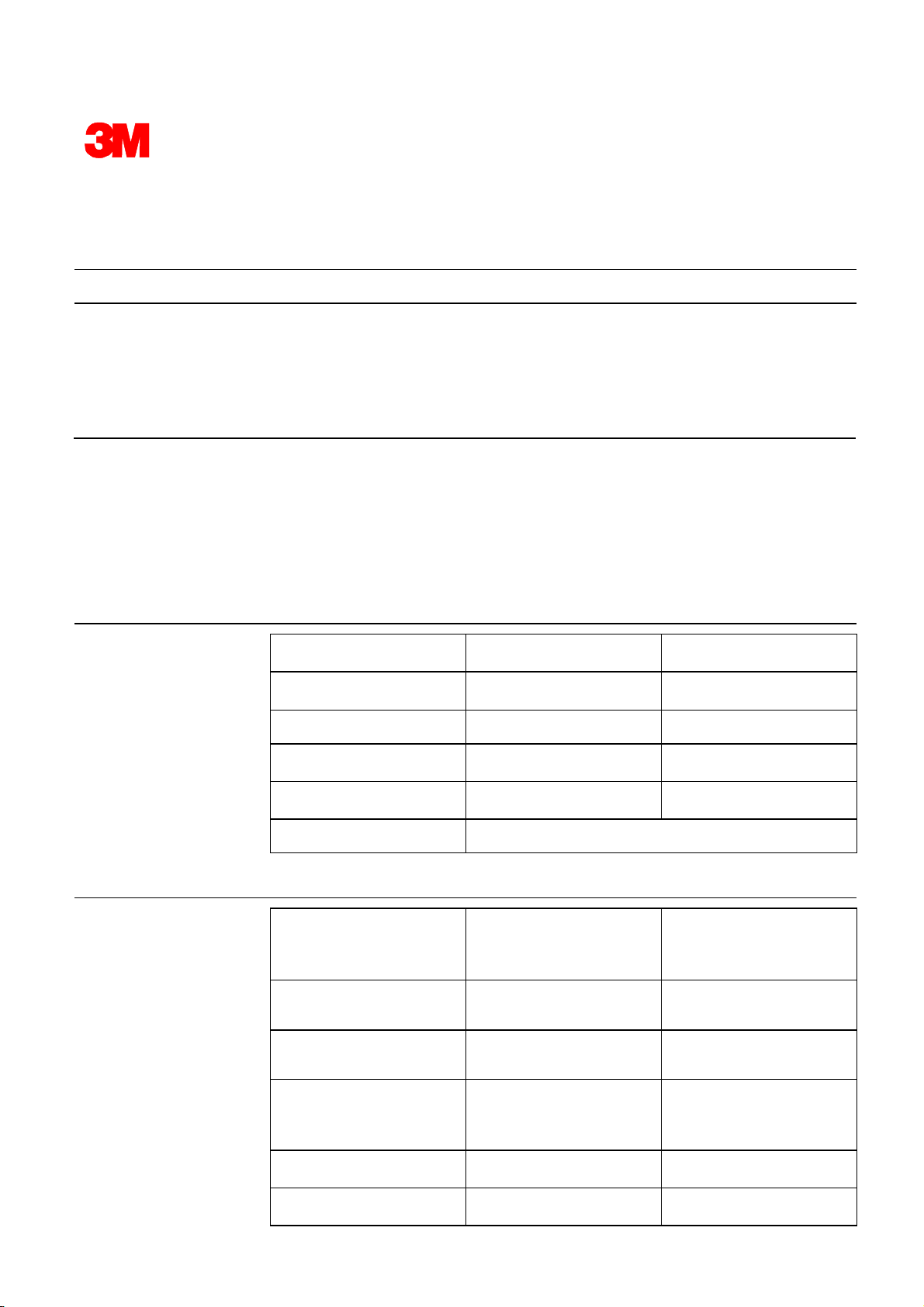

Physical Properties

Not for specification purposes

A translucent polyimide film

backed silicone adhesive

tape with unique and

extremely low electrostatic

discharge properties for

gold edge protection during

wave soldering of printed

circuit boards.

Adhesive Type

Backing

Thickness (ASTM D-3652)

Backing Thickness

Tape Colour

Shelf Life

Silicone

Polyimide

70 µm

30 µm

Gold

12 months from date of despatch by 3M when stored in the

original carton at 21°C (70°F) & 50 % Relative Humidity

Performance

Characteristics

Not for specification purposes

Adhesion to Stainless

Steel ASTM D-3330

Tensile Strength

ASTM D-3759

Elongation at Break

ASTM D-3759

Temperature Range

Maximum

Minimum

Dielectric Strength

Insulation Resistance

2.2 N/10mm

577.8 N/10mm

60 %

260 °C

-73 °C

7000 volts

6

>1*10

ohms

Page 2

Date : March 1996

5419 Low Static Polyimide

Film Tape

2

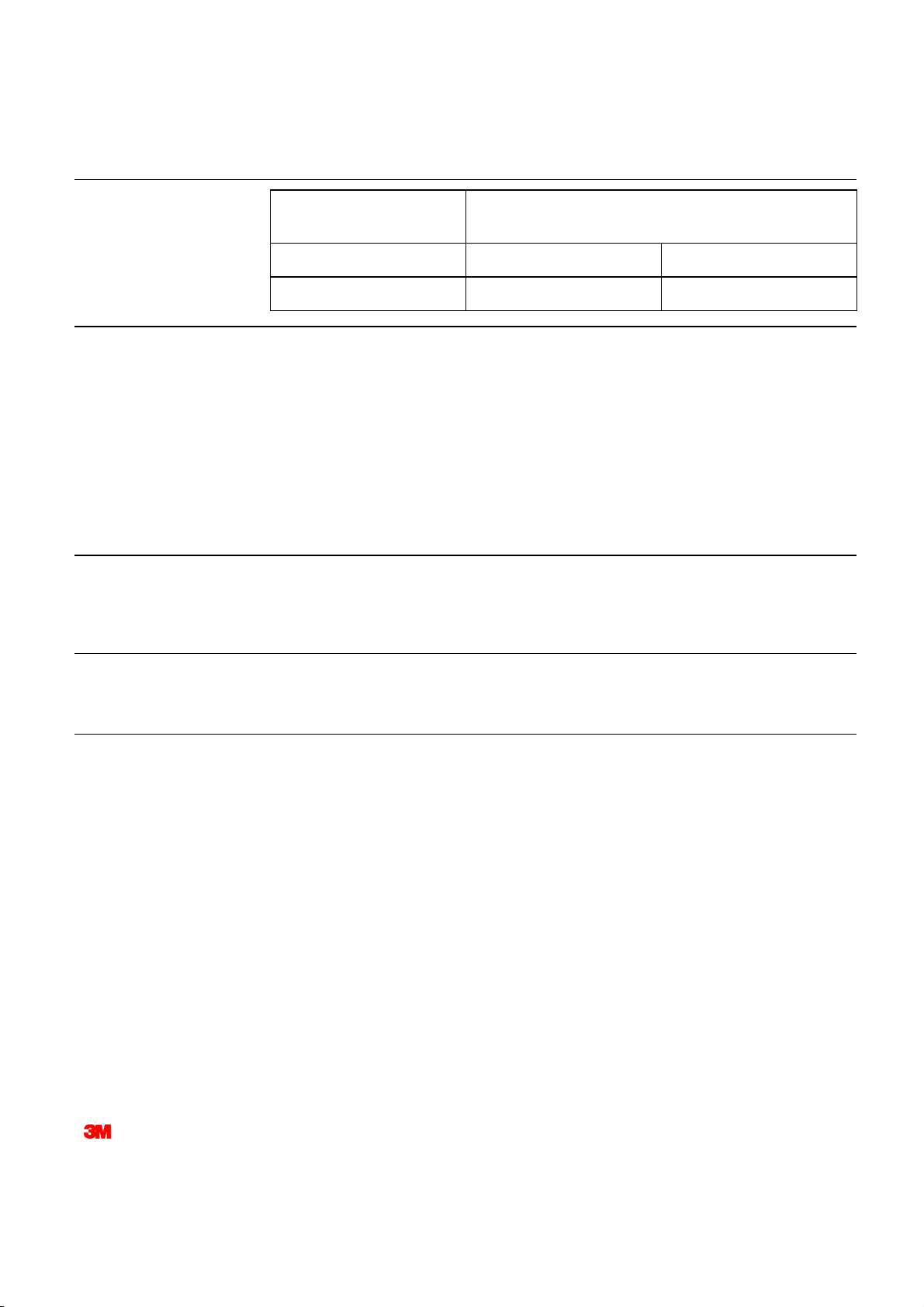

Performance

Characteristics

Not for specification purposes

Additional Product

Information

Application Techniques

Static Charge

Removal from roll

Removal from PCB

5419 tape employs a

proprietary technology that

results in extremely low

electrostatic discharge at

unwind and removal from

the PCB. Conventional

polyimide tapes can

typically generate over

10,000 volts during use

which can damage board

mounted electronic

components.

Best results are attained

when applied to a clean, dry

and non dusty surface

above 0°C.

(Measured at 50% RH, 21° in an ESD Controlled

Environment.

< 150 volts

< 50 volts

5419 tape overcomes this

problem without any of the

typical drawbacks of

conventional "anti-static" or

"static-free" tapes (e.g.

variable adhesion and

opaqueness).

At room temperature the

properties of polyimide and

polyester film are similar.

However, as the

temperature increases or

decreases, to properties of

the polyimide film are less

affected than polyester.

Polyimide film does not

soften at elevated

temperatures, thus, the film

provides an excellent

release surface at elevated

temperatures.

To improve adhesion ensure

firm and even application

pressure is applied.

Applications

Mask for printed circuit

boards during wave solder

or solder dip process.

Used as release surface in

fabrication of parts cured at

elevated temperatures.

Features Advantages Benefits

Polyimide Film Dimensionally stable at high

temperatures.

Flame retardant and chemical

resistant.

Silicone Adhesive High temperature performance

reduces adhesive transfer.

Low Static Virtually eliminates circuit board

degradation due to electrostatic

discharge.

3M is a trademark of the 3M Company.

Values presented have been determined by standard test methods and are average values not to be used for specification purposes.

Our recommendations on the use of our products are based on tests believed to be reliable but we would ask that you conduct your own tests to

determine their suitability for your applications.

This is because 3M cannot accept any responsibility or liability direct or consequential for loss or damage caused as a result of our

recommendations.

Helps promote high productivity.

Protect surfaces, helping reduce

replacement.

Helps promote high productivity.

Reduces costly board waste due

to component failure.

Specialty Tapes & Adhesives

3M United Kingdom PLC

3M House,

28 Great Jackson Street,

Manchester,

M15 4PA

Customer Service :

Tel 0161 236 8500

Fax 0161 237 1105

3M Ireland

3M House, Adelphi Centre,

Upper Georges Street,

Dun Laoghaire,Co. Dublin,

Ireland

3M United Kingdom PLC 1996

Customer Service :

Tel (01) 280 3555

Fax (01) 280 3509

Loading...

Loading...