Motor Lead Pigtail Splice

for 5/8 kV Non-Shielded Cables

for 1000 Volts or less cables (heavy-duty and two-hole lug applications)

Instructions

Kit Contents (kit contains 3 splices):

3—Lug Covers

3—Locking Pins

3—Tubes Silicone Grease

3—Bag Solvent Cleaning Cloths

3—Mastic Sealing Strip(s)*

3— Strips Scotch

3—Instruction Sheet

*Quantity varies with kit number.

®

Linerless Rubber Splicing Tape 130C

Table 1

Kit Cable

Number

Feeder Motor

5316 8–4 10–4 0.30–0.51

5317 2–1/0 4–1/0 0.43–0.65

5318 1/0–250 2–250 0.53–0.88

5319 250–500 4/0–500 0.75–1.12

Size

(AWG/kcmil)

Range

Insulation

Lead O.D.

Cable

Range Length

CSA Certified for

600V or Less

Max.

in.

in.

in. 1

in. 1

Bolt

1

3

⁄

in.

⁄

2

in.

4

1

in.

⁄

4

1

⁄

in.

2

Technical Information:

• For non-shielded cables

• Rated 5/8 kV

• For cables rated 1000 Volts or less (heavy-duty and two

hole lug applications)

• Cable Size Range: Feeder: #8 AWG—500 kcmil

Motor Lead: #10 AWG—500 kcmil

• Copper Conductors

Caution

Working around energized systems may cause serious

injury or death. Installation should be performed by

personnel familiar with good safety practice in handling

electrical equipment. De-energize and ground all

electrical systems before installing product.

3M

™

Motor Lead

Pigtail Splice Kits

for 5/8 kV or less Non-Shielded Cables

5316, 5317, 5318, 5319

78-8096-4634-8-F

1.0 Prepare Cable According to Standard Procedures

1.1 Check to be sure cables fit within cable kit range as shown in Table 1 on cover.

1.2 Remove cable insulation for length recommended by terminal lug manufacturer; if no information is available, remove

fordepth of lug barrel.

2.0 Install Lugs

2.1 Install and crimp lugs per manufacturer’s direction. See back page if 3M™ Scotchlok™ Copper Lugs are used.

2.2 Clean insulation for approximately 6 using solvent saturated cloths provided in kit.

2.3 FOR 8kV ONLY. Fill lug/insulation gaps with Scotch

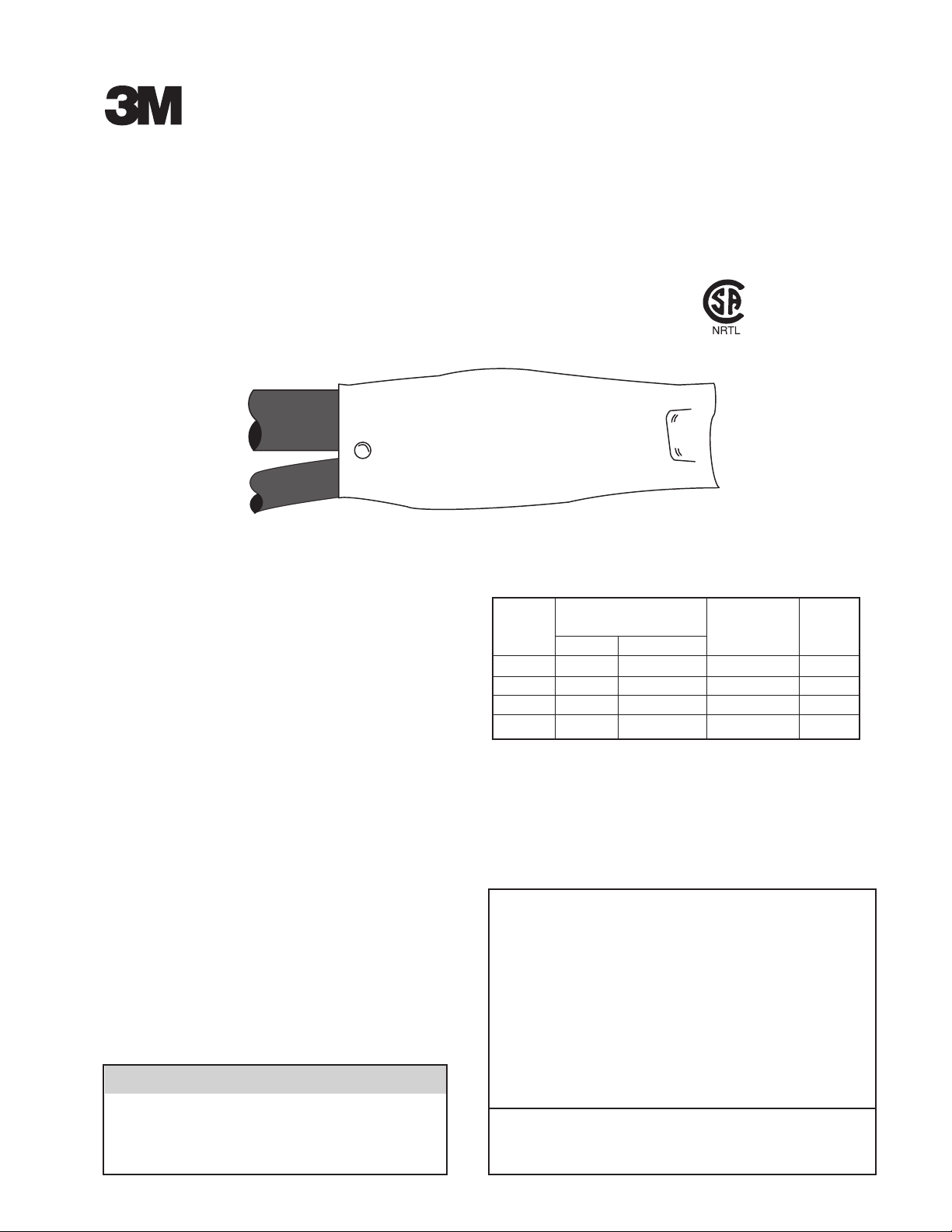

Figure 1

®

Scotch

Linerless Rubber Splicing Tape 130C

®

Linerless Rubber Splicing Tape130C (Figure 1).

2.4

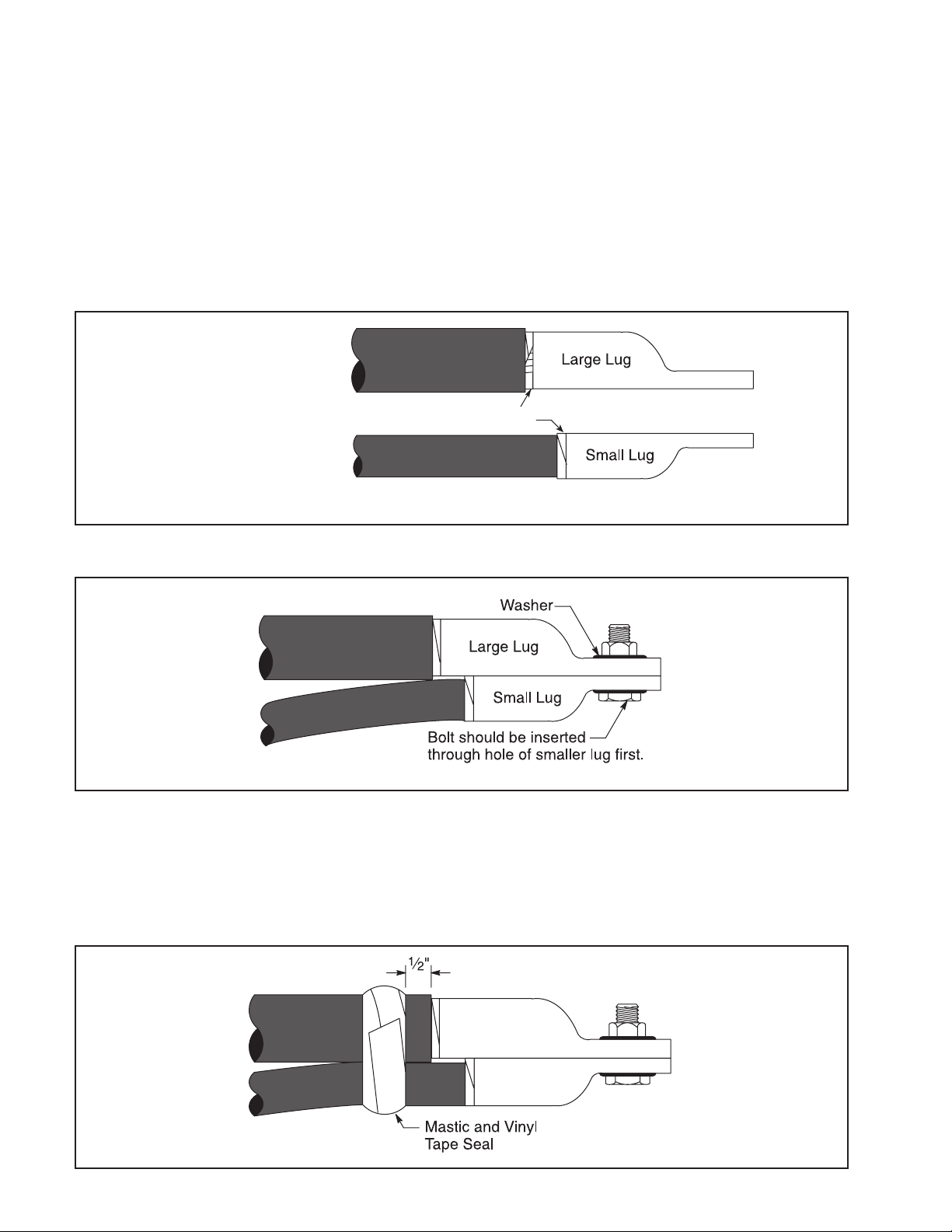

Bolt lugs together. See Table 1 on cover for maximum bolt length. See Figure 2 for proper bolt/lug arrangement.

Figure 2

3.0 Install Lug Cover

3.1 Separate cables and apply mastic strip between and around them, 1⁄2" from ends of cable insulations (Figure 3). Build

mastic to an overall diameter that is greater than the inside diameter of the Lug Cover. Press cables together and make

certain that no void exists between them (Figure 3).

3.2 Overwrap the mastic with 1 or 2 wraps of vinyl tape (Figure 3).

Figure 3

2

78-8096-4634-8-F

Loading...

Loading...