Page 1

RANDOM ORBITAL SANDER

INSTRUCTION MANUAL

127 mm (5 in) and 150 mm (6 in) 12,000 RPM

Important Safety Information

Please read, understand and follow all safety information contained in these instructions prior to the use of this tool. Retain these

instructions for future reference.

Intended Use

This pneumatic tool is intended for use in industrial locations, and used only by skilled, trained professionals in accordance with the

instructions in this manual. This pneumatic tool is designed to be used with a disc pad and appropriate abrasive for sanding metals,

wood, stone, plastics and other materials. It should only be used for such sanding applications and within marked capacity and ratings.

Only accessories specifically recommended by 3M should be used with this tool. Use in any other manner or with other accessories

could lead to unsafe operating conditions.

Do not operate tool in water or in an excessively wet application.

Do not use disc pads that have a Max RPM or Max OPM less than the tool Max RPM or Max OPM rating. Never use disc pads that have

a weight and/or size different than what the tool was specifically designed for.

Explanation of Signal Word Consequences

WARNING:

CAUTION:

Indicates a potentially hazardous situation which, if not avoided, may result in death or serious injury

and/or property damage.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate

injury and/or property damage.

WARNING

To reduce the risks associated with impact from abrasive product, disc pad, or tool breakup, sharp edges, hazardous

pressure, rupture, vibration and noise:

• Read, understand and follow the safety information contained in these instructions prior to the use of this tool. Retain these

instructions for future reference.

• Only personnel who are properly trained should be allowed to service this tool.

• Practice safety requirements. Work alert, have proper attire, and do not operate tools under the inuence of alcohol or drugs.

• Operators and other personnel must always wear protection for eyes, ears, and respiratory protection when in the work area or

while operating this product. Follow your employer’s safety policy for PPE’s and/or ANSI Z87.1 or local/national standards for

eyewear and other personal protective equipment requirements.

• Wear protective apparel, taking into consideration the type of work being done.

• Never exceed marked maximum input pressure (90psi / .62Mpa / 6.2Bars).

• Proper eye protection must be worn at all times.

• Tool shall not be operated in the presence of bystanders.

• If you notice any abnormal noise or vibration when operating the tool, immediately discontinue its use and inspect for worn or

damaged components. Correct or replace the suspect component. If abnormal noise or vibration still exists, return the tool to 3M

for repair or replacement. Refer to warranty instructions.

• Never operate this tool without all safety features in place and in proper working order.

• Never over-ride or disable the safety features of the start-stop control such that it is in the on position.

• Make sure the tool is disconnected from its air source before servicing, inspecting, maintaining, cleaning, and before changing

abrasive product.

• Prior to use, inspect abrasive product and accessories for possible damage. If damaged, replace with new abrasive product and

accessories available from 3M.

• Only use accessories supplied or recommended by 3M.

• Never allow this tool to be used by children or other untrained people.

• Do not leave an unattended tool connected to air source.

• Immediately discontinue use of tool if its noise reduction mufer system has been damaged or is otherwise not functioning

properly. Have tool repaired before placing back into use.

3M™ 5 in & 6 in Random Orbital Sander 1 Revision 051210

Original Instructions

Page 2

WARNING

To reduce the risks associated with vibration:

• If any physical hand/wrist discomfort is experienced, work should be stopped promptly to seek medical attention. Hand, wrist and

arm injury may result from repetitive work, motion and overexposure to vibration.

To reduce the risks associated with loud noise:

• Always wear hearing protection while operating this tool. Follow your employer’s safety policy or local/national standards for

personal protective equipment requirements.

To reduce the risks associated with fire or explosion:

• Do not operate the tool in explosive atmospheres, such as in the presence of ammable liquids, gases, or dust. The abrasives are

able to create sparks when working material, resulting in the ignition of the ammable dust or fumes.

• Refer to MSDS of material being worked as to potential for creating re or explosion hazard.

To reduce the risks associated with hazardous dust ingestion or eye/skin exposure:

• Use appropriate respiratory and skin protection, or local exhaust as stated in the MSDS of the material being worked on.

To reduce the risks associated with hazardous voltage:

• Do not allow this tool to come into contact with electrical power sources as the tool is not insulated against electrical shock.

CAUTION

To reduce the risks associated with skin abrasion, burns, cuts, or entrapment:

• Keep hands, hair, and clothing away from the rotating part of the tool.

• Wear suitable protective gloves while operating tool.

• Do not touch the rotating parts during operation for any reason.

• Do not force tool or use excessive force when using tool.

To reduce the risks associated with whipping or hazardous pressure-rupture:

• Ensure supply hose is oil resistant and is properly rated for required working pressure.

• Do not use tools with loose or damaged air hoses or ttings.

• Be aware that incorrectly installed hoses and ttings might unexpectedly come loose at any time and create a whipping/impact

hazard.

To reduce the risks associated with fly off of abrasive product or parts:

• Use care in attaching abrasive product and disc pad; following the instructions to ensure that they are securely attached to the tool

before use.

• Never free spin the tool or otherwise allow it to be started unintentionally.

• Never point this product in the direction of yourself or another person, or start tool unintentionally.

• Never over-tighten accessory fasteners.

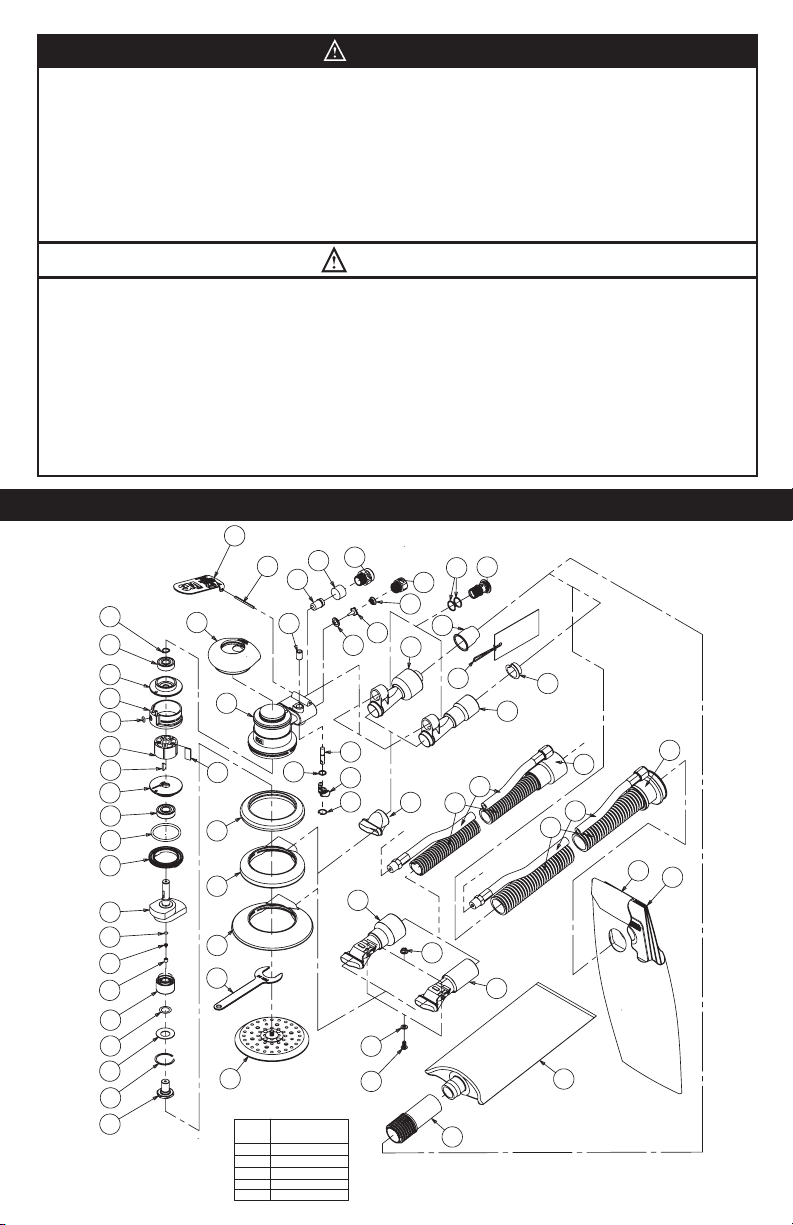

Parts Page

23

39

38

24

37

1

2

3

4

5

6

8

9

10

11

12

13

14

15

16

18

19

20

21

22

25

27

7

32

33

34

35

36

ITEM

26

29

TORQUE SETTING

in.-lbs. (Nm)

12 55 - 65 (6.2 - 7.3)

39 16 - 20 (1.8 - 2.3)

43 60 - 72 (6.8 - 8.1)

45 36 - 48 (4.1 - 5.2)

58 30 - 35 (3.4 - 3.9)

40

28

30

31

54

43

42

41

47

51

TO

INLET

57

58

45

44

46

48

64

52

55

62

INLET

TO

56

50

TO VACUUM SYSTEM

FOR CENTRAL VAC

49

63

64

52

61

53

59

60

Page 3

Parts List

Item 3M Part Number UPC Description Qty.

1 A0040 28113 EXTERNAL RETAINING RING 1

2 A0021 28107 BEARING - 2 SHIELDS 1

3 B0017 28173 REAR ENDPLATE 1

4 A0005 28094 CYLINDER ASSEMBLY 1

5 A0042 28115 5 mm x 2 mm O-RING 1

6 B0005 28170 ROTOR 1

7 A0010 28099 VANE 5

8 A0041 28114 WOODRUFF KEY 1

9 B0016 28172 FRONT ENDPLATE 1

10 A0019 28106 BEARING - 2 SHIELDS 1

11 A0045 28118 39.4 mm x 3.1mm O-RING 1

12 A0001 28093 LOCK RING 1

13 B0279 28180 5 in x 3/32 in ORBIT SHAFT BALANCER 1

B0277 28178 5 in x 3/16 in ORBIT SHAFT BALANCER 1

B0348 30325 5 in x 5/16 in (8.0 mm) ORBIT ROS BALANCER 1

B0278 28179 6 in x 3/16 in ORBIT SHAFT BALANCER 1

B0280 28181 6 in x 3/32 in ORBIT SHAFT BALANCER 1

B0334 28184 6 in x 5/16 in (8 mm) ORBIT SHAFT BALANCER 1

14 A0122 28132 FILTER 1

15 A0121 28131 DUCKBILL CHECK VALVE 1

16 A0120 28130 VALVE RETAINER 1

17 N/A N/A N/A 1

18 A0938 28148 DOUBLE ROW ANGULAR CONTACT BEARING - SEAL 1

19 A0016 28103 SPACER 12.1 mm ID x 18.0 mm OD x 0.2 mm THK 1

20 A0017 28104 BELLEVILLE WASHER 1

21 A0018 28105 RETAINING RING 1

22 B0018 28174 SPINDLE 1

23 A1351 28163 LEVER FOR 2.5 mm (3/32 in) ORBIT 1

A1352 28164 LEVER FOR 5.0 mm (3/6 in) ORBIT 1

A1447 28169 LEVER FOR 8 mm (5/6 in) ORBIT 1

24 A0031 28109 LEVER SPRING PIN 1

25 20342 20342 GRIP 2.5 in OPT

20343 20343 GRIP 2.75 in 1

20344 20344 GRIP 3 in OPT

26 A0015 28102 VALVE SLEEVE 1

27 A1330 28150 HOUSING 1

28 A0008 28097 VALVE STEM ASSEMBLY 1

29 A0043 28116 9.0 mm x 1.5 mm O-RING 1

30 B0014 28171 SPEED CONTROL 1

31 A0039 28112 INTERNAL RETAINING RING 1

32 A1346 28158 5/6 in NON-VACUUM SHROUD 1

33 A1347 28159 5/6 in SHROUD 1

A1348 28160 Ø 6 In CLEAN SANDING ROS DISC PAD SHROUD 1

35 A0022 28108 24 mm PAD WRENCH 1

36 N/A N/A DISC PAD SUPPLIED WITH EACH TOOL (TYPE DETERMINED BY MODEL) 1

37 A0062 28121 INTERNAL MUFFLER 1

38 A0068 28122 MUFFLER INSERT 1

39 A0166 28138 MUFFLER HOUSING 1

40 A0009 28098 VALVE SEAT 1

41 A0007 28096 VALVE 1

42 A0014 28101 VALVE SPRING 1

43 A0013 28100 INLET BUSHING ASSEMBLY 1

44 A0044 28117 14 mm x 1.5 mm O-RING 2

45 A0006 28095 SGV RETAINER 1

46 A0778 28146 1 in/28 mm HOSE SEAL 1

47 A1338 28156 ASSEMBLY FOR 1 in/28 mm HOSE SGV SWIVEL EXHAUST FITTING 1

48 N/A N/A TAG W/ INSTRUCTION FOR 1 in/28 mm HOSE SEAL 1

49 N/A N/A 3/4 in/19 mm HOSE SEAL N/A

50 N/A N/A ASSEMBLY FOR 3/4 in/19 mm HOSE SGV SWIVEL EXHAUST FITTING N/A

51 A1333 28153 SGV SKIRT/SHROUD ADAPTER 1

52 28301 28301 VACUUM HOSE, 1 in ID x 6 ft OPT

53 28302 28302 VACUUM HOSE ADAPTOR, 1 in Internal Hose Thread OPT

54 A1343 28157 ASSEMBLY FOR ROS CV 1 in/28 mm SWIVEL EXHAUST 1

55 A0048 28120 FLANGED NUT 1

56 A1345 28157 ASSEMBLY FOR ROS CV 3/4 in. SWIVEL EXHAUST OPT

57 A0047 28119 WASHER 1

58 A0769 28145 SCREW 1

59 A1434 28303 VACUUM BAG COVER (CLOTH) OPT

60 20338 20338 VACUUM BAG INSERT (PAPER) OPT

61 20452 20452 CLEAN SANDING FILTER BAG 1

62 20453 20453 FILTER BAG ADAPTOR 1

63 20341 20341 VACUUM HOSE FITTING ADAPTOR, 1 in Internal Hose Thread x 1-1/2 in OD Hose Adpator OPT

64 20209 20209 RANDOM ORBITAL SANDER AIR LINE EXTENSION, 3/8 in x 4 ft OPT

3M™ 5 in & 6 in Random Orbital Sander 3 Revision 051210

Page 4

Product Configuration/Specifications: 12,000 RPM Random Orbital Sander

Note: All Vacuum machines use Ø 28 mm (1 in.) Vacuum Hose Fittings.

Orbit Pad Face

2.5 mm

(3/32 in)

5 mm

(3/16 in)

8 mm

(5/16 in)

† Available only in Europe.

‡ Available only in APAC.

* Declared noise levels; measurements carried out in accordance with standard EN ISO 15744:2008.

** Declared vibration levels in accordance with EN12096; measurements carried out in accordance with standard EN ISO 8662-8:1997.

IMPORTANT NOTE: The noise and vibration values stated in the table are from laboratory testing in conformity with stated codes and

standards and are not sufficient risk evaluation for all exposure scenarios. The actual exposure values and amount of risk or harm

experienced to an individual is unique to each situation and depends upon the surrounding environment, the way in which the individual

works, the particular material being worked, work station design, as well as upon the exposure time and the physical condition of

the user. 3M™ cannot be held responsible for the consequences of using declared values instead of actual exposure values for any

individual risk assessment.

Vacuum

Type

Non

Stikit™

Vacuum

Central

Vacuum

Hookit™

Self-Gen

Vacuum

Stikit™

Non

Vacuum

Hookit™

Hookit™

Central

Vacuum

Stikit™ Low Prole

Self-Gen

Stikit™

Vacuum

Self-Gen

Hookit™

Vacuum

Non

Stikit™

Vacuum

Central

Vacuum

Hookit™

Self-Gen

Vacuum

Non

Stikit™

Vacuum

Central

Vacuum

Hookit™

Self-Gen

Vacuum

Pad Type

Low Prole

Clean

Sanding

Clean

Sanding

Low Prole

Clean

Sanding

Low Prole

Clean

Sanding

Low Prole

Clean

Sanding

Low Prole

Clean

Sanding

Pad Size

Model

Pad Part

mm (in)

Number

127 (5) 20320 20351 0.72 (1.59) 82.9 (3.26) 148.4 (5.84) 77 (83) 3.1 (10.2) 1.55

150 (6) 20328 20354 0.76 (1.68) 82.9 (3.26) 161.1 (6.34) 83 (89) 3.3 (10.8) 1.65

127 (5) 20321 20353 0.78 (1.72) 84.5 (3.33) 209.5 (8.25) 77 (83) 3.1 (10.2) 1.55

150 (6) 20329 20356 0.83 (1.83) 84.5 (3.33) 222.2 (8.75) 83 (89) 3.3 (10.8) 1.65

150 (6)

20463‡

127 (5) 20322 20353 0.80 (1.76) 84.5 (3.33) 217.9 (8.58) 84 (95) 3.1 (10.2) 1.55

150 (6) 20330 20356 0.86 (1.90) 84.5 (3.33) 230.6 (9.08) 83 (92) 3.1 (10.2) 1.55

150 (6)

20464‡

127 (5) 20317 20351 0.75 (1.65) 82.9 (3.26) 149.6 (5.89) 80 (88) 3.2 (10.5) 1.60

150 (6) 20325 20354 0.79 (1.74) 82.9 (3.26) 162.3 (6.39) 79 (83) 3.3 (10.8) 1.65

127 (5)

20457‡

150 (6)

20460‡

127 (5) 20318 20353 0.81 (1.79) 84.5 (3.33) 210.8 (8.30) 81 (88) 3.2 (10.5) 1.60

150 (6) 20326 20356 0.86 (1.90) 84.5 (3.33) 223.5 (8.80) 77 (85) 3.3 (10.8) 1.65

150 (6)

20461‡

127 (5)

20455‡

150 (6)

20458‡

127 (5)

20456‡

150 (6)

20459‡

127 (5) 20319 20353 0.83 (1.83) 84.5 (3.33) 219.2 (8.62) 85 (93) 3.2 (10.5) 1.60

150 (6) 20327 20356 0.89 (1.96) 84.5 (3.33) 231.9 (9.1) 83 (92) 3.3 (10.8) 1.65

150 (6)

20462‡

20253 20351 0.76 (1.68) 82.9 (3.26) 150.37 (5.92) 74 (83)) <2.5 (<8.2) N/A

20254/

127 (5)

†63378

20255/

†63379

20324 20354 0.79 (1.74) 82.9 (3.26) 163.42 (6.45) 77 (85) 3.3 (10.8) 1.65

20213 20356 0.87 (1.92) 82.9 (3.26) 224.8 (8.85) 75 (85) 3.5 (11.4) 1.75

150 (6)

63373† 20465 0.87 (1.92) 82.9 (3.26) 224.8 (8.85) 75 (85) 3.5 (11.4) 1.75

20208 20356 0.90 (1.98) 82.9 (3.26) 233.4 (9.18) 82 (92) 3.4 (11.1) 1.70

63372† 20465 0.90 (1.98) 82.9 (3.26) 233.4 (9.18) 82 (92) 3.4 (11.1) 1.70

Product Net Wt

Number

20465 0.83 (1.83) 84.5 (3.33) 222.2 (8.75) 83 (89) 3.3 (10.8) 1.65

20465 0.86 (1.90) 84.5 (3.33) 230.6 (9.08) 83 (92) 3.1 (10.2) 1.55

20352 0.75 (1.65) 82.9 (3.26) 149.6 (5.89) 80 (88) 3.2 (10.5) 1.60

20355 0.79 (1.74) 82.9 (3.26) 162.3 (6.39) 79 (83) 3.3 (10.8) 1.65

20465 0.86 (1.90) 84.5 (3.33) 223.5 (8.80) 77 (85) 3.3 (10.8) 1.65

20442 0.81 (1.79) 84.5 (3.33) 210.8 (8.30) 81 (88) 3.2 (10.5) 1.60

20454 0.86 (1.90) 84.5 (3.33) 223.5 (8.80) 77 (85) 3.3 (10.8) 1.65

20442 0.83 (1.83) 84.5 (3.33) 219.2 (8.63) 85 (93) 3.2 (10.5) 1.60

20454 0.89 (1.96) 84.5 (3.33) 231.9 (9.1) 83 (92) 3.3 (10.8) 1.65

20465 0.89 (1.96) 84.5 (3.33) 231.9 (9.1) 83 (92) 3.3 (10.8) 1.65

0.82 (1.81) 82.9 (3.26) 212.08 (8.35) 77 (85) <2.5 (<8.2) N/A

20353

0.84 (1.85) 82.9 (3.26) 220.66 (8.68) 91 (99) <2.5 (<8.2) N/A

kg (lb)

Height mm

(in)

Length mm

*Noise Level

dBA Pressure

(in)

(Power)

**Vibration

Level m/s

(ft/s2)

2

**Uncertainty

K

2

m/s

Operating / Maintenance Instructions

PRIOR TO THE OPERATION

The tool is intended to be operated as a hand held tool. It is always recommended that while using the tool, operators stand on a

solid oor, in a secure position with a rm grip and footing. Be aware that the sander can develop a torque reaction. See the section

“SAFETY PRECAUTIONS”.

Use a clean lubricated air supply that will give a measured air pressure at the tool of 6.2 bar (90 psig) when the tool is running with

the lever fully depressed. It is recommended to use an approved 10 mm (3/8 in) x 8 m (25 ft) maximum length airline. Connect the tool

to the air supply as shown in Figure 1. Do not connect the tool to the airline system without an easily accessible air shut off valve. It is

strongly recommended that an air lter, regulator and lubricator (FRL) be used as shown in Figure 1as this will supply clean, lubricated

air at the correct pressure to the tool. In any case appropriate air pressure regulators shall be used at all times while operating this

tool where the supply pressure exceeds the marked maximum of the tool. Details of such equipment can be obtained for your tool

distributor. If such equipment is not used, the tool should be manually lubricated. To manually lubricate the tool, disconnect the airline

and put 2 to 3 drops of suitable pneumatic motor lubricating oil such as 3M™ Air Tool Lubricant PN 20451, Fuji Kosan FK-20, Mobil

ALMO 525 into the hose end (inlet) of the tool. Reconnect tool to the air supply and run tool slowly for a few seconds to allow air to

circulate the oil. If the tool is used frequently, lubricate it on a daily basis or lubricate it if the tool starts to slow or lose power. It is

recommended that the air pressure at the tool be 6.2 bar (90 psig) while the tool is running so the maximum RPM is not exceeded. The

tool can be run at lower pressures but should never be run higher than 6.2 bar (90 psig). If run at lower pressure the performance of

the tool is reduced.

Page 5

Closed Loop Pipe System

Sloped in the direction of air flow

Drain Leg

Ball Valve

To Tool Station

Filter

Drain Valve

Regulator

Lubricator

Ball

Valve

Ball Valve

Air Flow

Air Dryer

Air Compressor

and Tank

Air Hose

To Coupler

at or near Tool

Recommended Airline

Size - Minimum

10 mm 3/8 in

Recommended Maximum

Hose Length

8 meters 25 feet

Maximum Working Pressure 6.2 bar 90 psig

Air Pressure

Recommended Minimum NA NA

Safety Precautions

1. Read all instructions before using this tool. All operators

must be fully trained in its use and aware of these safety

rules.

2. The tool RPM should be checked on a regular basis to

ensure proper operating speed.

3. Make sure the tool is disconnected from the air supply.

Select a suitable abrasive and secure it to the disc pad. Be

careful to center the abrasive on the disc pad.

4. Always wear required safety equipment when using this

tool.

5. When sanding/bufng always start the tool on the

workpiece. This will prevent gouging due to excess speed

of the buff pad. Stop air ow to the tool as it is removed

from the workpiece.

6. Always remove the air supply to the sander before fitting,

adjusting or removing the abrasive or disc pad.

7. Always adopt a firm footing and grip and be aware of

torque reaction developed by the sander.

8. Use only 3M approved spare parts.

9. Always ensure the material being sanded is rmly xed to

avoid movement.

10. Check hose and fittings regularly for wear. Do not carry

the tool by its hose; always be careful to prevent the tool

from being started when carrying the tool with the air

supply connected.

11. Dust can be highly combustible.

12. If tool is serviced or rebuilt check to ensure that the

maximum tool RPM is not exceeded and that there is no

excessive tool vibration.

13. Do not exceed maximum recommended air pressure.

Use safety equipment as recommended.

14. Prior to installing any sanding or polishing accessory,

always check that its marked maximum operating speed

is equal or higher than the rated speed of this tool.

15. The tool is not electrically insulated. Do not use where

there is a possibility of contact with live electricity, gas

pipes, and/or water pipes.

16. This tool is not protected against hazards inherent in

grinding and cutting operations and no such accessories

should ever be attached.

17. Take care to avoid entanglement with the moving parts

of the tool with clothing, ties, hair, cleaning rags or loose

hanging objects. If entangled, stop air supply immediately

to avoid contact with moving tool parts.

18. Keep hands clear of the spinning pad during use.

19. If the tool appears to malfunction, remove from use

immediately and arrange for service and repair.

20. Immediately release the start handle in the event of any

disruption of pressure; do not attempt to re-start until the

disruption has been corrected.

21. When tool is not in use, store in a clean dry environment

free of debris.

22. Recycle or dispose of tool according to Local, State, and

Federal Regulations.

3M™ 5 in & 6 in Random Orbital Sander 5 Revision 051210

3M Disc Pads are perfectly mated for use on the 3M Sander.

Constructed from premium, industrial-quality materials and

featur ing a riveted fiberglass and steel hub with molded urethane,

their durability and precise construction are the ideal complement

to the performance of the 3M Sander. See Product Configuration/

Specifications table for the correct replacement pad for a

particular model. The following chart is a sample of products

offered.

Description Part number

3M™ Stikit™ Low Prole Disc Pad 5 in., non-vacuum 20351

3M™ Hookit™ Low Prole Disc Pad 5 in., non-vacuum 20352

3M™ Hookit™ Clean Sanding Low Prole Disc Pad 5 in., vacuum 20353

3M™ Stikit™ Low Prole Disc Pad 6in., non-vacuum 20354

3M™ Hookit™ Low Prole Disc Pad 6 in., non-vacuum 20355

3M™ Hookit™ Clean Sanding Low Prole Disc Pad 6 in., vacuum 20356

3M™ Stikit™ Low Prole D/F Disc Pad 5 in., vacuum 20442

3M™ Stikit™ Low Prole D/F Disc Pad 6 in., vacuum 20454

3M™ Hookit™ Clean Sanding Low Prole Disc Pad-861 6 in., vacuum 20465

See 3M ASD Accessory catalog 61-5002-8098-9 for additional

Accessories.

Removing and Mounting Disc Pad to Random

1. Disconnect air line from sander.

2. Remove old disc pad from sander by inserting the wrench,

supplied with the tool, between the rubber shroud and the

disc pad. Use the wrench to secure the sander spindle while

turning the disc pad counter clockwise.

3. After the old disc pad has been removed from the sander,

inspect the threaded hole in the spindle to ensure that the

threads are free of debris and undamaged.

4. Ensure that the phenolic washer is in place around the

threaded shaft of the new disc pad.

5. Secure the sander spindle with the wrench and tighten the

new disc pad securely to the tool.

An inadequately tightened disc pad could cause the threaded

spindle to break causing damage to the tool and work piece and

possible injury to the operator or bystanders.

3M™ Disc Pads

Orbital Sander

WARNING

Figure 1

Page 6

Product Use: All statements, technical information and

recommendations contained in this document are based

up on tests or experience that 3M believes are reliable.

However, many factors beyond 3M’s control can affect

the use and performance of a 3M product in a particular

application, including the conditions under which the 3M

product is used and the time and environmental conditions

in which the product is expected to perform. Since these

factors are uniquely within the user’s knowledge and

control, it is essential that the user evaluate the 3M product

to determine whether it is fit for a particular purpose and

suitable for the user’s method of application.

Warranty and Limited Remedy: 3M warrants this tool

against defects in workmanship and materials under

normal operating conditions for one (1) year from the date

of purchase. 3M MAKES NO OTHER WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED

TO, ANY IMPLIED WARRANTY OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE OR ANY

IMPLIED WARRANTY ARISING OUT OF A COURSE

OF DEALING, CUSTOM OR USAGE OF TRADE. User is

responsible for determining whether the 3M tool is fit for a

particular purpose and suitable for user’s application. User

must operate the tool in accordance with all applicable

operating instructions, safety precautions, and other procedures

stated in the operating manual to be entitled to warranty coverage.

3M shall have no obligation to repair or replace any tool or part that

fails due to normal wear, inadequate or improper maintenance,

inadequate cleaning, nonlubrication, improper operating

environment, improper utilities, operator error or misuse, alteration

or modification, mishandling lack of reasonable care, or due to any

accidental cause. If a tool or any part thereof is defective within this

warranty period, your exclusive remedy and 3M’s sole obligation

will be, at 3M’s option, to repair or replace the tool or refund the

purchase price.

Limitation of Liability: Except where prohibited by law, 3M

and seller will not be liable for any loss or damage arising from

the 3M product, whether direct, indirect, special, incidental or

consequential, regardless of the legal theory asserted, including

warranty, contract, negligence or strict liability.

Submitting a Warranty Claim: Contact your dealer when

submitting a warranty claim in accordance with the restrictions

listed above. Please note that all warranty claims are subject to

manufacturer’s approval. Be sure to keep your sales receipt in a

safe place. This must be submitted when filing a warranty claim,

within 1 year from the date of purchase. For additional assistance

call 1-800-362-3550.

Abrasive Systems Division

3M Center

St. Paul, MN 55144-1000

www.3M.com/abrasives

© 3M 2010

3M, Hookit and Stikit are trademarks of 3M Company.

34-8704-3111-0

Loading...

Loading...