Page 1

Instructions

FibrlokTM 2600 Series

Multi-Fiber Optical Splice

Issue 2, May 1993

Page 2

2

Page 3

Contents:

1.0 General.......................................................................................................................................................... 3

2.0 Preparation Kit .............................................................................................................................................. 3

3.0 Cable Preparation ......................................................................................................................................... 4

4.0 Ribbon Preparation ....................................................................................................................................... 4

5.0 Ribbon Holder Preparation ........................................................................................................................... 6

6.0 Cleaver Operation ......................................................................................................................................... 7

7.0 Visual Inspection of the Cleave..................................................................................................................... 9

8.0 Fiber Insertion ............................................................................................................................................... 10

9.0 Applying the Pre-load.................................................................................................................................... 11

10.0 Splice Actuation............................................................................................................................................. 12

11.0 Multi-Fiber Stripper Cleaning and Maintenance ........................................................................................... 13

12.0 Helpful Hints .................................................................................................................................................. 15

13.0 Ordering Information ..................................................................................................................................... 16

3

Page 4

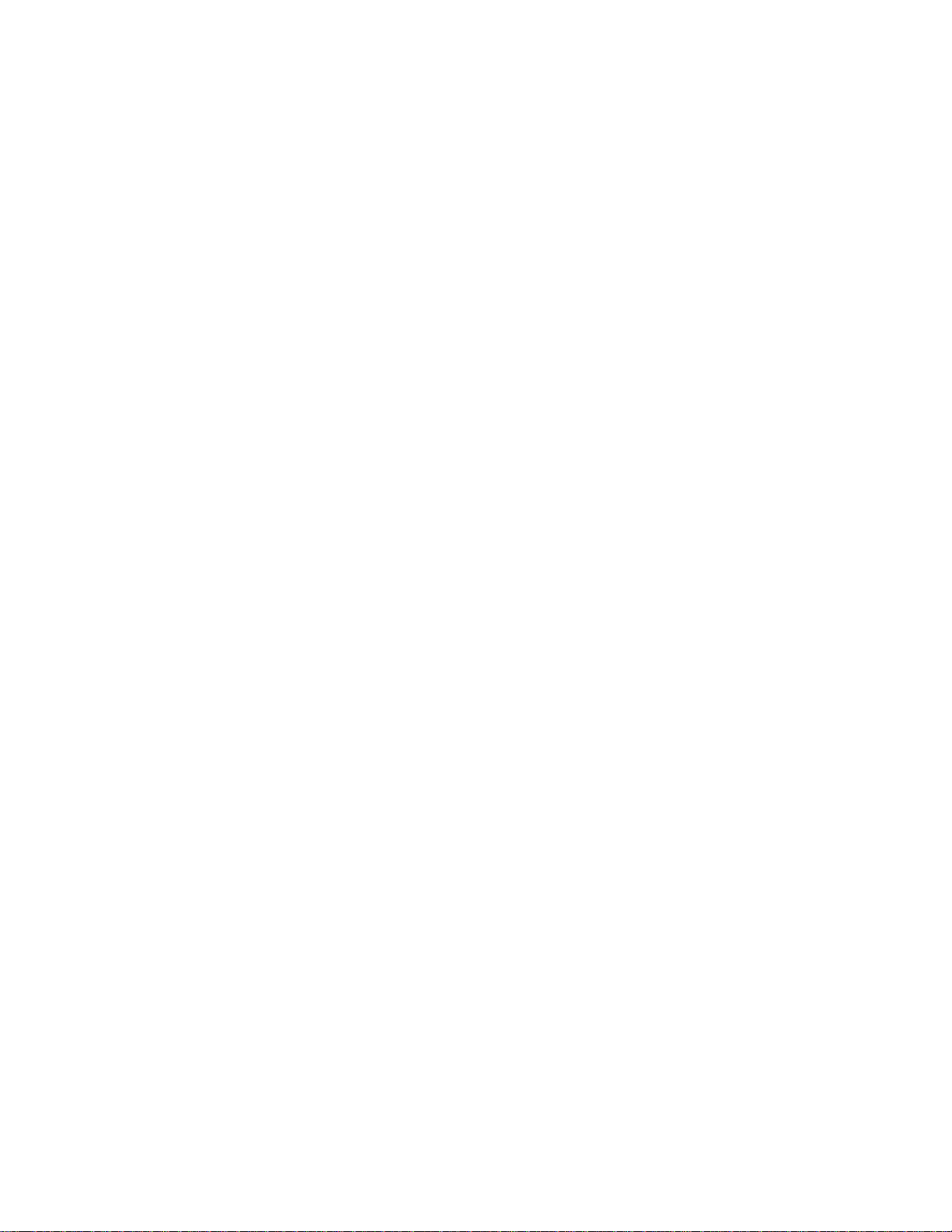

.50"

(1.27

cm)

.265"

(.673

cm)

1.50"

(3.81

cm)

4

Page 5

1.0 General

The FibrlokTM 2600 Series Multi-Fiber Optical Splicing System

provides permanent mechanical splices for single-mode or

multimode optical fibers with a nominal cladding diameter of 125

m.

The Fibrlok Multi-Fiber Optical Splicing System can be used with

either fiber optic ribbon cable or individual 250 m coated fibers

which have been organized into a ribbon structure (i.e.

"ribbonized"). For additional information concerning the use of

250 m fiber, refer to the FibrlokTM 2670 Multi-Fiber Ribbon

Construction Tool instruction bulletin.

1.01 Five color-coded splices are available to splice 4, 6, 8, 10 or 12

fibers:

Product Number Fiber Count Color Code

2604 4 Red

2606 6 Green

2608 8 Blue

2610 10 Gray

2612 12 Yellow

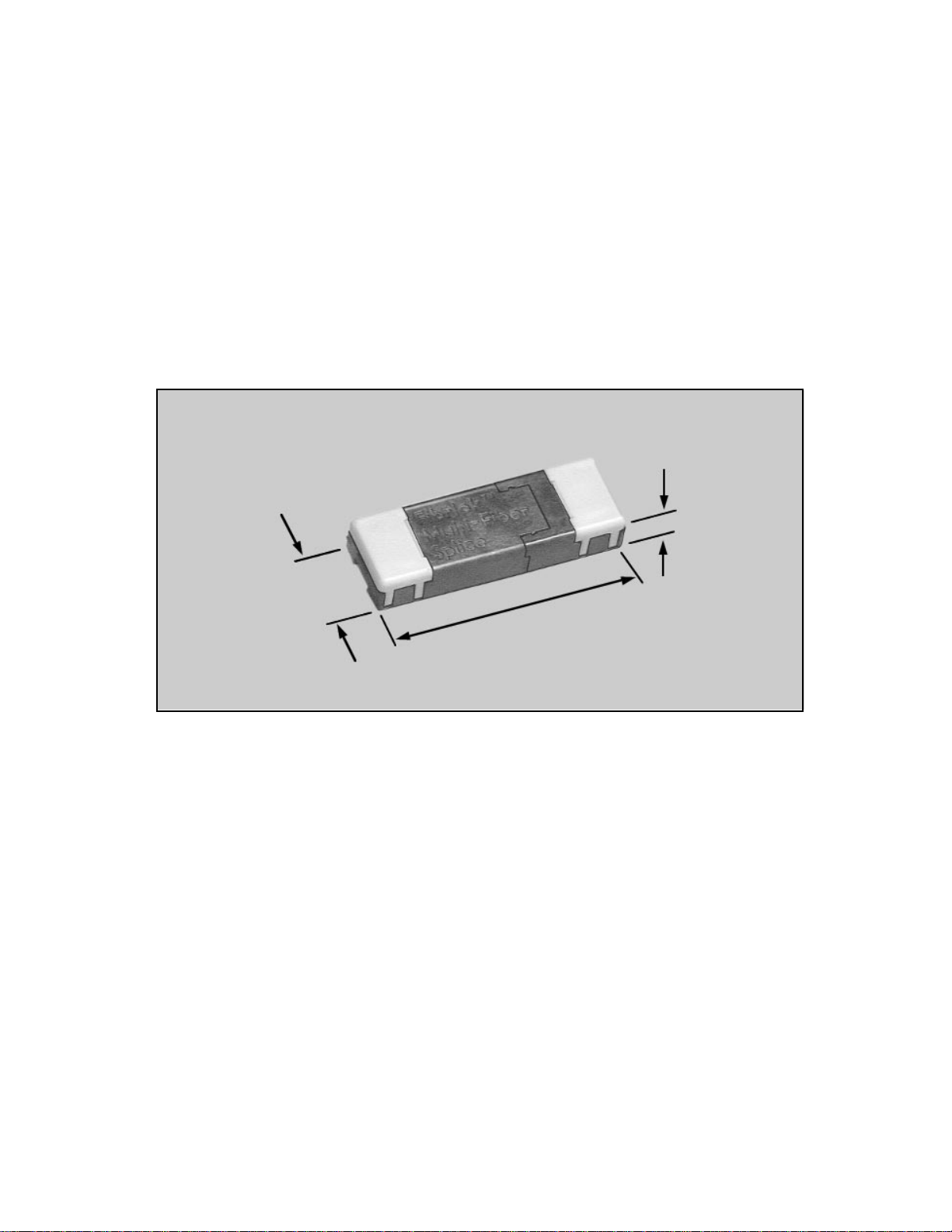

2.0 Preparation Kit

FibrlokTM Multi-Fiber Optical Splice Preparation Kit

(B)

(C)

(G)

(F)

(I)

(E)

(K)

(D)

(J)

2.01 Preparation Kit Components:

Fibrlok Multi-Fiber Optical Splice Actuator Tool (A)

Fibrlok Multi-Fiber Magnifying Lens Assembly (B)

Multi-Fiber Pen Light Assembly (C)

Multi-Fiber Stripper Handle Assembly (D)

Multi-Fiber Stripper Wall Plug Transformer (E)

Multi-Fiber Stripper Tube Guides (F)

Fibrlok Fiber Viewer Assembly (G)

Fibrlok Multi-Fiber Cleaver Spacer Gauge (H)

Fibrlok Multi-Fiber Holder Assembly (I)

Lint Free Wiping Cloths (J)

Alcohol Bottle (K)

Note: A compartment under the lint free wipes

is available for storing extra AAA

penlight

(A)

(H)

2.02 Additional Tools and Materials Required:

Alcoa-Fujikura Model CT-03, CT-04, CT-04B, or CT-07

Cleaver

ScotchcastTM 4415 Service Wire Cleaning Kit

Cable Sheath Removal Tools

Reagent Grade Isopropyl Alcohol

Note: Sumitomo Model FC-4 Cleaver may be used

instead of the Alcoa-Fujikura Cleaver. The

2651-A Fiber Viewer must be used with this

cleaver .

5

Page 6

3.0 Cable Preparation

3.01 Remove sheath from the end of the cable per case instructions. A minimum of 8 ft. (2.4 m) is typically

required.

3.02 Clean gel from the ribbons with cleaning pads in the 3M brand 4415 Service Wire Cleaning Kit. Wipe ribbon

dry with towels provided in the kit.

Note: Carefully follow safety, health, and disposal information on cleaning pad label or Material Safety

Data Sheet.

3.03 Install breakout kit if required per company practice.

3.04 Secure cable to the splice case or distribution panel housing.

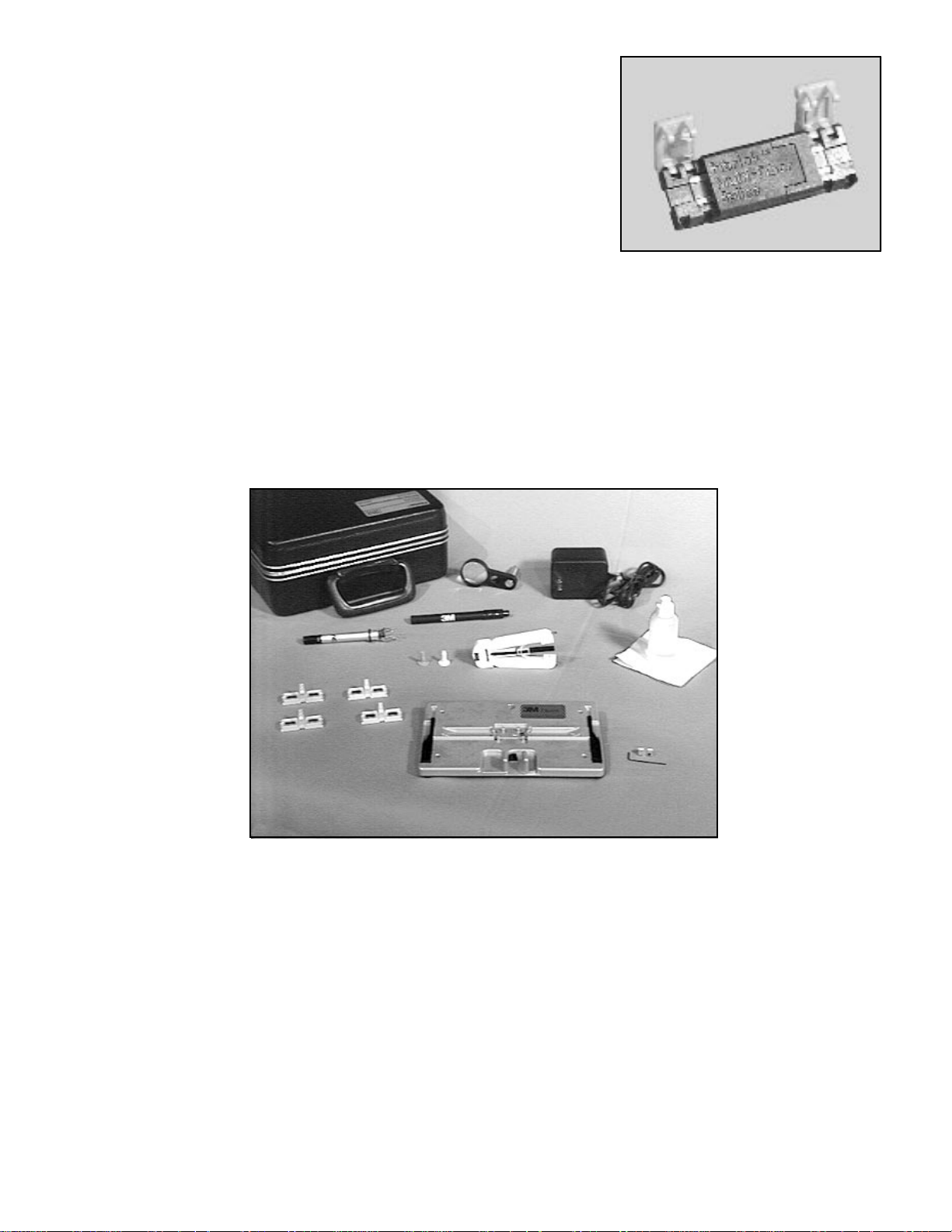

4.0 Ribbon Preparation

4.01 Ribbon is constructed in four different ways: bonded, ribbonized, encapsulated, and Adhesive Sandwich

Ribbon. It is important to identify the type of construction so that the proper tube guide and ribbon holder can

be selected.

Bonded construction has a thin layer of material

that holds the fibers together. Examples are AT&T

XAR Accuribbon 12 fiber and Alcatel 12 fiber

Uniribbon.

Ribbonized construction is performed in the field

using individual fibers and adhesive tape.

Encapsulated construction has a thick layer of

material all around the fibers. Examples are NTT 2,

4, and 8 fiber ribbon.

Adhesive Sandwich Ribbon construction is used

only in AT&T 12 fiber ASR ribbon. It has a polyester

tape construction that is wider than the fibers.

4.02 Select the proper size tube guide from the chart.

3M Part # Construction Color

2634 12 fiber bonded or ribbonized Light Yellow

2635 12 fiber AT&T ASR White

2637 10 fiber bonded or ribbonized Light Gray

2639 8 fiber bonded or ribbonized Light Blue

2640 8 fiber encapsulated Dark Blue

2641 6 fiber bonded or ribbonized Light Green

2645 4 fiber bonded or ribbonized Light Red (Pink)

2646 4 fiber encapsulated Dark Red

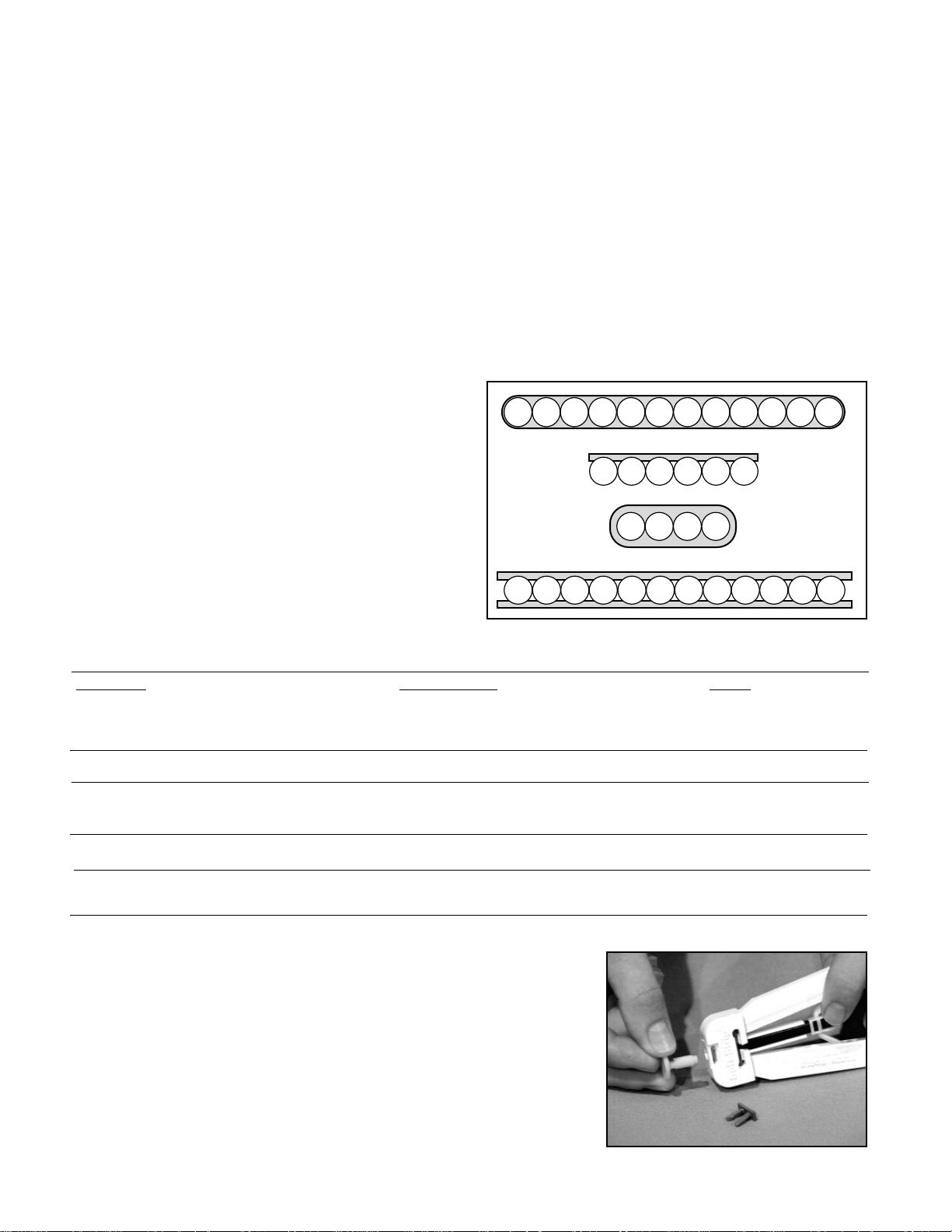

4.03 Install the tube guide into the stripper handle.

Note: If necessary, remove the tube lock with the removal tool.

Pull the tube guide out with your fingers.

6

Page 7

4.04 Connect the power cord from the AC adapter to the stripper

handle. Plug the AC adapter into an electrical outlet.

Note: An optional 6 volt battery and cord are available.

4.05 Arrange the fibers in the splice tray per tray instructions. Trim the

ribbon end so that it extends approximately 3/4" (19 mm) beyond

the center of the splice.

4.06 Insert the ribbon into the tube guide and position the ribbon so

that

1 1/4" to 1 1/2" (32 mm to 38 mm) of coating will be removed.

4.07 Close the handle on the stripper. This will activate the heating unit

which will soften the coating of the ribbon.

Note: The heating unit becomes hot. Use care when handling.

4.08 Heat the coating until it softens (usually 8 to 10 seconds at room

temperature). Slowly pull the ribbon straight out of the stripper.

The handles should remain closed until the ribbon is completely

out of the stripper.

Note: Do not keep the handles closed for more than 25 seconds

or the heating unit may become damaged.

Note: Heating time will vary with fiber type and ambient

temperature. If difficulty is experienced, refer to Section

12.

7

Page 8

4.09 Release the handles. Clean the stripped fibers with alcohol and a

lint free cloth. Inspect for broken fibers. Repeat steps 4.05

through 4.09 if necessary.

Note: Reagent grade isopropyl alcohol and lint free wipes are

required. Carefully follow safety, health and disposal

information on label or Material Safety Data Sheet for

isopropyl alcohol being used.

4.10 Clean the stripper before stripping the next ribbon. Slide the

heating unit backwards about 1" (25 mm), or remove it from the

handle. Clean the channel with the loop end of the cleaning tool.

Note: Be gentle when cleaning the coating residue from the

channel or the heating unit may become damaged. Do not

press the loop hard against the channel walls. It is not

necessary for the channel to be completely clean.

Clean the stripper blades with the brush end of the cleaning tool.

5.0 Ribbon Holder Preparation

5.01 Select the proper size ribbon holder from the chart below.

3M Part # Application Color

2653 12 fiber ASR White

2654 12 fiber bonded or ribbonized Light Yellow

2656 10 fiber bonded or ribbonized Light Gray

2658 8 fiber bonded or ribbonized Light Blue

2659 8 fiber encapsulated Dark Blue

2660 6 fiber bonded or ribbonized Light Green

2664 4 fiber bonded or ribbonized Light Red (Pink)

2665 4 fiber encapsulated Dark Red

5.02 Remove the cover of the ribbon holder by squeezing the center

tabs and lifting the clear outer tabs.

8

Page 9

5.03 Lay the stripped ribbon between the guide forks. The ribbon

should be positioned so that 1" to 2" (25 mm to 51 mm) of

unstripped ribbon extends beyond the end of the holder.

5.04 Place the cover over the ribbon and snap into place.

6.0 Cleaver Operation

6.01 The Alcoa Fujikura Model CT-03, CT-04, CT-04B, or CT-07, is

required for the cleaving process.

Note: Sumitomo Model FC-4 Cleaver may also be used, along

with the 2651-A Fiber Viewer.

6.02 If present, the guide plate must be removed so that the cleaver

spacer gauge assembly can be installed. Remove the screws

that secure the guide plate. Remove the guide plate.

6.03 Install the cleaver spacer gauge in the slot. The spacer should be

snug against the wall near the rubber pad.

9

Page 10

6.04 Lock the spacer in place by tightening the locking screw using the

supplied allen wrench.

6.05 Place the ribbon holder into the cleaver. Push the ribbon holder

against the cleaver spacer gauge .

6.06 Align the end of the ribbon coating to be within the slot in the

cleaver gauge. Adjust the ribbon position by pushing the ribbon

holder firmly against the cleaver gauge and pulling back on the

ribbon.

Note: Ensure that no fibers are crossed.

6.07 Close the cleaver clamping lid 1 .

6.08 Slide the scoring sled 2 across the bottom of the fibers.

10

Page 11

6.09 Depress the cleaving lever 3 firmly.

6.10 While holding the cleaving lever down, remove the cleaved fiber

stubs, and dispose of per company practice.

6.11 Open the cleaving lever and clamping lid.

7.0 Visual Inspection of the Cleave

7.01 Install the fiber viewer on the cleaver and rotate the viewer barrel

to focus. Observe the cleaved ends of the fiber. If defects are

observed, repeat steps 4.05 through 6.11.

Note: For the best viewing results, allow ample light to enter

from the top and left side. In dark surroundings use the

penlight supplied.

7.02 Properly cleaved fibers.

11

Page 12

7.03 Defect in cleaved fibers.

7.04 If fibers are properly cleaved:

- Remove the fiber viewer from the cleaver, and

- Remove the ribbon holder from the cleaver.

8.0 Fiber Insertion

8.01 Move the actuation lever on the actuator tool all the way to the

right. Install the magnifying lens and pen light assemblies. Move

the preload levers to the up position.

8.02 Place a Fibrlok Multi-Fiber Optical Splice into the actuator tool so

that the covers open toward the back of the actuator tool. Open

both covers completely.

Note: Carefully follow safety, health, and disposal information on

splice label or Material Safety Data Sheet.

defective

Preload

Lever

Actuation Lever

Preload

Lever

8.03 Lay the back end of the ribbon holder against the backstop of the

holder guide track.

8.04 Position the magnifying lens assembly and pen light assembly

over the splice.

12

Page 13

8.05 Lower the front end of the ribbon holder to lay the cleaved fibers in

the V grooves of the splice. If the fibers are not positioned

properly in the V grooves, raise and lower the front end of the

ribbon holder until the fibers are positioned properly.

8.06 Proper positioning of fibers.

8.07 Slowly slide the fibers into the splice by moving the ribbon holder

down the ramp until it stops.

Note: If resistance is felt, back out fibers slightly and continue

insertion.

8.08 Select the mating fiber ribbon and identify fiber #1 for proper alignment into the splice. Repeat the Ribbon

Preparation, Ribbon Holder Preparation, Cleaver Operation, Visual Inspection of the Cleave, and Fiber

Insertion (sections 4.05 to 8.07) for the other side of the splice.

Note: Fiber contact can be confirmed by observing the movement of the first ribbon and holder as the

second ribbon is inserted.

If no movement is observed, a successful splice is not likely. It is recommended that the cleaver, ribbon

holders, and actuator tool be cleaned and checked for proper operation. Repeat Steps 4.05 through 8.08 for

both ribbons. Use a new Fibrlok Multi-Fiber Optical Splice.

9.0 Applying the Pre-load

9.01 Move the pre-load levers, one at a time, toward you as far as they

will go.

13

Page 14

9.02 Look at the amount of bare glass where each ribbon enters the

splice. The amount of bare glass should be about the same on

each side.

9.03 If necessary, center the ribbons by selecting the pre-load lever

that is closest to the shorter length of bare glass. Slowly slide the

lever back (away from you) until the holders move and the ribbons

appear centered.

NOT CENTERED

9.04 Return the lever to its forward position. If the ribbon was adjusted

too far, re-adjust using the other lever.

Note: Make sure both pre-load levers are all the way forward

(toward you) when done.

10.0 Splice Actuation

10.01 Actuate the splice by squeezing the actuation lever slowly until it

stops.

10.02 Close both splice covers.

CENTERED

Note: Some protective gel may be visible after closing covers.

14

Page 15

10.03 Remove the cover of each ribbon holder by squeezing the center

tabs and lifting the outer tabs.

10.04 Gently lift the splice and ribbons out of the actuator tool.

10.05 Turn the splice over and verify that the wedge has been fully

pushed against the splice body.

10.06 If the wedge is not against the splice body, move the actuation

lever to the right, place the splice back into the actuator tool and

squeeze the actuation lever again.

10.07 Remove the ribbon holders from the actuator tool.

11.0 Multi-Fiber Stripper Cleaning and Maintenance

11.01 Tube Guide

a. The stripper tube guide should be cleaned periodically to

ensure good performance. Remove the tube guide by

unlatching the tube lock with the white pushout tool. Pull the

tube guide out of the pivot housing.

b. Clean the inside of the tube guide with compressed air. A

length of unstripped ribbon may also be used for cleaning if

compressed air is not available. Also clean around the

outside tip of the tube guide.

Clean

15

Page 16

c. Insert the tube guide into the pivot housing. Secure the tube

guide with the tube guide lock.

11.02 Stripper Blades - Cleaning

a. If the stripper performance is unsatisfactory after the normal cleaning procedure (section 4.10), the

stripper blades may need to be removed from the handle assembly for a more thorough cleaning.

b. Remove the tube guide per section 11.01 a. Use the pushout

tool to push the blades out of the handle assembly.

c. Remove all foreign material from the front and back sides of

the blades, especially around the semicircular region.

d. Replace the blades in the pivot housing. The molded

recesses in the blades should face outward. Push the

blades into place with the pushout tool. Reinstall and secure

the tube guide per section 11.01 c.

e. After installing blades, tube guide, and tube lock, close the

handles once to align the blades.

16

Page 17

11.03 Stripper Blades - Replacement

a. If the stripper performance is unsatisfactory after a thorough cleaning, the blades need to be replaced.

Remove the blades per 11.02 b.

b. Place the new blades into the pivot housing per 11.02 d and e.

12.0 Helpful Hints

Hint 1: Stripping in Cold Temperatures:

When stripping in cold temperatures, the heating time for the stripper will be longer. For an ambient

temperature around 32〉 F (0〉 C), most ribbons should be heated approximately 12 to 15 seconds before

pulling the ribbon through. The handles can also be held closed for a longer time without damaging the

heater unit.

Hint 2: Stripping in Hot Temperatures:

At high temperatures, the heating time will be less. At a temperature of 100〉 F (40〉 C), the heating time

should be approximately 6 to 8 seconds. For other temperatures, adjust the time accordingly.

Hint 3: Stripping Ribbonized Fibers:

Sometimes stripping ribbonized fiber can be difficult. This is due to the fiber, not the ribbonizing process.

The coating material of some loose tube fibers reacts to heat and bonds to the glass. If this is the case, the

stripped fibers will have heavy residue that cannot be easily wiped off. This type of fiber must be stripped

with less heat. Therefore, heat it only a short time and then pull hard on the ribbon, to move it through the

tool quickly. See Hint 5.

Hint 4: Broken Fibers:

When stripping the ribbon, sometimes broken fibers occur. Fibers broken at the very beginning of the strip

are usually caused by poorly made ribbon or using the wrong size tube guide. Always close the handles

slowly, as this allows the fibers to align with the blades.

Fibers that are broken somewhere along the length of fibers are caused by stripping technique or poor

ribbon. Try heating the ribbon longer, pulling more slowly, and being careful to pull the ribbon straight out of

the tool.

Hint 5: Fiber Residue:

After cleaning the fibers, some residue may remain. Often the residue is found on the region of glass that is

removed in the cleaving process, so is not a problem (if it doesn't affect the cleave). Sometimes, residue

can be seen on the portion of glass that is to be inserted into the splice. A light amount of residue found

along the sides of the fibers or away from the cleaved ends will not affect the splice. But if residue is found

on the top or bottom of the glass and near the cleaved ends, the fibers should be re-stripped, cleaned, and

cleaved.

Hint 6: Disposing of Cleaved Fiber Stubs:

With some cleaver models, the fiber stubs can be grasped before opening the clamping lid, as shown in

6.10. This is the easiest way to dispose of cleaved stubs. With other models the clamping lid must be

opened first. In this case, using adhesive-backed tape is a convenient way to collect the fiber ends.

Hint 7: Viewing the Cleaved Ends:

The key to good inspection is good lighting. Allow light to enter from the side of the cleaver that the holder

is on. This is the top and left for the Fujikura cleaver, and the top and right for the Sumitomo cleaver. In

dark areas, use the penlight provided in the kit for additional lighting.

Hint 8: Laying the Fibers into the V-Grooves:

Sometimes the fibers are difficult to lay into the V-grooves, because they have shifted to one side or the

other. To solve the problem, lift the holder up and grasp the coated ribbon between the holder and the bare

fiber. Now shift the ribbon in the appropriate direction. The fibers should now lay into the V-grooves.

17

Page 18

13.0 Ordering Information

P/N Description Packaging

Splices

2604 FibrlokTM Multi-Fiber Optical Splice (4 Fiber) 3/Pkg; 4 Pkg/

Case

2606 FibrlokTM Multi-Fiber Optical Splice (6 Fiber) 3/Pkg; 4 Pkg/

Case

2608 FibrlokTM Multi-Fiber Optical Splice (8 Fiber) 3/Pkg; 4 Pkg/

Case

2610 FibrlokTM Multi-Fiber Optical Splice (10 Fiber) 3/Pkg; 4 Pkg/

Case

2612 FibrlokTM Multi-Fiber Optical Splice (12 Fiber) 3/Pkg; 4 Pkg/

Case

Splice Preparation Kits

2600 FibrlokTM Multi-Fiber Optical Splice Preparation Kit (U.S.) 1 Kit/Case

2601 FibrlokTM Multi-Fiber Optical Splice Preparation Kit (O.U.S.) 1 Kit/Case

Ribbon Construction Tool Kit

2670 FibrlokTM Multi-Fiber Ribbon Construction Tool 1 Kit/Case

Splice Organizer Trays and Accessories

2524-MF FibrlokTM Multi-Fiber Splice Tray 3/Case

2672 FibrlokTM Multi-Fiber High Density Splice Tray 3/Case

2673 FibrlokTM Multi-Fiber High Density Splice Tray Pedestal Base 1/Case

78-8079-7864-4 Multi-Fiber Splice Holder (For use with 2672 Splice Tray) 12/Case

System Components/Spare Parts

2620 FibrlokTM Multi-Fiber Optical Splice Actuator Tool 1/Case

2621 FibrlokTM Multi-Fiber Magnifying Lens Assembly (w/o Light) 1/Case

2622 FibrlokTM Multi-Fiber Pen Light Assembly 1/Case

2630 Multi-Fiber Stripper Handle Assembly 1/Case

2631 Multi-Fiber Stripper Wall Plug Transformer - 110 volt 1/Case

2631-A Multi-Fiber Stripper Wall Plug Transformer - 220 volt 1/Case

2634 Multi-Fiber Stripper Tube Guide (12 Fiber bonded or ribbonized) 1/Case

2635 Multi-Fiber Stripper Tube Guide (For AT&T 12 Fiber ASR Ribbon) 1/Case

2637 Multi-Fiber Stripper Tube Guide (10 Fiber bonded or ribbonized) 1/Case

2639 Multi-Fiber Stripper Tube Guide (8 Fiber bonded or ribbonized) 1/Case

2640 Multi-Fiber Stripper Tube Guide (8 Fiber encapsulated) 1/Case

2641 Multi-Fiber Stripper Tube Guide (6 Fiber bonded or ribbonized) 1/Case

2645 Multi-Fiber Stripper Tube Guide (4 Fiber bonded or ribbonized) 1/Case

2646 Multi-Fiber Stripper Tube Guide (4 Fiber encapsulated) 1/Case

78-8079-7875-0 Multi-Fiber Stripper Replacement Blades 1 Set/Case

78-8079-7876-8 Multi-Fiber Stripper Heater Unit 1/Case

78-8091-2193-8 Cleaning Brush 3/Case

2651 FibrlokTM Fiber Viewer Assembly (For use with Fujikura Cleaver) 1/Case

2651-A FibrlokTM Viewer Assembly (For use with Sumitomo Cleaver) 1/Case

2652-A FibrlokTM Multi-Fiber Cleaver Spacer Gauge 1/Case

2653 FibrlokTM Multi-Fiber Holder Assembly (For AT&T 12 Fiber ASR Ribbon) 2/Set, 1 Set/Case

2654 FibrlokTM Multi-Fiber Holder Assembly (12 Fiber bonded or ribbonized) 2/Set, 1 Set/Case

2656 FibrlokTM Multi-Fiber Holder Assembly (10 Fiber bonded or ribbonized) 2/Set, 1 Set/Case

2658 FibrlokTM Multi-Fiber Holder Assembly (8 Fiber bonded or ribbonized) 2/Set, 1 Set/Case

2659 FibrlokTM Multi-Fiber Holder Assembly (8 Fiber encapsulated) 2/Set, 1 Set/Case

2660 FibrlokTM Multi-Fiber Holder Assembly (6 Fiber bonded or ribbonized) 2/Set, 1 Set/Case

2664 FibrlokTM Multi-Fiber Holder Assembly (4 Fiber, bonded or ribbonized) 2/Set, 1 Set/Case

2665 FibrlokTM Multi-Fiber Holder Assembly (4 Fiber, encapsulated) 2/Set, 1 Set/Case

2671 FibrlokTM Fiber Optic Ribbon Construction Tape 200 Strips/ Pkg; 5 Pkg/

Case

2680 Multi-Fiber Stripper Power Cord (For use with 6v battery) 1/Case

2681 Battery Carrying Case, Multi-Fiber Stripper 1/Case

78-8079-7686-1 Blade and Mount Assembly, Multi-Fiber Ribbon Construction Tool 1/Case

80-6104-4329-5 Alcohol Bottle 1/Case

80-6104-4324-6 Lint Free Cloth 100/Pkg.

78-8079-7975-8 Carrying Case, Splice Preparation Kit 1/Case

18

Page 19

19

Page 20

Important Notice

All statements, technical information and recommendations related to the Seller's products are based on information believed

to be reliable, but the accuracy or completeness thereof is not guaranteed. Before utilizing the product, the user should

determine the suitability of the product for its intended use. The user assumes all risks and liability whatsoever in connection

with such use.

Any statements or recommendations of the Seller which are not contained in the Seller's current publications shall have no

force or effect unless contained in an agreement signed by an authorized officer of the Seller. The statements contained

herein are made in lieu of all warranties, express or implied, including but not limited to the implied warranties of

merchantability and fitness for a particular purpose which warranties are hereby expressly disclaimed.

SELLER SHALL NOT BE LIABLE TO THE USER OR ANY OTHER PERSON UNDER ANY LEGAL THEORY, INCLUDING

BUT NOT LIMITED TO NEGLIGENCE OR STRICT LIABILITY, FOR ANY INJURY OR FOR ANY DIRECT OR

CONSEQUENTIAL DAMAGES SUSTAINED OR INCURRED BY REASON OF THE USE OF ANY OF THE SELLER'S

PRODUCTS THAT WERE DEFECTIVE.

34-7033-9594-6

© 1993 3M

Litho in U.S.A.

3M Telecom Systems Group

6801 River Place Blvd.

Austin, TX 78726-9000

800/426-8688

Loading...

Loading...