Page 1

™

3M

ME & DF

Series Housings

3M™ ME Series ASME Code Housings for 3M™ DF Series Elements and Bag Filters

The compact design of the 3M™ ME series bag housings and

in-line bottom inlet and outlet connections offer tremendous

exibility for installation and operation. The swing bolt closure

design and davit arm operation allow for easy lter element

change-out.

3M ME series bag housings come standard with a swing bolt

cover closure and davit arm for ease of cover opening. An

optional quick open/close (QOC) cover closure version is also

available. Through the use of a band clamp and hinged cover,

the QOC design allows for rapid vessel opening and closing with

minimum labor requirements. This can be of signicant benet

for operations requiring frequent lter change-outs. For more

information on the QOC design, please refer to 3M Purication

Literature LITHSHQC1.

3M Purication Inc. offers the 3M™ ME series bag housings,

for use with 3M™ DF series lter elements or conventional

bag lters, in 3, 4, 6, 8, and 12 lter element congurations.

Constructed with carbon steel, 304, or 316L Stainless Steel,

the housings are designed for use with #2 size lter bags or

elements. The housings have been engineered for maximum ow

throughput for a given vessel footprint to minimize the required

oor space. All ME series bag housings include stainless steel

baskets, for either 3M DF series element or bag lter support. The

housings are rated for operation up to 150 psi @ 300 °F and are

manufactured in accordance with ASME code and “U” stamped.

Applications

Industrial Processes Parts, Washers, Coolants, Cooling Water

Water Treatment Pre-RO, Wastewater

Refining Amine, Final Products

Food & Beverage Process Water, Edible Oils

Paint & Coatings Phosphate E-Coat

Chemicals & Petrochemicals

Electronics Pre-RO

Available Options – Consult Factory

Quick Open/Close Cover Design

Different Inlet/Outlet Connection Sizes

Different Exterior/Interior Coatings/Finishes

Tangential Bottom Outlet Design

Corrosion Allowances (carbon steel)

21 CFR compliant materials of construction

Housing Pressure by Nozzle Size*

6.0

5.0

4 in. Nozzle

4.0

3.0

2.0

Differential Pressure (psid)

1.0

8 in. Nozzle

8 in. Nozzle

Pharmaceutical Bulk Chemicals

0

0 1000 2000

500 15 00 2500

Water Flow Rate (gpm)

* Pressure drop for standard housings without filters installed.

1

Page 2

Features & Benefits

Compact vessel design

Reduced footprint requirement

Drains at lowest point in housing

No residual build-up or fluid loss

Integral cover assembly

No additional parts required to seal filter elements

In-line piping configuration

Capital expenditure and installation coat savings

Isolated dirty fluid chamber

Helps prevent clean-side contamination during filter change-out

Minimizes build-up of dirty fluid

Designed for use with 3M™ DF series or conventional bag filter

elements

Flexibility for using optimum filter element for application

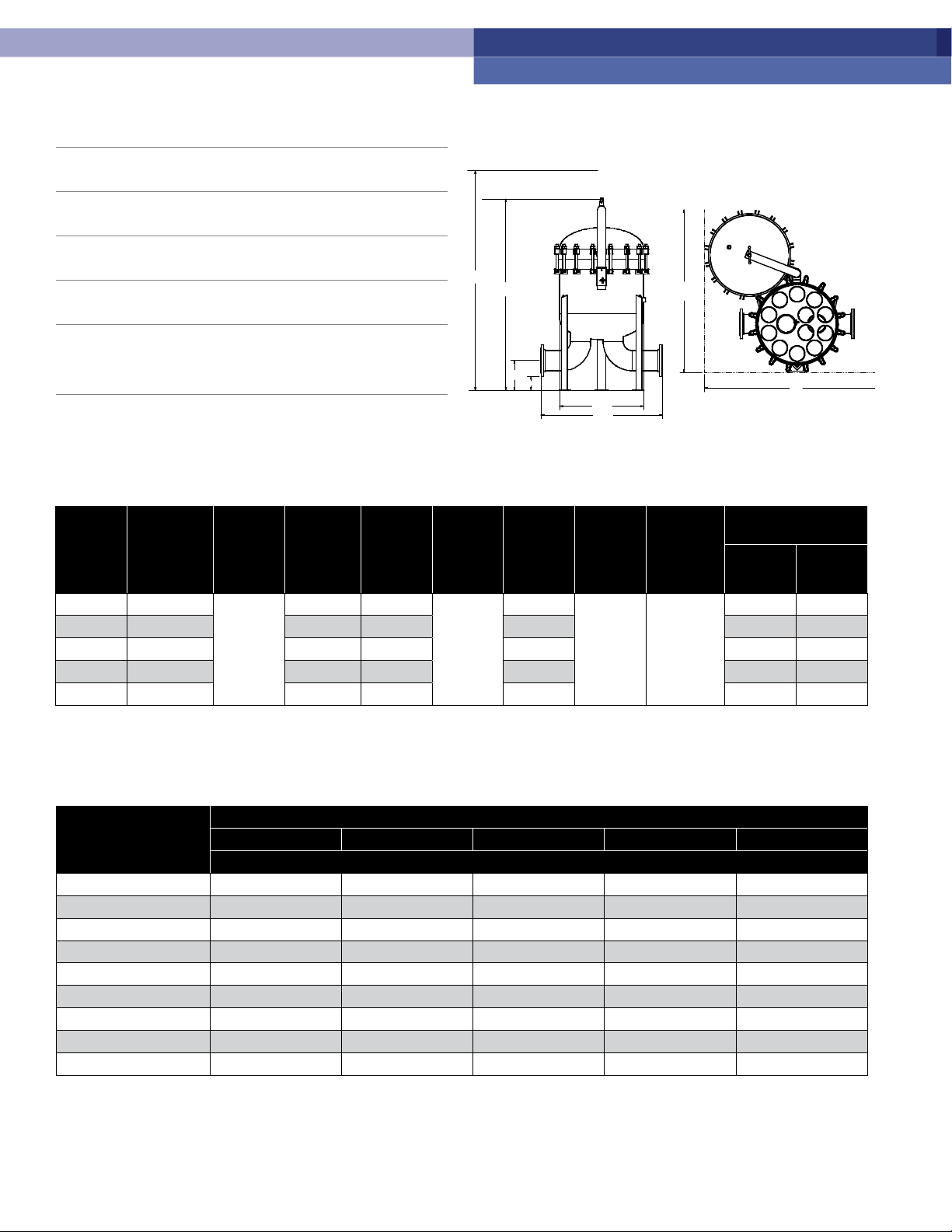

3M™ ME Series Bag Housing Specifications

A

B

C

D

E

F

G

H

Model

Number of

Filter Elements

Material

3ME 3

4ME 4 4 1 450 / 1703 585/265 NA

6ME 6 6 1 1000/3785 720/327 850/386

8ME 8 6 2 1000/3785 960/435 1050/476

Carbon

Steel, 304

or 316L

Stainless

Steel

Connection

Size (inches)

4 1

Drain Size

Inches

(NPT)

Vent/Gauge

Size Inches

(NPT)

1/2

Maximum

Flow (gpm/

lpm)*

450 / 1703

Maximum

Operating

Pressure

(pst/bar)

150 /10.3

Operating

Temper atur e

Range

( °F/ °C)

-20 to 300/

-28 to 148

Approximate Housing

Weight (lbs/kgs)

Swing Bolt

Closure

Quick

Open/Close

470/ 213 NA

12M E 12 8 2 1750/ 6 624 127 0/576 145 0 /658

* Values represent maximum aqueous flow rates for ME series bag housings (without filter elements in stalled) yielding housing pressure drop of 3 psid. When determining vessel flow rates, the

type of filter element to be used needs to be taken into account. The total filtration system pressure drop is the sum of the housing and filter element pressure drops. For some models, larger

inlet/outlet connection sizes are avail able providing lower vessel pressure drops at higher flow rates.

™

3M

ME Series Bag Housing Dimensions (inches/cm)*

Model

3 ME 4 ME 6 ME 8 ME 12 ME

Nominal Dimensions (inches/cm)

A – Clearance (Swingbolt) 76 /193 76/193 82/208 83/211 88/223

Clearance (Quick Open) N/A N/A 88/223 96/244 110/279

B – Overall Unit Height 63 /160 65/165 70/ 178 75/ 191 81/206

C – Floor to flange centerline 11/ 2 8 11/28 12/30 12/30 13/33

D – Floor to flange clearance 6/15 6/15 6/15 6/ 15 6/15

E – Unit diameter 18/46 20/51 24/61 30/76 36/91

F – Flange to flange 33/84 34/86 40 /102 42 / 107 52 /132

G – Space to cover reduction 40/102 42 /107 48/12 2 58/147 74/188

H – Space for cover reduction 52 / 132 54/137 64 /163 77/ 19 6 84 / 213

* Dimensions are for overall space requirements only. For all other uses, request a certified drawing

2

Page 3

3M™ ME Series Bag Housing Ordering Guide (Example Part Number = XME2XFXXX)

X ME 2 X F X X Q

Number of Elements Product Designation Element Size Housing Material Connection Type Gasket Material/O-ring Basket Type Closure Type

3

4

6

ME 2 = #2

8

12

* Limits maximum operation temperature to 250 °F (121°C).

**Quick Open/Close available for models 6ME, 8ME, and 12ME 316L SS only. Standard gasket/O-ring is nitrile, consult factory for other available gasket materials.

A – Carbon Steel

B – 304 Stainless

Steel

C – 316L Stainless

Steel

F – ANSI Flange

GA – Nitrile*

GB – EPR

GC – Fluorocarbon

B = Bag

Basket

D = DF Basket

Q – Quick Open/

Close** (Leave

blank for swing

bolt)

Important Notice

The information described in this literature is accurate to the best of our knowledge. A variety of factors, however, can affect the performance of the Product(s) in a particular

application, some of which are uniquely within your knowledge and control. INFORMATION IS SUPPLIED UPON THE CONDITION THAT THE PERSONS RECEIVING THE

SAME WILL MAKE THEIR OWN DETERMINATION AS TO ITS SUITABILIT Y FOR THEIR USE. IN NO EVENT WILL 3M PURIFICATION INC. BE RESPONSIBLE FOR DAMAGES

OF ANY NATURE WHATSOEVER RESULTING FROM THE USE OF OR RELIANCE UPON INFORMATION.

It is your responsibility to determine if additional testing or information is required and if this product is fi t for a particular purpose and suitable in your specifi c application.

3M PURIFICATION INC. MAKES NO REPRESENTATIONS OR WARRANTIES, EITHER EXPRESS OR IMPLIED INCLUDING WITHOUT LIMITATION ANY WARRANTIES OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR OF ANY OTHER NATURE HEREUNDER WITH RESPECT TO INFORMATION OR THE PRODUCT TO WHICH

INFORMATION REFERS.

Limitation of Liability

3M Purifi cation Inc. will not be liable for any loss or damage arising from the use of the Product(s), whether direct, indirect, special, incidental, or consequential, regardless of

the legal theory asserted, including warranty, contract, negligence or strict liability. Some states do not allow the exclusion or limitation of incidental or consequential damages,

so the above limitation may not apply to you.

3M Purifi cation Inc.

400 Research Parkway

Meriden, CT 06450

U.S.A.

Phone (800) 243-6894

(2 03) 237-5541

Fax (203) 630-4530

www.3Mpurifi cation.com

Please recycle. Printed in U.S.A.

3M is a trademark of 3M Company.

© 3M 2011. All rights reserved.

70-0202-3002-8 REV 1011b

Loading...

Loading...