Page 1

3B SCIENTIFIC

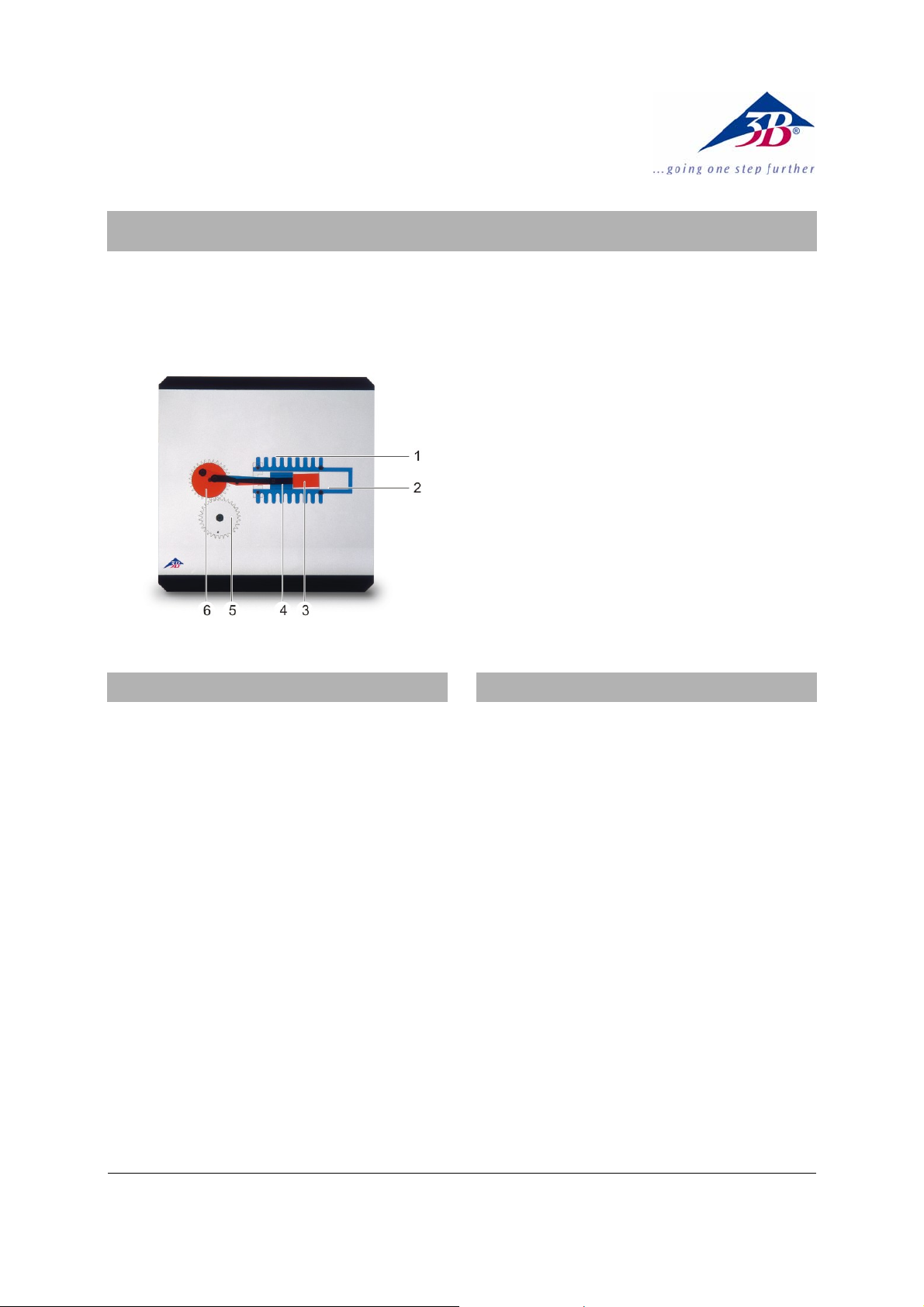

Stirling Engine, Transparent 1003000

Instruction sheet

04/12 JS

®

PHYSICS

1 Cold side

2 Hot side

3 Working piston

4 Displacement piston

5 Flywheel

6 Crank shaft

1. Description

The way a Stirling engine works can be divided

into four sections, or piston strokes.

1) Heat is fed to the system when the displacement piston pushes the air to the heated side of

the displacement cylinder. At this time the piston

is in a position known as top dead centre, here

at its rightmost extreme.

2) Expansion of heated air drives the working

piston towards the left. This causes mechanical

work to be transferred via the crankshaft to the

flywheel.

3) Heat is dissipated when the displacement

piston causes the air to move to the cooler side

of the displacement cylinder.

4) The cooled air is compressed as the working

piston moves to the left, the mechanical energy

(work) for this being provided by the flywheel.

2. Operation

Additionally recommended:

Overhead Projector (230 V, 50/60 Hz) 1003264

or

Overhead Projector (115 V, 50/60 Hz) 1003263

• Lay the transparency on the daylight projec-

tor.

• Move the components by hand to the places

which correspond to the various strokes.

3B Scientific GmbH ▪ Rudorffweg 8 ▪ 21031 Hamburg ▪ Germany ▪ www.3bscientific.com

Subject to technical amendments

© Copyright 2012 3B Scientific GmbH

Page 2

Loading...

Loading...