Page 1

3B SCIENTIFIC

Instruction sheet

03/11 Alf

®

PHYSICS

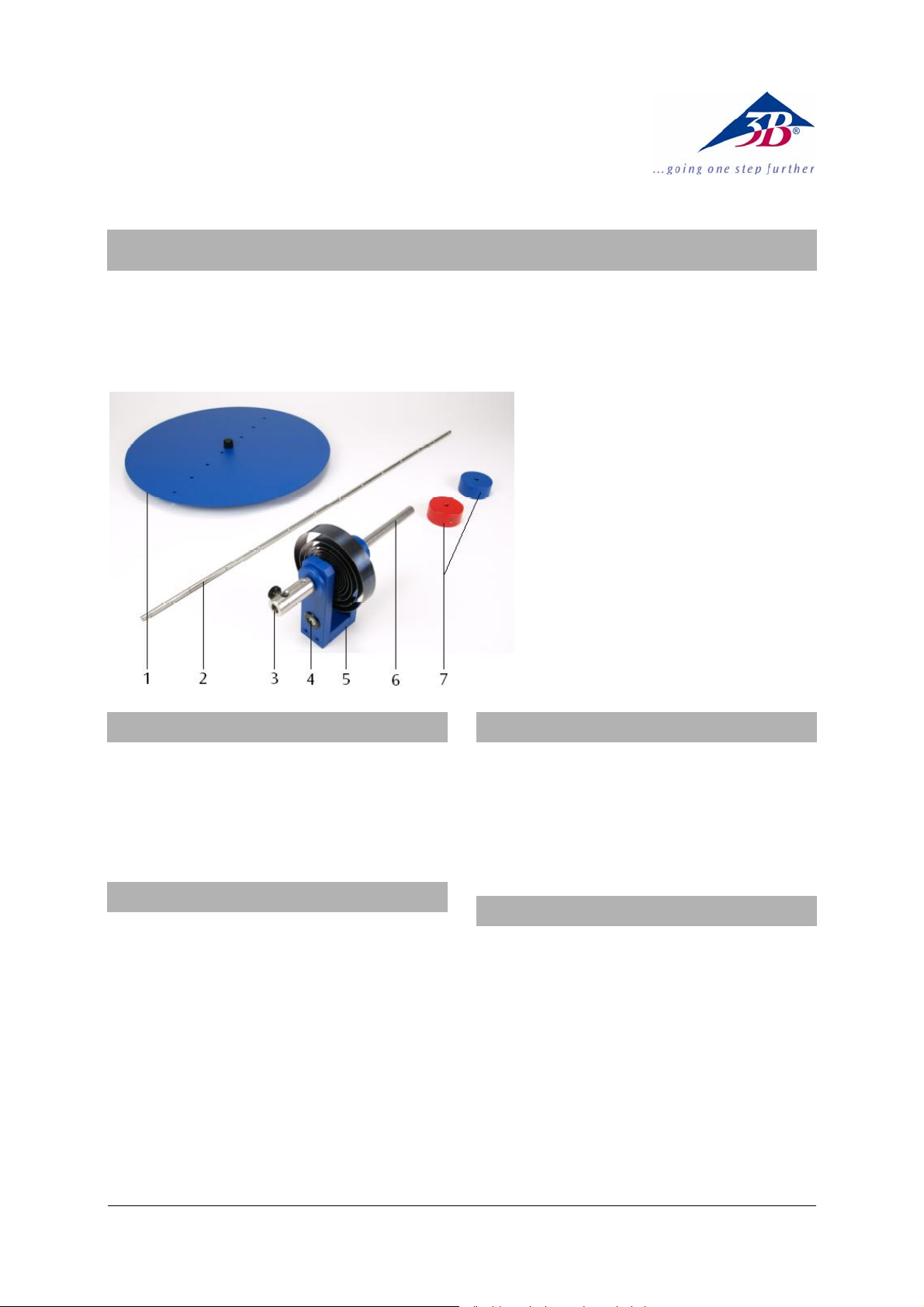

Torsion Axle U20050

1 Circular disc

2 Cross bar

3 Mount for test bodies

4 Spirit level

5 Bracket with coiled spring

6 Support rod

7 Weights

1. Safety instructions

If the coiled spring is too tightly wound, there is the

danger that high centrifugal forces cause the test

bodies to be hurdled away.

• Do not displace the test bodies more than a maxi-

mum of 360° (180° is recommended).

2. Description

The torsion axle with its corresponding accessories

and parts are used to investigate rotational oscillation and for determining the moments of inertia of

various sample objects from the period of oscillation.

The torsion axle consists of a shaft with twin ball races

which is coupled to a bracket by a coiled spring. A

support rod permits assembly on a stand base or a

table clamp. A spirit level is provided so that the torsion axle can be aligned to the horizontal. The test

bodies are a cross bar with weights that can be

moved along its length and a circular disc with one

hole in the centre and eight away from the centre for

determining moments of inertia for eccentric axes of

rotation and confirming Steiner’s theorem.

3. Equipment supplied

1 shaft with bracket, coiled spring, support rod and

mount for test bodies

1 cross bar

2 weights

1 circular disc

4. Technical data

Restoring torque of the spring: 0.028 Nm/rad

Height of the torsion axle: approx. 200 mm

Cross bar:

Length: 620 mm

Mass: approx. 135 g

Weights: 260 g each

Circular disc:

Diameter: 320 mm

Mass: 495 g

Boreholes: 9

Borehole spacing: 20 mm

1

Page 2

5. Accessories

6. Theory

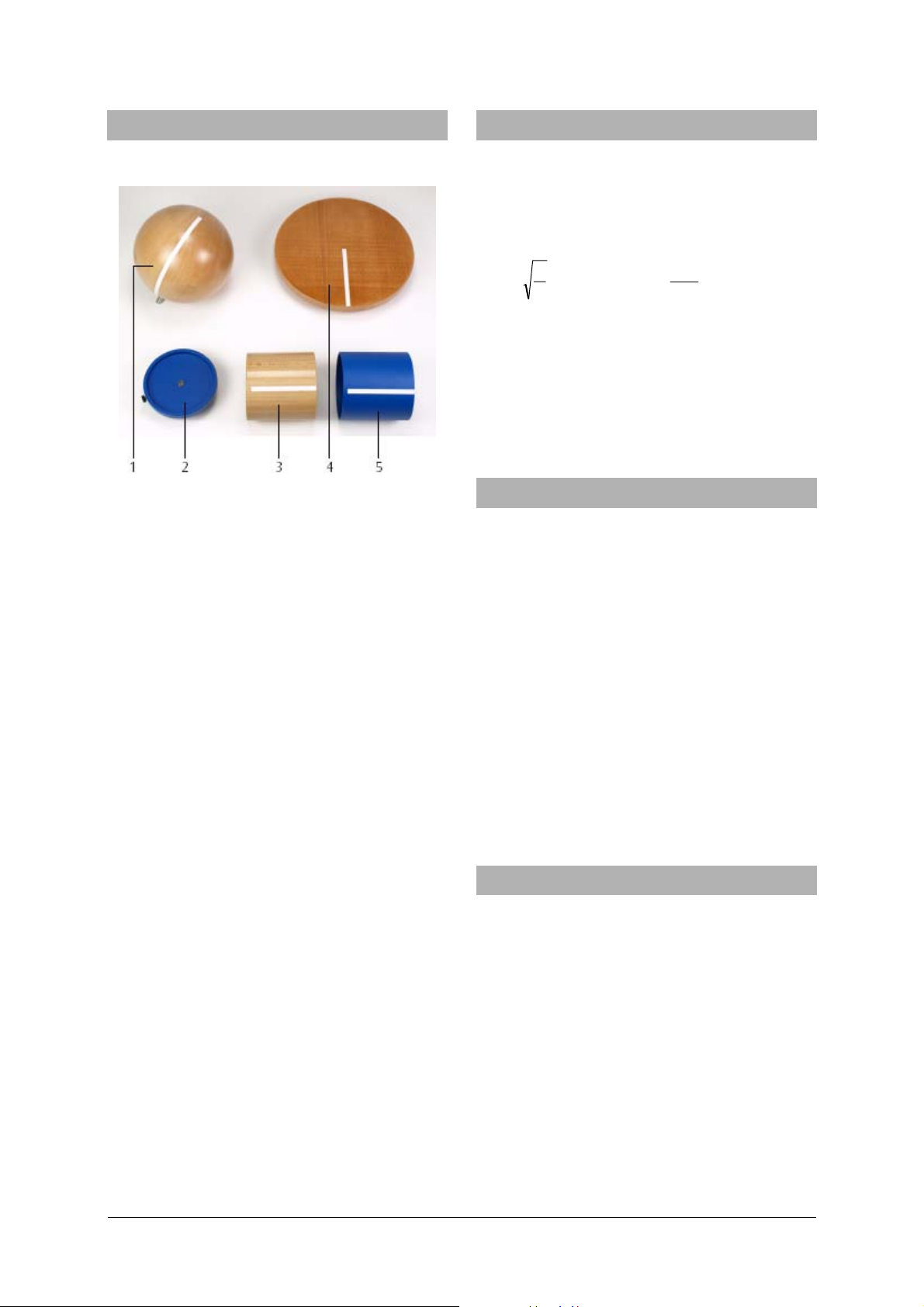

Set of Test Bodies for Torsion Axle U20051

Fig. 1 Set of Test Bodies for Torsion Axle

1 Wooden sphere, 2 Mounting plate, 3 Solid cylinder, 4 Wooden disc, 5 Hollow cylinder

The accessories for the torsion axle (U20050) consist

of two cylinders with nearly identical weights but

different weight distributions, a mounting plate for

the cylinders, a wooden disc and a wooden sphere.

Hollow cylinder (metal):

External diameter: 90 mm

Height: 90 mm

Mass: approx. 425 g

Solid cylinder (wood):

Diameter: 90 mm

Height: 90 mm

Mass: approx. 425 g

Mounting plate:

Diameter: 100 mm

Mass: approx. 122 g

Wooden disc:

Diameter: 220 mm

Height: 15 mm

Mass: approx. 425 g

Moment of inertia: 0.51 kgm

2

Wooden sphere:

Diameter: 146 mm

Mass: approx. 1190 g

Moment of inertia: 0.51 kgm

2

To determine various moments of inertia for different test bodies, these objects are placed on a ballbearing supported shaft which has a coiled spring

attached. The coiled spring is subjected to restoring

torque D. The oscillation period

T

of the torsion

pendulum results in the moment of inertia J.

T π= 2

J

D

D

J ⋅

=

2

4

π

2

T

The values determined experimentally confirm the

findings theoretically postulated for a body of the

mass m, whose mass elements

r

z around a fixed axis:

tance

∑

n

1z

=

2

2

=⋅Δ=

z

z

dmrrmJ

∫

Δm rotate at a dis-

7. Operating notes

• Mount the torsion axle in a tripod stand and

align it horizontally using the spirit level.

• Do not adjust the screws that press the securing

spheres to the rod. (They are adjusted so that the

weights can be moved along the rod but are not

forced outwards by centrifugal forces.)

• Always arrange the experiment so that the spring is

compressed and not extended.

• Start the oscillation by turning the rod 180°

(max. 360°).

• Determine the oscillation period from several

measurements by forming the mean value out of

e.g. 5 oscillations.

• Note down the exact value of the restoring torque

D on the torsion axle or in the operating manual.

This value is used to determine the moment of

inertia J from the oscillation period T.

8. Experiments

To perform the experiments the following apparatus

are required (recommended):

1 Stand Base Tripod, 185 mm U13271

1 Digital Stopwatch U11902

1 Precision Dynamometer 1 N U20032

1 Set of Test Bodies for Torsion Axle U20051

8.1 Determination of the restoring torque D

• Insert the rod without weights onto the torsion axle.

• Attach the 1 N dynamometer to the rod so that it

acts perpendicularly to it.

• At distances of r = 10 cm, 15 cm and 20 cm from

the centre of the rod measure the force F needed

to rotate the rod from its state of equilibrium by

about

α = 180°.

2

Page 3

Torque:

rFM ⋅=

Restoring torque:

=MD

α

8.3.2 Solid cylinder (SC) and hollow cylinder (HC)

• Attach the mounting plate (P) to the torsion axle.

• Determine the moment of inertia J(P).

• Place a cylinder onto the mounting plate (P).

• Determine the moments of inertia J(SC + P) and

J(HC + P).

• Determine the moments of inertia

J(SC) = J(SC + P) – J(P)

J(HC) = J(HC + P) – J(P) by subtracting.

Fig. 2 Determination of the restoring torque

8.2 Dependency of the moment of inertia J on

the distance r, in which a mass m rotates

round a fixed axis

• Attach the rod without weights to the torsion axle.

• Determine the moment of inertia J(rod).

• Arrange the weights at symmetrical distances of

r = 5 cm, 10 cm, 15 cm, 20 cm and 25 cm from

the centre of the rod.

• Determine the moment of inertia J(rod + weights).

• Calculate the moment of inertia J(weights) =

J(rod + weights) – J(rod).

Fig. 3 Dependency of the moment of inertia J on the

distance r

8.3 Comparison of the moments of inertia of

cylinders of the same weight but with

different weight distribution

8.3.1 Wooden disc (WD)

• Attach the wooden disc (WD) to the torsion axle.

• Determine the moment of inertia J(WD).

Fig.4 Determination of the moment of inertia of a

wooden disc

Fig. 5 Comparison of the moments of inertia of cylin-

ders

8.4 Determination of the moment of inertia of a

sphere (S)

• Attach the sphere (S) to the torsion axle.

• Determine the moment of inertia J(S).

A comparison of the sphere with the wooden disc

(refer to 8.3.1.) reveals that they both have the same

moment of inertia. Spheres (S) and wooden discs

(WD) have the same moment of inertia if the following holds true with regard to their mass

R

:

radii

4

)WD()WD( RmRm ⋅=⋅

5

22

)S()S(

Fig. 6 Determination of the moment of inertia of a

sphere

m

and their

8.5 Dependency of the moment of inertia J on

the distance a between the rotation axis and

the axis of the centre of gravity, verification

of Steiner’s theorem

• Attach the round disc to the torsion axle and

align it horizontally.

• Start the disc turning about its centre of gravity

(a = 0).

• Determine the moment of inertia J

• Determine the moments of inertia J

.

0

for different

a

distances of a = 2 cm, 4 cm, 6 cm......16 cm be-

3

Page 4

tween the rotation axis and the axis of the centre

of gravity.

• Re-adjust the horizontal alignment of the disc

after each change of distance a.

JJ

−

• Form the ratios =

Thus Steiner’s theorem

a

2

0a

constant

2

maJJ +=

0a

is verified.

Fig. 7 Verification of Steiner’s theorem

3B Scientific GmbH • Rudorffweg 8 • 21031 Hamburg • Germany • www.3bscientific.com

Subject to technical amendments

© Copyright 2011 3B Scientific GmbH

Loading...

Loading...