Page 1

Galaxy RAID

Model GHDX2-2430S-24F4D

24 bay FC-4G to SATA-II RAID Subsystem

Single Controller

Model GHDX2-2430R-24F4D

24 bay FC-4G to SATA-II RAID Subsystem

Dual Controller

Installation and Hardware

Reference Manual

Version 1007

Version 1.0 (08, 2005)

Page 2

Galaxy Raid GHDX2-2430S/R-24F4D Installation and Hardware Reference Manual

Contact Information

Americas

Rorke Data Inc

7626 Golden Triangle Drive

Eden Prairie, MN 55344

USA

Tel: +1-800 328 8147

Fax: +1-952 829 0988

sales@rorke.com

techsupport@rorke.com

http://www.rorke.com

ii

Page 3

Copyright 2007

This Edition First Published 2007

All rights reserved. This publication may not be reproduced, transmitted,

transcribed, stored in a retrieval system, or translated into any language or

computer language, in any form or by any means, electronic, mechanical,

magnetic, optical, chemical, manual or otherwise, without the prior written

consent of Rorke Data , Inc.

Disclaimer

Rorke Data makes no representations or warranties with respect to the contents

hereof and specifically disclaims any implied warranties of merchan tability or

fitness for any particular purpose. Furthermore, Rorke Data reserves the right to

revise this publication and to make changes from time to time in the content

hereof without obligation to notify any person of such revisions or changes.

Product specifications are also subject to change without prior notice.

Galaxy Raid Installation and Hardware Reference Manual

Trademarks

Galaxy and the Galaxy logo are registered trademarks of Rorke Data , Inc.

®

PowerPC

Motorola Inc.

Solaris and Java are trademarks of Sun Microsystems, Inc.

All other names, brands, products or services are trademarks or registered

trademarks of their respective owners.

is a trademark of International Business Machines Corporation and

iii

Page 4

Galaxy Raid GHDX2-2430S/R-24F4D Installation and Hardware Reference Manual

Warnings and Certifications

Restricted Access Location:

This equipment is intended to be installed in a RESTRICTED ACCESS LOCATION only.

Electric Shock Warning!

To Prevent Electric Shock:

Access to this equipment is granted only to trained operators and service personnel who have

been instructed of and fully understand the possible hazardous conditions and the

consequences of accessing non-field-serviceable units. For example, accessing the backplane

may cause electric shock.

FCC (applies in the U.S. and Canada)

FCC Class A Note

This device complies with Part 15 of the FCC rules. Operation is subject to the

following two conditions: (1) this device may not cause harmful interference,

and (2) this device may accept any interference received, including interference

that may cause undesired operation.

NOTE:

This equipment has been tested and found to comply with the limits for a Class

A digital device, pursuant to Part 15 of the FCC Rules. These limits are designed

to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residen tial area is likely to

cause harmful interference in which case the user will be required to correct the

interference at his own expense.

iv

The changes or modifications not expressly approved by the party responsible

for compliance could void the user’s authority to operate the equipment.

WARNING:

Page 5

Galaxy Raid Installation and Hardware Reference Manual

Use only shielded cables to connect I/O devices to this equipment.

You are cautioned that changes or modifications not expressly approved by the

party responsible for compliance could void your authority to operate the

equipment.

This device is in conformity with the EMC.

CB

This device is in conformity with the CB safety specifications.

This device meets the requirements of the CB standard for electrical

equipment with regard to establishing a satisfactory level of safety for

persons using the device and for the area surrounding the apparatus.

This standard covers only safety aspects of the above apparatus; it does

not cover other matters, such as style or performance.

CCC for Power Supplies’ compatibility to China Compulsory Certification.

This device is in conformity with UL standards for safety.

ITE BSMI Class A, CNS 13438 (for Taiwan)

v

Page 6

Galaxy Raid GHDX2-2430S/R-24F4D Installation and Hardware Reference Manual

This device is in conformity with UL standards for safety.

RoHS 2002/96/EC compliant

WEEE Disposal of Old Electrical and Electronic Equipment

vi

Page 7

Galaxy Raid Installation and Hardware Reference Manual

Table of Contents

CHAPTER 1 INTRODUCTION

1.1. PRODUCT OVERVIEW ................................................................................................1-1

1.1.1 Product Introduction........................................................................................1-1

1.1.2 Enclosure Chassis ............................................................................................1-2

1.1.2.1 Chassis Overview........................................................................................................... 1-2

1.1.2.2 Physical Dimensions................................................................................................... ... 1-3

1.1.2.3 Front Panel Overview....................................................................................................1-3

1.1.2.4 Hard Drive Numbering.................................................................................................. 1-4

1.1.2.5 Rear Panel Overview.....................................................................................................1-4

1.1.2.6 Back-plane Board........................................................................................................... 1-5

1.2. SUBSYSTEM COMPONENTS........................................................................................1-5

1.2.1 LCD Panel........................................................................................................1-5

1.2.2 Drive Trays.......................................................................................................1-6

1.2.3 RAID Controller Modules ................................................................................1-6

1.2.4 Controller Module Interfaces...........................................................................1-7

1.2.5 DIMM Modules ................................................................................................1-9

1.2.6 BBU..................................................................................................................1-9

1.2.7 PSUs...............................................................................................................1-10

1.2.8 Cooling Modules ............................................................................................1-11

1.3. S

1.4. H

UBSYSTEM MONITORING.......................................................................................1-12

1.3.1 I2C bus ...........................................................................................................1-12

1.3.2 LED Indicators...............................................................................................1-12

1.3.3 Firmware (FW) and RAIDWatch GUI ...........................................................1-13

1.3.4 Audible Alarms...............................................................................................1-13

OT-SWAPPABLE COMPONENTS..............................................................................1-13

1.4.1 Hot-swap Capabilities....................................................................................1-13

1.4.2 Components....................................................................................................1-14

1.4.3 Normalized Airflow ........................................................................................1-14

CHAPTER 2 HARDWARE INSTALLATION

2.1. INSTALLATION OVERVIEW...............................................................................2-1

2.2. INSTALLATION

2.3. SAFETY

PRECAUTIONS:......................................................................................2-2

2.3.1 Precautions and Instructions............................................................................2-2

2.3.2 Static-free Installation......................................................................................2-3

2.4. GENERAL

2.4.1 Installation Procedure Flowchart....................................................................2-4

2.5. UNPACKING

2.6. INSTALLATION

2.6.1 Pre-installed Components................................................................................2-5

2.6.2 Uninstalled Components ..................................................................................2-5

vii

PRE-REQUISITES.....................................................................2-1

INSTALLATION PROCEDURE.........................................................2-3

THE SUBSYSTEM..........................................................................2-5

OVERVIEW...............................................................................2-5

Page 8

Galaxy Raid GHDX2-2430S/R-24F4D Installation and Hardware Reference Manual

2.7. INSTALLING

THE OPTIONAL BBU....................................................................2-6

2.7.1 BBU Installation Overview...............................................................................2-6

2.7.2 BBU Warnings and Precautions.......................................................................2-6

2.7.3 Installation Procedure......................................................................................2-7

2.8. HARD

DRIVE INSTALLATION............................................................................2-9

2.8.1 Hard Drive Installation Prerequisites..............................................................2-9

2.8.2 SATA Drive Installation ...................................................................................2-9

2.9. DRIVE

2.10. RACK/CABINET

TRAY INSTALLATION ..........................................................................2-10

INSTALLATION.....................................................................2-12

CHAPTER 3 SUBSYSTEM MONITORING

3.1. SUBSYSTEM MONITORING OVERVIEW ......................................................................3-1

3.2. S

3.3. A

3.4. I2C

TATUS-INDICATING LEDS .......................................................................................3-2

3.2.1 Brief Overview of the LEDs..............................................................................3-2

3.2.2 LCD Panel........................................................................................................3-3

3.2.3 Drive Tray LEDs ..............................................................................................3-4

3.2.4 Controller Module LEDs..................................................................................3-5

3.2.5 LAN Port LEDs ................................................................................................3-6

3.2.6 BBU LED..........................................................................................................3-7

3.2.7 PSU LEDs.........................................................................................................3-8

3.2.8 Cooling Module LEDs......................................................................................3-9

UDIBLE ALARM ....................................................................................................3-10

3.3.1 Default Threshold Values...............................................................................3-10

3.3.2 Failed Devices................................................................................................3-11

MONITORING....................................................................................................3-11

CHAPTER 4 SUBSYSTEM CONNECTION AND OPERATION

4.1 FC HOST CONNECTION PREREQUISITES ........................................................4-1

4.1.1 Choosing the Fibre Cables...............................................................................4-1

4.1.2 FC Lasers.........................................................................................................4-2

4.1.3 FC Speed Auto-detection..................................................................................4-2

4.1.4 SFP Transceivers..............................................................................................4-2

4.2 TOPOLOGY

4.2.1 Basic Configuration Rules................................................................................4-3

4.2.2 Fibre Channel Topologies................................................................................4-3

4.2.3 Host-side Topologies........................................................................................4-4

4.2.4 Unique Identifier ..............................................................................................4-4

4.2.5 ID/LUN Mapping..............................................................................................4-4

4.3 SAMPLE

4.3.1 Sample Topology – Clustered Hosts.................................................................4-4

4.3.2 Sample Topology – Direct-Attached.................................................................4-5

4.4 POWER

4.4.1 Check List.........................................................................................................4-6

4.4.2 Power On Procedure........................................................................................4-7

4.4.3 Power On Status Check....................................................................................4-8

viii

AND CONFIGURATION CONSIDERATIONS ..............................4-3

TOPOLOGIES.........................................................................................4-4

ON .............................................................................................................4-6

Page 9

Galaxy Raid Installation and Hardware Reference Manual

4.4.4 LCD Screen ......................................................................................................4-9

4.5 POWER

OFF PROCEDURE .................................................................................4-10

CHAPTER 5 SUBSYSTEM MAINTENANCE

5.1. OVERVIEW.............................................................................................................5-1

5.1.1 Maintenance.....................................................................................................5-1

5.1.2 General Notes on Component Replacement.....................................................5-1

5.2. REPLACING

5.2.1 Overview...........................................................................................................5-2

5.2.2 Notes on Controller Module Maintenance.......................................................5-3

5.2.3 Removing the Controller Module.....................................................................5-3

5.2.4 Replacing the Controller Module.....................................................................5-4

5.3. DIMM

5.3.1 DIMM Module Considerations.........................................................................5-6

5.3.2 DIMM Module Replacement Procedure...........................................................5-6

5.4. REPLACING

5.5. REPLACING

5.5.1 PSU Module Overview .....................................................................................5-9

5.5.2 Replacing the PSU Module.............................................................................5-10

5.6. COOLING

5.6.1 Cooling Module Overview..............................................................................5-13

5.6.2 Replacing a Cooling Module..........................................................................5-14

5.7. REPLACING

5.7.1 Hard Drive Maintenance Overview................................................................5-16

5.7.2 Replacing a Hard Drive .................................................................................5-17

CONTROLLER MODULE COMPONENTS ...................................5-2

MODULE REPLACEMENT.......................................................................5-6

A FAULTY BBU ..............................................................................5-7

A FAULTY PSU MODULE..............................................................5-9

MODULE MAINTENANCE ..............................................................5-13

A FAILED HARD DRIVE..............................................................5-16

APPENDIX A SPECIFICATIONS

A.1. TECHNICAL SPECIFICATIONS.................................................................................. A-1

A.2. CONTROLLER SPECIFICATIONS............................................................................... A-3

A.2.1 Configuration .................................................................................................A-3

A.2.2 Architecture....................................................................................................A-3

A.3. DRIVE TRAY SPECIFICATIONS ................................................................................A-4

A.4. POWER SUPPLY SPECIFICATIONS............................................................................A-4

A.5. COOLING MODULE SPECIFICATIONS ......................................................................A-5

A.6. RAID MANAGEMENT............................................................................................. A-5

A.7. FAULT TOLERANCE MANAGEMENT........................................................................ A-6

APPENDIX B SPARE PARTS AND ACCESSORIES

B.1. SPARE PARTS ......................................................................................................... B-1

B.2. ACCESSORIES ......................................................................................................... B-2

APPENDIX C PIN OUTS

C.1. SFP CONNECTOR PIN OUTS ................................................................................... C-1

ix

Page 10

Galaxy Raid GHDX2-2430S/R-24F4D Installation and Hardware Reference Manual

C.2.

COM1 CABLE: DB9 AUDIO JACK PIN OUTS.......................................................... C-3

C.3. COM2 CABLE: DB9 AUDIO JACK PIN OUTS.......................................................... C-4

C.4. GAL-9011 NULL MODEM...................................................................................... C-5

C.5. ETHERNET PORT PIN OUTS..................................................................................... C-6

C.6. MAIN POWER ......................................................................................................... C-6

x

Page 11

Safety Precautions

Precautions and Instructions

• Prior to powering on the subsystem, ensure that the correct power range is being

used.

• The Galaxy subsystem comes with twenty four (24) drive bays. Leaving any of th ese

drive bays empty will greatly affect the efficiency of the airflow within the

enclosure, and will consequently lead to the system overheating, which can cause

irreparable damage.

• If a module fails, leave it in place until you have a replacement unit and you are

ready to replace it.

• Airflow Consideration: The subsystem requires an airflow clearance, especially at

the front and rear.

Galaxy Raid Installation and Hardware Reference Manual

• Handle subsystem modules using the retention screws, eject levers, and the metal

frames/face plates. Avoid touching PCB boards and connector pins.

• To comply with safety, emission, or thermal requirements, none of the covers or

replaceable modules should be removed. Make sure that during operation, all

enclosure modules and covers are securely in place.

• Be sure that the rack cabinet into which the subsystem chassis will be installed

provides sufficient ventilation channels and airflow circulation around the

subsystem.

• Provide a soft, clean surface to place your subsystem on before working on it.

Servicing on a rough surface may damage the exterior of the chassis.

• If it is necessary to transport the subsystem, repackage all disk drives separately.

• Dual redundant controller models come with two controller modules that must be

installed into the subsystem. Single controller modules come with a single controller

module and a metal sheet is placed over the lower controller bay at the rear of the

subsystem. Since single controller modules cannot be upgraded, this metal sheet

should NEVER be removed.

ESD Precautions

Observe all conventional anti-ESD methods while handling system modules.

The use of a grounded wrist strap and an anti-static work pad are recommended.

Avoid dust and debris in your work area.

xi

Page 12

Galaxy Raid GHDX2-2430S/R-24F4D Installation and Hardware Reference Manual

About This Manual

This manual:

• Introduces the Galaxy RAID GHDX2-2430S/R-24F4D 400mhz ASIC

subsystem.

• Describes all the active components in the subsystem.

• Provides recommendations and details about the hardware installation

process.

• Briefly describes how to monitor the subsystem.

• Describes how to maintain the subsystem.

This manual does not:

• Describe components that are not user-serviceable.

• Describe the configuration options of firmware, using terminal emulation

programs, or the RAIDWatch GUI software that came with your subsystem.

• Give a detailed description of the RAID controllers embedded within the

subsystem.

Revision History

♦ Initial release

Who should read this manual?

This manual assumes that its readers are experienced with computer hardware

installation and are familiar with storage enclosures.

Related Documentation

• User’s Operation Manual

• RAIDWatch User’s Manual

xii

Page 13

These two documents can be found in the product utility CD included with yo ur

subsystem package.

Conventions

Naming

From this point on and throughout the rest of this manual, the Galaxy series is

referred to as simply the “subsystem” or the “system” and Galaxy is frequently

abbreviated as “Gal.”

Lists

Bulleted Lists: Bulleted lists are statements of non-sequential facts. They can be

read in any order. Each statement is preceded by a round black dot “•.”

Numbered Lists: Numbered lists are used to describe sequential steps you

should follow in order.

Galaxy Raid Installation and Hardware Reference Manual

Important information that users should be aware of is indicated with the

following icons:

NOTE:

These messages inform the reader of essential but non-critical

information. These messages should be read carefully as any directions

or instructions contained therein can help you avoid making mistakes.

CAUTION!

Cautionary messages should also be heeded to help you reduce the

chance of losing data or damaging the system.

IMPORTANT!

The Important messages pertain to use the Galaxy subsystem introduced

in this manual.

WARNING!

Warnings appear where overlooked details may cause damage to the

xiii

Page 14

Galaxy Raid GHDX2-2430S/R-24F4D Installation and Hardware Reference Manual

equipment or result in personal injury. Warnings should be taken

seriously.

Software and Firmware Updates

Please contact Rorke Technical Support for the latest software or firmware

updates.

Problems that occur during the updating process may cause unrecoverable errors

and system down time. Always consult technical personnel before proceeding

with any firmware upgrade.

NOTE:

The firmware version installed on your system should provide the

complete functionality listed in the specification sheet/user’s manual.

We provide special revisions for various application purposes.

Therefore, DO NOT upgrade your firmware unless you fully understand

what a firmware revision will do.

xiv

Page 15

Galaxy Raid Installation and Hardware Reference Manual

xv

Page 16

Chapter 1

Introduction

1.1. Product Overview

This hardware manual briefly introduces the Galaxy GHDX2-2430S/R-16F4D Fibre-4G

to SATA-II RAID subsystem as shown in Figure 1-1.

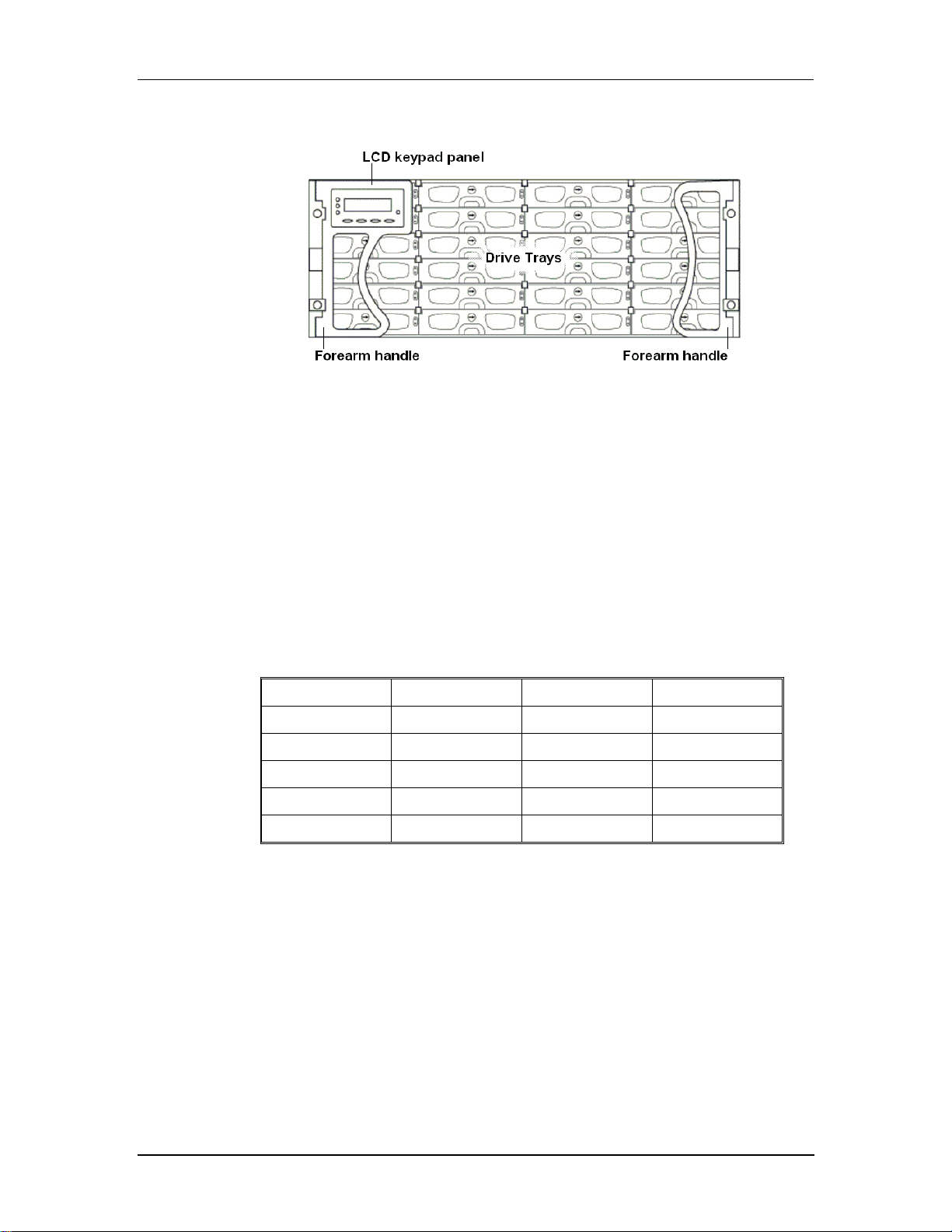

Figure 1-1: GHDX2-2430S/R-24F4D FC-to-SATA RAID Subsystem

The GHDX2-2430S-24F4D RAID subsystem is powered by a single RAID controller,

the GHDX2-2430R-24F4D by dual redundant RAID contro llers. Each RAID controller

comes with two (2) 4Gbps Fibre host channels that are interfaced through four (4)

separate SFP ports. A total of eight (8) SFP ports are available in a redundant-controller

configuration. The additional SFP ports facilitate connection to multiple application

servers and for connecting fault-tolerant data paths. The subsystem houses twenty-four

(24) 3Gbps SATA-II disk drives each with dedicated channel bandwidth. Each controller

board comes with a pre-installed 512MB DDR RAM DIMM module and can support

memory modules with the capacities up to 2GB.

The Galaxy HDX2 series is built around a custom ASIC400 specifically designed with

the hardware RAID6 capability. RAID6 can sustain two member drives of a RAID array

to fail at the same time and thereby helps achieve a higher level of data availability.

There are six (6) dedicated RCC paths strung between the partner RAID controllers in a

dual-active configuration. The RCC chips reside on the third, separate PCI-X bus. This

design takes benefits of the abundant system bandwidth brought by the new architecture

and hence the inter-controller communications do not affect drive channel throughput.

Introduction 1-1

Page 17

Galaxy GHDX2-2430S/R-24F4D Installation and Hardware Reference Manual

A SAS expansion port comes with each RAID controller and provides easy connectivity

to terabytes of expansion capacity over the 4x, wide SAS link cables.

Two (2) RS-232C (audio jack) serial port connectors are located on the controller

faceplate. One serial port (COM1) enables serial communication between the controller

and an external PC running terminal emulation software that can be used to configure and

manage the RAID subsystem. The second serial port (COM2) connects to an

uninterruptible power supply (UPS). An RJ-45 Ethernet connector allows telnet access

and web-based management using the included browser-based or Java-based versions of

the RAIDWatch manager software.

Disk drives in the front section of the subsystem are directly mated with a common

backplane. The backplane receives a maximum of twenty-four (24) SATA-II hard drives

that should be separately purchased.

Two (2) redundant, hot-swappable, dual-fan cooling modules protect the RAID

subsystem from overheating and three (3) redundant, hot-swappable, 1U 405W power

supply unit (PSU) modules provide constant power to the RAID subsystem. The modular

nature of the subsystem and the easy accessibility to all major components ensure that the

subsystem can be reliably and efficiently operated and maintained.

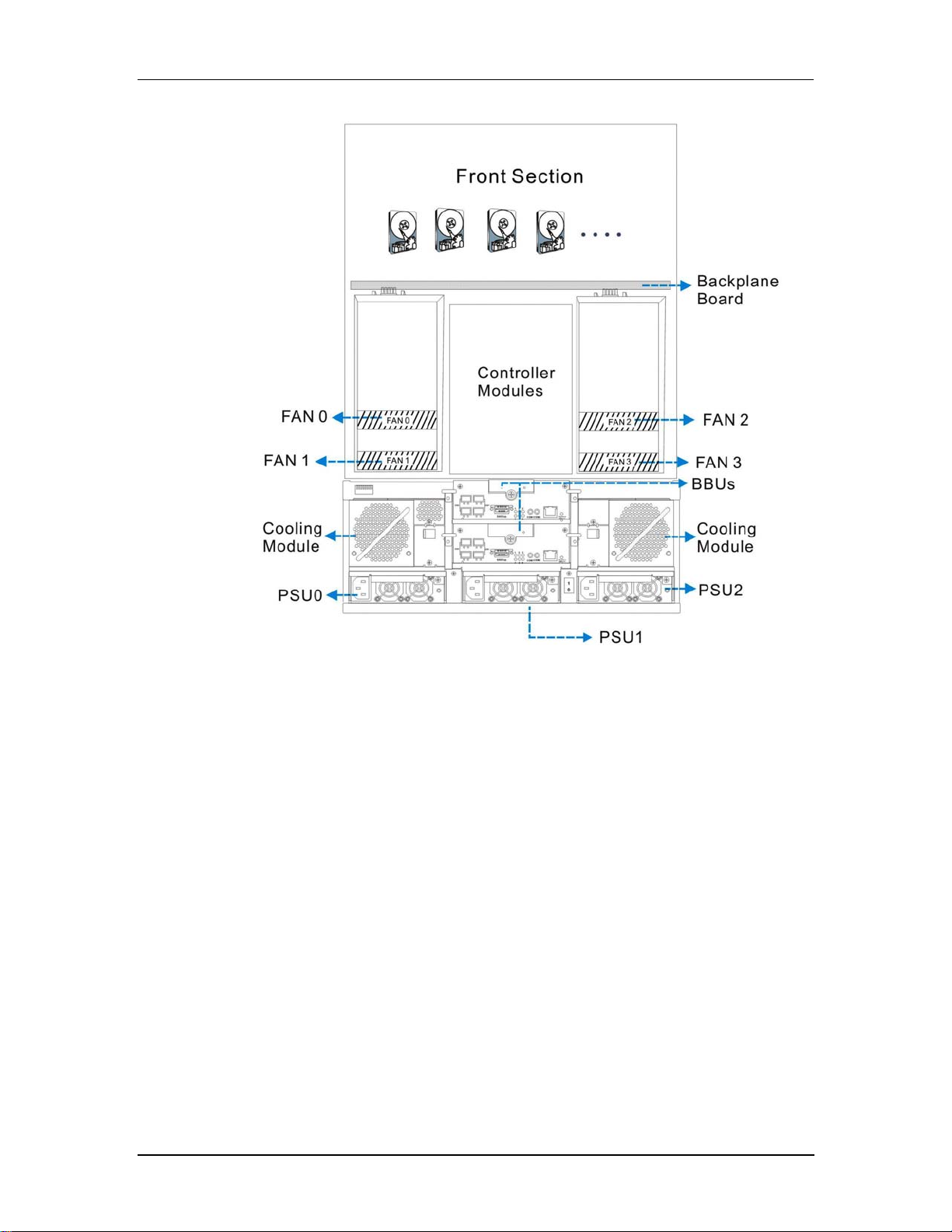

1.1.1 Enclosure Chassis

1.1.1.1 Chassis Overview

The Galaxy HDX2 24bay subsystem comes with a 4U compact steel chassis and

aluminum alloy framework for even distribution of component heat. A back-end PCB is

enclosed in thick gauge sheet metal that divides the enclo sure intern ally into th e front and

rear sections. (See Figure 1-2) The front section accommodates twenty-four (24) drive

trays (with their associated hard drives) and the rear section accommodates three (3) PSU

modules, two (2) dual-fan cooling modules, and RAID controllers in a single- or dualcontroller configurations. The two (2) foldable handles on the front of the chassis enable

you to easily extract the chassis from a rack cabinet. The subsystem enclosure can be

mounted into standard 19-inch rack cabinets using separately purchased slide rails.

1-2

Introduction

Page 18

Chapter 1: Introduction

Figure 1-2: Galaxy 24-bay SATA RAID Subsystem Overview

1.1.1.2 Physical Dimensions

The Galaxy HDX2 24bay subsystem comes in a standard 4U chassis with the following

dimensions:

♦ With forearm handles: 482W x 174.4H x 514D mm (19 x 6.87 x 20.2 inches)

♦ Without forearm handles: 445W x 174.4H x 498D mm (17.5 x 6.87 x 19.6

inches)

1-3

Page 19

Galaxy GHDX2-2430S/R-24F4D Installation and Hardware Reference Manual

1.1.1.3 Front Panel Overview

Figure 1-3: Galaxy HDX2 24bay RAID Subsystem Front View

As shown above, the front section of the subsystem features a 4-column by 6-row layout

to accommodate twenty-four (24) drive trays that are designed to house standard 3.5-inch

SATA drives. The left-side forearm handle comes with a 16 characters by 2 rows LCD

screen and four (4) function keys that can be used to configure and monitor the

subsystem.

1.1.1.4 Drive Slot Numbering

The front section of the enclosure houses twenty-four (24) hard drives. When viewed

from the front, the drive bays (slots) are numbered 1 to 24 from left to right, then from

top to bottom.

Slot-1 Slot-2 Slot-3 Slot-4

Slot-5 Slot-6 Slot-7 Slot-8

Slot-9 Slot-10 Slot-11 Slot-12

Slot-13 Slot-14 Slot-15 Slot-16

Slot-17 Slot-18 Slot-19 Slot-20

Slot-21 Slot-22 Slot-23 Slot-24

Figure 1-4: Hard Drive Slot Numbering

1-4

Introduction

Page 20

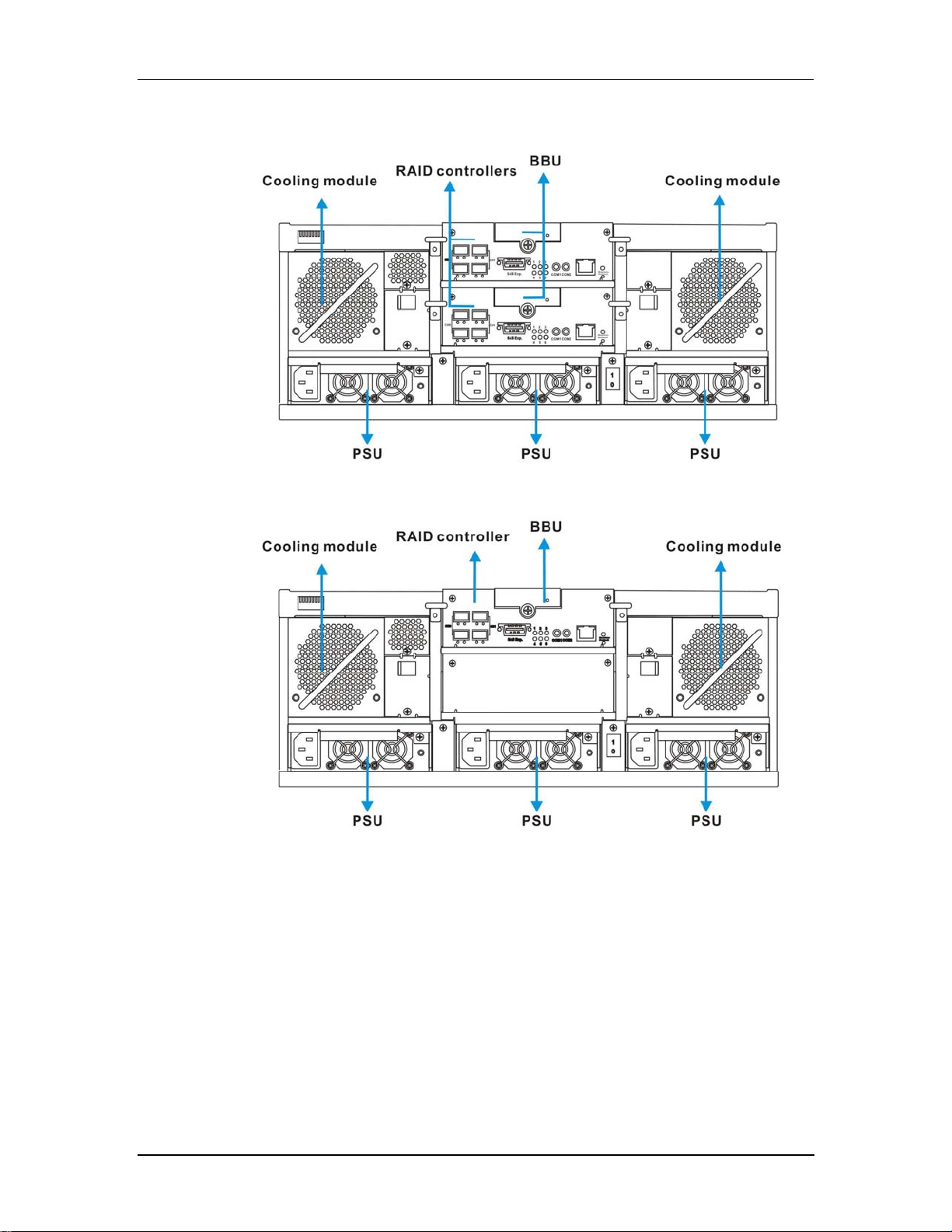

1.1.1.5 Rear Panel Overview

Figure 1-5: Galaxy GHDX2-2430R-24F4D Rear View

Chapter 1: Introduction

Figure 1-6: Galaxy GHDX2-2430S-24F4D Rear View

The rear panel of the Dual redundant controller version of the Galaxy HDX2 subsystem

is shown in Figure 1-5. The rear panel provides access to all the components located in

the rear half of the RAID subsystem enclosure. The rear panel of the single controller

version of the Galaxy HDX2 subsystem is shown in Figure 1-5.

Three (3) (N+1) redundant, hot-swappable 405W PSU modules provide converted power

from the power source. Two (2) redundant, hot-swappable, dual-fan cooling modules are

located above the PSU modules. One power switch on the chassis rear panel controls all

PSU modules. Each PSU module contains two cooling fans.

1-5

Page 21

Galaxy GHDX2-2430S/R-24F4D Installation and Hardware Reference Manual

Each RAID controller module comes with four (4) SFP host ports, two (2) RS-232C

(audio jack) serial ports, one (1) RJ-45 Ethernet connector and status-indicating LEDs

located on its rear-facing faceplate.

1.1.1.6 The Backplane Board

An integrated backplane board receives disk drives on the front end and connects the

RAID controller, cooling, and PSU modules on the other side. The PCB board provides

logic level signals and low voltage power paths. It contains no user-serviceable

components.

1.1.1.7 Subsystem Rack/Cabinet Installation

The subsystem chassis has pre-drilled screw holes for rackmounting. Separately

purchased, independently installed rackmount rails are available for rack or cabin et

installation.

The slide rails come with their own printed copies of installation guide.

1.2. Subsystem Components

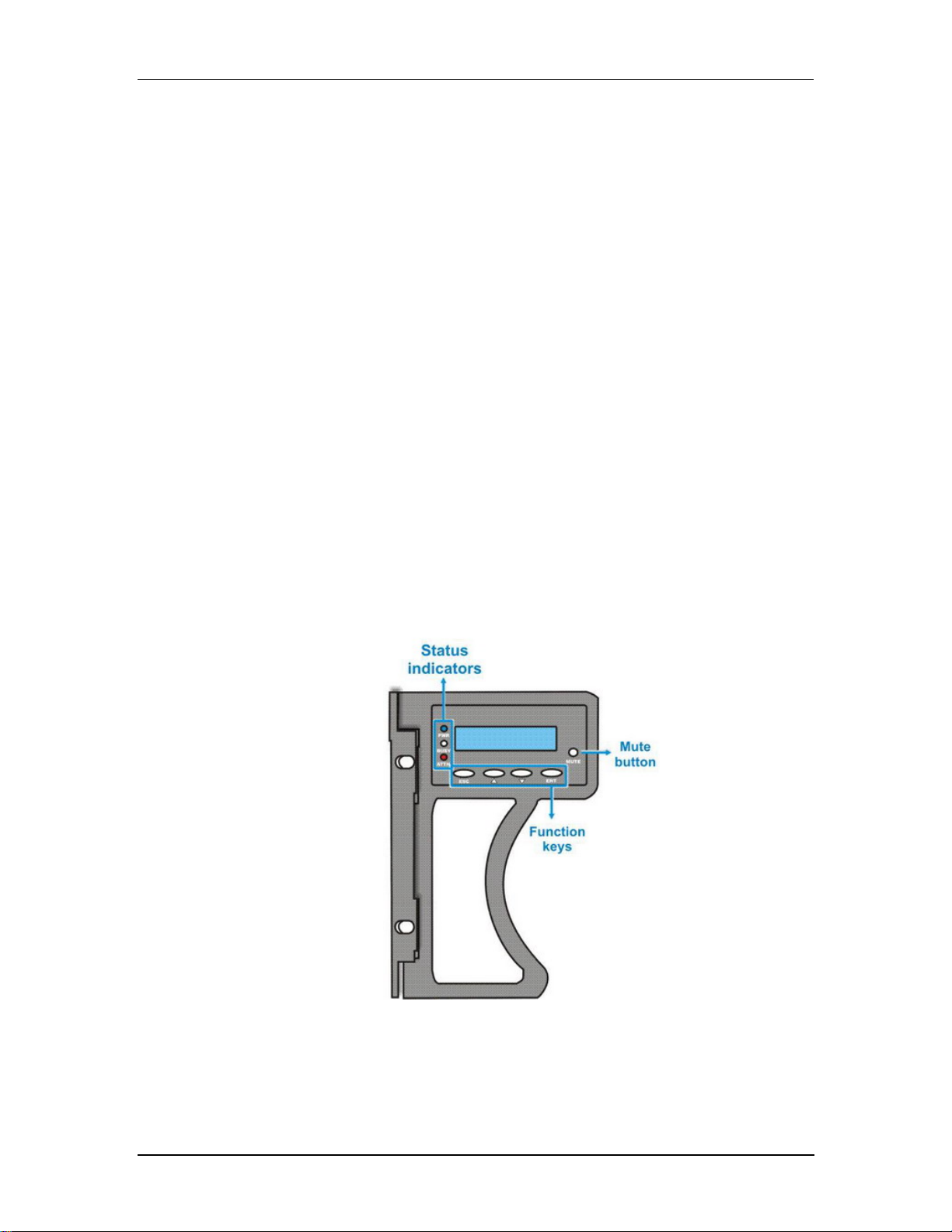

1.2.1 LCD Keypad Panel

Figure 1-7: LCD Keypad Panel

The LCD keypad panel consists of an LCD display with push buttons and LEDs that

indicate array statuses. The LCD panel provides full access to all RAID configurations

and monitoring options. After powering up the subsystem, the initial screen will display

1-6

Introduction

Page 22

the subsystem model name. A different name can be assigned for the subsystem or

specific logical drives. This enables ease of identification in a topology consisting of

numerous arrays.

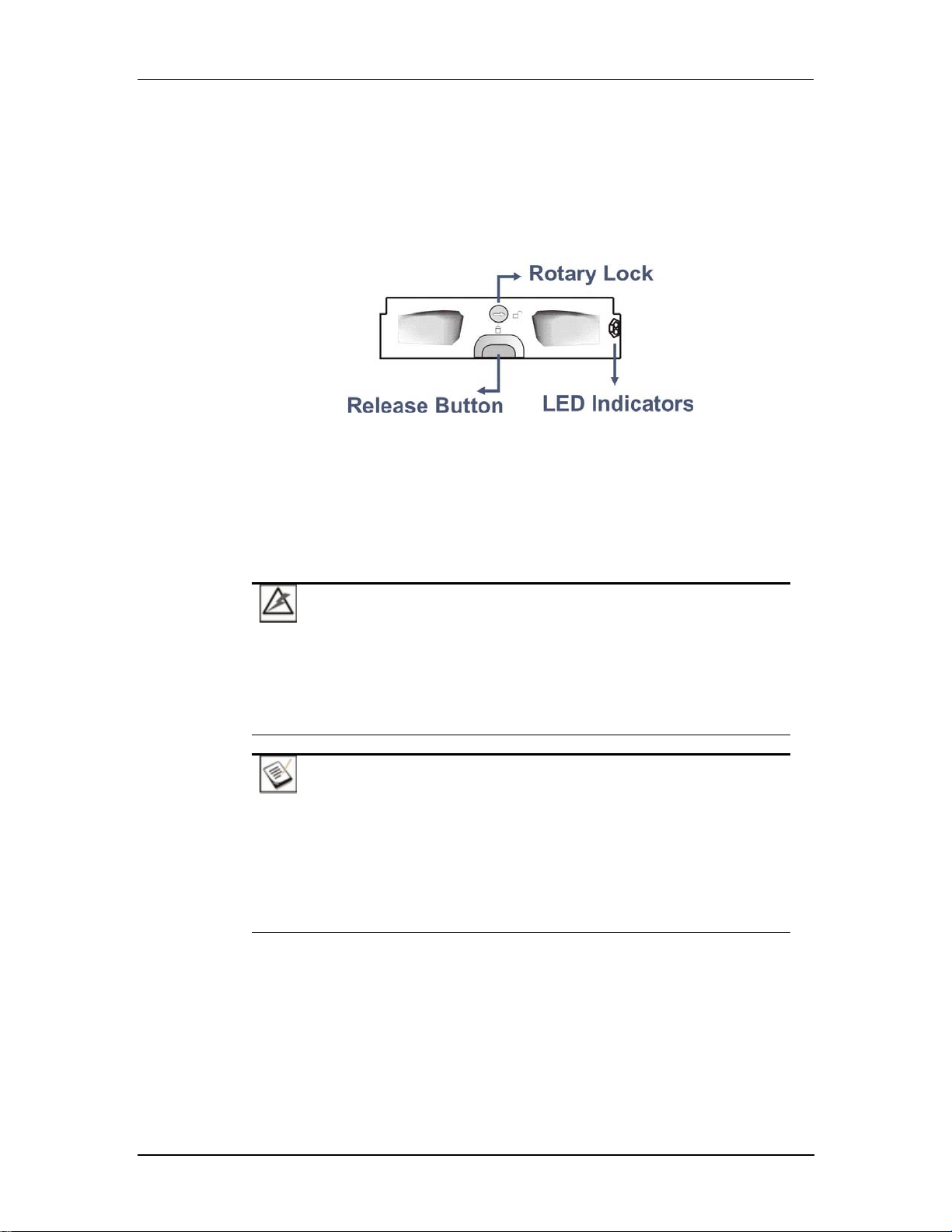

1.2.2 Drive Trays

The subsystems’ twenty-four (24) drive trays accommodate separately purchased,

standard 1-inch pitch, 3.5-inch disk drives. The drive bays are accessed through the front

of the enclosure. Two (2) LEDs on each tray bezel indicate the disk drive’s operation

status. A rotary bezel lock on each drive tray secures the hard drive in place, while a

release button can be used to open the front bezel.

Chapter 1: Introduction

Figure 1-8: Drive Tray

WARNING!

Be careful not to warp, twist, or contort the drive tray in any way (e.g., by dropping

it or resting heavy objects on it). The drive tray has been customized to fit into th e

drive bays in the subsystem and if it is deformed or altered it may not fit into the

drive bay.

NOTE:

The redundant-controller subsystem is shipped with twenty-four drive trays with

multiplexer (MUX) adapter boards. These MUX boards provide access routes for

different RAID controllers.

Please DO NOT use drive trays from a previous Galaxy model, GHDX-7376R624F2D. They are not compatible.

1.2.3 RAID Controller Module

The RAID controller module contains a main circuit board and a daughter card providing

additional interface connectors, management and host interfaces, and a preinstalled

512MB DDR RAM DIMM. The subsystem comes standard with BBU protection. The

BBU is installed in the module bay located at the top center of the controller module. The

BBU can be independently inserted or removed. Please note: The controller module

1-7

Page 23

Galaxy GHDX2-2430S/R-24F4D Installation and Hardware Reference Manual

contains no user-serviceable components. Only remove the controller when replacing a

faulty unit or installing/ the cache memory inside.

WARNING!

Although the RAID controllers are hot-swappable, the only time you should handle

the controller itself is to remove a failed controller, or to install and replace

memory modules. Unnecessary tampering with the RAID controller can damage

the controller.

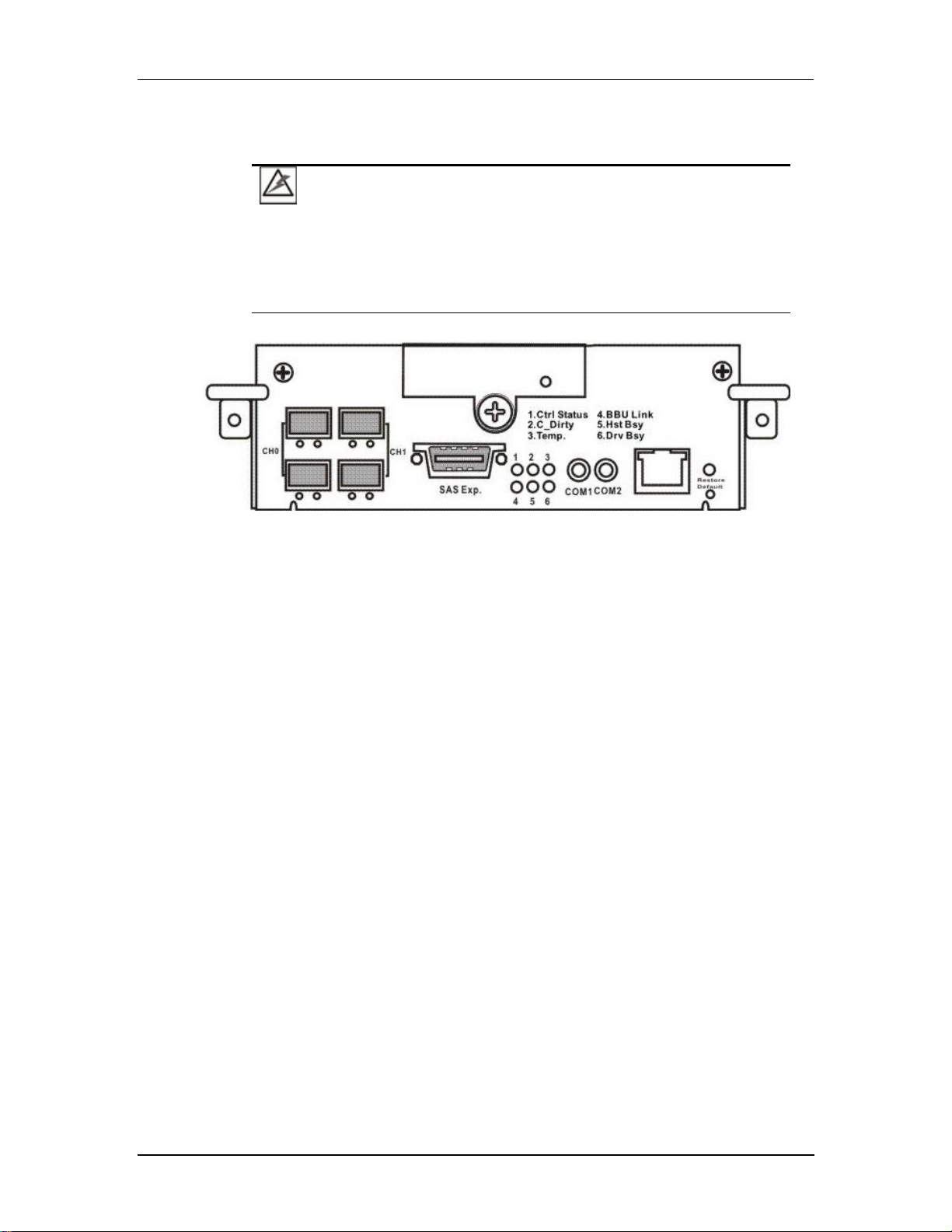

Figure 1-9: RAID Controller Faceplate

The controller faceplate provides external interfaces including four (4) SFP host ports,

two (2) RS-232C (audio jack) serial ports (labeled COM1 and COM2), one (1) RJ-45

Ethernet connector and six (6) status-indicating LEDs (labeled from 1 to 6), one Restore

Default LED and the associated push button. The controller main circuit board is hou sed

in a metal canister and can only be seen after the controller is removed from the chassis.

The controller canister has two (2) ejection levers that can be used to retrieve or secure

the controller module to the chassis. These levers are secured to the enclosure chassis

using two (2) retention screws through the screw holes underneath each lever.

1.2.4 Controller Module Interfaces

All host I/O and management interfaces are located on the controller faceplate. The

interfaces are listed below.

SFP host ports: Host ports are SFP sockets that receive 4Gb/s interface fiber optical

transceivers. It is recommended to use only certified transceivers and cables.

SAS expansion port: The SAS expansion port provides a 12Gb/s wide link to the

Galaxy series expansion JBODs.

RS-232C (Audio Jack): All controller modules come with two (2) RS-232C (audio

jack) serial ports The serial ports can be used for establishing a management session

through terminal emulation and uninterruptible power supply ( UPS) support.

1-8

Introduction

Page 24

Chapter 1: Introduction

The dual-controller subsystem comes with a serial port Y-cable that allows you to

access a surviving controller in the event of controller failure without physically

changing the connection.

TIPS:

Connect both Ethernet ports (if you are using a dual-controller subsystem) to

the Ethernet ports of your network switch.

The Ethernet port on a non-dominant (secondary) controller will stay idle until

the occurrence of primary controller failure.

Ethernet port: A single 10/100BaseT Ethernet port is used for local/remote

management over LAN/WAN. For a dual-controller configuration, connect the

Ethernet ports on both RAID controllers to your local network. The Ethernet port on

a non-dominant (stand-by, usually the controller in the lower slot) controller will

remain idle until a dominant, primary controller fails and the management service is

transferred to the surviving controller.

Disk Drive Channels: All models come with twenty-four (24) SATA drive channels

that are interfaced thorough a backplane to the hard disk drives.

1.2.5 DIMM Module

Each controller module comes with a preinstalled 512MB DDR RAM DIMM module

mounted on the controller board within a metal chassis. The controller module supports

memory modules with sizes from 512MB to 2GB.

1.2.6 BBU Module

The BBU can sustain cached data for days during a power failure. If power outage

occurs, the BBU supplies power to sustain the unfinished writes in cache memory.

1-9

Page 25

Galaxy GHDX2-2430S/R-24F4D Installation and Hardware Reference Manual

Figure 1-10: BBU Module, Controller Top Cover, and the Module Slot

The BBU functionality consists of two major parts. One is the charger circuitry mounted

on top of the controller main board. The other is an optional BBU module that contains

several battery cells. On a single-controller configuration, the BBU is an optional

accessory. The BBU module is hot-swappable so it can be replaced while the subsystem

is running.

New Feature:

The battery cell packs come with an EEPROM to record the date of installation and other

service data; and when the appro ximate on e-year life expectancy is reached (by checking

against the real-time-clock), system administrators will be notified for replacing the

BBU.

In accordance with international transportation regulations, the BBU is only charged to

between 35% and 45% of its total capacity when shipped. After powering on the

subsystem (see Section 4.1) the BBU will automatically start charging its battery cells. It

usually requires approximately twelve (12) hours for the battery to be fully charged.

The BBU is aware of its life expectancy as well as its charge level. Charge level

awareness helps avoid frequent re-charge.

1.2.7 Power Supply Units

The subsystem is equipped with three (3) hot swappable, 1U-profile, 405W PSU

modules. The PSU modules are located on the rear panel of the subsystem.

1-10

Introduction

Page 26

Chapter 1: Introduction

Figure 1-11: PSU Module

Each PSU module comes with a power socket for power cord plug-in. All three power

supplies are turned on and off using a single powe r switch on th e enclos ure chas sis. Each

PSU also comes with two (2) embedded cooling fans to provide sufficient airflow across

its heat-generating components and one (1) LED to indicate the PSU status. An extraction

handle makes it easier to install or remove the PSU from the subsystem. While a PSU

may be removed when the system is still online, this should only be done if the PSU has

failed and needs to be replaced.

A retention screw through the extraction handle secures the PSU to the chassis. If the

PSU needs to be removed, the retention screw must be removed first. After installing a

new PSU module, make sure that the retention screw has been firmly secured. The

shipping package contains adjustable cable clamps that can be used to secure power cord

connections.

PSU specifications are shown in Appendix A.

Power Supply Safety Restrictions

No. of Failed PSUs Responses and Preventive Actions

1. Warning messages are issued.

2. Cached data is flushed to the hard drives (also depends on

the Event Triggered configuration settings of the

1

firmware).

3. If previously configured to the Write-back mode, the

caching mode is automatically switched to the

conservative Write-through mode.

1-11

Page 27

Galaxy GHDX2-2430S/R-24F4D Installation and Hardware Reference Manual

1. Warning messages are issued.

2. The subsystem is temporarily held in an idle state.

3. The firmware forces the subsystem to stop serving host

I/O requests.

2

4. After the failed PSUs are replaced, array administrators

should manually turn the power switch off and then on.

5. If the subsystem is powered on with only one PSU, the

firmware will start the initialization process but stays idle

until at least one other PSU is added.

Table 1-1: Power Supply Safety Restrictions

1.2.8 Cooling Modules

These Galaxy 24 bay subsystems come with two (2) hot swappable, redundant, dual-fan

cooling modules. Two (2) 8cm blowers are housed in each cooling module and provide

ventilation airflow from the front to the rear of the subsystem, extracting the heat

generated by the SATA hard drives and other components.

Intelligent Dual Speed Operation

The fans in the cooling module operate with two rotation speeds. Under normal operating

conditions, the cooling fans run at the low speed, which is sufficient for maintaining an

efficient airflow across components. Under the following conditions, the cooling fans

automatically increase their rotation speed to increase the airflow:

1. Component Failure: if a cooling fan, PSU, or temperature sensor fails, the

remaining cooling fan(s) automatically raises its rotation speed.

2. Elevated Temperature: if the temperature breaches the upper threshold set for any

of the interior temperature sensors, the cooling fans automatically raise its rotation

speed.

3. During the initialization stage, the cooling fans operate at the high speed and

return to low speed once the initialization process is completed and no erro neous

condition is detected.

1-12

Introduction

Page 28

1.2.9 Enclosure DIP Switches

Chapter 1: Introduction

Figure 1-12: Cooling Module

Figure 1-13: Enclosure DIP Switches

DIP switches are located on the upper left corner of enclosure rear panel. The first tree

switches determine an enclosure ID and should always be kept at their default, “0-0-0.”

The two (2) switches marked as #7 and #8 have no function. The #4 switch is for

controlling the onboard hub across the host ports on partner controllers, to enable/d isable

the onboard bypass. Switch #4 is only applicable in a dual-controller configuration.

Switches #5 and #6 control host channel 4G or 2G speed.

When the onboard hub is enabled, host channels on the partner controllers will be

combined, e.g., Channel 0 on Controller A and Channel 0 on Controller B combined into

a host loop. Using the onboard hub enables fault-tolerant host links without the use of

expensive FC switches in a DAS (Direct Attach Storage) topology.

The configuration options for setting the DIP switches is fully discussed in Chapter 4.

1-13

Page 29

Galaxy GHDX2-2430S/R-24F4D Installation and Hardware Reference Manual

1.3. Subsystem Monitoring

The RAID subsystem comes with several monitoring methods to give you constant

updates on the status of the system and its individual components. The following

monitoring features are included in the subsystem.

1.3.1 I2C bus

The following subsystem elements interface to the RAID controller over a non-userserviceable I

Disk drives (drive failure output)

PSU modules

Cooling modules

2

C bus:

Temperature sensors

1.3.2 LED Indicators

The following active components all come with LEDs that indicate the status of the

individual component:

RAID controller (7 LEDs)

LCD keypad panel (3 LEDs)

Cooling module (2 LEDs)

PSU module (1 LED)

Drive tray (2 LEDs)

BBU module (1 LED)

1.3.3 Firmware and RAIDWatch® GUI

Firmware: The firmware (FW) is pre-installed software that is used to configure the

subsystem. The FW can be accessed through either the front panel LCD keypad or a

terminal emulation program that is installed on an external computer/application server

used as a management station.

1-14

Introduction

Page 30

RAIDWatch: RAIDWatch is a premier, web-based or Java-based graphical user

interface (GUI) that can be installed on an adjacent or a remote computer and accessed

via standard TCP/IP.

1.3.4 Audible Alarm

The RAID subsystem comes with audible alarms that are triggered when certain active

components fail or when certain controller or subsystem thresholds are exceeded. When

you hear an audible alarm emitted from the subsystem, it is imperative that you determine

the cause and rectify the problem immediately.

WARNING!

Failing to respond when an audible alarm is heard can lead to permanent

subsystem damage. When an audible alarm is heard, rectify the problem as soon as

possible.

Chapter 1: Introduction

1.4. Hot-swappable Components

1.4.1 Hot-swap Capabilities

The subsystem comes with hot-swappable components that can be exchanged while the

subsystem is still online without affecting the operational integrity of the subsystem.

These components should only be removed from the subsystem when they are being

replaced. At no other time should these components be removed from the subsystem.

1.4.2 Components

The following components are all hot swappable:

RAID controller modules

PSU modules

Host I/O modules

Cooling modules

Hard drives

BBU modules

1-15

Page 31

Galaxy GHDX2-2430S/R-24F4D Installation and Hardware Reference Manual

1.4.3 Normalized Airflow

Proper subsystem cooling is referred to as “normalized” airflow. Normalized airflow

ensures the sufficient cooling of the subsystem and is only attained when all the

components are properly installed. Therefore, a failed component should only be hotswapped when a replacement is available. If a failed component is removed but not

replaced, permanent damage to the subsystem can result.

1-16

Introduction

Page 32

Chapter 1: Introduction

This page is intentionally left blank.

1-17

Page 33

Chapter 2

Hardware Installation

2.1. Installation Overview

This chapter gives detailed instructions on how to install hard disk drives and drive trays

into the subsystem. Installation into a rack or cabinet should occur before hard drive

installation. Please confirm that you received all of the components listed on a printed

copy of Unpacking List included in the shipping package before proceeding with the

installation process.

2.2. Installation Pre-requisites

1. Static-free installation environment: The subsystem must be installed in a static-

free environment to minimize the possibility of electrostatic discharge (ESD)

damage. (See Section 2.3) Use of anti-static wristband and static-control devices

such as ionizers, is recommended.

2. Component check: Before installing the subsystem, you should confirm that you

have received all of the required components by checking the package contents

against the Unpacking List.

3. Memory modules: If you wish to change the pre-in stalled memory modules, it is

preferred that you install the separately purchased modules during the initial

installation stage. (See Section 2.6.2)

4. Hard drives: Up to 24 hard drives have been pre-integrated into drive trays. On the

rare occasion that a drive needs to be replaced, use this procedure. (See Section 2.7)

5. Cabling: All optical FC cables and SFP transceivers are user-supplied and should be

purchased separately. (See Chapter 4)

Hardware Installation

2-1

Page 34

Galaxy GHDX2-2430S/R-24F4D Installation and Hardware Reference Manual

6. Rack installation: The enclosure chassis can be installed into standard, 19-inch

wide rack cabinet using self-purchased mounting rails the Galaxy slide rails.

2.3. Static-free Installation

Static electricity can damage the system’s electronic components. Most of the subsystems

that are returned for repair result from improper installation and ESD damage. To prevent

ESD damage, follow these precautions before handling any of the components:

When installing the subsystem, you should wear an anti-static wristband or touch a

grounded metal surface to discharge any static electricity from your body.

Avoid carpets, plastic, vinyl, and Styrofoam in the work area.

Handle all components by holding their edges or metal frame. Avoid touching circuit

boards or connector pins.

2.4. General Installation Procedure

Detailed, illustrated instructions for each step are given in the following sections.

CAUTION!

To ensure that the system is correctly installed, please follow the steps outlined

below. If these steps are followed, the installation will be fast and efficient. If these

steps are not followed, the hardware may accidentally be installed incorrectly.

Step 1. Unpack the subsystem. Make sure that all the required subsystem

components have indeed arrived.

Step 2. Change the DIMM module. Although a DIMM module comes with

the RAID controller, if you wish to use a different DIMM module

with a larger memory capacity, then the DIMM module exchange

should be made first. (See Section 2.6.2)

Step 3. Rack/Cabinet installation. The subsystem should be installed into a

rack cabinet prior to installing the hard drives. Installation into a rack

cabinet requires separately purchased mounting rails. There are also

Galaxy rail kits for 32 or 36-inch deep racks. Installing the subsystem

into a rack or cabinet requires at least two or three people.

Hardware Installation

2-2

Page 35

Chapter 2 Hardware Installation

Step 4. Verification of hard drive installation into the drive trays.

Although SATA-II interface hard drives have been installed into drive

trays for you, follow this procedure to replace individual hard drives.

(See Section 2.7)

Step 5. Install the drive trays into the enclosure. Note that the drive trays

used in single- or redundant-controller subsystems are different. Make

sure not to mix the drive trays. A redundant-controller subsystem

requires the MUX boards on its drive trays.

Step 6. Connect the cables. Use the supplied power cords to connect the

subsystem to power mains. It is recommended to connect power cords

to separate and independent power sources, e.g., UPS systems, for

higher redundancy. Make sure your subsystem is electrically

grounded.

It is also recommended to use the included cable clamps to prevent

accidental disconnection of the power cords. Use separately purchased

Fibre Channel optical cables and transceivers to connect the host ports

to your Fibre Channel storage network or directly to the host

computers. (See Chapter 4)

SAS expansion JBODs come with SAS 4x, wide link cables.

Step 7. Power up. Once all of the components have been properly installed

and all the cables properly connected, the subsystem can be powered

up and the RAID array configured. (See Chapter 4)

2.4.1 Installation Procedure Flowchart

Figure 2-1 shows a flowchart of the installation procedu re. As you complete each step,

check off the “Done” box on the right. Please use this flowchart in conjunction with the

instructions that follow.

Hardware Installation

2-3

Page 36

Galaxy GHDX2-2430S/R-24F4D Installation and Hardware Reference Manual

Figure 2-1: Installation Procedure Flowchart

2.5. Unpacking the Subsystem

The subsystem components are packed in several boxes.

WARNING!

For a detailed packing list, refer to the included Unpacking List. Do not rely on the

non-definitive, summarized checklist shown below - it is for reference only.

The following items should be packed in individual boxes and are not pre-installed:

Twenty four (24) drive trays an d pre-installed drives

Accessory items

The enclosure chassis, with its pre-installed components, is located at the bottom of the

package. The pre-installed components include:

Two (2) controller modules

Three (3) PSU modules

Two (2) cooling modules

Two (2) foldable forearm handles

Hardware Installation

2-4

Page 37

One (1) LCD keypad panel on the left side foldable handle

Back-end PCBs

2.6. Memory Module Installation

2.6.1 Memory Module Installation Overview

The subsystem comes with a pre-installed 512MB DDR RAM DIMM module on each

controller. The controller supports memory modules with sizes up to 2GB. If memory

modules with a different size need to be used, the pre-installed DIMM module can be

removed and the new ones installed. Replacement and installation instructions are

described fully below.

NOTE:

A DIMM of a different size can be ordered from your subsystem supplier. Using

non-certified modules can cause unexpected compatibility problems.

Chapter 2 Hardware Installation

Considerations:

1. A DIMM socket is located on the side of the controller main board. Prior to changing

the DIMM module, the controller canister must first be removed from the enclosure

chassis.

2. With a new subsystem, there may not be cached data in the DIMM module. If the

subsystem has been operating and there is cached data, the BBU will discharge to

support the cache contents. It is therefore recommended to make sure BBU module

is removed before replacing the DIMM module. The BBU can be removed simply by

loosening its retention screw.

If you are replacing the memory modules, please refer to the installation procedure

below. If the memory modules do not need to be changed, proceed to Section 2.7.

Hardware Installation

2-5

Page 38

Galaxy GHDX2-2430S/R-24F4D Installation and Hardware Reference Manual

WARNING!

The controller board in the controller module is a sensitive item. Please

ensure that all anti-static precautions stipulated above a re strictly adhered to.

Only qualified engineers should replace the DIMM module.

Removing the DIMM module while it contains cached data and when the

BBU is still attached to the controller can damage the DIMM module. When

the controller is removed from chassis, the BBU will start to discharge

supplying power to memory. Removing the DIMM module while it is being

powered by the BBU may damage the DIMM module.

Therefore, remove a BBU module before you replace a DIMM module if you

prefer using a different DIMM module.

2.6.2 Selecting the Memory Modules

If the memory module on the RAID controller is going to be replaced, the following

factors must be considered when purchasing replacement DIMM modules:

DDR DIMM modules supported: The subsystem supports DDR RAM DIMM

modules with memory capacities ranging from 512MB to 2GB.

Installation considerations: When installing the DIMM module, it is necessary to

handle the controller module. The controller board is more susceptible to damage

than the other components and must therefore be handled with extreme care. ALL

anti-static precautions specified in Section 2.3 must be strictly adhered to.

Secure installation: If the DIMM module is not firmly in place, the subsystem will

not run and the controller will need to be removed and the DIMM module correctly

installed.

Purchasing considerations: When purchasing a DDR DIMM to install on the

controller board, contact your system vendor for an adequate module.

2.6.3 DIMM Module Installation/Replacement

WARNING!

1. Consult the technical support of your reseller or distributor if you are not

sure which memory module can be installed into the controller. To avoid

compatibility problems, it is recommended to purchase only certified

DIMM modules for the Galaxy RAID.

2. The BBU and controller module must be removed prior to installing a new

memory module. Do this with care. Sensitive components can be damaged

during the process.

Hardware Installation

2-6

Page 39

Chapter 2 Hardware Installation

3. The BBU module is hot-swappable and can be independently swapped

from the controller. However, as a safety precaution and just in case your

memory still holds cached data, it is recommended to flush the unfinished

writes using the “Controller Shutdown” command in firmware and remove

the BBU module before handling the DDR RAM module. If the BBU is

supplying power to the memory when the DDR module is being removed,

damage may occur.

Step 1. Prepare an anti-static work pad for placing a removed controller. Use

of an ESD grounding strap is highly recommended.

Step 2. Remove the pre-ins talled BBU module. Use a Phillips screwdriver

to loosen the retention screw that secures the BBU module to the

enclosure chassis and carefully remove the module. Carefully place

the module for it contains Li-ION batteries. Do not drop it to the floor

or place it near any heat source or fire.

Figure 2-2: Removing the BBU Module

Step 3. Remove the controller module. Remove the retention screws

that secure the controller’s ejection levers using a cross-head

screwdriver. Using both hands, simultaneously press the ejection

levers downward until the controller is removed from the chassis.

Hardware Installation

2-7

Page 40

Galaxy GHDX2-2430S/R-24F4D Installation and Hardware Reference Manual

Figure 2-3: Removing the Controller Module

Step 4. Remove the DDR DIMM module. You can access the DIMM

module from the opening on the right side of the controller canister.

To remove the DIMM module, press the white, plastic ejectors (clips)

on the sides of the DIMM socket. Grasp the DIMM module by its

edges and pull it out of the socket without touching the electrical

components nearby. Place the module in an anti-static bag.

Hardware Installation

2-8

Page 41

Chapter 2 Hardware Installation

Figure 2-4: Accessing a DIMM Module

Step 5. Install the replacement DIMM module. Carefully remove the

replacement module from its anti-static bag. Grasp the module by

edges. Make sure the white, plastic ejectors on the sides of DIMM

socket are open. Carefully align the DIMM module to the socket.

Pressing firmly on both ends, push the module into the socket until the

ejectors return to the closed position.

Figure 2-5: Accessing a DIMM Module

Step 6. Install the controller and the BBU module (if installed). Proceed

with the following to install the controller:

1. Insert the controller into the respective module slot with the

ejector levers at the lowest position.

2. Push the controller in until you feel contact resistance with its

back-end connectors. Use slightly more force to engage the backend connectors.

Hardware Installation

2-9

Page 42

Galaxy GHDX2-2430S/R-24F4D Installation and Hardware Reference Manual

3. Use the ejector levers on the sides to secure the controller into the

chassis slot. Make sure the squared notches of the ejector levers

lock onto the metal grooves on the interior walls of the module

slot. Once in place, pull the levers up to secure the controller.

Insert and fasten the retention screws underneath each ejector

4.

lever to secure the modules. After the controller is properly

installed, install the BBU module by pushing it into the module

slot and fasten its retention screws.

Figure 2-6: Installing the Controller Module

Hardware Installation

2-10

Page 43

2.7. Rackmounting the Subsystem

2.7.1 Package Contents

The slide rail kit (32- or 36-inch versions) includes the following components. You

should check to ensure that the slide rail kit you received contains the items listed below.

NOTE:

Except for the different length of mounting brackets, the 32- and 36-inch versions

use the same mounting screws and mounting holes on rack posts.

32-inch/812.8mm; 36-inch/914.4mm

Item

Chapter 2 Hardware Installation

Quantity

1

2

3

4

5

6

7

8

9

10

Mounting bracket assembly, left

Mounting bracket assembly, right

End bracket, left

End bracket, right

Screw, cross recess round head, M5x35, rev.: 1.0

Screw, M5x5mm, position screws for square racks, free cutting

steel, rev.: 1.0

Screw, crosshead flat head, #6-32x8mm, rev.: 1.0

Screw, M5 cage nuts, rev.: 1.0

Screw, crosshead round screws, P+6#-32x6mm, rev.: 1.0

4U spacer behind forearm handle

1

1

1

1

4

8

6

4

4

2

Hardware Installation

2-11

Page 44

Galaxy GHDX2-2430S/R-24F4D Installation and Hardware Reference Manual

Figure 2-7: Package Contents

The rackmount rails secure the Galaxy 4U chassis to standard 19-inch wide, four-post

cabinets or racks that are between 23 and 36 inches deep. These heavy-duty

rackmount rails provide an easy and safe access to the subsystems as well as a solid

support.

Prepare the tools needed to install the enclosure into rack. The following

should be necessary:

• A medium-sized cross-head screwdriver.

• A small-sized cross-head screwdriver.

• A medium-sized flathead screw driver.

2.7.2 Installation Steps

Step 1. Determine the exact position where you want to install the

Galaxy RAID enclosure in the rack, and then measure the

position.

Step 2. The mounting kit comes with M5 cage nuts that can be used

with racks that have square, unthreaded holes. Align the front

edge of a support bracket against a rack post and adjust spacing

Hardware Installation

2-12

Page 45

Chapter 2 Hardware Installation

so that the front and rear edges of the bracket fit the vertical

rack posts.

Figure 2-8: Fitting a Support Bracket to Rack Posts

Step 3. Determine where in the rack the subsystem is going to be

installed. Attach four (4) M5 flathead screws (#6 in the packing

list) to secure the bracket to the front and the rear rack posts.

See the drawing above. Note that the lower part of the Lshaped brackets should always face inward.

Step 4. Attach two (2) M5 cage nuts (#8 in the packing list) onto each

front rack post. The first cage nut is inserted through the hole

right above the M5 screw at the bottom. Cage nuts should be

attached from the inside of the rack facing outward. Leave six

holes between the two cage nuts on each rack post. These cage

nuts allow you to secure the enclosure from the front of the

chassis through the mounting holes on the forearm handles.

Repeat the process to install another support bracket on the left.

Hardware Installation

2-13

Page 46

Galaxy GHDX2-2430S/R-24F4D Installation and Hardware Reference Manual

Figure 2-9: Attaching M5 Cage Nuts to Rack Posts

CAUTION!

The mounting positions on the rack posts must be carefully measured so that rails are

mounted parallel to each other. Also pay attention to the clearance between the rackmounted units.

Step 5. Attach a spacer (#10 in the packing list) to the back of each

enclosure forearm handle using three (3) included flathead

screws (#7 in the packing list).

Figure 2-10: Attaching Spacers to the Back of Enclosure Forearm Handles

Hardware Installation

2-14

Page 47

Chapter 2 Hardware Installation

Step 6. Use the included crosshead round screws (#9 in the packing

list) to secure two (2) end brackets (#3 or #4) to the back of the

subsystem.

Figure 2-11: Attaching End Brackets to the Rear Side of Enclosure

Step 7. Gently slide the subsystem into the rack by aligning the tips of

the end brackets with the support brackets. Carefully rest the

tips of the end brackets onto the support brackets and slide the

chassis forward.

Step 8. When the chassis is inserted towards the end of the rack, the

recessed parts of end brackets should engage the two rivets on

the support brackets. Once the enclosure reaches the end,

proceed with securing the chassis through the mounting holes

on the forearm handles.

Figure 2-12: Installing Enclosure

Step 9. Slide the subsystem in as far as it will go, then secure the

system using four (4) pan head screws (see #5 in the packing

Hardware Installation

2-15

Page 48

Galaxy GHDX2-2430S/R-24F4D Installation and Hardware Reference Manual

list) through the holes on the left- and right-side handles to

both of the front rack posts.

Figure 2-13: Securing Enclosure through the Front

2.8. Hard Drive Installation

2.8.1 Hard Drive Installation Overview

WARNING!

1. Handle hard drives with extreme care. Hard drives are very delicate.

Dropping a drive onto a hard surface (even from a short distance) and hitting

or touching the circuits on the drives with your tools may all cause damage to

drives.

2. Observe all ESD prevention m e t hods when handling hard drives.

3. Only use screws supplied with the drive canisters. Longer screws can damage

the disk drives.

2.8.2 Hard Drive Installation Pre-requisites

CAUTION!

The hard drives and drive trays should only be installed into the subsystem after

the subsystem has been mounted into a rack cabinet. If the hard drives are

installed first, the subsystem will be too heavy to lift into position and the possible

Hardware Installation

2-16

Page 49

Chapter 2 Hardware Installation

impact during installation may damage your hard drives.

Hard drives for the subsystem must be purchased separately. When purchasing the hard

drives, the following factors should be considered:

Capacity (MB/GB): Use drives with the same capacity. RAID arrays use a “least-

common-denominator” approach meaning the maximum

applicable capacity from each member drive in the array is

the maximum capacity of the smallest drive.

Profile: The drive trays and bays of the system are designed for 3.5-

inch wide x 1-inch high hard drives.

Drive type: The Galaxy subsystem complies with SATA-II interface hard

drives.

2.8.3 Drive Installation

NOTE:

Although your drives have been preinstalled and tested you may need to replace a

faulty drive. Use the following procedure to replace a faulty drive.

Step 1. Place the hard drive into the drive tray. Make sure the hard drive is

oriented that the drive’s SATA connector is facing the open side of the

drive tray and its label side facing up.

Hardware Installation

2-17

Page 50

Galaxy GHDX2-2430S/R-24F4D Installation and Hardware Reference Manual

Figure 2-14: Installing a Hard Drive

Step 2. Adjust the drive’s location until the mounting holes in the drive

canister are aligned with those on the hard drive. Secure the drive with

four (4) supplied 6/32 flathead screws. See the diagram below for the

screw hole locations using a drive tray with or without a MUX board.

Figure 2-15: Screw Hole Locations

WARNING!

Only use screws supplied with the drive canisters. Longer screws can damage the

hard drives.

Hardware Installation

2-18

Page 51

2.9. Drive Tray Installation

Before drive tray installation, you need to access the drive bays on the left- and right-side

columns:

To access drive bays hidden behind the forearm handles, first release the retention latches

on the enclosure front handles, and then swing the handles to the left and right-hand

sides. To close the handles, see Figure 2-16, first swing the handles towards the center to

reveal the retention latch, release the latch, and then close the handles.

Chapter 2 Hardware Installation

Figure 2-16: Closing the front handles

Install the drive trays into the subsystem once the hard drives have been installed in the

drive trays.

Step 1. Use a flat blade screwdriver to turn the ro tary bezel lock to the

unlocked position, i.e., the groove on its face is in a horizontal

orientation. If the groove is in a vertical position, then the bezel lock is

locked and the front bezel cannot be opened.

Clip

Figure 2-17: Drive Tray Front Bezel

Step 2. Open the front bezel by pushing the release button. The front bezel

will automatically swing open.

Hardware Installation

2-19

Page 52

Galaxy GHDX2-2430S/R-24F4D Installation and Hardware Reference Manual

Figure 2-18: Opening Front Bezel

Step 3. Line up with the tray slot in which you wish to insert it. Once the

drive tray is lined up with the slot, gently slide it in. This should be

done smoothly and gently.

Step 4. Close the front bezel. Make sure the front bezel is closed properly to

ensure that the back-end connector is firmly mated with the

corresponding connector on the backplane. If the front bezel is not

closed properly, the connection between the hard drive and the

subsystem will not be secure.

Figure 2-19: Installing a Drive Tray

Step 5. Lock the bezel. Use a flat blade screwdriver to turn the rotary bezel

lock until the groove on its face is in a vertical orientation.

Hardware Installation

2-20

Page 53

Chapter 2 Hardware Installation

Figure 2-20: Drive Tray Bezel Lock Rotation

WARNING!

All the drive trays must be installed into the enclosure even if they currently do

not contain a hard drive. If the drive trays are not installed, then the ventilation

required for cooling will not be normalized and the subsystem will be damaged.

2.10. Power Cord Cable Clamp Installation

Several cable clamp assemblies are included in the accessories boxes in the RAID

shipping package. When installing the subsystem, it is recommended to secure all power

cords using these cable clamps to help prevent accidental disconnection that could result

in costly down time.

2.10.1 Component Description

Each cable clamp consists of the following:

1. A cable strap with a “push barb” anchor mount

2. An adjustable cable clamp

The cable strap is secured to the chassis by inserting the barb anchor into th e pre-drilled

hole located under each power supply module. The cable clamp is then secured to the

cable strap and is wrapped around the power plug to hold it in place to ensure that the

power cord connection can withstand vibration and accidental impact.

Hardware Installation

2-21

Page 54

Galaxy GHDX2-2430S/R-24F4D Installation and Hardware Reference Manual

Figure 2-21: Cable Clamp and Cable Strap (Cable Mount)

2.10.2 Cable Clamp Installation

Step 1. Connect a power cord to a subsystem power socket so that you can

determine the correct position of the cable clamp along the cable

strap. The diagram below shows the relative positions of a power

cord, cable clamp, and cable strap.

Figure 2-22: Power Cord, Cable Clamp and Cable Strap Positions

Step 2. Connect the cable clamp to the cable strap. Insert the flat angled

end of the cable strap through the small opening (the tie head)

underneath the cable clamp with the smooth side of the strap facing up

Hardware Installation

2-22

Page 55

Chapter 2 Hardware Installation

and the ribbed side facing down. Press the release tab and adjust the

position of the cable clamp along the strap.

Figure 2-23: Inserting Cable Strap into Cable Clamp

Step 3. Mount the cable strap to the chassis by inserting the push -in barb

anchor into the pre-drilled hole underneath the power supply.

Step 4. Secure the power cord with the cable clamp Flip open the cable

clamp and wrap it around the power plug. If necessary, press on the

release tab to adjust the location of the clamp so it aligns with the b ase

of the power plug as shown below. Press the clip lock on the side of

the clamp until it snaps into position.

Figure 2-24: Power Cord Locked into Position

Step 5. Repeat the process to secure every power cords to the subsystem.

Hardware Installation

2-23

Page 56

Galaxy GHDX2-2430S/R-24F4D Installation and Hardware Reference Manual

This page is intentionally left blank.

Hardware Installation

2-24

Page 57

Subsystem Monitoring

3.1. Subsystem Monitoring Overview

The Galaxy GHDX2-2430S-24F4D and GHDX2-2430R-24F4D subsystems are equipped

with a variety of self-monitoring features that keep you informed of the subsystem’s

operational statuses. These monitoring features provide vital feedback to help you

maintain the operational integrity of the subsystem. Prompt response to warnings and

component failure notifications will help ensure data integrity and the longevity of the

RAID subsystem.

Chapter 3

Self-monitoring features include:

Management firmware (FW): The firmware manages the array, provides device

status information, and is preinstalled in the subsystem controller. You can access

firmware functionalities using either the LCD keypad panel or a PC running a

terminal emulation program and is connected through the subsystem’s COM 1 RS232C (audio jack) serial port. The firmware is fully described in the firmware

Operation Manual that came with the subsystem. Please refer to this manual for

further details.

RAIDWatch: RAIDWatch is a Java-based program that came with the subsystem

and can be used to monitor and manage the subsystem locally or remotely over

TCP/IP. You can use the powerful Configuration Client or Notification Process

Center (NPC) sub-modules to keep you informed over a variety of communications

methods such as fax, pager, email, etc. For further details on the installation and

operation of RAIDWatch, please refer to the RAIDWatch User’s Manua l .

LEDs: Device-status-indicating LEDs are placed on all of the active components to

inform users of the integrity of a given component. You should become familiar with

the different LEDs and be aware of their functions.

System Monitoring 1

3-1

Page 58

Galaxy GHDX2-2430S/R-24F4D Installation and Hardware Reference Manual

Audible alarm: The audible alarm on the subsystem controller board will be

triggered if any of a number of threatening events occurs. These events usually

jeopardize the functional and operational integrity of the controller board and must

be heeded at all times. Events such as a breach of the temperature threshold will

trigger the alarm and if an onsite subsystem manager is present, the manager should

use either the LCD keypad panel or a PC running terminal software to determine the

cause of the alarm and take appropriate corrective measures.

2

I

C: An I2Cbus connects sensors and presence detection circuitries within the

subsystem (present/not present, ready/failed, etc.).

Subsystem monitoring is a necessary part of subsystem management. When system fault