Page 1

DVPDNET-SL

DeviceNet Network Scanner

Operation Manual

DVP-0204520-03

2012-3-27

Page 2

DeviceNet Network Scanner DVPDNET-SL

Warning

Please read this instruction carefully before use and follow this instruction to operate the de vice in order to

prevent damages on the device or injuries to staff.

Switch off the power before wiring.

DVPDNET-SL is an OPEN TYPE device. Therefore it should be installed in an enclosure free of airborne

dust, humidity, electric shock and vibration. The enclosure should prevent non-maintenance staff from

operating the device (e.g. key or specific tools are required for operating the enclosure) in case danger

and damage on the device may occur.

DVPDNET-SL is to be used for controlling the operating machine and equipment. In order not to damage

it, only qualified professional staff familiar with the structure and operation of DVPDNET-SL can install,

operate, wire and maintain it.

DO NOT connect AC power supply to any of the I/O terminals; otherwise serious damage may occur.

Check all the wirings again before switching on the power and DO NOT touch any terminal when the

power is switched on. Make sure the ground terminal

electromagnetic interference.

is correctly grounded in order to prevent

Table of Contents

1 INTRODUCTION ....................................................................................................................................1

1.1 Features .............................................................................................................................................1

1.2 Basic Functions of DVPDNET-SL ......................................................................................................1

1.3 Specifications .....................................................................................................................................2

2 PRODUCT PROFILE & OUTLINE .........................................................................................................3

2.1 Dimension ..........................................................................................................................................3

2.2 Product Profiles ..................................................................................................................................3

2.3 DeviceNet Connection Port ................................................................................................................3

2.4 Address Switch...................................................................................................................................4

2.5 Function Switch ..................................................................................................................................4

2.6 Digital Indicator...................................................................................................................................5

2.7 Extension Port ....................................................................................................................................5

3 INSTALLATION ......................................................................................................................................6

3.1 Connecting DVPDNET-SL to DVP-SV MPU ......................................................................................6

3.2 Installing DVPDNET-SL and DVP-SV MPU on DIN Rail ....................................................................6

3.3 Connecting to DeviceNet Connection Port.........................................................................................7

DVP-PLC Operation Manual

Page 3

DeviceNet Network Scanner DVPDNET-SL

4 CONFIGURATION OF DVPDNET-SL.................................................................................................... 8

4.1 Configuration through DeviceNet Builder Software ...........................................................................8

4.1.1 Selection of Communication Channel......................................................................................... 8

4.1.2 Setup of Scan Module ................................................................................................................ 9

4.1.3 Setup of Scan List..................................................................................................................... 10

4.1.4 Input List and Output List...........................................................................................................11

4.2 Data Mapping Areas ........................................................................................................................ 12

4.3 I/O Mapping Table (as master mode) .............................................................................................. 12

4.4 I/O Mapping Table (as slave mode) ................................................................................................. 13

5 SENDING EXPLICIT MESSAGE FROM LADDER DIAGRAM........................................................... 14

5.1 The Principle of Explicit Message Sending...................................................................................... 14

5.2 Structure of Explicit Message .......................................................................................................... 15

6 BIT-STROBE COMMAND ................................................................................................................... 22

6.1 Principle of Bit-Strobe ...................................................................................................................... 22

7 DISPLAY OF NODE STATUS ON NETWORK.................................................................................... 23

7.1 Display of Node Status in Scan List................................................................................................. 23

7.2 Status of DVPDNET-SL ................................................................................................................... 23

8 SETUP OF SLAVE MODE................................................................................................................... 24

9 SETUP OF EXTENDED BAUD RATE.................................................................................................26

9.1 Setup of Extended Baud Rate (as master mode) ............................................................................ 26

9.2 Setup of Extended Baud Rate (as slave mode)............................................................................... 28

10 APPLICATION EXAMPLE ON CONSTRUCTING DEVICENET NETWORK ..................................... 31

10.1 How to Construct a DeviceNet Network ........................................................................................ 31

10.2 How to Configure Network by DeviceNet Network Configuration Tool .......................................... 32

10.3 Ladder Diagram Program .............................................................................................................. 38

11 LED INDICATOR & TROUBLE-SHOOTING ....................................................................................... 39

11.1 LED Indicator Diagnosis ................................................................................................................ 39

11.2 Digital displayer diagnosis ............................................................................................................. 40

DVP-PLC Operation Manual

Page 4

DeviceNet Network Scanner DVPDNET-SL

1 Introduction

1) Thank you for choosing Delta DVPDNET-SL. To ensure correct installation and operation of DVPDNET-SL,

please read this chapter carefully before using your DVPDNET-SL.

2) DVPDNET-SL running on the left side of PLC can serve as the DeviceNet master or slave with PLC MPU

together. It can be configured through DeviceNet software.

1.1 Features

z Serves as DeviceNet master by connecting to PLC MPU and Supports standard DeviceNet protocol.

z

DeviceNet Builder provides convenient graphic configuration interface; automatically scans and

recognizes all slaves in the bus.

z Supports DeviceNet Master mode and Slave mode.

z Supports eight types of baud rates: 10 kbps, 20 kbps, 50 kbps, 125 kbps, 250 kbps, 500 kbps, 800kbps,

1M kbps

1.2 Basic Functions of DVPDNET-SL

¾ DVPDNET-SL DeviceNet Network Scanner can be used both as a master or a slave in DeviceNet. When

being used as a master, it supports the following functions:

z Automatically carrying out the data exchange with PLC MPU. User needs only to operate the special

register in PLC to realize the monitoring of all slaves.

z Supports client function of explicit message.

z Supports slave to establish all kinds of I/O connections: polled, bit-strobed, change of state and cyclic.

z As the connection medium between DeviceNet Builder configuration software and DeviceNet network.

The configuration software is able to directly configure the network through DVPDNET-SL.

z Sending explicit messages for reading/writing the data in slave through PLC ladder diagrams.

z Max length for output data and input data are both 380 bytes.

¾ When being used as a slave, it supports the following functions:

z Explicit message serve and Group 2 only serve connection mode.

z Polling

z Offering 256 bytes for input data and 256 bytes for output data in data exchange with master.

z Automatically exchanging data with PLC MPU. The user needs only to edit the D register in the PLC

without using FROM/TO instruction.

z Max length for output data and input data are both 255 bytes.

DVP-PLC Operation Manual

1

Page 5

DeviceNet Network Scanner DVPDNET-SL

1.3 Specifications

PLC that DVPDNET-SL supports

Item Specification

PLC Model

DVPDNET-SL supports PLC MPU which can be extendable in its left side

g. DVP-SV, DVP-EH2_L, DVP-SX2, DVP-SA2, DVP10MC11T etc.)

DeviceNet Interface

Item Specification

Transmission

method

Electrical

isolation

Interface Removable connector (5.08mm)

Transmission

cable

Voltage

CAN

500V DC

TAP-CB01 cable and TAP-CB02 cable are recommended. (The shielded wire

must be grounded and the cable should be away from power line)

DeviceNet network provides direct current: 11~25V, 28mA(typical value),

125mA impulse current(24 VDC)

DeviceNet Communication

Item Specification

Message type

Baud rate

Explicit connection, IO polled connection, bit-strobe connection, COS/CC

connection

Standard mode: 125 kbps; 250 kbps; 500 kbps

Extended mode: 10 kbps; 20 kbps; 50 kbps; 125 kbps; 250 kbps; 500 kbps;

800kbps; 1M kbps

Environment

Item Specification

ESD (IEC 61131-2, IEC 61000-4-2): 8KV Air Discharge

EFT (IEC 61131-2, IEC 61000-4-4): Power Line: 2KV, Digital I/O: 1KV

Noise immunity

Operation 0ºC ~ 55ºC (temperature); 50 ~ 95% (humidity); pollution degree 2

Storage -25ºC ~ 70ºC (temperature); 5 ~ 95% (humidity)

Vibration/shock

resistance

Certificates IEC 61131-2, UL508

Analog & Communication I/O: 1KV

Damped-Oscillatory Wave: Power Line: 1KV, Digital I/O: 1KV

RS (IEC 61131-2, IEC 61000-4-3): 26MHz ~ 1GHz, 10V/m

Standard: IEC 61131-2、IEC 68-2-6 (TEST Fc)/IEC 61131-2 & IEC 68-2-27

(TEST Ea)

2

DVP-PLC Operation Manual

Page 6

DeviceNet Network Scanner DVPDNET-SL

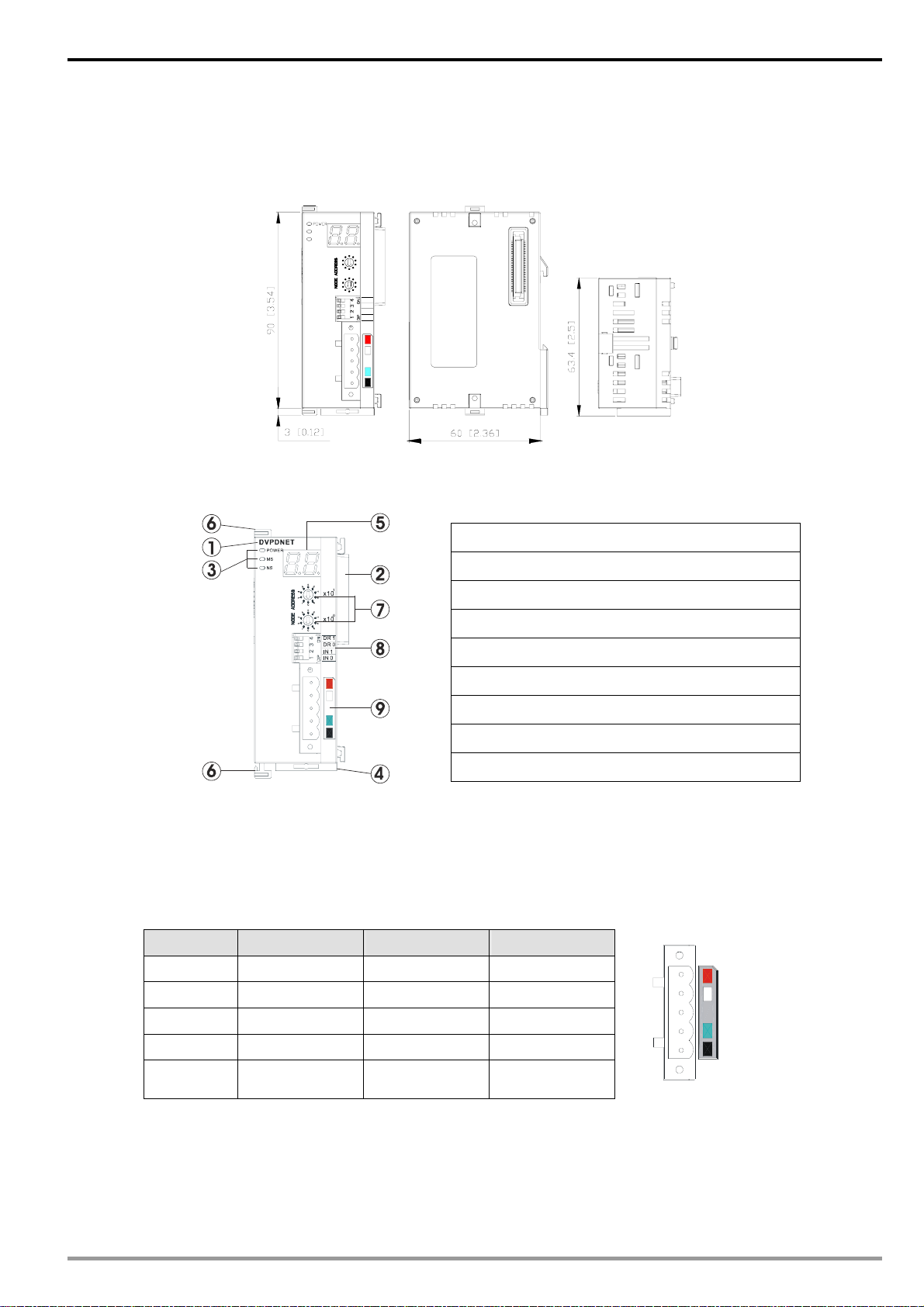

2 Product Profile & Outline

2.1 Dimension

DVPDNET

MS

NS

5

6

4

1

7

3

x10

8

2

9

1

0

5

6

4

0

7

3

x10

8

2

9

1

0

DR 1

DR 0

IN 1

IN 0

2.2 Product Profiles

1. Model name

2. Extension port

3. Power, MS, NS LED

4. DIN rail clip

5. Digital indicator

6. Extension clip

7. Address switch

8. Function switch

9. DeviceNet connection port

2.3 DeviceNet Connection Port

The connector is used on the connection to DeviceNet. Wire by using the connector enclosed with

DVPDNET-SL.

PIN Signal Color Content

1 V- Black 0V DC

2 CAN_L Blue Signal-

3 SHIELD - Shielded

4 CAN_H White Signal+

5

4

3

2

1

5 V+ Red 24V DC

Note: Either end of the communication cable should be connected with the terminal resistor of

121Ω and the resistors should be connected between “Signal+” and “Signal-”.

DVP-PLC Operation Manual

3

Page 7

DeviceNet Network Scanner DVPDNET-SL

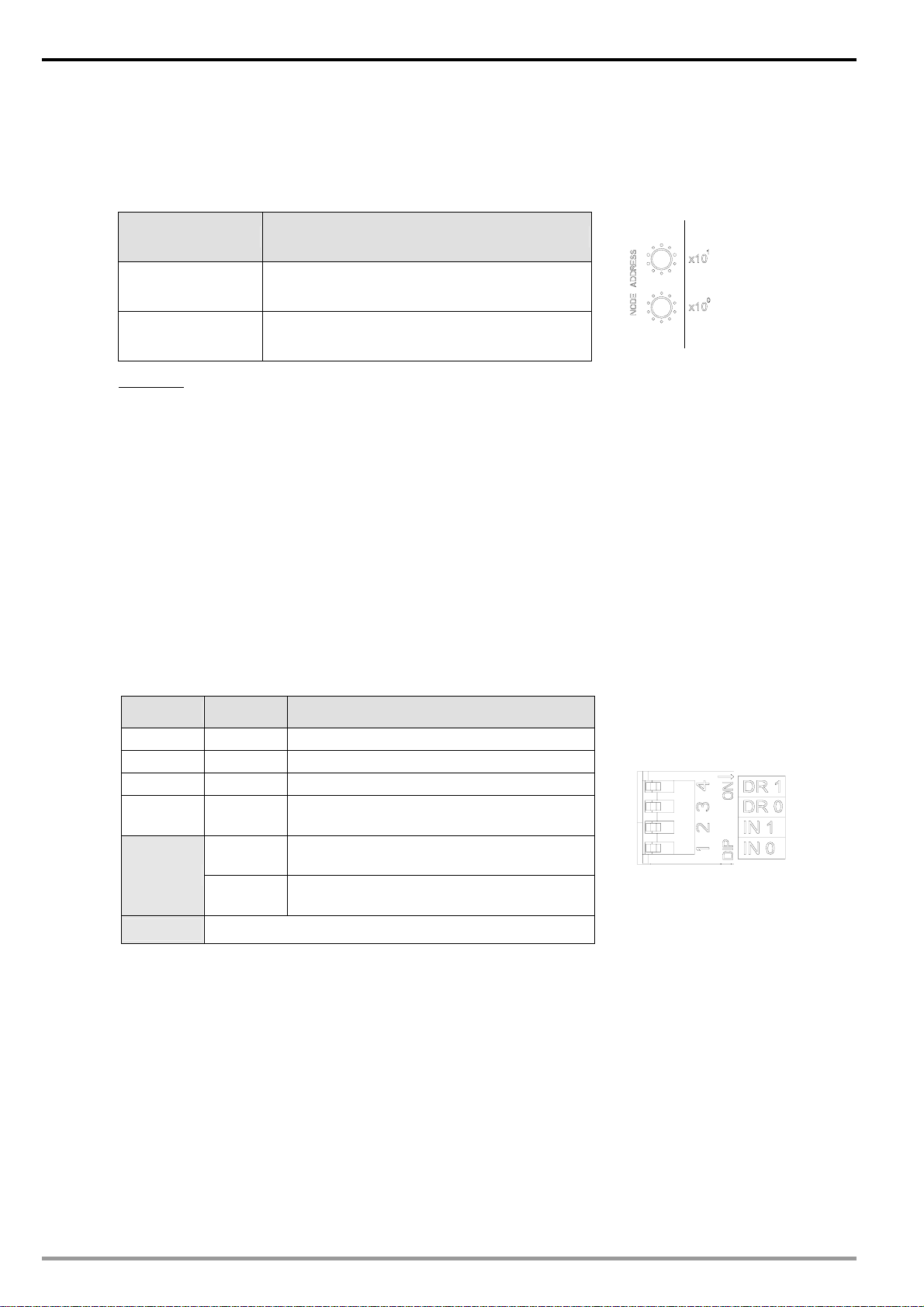

2.4 Address Switch

The switch is used on setting up the node address of DVPDNET-SL on DeviceNet. Range: 00 ~ 63 (64 ~ 99

are forbidden).

Switch setting Content

0 … 63 Valid DeviceNet node address

64…99 Invalid DeviceNet node address

Example: If you need to set the node address of DVPDNET-SL to 26, simply switch the corresponding

switch of x10

1

to 2 and the corresponding switch of x100 to 6.

Note:

z Please set up the node address when the power is switched off. After the setup is completed, re-power

DVPDNET-SL.

z When DVPDNET-SL is operating, changing the setting of node address will be invalid.

z Use slotted screwdriver to rotate the switch carefully in case you scratch the switch.

2.5 Function Switch

The function switches are for:

Setting up the work mode (IN0)

Setting up the baud rate of DeviceNet (DR0 ~ DR1)

5

6

4

7

3

8

2

9

1

0

5

6

4

7

3

8

2

9

1

0

DR1 DR0 Baud rate

OFF OFF 125kbps

OFF ON 250kbps

ON OFF 500kbps

ON ON

ON

IN0

OFF

Entering the mode of extended baud rate

( see Chapter 9)

When the slave is off-line, the I/O data in

the buffer area will be held.

When the slave is off-line, the I/O data in

the buffer area will be cleared.

IN1 Reserved

Note:

z Please set up the function switch when the power is switched off. After the setup is completed, re-power

DVPDNET-SL.

z When DVPDNET-SL is operating, changing the setting of the function switch will be invalid.

z Use slotted screwdriver to adjust the DIP switch carefully in case you scratch the switch.

4

DVP-PLC Operation Manual

Page 8

DeviceNet Network Scanner DVPDNET-SL

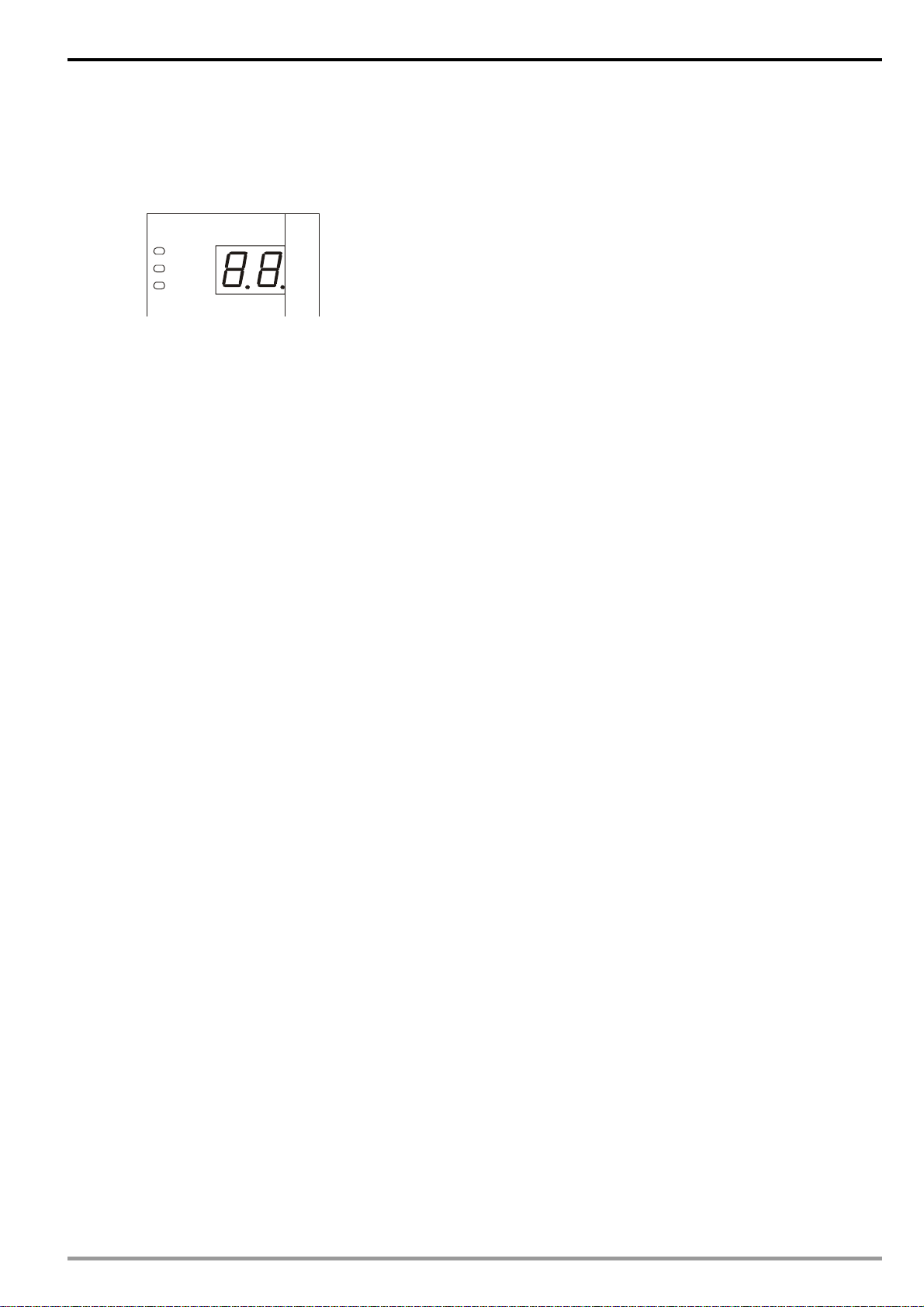

2.6 Digital Indicator

The digital indicator provides the following two functions:

DVPDNET

POWER

MS

NS

1) Displaying the node address and error messages of DVPDNET-SL .

2) Displaying the error message of slave.

Note:

z When the module works normally, the digital displayer will show its own node ID.

z When "E1" and "03" are on display continuously, it indicates that the error that "E1" refers to

occurs in the slave of node 03.

z When the error codes such as "E7" and "E1" are on display, please refer to section 11.2 for the

correction.

2.7 Extension Port

The extension port is mainly used on connecting DVPDNET-SL to the left-side extension port on DVP-SV PLC

MPU.

DVP-PLC Operation Manual

5

Page 9

DeviceNet Network Scanner DVPDNET-SL

3 Installation

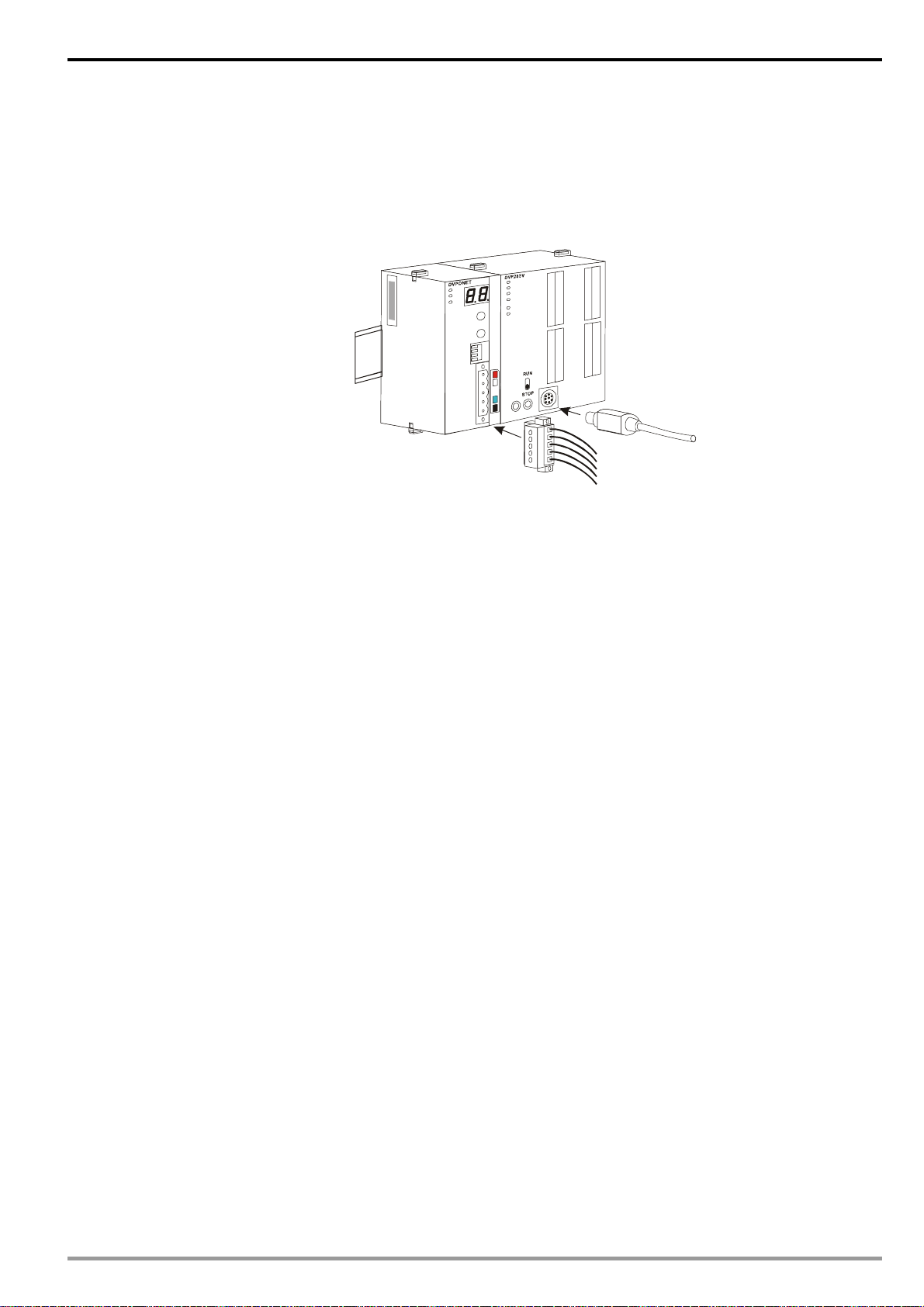

3.1 Connecting DVPDNET-SL to DVP-SV MPU

Adjust the extension clip on the left side of DVP-SV.

Meet the extension port of the MPU with DVPDNET-SL as shown in the figure below.

Fasten the extension clip.

DVPDNET DVP28SV

RUN

STOP

3.2 Installing DVPDNET-SL and DVP-SV MPU on DIN Rail

Use 35mm DIN rail.

Open the DIN rail clip on DVP-SV and DVPDNET-SL. Insert DVP-SV and DVPDNET-SL onto the DIN

rail.

Clip up the DIN rail clips on DVP-SV and DVPDNET-SL to fix DVP-SV and DVPDNET-SL on the DIN rail,

as shown below.

DVPDNET

DVP28SV

35mm DIN rail

RUN

STOP

6

DVP-PLC Operation Manual

Page 10

DeviceNet Network Scanner DVPDNET-SL

3.3 Connecting to DeviceNet Connection Port

The colors on the PINs on the DeviceNet connection port match the colors of the connection cables.

Make sure you connect the cable to the right PIN.

We recommend you also apply Delta’s power module in the connection.

DVP-PLC Operation Manual

7

Page 11

DeviceNet Network Scanner DVPDNET-SL

4 Configuration of DVPDNET-SL

4.1 Configuration through DeviceNet Builder Software

Before DVPDNET-SL starts to work normally, it must be configured through DeviceNet Builder

software.

4.1.1 Selection of Communication Channel

Max 8 DVPDNET-SL modules can be connected to the left side of PLC and every DVPDNET-SL is a

communication channel. When there are three DVPDNET-SL modules connected to PLC’s left side and

DeviceNet Builder software is on line, the following dialog box will pop up for selecting the current channel.

Parameter Explanation

The unit No. of the first DVPDNET-SL(DNET Scanner)on the left side of PLC is 1.

Unit No.

Name

Code

Input

mapping

Output

mapping

PLC’s left side can be connected with max 8 DVPDNET_SL. The further

DVPDNET-S is from PLC MPU, the larger its unit No is.

DVPDNET-SL’s name in DeviceNet Builder software.

For displaying the current mode of DVPDNET-SL: master mode or slave mode.

The register areas which PLC MPU distributes to DVPDNET-SL.The areas are

mainly used to receive the message from DeviceNet Slave and the data from

slave in the bus will be automatically updated to these registers.

The register areas which PLC MPU distributes to DVPDNET-SL. The areas are

mainly used to control DeviceNet slave and the control data in these registers will

be automatically sent to DeviceNet slave in the bus. Slave will take some action

accordingly after receiving the data.

8

DVP-PLC Operation Manual

Page 12

DeviceNet Network Scanner DVPDNET-SL

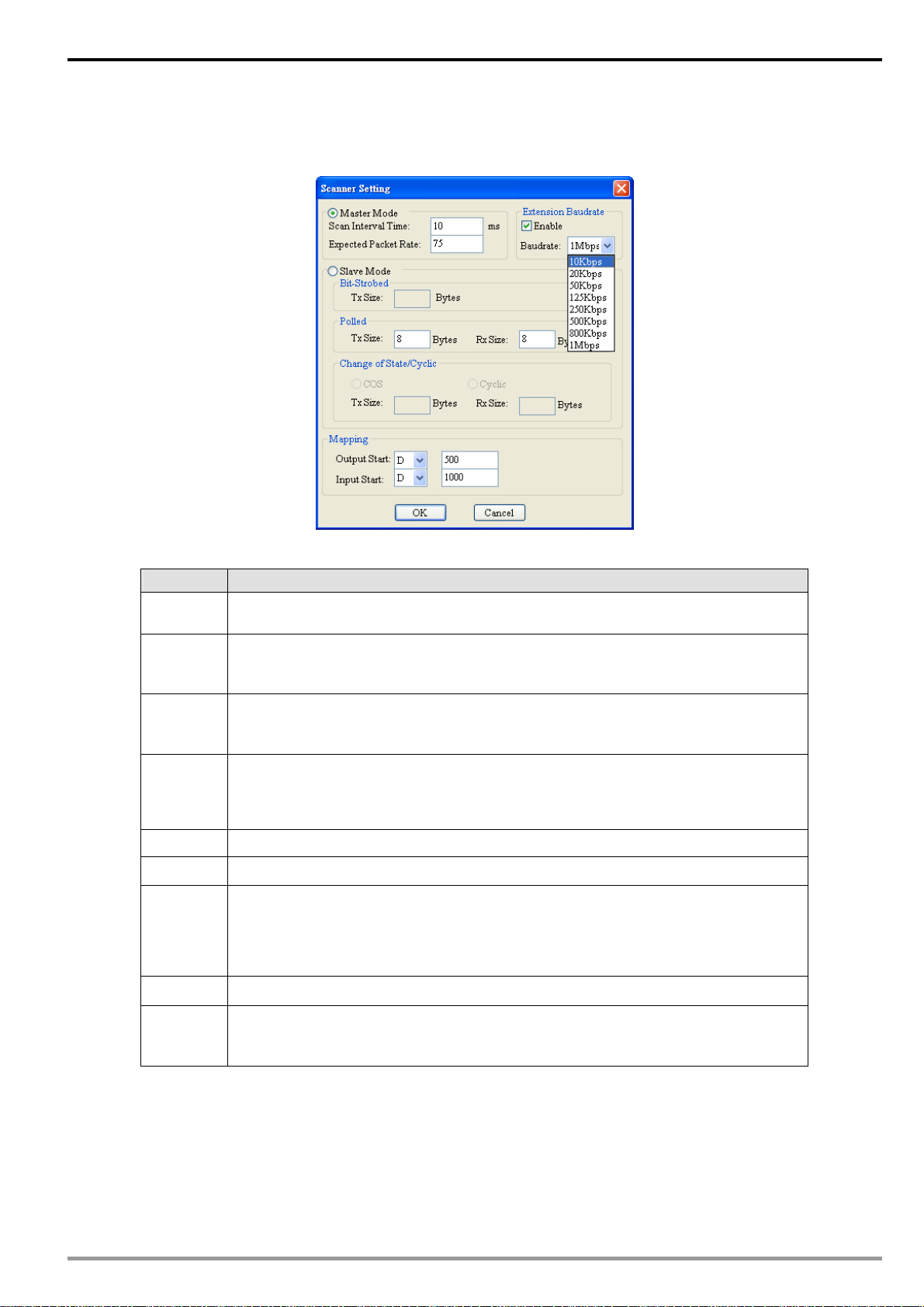

4.1.2 Setup of Scan Module

The following dialog is for setting DVPDNET-SL’s current mode: master mode or slave mode.

Parameter Explanation

Master

mode

Scan

interval

time

Timeouts

(EPR)

Extended

baud rate

Slave mode

Bit-strobe

Polled

For setting DVPDNET-SL as master mode.

The cycle time for master to send and receive the real time data after real-time

data connection is successful.

The result value of the parameter multiplied by 4. (Unit:ms)

Master assumes that the slave is offline if it receives no response from slave after

timeout.

The parameter gets effective only in master mode.

Selecting “Startup” activates the function of extended baud rate.

Select the appropriate baud rate according to actual demand then.

For setting DVPDNET-SL as slave mode

Reserved; no actual purpose now.

The parameters get effective only in slave mode.

The filled byte number corresponds to the data length for output and input as

DVPDNET-S is taken as slave. “Sending data length” corresponds to “Output

length” and “Receiving data length” corresponds to “Input length”.

COS/CC

Device

mapping

address

Note: These parameters and the configuration information are downloaded to DVPDNET-SL together.

DVP-PLC Operation Manual

Reserved; no actual purpose now.

For AH modes specially; no actual purpose now.

9

Page 13

DeviceNet Network Scanner DVPDNET-SL

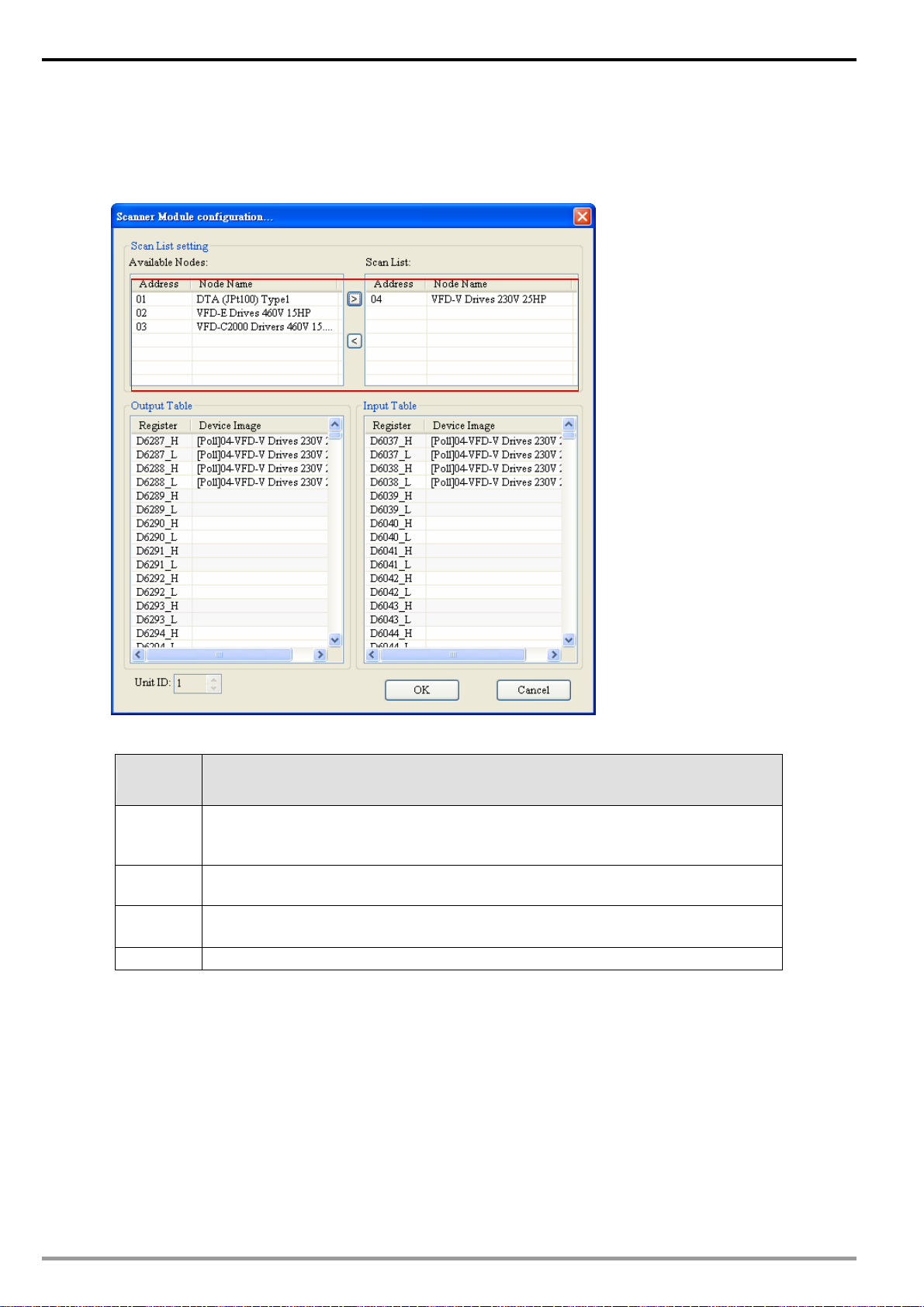

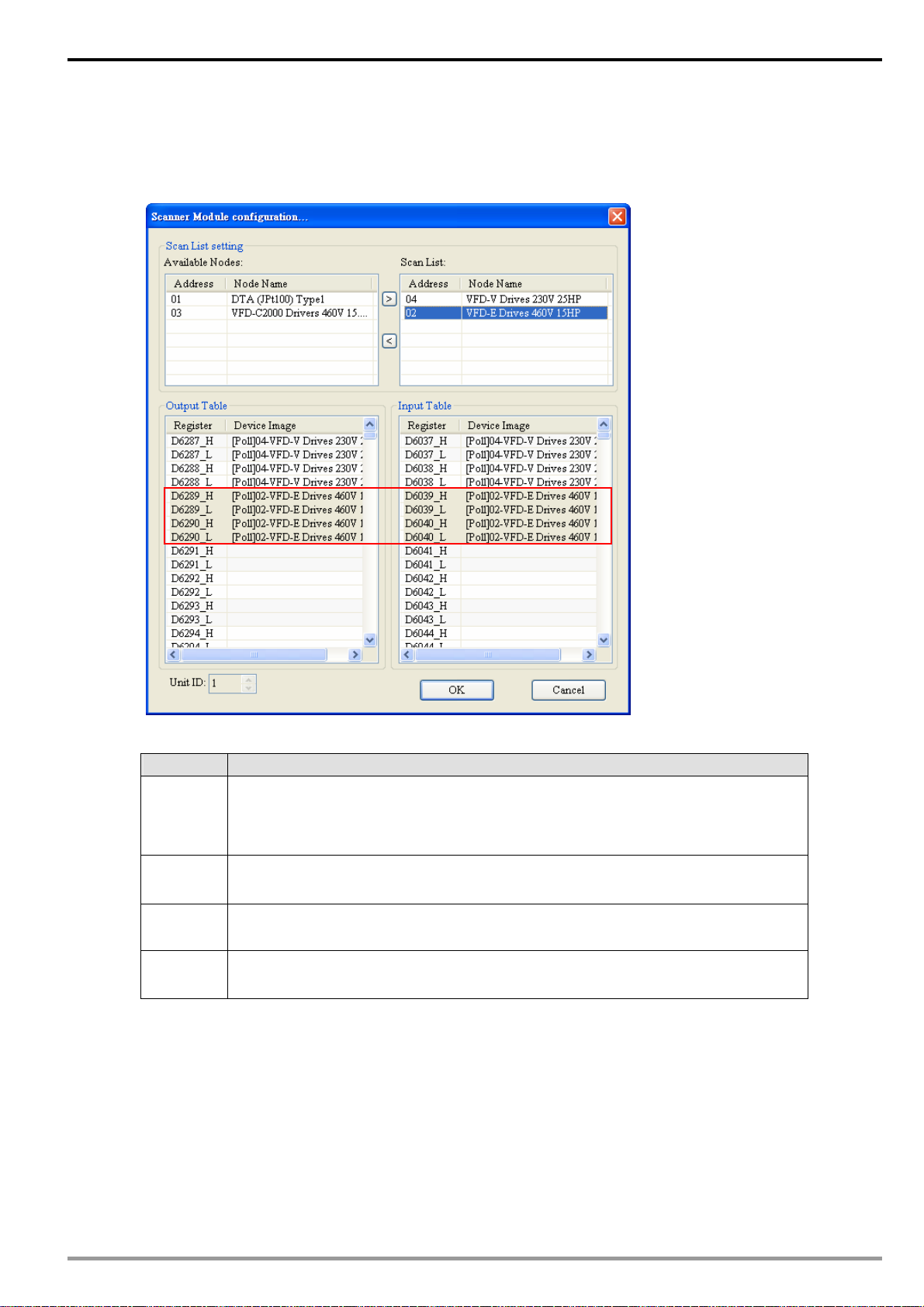

4.1.3 Setup of Scan List

Double click the existing icon of DVPDNET-SL in the DeviceNet Builder interface and then the following

dialog box appears for configuring the scan module.

Parameter Explanation

Available

node

Scan list

Node

address

Node name

All already scanned slaves appear in “Available list”.

After the configuration information is downloaded to DVPDNET-SL, the slave in

“Available node” will not conduct the real-time data exchange with DVPDNET-SL.

After the configuration information is downloaded to DVPDNET-SL, the slave in

“Scan list” will conduct the real-time data exchange with DVPDNET-SL.

The station No. for the slave in DeviceNet bus.

The name that “Node address” corresponds to.

10

DVP-PLC Operation Manual

Page 14

DeviceNet Network Scanner DVPDNET-SL

4.1.4 Input Table and Output Table

Select the device in “Scan list” and then the data length of input and output of the device will be displayed

respectively in the lower part of the following dialog box.

Parameter Explanation

Output

Table

Input Table

Register

Device

mapping

PLC MPU’s registers and the corresponding output data are shown in “Output list”.

The values in PLC’s registers will be sent to slave in real time as the control data

of slave.

PLC MPU’s registers and the corresponding input data are shown in “input list”.

The data that slave sends to master will be updated in PLC’s registers in real time.

The number of the register of PLC MPU; “D6289_H” indicates the high byte of

register D6289; “D6289_L” indicates the low byte of register D6289.

For displaying the data type and the name of current slave; “Poll” means the polled

data.

DVP-PLC Operation Manual

11

Page 15

DeviceNet Network Scanner DVPDNET-SL

4.2 Data Mapping Areas

The data mapping introduced in this chapter is the data mapping between PLC MPU and DVPDNET-SL. The

mapping relation is unchanged and user has no right to revise this area.

Max 8 PLC DVPDNET-SL modules can be connected to PLC’s left side. After all DVPDNET-SL are connected

to DVP-SV, DVP-SV will distribute data mapping areas to every DVPDNET-SL.

DVPDNETDVPDNETDVPDNETDVPDNETDVPDNETDVPDNETDVPDNET

DVPDNET DVP28SV

RUN

STOP

The index of DVPDNET-SL is its unit number. The first DVPDNET-SL on the left hand side of DVP-SV is No. 1,

the following DVPDNET-SL modules are No. 2, No. 3, No. 4 and so on.

DVPDNET-SL

index

Output mapping Input mapping

1 D6250 ~ D6497 D6000 ~ D6247

2 D6750 ~ D6997 D6500 ~ D6747

3 D7250 ~ D7497 D7000 ~ D7247

4 D7750 ~ D7997 D7500 ~ D7747

5 D8250 ~ D8497 D8000 ~ D8247

6 D8750 ~ D8997 D8500 ~ D8747

7 D9250 ~ D9497 D9000 ~ D9247

8 D9750 ~ D9997 D9500 ~ D9747

Mapped D registers

4.3 I/O Mapping Table (as master mode)

As DVPDNET-SL of unit No. 1 serves as master mode, the data mapping areas are distributed as below table.

Output mapping area Input mapping area

D register Mapping area Data length D register Mapping area Data length

D6250 ~ D6281

D6282 ~ D6285

Explicit message

program request

Bit-strobe

command

D6286 Reserved

D6287 ~ D6476

DeviceNet output

data

D6477 ~ D6497 Reserved

12

32 words D6000 ~ D6031

4 words

1word

D6032 ~ D6035

D6036

190 words D6037 ~ D6226

21 words

D6227 ~ D6247 Reserved 21 words

Explicit message

program response

Status of nodes in

the scan list

DVPDNET-SL

status

DeviceNet input

data

DVP-PLC Operation Manual

32 words

4 words

1 word

190 words

Page 16

DeviceNet Network Scanner DVPDNET-SL

Note: If the unit No. is 2, the number of the registers above will all be added by 500 respectively; if the unit No.

is 3, the number of the registers above will all be added by 1000 respectively; if the unit No. is 4, the number of

the registers above will all be added by 1500 respectively and so on.

4.4 I/O Mapping Table (as slave mode)

As DVPDNET-SL serves as slave mode, the data mapping areas are distributed as below table and these

registers are applied for real-time data exchange.

Unit No.

1 D6000 255Bytes D6250 255Bytes

2 D6500 255Bytes D6750 255Bytes

3 D7000 255Bytes D7250 255Bytes

4 D7500 255Bytes D7750 255Bytes

5 D8000 255Bytes D8250 255Bytes

6 D8500 255Bytes D8750 255Bytes

7 D9000 255Bytes D9250 255Bytes

8 D9500 255Bytes D9750 255Bytes

When the unit No. of DVPDNET_SL is 1, the control data which DeviceNet sends out will be updated in real

Initial register Max data length Initial register Max data length

Input mapping area Output mapping area

time in the registers of PLC MPU with D6000 as the initial register. In the meanwhile, the value in the registers

of PLC MPU with D6250 as the initial register will be automatically sent back to DeviceNet master so as to

realize the real-time data exchange.

DVP-PLC Operation Manual

13

Page 17

DeviceNet Network Scanner DVPDNET-SL

3

5 Sending Explicit Message from Ladder Diagram

DVPDNET-SL supports the sending of explicit messages through WPL programs.

5.1 The Principle of Explicit Message Sending

1

Explicit request message

(PLC DVPDNET-SL)

4

Explicit response message

DVPDNET DVP28SV

RUN

STOP

(DVPDNET-SL PLC)

Explicit request message

from master

2

DeviceNet

DNA02

RJ12

VFD-B

Explicit response message

from slave

①: DVP-SV MPU sends out explicit request message to DVPDNET-SL according to WPL program.

②: DVPDNET-SL sends out request message to the target equipment.

③: The target equipment processes the request message and responds DVPDNET-SL.

④: DVP-SV MPU stores the response message from DVPDNET-SL to D register. One explicit message

transmission is therefore completed.

14

DVP-PLC Operation Manual

Page 18

DeviceNet Network Scanner DVPDNET-SL

5.2 Structure of Explicit Message

You can edit explicit messages in “explicit request message editing area” and “explicit response message

editing area”. See the table below for the corresponding relation between the two areas and PLC devices. If

you transmit the request message to be sent out to D6250 ~ D6281, DVPDNET-SL will fill the response

message to D6000 ~ D6031.

PLC device Mapping area Mapping length

D6000 ~ D6031 Explicit response message editing area 64 bytes

D6250 ~ D6281 Explicit request message editing area 64 bytes

1) Structure of request message

See the table below:

PLC device

D6250 ReqID Command

D6251 Port Size

D6252

D6253 High byte of Class ID Low byte of Class ID

D6254 High byte of Instance ID Low byte of Instance ID

D6255

D6256 ~ D6281 Service Data

Command: Fixed to “01Hex”.

ReqID: The request ID. Whenever an explicit message is sent out, the message will be given a ReqID

for DVPDNET-SL to identify. For the next explicit message to be sent out, you have to change the ID

number. ReqID = 0 indicates that DVPDNET-SL will not send out explicit message. Range of ReqID:

00Hex ~ FFHex.

Size: The length of the message, starting from D6253. The high bytes of D6255 are reserved. When

the data length is being calculated, D6255 is counted as 1 byte. The maximum data length is 58 bytes.

Errors will occur when the length is longer than 58 bytes. Unit: byte.

Message Header

Message Data

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Service Code MAC ID

Reserved Attribute ID (optional)

Request Message

Port: The communication port. Fixed to “00Hex".

MAC ID: The node address of the target equipment on DeviceNet.

Service Code: The service code of the explicit message. See the meanings of the codes in the table

below:

Service Code Explanation

01Hex Read all attributes (Get_Attribute_All)

02Hex Set up all attributes (Set_Attribute_All)

0EHex Read a single attribute (Get_Attribute_Single)

10Hex Set up a single attribute (Set_Attribute_Single)

DVP-PLC Operation Manual

15

Page 19

DeviceNet Network Scanner DVPDNET-SL

2) Structure of response message

See the table below:

PLC device

D6000 ReqID Status

D6001 Port Size

D6002

D6003 ~ 6031 Message Data Service Response Data

The definitions of ReqID, Port, Service Code and MAC ID are the same as their definitions in request

message.

Size: The length of the message, starting from D6003. Max. 58 bytes. Errors will occur when the

length is longer than 58 bytes. Unit: byte.

See the table below for the meanings of Status (status codes):

Status Explanation

0 No explicit message is sent out.

1 The communication of explicit message is successful.

2 The explicit message is being sent out.

3 Error: No response from the target equipment.

4 Error: Command is invalid.

5 Error: Size of request message is invalid.

6 Error: Size of response message is invalid.

7 Error: Failing to establish a connection to the target equipment.

8 ~ 255 Reserved

Message Header

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Service Code MAC ID

Response Message

3) Notes:

DVPDNET-SL can only send out 1 explicit message at a time.

Before sending explicit message by using WPL program, we suggest you clear the request message

editing area and response message editing area to 0.

If the slave responds with standard error code, and DVPDNET-SL also consider the communication

being successful, “The communication of explicit message is successful.” will indicate that the

communication has been completed successfully.

16

DVP-PLC Operation Manual

Page 20

4) Application example (I)

Target When M0 = On, read Class 1>>Instance 1>>Attribute 1 of IFD9502

1> The connection

DeviceNet Network Scanner DVPDNET-SL

DVPDNET DVP28SV

RUN

STOP

Node Address:00

DeviceNet

Node Address:02

RJ12

Note: IFD9502, a Delta DeviceNet slave module can connect VFD AC motor drive to DeviceNet network.

2> Compulsory settings and explanations on devices

Compulsory settings in DVPDNET-SL

Parameter Set value Explanation

Node address 00 Set the node address of DVPDNET-SL to “00”.

Baud rate 500kbps

Set the communication speed of DVPDNET-SL and bus to

“500kbps”.

Compulsory settings in DNA02

Parameter Set value Explanation

Node address 02 Set the node address of DNA02 to “02".

Baud rate 500kbps

Set the communication speed of DNA02 and bus to

“500kbps”.

Compulsory settings in VFD-B

Parameter Set value Explanation

02-00 04 The main frequency is operated on RS-485 interface.

02-01 03

09-00 01 Communication address of VFD-B: 01

09-01 03 Baud rate: 38,400

09-04 03 Modbus RTU mode. Data format <8, N, 2>

DVP-PLC Operation Manual

The operation commands are operated on the

communication interface. Operation by keys is valid.

17

Page 21

DeviceNet Network Scanner DVPDNET-SL

Explanations on devices

PLC device Content

Request

message

editing area

Response

message

editing area

3> PLC program

M1002

Explanation

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

D6250 0101Hex ReqID = 01Hex Command = 01Hex

D6251 0005Hex Port = 00Hex Size = 05Hex

D6252 0E02Hex Service Code = 0EHex MAC ID = 02Hex

D6253

D6254

D6255

0001Hex

0001Hex

0001Hex

High bye of Class ID =00Hex Low byte of Class ID = 01Hex

High byte of Instance ID =

00Hex

Low byte of Instance ID =

01Hex

N/A Attribute ID = 01Hex

D6000 0101Hex ReqID = 01Hex Status = 01Hex

D6001 0002Hex Port = 00Hex Size = 02Hex

D6002 8E02Hex Service Code = 8EHex MAC ID = 02Hex

D6003 031FHex

ZRST D6000 D6031

ZRST D6250 D6281

High byte of Service Data =

03Hex

Reset response message editing area

& request message editing area

Low byte of Service Data =

1FHex

M0

MOV H0101 D6250

MOV H0005 D6251

MOV H0E02 D6252

MOV H0100 D6253

MOV H0100 D6254

MOV

H0100 D6255

ReqID = 01, Command = 01

Port = 00, Size = 05

Service Code = 0E, MAC ID = 02

Class ID to be read = 01

Instance ID to be read = 01

Attribute ID to be read = 01

4> Program explanations:

In the beginning of the program, clear the response message editing area and request message

editing area to 0.

When M0 = On, DVPDNET-SL will send out request message, reading Class 1>>Instance 1>>

Attribute 1 of the target equipment (node address: 02). If the communication of explicit message is

successful, the slave will return with a response message.

18

When M0 = On, DVPDNET-SL will only send out request message once. If you would like it to send out

request message again, you will have to change ReqID.

When the reading is successful, the message responded from the target equipment will be stored in

D6000 ~ D6003.

DVP-PLC Operation Manual

Page 22

5) Application example (II)

Target M1 = On, set 0x99>>Instance 1>>Attribute 2 of IFD9502 to “0004Hex”.

1> The connection

DeviceNet Network Scanner DVPDNET-SL

Note: IFD9502, a Delta DeviceNet slave module can connect the temperature controller to DeviceNet

network.

2> Compulsory settings and explanations on devices

Compulsory settings in DVPDNET-SL

Parameter Set value Explanation

Node address 00 Set the node address of DVPDNET-SL to “00”.

Baud rate 500kbps

Compulsory settings in DNA02

Parameter Set value Explanation

Node address 02 Set the node address of DNA02 to “02”.

Baud rate 500kbps

Compulsory settings in VFD-B

Parameter Set value Explanation

02-00 04 The main frequency is operated on RS-485 interface.

02-01 03

09-00 01 Communication address of VFD-B: 01

09-01 03 Baud rate: 38,400

09-04 03 Modbus RTU mode. Data format <8, N, 2>

Set the communication speed of DVPDNET-SL and bus to

“500kbps”.

Set the communication speed of DNA02 and bus to

“500kbps”.

The operation commands are operated on the

communication interface. Operation by keys is valid.

DVP-PLC Operation Manual

19

Page 23

DeviceNet Network Scanner DVPDNET-SL

Explanations on devices

PLC device Content

Request

message

editing area

Response

message

editing area

3> PLC program

M1002

Explanation

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

D6250 0101Hex ReqID = 01Hex Command = 01Hex

D6251 0005Hex Port = 00Hex Size = 07Hex

D6252 0E02Hex Service Code = 10Hex MAC ID = 02Hex

D6253

D6254

D6255

0099Hex

0001Hex

0002Hex

High byte of Class ID = 00Hex Low byte of Class ID = 99Hex

High byte of Instance ID =

00Hex

Low byte of Instance ID =

01Hex

N/A Attribute ID = 02Hex

D6256 0004Hex High byte of data = 00Hex Low byte of data = 04Hex

D6000 0101Hex ReqID = 01Hex Status = 01Hex

D6001 0002Hex Port = 00Hex Size = 02Hex

D6002

D6003

9002Hex

0004Hex

Service Code = 90EHex MAC ID = 02Hex

High byte of Service Data =

00Hex

ZRST D6000 D6031

ZRST D6250 D6281

Low byte of Service Data =

04Hex

Reset response message editing area

& request message editing area

M1

MOV H0101 D6250

MOV H0008 D6251

MOV H0E02 D6252

MOV H0099 D6253

MOV H0001 D6254

MOV

MOV

H0002

H0004

D6255

D6256

ReqID = 01, Command = 01

Po rt = 00, Si ze = 08

Servi ce Code = 0E, MAC ID = 02

Class ID to be write= 99

Instance ID to be = 01written

Attribute ID to be = 02written

Data to be written = 0004

4> Program explanations

In the beginning of the program, clear the response message editing area and request message

editing area to 0.

20

When M1 = On, DVPDNET-SL will send out request message. Write 0004Hex into Class 99 >>

Instance 1 >> Attribute 2 of the target equipment (node address: 02). If the communication of

explicit message is successful, the slave will return with a response message.

DVP-PLC Operation Manual

Page 24

DeviceNet Network Scanner DVPDNET-SL

When M1 = On, DVPDNET-SL will only send out request message once. If you would like it to

send out request message again, you will have to change ReqID.

When the writing is successfully done, the message responded from the target equipment will be

stored in D6000 ~ D6003.

DVP-PLC Operation Manual

21

Page 25

DeviceNet Network Scanner DVPDNET-SL

6 Bit-Strobe Command

6.1 Principle of Bit-Strobe

Bit-strobe is one of the standard I/O transmission methods for DeviceNet. The length of command is fixed to 8

bytes (i.e. 64 bits), and every bit corresponds to a slave.

PLC

device

D6282 Node 15 Node 14 Node 13 … Node 1 Node 0

D6283 Node 31 Node 30 Node 29 … Node 17 Node 16

D6284 Node 47 Node 46 Node 45 … Node 33 Node 32

D6285 Node 63 Node 62 Node 61 … Node 49 Node 48

When b0 of D6282 = 0, the node 0 equipment will be selected, and it will need to respond with a message to

the master. When b0 and b1 of D6282 = 0, the node 0 and node 1 equipment will be selected, and they will be

to respond with a message to the master.

In the bit-strobe mode, the master will not send control data to the slave node. However, when its

b15 b14 b13 … b1 b0

D8283

Corresponding nodes on the network

D6282

b0b1b17 b15 b14b30 b2b18 b16b31

Node 0

Node 1

Node 2

Node 14

corresponding bit is set to 0, the slave node will have to respond with I/O data to the master. When its

corresponding bit is set to 1, the slave node will not have to respond with I/O data to the master.

22

DVP-PLC Operation Manual

Page 26

DeviceNet Network Scanner DVPDNET-SL

7 Display of Node Status on Network

7.1 Display of Node Status in Scan List

This function is to monitor if DeviceNet slave is offline or not. DVPDNET-SL does read-time monitoring to the

nodes in the scan list and maps the status of every node to a bit. You can acquire the node status by

monitoring D6032 ~ D6035. See the table below for the corresponding relation between PLC devices and the

nodes on the network:

PLC

device

D6032 Node 15 Node 14 Node 13 … Node 1 Node 0

D6033 Node 31 Node 30 Node 29 … Node 17 Node 16

D6034 Node 47 Node 46 Node 45 … Node 33 Node 32

D6035 Node 63 Node 62 Node 61 … Node 49 Node 48

When the node in the scan list is normal, the corresponding bit will be off. If the node occurs with abnormality,

its corresponding bit will be On.

b15 b14 b13 … b1 b0

7.2 Status of DVPDNET-SL

You can acquire the real-time status of DVPDNET-SL by monitoring D6036. When DVPDNET-SL runs

normally, D6036 = 0. When DVPDNET-SL is being initialized, the high byte of D6036 = 1 and the low byte = 0.

When error occurs in DVPDNET-SL, the high byte of D6036 = 2. For detailed error information, please refer

to the error codes, i.e. the low byte of D6036.

PLC

device

D6036

b15 b14 b13 b12 b11 b10 b9 b8 b7 b6 b5 b4 b3 b2 b1 b0

Status of DVPDNET-SL

(0: normal, 1: initializing, 2: error)

Corresponding nodes on the network

Explanation

Error codes of DVPDNET-SL

DVP-PLC Operation Manual

23

Page 27

DeviceNet Network Scanner DVPDNET-SL

8 Setup of Slave Mode

DVPDNET-SL can serve as slave through modifying of the mode by software. As DVPDNET-SL serves as slave,

the default input / output data length is 8 bytes and max input / output data length is 255 bytes.

DVPDNET-SL can be set as slave mode in the following method.

1) Connect the devices according to below figure. PC accesses PLC MPU via RS232 or RS485.

DVPDNET-SL

DVP28SV

DeviceNet Builder

2) Open DeviceNet Builder software, and select “Setup” => “Communication Setting” => “System Channel”,

and the “Serial Port Setting” dialog box will appear as below.

3) Set up the communication parameters in the PC and DVP-SV, e.g. the communication port, address, baud

rate and communication format. Click on “OK” after configuration is finished.

24

Item Function Default

COM Port

Address

Baud rate

Data Bits 7

Parity Even Parity

Stop Bit

Mode

COM port on the PC to be used to communicate

with DVP-SV

Communication address of DVP-SV

Communication speed between the PC and

DVP-SV

Communication protocol between the PC and

DVP-SV

Communication mode between the PC and

DVP-SV

COM1

01

9,600 (bps)

1

ASCII

DVP-PLC Operation Manual

Page 28

DeviceNet Network Scanner DVPDNET-SL

4) Select “Network” => "Online” and the “Select Communication Channel” dialog box will appear. Click on “OK”

to start scanning the DeviceNet network after selecting “analog online” in the following window.

5) Select “Network” >> “Scan module” and then “Scan module setting” dialog box appears. After “Slave mode”

is selected there, fill the appropriate slave data length. Finally click on “OK” to finish the setting.

6) Select “Network” >> “Download” and then below dialog box appears. Click on “Y” to download the

configuration data to DVPDNET-SL.

7) After download is finished, power PLC off and then repower it. At this time, DVPDNET-SL has been set as

slave mode.

DVP-PLC Operation Manual

25

Page 29

DeviceNet Network Scanner DVPDNET-SL

9 Setup of Extended Baud Rate

9.1 Setup of Extended Baud Rate (as master mode)

1) Connect the device to the Devicenet network according to the following figure. PC accesses PLC MPU via

RS232 or RS485.

DVPDNET-SL

DVP28SV

DeviceNet Builder

2) Open DeviceNet Builder software and select “Setup” => “Communication Setting” => “System Channel”. And

then the following dialog box appears.

3) Set up the communication parameters in the PC and DVP-SV, e.g. the communication port, address, baud

rate and communication format. Click on “OK” after configuration is finished.

Item Function Default

COM Port

Address

Baud rate

Data Bits 7

Parity Even Parity

Stop Bit

Mode

COM port on the PC to be used to communicate

with DVP-SV

Communication address of DVP-SV

Communication speed between the PC and

DVP-SV

Communication protocol between the PC and

DVP-SV

Communication mode between the PC and

DVP-SV

COM1

01

9,600 (bps)

1

ASCII

4) Select “Network” => "Online” and the following “Select Communication Channel” dialog box will appear. Click

on “OK”.

26

DVP-PLC Operation Manual

Page 30

DeviceNet Network Scanner DVPDNET-SL

5)

Select “Network” => "Setup of scan module” and the following "Setup of scan module” dialog box appears.

Select “Master mode” and “Startup” to activate the function of extended baud rate. In the meanwhile, select

the appropriate baud rate according to the actual demand. Click “OK” to finish setting.

6) Select “Network” => “Download” and the following dialog box appears. Click “OK” to download the

configuration information to DVPDNET-SL.

7) After download is completed, set DVPDNET-SL’s function switch DR0 and DR1 as ON and then repower

PLC to finish the setting of the extended baud rate.

DVP-PLC Operation Manual

27

Page 31

DeviceNet Network Scanner DVPDNET-SL

)

9.2 Setup of Extended Baud Rate (as slave mode)

1) Connect the relevant devices to the DeviceNet network according to the following figure.

DVPDNET-SL(Master

DVP28SV

DeviceNet Builder

DeviceNet

DVP28SV

DVPDNET-SL(Slave)

Note:

a. DVPDNET-SL at the bottom of the above figure has been set as slave mode.

b. The node addresses of two DVPDNET-SLs must not be repeated. (See section 2.4).

c. The baud rates of two DVPDNET-SLs are both 500K bps (See section 2.5).

2) Open DeviceNet Builder software and select “Setup” => “Communication Setting” => “System Channel”,

In result, you can see the following dialog box.

28

DVP-PLC Operation Manual

Page 32

DeviceNet Network Scanner DVPDNET-SL

3) Set up the communication parameters in the PC and DVP-SV, e.g. the communication port, address, baud

rate and communication format. Click on “OK” after configuration is finished.

Item Function Default

COM Port

Address

Baud rate

Data Bits 7

Parity Even Parity

Stop Bit

Mode

4) Select “Network” => "Online” and the “Select Communication Channel” dialog box will appear. Click on “OK”

to start scanning the entire DeviceNet network.

COM port on the PC to be used to communicate

with DVP-SV

Communication address of DVP-SV

Communication speed between the PC and

DVP-SV

Communication protocol between the PC and

DVP-SV

Communication mode between the PC and

DVP-SV

COM1

01

9,600 (bps)

1

ASCII

5) After scanning is successful, right click DNET (Slave) to select “Parameter editing”.

DVP-PLC Operation Manual

29

Page 33

DeviceNet Network Scanner DVPDNET-SL

6)

Set parameter 5 as “Enable” and select the baud rate in parameter 6 in the following page. Click on

“Download” to download the newly set parameter value to

DVPDNET-SL(Slave).

7) After download is completed, set DVPDNET-SL(Slave)’s function switch: DR0 and DR1 as ON. And then

30

repower PLC to finish the setting of the extended baud rate.

DVP-PLC Operation Manual

Page 34

DeviceNet Network Scanner DVPDNET-SL

10 Application Example on Constructing DeviceNet Network

In this section, we will present an application example, illustrating how to construct a DeviceNet network and the

configuration of the network.

Target Using an X point of DVP28SV to control RUN/STOP of the remote VFD-L AC motor drive.

10.1 How to Construct a DeviceNet Network

1) The connection

DVPDNET-SL

DVP28SV

DeviceNet

VFD-L

VFD-L

START

STOP

RS232

X0

X1

DeviceNet Builder

RTU-DNET

T

E

N

D

U

T

R

Note:

RTU-DNET, a Delta DeviceNet remote IO communication module supports the MODBUS communication

function.

2) Set up DVPDNET-SL, RTU-DNET and

Module Node address Baud rate

DVPDNET-SL 01 500kbps

RTU-DNET 02 500kbps

DVP-PLC Operation Manual

RS485

VFD-L according to the table below.

31

Page 35

DeviceNet Network Scanner DVPDNET-SL

VFD-L

parameter

02-00 4 Transmit the frequency of VFD-L via RS485

02-01 3 Control operation of VFD-L via RS485

09-00 1 Set the node address of VFD-L in Modbus to 1.

09-01 1 Set the communication rate of VFD-L in Modbus 9600

09-04 1 Set the communication format of VFD-L in Modbus to

10.2 How to Configure Network by DeviceNet Network Configuration Tool

1) Configuration of DeviceNet slave

1> Open DeviceNet Builder software and select “Setup” => “Communication Setting” => “System

Channel”, and the “Serial Port Setting” dialog box will appear as below.

Set value Explanation

communication.

communication.

7, E, 1, ASCII.

2> Set up the communication parameters in the PC and DVP-SV, e.g. the communication port, address,

baud rate and communication format. Click on “OK” after configuration is finished.

Item Function Default

COM Port

Address

Baud rate

Data Bits 7

Parity Even Parity

Stop Bit

Mode

COM port on the PC to be used to

communicate with DVP-SV

Communication address of DVP-SV

Communication speed between the PC and

DVP-SV

Communication protocol between the PC

and DVP-SV

Communication mode between the PC and

DVP-SV

COM1

01

9,600 (bps)

1

ASCII

32

DVP-PLC Operation Manual

Page 36

DeviceNet Network Scanner DVPDNET-SL

3> Select “Network” => "Online”, and the “Select Communication Channel” dialog box will appear.

Clicking on “OK” starts scanning the DeviceNet network.

4> If the bar on the dialog box does not progress, it means the connection between the PC and DVP-SV

is abnormal, or there are other programs also using the COM port on the PC. After the scan is

completed, the dialog box will tell you that the scan is completed, and the icons and device names of

all the nodes scanned on the network will be shown on the screen. See the figure below, in which the

node address of DVPDNET-SL and

RTU-DNET are 01 and 02 respectively.

DVP-PLC Operation Manual

33

Page 37

DeviceNet Network Scanner DVPDNET-SL

5> Double click on RTU-DNET (node 02), and the "Node Configuration…” dialog box will appear.

6> Click on “IO Configure…” button in “Node Configuration” dialog box, and you will then see “RTU

Configuration” page where you click on “Scan IO” button and “Warning” dialog box will appear. Click

“OK” then DeviceNet Builder will detect the devices connected to RTU-DNET as below.

7> Because no special module is connected to the right side of RTU-DNET, “None” will show in the

location of the special module in the following window. The point number for X and Y are both 0.Then

34

click on “Gateway setting”.

DVP-PLC Operation Manual

Page 38

DeviceNet Network Scanner DVPDNET-SL

8> In the interface of “Modbus gateway setting”, use the parameters of one slave and fill the relevant

values there. You can refer to the user manual of RTU-DNET.

Note: The slave here is the slave in Modbus network without direct relation with DeviceNet network.

9> Click on “OK” in the above window and then click on “Download” in the following window to

download the configuration data to RTU-DNET. After download is finished, the configuration

of RTU-DNET is completed.

DVP-PLC Operation Manual

35

Page 39

DeviceNet Network Scanner DVPDNET-SL

>

2) Configuration of DeviceNet Master

1> Double click on DNET Scanner (node 01), and the “Scan Module Configuration..." dialog box will

appear. You can find the currently available nodes, RTU-DNET and VFD-B Drives 230V 3HP, in

the list on the left side. On the right side, there is an empty “Scan List”.

2> (2) Move the slave devices on DeviceNet in the "Available Nodes” list on the left side to the "Scan

List” on the right side. Select a node and click on

scan list.

36

. Follow the steps to move all the nodes to the

DVP-PLC Operation Manual

Page 40

DeviceNet Network Scanner DVPDNET-SL

3> Confirm all the settings and click on “OK”. Next, download the configuration to DVPDNET-SL. If

DVP-SV is in RUN mode while you are downloading the configuration, a “Warning” dialog box will

appear.

4> Click on “OK” to continue the download. Make sure DVP-SV is in RUN mode.

The mapping relation between DVPDNET-SL and slave device is shown as below after

configuration of the DeviceNet network following the above steps is completed.

DVP28SV → DVPDNET-SL → slave device

DVP28SV DVPDNET-SL RTU-DNET & VFD-L

D6287

D6288

Control word of VFD-L

(2000H)

Control frequency of VFD-L

(2001H)

DVP28SV ← DVPDNET-SL ←slave device

DVP28SV DVPDNET-SL RTU-DNET & VFD-L

D6037

DVP-PLC Operation Manual

Output frequency of VFD-L

(2103H)

37

Page 41

DeviceNet Network Scanner DVPDNET-SL

d

s

10.3 Ladder Diagram Program

This section introduces how to edit the ladder diagram program to meet the control request of DeviceNet network.

When X0=ON, VFD-L AC motor drive runs;

Control

request

Explanation of PLC Program

X0

X1

When X1=ON, VFD-L AC motor drive stops;

After VFD-L has run for 6 seconds and at this time the running frequency still has not

reached the designated frequency, Y0 of DVP28SV=ON.

MOV H12 D6287

When X0=ON, VFD-L starts up and

its target frequency is 20Hz.

MOV K2000 D6288

MOV H1 D6287

When X1=ON, VFD-L stops running.

X0

T0

TMR T0 K60

LD<> K2000 D6037

Y0

( )

Y0 will be ON in DVP28SV if the

frequency of VFD-L has not reache

20Hz after starting up for 6 second

38

DVP-PLC Operation Manual

Page 42

DeviceNet Network Scanner DVPDNET-SL

11 LED Indicator & Trouble-shooting

DVPDNET-SL supports two diagnostic methods: indicator diagnosis and digital displayer diagnosis.

DVPDNET

POWER

MS

NS

11.1 LED Indicator Diagnosis

POWER LED

LED status Indication How to correct

Off Power is abnormal. Make sure DVPDNET-SL is powered.

Green light on Power is normal. --

NS LED

Green light on Normal operation --

MS LED

Green light on Normal operation --

LED status Indication How to correct

Off

Green light

blinking

Red light

blinking

Red light on

LED status Indication How to correct

Off No power Make sure DVPDNET-SL is powered.

Green light

blinking

Red light

blinking

Red light on Internal error

No power or duplicate ID

check has not completed

No communication

Error in communication Check the digital indicator and eliminate the error.

Network error; cannot check

duplicate ID; bus-off (check

the digital indicator)

The master is not

configured.

Some slaves encounter

communication error.

1. Make sure DVPDNET-SL is powered.

2. Make sure at least 1 node or more are

communicating on the network.

No correction is needed; check the digital indicator for

the error.

1. Make sure all the devices have their unique node

address.

2. Check the network for correcting media installation

and baud rate.

3. Check if the node address of DVPDNET-SL is valid.

4. Check if the network power is normal.

Configure the scan list and re-download it to

DVPDNET-SL.

Check the digital indicator and make sure the salve

information in the scan list is consistent with the salve

actually connected.

1. Check if the configuration is valid.

2. Re-power it. If the error still exists, send it back to

the factory for repair.

DVP-PLC Operation Manual

39

Page 43

DeviceNet Network Scanner DVPDNET-SL

MS & NS LED

LED status

NS LED MS LED

Off Off No power Make sure DVPDNET-SL is powered.

Off

Red light on

Red light on

Red light on Red light on Hardware error

Green light

on

Green light

on

Red light

blinking

Duplicate ID check has not

completed.

MAC ID detection failure

or bus-off

No 24V DC power from

DeviceNet network

Indication How to correct

11.2 Digital displayer diagnosis

Code Indication How to correct

Node address of

0 ~ 63

80

F0

F1

F2 Low voltage is detected.

F3 Entering test mode

F4 Bus-off

F5 No network power

F6

F7

F8

F9

FA Invalid configuration data

E0

E1

DVPDNET-SL (in normal

operation)

DVPDNET-SL is in STOP

status.

Duplicate MAC ID check

failure

No slave device in the scan

list.

Internal error; Flash or RAM

check error

Internal error; GPIO check

error

Error produced in factory

manufacturing

Internal error; EEPROM

access failure

Device key parameter does

not match the scan list

table.

Data size returned does not

match the scan list.

Make sure at least 1 node or more are

communicating in the network, and the baud

rate is the same as the setting in

DVPDNET-SL.

Change the MAC ID setting and re-power

DVPDNET-SL.

1. Check if the network cable is correctly

connected to DVPDNET-SL.

2. Check the 24V DC network power.

Go to your manufacturer or distributor for

problem-solving.

--

Turn the PLC MPU to RUN and start I/O data

exchange.

Check the node address and re-power DVPDNET-SL.

Configure the scan list and download it to

DVPDNET-SL.

Check if the power of DVPDNET-SL and PLC MPU is

normal.

Switch IN1 from On to Off and re-power

DVPDNET-SL.

1. Check if the network cable is normal.

2. Check if the baud rate is correct.

3. Re-power DVPDNET-SL.

Make sure the cable is correctly connected and check

if the network power is normal.

If the error still exists after re-power, send your

DVPDNET-SL back to the factory for repair.

If the error still exists after re-power, send your

DVPDNET-SL back to the factory for repair.

If the error still exists after re-power, send your

DVPDNET-SL back to the factory for repair.

If the error still exists after re-power, send your

DVPDNET-SL back to the factory for repair.

1. Configure the network correctly and re-download it

to DVPDNET-SL.

2. Check if the node address of the slave in the scan

list is the same as the node address of

DVPDNET-SL.

Make sure that the device parameter in the scan list

matches the desired key parameter, including vendor

ID, product code, device type and version.

Re-configure the scan list using correct data size.

40

DVP-PLC Operation Manual

Page 44

DeviceNet Network Scanner DVPDNET-SL

Code Indication How to correct

1. Check if there is any change for the node address of

E2

E3

E4

E5

E6

E7

Slave device in the scan list

does not exist or is offline.

DVPDNET-SL fails to

transmit a message.

Error detected in sequence

of fragmented I/O

messages from device

Slave device returns error

when DVPDNET-SL

attempts to communicate

with it.

Data size returned is bigger

than expected.

DVPDNET-SL is checking

MAC ID.

the slave.

2. Check if the communication cable is disconnected

or connected loosely.

Make sure that the connection is valid and check if the

baud rate is correct.

Check if the slave is operating normally.

Check if the slave is operating normally.

Check the configuration of slave device and scan list.

If the code is displayed long, do the troubleshooting

according to the following steps.

1. Make sure that at least two nodes work normally in

the network.

2. Check if either end of the network is connected with

the terminal resistor of 121Ω.

3. Check if the baud rates of the node devices in the

network are consistent with each other.

4. Check if the communication cable is normal so as to

avoid that the cable is disconnected or connected

loosely.

5. Re-power 10DNET scanner module.

DVP-PLC Operation Manual

41

Loading...

Loading...