UEi INF200 User Manual

INSTRUCTION MANUAL

INF200

1-800-547-5740 • Fax: (503) 643-6322 www.ueitest.com • email: info@ueitest.com

Introduction

The INF 100/200 non-contact infrared thermometer provides a faster, easier way to take diagnostic temperature measurements. Monitor the

temperature of transformers, circuit breaker panels, motors and bearings, supply and return registers, ducts, inlet/outlet steam lines, furnace flues and many other surfaces. Use the INF 200 when diagnosing tempera t u r e problems to save time and reduce the risk of burns and injuries.

Features include

•Switchable ˚F or ˚C readings

•Quick and simple operation

•Back-light

•Long battery life

•Temperature range of 0 to 788˚F (-20 to 420˚C)

•On-board nine measurement memory

•Barrel sight targeting

•Laser targeting

•User programmable alarm

Safety Notes

Before using this instrument, read all safety information carefully. In this manual the word "WARNING" is used to indicate conditions or actions that may pose physical hazards to the user. The word "CAUTION" is used to indicate conditions or actions that may damage this instrument.

WARNING!

WARNING!

DO NOT point the laser toward the eyes or face of a person or animal. Laser light can cause eye injury, if the beam makes direct eye contact. Reflective laser light can also cause damage, if a mirror or a glass-like surface reflects the beam directly into the eye. Laser’s potential to cause damage is retained for hundreds of feet. Use caution.

CAUTION!

CAUTION!

This equipment is intended for use be industry professionals who know their professional environments. Temperature measurements are often taken in potentially hazardous ares. Know and use the safety standards prescribed by your profession.

Validate Measurements

The accuracy and validity of measurements taken with this device depends on various criteria. One of the most critical criteria to consider is emissivity (a more detailed explanation is provided in the validation section of this manual). Before using this instrument to determine if an area is safe to touch, or enter, verify your readings are reasonably accurate by using comparisons with already known measurements.

Laser Splash:

Indicates the use of laser equipment and the category of laser used.

International Symbols

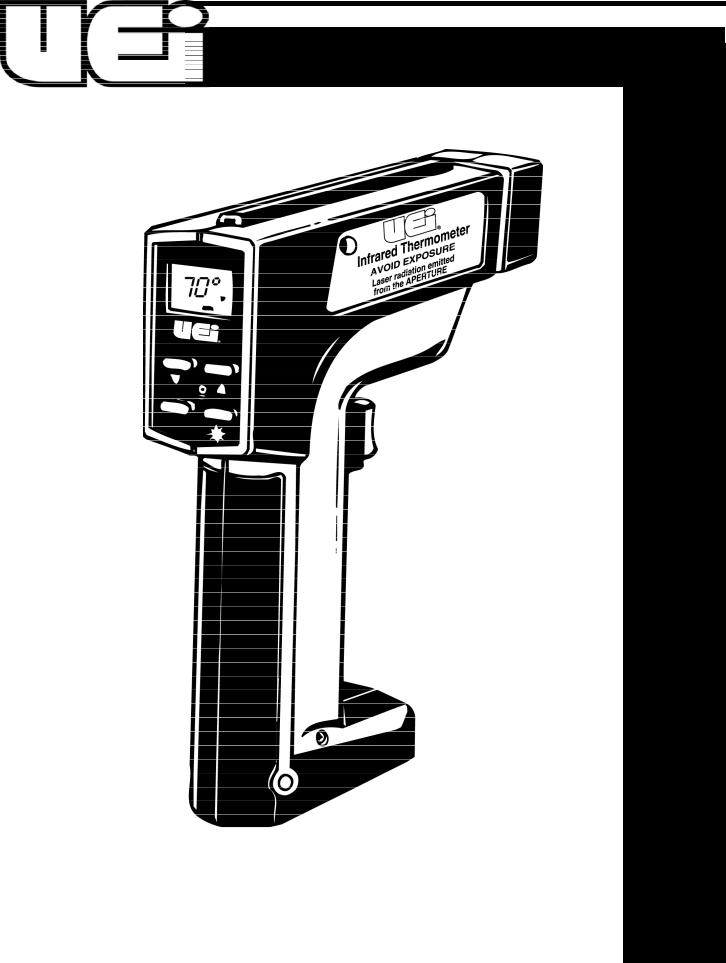

Controls and Indicators

12 |

11 |

|

|

8 |

|

|

|

9 |

|

|

6 |

|

|

|

|

|

|

||

|

|

|

|

|

5 |

||

4 |

7 |

||

1 |

2 |

3 |

10 |

1.Fahrenheit / Centigrade select push-button, and mode down / decrease push-button.

2.Backlight push-button, and up / increase selector.

3.Te m p e rature display mode select, memory recall and programming select (INF 200) push-button.

4.Te m p e rature display mode indica t o r.

5.Te m p e rature measurement.

6.Fahrenheit / Centigrade scale indicator.

7.Low battery annunciator.

8.Memorylocation annunciator.

9.Emissivityannunciator.

10.Laser targeting on / off push-button.

11.Laser on annunciator.

12.Alarm mode indica t o r.

INF200-MAN |

P. 1 |

Operating Instructions

Taking Measurement Samples

To take temperature measurements, point the instrument at the surface to be measured and pull the trigger. A tube has been incorporated along the top of the barrel to aid the user in spotting the surface area to be measured (target).

Although this simple explanation works well in most cases, there are other factors that may impact the measurement accuracy. Consider there influences before using the data you obtain with your infrared thermometer.

•The target must completely fill the spot diameter seen by the infrared sensor, otherwise the temperature displayed will be influenced by the surface surrounding the target. The ratio of the distance from the end of the barrel to the size of the spot being measured is 8:1. For example, using the INF200, an object that is 6” in diameter can be accurately measured from 4’ away. When using the gun to find hot-spots, accuracy of the reading is not as important as keeping the gun at the same distance from the target for each sample measurement. If you are looking for hot-spots on electrical panels, for instance, you could take the readings from 6’ away each time, even though you may only be filling half the spot diameter. The critical information in this process would be any significantly

higher temperatures

•Emissivity of an object will also affect accuracy. See the “Validation” section for details

•This instrument is sensitive to electromagnetic interference (EMI), such as that generated by spark plug wires, radio transmitters and welders. Do not use this instrument in close proximity to equipment that may produce such interference

•The instrument must be used within the ambient temperature range specified in the specification table

Each time the trigger is pulled your INF200 monitors four different readings, regardless of the selected mode. They are:

•The highest temperature measured

•The lowest temperature measured

•The average temperature (time weighted)

•The Net difference between the light and low temperature “DT”

These four measurements go into the first memory location for future recall, when the trigger is released. See “Recalling memory points” for more details.

While the trigger is pulled, a temperature sample is taken at a minimum of once every 1/2 second (500 milliseconds). The four parameters mentioned above are updated at the same rate.

Selecting Fahrenheit or Centigrade Scales

Select the scale you prefer to use (˚F or ˚C) by pressing the (“˚F/˚C▼”) push-button while the trigger is pulled.

Backlight Operation

To toggle the backlight on or off, press the push-button with the backlight “  “ symbol while the trigger is pulled. Once the backlight has been turned on, it will come on each time the trigger is pulled until it is toggled off. Please note that this feature significantly reduces the battery’s life.

“ symbol while the trigger is pulled. Once the backlight has been turned on, it will come on each time the trigger is pulled until it is toggled off. Please note that this feature significantly reduces the battery’s life.

Measurement Modes

This instrument allows you to select from one of five display modes. You can cycle through the modes in this order:

•Real-time temperature measurements

•Maximum temperature measured (MAX mode)

•Minimum temperature measured (MIN mode)

•Temperature difference between MAX and MIN (∆T mode)

•Calculated (time weighted) average temperature (AVG mode)

The last mode selected will remain selected the next time you pull the trigger.

Real-time Temperature Measurement Mode

This display mode shows the actual temperature of surfaces measured. This value is updated at least once ever 1/2 second. When the instrument is powered up for the first time, this mode is pre-set.

Maximum Temperature (MAX) Mode

To enter the “MAX” display mode, pull the trigger, and press and release the “MODE” push-button repeatedly until you see the word “MAX” displayed on the LCD. In the “MAX” mode the highest temperature measurement taken, during the current trigger pull, is displayed on the LCD. The temperature reading will update each time a higher temperature is measured.

Minimum Temperature (MIN) Mode

To enter the “MIN” display mode, pull the trigger, and press and release the “MODE” push-button repeatedly until you see the word “MIN” displayed on the LCD. In the “MIN” mode, the lowest temperature measurement taken, during the current trigger pull, is displayed on the LCD. The temperature reading will update each time a new lower

temperature is measured.

Average (AVG) Mode

To select the “AVG” display mode, pull the trigger and press and release the “MODE” push-button repeatedly until “AVG” is displayed on the LCD. The term “time weighted” in reference to the averaging mode means all temperature measurements taken, from the time the trigger was first pulled, are averaged while taking measurements in this mode. If you were to walk along a wall for one minute taking readings that were generally 72 degrees, then walk by a spot for

1/2 second that was 20 degrees, no significant change in average temperature would be displayed.

Temperature Differential (∆T) Mode

To select the temperature differential display mode “∆T”, pull the trigger and press and release the “MODE” push-button repeatedly until “∆T” is displayed on the LCD. This display mode is used to determine the

net temperature difference between two surfaces. This is particularly valuable when calculating net heating or cooling, since ambient temperature is effectively removed from the equation.

INF200-MAN |

P. 2 |

Loading...

Loading...