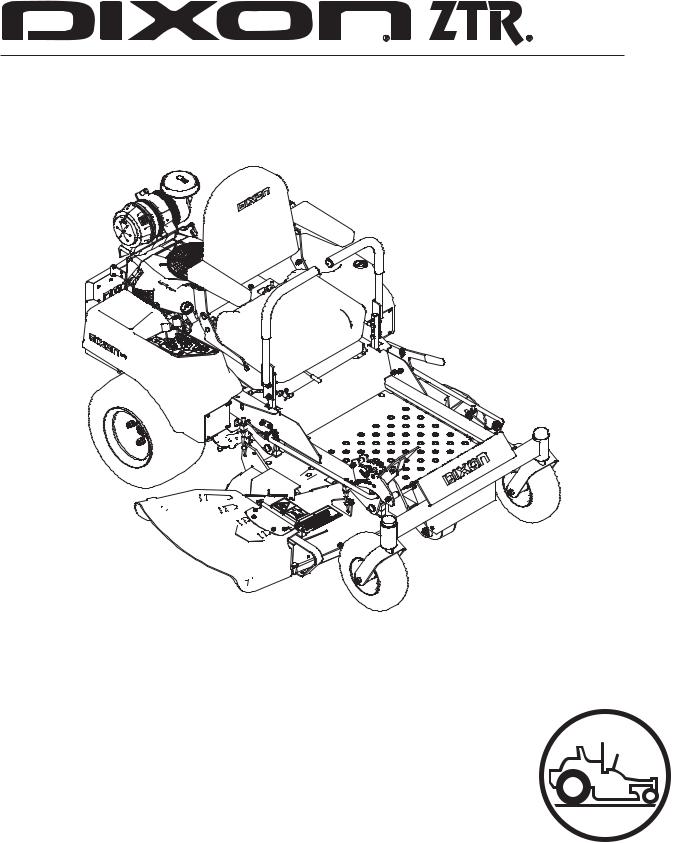

Dixon RAM MAG 44 - 968999650, RAM MAG 50 - 968999561, RAM 50 - 968999552, RAM MAG 50 - 968999651, RAM MAG 44 - 968999559 User Manual

...

Operator's manual

RAM 44 / 968999551, RAM 50 / 968999552

RAM MAG 44 / 968999559, RAM MAG 50 / 968999561 RAM MAG 50 / 968999562, RAM MAG 44 / 968999650 RAM MAG 50 / 968999651

Please read the operator’s manual carefully and make sure you understand the instructions before using the machine.

English

OPERATOR’S MANUAL

Contents |

|

Contents................................................................... |

1 |

Introduction ............................................................. |

3 |

Congratulations.................................................... |

3 |

General ................................................................ |

3 |

Driving and Transport on Public Roads ............... |

3 |

Towing ................................................................. |

3 |

Operating ............................................................. |

3 |

Good Service ....................................................... |

4 |

Manufacturing Number ........................................ |

4 |

Symbols and Decals ............................................... |

5 |

Safety Instructions.................................................. |

7 |

General Operation ............................................... |

7 |

Personal Safety Equipment ................................. |

9 |

Slope Operation ................................................... |

9 |

Children.............................................................. |

10 |

Maintenance ...................................................... |

11 |

Transport............................................................ |

14 |

Customer responsibilities................................... |

15 |

Controls ................................................................. |

16 |

Control Locations ............................................... |

16 |

1. Parking Brake ................................................ |

17 |

2. Motion Control Levers.................................... |

17 |

3. Fuel Shut Off Valve........................................ |

18 |

4. Seat adjustment knobs .................................. |

18 |

5. Refueling........................................................ |

19 |

6. By pass linkage.............................................. |

20 |

7. Fuses ............................................................. |

20 |

8. Hour Meter ..................................................... |

21 |

9. Choke Control ................................................ |

21 |

10. Ignition Switch.............................................. |

21 |

11. Throttle Control ............................................ |

22 |

12. Blade switch................................................. |

22 |

13. Cutting height pedal ..................................... |

23 |

Accessories........................................................ |

23 |

Operation ............................................................... |

24 |

Training .............................................................. |

24 |

Before Starting ................................................... |

25 |

Starting the Engine ............................................ |

25 |

To start an engine with a weak battery .............. |

29 |

Running.............................................................. |

30 |

Operating on hills ............................................... |

31 |

Mowing Tips....................................................... |

32 |

Stopping the Engine........................................... |

33 |

Moving by Hand ................................................. |

34 |

Maintenance ......................................................... |

35 |

Maintenance Schedule...................................... |

35 |

Battery............................................................... |

37 |

Ignition System.................................................. |

38 |

Checking the Safety System ............................. |

39 |

Checking the Engine's Cooling Air Intake ......... |

40 |

Checking and Adjusting the Throttle Cable....... |

40 |

Checking and Adjusting the Choke Cable......... |

40 |

Replacing the Air Filter...................................... |

41 |

Replacing the Fuel Filter ................................... |

44 |

Checking the Fuel Pump’s Air Filter.................. |

44 |

Checking Tire Pressures................................... |

44 |

Checking the Parking Brake.............................. |

45 |

Checking the V-belts ......................................... |

45 |

Deck belt ........................................................... |

45 |

IZT belt .............................................................. |

46 |

Checking the Blades ......................................... |

48 |

Adjusting the Mower Deck ................................ |

50 |

Cleaning and Washing ...................................... |

52 |

Caster Wheels................................................... |

52 |

Hardware........................................................... |

52 |

Parking brake .................................................... |

53 |

Tracking adjustment.......................................... |

53 |

Lubrication............................................................ |

54 |

Lubrication Schedule......................................... |

54 |

General ............................................................. |

54 |

Lubricating the Cables ...................................... |

55 |

Lubricating in Accordance with the Lubrication |

|

Schedule ........................................................... |

55 |

Trouble Shooting Guide ...................................... |

61 |

Storage .................................................................. |

64 |

Winter Storage .................................................. |

64 |

Service .............................................................. |

64 |

Wiring diagram ..................................................... |

65 |

Technical Data ...................................................... |

66 |

Accessories....................................................... |

74 |

Torque Specifications........................................ |

74 |

Conformity Certificates........................................ |

75 |

USA requirements............................................. |

75 |

CE requirement ................................................. |

75 |

Service Journal .................................................... |

76 |

Delivery Service ................................................ |

76 |

After the First 5-8 Hours.................................... |

77 |

25-Hour Service ................................................ |

78 |

50-Hour Service ................................................ |

79 |

100-Hour Service .............................................. |

80 |

300-Hour Service .............................................. |

81 |

At Least Once Each Year.................................. |

82 |

Warranty................................................................ |

83 |

English-1

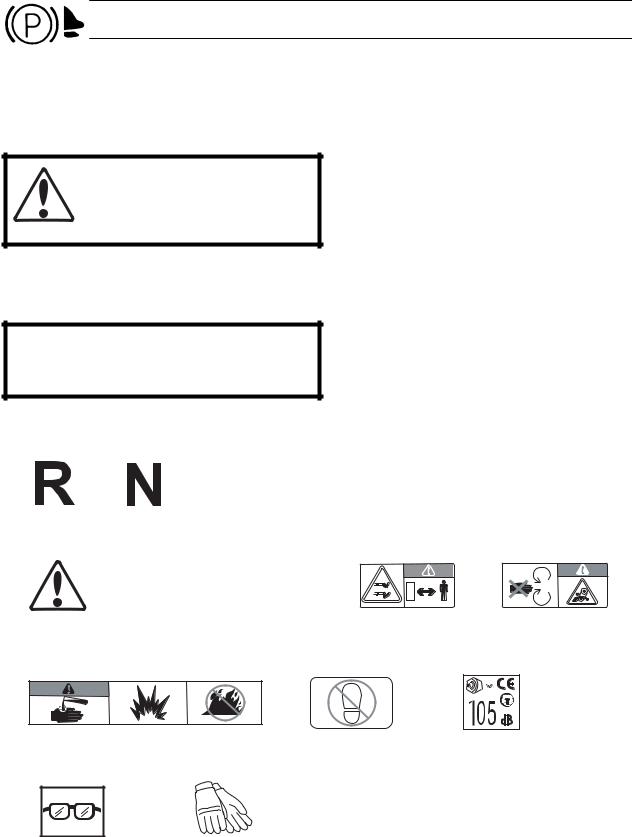

WARNING!

Failure to follow cautious operating practices can result in serious injury to the operator or other persons. The owner must understand these instructions, and must allow only trained persons who understand these instructions to operate the mower. Each person operating the mower must be of sound mind and body and must not be under the influence of any mind altering substance.

WARNING!

Engine exhaust, some of its constituents, and certain vehicle components contain or emit chemicals known to the State of California to cause cancer and birth defects or other reproductive harm.

WARNING!

Battery posts, terminals and related accessories contain lead and lead compounds, chemicals know to the State of California to cause cancer and birth defects or other reproductive harm. Wash hands after handling.

English-2

INTRODUCTION

Introduction

Congratulations

Thank you for purchasing a Dixon ride-on mower. This machine is built for the greatest efficiency and rapid mowing primarily of large areas. Controls in one place and a hydrostatic transmission regulated by steering controls also contribute to the machine’s performance.

This manual is a valuable document. Read the manual carefully before using or servicing the machine. Following the instructions (use, service, maintenance, etc.) by all who operate this machine can considerably increase the lifespan of your machine and even increase its resale value. It is also very important to follow the instructions for the safety of you and others.

If you sell your machine, be sure to give the operator’s manual to the new owner.

The final chapter of this operator’s manual comprises a Service Journal. Ensure that service and repair work is documented. A well kept service journal reduces service costs for the season-based maintenance and affects the machine’s resale value. Please contact your dealer for more information. Take the operator’s manual along when the machine is left to the workshop for service.

General

In this operator’s manual, left and right, backward and forward are used in relation to the machine’s normal driving direction.

Continuous dedication to improve our products require that specifications and design are subject to change without notice.

Driving and Transport on Public Roads

Check applicable road traffic regulations before transporting on public roads. If the machine is transported, you must always use approved fastening equipment and ensure that the machine is well anchored. DO NOT operate this machine on public roadways.

Towing

Do not tow this machine, it may cause damage to the drive system.

Do not tow any trailers, etc with this mower. They may jackknife or overturn causing damage to the mower and possibly serious injury to the operator.

Operating

This machine is constructed only for mowing grass on lawns and other free and even ground without obstacles such as stones, tree stubs, etc. The machine can also be used for other tasks when equipped with special accessories provided by the manufacturer, for which the operating instructions are provided in conjunction with delivery. All other types of use are incorrect. The manufacturer’s directions concerning operation, maintenance, and repairs must be carefully followed.

Lawnmowers and all power equipment, can be potentially dangerous if used improperly. Safety requires good judgement, careful use in accordance with these instructions and common sense.

The machine must only be operated, maintained, and repaired by persons that are familiar with the machine’s special characteristics and who are well versed in the safety instructions. Use only approved repair parts to maintain this machine.

Accident prevention regulations, other general safety regulations, occupational safety rules, and traffic regulations must be followed without fail.

Unauthorized modifications to the design of the machine may absolve the manufacturer from liability for any resulting personal injury or property damage.

English-3

INTRODUCTION

Good Service

Dixon’s products are sold all over the world and only in specialized retail stores with complete service. This ensures that you as a customer receive only the best support and service. Before the product is delivered, the machine has, for example, been inspected and adjusted by your retailer, see the certificate in the Service Journal in this operator’s manual.

When you need spare parts or support in service questions, warranty issues, etc., please consult the following professional:

|

|

|

This Operator’s Manual belongs to the |

Engine |

Transmission |

machine with manufacturing number: |

|

|

|

|

|

Manufacturing Number

The machine’s manufacturing number can be found on the printed plate affixed to the left in the engine compartment. Stated on the plate, from the top are:

•The machine’s type designation (I.D.).

•The manufacturer's type number (Model).

•The machine’s serial number (Serial no.)

Please state the type designation and serial number when ordering spare parts.

The engine’s manufacturing number is stamped on one of the valve covers.

The plate states:

•The engine’s model.

•The engine’s type.

•Code

Please state these when ordering spare parts.

The Hydro Drive IZ gears have a barcode decal affixed to the rear of the gears.

English-4

SYMBOLS AND DECALS

Symbols and Decals

These symbols are found on the machine and in the operator’s manual.

Study them carefully so that you know what they mean.

WARNING!

Xxxxxxx xxxx xxxxxxxx xxx x

Xxxxx xxxxxx xx.

xx xxxxxxxx xxxxx xxx xx.

Used in this publication to notify the reader of a risk of personal injury or death, particularly if the reader does not follow instructions given in the manual.

IMPORTANT INFORMATION Xxxxxxx xxxx xxxxxxxx xxx xxx

xxxx xxxxxx xx.

Used in this publication to notify the reader of a risk of material damage, particularly if the reader does not follow instructions given in the manual. Used also when there is a potential for misuse or misassembly.

Reverse |

Neutral |

Fast |

Slow |

Choke |

Fuel |

Warning! Parking brake |

CE conformity |

|

marking. Only for |

|

European market |

Warning! Rotating |

Do not touch rotating |

blades, keep away from |

parts |

the discharge deck |

|

Battery acid is corrosive, explosive, |

Do not stand here Noise emissions to the surroundings |

|

and flammable |

|

in accordance with the European |

|

|

Union’s directive. The machine’s |

|

|

emission is stated in the chapter |

|

|

TECHNICAL DATA and on the decals. |

|

|

Only machines for European |

Use protective glasses |

Use protective gloves |

market |

|

||

English-5

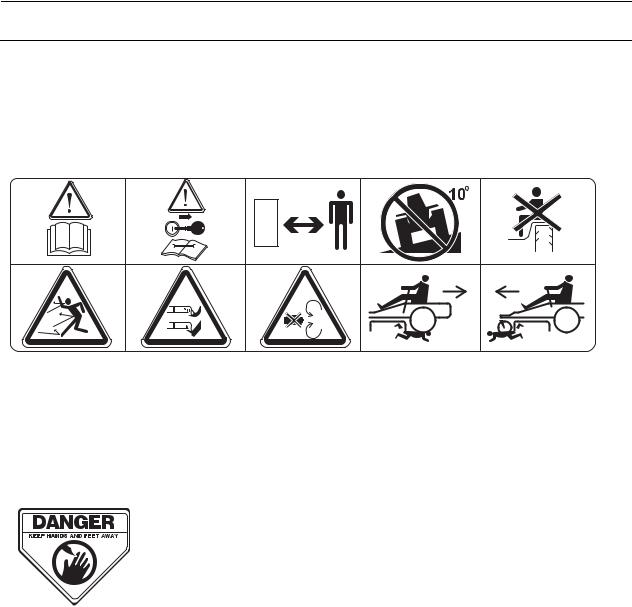

SYMBOLS AND DECALS

Read |

Shut off engine |

Operator´s |

& remove key |

Manual. |

before |

|

performing any |

|

maintenance or |

|

repair work. |

Whole |

Severing |

body |

of fingers |

exposure |

& toes. |

to thrown |

|

objects. |

|

Moving sharp blades under cover

Keep a safe distance from the machine.

Do not open or remove safety shields while engine is running.

Use on |

|

No |

|

|||||||||

slopes no |

|

passengers |

|

|||||||||

greater |

|

|

|

|

|

|

|

|

||||

than 10°. |

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Careful |

Careful going |

backing up, |

forward, |

watch for |

watch for |

other people. |

other people. |

English-6

SAFETY INSTRUCTIONS

Safety Instructions

These instructions are for your safety. Read them carefully.

WARNING!

This symbol means that important safety instructions need to be emphasized. It concerns your safety.

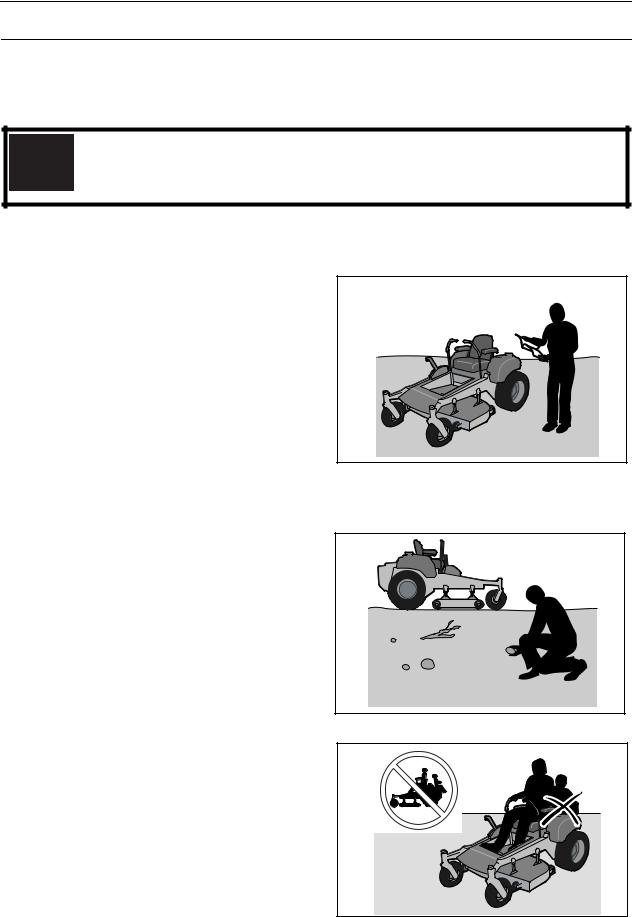

IMPORTANT: THIS CUTTING MACHINE IS CAPABLE OF AMPUTATING HANDS AND FEET AND THROWING OBJECTS. FAILURE TO OBSERVE THE FOLLOWING SAFETY INSTRUCTIONS COULD RESULT IN SERIOUS INJURY OR DEATH.

General Operation

•Read, understand, and follow all instructions on the machine and in the manual before starting.

•Do not put hands or feet near rotating parts or under the machine. Keep clear of the discharge opening at all times.

•Only allow responsible adults, who are familiar with the instructions, to operate the machine.

•Clear the area of objects such as rocks, toys, wire, etc., which could be picked up and thrown by the blades.

•Be sure the area is clear of bystanders and pets before operating. Stop machine if anyone enters the area.

•Never carry passengers. The machine is only intended for use by one person.

•Do not mow in reverse unless absolutely necessary. Always look down and behind before and while backing.

•Never direct discharged material toward anyone. Avoid discharging material against a wall or obstruction. Material may ricochet back toward the operator. Stop the blades when crossing gravel surfaces.

•Do not operate machine without the entire grass catcher, discharge guard, or other safety devices in place and working

•Slow down before turning.

•Never leave a running machine unattended. Always turn off blades, set parking brake, stop engine, and remove keys before dismounting.

8011-512

Read the operator’s manual before starting the machine

8011-513

Clear the area of objects before mowing

8011-520

Never take passengers

English-7

SAFETY INSTRUCTIONS

•Disengage blades when not mowing. Shut off engine and wait for all parts to come to a complete stop before cleaning the machine, removing the grass catcher, or unclogging the discharge guard.

•Operate machine only in daylight or good artificial light.

•Do not operate the machine while under the influence of alcohol or drugs.

•Watch for traffic when operating near or crossing roadways.

•Use extra care when loading or unloading the machine into a trailer or truck.

•Always wear eye protection when operating machine.

•Data indicates that operators, age 60 years and above, are involved in a large percentage of riding mower-related injuries. These operators should evaluate their ability to operate the riding mower safely enough to protect themselves and others from serious injury.

•Follow the manufacturer’s recommendation for wheel weights or counterweights.

•Never allow children or other persons not trained in the use of the machine to use or service it. Local laws may regulate the age of the user. Anyone who operates this machine should first read and understand this Operator’s Manual.

•Keep machine free of grass, leaves or other debris build-up which can touch hot exhaust / engine part and burn. Do not allow the mower deck to plow leaves or other debris which can cause build-up to occur. Clean any oil or fuel spillage before operating or storing the machine. Allow machine to cool before storage.

WARNING!

Engine exhaust and certain vehicle components contain or emit chemicals considered to cause cancer, birth defects, or other reproductive system damage. The engine exhaust contains carbon monoxide, which is a odorless, colorless, poisonous gas. Do not use the machine in enclosed spaces.

English-8

SAFETY INSTRUCTIONS

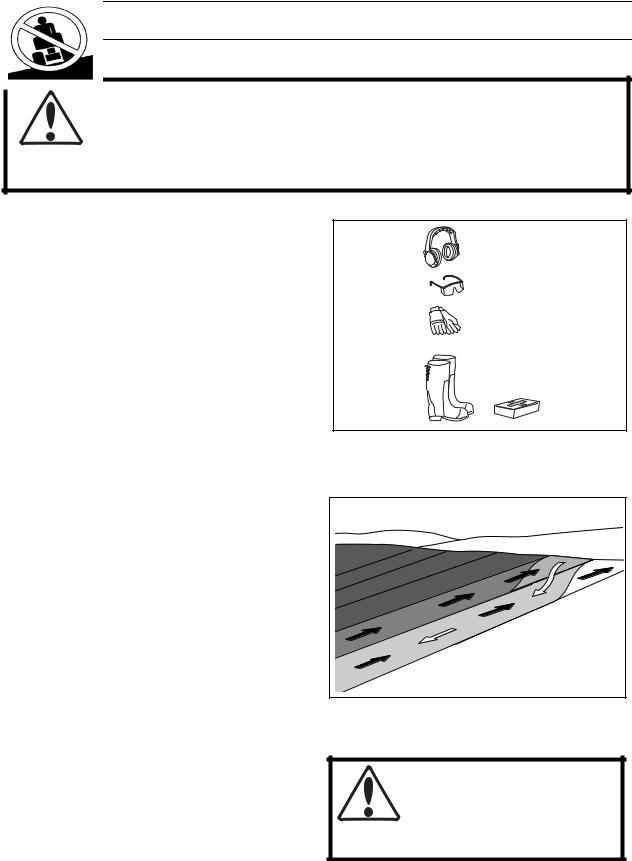

Personal Safety Equipment

WARNING!

When using the machine, approved personal protective equipment (shown in illustrations) shall be used. Personal protective equipment cannot eliminate the risk of injury but it will reduce the degree of injury if an accident does happen. Ask your retailer for help in choosing the right equipment.

•Make sure that you have first aid equipment close at hand when using the machine.

• Never use the machine when barefoot. Always wear protective shoes or boots, preferably with steel toecaps.

•Always wear approved protective glasses

or a full visor when assembling or driving.

•Always wear gloves when handling the

blades.

• |

Never wear loose clothing that can get caught |

|

|

in moving parts. |

|

• |

Use ear protectors to avoid damage to |

|

|

hearing. |

8011-670 |

|

|

|

|

|

Personal protective equipment |

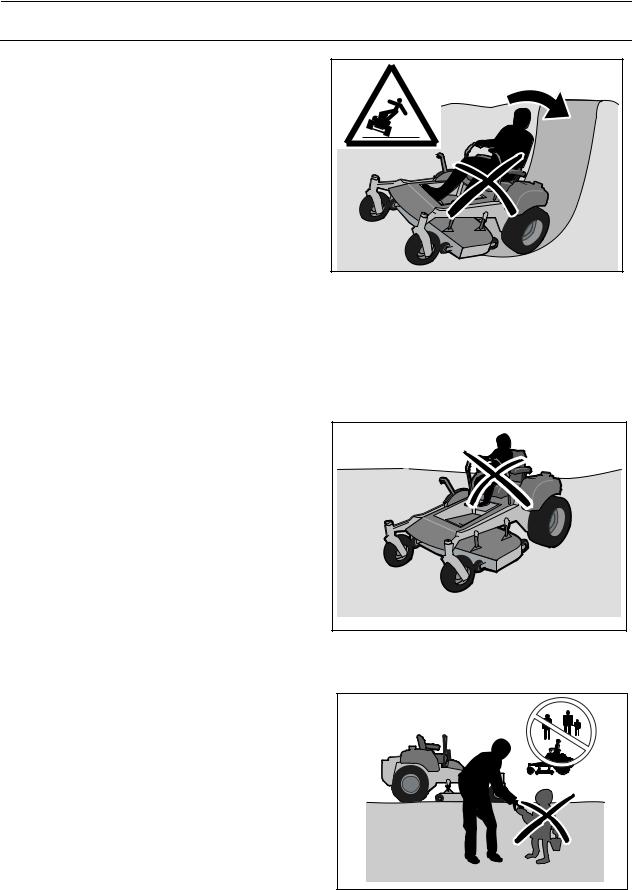

Slope Operation

Slopes are a major factor related to loss of control and tip-over accidents, which can result in severe injury or death. Operation on all slopes requires extra caution. If you cannot back up the slope or if you feel uneasy on it, do not mow it.

•Mow up and down slopes (10 degrees maximium), not across.

•Watch for holes, ruts, bumps, rocks, or other hidden objects. Uneven terrain could overturn the machine. Tall grass can hide obstacles.

•Choose a low ground speed so that you will not have to stop while on the slope.

•Do not mow on wet grass. Tires may lose traction.

•Avoid starting, stopping, or turning on a slope. If the tires lose traction, disengage the blades and proceed slowly straight down the slope.

•Keep all movement on the slopes slow and gradual. Do not make sudden changes in speed or direction, which could cause the machine to roll over.

6003-004 |

Mow up and down, not side-to-side

WARNING!

Do not drive up or down hills with slopes greater than 10 degrees. And do not drive across any slopes.

English-9

SAFETY INSTRUCTIONS

•Use extra care while operating machine with grass catchers or other attachments; they can affect the stability of the machine. Do not use on steep slopes.

•Do not try to stabilize the machine by putting your foot on the ground.

•Do not mow near drop-offs, ditches, or embankments. The machine could suddenly roll over if a wheel is over the edge or if the edge caves in.

•Do not make any sudden changes in speed or direction

•Take special care if attachments are fitted that can change the stability of the machine.

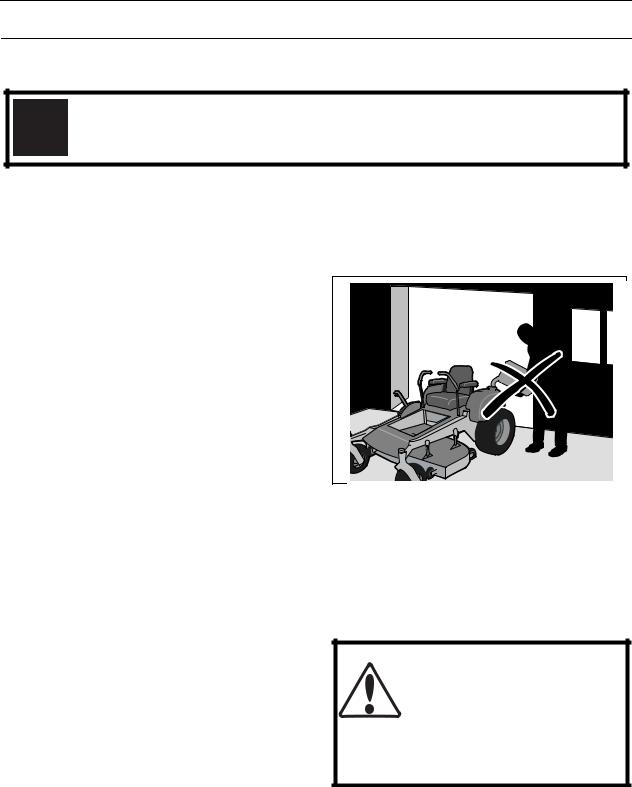

Children

Tragic accidents can occur if the operator is not alert to the presence of children. Children are often attracted to the machine and the mowing activity. Never assume that children will remain where you last saw them.

•Keep children out of the mowing area and in the watchful care of a responsible adult other than the operator.

•Be alert and turn machine off if a child enters the area.

•Before and while backing, look behind and down for children.

•Never carry children, even with the blades shut off. They may fall off and be seriously injured or interfere with safe machine operation. Children who have been given rides in the past may suddenly appear in the mowing area for another ride and be run over or backed over by the machine.

•Never allow children to operate the machine.

•Use extra care when approaching blind corners, shrubs, trees, or other objects that may block your view of a child.

8011-519 |

Be extra cautious when driving on slopes

8011-517 |

Never allow children to operate the machine

8011-518

Keep children away from the work area

English-10

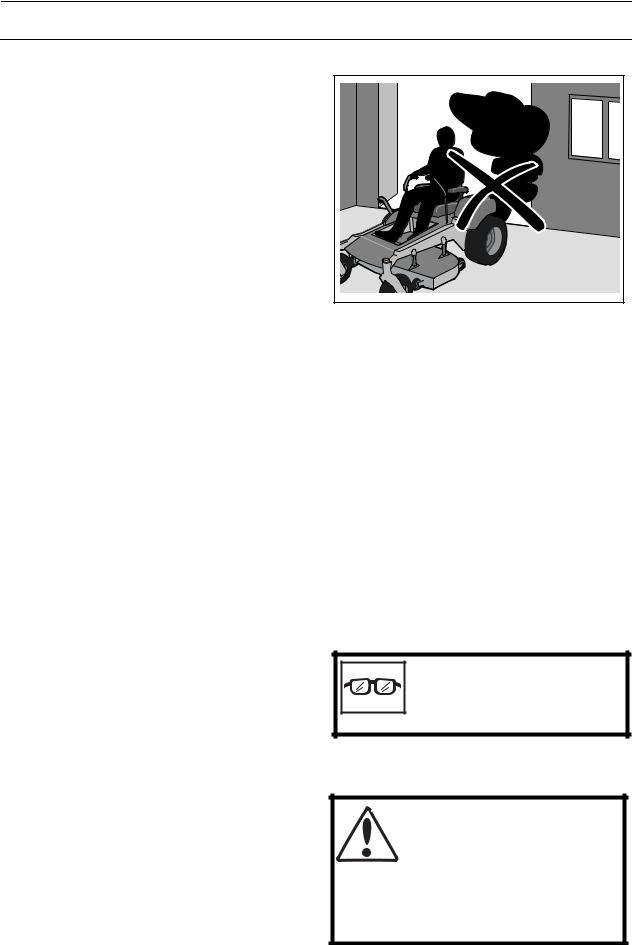

SAFETY INSTRUCTIONS

Maintenance

WARNING!

The engine must not be started when the driver’s floor plate or any protective plate for the mower deck’s drive belt is removed.

Safe Handling of Gasoline

To avoid personal injury or property damage, use extreme care in handling gasoline. Gasoline is extremely flammable and the vapors are explosive.

•Extinguish all cigarettes, cigars, pipes, and other sources of ignition.

•Use only approved gasoline container.

•Never remove gas cap or add fuel with the engine running. Allow engine to cool at least two (2) minutes before refueling.

•Never fuel the machine indoors.

•Never store the machine or fuel container where there is an open flame, spark, or pilot light such as on a water heater or other appliances.

•Never fill containers inside a vehicle or on a truck or trailer bed with plastic liner. Always place containers on the ground away from your vehicle when filling.

•Remove gas-powered equipment from the truck or tailer and refuel it on the ground. If this is not possible, then refuel such equipment with a portable container, rather than from a gasoline dispenser nozzle.

•Keep the nozzle in contact with the rim of the fuel tank or container opening at all times until fueling is complete. Do not use a nozzle lock-open device.

•If fuel is spilled on clothing, change clothing immediately.

•Never overfill fuel tank. Replace gas cap and tighten securely.

•Do not start the engine near spilled fuel.

•Never use gasoline as a cleaning agent.

•If leaks arise in the fuel system, the engine must not be started until the problem has been resolved.

•Check the fuel level before each use and leave space for the fuel to expand, because the heat from the engine and

8011-516 |

Never fill the fuel tank indoors

WARNING!

The engine and the exhaust system, become very hot during operation.

Risk for burns if touched.

Allow engine and exhaust system to cool at least two (2) minutes before refueling

English-11

SAFETY INSTRUCTIONS

the sun may otherwise cause the fuel to expand and overflow.

General Maintenance

•Never operate machine in a closed area.

•Keep all nuts and bolts tight to be sure the equipment is in safe working condition.

•Never tamper with safety devices. Check their proper operation regularly.

•Keep machine free of grass, leaves, or other debris build-up. Clean oil or fuel spillage and remove any fuel-soaked debris. Allow machine to cool before storing.

•If you strike a foreign object, stop and inspect the machine. Repair, if necessary, before restarting.

•Never make any adjustments or repairs with the engine running. Prevent starting by removing the spark plug wire before making adjustments or carrying out maintenance.

•Check grass catcher components and the discharge guard frequently and replace with manufacturer’s recommended parts, when necessary.

•Mower blades are sharp. Wrap the blade or wear gloves, and use extra caution when servicing them.

•Check brake operation frequently. Adjust and service as required.

•Maintain or replace safety and instruction labels, as necessary.

•Do not modify safety equipment. Check regularly to be sure it works properly. The machine must not be driven with defective or unmounted protective plates, protective cowlings, safety switches, or other protective devices.

•Do not change the settings of governors and avoid running the engine with overly high engine speeds. If you run the engine too fast, you risk damaging the machine components.

•Be very careful when handling battery acid. Acid on skin can cause serious corrosive burns. If you spill battery acid on your skin, rinse immediately with water.

English-12

8011-515 |

Never drive the machine in an enclosed space

Always use protective glasses when handling the battery.

WARNING!

The battery contains lead and lead compounds, chemicals that are considered to cause cancer, birth defects, and other reproductive system damage. Wash your hands after handling the battery.

SAFETY INSTRUCTIONS

•Acid in the eyes can cause blindness, contact a doctor immediately.

•Be careful when servicing the battery. Explosive gases form in the battery. Never perform maintenance on the battery when smoking or near open flames or sparks. The battery can explode and cause serious injury/damage.

•Ensure that nuts and bolts, especially the fastening bolts for the blade attachments, are properly tightened, torqued and that the equipment is in good condition.

•

•Sparking can occur when working with the battery and the heavy cables of the starter circuit. This can cause battery explosion, fire or eye injury. Sparking in this circuit can not occur after the chassis cable (normally negative, black) is removed from the battery.

WARNING!

Avoid electrical sparking and its consequences by the following routines:

•Use protective goggles.

•Ensure that the fuel filler cap is mounted tightly and no flammable substances is stored in an open vessel.

•Never work with the starter circuit if there is spilled fuel.

•Disconnect the chassis cable from the battery first and reconnect it last.

•Do not make a bridge short circuit across the starter relay to run the starter.

•Never use the machine indoors or in spaces lacking proper ventilation. The exhaust fumes contain carbon monoxide, an odorless, poisonous, and lethal gas.

•Stop and inspect the equipment if you run over or into anything. If necessary, make repairs before starting.

•Never make adjustments with the engine running.

•The machine is tested and approved only with the equipment originally provided or

6003-009 |

Do not smoke when performing maintenance on the battery. The battery can explode and cause serious injury/damage

8009-728

Risk of sparking

English-13

SAFETY INSTRUCTIONS

recommended by the manufacturer. Only use approved repair parts for the machine.

•The blades are sharp and can cause cuts and gashes. Wrap the blades or use protective gloves when handling them.

•Check the parking brake’s functionality regularly. Adjust and service as necessary.

•The mulch blades should only be used in familiar areas when higher quality mowing is desired.

•Reduce the risk of fire after using the machine by removing grass, leaves, and other debris that may have accumulated on the machine. Allow the machine to cool before putting it in storage.

•Clean deck and underside of deck after each use and, avoid spraying engine and electrical components with water.

Transport

•The machine is heavy and can cause serious crushing injuries. Be extra cautious when it is loaded on or unloaded from a vehicle or trailer.

•Use an approved trailer to transport the machine. Activate the parking brake, turn off the fuel supply, and fasten the machine with approved fastening devices, such as bands, chains, or straps, when transporting.

•Do not operate this machine on public roadways.

•Check and abide by local traffic regulations before transporting the machine on any road.

•Do not tow this machine, it may cause damage to the drive system.

•Do not tow any trailers, etc. with this mower. They may jackknife or overturn causing damage to the mower and possibly serious injury to the operator.

•Load the unit onto truck or trailer by driving up ramps of suitable strength using a slow speed. Do not lift! The machine is not intended to be lifted by hand.

8011-644 |

Clean the machine regularly

IMPORTANT INFORMATION

The parking brake is not sufficient to lock the machine in place during transport. Ensure that the machine is well fastened to the transport vehicle. Always reverse the machine onto the transport vehicle to avoid tipping it over.

English-14

SAFETY INSTRUCTIONS

Customer responsibilities

•Read and observe the safety rules.

•Follow a regular schedule in maintaining, caring for and using your mower.

•Follow the instructions under "Maintenance” and "Storage” sections of this owner’s manual.

•This machine has no brain. Use yours!

WARNING!

This mower is equipped with an internal combustion engine and should not be used on or near any unimproved forest-covered, bush-covered or grass-covered land unless the engine’s exhaust system is equipped with a spark arrester meeting applicable local or state laws (if any). If a spark arrester is used, it should be maintained in effective working order by the operator.

A spark arrester for the muffler is available through your authorized Dixon dealer.

English-15

CONTROLS

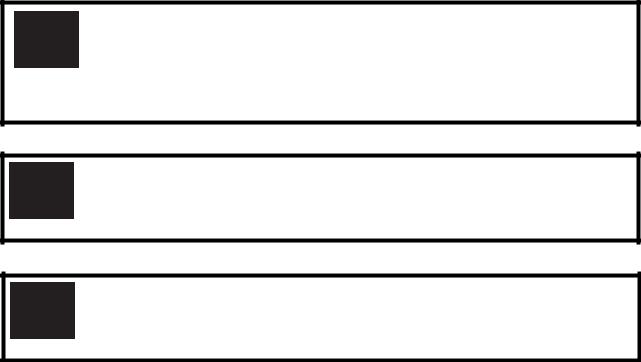

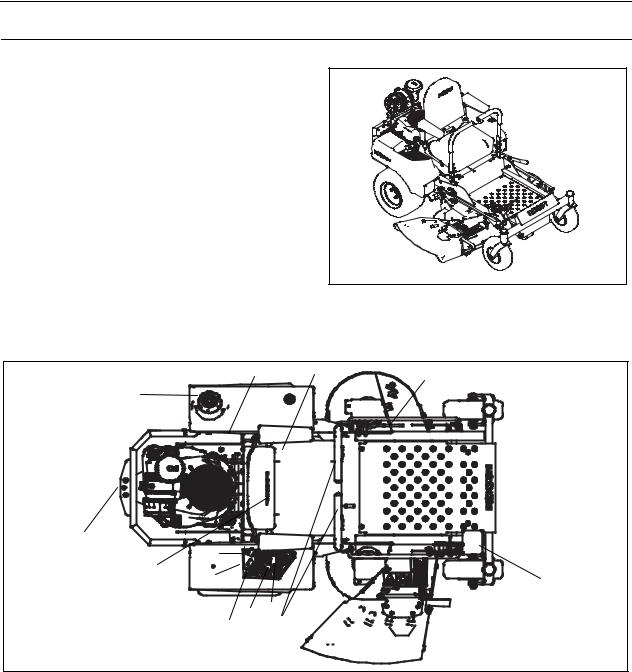

Controls

This operator’s manual describes the Dixon Zero Turn Rider. The rider is fitted with a Briggs & Stratton, Kohler, Honda or Kawasaki four stroke V-twin engine developing 20 - 26 horse power.

Transmission from the engine is made via two belt-driven hydraulic transaxles, one for each drive wheel. Using the left and right steering controls, the flow is regulated and thereby the direction and speed.

Zero Turn Rider |

8050-145 |

|

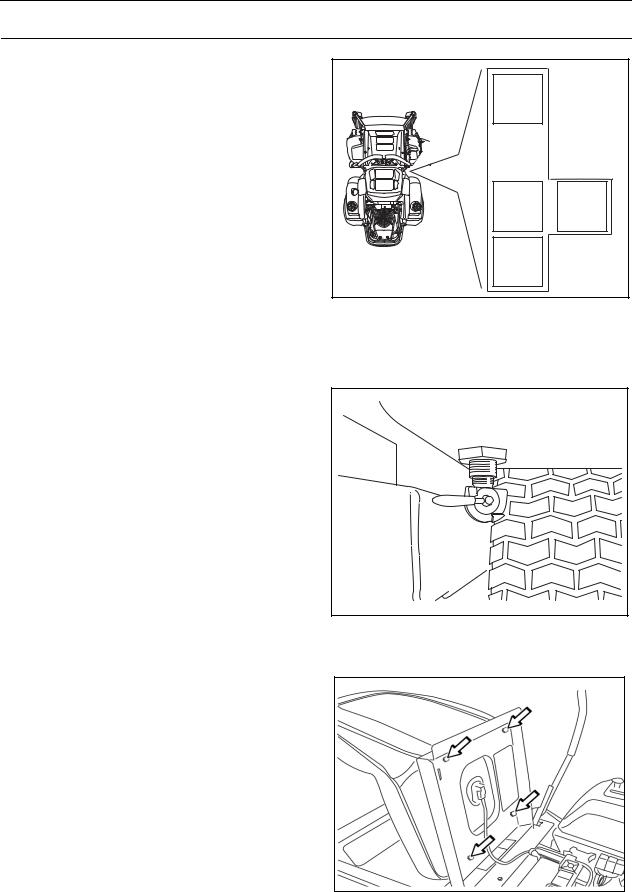

Control Locations

3 |

7 |

1 |

5

|

6 |

9 |

|

|

|

|

4 |

|

|

|

|

|

11 |

|

|

13 |

|

|

|

|

|

|

|

|

|

12 |

10 |

|

|

|

|

8 |

2 |

|

|

Locations of the controls |

|

|

|

8050-146 |

|

|

|

|

|

||

|

|

Page |

|

|

Page |

1. |

Parking brake |

17 |

8. |

Hour meter |

21 |

2. |

Motion control levers |

16 |

9. |

Choke control |

21 |

3. |

Fuel shut off valve |

18 |

10. |

Ignition switch |

21 |

4. |

Seat adjustment bolts |

18 |

11. |

Throttle control |

22 |

5. |

Fuel tank cap |

19 |

12. |

Blade switch |

22 |

6. |

By pass linkage |

19 |

13. |

Cutting height pedal |

23 |

7. |

Fuses |

20 |

|

|

|

English-16

CONTROLS

1. Parking Brake

IMPORTANT INFORMATION

The machine must be absolutely standing still when applying the parking brake.

The parking brake is found on the left of the machine. Pull the lever backward to activate the brake and forward to release it.

8011-711 |

Parking brake not activated

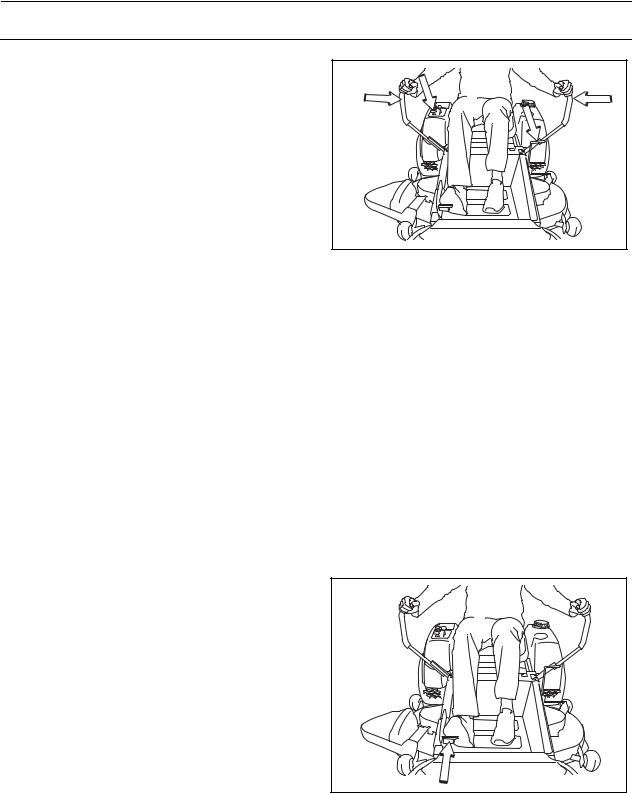

2. Motion Control Levers

The machine’s speed and direction are continuously variable using the two steering controls. The steering controls can be moved forward or backward about a neutral position. Furthermore, there is a neutral position, which is locked if the steering controls are moved outward.

When both controls are in the neutral position (N), the machine stands still.

By moving both controls an equal amount forward or backward, the machine moves in a straight line forward or backward respectively.

In order, for example, to turn right while moving forward, move the right control towards the neutral position. The rotation of the right wheel is reduced and the machine turns to the right.

Zero turn can be achieved by moving one control backward (behind the neutral position) and carefully moving the other steering control forward from its neutral position. The rotation direction when zero turning is determined by which steering control is moved backward behind the neutral position. If the left steering control is pulled backward, the machine turns to the left. Use extra care when using this maneuver.

If the steering controls are in uneven

8011-789

Steering controls

WARNING!

The machine can turn very rapidly if one steering control is moved much further forward than the other.

English-17

CONTROLS

positions when standing still or do not fit in the slots for moving the controls outward, they can be adjusted.

Tracking

If the mower is not tracking straight, check the air pressure in both rear tires. Recommended air pressure is 15 psi. (1 bar) Tracking must be checked on a flat and level concrete or blacktop surface. If the unit still does not track straight contact your Dixon workshop for adjustments.

3. Fuel Shut Off Valve

The fuel shut off valve is located under the fuel tank. The valve has two positions; ON and OFF.

4. Seat adjustment bolts

With the machine off remove the two bolts holding the seat pan down and flip the seat forward.

The seat can be adjusted lengthways. When making adjustments, loosen the four bolts under the seat pan, after which the seat can be moved backward or forward.

Once the seat is adjusted to your liking. Flip the seat back down and rebolt the seat pan to the frame.

1 |

|

2 |

3 |

4 |

|

1. Forward |

8011-791 |

|

2.Neutral

3.Neutral slot, Neutral lock

4.Reverse

Fuel shut off valve in OFF position

8011-712 |

Fuel shut off valve in OFF position

CZ-1

Lengthways adjustment

English-18

CONTROLS

5. Refueling

Read the safety instructions before refueling. The machine has one fuel tank, just behind the seat. The tank volume is 5.4 gallons (20.4 liters).

Make sure the fuel cap is properly tightened and the cap gasket is not damaged.

The engine will run on a minimum of 85octane unleaded gasoline (no oil mix). Environmentally adapted alkylate gasoline can be used beneficially. See also Technical Data concerning ethanol fuel. Methanol fuel is not allowed.

WARNING!

Gasoline is highly flammable. Observe caution and fill the tank outdoors

(see the safety instruction).

WARNING!

The engine and the exhaust system, become very hot during operation.

Risk for burns if touched.

Allow engine and exhaust system to cool at least two (2) minutes before refueling

WARNING!

Fill to bottom of filler neck. Do not overfill. Wipe off any spilled oil or fuel. Do not store, spill or use gasoline near an open flame.

When operating in temperatures below 32° F. (0° C.), use fresh, clean winter grade gasoline to help insure good cold weather starting.

8011-761 |

Fuel tank

IMPORTANT INFORMATION

Experience indicates that alcohol blended fuels (called gasohol, ethanol or methanol) can attract moisture which leads to separation and formation of acids during storage. Acidic gas can damage the fuel system of an engine while in storage. To avoid engine problems, the fuel system should be emptied before storage of 30 days or longer. Drain the gas tank, start the engine and let it run until the fuel lines and carburetor are empty. Use fresh fuel the next season. See Storage Instructions for additional information. Never use engine or carburetor cleaners in the fuel tank or permanent damage may occur.

English-19

CONTROLS

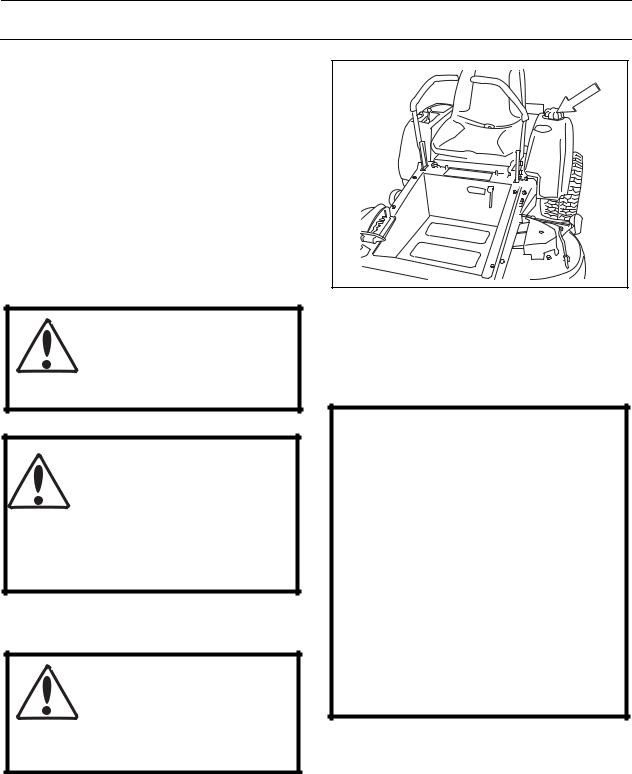

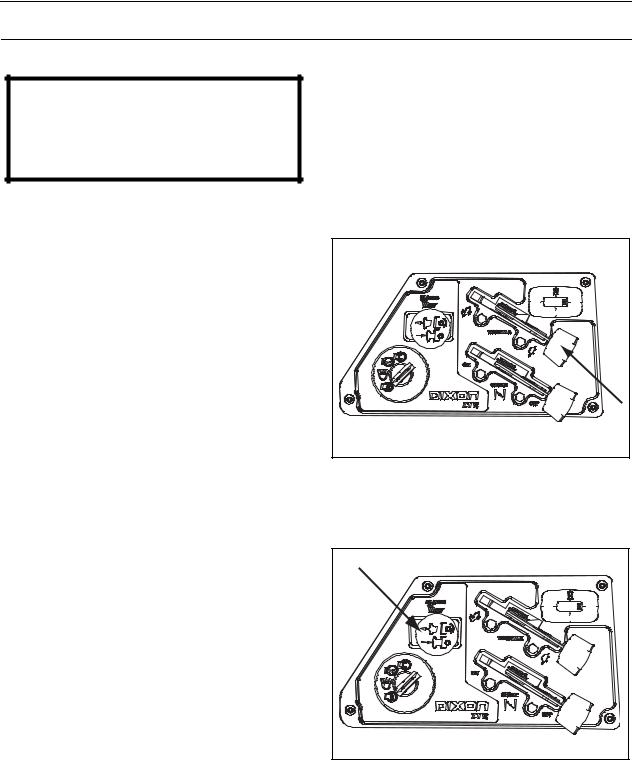

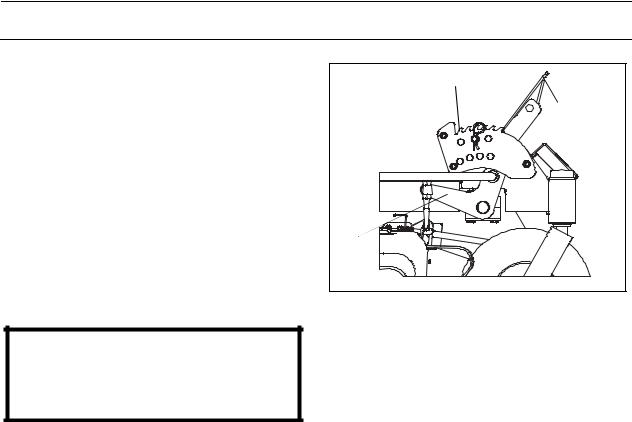

6. By pass linkage

When pushing or pulling the mower, be sure to engage the IZT (Integrated Zeroturn Transaxle) bypass linkages. The IZT bypass linkages are located on the rear of the frame, below the rear engine guard.

•Raise the deck into the highest cutting position.

•Pull the IZT bypass linkages out and into the slots and release so that it is held in the bypass position.

•To reengage the IZT’s to drive, reverse the above procedure.

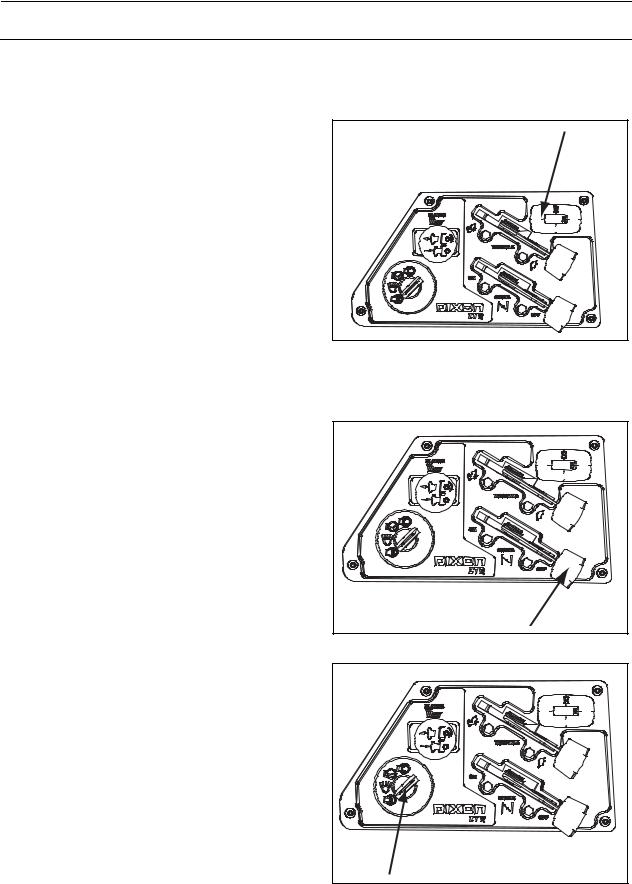

7. Fuses

The fuses are located in a holder at the right hand side of the battery compartment. They are flat pin fuses of the same type used in automobiles.

There are two fuses.

Fuse ratings and functions:

•20 A, Primary fuse.

•7.5 A, Mower deck coupling.

CZ10-2 |

1. IZT Bypass linkage

Bypass linkages

1

2

2

CZ12

1.Head outside of rear deck

2.IZT Bypass linkage in bypass position

Bypass position

8011-483

Fuses

English-20

CONTROLS

8. Hour Meter

The hour meter displays the total operating time.

It will flash CHG OIL (Change Oil) at 50 hour intervals. The flash duration is one hour before and one hour after the interval. The CHG OIL icon will come on and shut off automatically. The hour meter can not be manually reset.

9. Choke Control

The choke control is used for cold starts in order to provide the engine with a richer fuel mixture.

For cold starts the control should be pulled out.

10. Ignition Switch

The ignition key is placed on the control panel and is used to start and stop the engine.

8050-147 |

Hour meter

8050-148 |

Choke control

8050-149 |

Ignition key

English-21

CONTROLS

IMPORTANT INFORMATION

Do not run the starter for more than five seconds each time. If the engine does not start, wait about 10 seconds before retrying.

11. Throttle Control

The throttle control regulates the engine speed and thereby the rate of rotation of the blades, assuming the blade switch is pulled out, see Engaging the Mower Deck.

In order to increase or decrease the engine speed, the control is moved forward or backward respectively.

Avoid idling the engine for long periods, as there is a risk of fouling the spark plugs.

USE FULL THROTTLE WHEN MOWING, for best mower performance and battery charging.

12. Blade switch

In order to engage the mower deck, pull the knob out; the mower blades are disengaged when the knob is depressed.

8050-150 |

Throttle control

8050-151 |

Blade Switch

English-22

CONTROLS

13. Cutting height pedal

The cutting deck height is obtained by pressing the foot pedal lift arm forward and releasing the transport latch. Then lower the deck to the preset height. To raise the deck push forward on the foot pedal lift arm until the transport latch locks. The cutting height range is from 1 1/2" (38 mm) to 4 1/2"

(114 mm) in 1/4" (6.4 mm) increments. The heights are measured from the ground up to the blade tip with the engine not running.

To change cutting heights move the pin on the cutting height plates to the desired height of cut.

IMPORTANT INFORMATION

In order to obtain an even cutting height it is important that the air pressure in all four tires is the same 15 psi (1 bar).

3 |

1 |

2 |

1. Foot pedal |

8050-152 |

|

2.Lift arm

3.Height plate

Cutting height pedal

Accessories

For mulching, there is a BioClip attachment available. This is mounted underneath the mower deck and consists of control plates and BioClip blades.

English-23

OPERATION

Operation

Read "Safety Instructions", the "Controls" section and following pages, if you are unfamiliar with the machine. Conduct all daily maintenance on the machine before starting.

Training

Zero turn mowers are far more manueverable than typical riding mowers due to their unique steering capabilities.

We suggest when first operating the mower, use a reduced throttle speed and reduced ground speed by NOT moving control levers to the furthest forward or reverse positions during initial operation, or until operator becomes comfortable with controls. We also suggest first time users, or new users to ZeroTurn mowers to become familiar with the mowers movement on a hard surface, such as concrete or blacktop PRIOR to attempting to operate on turf. Until operator becomes comfortable with mower controls and zero turning capability, they may damage turf due to over aggressive maneuvers.

To move forward and backward

The direction and speed of the mowers movements is effected by the movement of the control lever(s) on each side of mower. The left control lever controls the left wheel. The right control lever controls the right wheel.

IMPORTANT INFORMATION

When control levers are in the reverse position they return to neutral when released. This may cause the mower to suddenly stop.

First time users should push mower (see "Moving by Hand" in the "Operation" section) to an open, flat area, without other people or vehicles/obstacles near by. In order to move unit under its own power, the operator must be in the seat, start engine (see " Before Starting" in "Operation" section), adjust engine speed to idle, disengage park brake, do not engage blades at this time, rotate control levers inward. As long as the control levers have not been moved forward or backwards, mower will not move. Slowly move both control levers forward slightly, this will allow mower to start moving forward in a straight line. Pull back on control levers to the neutral position and mower should stop moving. Pull back slightly on control levers, this will allow mower to start moving backwards. Push forward on control levers to the neutral position and mower should stop moving.

To turn to the right

While moving in a forward direction, pull the right lever back towards the neutral position while maintaining the position of the left lever, this will slow the rotation of the right wheel and cause the machine to turn in that direction.

To turn to the left

While moving in a forward direction pull the left lever back towards the neutral position while maintaining the position of the right lever, this will slow the rotation of the left wheel and cause the machine to turn in that direction.

To zero turn

While moving in a forward direction, first pull both control levers back until the mower stops or slows dramatically. Then by alternating one lever slightly to the forward position and the other in the reverse position.

English-24

OPERATION

Before Starting

•Read the sections Safety Instructions and Controls before starting the machine.

•Perform the daily maintenance before starting (see Maintenance Schedule in the Maintenance section).

•Check that there is sufficient fuel in the fuel tank.

•Make sure all guards are in place and in good condition.

•Adjust the seat to the desired position.

The following conditions must be fulfilled before the engine can be started:

•the driver must be seated on the seat,

•the blade switch for engaging the mower blades must be depressed,

•the parking brake must be on,

•use the personal safety equipment described in the safety instruction section,

•both steering controls must be in the locked (outer) neutral position.

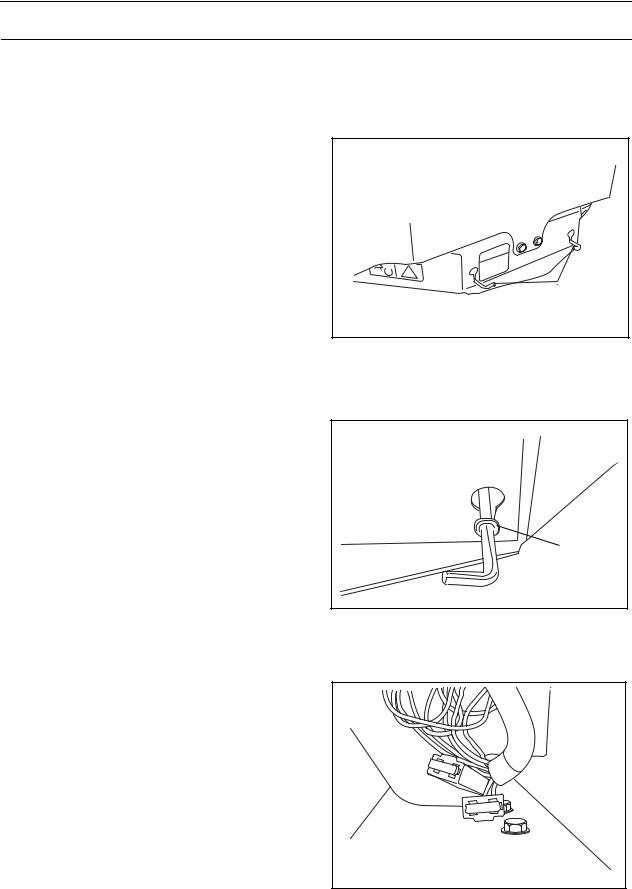

Starting the Engine

1.Sit on the seat.

2.Raise the mower deck by depressing the pedal forward to the locked position (transport position). The mower deck will latch in the transport position when the lift pedal is fully depressed.

3.Activate the parking brake.

8011-718 |

Start conditions

8011-718-2 |

Raise the mower deck

English-25

Loading...

Loading...