Black & Decker 2187, 2233, 2097, 2227 User Manual

LEVEL COMMAND |

2097 / 2187 / 2227 / 2233 |

|||||

WITH 9210 COMPRESSOR |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

60 |

90 |

|

|

400 |

600 |

|

|

|

|

30 |

200 |

|

800 120 |

|

|

||

|

psi |

|

1000 |

|

kPa |

PSI |

|

|

|

0 150

LEVEL COMMAND

INSTALLATION INSTRUCTIONS

Congratulations on your purchase of a new Level Command kit. This kit was designed to provide inflation control of your air helper springs. This kit will be an asset to your vehicle, meeting nearly all of your air supply needs.

Please take a few minutes to read through the instructions, identify the components, and learn how to properly install your Level Command kit.

NOTE:

The Level Command kit can be used with all air helper spring products. If you are installing an air suspension system, do not install the air line tubing to the air springs as stated in the suspension system instruction manual. If you are adding the Level Command kit to an existing air suspension system, you will need to deflate the air springs and remove the air line tubing.

PARTS LIST

NOTE ON CONNECTING THE AIR LINE TUBING:

Cut the air line tubing as squarely as possible. To connect the air line tubing to the fittings, push the tubing into the fittings as far as possible. If for any reason the tubing must be removed, first release the air pressure from the air helper spring. Push the collar toward the body of the fitting and the pull out the tubing. To reassemble, make sure the tubing is cut squarely and push the tubing back into the fitting.

TOOLS REQUIRED:

• |

3/16" DRILL BIT |

• |

3/8" DRILL BIT |

• |

1/4" DRILL BIT |

• |

POWER DRILL |

• |

WIRE CRIMPER/STRIPPER |

• |

PLIERS |

• |

PHILLIPS SCREW DRIVER |

• UTILITY KNIFE |

|

• |

(2) 7/16" WRENCHES |

• |

CENTER PUNCH |

SINGLE AIR CONTROL PANEL |

|

1 |

#10 FLAT WASHER |

7 |

COMPRESSOR |

9210 |

1 |

15 FT. 16 GAGE WIRE |

1 |

30 FT. AIR LINE TUBING |

|

1 |

IN-LINE FUSE HOLDER |

1 |

1/8" NPT PUSH-TO-CONNECT |

|

|

20 AMP BLADE FUSE |

1 |

STRAIGHT FITTING |

3055 |

1 |

FEMALE SPADE CONNECTOR |

2 |

PUSH-TO-CONNECT |

|

|

MALE SPADE CONNECTOR |

1 |

T-FITTING |

3025 |

2 |

RING TERMINAL |

1 |

10 -32 x 1" MACHINE SCREW |

|

5 |

WIRE CONNECTOR |

2 |

10 -32 LOCK NUT |

|

5 |

NYLON TIE |

15 |

|

|

|

|

|

|

|

|

|

|

24-8204 |

|

|

03-01 |

NAD-30665-2 |

|

|

|

|

|

|

STRAIGHT AIR FITTING |

2227 |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

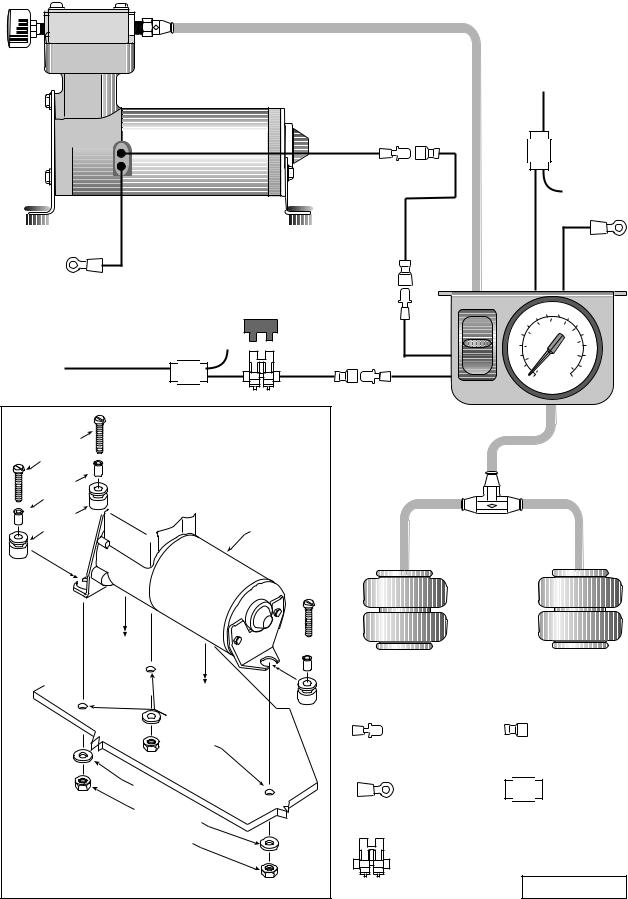

AIR LINE

POSITIVE, 12 VOLT

DASHBOARD

Air Line & Wiring Diagram ILLUMINATION

CIRCUIT

RED |

GROUND

BLACK (TO GROUND)

FUSE |

60 |

90 |

12 VOLT, 20 AMP |

|

MINIMUM IGNITION |

WHITE |

ACTIVATED CIRCUIT |

|

|

WHITE |

|

|

400 |

600 |

30 |

200 |

|

800 120 |

|

psi |

|

1000 |

|

kPa |

PSI |

|

|

|

0150

|

|

|

|

|

|

|

|

|

AIR LINE |

MACHINE |

Compressor Attachment |

|

|

||||||

1” SCREW |

|

|

|||||||

BRASS |

|

|

|

|

|

|

|

|

|

INSERTS |

|

|

|

|

|

|

COMPRESSOR |

|

|

RUBBER |

|

|

|

|

|

|

“T” FITTING |

||

ISOLATORS |

|

|

|

|

|

|

AIR |

|

|

|

|

|

|

|

|

|

|

AIR SPRING |

AIR SPRING |

|

|

|

|

|

|

|

|

(sold separately) |

(sold separately) |

|

|

|

|

|

|

VEHICLE |

PANEL |

Connectors: |

|

|

|

|

|

1/4” |

|

|

|||

|

|

|

|

|

|

|

|||

|

|

|

BE |

|

HOLES |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DRILLED TO |

Male spade connector |

Femal spade connector |

||

|

|

|

|

|

|

|

|

||

|

#10 |

FLAT |

|

|

|

|

|

|

|

|

|

WASHER |

|

Ring Terminal |

Wire connector |

||||

|

10/32” |

|

|

||||||

|

|

|

|

|

|

|

|

||

|

|

|

LOCK |

NUT |

|

|

|

||

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

Inline fuse connector |

Figure “A” |

Loading...

Loading...