Page 1

Service

GETtheMANUALS.org

Workshop Manual

Rapid NH 2014 ➤

Rapid Spaceback 2014 ➤

Body Work

Edition 10.2018

Service Department. Technical Information

Page 2

List of Workshop Manual Repair Groups

GETtheMANUALS.org

Re pa ir G ro up

50 - Body - front

55 - Bonnet, rear lid

57 - Front doors, door components, central locking

58 - Rear doors, door components

60 - Sunroof

63 - Bumpers

64 - Glazing

66 - Exterior equipment

68 - Interior equipment

69 - Passenger protection

70 - Trim, insulation

72 - Seat frames

74 - Seat - padding, covers

Service

Technical information should always be available to the foremen and mechanics, because their

careful and constant adherence to the instructions is essential to ensure vehicle road-worthiness and

safety. In addition, the normal basic safety precautions for working on motor vehicles must, as a

matter of course, be observed.

Page 3

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

GETtheMANUALS.org

Body Work - Edition 10.2018

Contents

50 - Body - front

1 Front body

1.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Lock carrier with components parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3 Service position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.4 Removing and installing lock carrier with component parts . . . . . . . . . . . . . . . . . . . . . . . . 4

1.5 Front wing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.6 Removing and installing the wing support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.7 Bulkhead plenum chamber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.8 Plenum chamber cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.9 Noise insulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.10 V-ribbed belt protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.11 Underfloor trim panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.12 Tunnel bridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

55 - Bonnet, rear lid

1 Front flap

1.1 Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1.2 Removing and installing the bonnet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1.3 Removing and installing the hinge for the front flap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1.4 Removing and installing the support bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

1.5 Lock and unlock components of front flap - Summary of components . . . . . . . . . . . . . . . . 25

1.6 Removing and installing front flap lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

1.7 Separating the Bowden cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

1.8 Removing and installing the locking clamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

1.9 Removing and installing the operating lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

1.10 Adjusting the bonnet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2 Tailgate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2.1 Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2.2 Removing and installing tailgate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2.3 Removing and installing the locking mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2.4 Adjusting tailgate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2.5 Removing and installing the tailgate lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

2.6 Removing and installing pressurized gas strut of tailgate . . . . . . . . . . . . . . . . . . . . . . . . . . 40

2.7 Tailgate seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3 Fuel tank lid unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3.1 Fuel-tank lid unit - Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3.2 Removing and installing fuel tank lid unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3.3 Fuel-tank lid unit (Spacebook)- Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4 Removing and installing fuel tank lid unit (Spacebook) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

57 - Front doors, door components, central locking

1 Front door

1.1 Assembly overview - door hanger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

1.2 Removing and installing the door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

1.3 Door adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

2 Door internal parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

2.1 Front door - Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

2.2 Removing and installing the door cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

2.3 Door handle and door lock - Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

2.4 Removing and installing cap for lock cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

2.5 Removing and installing lock cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

. . . . . . . . . . . . . . . . . . . . . . . . . . 45

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Contents i

Page 4

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

GETtheMANUALS.org

Body Work - Edition 10.2018

2.6 Removing and installing cap (without lock cylinder)

2.7 Removing and installing the door handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

2.8 Removing and installing the door lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

2.9 Removing and installing bearing bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

2.10 Front door window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

2.11 Removing and installing door window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

2.12 Removing and installing window lifter motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

2.13 Remove and install window lifter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

2.14 Removing and installing the window run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

2.15 Removing and installing the inner window channel strip . . . . . . . . . . . . . . . . . . . . . . . . . . 80

2.16 Removing and installing the outer window channel strip . . . . . . . . . . . . . . . . . . . . . . . . . . 81

2.17 Removing and installing the inside door seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

2.18 Removing and installing the outside door seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

3 Central locking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

3.1 Adjustment of radio control keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

3.2 Summary of components – battery for the (foldable) radio control key . . . . . . . . . . . . . . . . 85

3.3 Removing and installing the battery for the foldable key with radio remote control . . . . . . 86

58 - Rear doors, door components

1 Rear door

1.1 Assembly overview - door hanger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

1.2 Removing and installing the door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

1.3 Door adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

2 Door internal parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

2.1 Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

2.2 Removing and installing the cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

2.3 Removing and installing the door retaining strap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

2.4 Removing and installing the locking clamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

2.5 Door handle and door lock - Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

2.6 Removing and installing the cap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

2.7 Removing and installing the door handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

2.8 Removing and installing the door lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

2.9 Removing and installing bearing bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

2.10 Rear door window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

2.11 Removing and installing door window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

2.12 Removing and installing window lifter motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

2.13 Removing and installing the manual drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

2.14 Removing and installing window crank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

2.15 Remove and install window lifter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

2.16 Removing and installing the window run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

2.17 Removing and installing the rear fixed door window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

2.18 Removing and installing the rear fixed door window (Spaceback) . . . . . . . . . . . . . . . . . . . . 120

2.19 Removing and installing the inner window channel strip . . . . . . . . . . . . . . . . . . . . . . . . . . 121

2.20 Removing and installing the outer window channel strip . . . . . . . . . . . . . . . . . . . . . . . . . . 123

2.21 Removing and installing the inside door seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

2.22 Removing and installing the outside door seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

60 - Sunroof

1 Panoramic roof

1.1 Summary of components of panoramic roof . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

1.2 Removing and installing panoramic roof . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

2 Removing and installing roof roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

3 Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

63 - Bumpers

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

ii Contents

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Page 5

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

GETtheMANUALS.org

Body Work - Edition 10.2018

1 Front bumper

1.1 Front bumper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

1.2 Front bumper bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

2 Rear bumper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

2.1 Rear bumper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

2.2 Rear bumper bracket and runners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

3 Rear bumper (Spacebook) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

4 Cutting out the openings for the parking aid sensors (drill) . . . . . . . . . . . . . . . . . . . . . . . . 140

64 - Glazing

1 Glued windows

1.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

1.2 Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

1.3 Windscreen - Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

1.4 Removing windscreen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

1.5 Rear window - Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

1.6 Removing and installing the rear window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

1.7 Installing rear window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

1.8 Extended rear window (Spacebook)- Summary of components . . . . . . . . . . . . . . . . . . . . 149

1.9 Removing and installing extended rear window (Spacebook) . . . . . . . . . . . . . . . . . . . . . . 150

1.10 Removing and installing side window (Spacebook) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

1.11 Removing and installing side window (Spacebook) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

1.12 Preparing the new window for fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

1.13 Prepare body flange for fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

1.14 Installation instructions for all panes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

1.15 Minimum hardening time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

1.16 Window repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

1.17 Cleaning necessary due to soiling through glue sealing material . . . . . . . . . . . . . . . . . . . . 157

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

66 - Exterior equipment

1 Wheelhouse liner

1.1 Front wheelhouse liner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

1.2 Rear wheelhouse liner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

2 Exterior mirrors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

2.1 Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

3 Strips and trims . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

3.1 Summary of components - trim strips and covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

3.2 Removing and installing the cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

3.3 Removing and installing door sill panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

3.4 B-pillar trim panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

3.5 Cover strip of wing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

4 Rear spoiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

4.1 Rear spoiler - Rapid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

4.2 Rear spoiler - Spaceback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

5 Letterings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

5.1 Installation instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

5.2 Removing and installing the emblem on the tailgate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

5.3 Dimensions of letterings on the tailgate - Spaceback . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

5.4 Dimensions of letterings on the tailgate - Rapid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

5.5 Trailer coupling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

68 - Interior equipment

1 Interior rear-view mirror

1.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Contents iii

Page 6

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

GETtheMANUALS.org

Body Work - Edition 10.2018

1.2 Removing and installing the interior rear-view mirror

1.3 Glueing the retaining plate for the interior rear-view mirror . . . . . . . . . . . . . . . . . . . . . . . . 199

2 Covers, storage areas and trim panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

2.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

2.2 Centre console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

2.3 Summary of components – armrest . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

2.4 Removing and installing the sustainer (vehicles with armrest) . . . . . . . . . . . . . . . . . . . . . . 205

2.5 Removing and installing the armrest . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

2.6 Removing and installing the sun visor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

3 Recessed handles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

3.1 Removing and installing the recessed handles of the roof . . . . . . . . . . . . . . . . . . . . . . . . . . 210

69 - Passenger protection

1 Seat belts

1.1 Removing and installing the front seat belts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

1.2 Removing and installing the front seat belt height adjuster . . . . . . . . . . . . . . . . . . . . . . . . 214

1.3 Removing and installing the front seat belt buckle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

1.4 Removing and installing the front seat belt buckle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

1.5 Removing and installing the outer rear seat belts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

1.6 Removing and installing the rear middle seat belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

1.7 Removing and installing the rear seat belt buckle with lap belt . . . . . . . . . . . . . . . . . . . . . . 218

1.8 Removing and installing the rear double belt buckle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

2 Inspect seat belts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

2.1 Test sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

2.2 Special instructions for the belt tensioner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

2.3 Storage, transport and disposal of airbag, belt tensioner and battery separation units

(pyrotechnical components) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

3 Airbag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

3.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

3.2 Airbag system - Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

3.3 Observe the general safety instructions for working on airbag, belt tensioner and battery

separation units (pyrotechnical components) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

3.4 Special instructions for driver and front passenger airbag . . . . . . . . . . . . . . . . . . . . . . . . . . 226

3.5 Storage, transport and disposal of airbag, belt tensioner and battery separation units

(pyrotechnical components) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

3.6 Replacing parts of the airbag system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

3.7 Removing and installing the airbag control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

3.8 After replacement, configure the control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

3.9 Installing and removing sensor for side impact on the B-pillar . . . . . . . . . . . . . . . . . . . . . . 230

3.10 Installing and removing sensor for side impact on the C-pillar . . . . . . . . . . . . . . . . . . . . . . 230

3.11 Removing and installing front passenger airbag key switch . . . . . . . . . . . . . . . . . . . . . . . . 231

3.12 Summary of components of steering wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

3.13 Removing and installing driver airbag unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

3.14 Removing and installing restoring ring with slip ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

3.15 Removing and installing airbag unit on the passenger side . . . . . . . . . . . . . . . . . . . . . . . . 235

3.16 Removing and installing side airbag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

3.17 Head airbag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

70 - Trim, insulation

1 Dash panel

1.1 Removing and installing the dash panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

1.2 Removing and installing the glove compartment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

1.3 Removing and installing the steering column trim panel . . . . . . . . . . . . . . . . . . . . . . . . . . 251

1.4 Removing and installing the decorative trim of the dash panel . . . . . . . . . . . . . . . . . . . . . . 251

1.5 Removing and installing the cross member for the dash panel . . . . . . . . . . . . . . . . . . . . . . 252

1.6 Removing and installing impact absorbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

iv Contents

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Page 7

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

GETtheMANUALS.org

Body Work - Edition 10.2018

2 Door and side trim panels

2.1 Removing and installing the front door trim panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

2.2 Removing and installing the rear door trim panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

3 Trim panels of pillars . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

3.1 Removing and installing top trim panel of pillar A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

3.2 Removing and installing bottom trim panel of pillar A on the driver's side . . . . . . . . . . . . . . 264

3.3 Removing and installing bottom trim panel of pillar A on the front passenger side . . . . . . 265

3.4 Removing and installing top B-pillar trim panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

3.5 Removing and installing bottom B-pillar trim panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

3.6 Removing and installing trim panel of pillar C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

3.7 Removing and installing C and D pillar trim panels (Spaceback) . . . . . . . . . . . . . . . . . . . . 270

3.8 Door sill panel and wheel house trim panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

4 Tailgate trim panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

4.1 Removing and installing tailgate trim panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

4.2 Removing and installing the tailgate trim panel (Spaceback) . . . . . . . . . . . . . . . . . . . . . . . . 275

5 Luggage compartment trim panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

5.1 Removing and installing the tailgate/luggage compartment cover . . . . . . . . . . . . . . . . . . . . 277

5.2 Removing and installing top part of side luggage compartment trim panel . . . . . . . . . . . . 278

5.3 Removing and installing side luggage compartment trim panel . . . . . . . . . . . . . . . . . . . . . . 279

6 Removing and installing side luggage compartment trim panel . . . . . . . . . . . . . . . . . . . . . . 281

7 Moulded headliner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

7.1 Removing and installing moulded headliner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

7.2 Removing and installing the dampings and roof reinforcements . . . . . . . . . . . . . . . . . . . . 284

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

72 - Seat frames

1 Front seats

1.1 Removing and installing front seat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

1.2 Removing and installing the seat upholstery on the rail side (seat without height

adjustment) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

1.3 Removing and installing the seat upholstery on the rail side (seat with height adjustment)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

1.4 Removing and installing the operating lever of the seat height adjustment . . . . . . . . . . . . 291

1.5 Removing and installing the seat trim panel on the tunnel side . . . . . . . . . . . . . . . . . . . . . . 291

1.6 Removing and installing the grip for the seat height adjuster . . . . . . . . . . . . . . . . . . . . . . . . 292

1.7 Removing the headrest guides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 293

2 Rear seats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

2.1 Removing and installing the rear seat bench . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

3 Removing and installing backrests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 298

74 - Seat - padding, covers

1 Covers and upholstery of the front seats

1.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

1.2 Removing and installing the cover and the upholstery of the front seat cushions . . . . . . . . 299

1.3 Removing and installing the cover and the upholstery of the front seat backrest . . . . . . . . 301

2 Rear covers and seat upholstery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

2.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

2.2 Removing and installing cover and seat upholstery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

2.3 Removing and installing entire cover and backrest upholstery . . . . . . . . . . . . . . . . . . . . . . 308

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

Contents v

Page 8

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

GETtheMANUALS.org

Body Work - Edition 10.2018

vi Contents

Page 9

50 – Body - front

GETtheMANUALS.org

1 Front body

(SRL001304; Edition 10.2018)

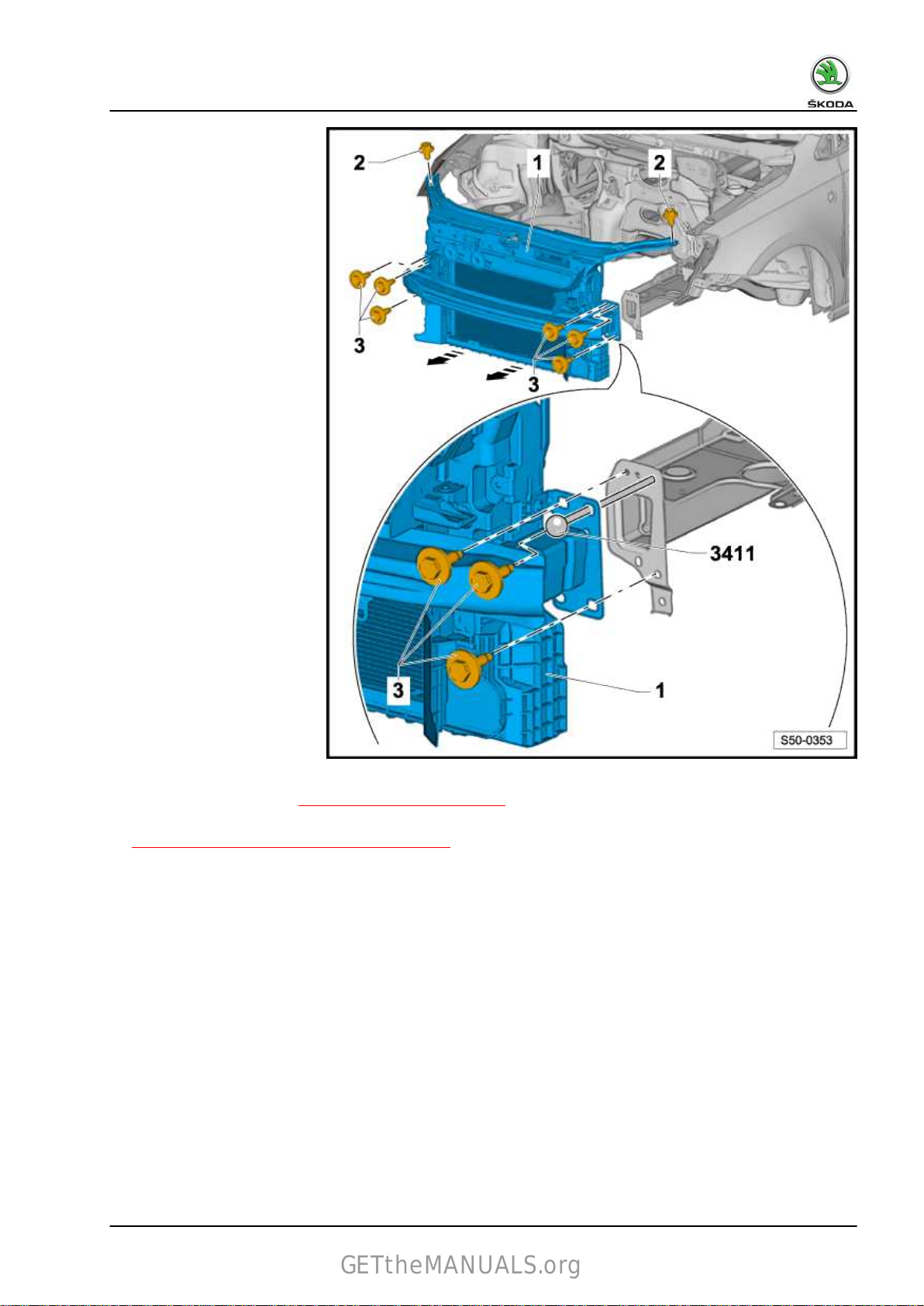

1.1 Tools

Special tools and workshop equipment required

♦ Guide bars - T30092 (3411)-

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

Body Work - Edition 10.2018

1.2 Lock carrier with components parts

Summary of components

Note

Depending on the model version, slight differences in the mounting parts are possible.

1. Front body 1

Page 10

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

GETtheMANUALS.org

Body Work - Edition 10.2018

1 - Lock carrier with compo‐

nents parts

❑

Service position

⇒ “1.3 Service position ”,

page 2 .

❑ Removing

⇒ “1.4 Removing and in‐

stalling lock carrier with

component parts”,

page 4 .

2 - Hose clamp

3 - Air guide duct

4 - Screw

❑

Tightening torque - 2

Nm.

5 - Screw

❑ Tightening torque - 20

Nm.

6 - Screw

❑ Tightening torque - 8

Nm.

7 - Lock carrier - top compo‐

nent parts

8 - Air deflector

9 - Screw

❑ Tightening torque - 8

Nm.

10 - Screw

❑ Tightening torque - 30

Nm.

11 - Bumper bracket

12 - Air deflector

and installing

1.3 Service position

Carry out the service position

2 Rep. gr.50 - Body - front

Page 11

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

GETtheMANUALS.org

Body Work - Edition 10.2018

– Removing front bumper ⇒ “1.1.2 Removing”, page 132 .

– Pull off the control cable from the lock carrier

⇒ “1.7 Separating the Bowden cable”, page 28 .

– Remove the screws -3- at the left and right frame side rails.

– Install the guide bars - T30092 (3411)- on the left and right

frame side rails.

– Remove top screws - 2 -.

– The lock carrier -1- can be pulled on the guide bars - T30092

(3411)- by approx. 10 cm forwards

-arrows-.

1. Front body 3

Page 12

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

GETtheMANUALS.org

Body Work - Edition 10.2018

1.3.1 Reinstallation

– Install screws -2- and -3-.

– Take

– Tightening torque of screws (Pos. 2) is 20 Nm.

– Tightening torque of screws (Pos. 3) is 30 Nm.

– Further installation occurs in reverse order.

Hoses and lines must not be pinched.

the mean of the lock carrier with component parts -1- at

the frame side rails and between the wings ⇒ Body Repairs;

Rep. gr. 00 ; technical data; body gaps; front body .

Note

1.4 Removing and installing lock carrier with component parts

Removing

4 Rep. gr.50 - Body - front

Page 13

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

GETtheMANUALS.org

Body Work - Edition 10.2018

– Bring to service position ⇒ “1.3 Service position ”, page 2 .

– Separate electrical plug connections.

– Drain the coolant and separate the coolant line ⇒ Engine

cooling; Rep. gr. 19 .

– Separate the lines for the condenser ⇒ Heating and air con‐

ditioning system; Rep. gr. 87 .

– Remove the guide bars - T30092 (3411)- at the left and right

frame side rails - 2 - with the help of a second mechanic and

remove the lock carrier with component parts

WARNING

- 1 -.

If the cables of the air-conditioning system and/or the coolant

are separated, the drive unit must no longer be started.

Note

♦

The condenser and hydraulic oil cooler must not be tied up to the cables.

♦

The condenser and hydraulic lines must not be kinked.

1. Front body 5

Page 14

Installing

GETtheMANUALS.org

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

Body Work - Edition 10.2018

– Position the lock carrier - 1 - on the frame side rails - 2 -.

– Install the left and right guide bars - T30092 (3411)- .

– Resetting service position ⇒ “1.3.1 Reinstallation”, page 4 .

– Further installation occurs in reverse order.

• Make sure that the plug connections and the hose connections

are correctly mounted during assembly.

– Take the mean of the lock carrier at the frame side rails and

between the wings ⇒ Body Repairs; Rep. gr. 00 ; technical

data; body gaps; front body .

6 Rep. gr.50 - Body - front

Page 15

1.5 Front wing

GETtheMANUALS.org

1.5.1 Summary of components

1 - Wing

❑

Removing

⇒ “1.5.2 Removing front

wing”, page 8 .

❑

Installing

⇒ “1.5.3 Installing the

front wing”, page 10 .

2 - Screw

❑

Tightening torque - 4

Nm.

3 - Screw

❑ Tightening torque - 8

Nm.

4 - Wing support

❑ Removing and installing

⇒ “1.6 Removing and in‐

stalling the wing sup‐

port”, page 11 .

5 - Interior trim

❑ Removing

⇒ “1.5.2 Removing front

wing”, page 8 .

6 - Foam part

❑

Inserted between the

wing and the front top

frame side rail.

7 - Damping of interior trim

and installing

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

Body Work - Edition 10.2018

1. Front body 7

Page 16

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

GETtheMANUALS.org

Body Work - Edition 10.2018

1.5.2 Removing front wing

– Remove front wheelhouse liner

⇒ “1.1 Front wheelhouse liner”, page 158 .

– Remove side turn signal ⇒ Electrical System; Rep. gr. 94 .

– On

vehicles fitted with a damping, first of all remove the damp‐

ing.

– Loosen catch hook -3- and clip -2-.

– Slightly pull the interior trim -1- in the lower area forwards

-arrow b- and then guide it out towards the bottom -arrow a-.

8 Rep. gr.50 - Body - front

Page 17

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

GETtheMANUALS.org

Body Work - Edition 10.2018

Carry out the following tasks

– Removing front bumper ⇒ “1.1.2 Removing”, page 132 .

– Pull out the foam part between the wing and the frame side

rail.

– Pull the damping of the interior trim out of the wheelhouse.

– Unscrew screw -2-.

– Unscrew screws -3-.

– For this step the bumper holder -4- must not be removed.

– The rear screw -2- can be reached when the front flap is

closed.

tect it from damage.

– Carefully remove the wing - 1 -.

Cover the front flap with adhesive tape in order to pro‐

1. Front body 9

Page 18

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

GETtheMANUALS.org

Body Work - Edition 10.2018

1.5.3 Installing the front wing

Carry out the following tasks

– The installation of the wing - 1 - occurs in the reverse order.

– Tightening torque of screw -2- (4 Nm).

– Tightening torque of screws -3- (8 Nm).

– Observe

pairs; Rep. gr. 00 ; technical data; body gaps; front body .

The wing support must be loosened when the fitting is carried out

⇒ “1.6 Removing and installing the wing support”, page 11 .

Install the wing -1- free of stress.

the parallelism and the correct gap sizes ⇒ Body Re‐

Note

10 Rep. gr.50 - Body - front

Page 19

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

GETtheMANUALS.org

1.6 Removing and installing the wing support

Body Work - Edition 10.2018

Removing

– Remove front bumper cover ⇒ “1.1.2 Removing”, page 132 .

– Release screws - 3 - and remove wing support - 2 -.

Installing

– Install wing support - 2 -.

– Adapt wing support with the wing -1- to the front flap and

bumper ⇒ Body Repairs; Rep. gr. 00 ; Technical data; body

gaps; front body .

– Tightening torque of screws -3- (8 Nm).

1. Front body 11

Page 20

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

GETtheMANUALS.org

Body Work - Edition 10.2018

1.7 Bulkhead plenum chamber

1.7.1 Summary of components

1 - Bulkhead plenum chamber

Removing

–

Remove the plenum

chamber cover

⇒ “1.8.2 Removing”,

page 14 .

–

Remove engine air duct

(depending on engine).

– Remove engine control

unit and engine control

module holder.

– Remove noise insula‐

tion.

– Unscrew screws -2-.

– Remove the bulkhead

plenum chamber -1- up‐

wards and out of the ple‐

num chamber -4-.

Installing

– The installation occurs

in reverse order.

2 - Screw

❑ Tightening torque - 8

Nm.

3 - Plenum chamber

4 - Seal

Note

Ensure that the seal is correctly

seated when installing the bulkhead

plenum chamber.

5 - Damping

❑ Attached to the bulkhead plenum chamber with clamping plates.

6 - Circlip

❑ For attaching the damping on the bulkhead plenum chamber.

12 Rep. gr.50 - Body - front

Page 21

1.8 Plenum chamber cover

GETtheMANUALS.org

1.8.1 Summary of components

1 - Additional cover

❑

Fitted on the wing web

plate.

2 - Plenum chamber cover

❑ Removing

⇒ “1.8.2 Removing”,

page 14 .

❑

Installing

⇒ “1.8.3 Installing”,

page 15 .

3 - Additional cover

❑

Fitted on the wing web

plate.

4 - Moulded foam part

5 - Seal

6 - Moulded foam part

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

Body Work - Edition 10.2018

1. Front body 13

Page 22

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

GETtheMANUALS.org

Body Work - Edition 10.2018

1.8.2 Removing

– Remove wiper arms ⇒ Electrical System; Rep. gr. 92 .

– Detach the seal -2- along the entire length of the plenum

chamber cover -1-.

Caution

The plenum chamber cover must not be levered off with a lever

tool (screwdriver, wedge). The washer is damaged and can

subsequently tear.

– Lift up the plenum chamber cover -1- on the edge of the wind‐

screen by hand.

– Pull the plenum chamber cover -1- starting at the edge of the

windscreen -6- towards the top and out of the fitting section

-5-.

– Remove plenum chamber cover -1- from vehicle.

14 Rep. gr.50 - Body - front

Page 23

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

GETtheMANUALS.org

1.8.3 Installing

Caution

Breaking open the plenum chamber cover -1- in the fitting sec‐

tion -5- of the windscreen -6- can lead to cracks in the wind‐

screen.

Body Work - Edition 10.2018

Note

♦

An inlay is installed in the fitting section on new windscreens. This inlay must be removed before installing

the plenum chamber cover.

♦

The plenum chamber cover must be slightly pressed into the fitting section by hand, but on no account knock

or press in using a tool.

Carry out the following tasks

– Wet the fitting section -5- with soapy water so that the plenum

chamber covers -1- can be pressed in more easily.

1. Front body 15

Page 24

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

GETtheMANUALS.org

Body Work - Edition 10.2018

– Place the plenum chamber covers -1- onto the fitting section

-5- and clip it, starting from the centre, into the fitting section

-5- with slight pressure.

– Fit the seal - 2 - onto the plenum chamber cover - 1 -.

– Installing windscreen wipers ⇒ Electrical System; Rep. gr.

92 .

1.9 Noise insulation

1.9.1 Summary of components

Note

Depending on the model version, slight differences must be taken into consideration when removing and in‐

stalling.

1 - Noise insulation

Removing

– Remove the screws -2-

and push out the noise

insulation towards the

rear.

2 - Screw

❑ Tightening torque - 2

Nm.

3 - Shock absorber cover

16 Rep. gr.50 - Body - front

Page 25

1.10 V-ribbed belt protection

GETtheMANUALS.org

1.10.1 Summary of components

1 - V-ribbed belt protection

Removing

–

Unscrew screws -2-.

Installing

– The installation occurs

in reverse order.

2 - Screw

❑ Tightening torque - 2

Nm.

3 - Snap nut

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

Body Work - Edition 10.2018

1. Front body 17

Page 26

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

GETtheMANUALS.org

Body Work - Edition 10.2018

1.11 Underfloor trim panel

1.11.1 Summary of components

1 - Floor covering

Removing

–

Unscrew nuts - 2 -.

Installing

– The installation occurs

in reverse order.

2 - Nut

❑ Tightening torque - 2

Nm.

3 - Threaded bores

❑ Welded to the floor pan‐

el.

18 Rep. gr.50 - Body - front

Page 27

1.12 Tunnel bridge

GETtheMANUALS.org

1.12.1 Summary of components

1 - Tunnel bridge

Removing

–

Remove underbody

panels

⇒ “1.11 Underfloor trim

panel”, page 18 .

–

Unscrew nuts - 2 -.

Installing

– The installation occurs

in reverse order.

2 - Nut

❑ Tightening torque - 20

Nm.

3 - Threaded bores

❑ Welded to the floor pan‐

el.

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

Body Work - Edition 10.2018

1. Front body 19

Page 28

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

GETtheMANUALS.org

Body Work - Edition 10.2018

55 – Bonnet, rear lid

1 Front flap

1.1 Summary of components

1 - Front flap

❑ Removing and installing

⇒ “1.2.1 Removing”,

page 21 .

❑ Setting

⇒ “1.10 Adjusting the

bonnet”, page 32 .

2 - Plug

3 - Adjusting buffer

4 - Locking clamp

5 - Damping

Removing

– Unclip all the clips for

the damping in se‐

quence.

– Remove the damping

from the bonnet.

Installing

– The installation occurs

in reverse order.

6 - Bump stop

7 - Adjusting buffer

8 - Plug

9 - Hinge

❑ Removing and installing

⇒ “1.3 Removing and in‐

stalling the hinge for the

front flap”, page 23 .

❑ Setting

⇒ “1.10 Adjusting the bonnet”, page 32 .

10 - Spray nozzles

❑ Removing and installing ⇒ Electrical System; Rep. gr. 92 .

11 - Support bar

❑ Removing and installing ⇒ “1.4 Removing and installing the support bar”, page 24 .

12 - Flap lock bonnet

❑ Removing and installing ⇒ “1.6 Removing and installing front flap lock ”, page 25 .

13 - Screw

❑ Tightening torque - 20 Nm.

14 - Nut

❑ Tightening torque - 20 Nm.

20 Rep. gr.55 - Bonnet, rear lid

Volkswagen Technical Site:

http://vwts.ru http://vwts.info

Page 29

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

GETtheMANUALS.org

15 - Retaining clip

1.2 Removing and installing the bonnet

1.2.1 Removing

Body Work - Edition 10.2018

– Remove

– Unclip the cable -4- from the front flap -1-.

– Pull the cable -4- out of the opening of the front flap -1-.

– Slacken the nuts -3- on the left and right at the hinge -2- (do

not unscrew).

Carry out further removal only with the assistance of a second

mechanic.

– Remove support bar -6- from the front flap.

– Only now unscrew the nuts -3- and lift the front flap -1- out of

the hinges -2-.

spray nozzles -5- ⇒ Electrical System; Rep. gr. 92 .

1. Front flap 21

Page 30

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

GETtheMANUALS.org

Body Work - Edition 10.2018

1.2.2 Installing

Installing

– The installation occurs in reverse order.

– Adjust front flap -1-

⇒ “1.10 Adjusting the bonnet”, page 32 .

22 Rep. gr.55 - Bonnet, rear lid

Page 31

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

GETtheMANUALS.org

1.3 Removing and installing the hinge for the front flap

1.3.1 Removing

Body Work - Edition 10.2018

– Remove front flap -3- ⇒ “1.2.1 Removing”, page 21 .

– Remove screws -2- (20 Nm).

– Remove hinge - 1 -.

1.3.2 Installing

– The installation occurs in reverse order.

1. Front flap 23

Page 32

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

GETtheMANUALS.org

Body Work - Edition 10.2018

1.4 Removing and installing the support bar

Removing

– Support the bonnet.

– Swivel

port bar out of the rubber grommet - 2 -.

Installing

– Push the support bar -1- into the rubber grommet (Pos.2)

-arrow a-.

– Swivel the support bar towards the lock carrier -arrow b-.

– Check the bracket -3- for damage, replace it if necessary.

the support bar - 1 - towards the front and pull the sup‐

24 Rep. gr.55 - Bonnet, rear lid

Page 33

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

GETtheMANUALS.org

Body Work - Edition 10.2018

1.5 Lock and unlock components of front flap - Summary of components

1 - Locking clamp

❑

Removing

⇒ “1.8 Removing and in‐

stalling the locking

clamp”, page 29 .

❑

Setting

⇒ “1.10.2 Adjusting the

locking clamp”,

page 34 .

2 - Release handle

❑ Removing

⇒ “1.9.2 Removing and

installing”, page 31 .

3 - Bowden cable

❑

From the Bowden cable

coupling to the operat‐

ing lever

⇒ “1.9 Removing and in‐

stalling the operating

lever”, page 30 .

4 - Retaining clip

5 - Bowden cable

6 - Bowden wire coupling

❑

The Bowden cable cou‐

pling is located above

the headlight on the

driver's side.

❑ Separate

⇒ “1.7 Separating the

Bowden cable”,

page 28 .

7 - Bowden cable

❑

From the front flap lock

to the Bowden cable

coupling.

❑ Clipped into the Bowden cable coupling.

8 - Flap lock bonnet

❑ Remove and install front flap lock

❑

Setting

and installing

⇒ “1.6 Removing and installing front flap lock ”, page 25 .

⇒ “1.10.1 Adjusting the flap lock”, page 33 .

1.6 Removing and installing front flap lock

Note

Depending on the model version, slight differences must be taken

into consideration when removing and installing the front flap lock.

1. Front flap 25

Page 34

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

GETtheMANUALS.org

Body Work - Edition 10.2018

1.6.1 Removing

Note

The Bowden cable -2- is not separated from the front flap lock.

– Open front flap.

– Separate

⇒ “1.7 Separating the Bowden cable”, page 28 .

– Depending on the additional equipment, disconnect the plug

connection for the contact switch of the engine hood.

– Release the screws - 4 - (12 Nm) and remove the flap lock

- 1 - in - direction of arrow a - from the lock carrier.

Depending on the additional equipment, remove and install the contact switch for the engine hood at the flap

lock ⇒ Electrical System; Rep. gr. 96 .

the Bowden cable -2- in the Bowden cable coupling

Note

26 Rep. gr.55 - Bonnet, rear lid

Page 35

1.6.2 Installing

GETtheMANUALS.org

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

Body Work - Edition 10.2018

– Clip the end part - 3 - of the Bowden cable - 2 - into the flap

lock (if it was removed) - arrow a -.

– Push the flap lock -1- into the lock carrier -arrow b-.

– Depending

nection for the contact switch of the engine hood.

– Tightening torque of screws -4- (12 Nm).

– Install the Bowden cable -2- in the Bowden cable coupling

⇒ “1.7 Separating the Bowden cable”, page 28 .

– Adjust flap lock ⇒ “1.10.1 Adjusting the flap lock”, page 33 .

• Before closing the front flap, carry out a functional test of the

operating lever and the Bowden cable.

on the additional equipment, connect the plug con‐

1. Front flap 27

Page 36

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

GETtheMANUALS.org

Body Work - Edition 10.2018

1.7 Separating the Bowden cable

Removing

– Open front flap.

– Unclip the Bowden cable coupling - 2 -, located above the

headlight on the driver's side, out of the lock carrier

-arrow a-.

– Take the Bowden cables -1- and -3- out of the Bowden cable

coupling -2-

– Swivel the Bowden cable -1- about 90° in

-direction of arrow b- and take the Bowden cable

-in direction of arrow c- out of the support of the Bowden cable.

Installing

– The installation occurs in reverse order.

in -arrows a-.

28 Rep. gr.55 - Bonnet, rear lid

Page 37

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

GETtheMANUALS.org

Body Work - Edition 10.2018

Note

♦

When installing the Bowden cable - 3 -, ensure that the grommet - 5 - is correctly secured.

♦

When attaching the Bowden cable - 3 -, pay attention to the mandatory clipping - 4 -.

• Before closing the front flap, carry out a functional test of the

operating lever and the Bowden cable.

1.8 Removing and installing the locking clamp

Removing

– Unscrew screws -3-.

– Remove the locking clamp - 1 - from the front flap - 2 -.

Installing

– Tightening torque of screws -3- (10 Nm).

– Adjust the locking clamp to the flap lock

⇒ “1.10.2 Adjusting the locking clamp”, page 34 .

1. Front flap 29

Page 38

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

GETtheMANUALS.org

Body Work - Edition 10.2018

1.9 Removing and installing the operating lever

1.9.1 Summary of components

1 - Bearing bracket

2 - Bowden cable

Installing

–

Insert the ball of the

Bowden cable into the

bracket -arrow a- and

secure the Bowden ca‐

ble in the bearing brack‐

et -arrow b-.

3 - Expanding nut

4 - Screw

❑ Tightening torque - 2

Nm.

5 - Release handle

❑ Removing and installing

⇒ “1.9.2 Removing and

installing”, page 31 .

30 Rep. gr.55 - Bonnet, rear lid

Page 39

1.9.2 Removing and installing

GETtheMANUALS.org

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

Body Work - Edition 10.2018

Removing

– Tighten the operating lever -1- and unlock the bonnet.

– Fit a small screwdriver into the gap between the operating

lever - 1 - and the retaining clip

– Lever the retaining clip -2- out of the operating lever (Pos. 1)

-arrow- and detach the operating lever from the bearing brack‐

et -3-.

When carrying out further work on the bearing bracket - 3 -, re‐

move the bottom A pillar trim panel - 4 -.

Installing

• The bottom A pillar trim panel -4- is installed.

– Push the retaining clip -2- into the operating lever.

– Press the operating lever - 1 - onto the bearing bracket - 3 -.

- 2 -.

1. Front flap 31

Page 40

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

GETtheMANUALS.org

Body Work - Edition 10.2018

1.10 Adjusting the bonnet

Note

♦

The vehicle must be positioned on the flat ground in order to adjust the bonnet.

♦

The adjusting buffers -2- on the left and right are not used for the adjustment. They have the function to

stabilise or dampen the bonnet.

♦

The bonnet is correctly adjusted if in the closed state it has an overall even gap size, is not positioned too

far outwards or inwards and the contours are aligned.

♦

The bonnet must latch in the flap lock without using increased force.

♦

The nuts are not unscrewed, only slackened.

– Remove locking clamp -1-

⇒ “1.8 Removing and installing the locking clamp”, page 29 .

– The

– Ensure parallelism of gap dimensions ⇒ Body Repairs; Rep.

mean of the front flap can be taken between the wings by

slackening the nuts -6- on the left and right hinges -7-.

gr. 00 ; Technical data; body gaps; front body .

32 Rep. gr.55 - Bonnet, rear lid

Page 41

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

GETtheMANUALS.org

Body Work - Edition 10.2018

Adjusting the adjusting buffer

Note

♦

Install the adjusting buffer - 2 and 3 - on the left and right up to the stop.

♦

Turn the adjusting buffers by 90° if required, in order to pretension the flap.

– After the front flap has been adjusted, the locking clamp - 1 -

can once again be installed and adjusted

⇒ “1.10.2 Adjusting the locking clamp”, page 34 .

– The

– After the flap has been adjusted, the locking clamp has been

– After carrying out adjustment work, perform corrosion protec‐

front flap can be adjusted in the front area to the height of

the wings with the flap lock -5-

⇒ “1.10.1 Adjusting the flap lock”, page 33 .

installed

justing buffers can be turned if required.

tion measures on the hinges -6- and the screws -7- .

and all the connections have been tightened, the ad‐

1.10.1 Adjusting the flap lock

1. Front flap 33

Page 42

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

GETtheMANUALS.org

Body Work - Edition 10.2018

– If the screws -2- are loosened, the front flap lock -1- can be

adjusted to the front flap laterally -arrow a-

-arrow b- ⇒ Body Repairs; Rep. gr. 00 ; body gaps; front body .

– Tightening torque of screws -2- (12 Nm).

and in height

1.10.2 Adjusting the locking clamp

– Release screws - 3 -.

– The locking clamp -1- can now be adjusted in the oversized

holes.

– Tightening torque of screws -3- (10 Nm).

34 Rep. gr.55 - Bonnet, rear lid

Page 43

2 Tailgate

GETtheMANUALS.org

2.1 Summary of components

1 - Screw

❑

Tightening torque - 8

Nm.

2 - Wedge buffer

3 - Tailgate trim panel

❑ Removing and installing

⇒ “4 Tailgate trim pan‐

el”, page 274 .

4 - Tailgate

❑ Removing

⇒ “2.2 Removing and in‐

stalling tailgate”,

page 36 .

❑

Setting

⇒ “2.4 Adjusting tail‐

gate”, page 37 .

5 - Rubber buffer

❑

Setting

⇒ “2.4.2 Adjusting the

rubber buffer”,

page 39 .

6 - Ball pin

–

Tightening torque - 20

Nm.

and installing

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

Body Work - Edition 10.2018

7 - Pressurized gas strut

– Removing and installing

⇒ “2.6 Removing and in‐

stalling pressurized gas

strut of tailgate”,

page 40 .

2. Tailgate 35

Page 44

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

GETtheMANUALS.org

Body Work - Edition 10.2018

2.2 Removing and installing tailgate

2.2.1 Removing

– Remove the tailgate trim panel

⇒ “4 Tailgate trim panel”, page 274 .

– Disconnect

ponents.

– Thread the electrical cables out of the tailgate.

– Slacken the screws - 3 - (10 Nm) on the left and right hinges

but do not yet unscrew.

Carry out further removal only with the assistance of a second

mechanic.

– Only now unscrew the screws - 3 - and remove the tailgate.

– Only if the complete hinge for the tailgate must be removed,

release the nuts - 2 - (20 Nm). In this case the moulded head‐

liner must be unhooked

the plug connections of the existing electrical com‐

36 Rep. gr.55 - Bonnet, rear lid

⇒ “7 Moulded headliner”, page 282 .

Page 45

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

GETtheMANUALS.org

Installing

– The installation occurs in reverse order.

Note

Adjust the tailgate after installing ⇒ “2.4 Adjusting tailgate”, page 37 .

2.3 Removing and installing the locking mechanism

2.3.1 Removing

Body Work - Edition 10.2018

– Unscrew

luggage compartment wall.

Installing

– The installation occurs in reverse order.

– Set the locking mechanism

⇒ “2.4.1 Setting the locking mechanism”, page 39 .

screw -2- and remove the closing wedge -1- from the

2.4 Adjusting tailgate

Note

♦

The vehicle must be standing on its wheels in order to adjust the tailgate.

♦

The flap lock is directly screwed onto the tailgate. It has no elongated holes and therefore it cannot be

adjusted.

♦

The adjusting buffers on the left and right are not used for the adjustment. They have the function to stabilise

or dampen the bonnet.

♦

The bonnet is correctly adjusted if in the closed state it has an overall even gap size, is not positioned too

far outwards or inwards and the contours are aligned.

♦

The tailgate must latch in the flap lock without using increased force.

2. Tailgate 37

Page 46

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

GETtheMANUALS.org

Body Work - Edition 10.2018

Use a setting gauge for setting or checking the gap sizes ⇒ Body

Repairs; Rep. gr. 00 ; Body gaps; rear body .

– The tailgate can be adjusted in the oversized bores of the

hinges horizontally and vertically by slackening the screws

- 3 -.

Tightening torque of screws -3- (10 Nm).

– After carrying out adjustment work, perform corrosion protec‐

tion measures at the hinges and screws.

– Adjust the tailgate on the closing wedge

⇒ “2.4.1 Setting the locking mechanism”, page 39 .

– Adjust the rubber buffer on the left and right

⇒ “2.4.2 Adjusting the rubber buffer”, page 39 .

38 Rep. gr.55 - Bonnet, rear lid

Page 47

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

GETtheMANUALS.org

2.4.1 Setting the locking mechanism

Note

♦

The closing wedge -2- can be moved in the oversized bores

-arrows a- and -arrows b- by loosening the screws - 1 -.

♦

Set the locking mechanism - 2 - in such a way that the recess

of the tailgate lock with the catch engages centrally in the

locking mechanism - 2 -.

– Release screws - 1 -.

– Push the locking mechanism -2- out into the upper position

and tighten the screws -1-.

– Close the tailgate and check the setting.

Tightening torque of screws -1- (20 Nm).

2.4.2 Adjusting the rubber buffer

Body Work - Edition 10.2018

– Adjust

– Remove rubber buffers -2- by approximately 2 mm out of the

– The tailgate -1- must latch in the flap lock without using in‐

2.5 Removing

If the tailgate does not open, the emergency release can be

opened mechanically from the luggage compartment via the lock

cylinder ⇒ Owner's Manual .

the rubber buffer in such a way that no excessive forces

must be used when closing the tailgate -1- and that it engages

in the lock.

tailgate -1-.

creased force.

and installing the tailgate lock

Note

2.5.1 Removing and installing

2. Tailgate 39

Page 48

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

GETtheMANUALS.org

Body Work - Edition 10.2018

Removing

– Remove lock cover - 3 -.

– Disconnect the plug connection from the tailgate lock control

- 1 -.

– Release

the tailgate.

Installing

– The installation occurs in reverse order.

the nuts -2- (21 Nm) and remove the flap lock -1- from

2.6 Removing and installing pressurized

gas strut of tailgate

Removing

– Open tailgate, support and lock it into position.

– Use a screwdriver to raise the locking element - 2 - and pull

the pressurized gas strut - 1 - off the ball stud - 3 -.

Note

If the pressurized gas strut is to be re-used, do not remove the

locking device fully from the ball socket, otherwise it will be dam‐

aged.

– 1 - Pressurized gas strut

– 2 - Locking device

– 3 - Ball stud

Installing

– The installation occurs in reverse order.

40 Rep. gr.55 - Bonnet, rear lid

Page 49

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

GETtheMANUALS.org

2.7 Tailgate seal

2.7.1 Installation instructions

♦ If the seal is re-installed, leak-tightness and tight fit can no

longer be guaranteed.

♦ For this reason, each seal which was completely removed

must be replaced with a so-called “hammer finish seal”.

♦ If the seals were detached partially, press together the sides

of the seal before installing.

2.7.2 Removing and installing tailgate seal

Body Work - Edition 10.2018

Removing

– Pay attention to installation instructions

⇒ “2.7.1 Installation instructions”, page 41 .

– Detach the seal for the tailgate -1- from the body flange.

Installing

– Press the seal -1- evenly onto the body flange.

2. Tailgate 41

Page 50

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

GETtheMANUALS.org

Body Work - Edition 10.2018

3 Fuel tank lid unit

3.1 Fuel-tank lid unit - Summary of components

1 - Locking mechanism

2 - Fuel tank lid unit

❑ Removing

⇒ “3.2 Removing and in‐

stalling fuel tank lid unit”,

page 42 .

3 - Water drain hose

❑ Laid

house and the wheel‐

house liner.

and installing

between the wheel‐

3.2 Removing

and installing fuel tank lid unit

3.2.1 Removing

– First pierce the unit in the upper area with a thin screwdriver

- 4 - or a nail - 1 - - 2 - in the - direction of arrow a - .

– Lightly ress the screwdriver in the -direction of arrow b - the

catches - 5 - will be unlocked as a result.

– After unlocking the upper latches, slightly swivel the unit out

of the side panel. The lower catches should then extend up‐

wards.

upper area.

– Remove the rubber grommet from the fuel filler neck.

– Remove the fuel tank lid unit from the side section.

If the lower area can not be removed, proceed as in the

3.2.2 Installing

– The installation occurs in reverse order.

42 Rep. gr.55 - Bonnet, rear lid

Page 51

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

GETtheMANUALS.org

Body Work - Edition 10.2018

Note

If the latches for the fuel tank lid unit are damaged, use a new

part.

3.3 Fuel-tank lid unit (Spacebook)- Summary of components

1 - Fuel tank lid

2 - Fuel tank lid unit

Removing and installing

⇒ “4 Removing and installing

fuel tank lid unit (Spacebook)”,

page 44 .

3 - Water drain hose

4 - Locking mechanism

5 - Fuel filler neck

6 - Side section

3. Fuel tank lid unit 43

Page 52

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

GETtheMANUALS.org

Body Work - Edition 10.2018

4 Removing and installing fuel tank lid unit (Spacebook)

Removing

– Unlock

panel- 2 -, in the same way as in the Rapid model

⇒ “3.2 Removing and installing fuel tank lid unit”, page 42 .

– Remove fuel tank lid unit - 1 - outwards.

Installing

– Perform the installation by pressing in the fuel tank lid unit in

the lateral part. Latch the fuel tank lid unit for the correct po‐

sition until it audibly clicks into place.

If the latches for the fuel tank lid unit are damaged, use a new part.

the catches - arrows -, which are clipped onto the side

Note

44 Rep. gr.55 - Bonnet, rear lid

Page 53

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

GETtheMANUALS.org

Body Work - Edition 10.2018

57 – Front doors, door components, central locking

1 Front door

1.1 Assembly overview - door hanger

Note

Always replace the screws for the door hinges after the removal.

1 - Door

❑ Removing and installing

⇒ “1.2 Removing and in‐

stalling the door”,

page 47 .

❑ Setting

⇒ “1.3 Door adjust‐

ment”, page 49 .

2 - Multi-point socket head bolt

❑ 32 Nm.

❑ Always replace the

screws after the remov‐

al.

3 - Door hinge

❑ The top part is connec‐

ted to the bottom part of

the hinge by the screw

- 4 -.

4 - Screw

❑ This screw must be un‐

screwed in order to re‐

move the door from the

hinge.

❑ 23 Nm.

5 - Multi-point socket head bolt

❑ Installed from the inside

of the vehicle.

❑ Remove bottom A-pillar

trim panel.

❑ 32 Nm.

❑ Always replace the

screws after the remov‐

al.

6 - Door hinge

❑ The bottom part is connected to the top part of the hinge by the screw -4-.

7 - Multi-point socket head bolt

❑ 32 Nm.

❑ Always replace the screws after the removal.

8 - Screw

❑ 32 Nm.

❑ 30 Nm - only for the assembly plant in Russia.

Volkswagen Technical Site:

http://vwts.ru http://vwts.info

1. Front door 45

Page 54

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

GETtheMANUALS.org

Body Work - Edition 10.2018

❑ This screw must be unscrewed in order to remove the door.

9 - Door retaining strap

10 - Screw

❑

9 Nm.

11 - Multi-point socket head bolt

❑ Installed from the inside of the vehicle.

❑ Remove and install the dash panel for loosening or tightening the screw on the driver's side

⇒ “1.1 Removing and installing the dash panel”, page 244 .

❑

Remove and install the dash panel for loosening or tightening the screw on the front passenger side

⇒ “1.1 Removing and installing the dash panel”, page 244 .

❑

32 Nm.

❑ Always replace the screws after the removal.

12 - Door hinge

❑ The bottom part is connected to the top part of the hinge by the screw -16-.

13 - Multi-point socket head bolt

❑ 32 Nm.

❑ Always replace the screws after the removal.

14 - Multi-point socket head bolt

❑ 32 Nm.

❑ Always replace the screws after the removal.

15 - Door hinge

❑ The top part is connected to the bottom part of the hinge by the screw - 12 -.

16 - Screw

❑ 23 Nm.

❑ This screw must be screwed down in order to remove the door from the hinge bolt.

46 Rep. gr.57 - Front doors, door components, central locking

Page 55

1.2 Removing and installing the door

GETtheMANUALS.org

1.2.1 Removing

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

Body Work - Edition 10.2018

– Release

detach it from the A pillar.

– Swivel the release lever -3- downwards -arrow b- and discon‐

nect the el. plug connection -4- from the connector station.

– Slacken the screws -7- at the hinges -arrows d-.

– Remove the screws -5- for the door retaining strap -6-.

– Pull the door -1- upwards -arrow e- and out of the hinges -8-.

the bellows -2- by pressing on the catch -arrow a- and

1. Front door 47

Page 56

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

GETtheMANUALS.org

Body Work - Edition 10.2018

1.2.2 Installing

Installing

– The installation occurs in reverse order.

– Tightening torques of screws

⇒ “1.1 Assembly overview - door hanger ”, page 45 .

– Observe

gr. 00 ; technical data; body gaps; front body .

the gap sizes of the front door ⇒ Body Repairs; Rep.

48 Rep. gr.57 - Front doors, door components, central locking

Page 57

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

GETtheMANUALS.org

Body Work - Edition 10.2018

1.3 Door adjustment

Note

♦

The vehicle must be standing on its wheels in order to adjust the door.

♦

The door is correctly adjusted if in the closed state it has an overall even gap size, is not positioned too far

outwards or inwards and the contours are aligned.

♦

For checking the gap sizes: ⇒ Body Repairs; Rep. gr. 00 ; Technical data; body gaps; front body .

♦

After carrying out adjustment work, perform corrosion protection measures at the screws and hinges.

Setting the gap sizes

In order to correctly set the gap sizes, the screws

-2, 5, 7, and 8- must be slackened at the A pillar.

– The bottom A pillar trim panel must be removed for slackening

the screw -5-

⇒ “3.2 Removing and installing bottom trim panel of pillar A on

the driver's side”, page 264 .

1. Front door 49

Page 58

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

GETtheMANUALS.org

Body Work - Edition 10.2018

– The dash panel must be removed on the driver's side for

slackening the screw

⇒ “1.1 Removing and installing the dash panel”, page 244 .

– The glove compartment must be removed on the front pas‐

senger side for slackening the screw

⇒ “1.2 Removing and installing the glove compartment”, page

249 .

Setting the gap sizes

The screws -3 and 9- must be released for correctly setting the

flushness.

Note

Other measures, such as aligning the doors towards the top are ineffective. The door will drop again at the

following overpressures.

Adjusting the locking clamp

⇒ “1.3.1 Adjusting the locking clamp”, page 50 .

- 7 -

- 7 -

1.3.1 Adjusting the locking clamp

50 Rep. gr.57 - Front doors, door components, central locking

Page 59

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

GETtheMANUALS.org

Body Work - Edition 10.2018

Note

♦

The arc outside the threaded plate must be firmly welded to the pillar. The lands to the threaded plate are

malleable.

♦

To adjust the locking clamp -2- once the screws -3- are loosened, increased force must be applied.

Note

♦

When closing the door it must lock completely without using

additional force and must have no play.

♦

When adjusting the locking clamp, the door must not be press‐

ed upwards or downwards.

The locking clamp is used for adjusting the following:

• If the front door adjustment is not flush with the rear door or

the side part.

Carry out the following tasks

– Slacken the locking clamp -1- by loosening the screws -2- at

the B pillar.

– Adjust the door with the locking clamp -2- in such a way that

the front door when in the closed state is flush with the rear

door (wind noise).

– Tighten screws - 2 - of locking clamp - 1 -.

Tightening torque of screws -2- (20 Nm).

1. Front door 51

Page 60

Rapid NH 2014 ➤ , Rapid Spaceback 2014 ➤

GETtheMANUALS.org

Body Work - Edition 10.2018

2 Door internal parts

2.1 Front door - Summary of components

1 - Door

❑ Removing

⇒ “1.2.1 Removing”,

page 47 .

❑

Setting

⇒ “1.3 Door adjust‐

ment”, page 49 .

2 - Clamp

❑ Removing