Page 1

Service

GETtheMANUALS.org

Workshop Manual

Rapid 2011 ➤

Axles, steering

Edition 12.2018

Service Department. Technical Information

Page 2

List of Workshop Manual Repair Groups

GETtheMANUALS.org

Re pa ir G ro up

00 - Technical data

40 - Front suspension

42 - Rear suspension

44 - Wheels, tyres, vehicle geometry

48 - Steering

Service

Technical information should always be available to the foremen and mechanics, because their

careful and constant adherence to the instructions is essential to ensure vehicle road-worthiness and

safety. In addition, the normal basic safety precautions for working on motor vehicles must, as a

matter of course, be observed.

Page 3

Rapid 2011 ➤

GETtheMANUALS.org

Axles, steering - Edition 12.2018

Contents

00 - Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1 Accident vehicle assessment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Checklist for assessing the chassis of accident vehicles . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 General Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1 Steering gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Seals and sealing rings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.3 Nuts and bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.4 Electrical components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

40 - Front suspension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1 Front axle - Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 Front axle - Overview of the repair chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Raise the wheel-bearing housing in the rebound state (unladen weight position) . . . . . . . . 5

2 Repairing front axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Summary of components of assembly carrier, track control arm, anti-roll bar, coupling rod,

support and pendulum support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Lower the assembly carrier in the service position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3 Inspecting the suspension link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.4 Removing and installing the suspension link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.5 Removing and installing the track control arm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.6 Replacing the rubber-metal bearing for track control arm . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.7 Removing and installing the anti-roll bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.8 Removing and installing the rubber bearing for the anti-roll bar . . . . . . . . . . . . . . . . . . . . . . 29

2.9 Removing and installing assembly carrier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3 Repairing front suspension strut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.1 Installation general view of the suspension strut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.2 Removing and installing the suspension strut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.3 Repairing suspension strut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.4 Inspect shock absorber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3.5 Disposing of the shock absorber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4 Repairing wheel bearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.1 Summary of components of the wheel bearing, suspension strut, drive shaft and brake C54

. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. . 45

4.2 Removing and installing wheel bearing housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.3 Removing and installing the wheel hub with wheel bearing with the wheel-bearing housing

fitted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

5 Drive shafts with inner CV joint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5.1 Summary of components of drive shaft with inner CV joint . . . . . . . . . . . . . . . . . . . . . . . . 58

5.2 Removing and installing fixing nut of drive shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

5.3 Removing and installing outer joint of drive shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5.4 Removing and installing drive shaft with CV joint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5.5 Push the cardan shaft out of the wheel hub. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

5.6 Repairing drive shaft with CV joint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

5.7 Inspecting the CV joints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

6 Drive shafts with inner tripod joint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

6.1 Summary of components of drive shaft with inner tripod joint . . . . . . . . . . . . . . . . . . . . . . 76

6.2 Removing and installing inner drive shaft with tripod joint . . . . . . . . . . . . . . . . . . . . . . . . . . 78

6.3 Repairing drive shaft with inner tripod joint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

6.4 Check outer joint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

6.5 Repairing outer CV joint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

42 - Rear suspension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

1 Rear axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Contents i

Page 4

Rapid 2011 ➤

GETtheMANUALS.org

Axles, steering - Edition 12.2018

1.1 Raise the wheel-bearing of the rear axle in the rebound state (unladen weight position) . . 85

1.2 Summary of components of rear axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

1.3 Fitting location of the shock absorber on the rear axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

1.4 Removing and installing rear suspension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

2 Repairing rear axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

2.1 Summary of components of shock absorber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

2.2 Inspect shock absorber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

2.3 Disposing of the shock absorber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

2.4 Removing and installing shock absorber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

2.5 Removing and installing coil spring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

2.6 Replacing the rubber-metal bearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

3 Repairing wheel bearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

3.1 Summary of components of the wheel bearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

3.2 Removing and installing the wheel hub with wheel bearing . . . . . . . . . . . . . . . . . . . . . . . . 119

3.3 Removing and installing axle studs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

44 - Wheels, tyres, vehicle geometry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

1 Chassis - Specified values of steering geometry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

1.1 Nominal values front axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

1.2 Nominal values rear axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

2 Axle alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

2.1 General points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

2.2 Axle alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

2.3 Test conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

2.4 Measurement preliminaries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

2.5 Check transversal inclination of the vehicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

2.6 Checking the camber on the front axle, if necessary take the mean . . . . . . . . . . . . . . . . . . 132

2.7 Checking the camber on the rear axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

2.8 Check misalignment of the rear axle, if necessary take the mean . . . . . . . . . . . . . . . . . . . . 134

2.9 Checking the track on the front axle, adjusting if necessary . . . . . . . . . . . . . . . . . . . . . . . . 136

2.10 Check position of steering wheel, align if necessary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

2.11 Calculation of the misalignment on the rear axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

2.12 Checking the left and right steering angle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

48 - Steering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

1 Steering wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

1.1 Steering wheel - Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

1.2 Removing and installing the steering wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

2 Steering column . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

2.1 Summary of components - steering column . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

3 Removing and installing steering column . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

3.1 Measures for handling and transportation of the steering column . . . . . . . . . . . . . . . . . . . . 147

3.2 Removing the steering column . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

3.3 Installing the steering column . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

3.4 Removing and installing steering column electronics control unit J500 . . . . . . . . . . . . . . 152

4 Steering lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

4.1 Removing and installing steering lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

5 Electro/mechanical power steering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

5.1 Assembly overview of the power-assisted steering drive . . . . . . . . . . . . . . . . . . . . . . . . . . 157

5.2 Disassembling and assembling the power-assisted steering gear . . . . . . . . . . . . . . . . . . . . 158

5.3 Removing and installing steering gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

5.4 Removing and installing track rods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

5.5 Inspecting boots, play and correct attachment of track rod ends . . . . . . . . . . . . . . . . . . . . 166

5.6 Removing and installing track rod ends . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

5.7 Check and adjust the length of the tie rod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

ii Contents

Page 5

Rapid 2011 ➤

GETtheMANUALS.org

Axles, steering - Edition 12.2018

5.8 Check the centre position of the gear rack of the power-steering gear, if necessary adjust

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

5.9 Adjusting the power-steering gear (adjusting the pressure plate clearance) . . . . . . . . . . . . 170

Contents iii

Page 6

Rapid 2011 ➤

GETtheMANUALS.org

Axles, steering - Edition 12.2018

iv Contents

Page 7

00 – Technical data

GETtheMANUALS.org

1 Accident vehicle assessment

(SRL001334; Edition 12.2018)

⇒ “1.1 Checklist for assessing the chassis of accident vehicles”,

page 1

1.1 Checklist for assessing the chassis of accident vehicles

Concealed chassis damage may remain after load-bearing and

wheel-bearing parts have been repaired on accident vehicles.

Under certain circumstances, this hidden damage could lead to

serious consequential damage during later vehicle operation. On

accident vehicles it is therefore necessary to check the specified

parts in the manner described and in the order specified, irre‐

spective of the axle alignment being carried out. If you cannot find

any deviations from the nominal values during axle alignment, this

means the suspension does not have any deformations.

Visual inspection and check functional reliability of the steering

system

♦ Visual inspection of deformations and cracks

♦ Check the play of the link rod and steering gear

♦ Check the state of the track rods

♦ Visual inspection: fault-free bellows and collars, greased

♦ Check electrical and hydraulic lines and hoses for abrasions,

cuts or bends

♦ Make sure hydraulic lines, thread connections and steering

gear are leak tight

♦ Make sure the steering gear and lines are securely fastened

♦ Check the faultless functioning of the steering over the entire

steering range by turning the steering from one extreme angle

to the other; when applying constant pressure, the steering

wheel should turn without juddering

Visual inspection and check functional reliability of the chassis

Adhere to the sequence of the following inspection steps!

♦ Check all of the parts listed in the summary of components to

make sure they are not deformed, cracked or otherwise dam‐

aged

♦ Replace damaged component parts

♦ Align the vehicle on a Škoda-approved alignment gauge

Visual inspection and check functional reliability of the wheels,

tyres

♦ Check for evenness and balance

♦ Make sure the profile or side wall has not cracked or been

damaged as a result of the impact

♦ Check tyre pressure; compare pressure with the specification

on the tank flap

The tyre must be replaced if the rim and/or tyre is/are damaged.

The same applies if non-recognizable damages are assumed to

have occurred, given the type of accident and ensuing damage

to the vehicle.

Rapid 2011 ➤

Axles, steering - Edition 12.2018

1. Accident vehicle assessment 1

Page 8

Rapid 2011 ➤

GETtheMANUALS.org

Axles, steering - Edition 12.2018

If in doubt, the following always applies:

Whenever a safety risk cannot be excluded, the tyre(s) must be

renewed.

Whole vehicle

Check other vehicle systems, such as:

♦ Brake system including ABS

♦ Exhaust gas system, occupant protection system: visual in‐

spection and check functional reliability

For check values, settings and notes, refer to the appropriate re‐

pair manual/the ELSA system.

The examination of accident vehicles described in this document

only relates to the chassis and does not constitute a complex ex‐

amination of the entire vehicle.

Electronic vehicle systems

For basic safety systems, such as: anti-block system; airbag;

electronically-controlled suspension systems; electro-mechani‐

cal and electro-hydraulic steering systems; on other driver assis‐

tance systems, the saved error messages may need to be

retrieved from the ⇒ Vehicle diagnostic tester system where nec‐

essary. If the indicated system faults are saved in the event

memories, they must be correct according to the instructions in

the repair manual/ELSA system. After a successful repair, the

systems concerned must be re-examined to make sure no entries

are in the event memory in order to make sure proper operation

has been restored.

2 Rep. gr.00 - Technical data

Page 9

2 General Instructions

GETtheMANUALS.org

⇒ “2.1 Steering gear”, page 3

⇒ “2.2 Seals and sealing rings”, page 3

⇒ “2.3 Nuts and bolts”, page 3

⇒ “2.4 Electrical components”, page 3

2.1 Steering gear

♦ Thoroughly clean all unions and the adjacent areas before

disconnecting.

♦ When installing the steering gear, ensure the dowel sleeves

are correctly located between the console and steering gear.

♦ Place removed parts on a clean supporting plate and cover,

in order to avoid contamination. Only use lint-free cloths.

♦ Only install clean parts: Remove spare parts from their wrap‐

ping immediately before installing.

♦ Use only the grease and sealants with specified part numbers.

♦ Carefully cover or close opened components if the repair is not

completed immediately.

Rapid 2011 ➤

Axles, steering - Edition 12.2018

2.2 Seals and sealing rings

♦ Replace all gaskets and seals every time they are removed.

♦ After removing gaskets, examine the contact surfaces in the

housing or on shafts for sharp edges or damage, and correct

if necessary.

♦ Completely remove all liquid sealants from the sealing sur‐

faces, making sure that no residual sealant gets into the

steering box housing.

2.3 Nuts and bolts

♦ Slacken and tighten securing bolts and nuts of covers and

housings diagonally.

♦ Avoid canting particularly sensitive parts such as servo motor

with control unit. Loosen and tighten them diagonally in

stages.

♦ Tightening torques are for unlubricated nuts, bolts and screws.

♦ Always replace the self-locking screws and nuts.

2.4 Electrical components

♦ Touch an earthed object - e.g. water pipe, heating, metal sup‐

port or lift platform - before working on the electrical compo‐

nents. Please do not touch the connector contacts.

2. General Instructions 3

Page 10

Rapid 2011 ➤

GETtheMANUALS.org

Axles, steering - Edition 12.2018

40 – Front suspension

1 Front axle - Overview

⇒ “1.1 Front axle - Overview of the repair chapter”, page 4

⇒ “1.2 Raise the wheel-bearing housing in the rebound state (un‐

laden weight position)”, page 5

1.1 Front axle - Overview of the repair chapter

Note

♦

Welding and straightening work is not allowed on the bearing and wheel control components of the wheel

suspension.

♦

Always replace the self-locking screws and nuts.

♦

Always replace corroded self-locking nuts and screws.

♦

All screws must always be tightened firmly in the unladen condition (unladen weight position) to the chassis

parts with rubber-metal bearings - do not load the vehicle ⇒ “1.2 Raise the wheel-bearing housing in the

rebound state (unladen weight position)”, page 5 .

I - ⇒ “2 Repairing front axle”,

page 7

II - ⇒ “4 Repairing wheel bear‐

ing”, page 45

III - ⇒ “3 Repairing front sus‐

pension strut”, page 34

4 Rep. gr.40 - Front suspension

Page 11

1.2 Raise the wheel-bearing housing in the

GETtheMANUALS.org

rebound state (unladen weight position)

Special tools and workshop equipment required

♦ Engine and gearbox jack e.g. -V.A.G 1383/A- or -VAS6931♦ Tensioning strap - T10038♦ Mounting bracket - T10149-

Note

The screws must always be tightened firmly in the unladen con‐

dition (unladen weight position) to the chassis parts with rubbermetal bearings - do not load the vehicle!

Unladen weight:

Vehicle weight with a full fuel tank and washer fluid/headlight

cleaning system reservoir, spare wheel and jack (if it is fitted at

the factory), tool kit and without driver. The spare wheel, tool kit

and jack must be located in the position prescribed by the vehicle

manufacturer.

Rubber-metal bearings can be twisted only to a limited extent.

Therefore the axle components with rubber-metal bearings must

be put in a position before tightening, which corresponds to the

position while driving.

Otherwise the rubber-metal bearing will be under tension and as

a result, will have a lower life.

This position can be simulated on the lift platform by raising the

corresponding wheel bearing housing with the engine/gearbox

jack e. g. -V.A.G 1383/A- or -VAS6931- and the uptake - T10149- .

– Before commencing work, measure e.g with a measuring

tape, the dimension -a- from wheel centre to lower edge of the

wheelhouse.

Measuring must be performed when the vehicle is on the ground

and in the unladen condition (unladen weight position) - do not

load the vehicle.

– Note the measured value. It is required when tightening the

screws to the chassis parts with rubber-metal bearings.

Before the corresponding wheel-bearing housing is lifted, the ve‐

hicle must be lashed securely at the supporting arms of the lift

platform with the tensioning straps - T10038- .

Rapid 2011 ➤

Axles, steering - Edition 12.2018

DANGER!

If the vehicle is not lashed, there is a risk of the vehicle toppling

off the lift platform.

– Remove wheel.

– Rotate the wheel hub until one of the holes for the wheel bolts

is located at the top.

– Install support - T10149- with wheel bolt at the wheel hub.

1. Front axle - Overview 5

Page 12

Rapid 2011 ➤

GETtheMANUALS.org

Axles, steering - Edition 12.2018

The tightening of the corresponding screw must only be per‐

formed, if the measured dimension -a- between the wheel hub

centre and the lower edge of the wheel house is achieved before

commencing work.

– Raise up the wheel-bearing housing using the engine and

gearbox jack e. g. -V.A.G 1383/A- or -VAS6931- with mount T10149- until dimension -a- is achieved.

Caution

♦ Do not raise or lower the vehicle, if the engine/gearbox

jack is positioned under the vehicle.

♦ Do not leave the engine/gearbox jack e. g. -V.A.G 1383/

A- or -VAS6931- positioned under the vehicle for longer

than necessary.

– Tighten up the corresponding screws fully to the specified

tightening torque.

– Lower the wheel bearing housing.

– Remove the engine/gearbox jack e.g. -V.A.G 1383/A- or -

VAS6931- from underneath the vehicle.

– Remove support - T10149- .

– Remove tensioning strap - T10038- .

6 Rep. gr.40 - Front suspension

Page 13

2 Repairing front axle

GETtheMANUALS.org

⇒ “2.1 Summary of components of assembly carrier, track control

arm, anti-roll bar, coupling rod, support and pendulum support”,

page 7

⇒ “2.2 Lower the assembly carrier in the service position”, page

9

⇒ “2.3 Inspecting the suspension link”, page 15

⇒ “2.4 Removing and installing the suspension link”, page

15

⇒ “2.5 Removing and installing the track control arm”, page

19

⇒ “2.6 Replacing the rubber-metal bearing for track control arm”,

page 22

⇒ “2.7 Removing and installing the anti-roll bar”, page 23

⇒ “2.8 Removing and installing the rubber bearing for the anti-roll

bar”, page 29

⇒ “2.9 Removing and installing assembly carrier”, page 30

Rapid 2011 ➤

Axles, steering - Edition 12.2018

2.1 Summary of components of assembly carrier, track control arm, anti-roll bar, coupling rod, support and pendulum support

Note

♦

Replace bolts / nuts that are tightened at an angle of rotation, as well as replacement components after

removal.

♦

Welding and straightening work is not allowed on the bearing and wheel control components of the wheel

suspension.

♦

Always replace the self-locking screws and nuts.

♦

Always replace corroded self-locking nuts and screws.

♦

All screws must always be tightened firmly in the unladen condition (unladen weight position) to the chassis

parts with rubber-metal bearings - do not load the vehicle ⇒ “1.2 Raise the wheel-bearing housing in the

rebound state (unladen weight position)”, page 5 .

2. Repairing front axle 7

Page 14

Rapid 2011 ➤

GETtheMANUALS.org

Axles, steering - Edition 12.2018

1 - Assembly carrier

❑ Removing and installing

⇒ “2.9 Removing and in‐

stalling assembly carri‐

er”, page 30

❑ Assignment ⇒ Elec‐

tronic Catalogue of

Original Parts

2 - Screw

❑ Screws for anti-roll bar

clamps

❑ replace after each re‐

moval

❑ 20 Nm + 90°.

3 - Self-locking nut

❑ replace after each re‐

moval

❑ Assignment ⇒ Elec‐

tronic Catalogue of

Original Parts

❑ 40 Nm

4 - Anti-roll bar

❑ to remove and install

lower assembly carrier

❑ Removing and installing

⇒ “2.7 Removing and in‐

stalling the anti-roll bar”,

page 23

❑ Assignment ⇒ Elec‐

tronic Catalogue of

Original Parts

5 - Rubber bearing

❑ Assignment ⇒ Elec‐

tronic Catalogue of

Original Parts

6 - Spring clip

❑ Assignment ⇒ Electronic Catalogue of Original Parts

7 - Self-locking nut

❑ replace after each removal

❑ Assignment ⇒ Electronic Catalogue of Original Parts

❑ 40 Nm

8 - Coupling rod

❑ Assignment ⇒ Electronic Catalogue of Original Parts

9 - Countersupport

10 - Nut

❑ replace after each removal

11 - Rubber-metal bearing

❑ Rear rubber-metal bearing for track control arm

❑ Replace ⇒ “2.6 Replacing the rubber-metal bearing for track control arm”, page 22

12 - Screw

❑ replace after each removal

❑ 20 Nm + 90°.

8 Rep. gr.40 - Front suspension

Page 15

Rapid 2011 ➤

GETtheMANUALS.org

Axles, steering - Edition 12.2018

13 - Screw

❑ replace after each removal

❑ 70 Nm + 90°.

14 - Self-locking nut

❑ replace after each removal

❑ 20 Nm + 90°.

15 - Steering joint

❑ Check ⇒ “2.3 Inspecting the suspension link”, page 15

❑ Removing and installing ⇒ “2.4 Removing and installing the suspension link”, page 15

16 - Nut

❑ replace after each removal

❑ 100 Nm

17 - Screw

❑ replace after each removal

❑ 70 Nm + 90°.

18 - Suspension link

❑ Removing and installing ⇒ “2.5 Removing and installing the track control arm”, page 19

19 - Screw

❑ replace after each removal

❑ 70 Nm + 90°.

20 - Rubber-metal bearing

❑ Front rubber-metal bearing for track control arm

❑ Replace ⇒ “2.6 Replacing the rubber-metal bearing for track control arm”, page 22

21 - Screw

❑ replace after each removal

❑ 70 Nm + 90°.

22 - Dowel screws

❑ replace after each removal

❑ 40 Nm + 90°.

23 - Screw

❑ replace after each removal

❑ Position the screws in the elongated holes of the pendulum support in such a way that there is maximum

distance between the gearbox and the assembly carrier

❑ 30 Nm + 90°.

24 - Pendulum support

❑ do not disassemble

❑ Position the screws in the elongated holes of the pendulum support in such a way that there is maximum

distance between the gearbox and the assembly carrier

❑ Assignment ⇒ Electronic Catalogue of Original Parts

2.2 Lower the assembly carrier in the ser‐

vice position

Special tools and workshop equipment required

♦ Engine and gearbox jack e.g. -V.A.G 1383/A- or -VAS6931♦ Fixing device - T10486/1♦ Fixing device - T10096-

2. Repairing front axle 9

Page 16

Rapid 2011 ➤

GETtheMANUALS.org

Axles, steering - Edition 12.2018

Release the assembly carrier - remove:

Caution

Bring the steering wheel to its central position (with the wheels

straight ahead) and make sure that it does not turn during re‐

pairs as this could damage the restoring ring with slip ring of

the airbag unit.

– Secure the steering wheel with the wheels in straight ahead

position with adhesive tape -arrow- against unintended turn‐

ing.

– Unscrew plastic nuts -arrows- and remove trim panel -1-.

– Release screw -1-.

– Remove the universal joint (in the direction of the arrow) from

the input shaft of the power-steering gear.

Vehicles with the exhaust system below the assembly carrier

– Remove pre-exhaust pipe ⇒ Engine; Rep. gr. 26 .

Continued for all vehicles

10 Rep. gr.40 - Front suspension

Page 17

– Unscrew the screws -1- and -2- of the pendulum support.

GETtheMANUALS.org

– Screw out the left and right nuts -1-.

– Pull out left and right coupling rod -3- from stabilizer -2-.

– Swivel the anti-roll bar upwards.

Rapid 2011 ➤

Axles, steering - Edition 12.2018

– Insert wooden insert -1- in the adapter , e. g. -V.A.G 1359/2- .

– Support the assembly carrier with engine/gearbox jack with

adapter.

Note

♦

Note the following work steps and absolutely ensure that you

follow the sequence.

♦

The fixing bolts out from -T10096- and -T10486/1- must only

be tightened to maximum 20 Nm as otherwise the fixing bolt

thread becomes damaged.

– Unscrew left screw -1- for assembly carrier -4-, screw in fixing

bolt of -T10096- and tighten to 20 Nm.

– Unscrew right screw -1- for assembly carrier (not shown in

figure), screw in a fixing bolt from -T10096- and tighten to 20

Nm.

– Unscrew bolts -3- on both sides.

– Unscrew the left screw -2- and remove support -5-.

– Screw in fixing bolt -T10486/1- and tighten to 20 Nm.

– Unscrew the right screw -2- and remove support -5-.

– Screw in fixing bolt -T10486/1- and tighten to 20 Nm.

The alignment of the assembly carrier is completed once all 4

screws (Pos. -1- and -2- on both vehicle sides) are consecutively

replaced with the fixing bolts.

If it is not possible to insert the fixing devices - T10096- or T10486/1- into the corresponding openings of the assembly car‐

rier, the following measures must be carried out:

2. Repairing front axle 11

Page 18

Rapid 2011 ➤

GETtheMANUALS.org

Axles, steering - Edition 12.2018

– Prepare the inlet openings in the lower area of the assembly

carrier e.g. with a file so that the fixing devices - T10096- or T10486/1- can be inserted into the openings.

– Treat prepared openings to protect against corrosion, e.g. with

zinc spray - D 007 500 04- .

For vehicles with exhaust pipe inserted on the assembly carrier

– Remove spring washer for exhaust system to assembly carrier

⇒ Engine; Rep. gr. 26 .

Continued for all vehicles

– Lower assembly carrier approx. 4 cm and through this slacken

from the fixing bolts.

Note

When lowering the assembly carrier make sure there is sufficient

clearance between the drive shafts and the stabilizer.

– Slowly lower the assembly carrier with engine/gearbox jack

and with adapter.

Tighten assembly carrier - install:

– Raise assembly carrier onto the fixing bolts until the consoles

touch both sides of the body.

Note

♦

Note the following work steps and absolutely ensure that you

follow the sequence.

♦

Unscrew the fixing bolts from -T10096- and -T10486/1- one at

a time. It should be subsequently replaced by a new bolt tight‐

ened to the recommended torque.

– Unscrew left fixing bolt -1- from -T10096- , screw in new screw

and tighten to the recommended tightening torque.

– Unscrew right fixing bolt -1- from -T10096- (not shown in fig‐

ure), screw in new screw and tighten to the recommended

tightening torque.

– Unscrew left fixing bolt -2- from -T10486/1- .

– Install left support.

– Screw in new bolts for the left support and tighten at the rear

by hand.

– Screw in new bolt for assembly carrier and left support and

tighten to the recommended tightening torque.

– Tighten the rear left support bolts to the recommended tight‐

ening torque.

– Unscrew right fixing bolt -2- from -T10486/1- (not shown in

figure).

– Install right support.

– Screw in new bolts for the right support and tighten at the rear

by hand.

– Screw in new bolt for assembly carrier and right support and

tighten to the recommended tightening torque.

12 Rep. gr.40 - Front suspension

Page 19

– Tighten up the rear right support bolts to the recommended

GETtheMANUALS.org

tightening torque.

– Remove engine/gearbox jack with adapter .

– Mount pendulum support on the gearbox and tighten new

screws -1- and -2-.

Note

Position the screws -1- in the elongated holes of the pendulum

support in such a way that there is maximum distance between

the gearbox and the assembly carrier.

Vehicles with the exhaust system below the assembly carrier

– Install the pre-exhaust pipe ⇒ Engine; Rep. gr. 26 .

For vehicles with exhaust pipe inserted on the assembly carrier

– Install spring washer for exhaust system to assembly carrier

⇒ Engine; Rep. gr. 26 .

Continued for all vehicles

– Install the noise insulation ⇒ Body Work; Rep. gr. 50 .

Rapid 2011 ➤

Axles, steering - Edition 12.2018

– Slide the universal joint of the steering column in the

-direction of the arrow- onto the input shaft of the power steer‐

ing and tighten with a new screw -1-.

– Position cover -1- and screw on plastic nuts -arrows-.

– Remove the securing mechanism which prevents the steering

wheel from turning (adhesive tape).

– Perform a test drive.

– Check the steering wheel position during the test drive.

Note

If after the test drive and with the front wheels pointing straight

ahead the steering wheel is off straight, perform an axle alignment

⇒ “2.2 Axle alignment”, page 129 .

2. Repairing front axle 13

Page 20

Rapid 2011 ➤

GETtheMANUALS.org

Axles, steering - Edition 12.2018

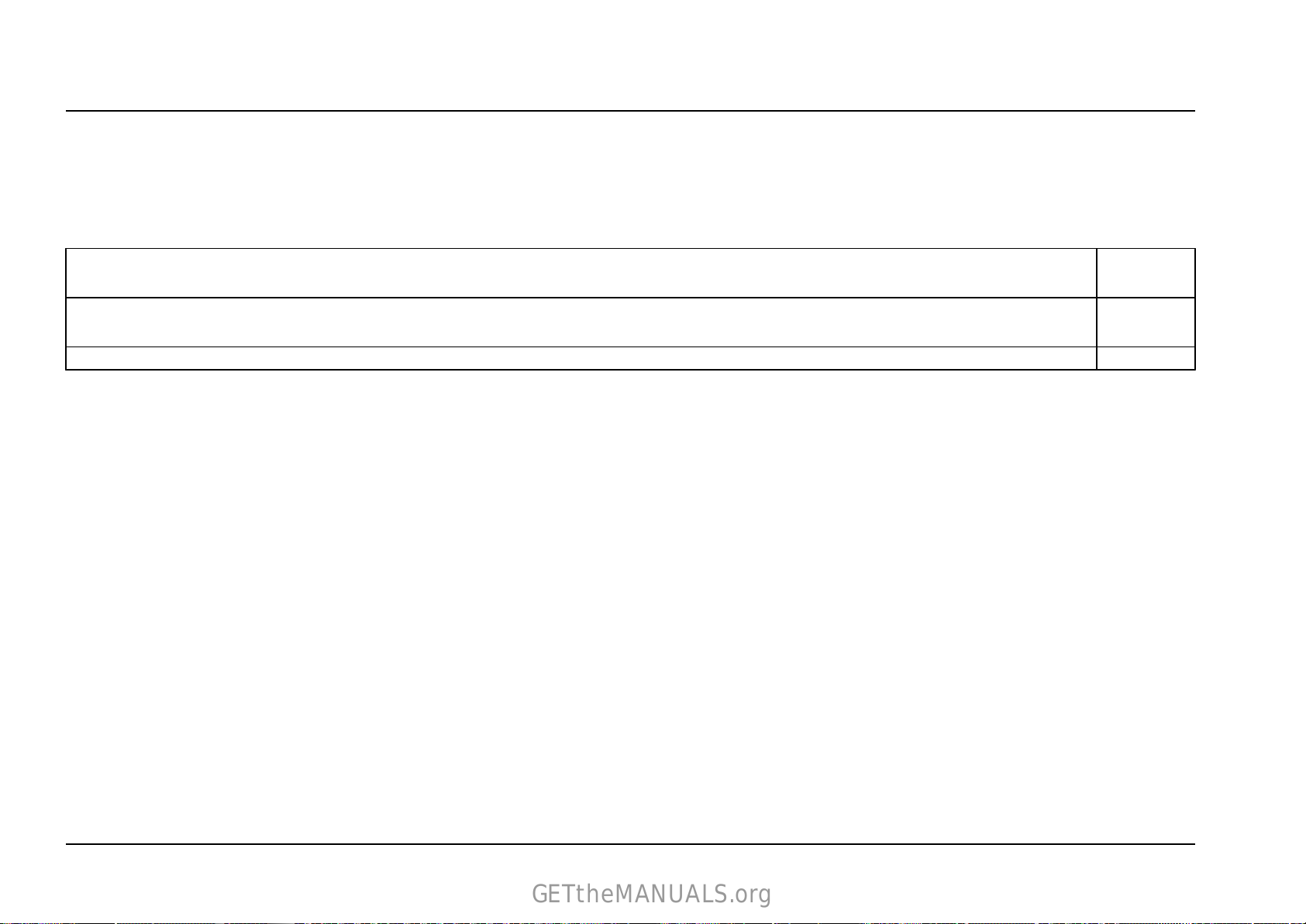

Tightening torques - summaries of components

Note

Replace bolts / nuts that are tightened at an angle of rotation, as well as replacement components after removal.

Assembly carrier to body

♦ Use new screws!

Support to body

♦ Use new screws!

Hinged support to gearbox

♦ Use new screws!

Universal joint of the steering column to power-steering gear

♦ Use new screw!

70 Nm + 90°.

20 Nm + 90°.

30 Nm + 90°.

20 Nm + 90°.

14

Page 21

2.3 Inspecting the suspension link

GETtheMANUALS.org

Note

♦

For these two tests no “play” may be felt or be visible.

♦

Observe the suspension link during the tests.

♦

Take into account possible wheel bearing play or “play” in top

suspension strut bearing.

♦

Inspect rubber bellows for damage, if necessary replace.

Inspecting axial play

– Forcefully push the track control arm down and up again.

Rapid 2011 ➤

Axles, steering - Edition 12.2018

Inspecting radial play

– Forcefully push the wheel towards the inside and the outside.

2.4 Removing and installing the suspension

link

Special tools and workshop equipment required

♦ Ball joint extractor - 3287ARemoving:

– Remove wheel.

– Release fixing nuts -arrows-.

– Release track control arm from the screws of the steering joint.

15

Page 22

Rapid 2011 ➤

GETtheMANUALS.org

Axles, steering - Edition 12.2018

– Position the ball joint extractor as shown in the figure.

Note

♦

To protect the thread, screw the nut a couple of thread turns

onto the steering joint.

♦

While pressing out the axle joint, be aware of the injury risk:

the ball joint puller may fall out when the pivot pin is loosened.

– Push out the steering joint with the ball joint extractor.

Installing:

Note

♦

Observe fitting position of the steering joints according to the

marking.

♦

The castor changes if the fitting position of the steering joint is

incorrect.

♦

Always fit new nuts for the drive shafts.

Fitting position according to the identification on the steering joint:

R - means right

L - means left

3 - means for vehicles with mechanical steering (is not available)

4 - means for vehicles with power steering

“arrow” - shows in the direction of travel on vehicles with power

steering

Left steering joint

Designation “L4” and “arrow” designates the left steering joint in

the direction of travel for vehicle with power steering

R3 - marks the right steering joint for vehicle with mechanical

steering (is not available)

Right steering joint

Designation “R4” and “arrow” designates the right steering joint

in the direction of travel for vehicle with power steering.

L3 - marks the left steering joint for vehicle with mechanical steer‐

ing (is not available)

– Insert the steering joint into the wheel-bearing housing (to do

so, pull the track control arm towards the bottom under the

steering joint to be inserted).

Note

16

Page 23

♦

GETtheMANUALS.org

Observe fitting position of the steering joints according to the

marking.

♦

The castor changes if the fitting position of the steering joint is

incorrect.

– Screw new nut onto the steering joint and tighten.

While doing this secure steering joint against spinning, so that

the steering joint boot is not damaged.

– Position the track control arm onto the steering joint and tight‐

en nuts -arrows-.

– Install and tighten the front wheel.

– Perform a test drive.

– Check the steering wheel position during the test drive.

Note

If after the test drive and with the front wheels pointing straight

ahead the steering wheel is off straight, perform an axle alignment

⇒ “2.2 Axle alignment”, page 129 .

Rapid 2011 ➤

Axles, steering - Edition 12.2018

17

Page 24

Rapid 2011 ➤

GETtheMANUALS.org

Axles, steering - Edition 12.2018

Tightening torques - summaries of components

Note

Replace bolts / nuts that are tightened at an angle of rotation, as well as replacement components after removal.

Steering joint to wheel-bearing housing

♦ Use new nut!

Steering joint to track control arm

♦ Use new nuts!

Wheel bolts 120 Nm

20 Nm + 90°.

100 Nm

18

Page 25

2.5 Removing and installing the track con‐

GETtheMANUALS.org

trol arm

Removing:

Note

Before commencing work, determine the measurement -a- ⇒

“1.2 Raise the wheel-bearing housing in the rebound state (un‐

laden weight position)”, page 5 .

– Remove front wheel.

– Release fixing nuts -arrows-.

Rapid 2011 ➤

Axles, steering - Edition 12.2018

– Unscrew screw -arrow 1- and screw with nut -arrow 2-.

– Release track control arm from the screws of the steering joint.

– Take the track control arm out of the assembly carrier.

Installing:

– Insert the track control arm into the assembly carrier.

– Insert screw -arrow 1- and screw with nut -arrow 2- and do not

tighten yet.

– Position the track control arm onto the steering joint and tight‐

en.

Note

The tightening of the screw for steering joint and assembly carrier

can be performed, if the dimension -a- is maintained (vehicle in

unladen condition - unladen weight position) ⇒ “1.2 Raise the

wheel-bearing housing in the rebound state (unladen weight po‐

sition)”, page 5 .

– Tighten screw -arrow 1- and screw with nut -arrow 2-.

– Installing and tightening the wheel.

– Perform a test drive.

– Check the steering wheel position during the test drive.

19

Page 26

Rapid 2011 ➤

GETtheMANUALS.org

Axles, steering - Edition 12.2018

Note

If after the test drive and with the front wheels pointing straight

ahead the steering wheel is off straight, perform an axle alignment

⇒ “2.2 Axle alignment”, page 129 .

20

Page 27

Tightening torques - summaries of components

GETtheMANUALS.org

Note

Replace bolts / nuts that are tightened at an angle of rotation, as well as replacement components after removal.

Rapid 2011 ➤

Axles, steering - Edition 12.2018

Track control arm to assembly carrier

♦ Use new screws and nuts!

♦ Tighten in unladen weight position ⇒ “1.2 Raise the wheel-bearing housing in the rebound state (unladen weight position)”, page 5

Steering joint to track control arm

♦ Use new nuts!

Wheel bolts 120 Nm

70 Nm + 90°.

100 Nm

21

Page 28

Rapid 2011 ➤

GETtheMANUALS.org

Axles, steering - Edition 12.2018

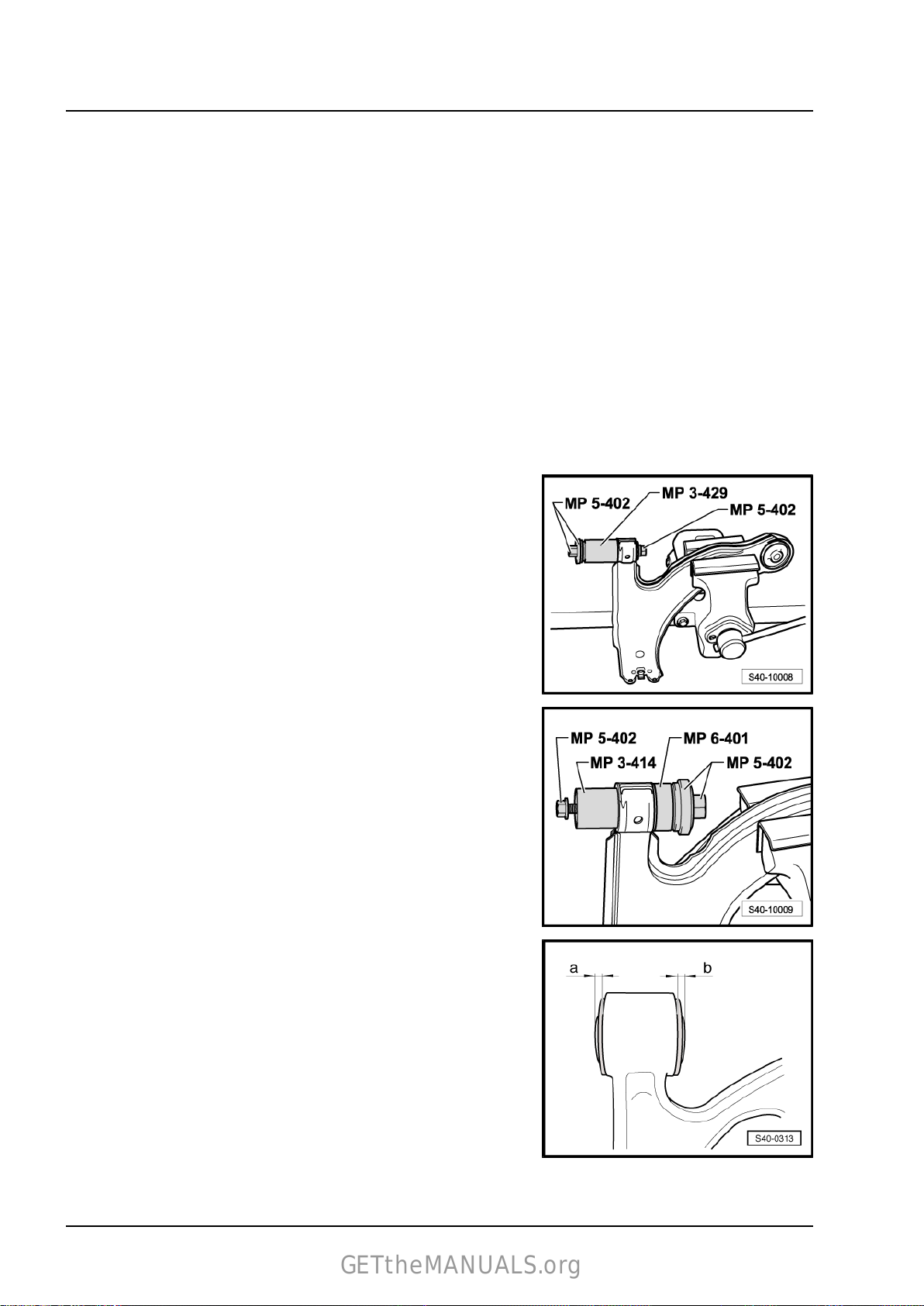

2.6 Replacing the rubber-metal bearing for track control arm

Special tools and workshop equipment required

♦ Pressure plate - MP3-406 (VW 401)♦ Pressure plate - MP3-407 (VW 402)♦ Pipe - MP3-414 (VW 516)♦ Pipe - MP3-429 (2010)♦ Thrust washer - MP3-456 (VW 447 I)♦ Assembly tool - MP5-402 (3301)♦ Assembly tool - MP6-401 (3288)♦ Base - MP6-407 (40-103)♦ Pipe - MP6-408 (30-14)♦ Workshop press , e.g. -VAS 6654Press off front bearing for track control arm:

Press out rubber-metal bearing as shown.

Press in front bearing for track control arm:

– Insert front bearing in - pipe section - MP3-414 (VW 516)- .

In order not to damage the rubber-metal bearing when inserting

it, it must be positioned at an angle. During the press-in proce‐

dure, insert the rubber-metal bearing in the straightahead posi‐

tion.

– Apply assembly sliding oil - G 294 421 A1- to the outside of

the rubber-metal bearing.

– Press the rubber-metal bearing into the hole of the track con‐

trol arm.

The dimensions -a- and -b- must be identical after pressing in.

If the dimensions -a- and -b- are not identical:

– Slightly press out the bearing from the track control arm so that

the values -a- and -b- are identical.

22

Page 29

Fitting position of rear bearing for track control arm

GETtheMANUALS.org

– The marking -2- of the rubber-metal bearing must be posi‐

tioned to one axle with the marking -1- on the track control arm.

– The kidney-shaped recess -3- of the rubber-metal bearing

must always point towards the longitudinal vehicle axis.

Pressing out and in the rear bearing for the track control arm

Pay attention to the correct installation position of the rubber-

metal bearing during the press-in procedure (see Fig. S40-0389).

Rapid 2011 ➤

Axles, steering - Edition 12.2018

Note

♦

Use the assembly sliding oil (acid-free). E.g. 294 421 A1 to

press in the bearings.

♦

Do not use another grease!

2.7 Removing and installing the anti-roll bar

Special tools and workshop equipment required

♦ Engine and gearbox jack e.g. -V.A.G 1383/A- or -VAS6931♦ Fixing device - T10486/1♦ Fixing device - T10096Removing:

Vehicles with the exhaust system below the assembly carrier

– Remove pre-exhaust pipe ⇒ Engine; Rep. gr. 26 .

For vehicles with exhaust pipe inserted on the assembly carrier

– Remove spring washer for exhaust system to assembly carrier

⇒ Engine; Rep. gr. 26 .

Continued for all vehicles

23

Page 30

Rapid 2011 ➤

GETtheMANUALS.org

Axles, steering - Edition 12.2018

– Unscrew the screws -1- and -2- of the pendulum support.

– Unscrew the clamps of the anti-roll bar from the assembly car‐

rier -arrows-.

Note

♦

The anti-roll bar clamp is located behind the assembly carrier

and is not visible in the figure shown.

♦

The bottom screw of the right clamp can only be removed once

the assembly carrier has been lowered.

– Screw out the left and right nuts -1-.

– Pull out left and right coupling rod -3- from stabilizer -2-.

– Unscrew the screws -arrows- and tie up the power-steering

gear e.g with wire (attach), so that it maintains its position.

24

Page 31

– Insert wooden insert -1- in the adapter , e. g. -V.A.G 1359/2- .

GETtheMANUALS.org

– Support the assembly carrier with engine/gearbox jack with

adapter.

Note

♦

Note the following work steps and absolutely ensure that you

follow the sequence.

♦

The fixing bolts out from -T10096- and -T10486/1- must only

be tightened to maximum 20 Nm as otherwise the fixing bolt

thread becomes damaged.

– Unscrew left screw -1- for assembly carrier -4-, screw in fixing

bolt of -T10096- and tighten to 20 Nm.

– Unscrew right screw -1- for assembly carrier (not shown in

figure), screw in a fixing bolt from -T10096- and tighten to 20

Nm.

– Unscrew bolts -3- on both sides.

– Unscrew the left screw -2- and remove support -5-.

– Screw in fixing bolt -T10486/1- and tighten to 20 Nm.

– Unscrew the right screw -2- and remove support -5-.

– Screw in fixing bolt -T10486/1- and tighten to 20 Nm.

The alignment of the assembly carrier is completed once all 4

screws (Pos. -1- and -2- on both vehicle sides) are consecutively

replaced with the fixing bolts.

– Lower assembly carrier approx. 4 cm and through this slacken

from the fixing bolts.

Rapid 2011 ➤

Axles, steering - Edition 12.2018

Note

When lowering the assembly carrier make sure there is sufficient

clearance between the drive shafts and the stabilizer.

– Slowly lower the assembly carrier with engine/gearbox jack

and with adapter.

– Turn the anti-roll bar upwards and remove towards the rear.

Installing:

– Insert the anti-roll bar.

– Insert new screws for the anti-roll bar clamps and tighten

-arrows-.

– Raise the assembly carrier onto the fixing bolts and simulta‐

neously fit the power steering gear onto the assembly carrier.

Note

♦

Before inserting the screws for fixing the assembly carrier to

body, position the power-steering gear on the assembly carrier

and tighten with the new screws for the power-steering gear.

♦

Check correct positioning of gasket for power steering gear

onto the footwell opening of the vehicle.

25

Page 32

Rapid 2011 ➤

GETtheMANUALS.org

Axles, steering - Edition 12.2018

– Insert screws -arrows- and tighten by hand.

– Raise assembly carrier until the assembly carrier touches the

body.

– Tighten screws -arrows- of power steering gear/assembly car‐

rier to specified tighening torque and remove attachment (sus‐

pension) of the power steering gear.

Note

♦

Note the following work steps and absolutely ensure that you

follow the sequence.

♦

Unscrew the fixing bolts from -T10096- and -T10486/1- one at

a time. It should be subsequently replaced by a new bolt tight‐

ened to the recommended torque.

– Unscrew left fixing bolt -1- from -T10096- , screw in new screw

and tighten to the recommended tightening torque.

– Unscrew right fixing bolt -1- from -T10096- (not shown in fig‐

ure), screw in new screw and tighten to the recommended

tightening torque.

– Unscrew left fixing bolt -2- from -T10486/1- .

– Install left support.

– Screw in new bolts for the left support and tighten at the rear

by hand.

– Screw in new bolt for assembly carrier and left support and

tighten to the recommended tightening torque.

– Tighten the rear left support bolts to the recommended tight‐

ening torque.

– Unscrew right fixing bolt -2- from -T10486/1- (not shown in

figure).

– Install right support.

– Screw in new bolts for the right support and tighten at the rear

by hand.

– Screw in new bolt for assembly carrier and right support and

tighten to the recommended tightening torque.

– Tighten up the rear right support bolts to the recommended

tightening torque.

– Remove engine/gearbox jack with adapter .

– Mount pendulum support on the gearbox and tighten new

screws -1- and -2-.

Note

Position the screws -1- in the elongated holes of the pendulum

support in such a way that there is maximum distance between

the gearbox and the assembly carrier.

26

Page 33

– Insert left and right coupling rod -3- into the stabilizer -2-.

GETtheMANUALS.org

– Screw in the left and right nut -1- and tighten.

Vehicles with the exhaust system below the assembly carrier

– Install the pre-exhaust pipe ⇒ Engine; Rep. gr. 26 .

For vehicles with exhaust pipe inserted on the assembly carrier

– Install spring washer for exhaust system to assembly carrier

⇒ Engine; Rep. gr. 26 .

Continued for all vehicles

– Perform a test drive.

– Check the steering wheel position during the test drive.

Note

If after the test drive and with the front wheels pointing straight

ahead the steering wheel is off straight, perform an axle alignment

⇒ “2.2 Axle alignment”, page 129 .

Rapid 2011 ➤

Axles, steering - Edition 12.2018

27

Page 34

Rapid 2011 ➤

GETtheMANUALS.org

Axles, steering - Edition 12.2018

Tightening torques - summaries of components

Note

Replace bolts / nuts that are tightened at an angle of rotation, as well as replacement components after removal.

Power-steering gear to assembly carrier

♦ Use new screws!

Assembly carrier to body

♦ Use new screws!

Support to body

♦ Use new screws!

Hinged support to gearbox

♦ Use new screws!

Coupling rod to anti-roll bar 40 Nm

Clamp of anti-roll bar to assembly carrier

♦ Use new screws!

50 Nm + 180°.

70 Nm + 90°.

20 Nm + 90°.

30 Nm + 90°.

20 Nm + 90°.

28

Page 35

2.8 Removing and installing the rubber

GETtheMANUALS.org

bearing for the anti-roll bar

Removing

– Remove right drive shaft from the gearbox and tie up.

– Remove the screws -arrows- on both sides.

– Detach the spring clip from the rubber bearing.

– Detach the rubber bearing from the anti-roll bar.

Installing

– Fit the rubber bearing with the spring clip -1- onto the anti-roll

bar.

Rapid 2011 ➤

Axles, steering - Edition 12.2018

Note

♦

Ensure that the rubber bearing is positioned at the stop -2-.

♦

Depending on the version, the stop -2- may be located at the

outer or inner side of the rubber bearing.

– Install the screws -arrows- on both sides.

– Install right drive shaft on gearbox.

Tightening torques - summaries of components

Note

Replace bolts / nuts that are tightened at an angle of rotation, as

well as replacement components after removal.

Clamp of anti-roll bar to assembly carrier

♦ Use new screws!

Drive shaft to gearbox flange “M8”

♦ Use new screws!

♦ Use new washers!

20 Nm + 90°.

40 Nm

♦ First tighten crosswise to 10 Nm

29

Page 36

Rapid 2011 ➤

GETtheMANUALS.org

Axles, steering - Edition 12.2018

Drive shaft to gearbox flange “M10”

♦ Use new screws!

♦ Use new washers!

♦ First tighten crosswise to 10 Nm

2.9 Removing and installing assembly car‐

rier

Special tools and workshop equipment required

♦ Engine and gearbox jack e.g. -V.A.G 1383/A- or -VAS6931♦ Extractor - MP6-425 (3283)♦ Polycarmade grease - G 052 142 A2Removing:

– Remove the nuts for the steering joint -arrows-.

– Pull the track control arm out of the steering joints.

70 Nm

– Screw out the left and right nuts -1-.

– Pull out left and right coupling rod -3- from stabilizer -2-.

– Swivel the anti-roll bar upwards.

– Unscrew the screws -arrows- and tie up the power-steering

gear e.g with wire (attach), so that it maintains its position.

– Release the assembly carrier and lower ⇒ “2.2 Lower the as‐

sembly carrier in the service position”, page 9 (do not remove

the universal joint of the steering column from the input shaft

of the power-steering gear).

– Remove assembly carrier.

Remove screws for anti-roll bar clamps and anti-roll bar, if nec‐

essary.

Installing:

Note

30

Page 37

Before inserting the fixing screws of the assembly carrier, position

GETtheMANUALS.org

the power-steering gear on the assembly carrier and tighten the

screws for the power-steering gear.

If necessary install anti-roll bar and tighten screws for anti-roll bar

clamps.

– Position the assembly carrier with engine/gearbox jack with

adapter.

– Raise the assembly carrier onto the fixing bolts and simulta‐

neously fit the power steering gear onto the assembly carrier.

– Insert screws -arrows- and tighten by hand.

– Raise assembly carrier until it touches the body.

Note

Check correct positioning of gasket for power steering gear onto

the footwell opening of the vehicle.

Rapid 2011 ➤

Axles, steering - Edition 12.2018

– Tighten screws -arrows- of power steering gear/assembly car‐

rier to specified tighening torque and remove attachment (sus‐

pension) of the power steering gear.

– Screw assembly carrier to body ⇒ “2.2 Lower the assembly

carrier in the service position”, page 9 .

– Insert left and right coupling rod -3- into the stabilizer -2-.

– Screw in the left and right nut -1- and tighten.

31

Page 38

Rapid 2011 ➤

GETtheMANUALS.org

Axles, steering - Edition 12.2018

– Insert the nuts for the steering joint -arrows-.

– Perform a test drive.

– Check the steering wheel position during the test drive.

Note

If after the test drive and with the front wheels pointing straight

ahead the steering wheel is off straight, perform an axle alignment

⇒ “2.2 Axle alignment”, page 129 .

32

Page 39

Tightening torques - summaries of components

GETtheMANUALS.org

Note

Replace bolts / nuts that are tightened at an angle of rotation, as well as replacement components after removal.

Rapid 2011 ➤

Axles, steering - Edition 12.2018

Power-steering gear to assembly carrier

♦ Use new screws!

Assembly carrier to body

♦ Use new screws!

Support to body

♦ Use new screws!

Coupling rod to anti-roll bar 40 Nm

Steering joint to track control arm

♦ Use new nuts!

Wheel bolts 120 Nm

50 Nm + 180°.

70 Nm + 90°.

20 Nm + 90°.

100 Nm

33

Page 40

Rapid 2011 ➤

GETtheMANUALS.org

Axles, steering - Edition 12.2018

3 Repairing front suspension strut

⇒ “3.1 Installation general view of the suspension strut”, page

34

⇒ “3.2 Removing and installing the suspension strut”, page

35

⇒ “3.3 Repairing suspension strut”, page 40

⇒ “3.4 Inspect shock absorber”, page 42

⇒ “3.5 Disposing of the shock absorber”, page 43

3.1 Installation general view of the suspension strut

Note

♦

Replace bolts / nuts that are tightened at an angle of rotation, as well as replacement components after

removal.

♦

The figure represents the wheel-bearing housing for disc brake FS-III. Different versions of the wheel-bear‐

ing housing do not influence the installation of the suspension strut.

1 - Wheel bearing housing

2 - Nut

❑ replace after each re‐

moval

❑ 60 Nm + 90°.

3 - Screw

❑ replace after each re‐

moval

4 - Shock absorber

❑ Removing and installing

⇒ “3.2 Removing and in‐

stalling the suspension

strut”, page 35

❑ can be replaced individ‐

ually

❑ Check ⇒ “3.4 Inspect

shock absorber”, page

42

❑ disposing of ⇒ “3.5 Dis‐

posing of the shock ab‐

sorber”, page 43

❑ Assignment ⇒ Elec‐

tronic Catalogue of

Original Parts

5 - Spring stop

6 - Boot

7 - Cap

8 - Flange nut, self-locking

♦ replace after each removal

❑ 60 Nm

9 - Spring cap

34

Page 41

Axles, steering - Edition 12.2018

GETtheMANUALS.org

10 - Suspension strut dome

11 - Flanged nut

♦ replace after each removal

❑ 60 Nm

12 - Suspension strut bearing

13 - Axial grooved ball bearing

14 - Spring cap

15 - Coil spring

❑ check colour coding

❑ The surface of the spring coil must not be damaged

❑ replace axle-wise

❑ the coil springs fitted to the axle must be of the same manufacturer

❑ Removing and installing ⇒ “3.3 Repairing suspension strut”, page 40

❑ Assignment ⇒ Electronic Catalogue of Original Parts

3.2 Removing and installing the suspension

strut

Rapid 2011 ➤

Special tools and workshop equipment required

♦ Engine and gearbox jack e.g. -V.A.G 1383/A- or -VAS6931♦ Spreader - 3424♦ Extractor - MP6-425 (3283)♦ Ball joint extractor - 3287A♦ Socket wrench insert WAF 21 - MP6-427 (3186)♦ Polycarbamide grease - G 052 142 A2Removing:

– Remove the outer joint of the drive shaft from the wheel-bear‐

ing housing ⇒ “5.3 Removing and installing outer joint of drive

shaft”, page 63 and tie up drive shaft to body.

– Screw steering joint to the track control arm. To do so use the

removed nuts.

– Unscrew the nut of the coupling rod -arrow B- from the sus‐

pension strut.

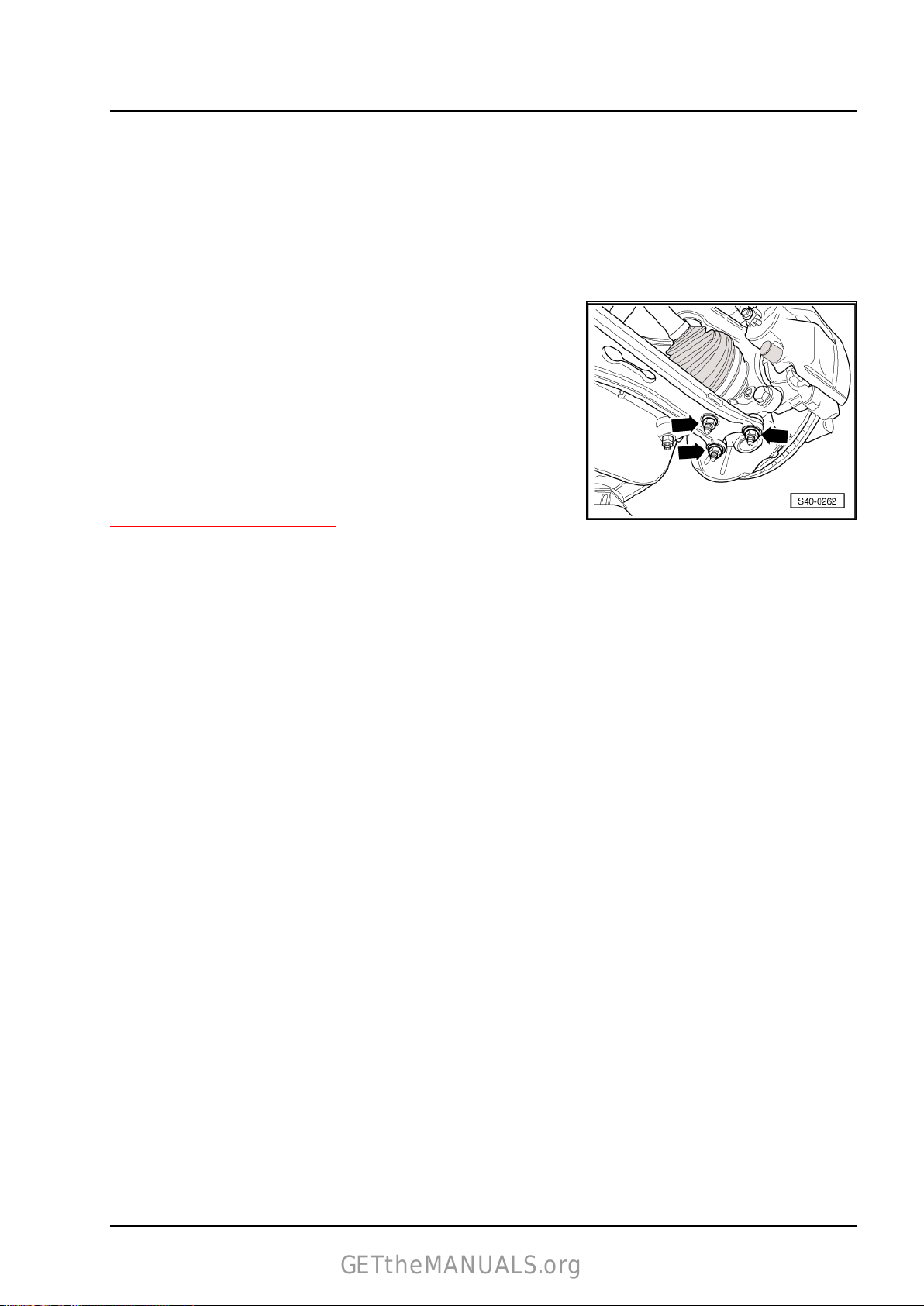

– Unhook ABS speed sensor cable from the suspension strut

(vehicles with ABS).

3. Repairing front suspension strut 35

Page 42

Rapid 2011 ➤

GETtheMANUALS.org

Axles, steering - Edition 12.2018

– Screw up nut -1- sufficiently so that the ball joint extractor is

supported on the nut.

– Use the ball joint extractor to remove the track rod with track

rod end -2- from the steering lever.

– Screw off the nut from the track rod end.

– Pull track rod end out of the steering arm.

– Tie up track rod.

– Position the engine/gearbox jack with adapter below the

wheel-bearing housing.

– Separate the screwed connection wheel-bearing housing/sus‐

pension strut -arrow-.

– Insert the clamping device - 3424- into the nut in the wheel-

bearing housing.

– Turn ratchet with spreader - 3424- by 90° and remove ratchet.

– Press the brake disc by hand towards the suspension strut.

Otherwise the shock absorber tube can cant in the opening of

the wheel bearing housing.

– Pull wheel-bearing housing downwards away from the shock-

absorber tube and lower with engine/gearbox jack with

adapter in such a way that the shock-absorber tube hangs

free.

– Secure thee wheel-bearing housing on the assembly carrier

(attach).

– Remove engine/gearbox jack with adapter.

– Unscrew the suspension strut from the body using the socket

wrench insert SW 21 - MP 6-427 (3186)- .

– Remove the suspension strut.

Installing:

– Insert suspension strut and screw into the suspension strut

dome.

– Tighten the nut to the specified tightening torque.

– Position the engine/gearbox jack with adapter below the

wheel-bearing housing.

– Insert suspension strut in the wheel-bearing housing.

– Loosen the suspension for the wheel-bearing housing from the

assembly carrier.

– Raise up the wheel-bearing housing using the engine/gearbox

jack with adapter to the point where the screw of the suspen‐

sion strut/wheel-bearing housing can be inserted.

36

Page 43

Caution

GETtheMANUALS.org

Never press on the steering joint with the engine/gearbox jack.

– Press the brake disc by hand towards the suspension strut and

make sure that the suspension strut tube does not clamp in

the opening for the wheel-bearing housing.

– Remove spreader - 3424- .

Rapid 2011 ➤

Axles, steering - Edition 12.2018

– Screw on the new nut and tighten up fully -arrow-.

– Install track rod with track rod end into the steering arm and

tighten.

– Hook the ABS speed sensor cable into the clips of the sus‐

pension strut (vehicles with ABS).

– Mount the coupling rod on the suspension strut and tighten

-arrow B-.

– Undo nuts -arrows- and remove lower arm from steering joint.

– Install the outer joint of the drive shaft into the wheel-bearing

housing ⇒ “5.3 Removing and installing outer joint of drive

shaft”, page 63 .

– Perform a test drive.

– Check the steering wheel position during the test drive.

Note

3. Repairing front suspension strut 37

Page 44

Rapid 2011 ➤

GETtheMANUALS.org

Axles, steering - Edition 12.2018

If after the test drive and with the front wheels pointing straight

ahead the steering wheel is off straight, perform an axle alignment

⇒ “2.2 Axle alignment”, page 129 .

38

Page 45

Tightening torques - summaries of components

GETtheMANUALS.org

Note

Replace bolts / nuts that are tightened at an angle of rotation, as well as replacement components after removal.

Rapid 2011 ➤

Axles, steering - Edition 12.2018

Suspension strut to suspension strut dome

♦ Use new screws!

Wheel-bearing housing to suspension strut

♦ Use new screws and nuts!

Track rod end/track rod to steering arm

♦ Use new nuts!

Coupling rod to suspension strut 40 Nm

Twelve-point nut for securing the drive shaft to wheel hub

♦ Use new nuts!

♦ Do not grease thread of the outer joint of the drive shaft.

Steering joint to track control arm

♦ Use new nuts!

Wheel bolts 120 Nm

60 Nm

60 Nm + 90°.

20 Nm + 90°.

50 Nm + 45°.

100 Nm

39

Page 46

Rapid 2011 ➤

GETtheMANUALS.org

Axles, steering - Edition 12.2018

3.3 Repairing suspension strut

Special tools and workshop equipment required

♦ Spring tensioner - V.A.G 1752/1♦ Spring holder , e.g. -V.A.G 1752/4♦ Socket wrench insert WAF 21 - MP6-427 (3186)-

Note

♦

Check correct seating of the helical spring in the spring ten‐

sioner , e.g. -V.A.G 1752/4- -arrow-.

♦

Do not use an impact screw driver when working with the

spring tensioner.

Removing the coil spring:

– Removing the suspension strut ⇒ “3.2 Removing and installing

the suspension strut”, page 35 .

– Preload the helical spring with the spring tensioner until the

spring cap ⇒ Item 14 (page 35) is relieved.

– Unscrew the nut from the piston rod using the socket wrench

insert SW 21 - MP6-427 (3186)- and counterhold with a

hexagon wrench -2-.

1 - Ratchet; when installing torque spanner

– Remove the individual parts of the suspension strut and the

coil spring with the spring tensioner.

Installing the coil spring:

– Insert the preloaded coil spring with the spring tensioner onto

the bottom coil spring bearing.

The thread end of the helical spring must lie against the

stop -arrow-.

Further installation occurs in reverse order.

– Assembly and summary of components of the suspension

strut ⇒ “3.1 Installation general view of the suspension strut”,

page 34 .

40

Page 47

Tightening torques - summaries of components

GETtheMANUALS.org

Note

Replace bolts / nuts that are tightened at an angle of rotation, as well as replacement components after removal.

Nut of suspension strut bearing on piston rod 60 Nm

Rapid 2011 ➤

Axles, steering - Edition 12.2018

41

Page 48

Rapid 2011 ➤

GETtheMANUALS.org

Axles, steering - Edition 12.2018

3.4 Inspect shock absorber

Leaks on the shock absorber

Minor oil leakage (sweating) on the piston rod seal does not entail

the replacement of the shock absorber.

If an oil leak is visible (but blunt, dull, possibly dried by dust) and

does not propagate any further than from the top shock-absorber

screw plug (piston rod seal) to the bottom spring cap -arrow-, the

shock absorber is deemed to be O.K.

Note

A slight oil leak is beneficial as the gasket is lubricated and this

increases the life time. This applies for shock absorbers on the

front as well as the rear axle.

Noises on the shock absorber

There is reason to believe that in the event of noise complaints

the shock absorbers are all too often considered as the source.

Possible causes of noise may be e.g.:

♦ defective shock absorber

♦ suspension strut/body attachment is loose

♦ defective axial grooved ball bearing

♦ poor operation of the suspension strut

♦ defective outer joint

♦ defective wheel bearing

♦ cracked welding points on body

♦ parts loosened or overtensioned when installed (exhaust sys‐

tem, attachments, flaps, etc.)

Note

In the event of complaints about noises interpreted as knocking

or cracking noises, always first perform a test drive with the cus‐

tomer to determine where, when and how these noises occur

(preferably on a bumpy dry road).

Inspecting the removed shock absorber without gas pressure

Defective shock absorbers become noticeable while driving be‐

cause of the knocking noises caused by wheel hopping, more

specifically on poor road surfaces and they must be replaced. The

failure is mainly caused by the loss of oil. The shock absorber

then compresses and/or expands in jolts. It exhibits “idle”, before

it begins to operate.

Note

The shock absorbers are maintenance-free. It is not possible to

top up the shock absorber oil.

Inspecting the removed shock absorber with gas pressure

42

Page 49

Damaged shock absorbers with gas pressure become noticeable

GETtheMANUALS.org

because of a laud banging sound, caused by wheel hopping, and

also because a strong oil leak occurs.

Manual testing, as described below, can determine if the

shock absorber is damaged or not:

– Compress the shock absorber by hand.

The piston rod must move evenly over the entire stroke without

jolting.

– Release the piston rod. On sufficiently pressurized shock ab‐

sorbers it will automatically return to its original position.

If this is not the case, the shock absorber need not necessarily

be replaced, as it will still operate as a conventional shock ab‐

sorber (see instructions below).

Note

♦

The absorbing function is still fully present without sufficient

gas pressure as long as the oil leakage is not too large. How‐

ever, the noise level may increase. On older vehicles it is

possible to continue using an operational yet pressureless

shock absorber without problem.

♦

Adequate gas pressure in the shock absorber improves the

noise behaviour and function when driving over poor road sur‐

faces.

Rapid 2011 ➤

Axles, steering - Edition 12.2018

3.5 Disposing of the shock absorber

Special tools and workshop equipment required

♦ Drill ∅ 3 mm (commercially available)

♦ Drill ∅ 6 mm (commercially available)

♦ Safety goggles (commercially available)

♦ Oil catch container (commercially available)

Degas front gas pressure shock absorber

– Clamp gas-filled shock absorber vertically with the piston rod

pointing downwards in a vice.

WARNING

Wear safety goggles during the drilling procedure.

– Drill a hole ∅ 3 mm -A- through the outer pipe of the shock

absorber.

Note

Gas will escape during drilling.

– Drill further until the inner pipe has also been drilled through

(approx. 25 mm deep).

– Drill a second hole ∅ 6 mm -B- through the outer and inner

shock absorber pipes.

43

Page 50

Rapid 2011 ➤

GETtheMANUALS.org

Axles, steering - Edition 12.2018

– Hold the shock absorber over an oil catching pan. Move the

piston rod several times up and down over its entire stroke until

no more oil escapes.

Degas rear gas pressure shock absorber

– Clamp the gas-filled shock absorber vertically in the vice.

WARNING

Wear safety goggles during the drilling procedure.

– Drill a hole ∅ 3 mm -A- through the outer pipe of the shock

absorber.

Note

Gas will escape during drilling.

– Drill further until the inner pipe has also been drilled through

(approx. 25 mm deep).

– Drill a second hole ∅ 6 mm -B- through the outer and inner

shock absorber pipes.

– Hold the shock absorber over an oil catching pan. Move the

piston rod several times up and down over its entire stroke until

no more oil escapes.

44

Page 51

Rapid 2011 ➤

GETtheMANUALS.org

Axles, steering - Edition 12.2018

4 Repairing wheel bearing

⇒ “4.1 Summary of components of the wheel bearing, suspension

strut, drive shaft and brake C54”, page 45

⇒ “4.2 Removing and installing wheel bearing housing”, page

48

⇒ “4.3 Removing and installing the wheel hub with wheel bearing

with the wheel-bearing housing fitted”, page 52

4.1 Summary of components of the wheel bearing, suspension strut, drive shaft and brake C54

Note

♦

Replace bolts / nuts that are tightened at an angle of rotation, as well as replacement components after

removal.

♦

Welding and straightening work is not allowed on the bearing and wheel control components of the front

wheel suspension.

♦

Always replace the self-locking screws and nuts.

♦

Always replace corroded self-locking nuts and screws.

4. Repairing wheel bearing 45

Page 52

Rapid 2011 ➤

GETtheMANUALS.org

Axles, steering - Edition 12.2018

1 - Suspension strut

❑ Removing and installing

⇒ “3.2 Removing and in‐

stalling the suspension

strut”, page 35

❑ repairing ⇒ “3.3 Repair‐

ing suspension strut”,

page 40

❑ Assignment ⇒ Elec‐

tronic Catalogue of

Original Parts

2 - Drive shaft with inner CV

joint

❑ Removing and installing

⇒ “5.4 Removing and in‐

stalling drive shaft with

CV joint”, page 66

❑ Check ⇒ “5.7 Inspecting

the CV joints”, page

72

❑ repairing ⇒ “5.6 Repair‐

ing drive shaft with CV

joint”, page 69

❑ Assignment ⇒ Elec‐

tronic Catalogue of

Original Parts

3 - Supporting plate

❑ Assignment ⇒ Elec‐

tronic Catalogue of

Original Parts

4 - Fillister head screw with in‐

ternal serrations

❑ replace after each re‐

moval

❑ first pre-tighten all

screws crosswise up to 10 Nm and subsequently tighten crosswise to final tightening torque:

Screw M 8 = 40 Nm

Screw M 10 = 70 Nm

❑ Assignment ⇒ Electronic Catalogue of Original Parts

5 - Drive shaft with inner tripod joint

❑ Removing and installing ⇒ “6.2 Removing and installing inner drive shaft with tripod joint”, page 78

❑ repairing ⇒ “6.3 Repairing drive shaft with inner tripod joint”, page 82

❑ Assignment ⇒ Electronic Catalogue of Original Parts

6 - Circlip

❑ replace after each removal

7 - Brake disc, internally ventilated

8 - Wheel bolt

❑ Assignment ⇒ Electronic Catalogue of Original Parts

❑ 120 Nm

9 - Twelve-point nut

❑ replace after each removal

❑ Do not grease thread of the outer joint of the drive shaft.

❑ Removing and installing ⇒ “5.2 Removing and installing fixing nut of drive shaft”, page 61

46

Page 53

Rapid 2011 ➤

GETtheMANUALS.org

Axles, steering - Edition 12.2018

❑ Assignment ⇒ Electronic Catalogue of Original Parts

❑ 50 Nm + 45°.

10 - Screw

❑ 4 Nm

11 - Brake pad

❑ removing and installing ⇒ Brake systems; Rep. gr. 46

12 - Pad retaining plate

❑ always replace when changing the brake pads

❑ contained in the repair kit for brake pads

13 - Brake carrier with guide bolts and boots

14 - Brake caliper

❑ Assignment ⇒ Electronic Catalogue of Original Parts

❑ do not release brake hose when working on the front wheel suspension

❑ tie up with wire or anything similar

❑ repairing ⇒ Brake systems; Rep. gr. 46

15 - Screw

❑ replace after each removal

❑ 30 Nm

16 - Track rod and track-rod ends

❑ Removing and installing ⇒ “5.4 Removing and installing track rods”, page 162

17 - Wheel hub with wheel bearing

❑ for vehicles with ABS the sensor ring is built into the wheel hub

❑ The wheel hub and the wheel bearing are a single unit; it does not need servicing and is free of play; it

is not possible to undertake any kind of adjustment or repair work on it.

❑ The sensor ring for ABS cannot be replaced individually

❑ replace after each disassembly, wheel hub with wheel bearing is destroyed during removal

❑ Removing and installing ⇒ “4.3 Removing and installing the wheel hub with wheel bearing with the wheel-

bearing housing fitted”, page 52

❑ Assignment ⇒ Electronic Catalogue of Original Parts

18 - Screw

❑ 10 Nm

19 - Protection plate

20 - Nut

❑ replace after each removal

❑ 20 Nm + 90°.

21 - Screw

❑ clean ribbing on underside each time removed

❑ 125 Nm

22 - Nut

❑ replace after each removal

❑ 60 Nm + 90°.

23 - Wheel bearing housing

❑ Removing and installing ⇒ “4.2 Removing and installing wheel bearing housing”, page 48

❑ Assignment ⇒ Electronic Catalogue of Original Parts

24 - Screw