Zytronic ZXY100 Integration Manual

PROJECTED CAPACITIVE ZXY100®

TOUCH CONTROLLER & SENSOR

INTEGRATION MANUAL

VERSION 1.1

ZXY100

PG 2

ZYTRONIC PROJECTED CAPACITIVE ZXY100/110® TOUCH CONTROLLER & SENSORINTEGRATION MANUAL ISSUE 1

ZYTRONIC

ZYTRONIC PROJECTED CAPACITIVE

ZXY100® TOUCH CONTROLLER & SENSOR

INTEGRATION MANUAL – ISSUE 1

CHAPTER TITLE PAGES

1.0 Introduction 5

2.0 Controller Variants 7–8

3.0 Integrating the Sensor 10–12

4.0 Integrating the Controller PCB 14–16

5.0 Attaching the Sensor Flexible Cables 18–20

6.0 Power and Data Connections 22–25

7.0 Using a Bezel 27

8.0 Integration Checks 29

9.0 Controller PCB Drawings 31–36

10.0 Serial Cable Drawing 38

11.0 Further Information 40

PG 3

ZYTRONIC PROJECTED CAPACITIVE ZXY100/110® TOUCH CONTROLLER & SENSORINTEGRATION MANUAL ISSUE 1

ZYTRONIC

USER MANUAL ISSUE RECORD

ISSUE NUMBER

Issue 1

RELEASE DATE

13th June 2013

COMMENTS

First Release

EXPLANATION OF SYMBOLS USED

WITHIN THIS MANUAL

Warning Hazardous Voltage.

Caution - item is susceptible to electrostatic discharge (ESD) damage

if proper precautions are not taken.

1.

INTRODUCTION

PG 5

ZYTRONIC PROJECTED CAPACITIVE ZXY100/110® TOUCH CONTROLLER & SENSORINTEGRATION MANUAL ISSUE 1

ZYTRONIC

INTRODUCTION

SHIPPING DAMAGE

On receipt of your Zytronic Projected Capacitive ZXY100® Touch Controller Touchscreen

Product, if you notice damage to the shipping carton, or concealed damage, be sure to save

all packing materials for later inspection by the carrier, who is responsible for any shipping

damage.

WARRANTY

If failure occurs during the warranty period of the product, please contact the point of sale

from which the product was purchased.

CARE AND CLEANING

Handle the touchscreen with care prior to and during installation. Do not pull or stress

cables/flexible cables and ensure no damage is caused to the touchscreen prior to

installation. Clean the touchscreen surfaces with a glass cleaning solution and soft lint-free

cloth. Ensure that the surfaces are clean and dry before integration of the touchscreen.

Industry standard Anti-static procedures for electronic equipment must be followed when

handling the touchscreen sensor and controller PCB during all stages of unpacking and

installation of the product to prevent damage to the product due to high levels of ESD.

UNPACKING YOUR TOUCHSCREEN

Ensure that the following items are present and in good condition:

Zytronic Projected Capacitive ZXY100® Touch Controller(s) and touchscreen sensor(s).

Users can download the latest Zytronic Projected Capacitive ZXY100® Touch Controller

Touchscreen Driver / Configuration Software and User Manual directly from the Zytronic

website. www.zytronic.co.uk/support

BEFORE YOU BEGIN

Before proceeding with the touchscreen installation ensure the following:

• Your Windows operating system is correctly installed and operating with your mouse.

• Ensure that all other touchscreen manufactures Driver Software/old touchscreen

Driver software is uninstalled from the host computer to avoid software conflicts.

• Ensure that there is a free USB or Serial port available on the host computer to connect

the desired Zytronic Projected Capacitive ZXY100® Touch Controller Touchscreen.

• Ensure that Industry standard Anti-static procedures for electronic equipment are

followed during unpacking and installation of the product.

2.

CONTROLLER

VARIANTS

PG 7

ZYTRONIC PROJECTED CAPACITIVE ZXY100/110® TOUCH CONTROLLER & SENSORINTEGRATION MANUAL ISSUE 1

ZYTRONIC

CONTROLLER VARIANTS

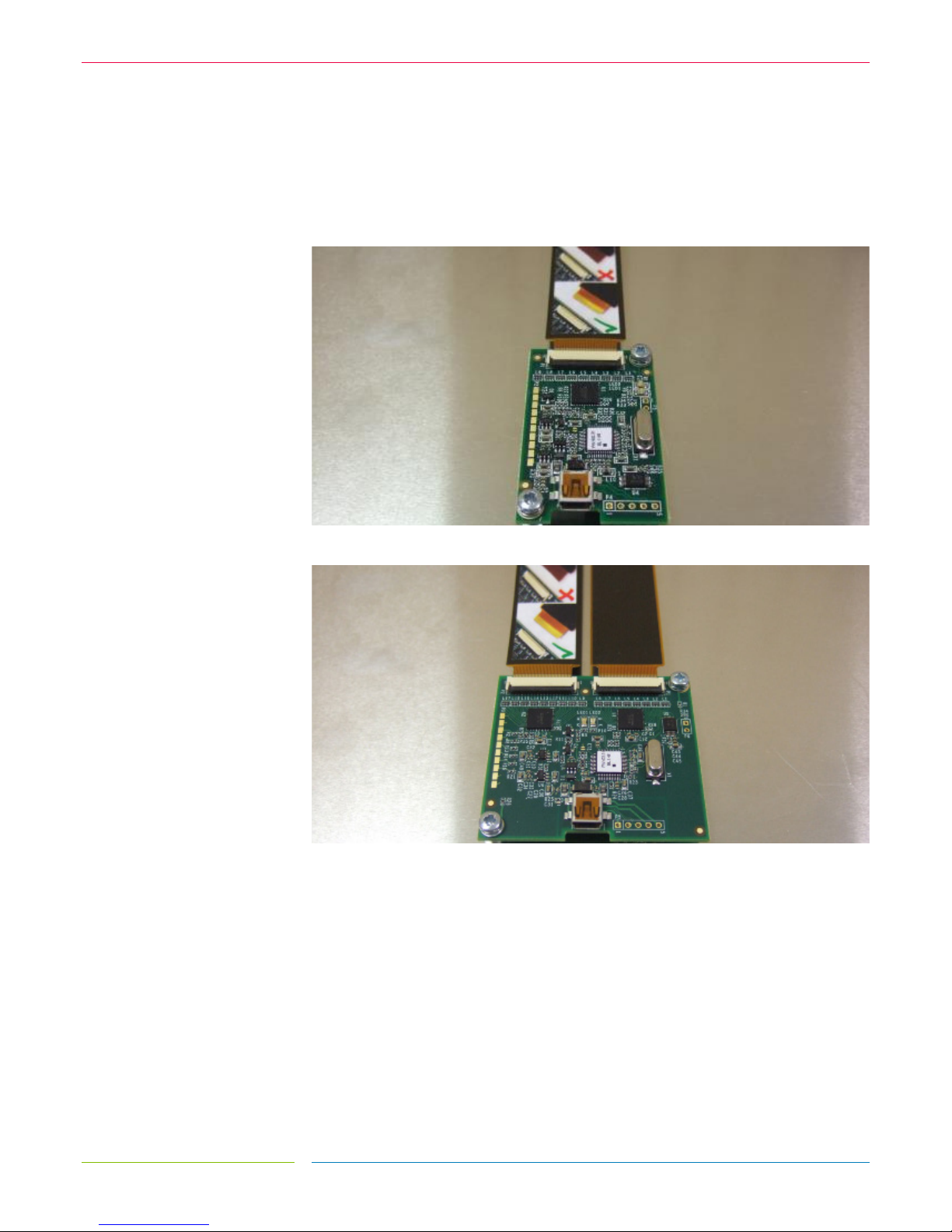

The Zytronic Projected Capacitive ZXY100® Touch Controller range consists of six distinct

variants. There are three different controller sizes suitable for different ranges of sensor sizes,

and each controller size is available in either USB or Serial versions.

FIGURE 1

32 INPUT ZXY100® USB CONTROLLER FOR SMALL SENSOR SIZES

FIGURE 2

64 INPUT ZXY100/110® USB CONTROLLER FOR MEDIUM SENSOR SIZES

PG 8

ZYTRONIC PROJECTED CAPACITIVE ZXY100/110® TOUCH CONTROLLER & SENSORINTEGRATION MANUAL ISSUE 1

ZYTRONIC

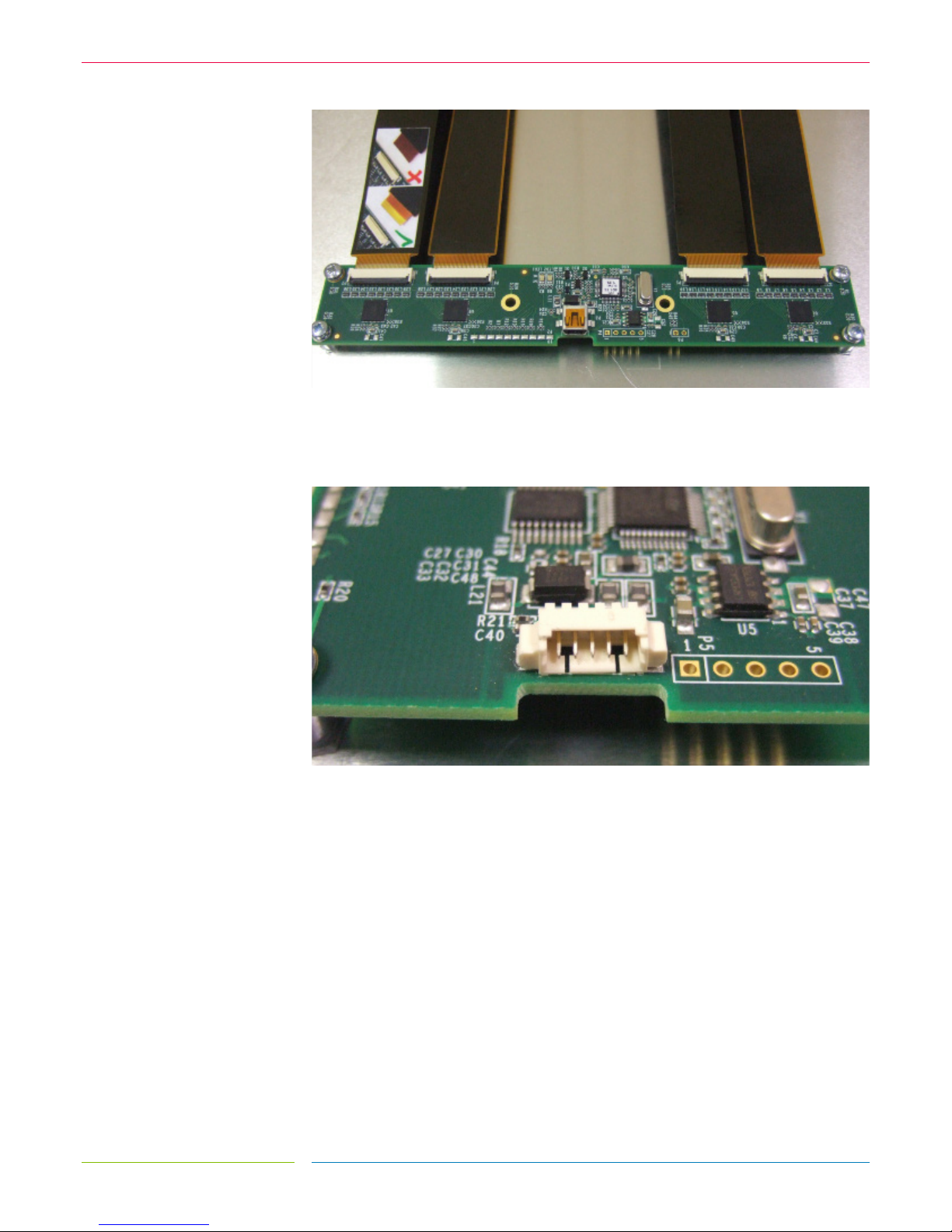

FIGURE 3

128 INPUT ZXY100® USB CONTROLLER FOR LARGE SENSOR SIZES

For USB versions, a USB cable with mini-B plug is required. Serial versions require a Serial

cable with a Molex type connector, as specified in the Serial Cable drawing in section 10.0.

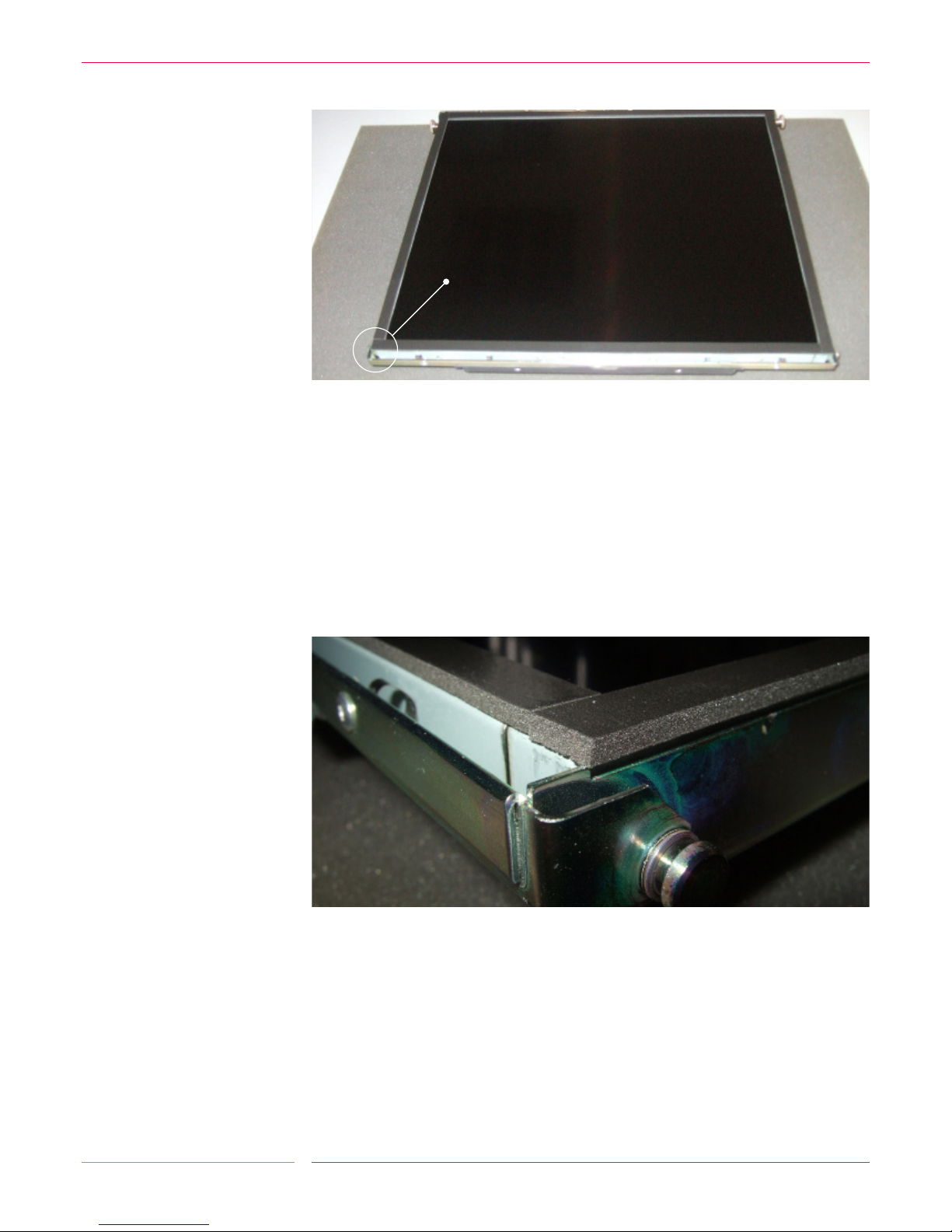

FIGURE 4

MOLEX CONNECTOR USED ON SERIAL CONTROLLERS

3.

INTEGRATING

THE SENSWOR

PG 10

ZYTRONIC PROJECTED CAPACITIVE ZXY100/110® TOUCH CONTROLLER & SENSORINTEGRATION MANUAL ISSUE 1

ZYTRONIC

INTEGRATING THE SENSOR

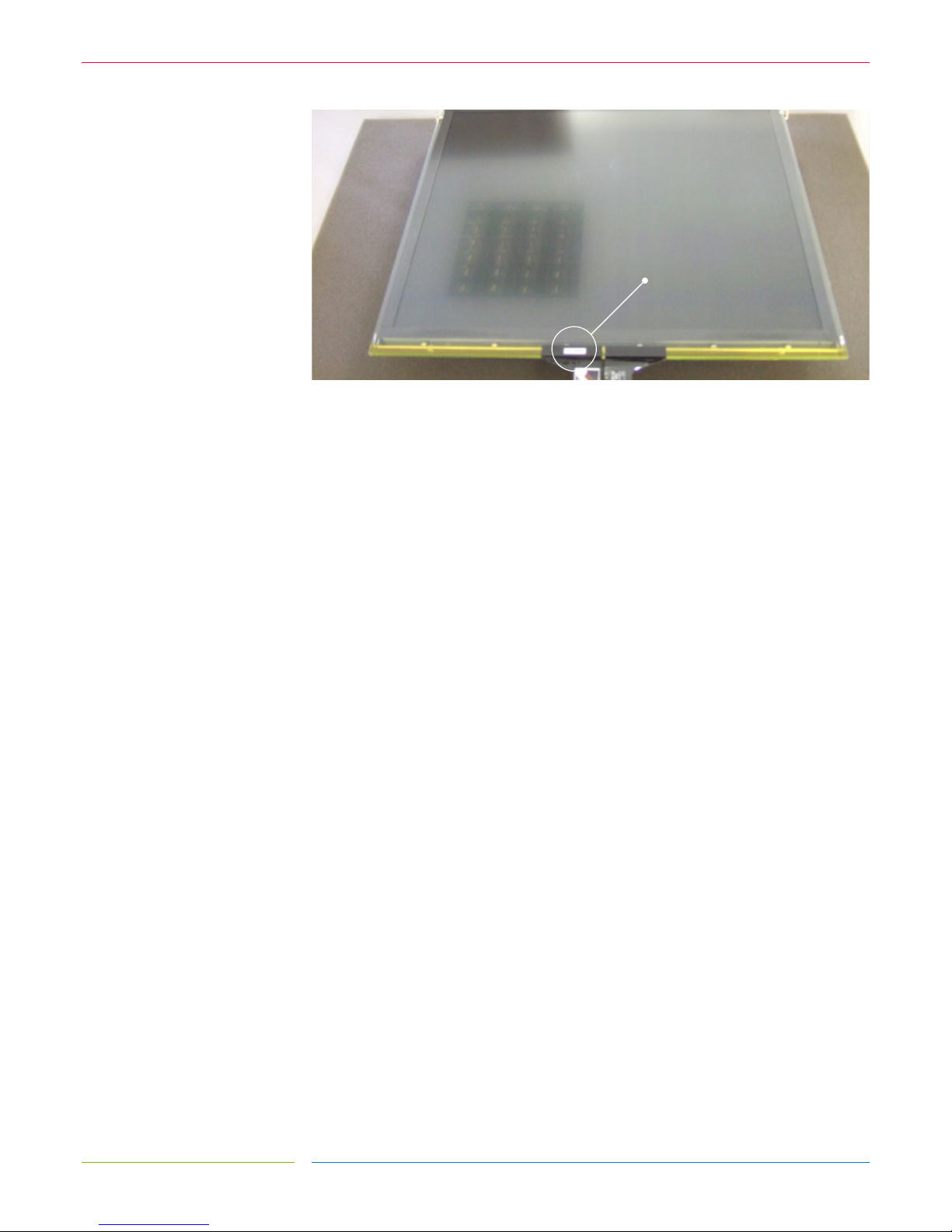

To integrate the sensor, you will require a suitably sized LCD with a display area close to the

active area of the sensor, as shown in Figure 5 (the active area of the sensor can be found on

the corresponding Zytronic sensor drawing). Where possible, it is advisable to have the

active area of the sensor 2-3 mm oversized on all four edges in relation to the LCD display

area. This will allow for some misalignment during integration.

FIGURE 5

SUITABLE LCD TO MOUNT THE SENSOR TO

Foam gasket should be used around the perimeter of the LCD to provide an air gap between

the LCD face and the rear of the sensor, as shown in Figure 6. This air gap is necessary to

prevent excessive electrical noise from the LCD causing interference to the sensor.

Guidelines for the required thickness of the gasket can be seen in the table below and are

sufficient for most LCDs. Some LCDs with very high levels of noise may require greater

spacing which would need to be determined by testing.

SENSOR SIZE GASKET THICKNESS

5 – 22˝ 3mm

22 – 32˝ 4mm

32 – 46˝ 6mm

46 – 65˝ 8mm

65 – 84˝ 10mm

PG 11

ZYTRONIC PROJECTED CAPACITIVE ZXY100/110® TOUCH CONTROLLER & SENSORINTEGRATION MANUAL ISSUE 1

ZYTRONIC

FIGURE 6

FOAM GASKET APPLIED TO LCD TO PROVIDE AIR GAP BETWEEN LCD AND SENSOR

If the sensor is only to be fitted to the LCD temporarily and kept horizontal, a single sided,

electrically non-conductive, low performance gasket can be used, such as EPDM (Ethylene

Propylene Diene Monomer) foam sealing strip, as shown in Figure 7. For permanent

applications, or where the weight of the sensor is to be held only by the gasket, a higher

performance gasket such as 3M VHB tape can be used. This will normally require the gasket

to be built up to the correct thickness with several layers.

Different VHB tapes are available depending on the material of the surfaces it is adhering to.

Any gasket used must be non-sulphurous and maintain its adhesion at any temperature that

it may be subjected to in service.

FIGURE 7

GASKET APPLIED TO THE LCD PERIMETER

The sensor should be positioned on the LCD with the sensor active area (as defined on the

Zytronic product drawing) centred on the LCD display area. The glass face (with ‘Viewing

Face’ label) should be visible, as shown in Figure 8. The sensor can be positioned as shown or

rotated by 180 degrees (so that the flexible cables are on the top edge). The position should be

chosen which gives the best clearance for mounting the controller PCB on the rear of the LCD.

Sensor designs are also available with the flexible cables in alternative positions. If required, the

sensor can be cleaned on the front (glass) face and rear (polyester) face with a glass cleaning

solution and a soft lint-free cloth.

FOAM GASKET

PG 12

ZYTRONIC PROJECTED CAPACITIVE ZXY100/110® TOUCH CONTROLLER & SENSORINTEGRATION MANUAL ISSUE 1

ZYTRONIC

FIGURE 8

SENSOR MOUNTED ONTO LCD WITH GASKET

VIEWING FACE LABEL

4.

INTEGRATING THE

CONTROLLER PCB

Loading...

Loading...