Zylight F8 User Manual

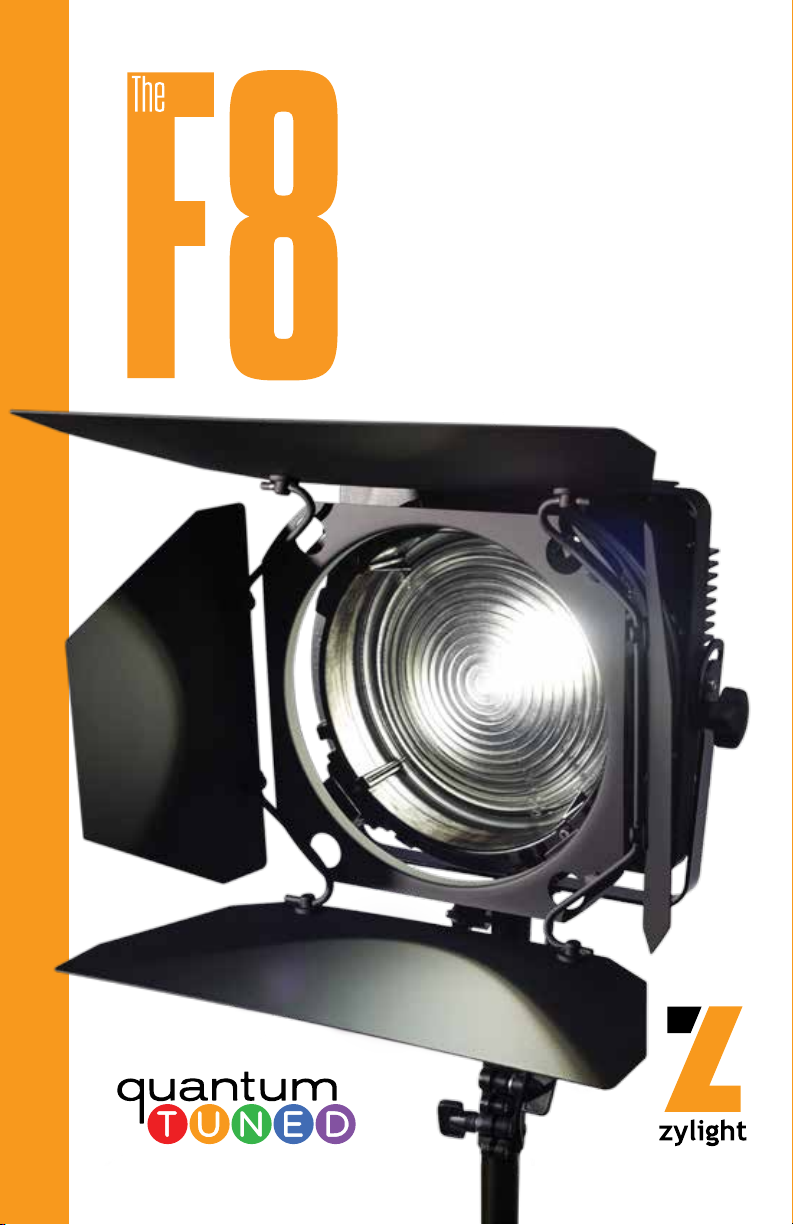

The Fresnel.

Reimagined.

Zylight F8 LED Fresnel

User Instructions

F8-D*, F8-T*, F8-H, F8-U

*

F8 Fresnel Introduction

Introduction: The multiple award-winning F8 LED Fresnel from Zylight

is the next generation of Fresnel lights. By incorporating a special

blend of Quantum nanoparticles with traditional phosphor the F8

boasts a high CRI (color rendering index) and a quality of light matched

only by traditional sunlight and incandescent bulbs, while using a

fraction of the energy. The F8 LED Fresnel is part of Zylight’s pursuit of

high quality, affordable, intelligent xtures. The unit can be controlled

manually, wirelessly or via DMX controller.

Every F8 LED Fresnel has been thoroughly tested and has been

shipped in optimal operating condition. Carefully check the shipping

carton for damage that may have occurred during shipping. If the

carton appears to be damaged, carefully inspect your xture for any

damage and be sure all accessories necessary to operate the unit have

arrived intact. If damage has been found or parts are missing, please

contact our customer support number for further instructions. Do not

return this unit to your dealer without rst contacting customer

support.

Your F8 includes the following items:

• One - Zylight F8 LED light head

• One – F8 4-way barn door

• One - Yoke bar with 5/8” baby pin adapter

• One - Yoke adjustment knob

• One – Slotted thumbscrew

• Two - 1/4" x .69" OD nylon washers (g 1)

• Three - 1/2" x .75" OD nylon washers (g 2)

• One -

Serrated #10/M5 x .36" OD, .02" Stainless Washer (g 3)

• One - Worldwide AC Adapter

• One - AC Adapter hanging pouch (for light stand use)

• One - Barn Door Safety cable

• One – F8 User Guide

g 2 g 3g 1

Page 1

Optional Accessories:

# 26-02012- F8 Chimera Kit

# 19-02028- F8 Egg Crate (50 deg.)

# 26-02009- F8 Gold Mount Battery Kit

# 26-02010- F8 V-Mount Battery Kit

# 26-02019- DMX Interface Box

# 19-02041- F8 Handle Kit

# 26-02014- F8 Pole Yoke Mount

# 20-06006- F8 Rear AC Adapter Bracket

# 19-02039- F8 Single Head Case

# 19-02040- F8 Dual Head Case

Customer Support: Zylight provides a customer support line, to

provide set up help and to answer any question should you encounter

problems during your set up or initial operation. You may also visit us

on the web at www.zylight.com for any comments or suggestions.

Service Hours are Monday through Friday 9:00 a.m. to 5:00 p.m.

Eastern Standard Time.

Voice: (978) 244-0011

Fax: (978) 244-0011

E-mail: support@zylight.com

Caution! There are no user serviceable parts inside this unit. Do not

attempt any repairs yourself; doing so will void your manufacturer's

warranty. In the unlikely event your unit may require service please

contact Zylight customer support.

PLEASE recycle the shipping carton whenever possible.

10718 McCune Avenue

Los Angeles, CA 90034

info@zylight.com

www.zylight.com

Page 2

F8 Fresnel General Instructions

To optimize the performance of this product, please read these

operating instructions carefully to familiarize yourself with the basic

operations of this unit. These instructions contain important safety

information regarding the use and maintenance of this unit. Please

keep this manual with the unit, for future reference.

Warranty Registration

The F8 Fresnel carries a two year limited warranty. Please go to

www.zylight.com/product-registration and register your product and

validate your purchase. All returned service items whether under

warranty or not, must be freight pre-paid and accompany a return

merchandise authorization (R.M.A.) number. The R.M.A. number must

be clearly written on the outside of the return package. A brief

description of the problem as well as the R.M.A. number must also be

written down on a piece of paper included in the shipping carton. If the

unit is under warranty, you must provide a copy of your proof of

purchase invoice. You may obtain an R.M.A. number by contacting our

customer support team through our customer support number. All

packages returned to the service department not displaying a R.M.A.

number on the outside of the package will be returned to the shipper.

Safety Precautions

IP Rating:

The F8 is rated IP54 for weather resistance: Ingress of dust is not

entirely prevented, but it will not interfere with satisfactory operation.

Splashing water or light rain or snow will also have no harmful effect.

While the F8 is protected against light moisture and dust exposure,

please protect the instrument when shooting in extreme conditions and

note that the instrument is not rated to be submerged in water, or

exposed to prolonged periods of moisture. Always use your best

judgment and protect the instrument from sustained moisture

exposure.

Page 3

Safety Precautions Cont.

• To reduce the risk of electrical shock or re, do not

submerge this xture in water.

• Do not spill large amounts of water or other liquids into or on

to your xture.

• Do not attempt to operate this unit if the power cord has been

frayed or broken. Do not attempt to remove or break off the

ground prong from the electrical cord. This prong is used to reduce

the risk of electrical shock and re in case of an internal short.

• Disconnect from main power before making any type of

connection.

• Do not remove the lens under any conditions. There are no user

serviceable parts inside.

• Never operate this xture if the Fresnel lens is removed.

• Never plug this unit in to a dimmer pack.

• Always be sure to mount this xture in an area that will allow proper

ventilation. Allow at least 6" (15cm) between this device and a wall.

• Do not attempt to operate this xture if it becomes damaged.

• During long periods of non-use, disconnect the xture's main

power.

• Always mount this xture in safe and stable matter. Always use a

safety cable as part of a secure installation. This includes securing

the barn doors with a safety cable.

• Power-supply cords should be routed so that they are not likely to

be walked on or pinched by items placed upon or against them,

paying particular attention to the point they exit from the xture.

• Cleaning: The xture should be cleaned only as recommended by

the manufacturer. See page 10 for cleaning details.

• Heat: The instrument should be situated away from heat sources

such as radiators, heat registers, stoves, or other appliances

(including ampliers) that produce heat.

• The xture should be serviced by qualied service personnel when:

A. The power-supply cord or the plug has been damaged.

B. Objects have fallen, or liquid has been spilled into the

instrument.

C. The instrument has been submerged in water

D. The instrument does not appear to operate normally or exhibits

a marked change in performance.

Page 4

First Set Up – Assembly Instructions

To optimize the correct performance of your xture, please follow these simple

assembly instructions, and refer to this manual if you ever need to reattach the

yoke assembly to your xture.

In some instances, the yoke assembly will be shipped separated from your

xture. There are several nylon washers that will be used to correctly space the

metal parts from one another. This will also allow the F8 to be adjusted and

tightened with only one lock point on the left or right side of the yoke. Proper

installation of the washers on the pivot points and the lock points are essential

to maintain the correct operation of the xture.

The lock point (yoke knob) can be mounted on the left or right side of the

instrument, although it is recommended in most common set ups to keep the

lock point on the right side of the xture (righty tighty). To install the yoke lay the

instrument on top of a protected surface. Layout your components to mimic

the conguration shown in gure 1. The side with the thumbscrew should have

the Serrated # 10/M5 x .36" OD, stainless washer and two of the 1/2" x .75

nylon washers. The side with the knob lock should have one 1/2" x .75 nylon

washer and the two 1⁄4” x .69 nylon washers. First place a 1/2" x .75 nylon

washer around each side of the pivot located on each of the yoke ears (g 2).

Next, set the yoke orientation to “lean forward.” You will notice that the base of

the yoke has been shaped so when the yoke mount is vertical in a stand or

perpendicular to the ground, the yoke will sit at an angle towards the front of

the light. This is so the xture can be pointed further down towards your

subject when placed on a stand (g 3).

Install the center of the yoke and capture each side of the pivot point screws.

You may need to gently stretch the yoke to engage the pivot point screws. Slide

the small serrated stainless washer onto the slotted thumbscrew (g 4). Note

the slight bend in the washer’s prole. The outer edge should touch the

thumbscrew (convex side), while the center points towards the pivot point

(concave side). Then take the third 1⁄ 2” x .75 nylon washer and install on the

top of the yoke on the side that will have the thumbscrew. (g 5). Install the

slotted thumbscrew into the pivot point, being sure to properly capturing the

nylon washer. Tighten the thumbscrew with a coin or other device only nger

tight. (g 6). Now ip the instrument to the other yoke point. Slide a 1⁄4” x .69

nylon washer under the yoke at the lock point where the threaded hole will

accept the 1⁄4-20 yoke knob. (g 7). Place the other 1⁄4” x .69 nylon washer

onto the yoke knob and tighten into the threaded hole, being sure to capture

the nylon washer below (g 8). This completes the proper installation of the

yoke assembly to the F8.

Page 5

Loading...

Loading...