Page 1

Operating Manual

S3 Digital Cutter

Page 2

Keep it in a safe place for future use!

Original operating manual

Software/Firmware version: FW1.71

Creation date: 05-2019

2

Page 3

Contents

Contents

1 Introduction.......................................................................................................................................7

1.1 Using the operating manual............................................................................................................. 8

1.2 Points to note when reading this operating manual.........................................................................9

1.3 Publishing details..............................................................................................................................9

2 Product description........................................................................................................................11

2.1 Important information about the product........................................................................................ 11

2.2 Orientation.......................................................................................................................................12

2.3 Product identification...................................................................................................................... 13

2.4 Intended use...................................................................................................................................13

2.5 Cutter overview...............................................................................................................................14

2.6 Modules, tools.................................................................................................................................16

2.7 Material handling............................................................................................................................ 21

2.8 Options............................................................................................................................................23

2.9 Accessories box..............................................................................................................................24

2.10 Technical description....................................................................................................................25

2.11 Technical data.............................................................................................................................. 27

3 Safety...............................................................................................................................................39

3.1 General........................................................................................................................................... 39

3.2 Proper use......................................................................................................................................39

3.3 Examples of reasonably predictable unintended use.....................................................................39

3.4 Hazard warnings, important instructions........................................................................................ 41

3.5 Areas of responsibility....................................................................................................................43

3.6 Personnel requirements..................................................................................................................43

3.7 Personal protective equipment.......................................................................................................44

3.8 Rules and occupational safety....................................................................................................... 45

3.9 Conduct in the event of malfunctions.............................................................................................45

3.10 Danger areas................................................................................................................................46

3.11 Warnings on the product..............................................................................................................49

3.12 Protective devices.........................................................................................................................51

3.13 Mechanical hazards......................................................................................................................55

3.14 Risk of burns................................................................................................................................ 56

3.15 Electrical hazard...........................................................................................................................56

3.16 Risks arising from the emission of toxic dust...............................................................................57

3.17 Risks arising from the processing of toxic materials/materials hazardous to health.....................57

3.18 Environmental hazards.................................................................................................................58

3.19 Handling and storage of chemicals..............................................................................................58

3.20 Risk of fire and explosion.............................................................................................................61

3.21 Danger from laser beam.............................................................................................................. 62

3.22 Safety instructions for the operating personnel............................................................................62

3.23 Safety precautions for service personnel.....................................................................................63

3.24 Disposal........................................................................................................................................ 63

4 Controls and operation..................................................................................................................65

4.1 Safe working practices................................................................................................................... 65

4.2 Controls...........................................................................................................................................66

4.3 Menu navigation............................................................................................................................. 72

4.4 Menus and functions......................................................................................................................73

3

Page 4

Contents

4.5 General settings..............................................................................................................................75

4.6 User level........................................................................................................................................76

4.7 Malfunctions....................................................................................................................................78

4.8 Daily checks prior to start-up.........................................................................................................81

4.9 Behavior in dangerous situations...................................................................................................81

4.10 Start-up......................................................................................................................................... 83

4.11 operating mode.............................................................................................................................85

4.12 Moving the beam/module manually..............................................................................................87

4.13 Handling modules/tools.................................................................................................................88

4.14 Material fixing..............................................................................................................................102

4.15 Material transport (optional)........................................................................................................110

4.16 Automatic tool initialization - AKI (optional)................................................................................114

4.17 Job processes.............................................................................................................................119

4.18 Film handling.............................................................................................................................. 124

4.19 Laser pointer, reference point (optional).................................................................................... 126

4.20 ICC camera, automatic registration (optional)............................................................................129

4.21 Module carriage slot protective plate......................................................................................... 132

4.22 Signal lights (optional)................................................................................................................ 133

5 Tips for cutting.............................................................................................................................135

5.1 Select tool.....................................................................................................................................135

5.2 Selecting a blade..........................................................................................................................135

5.3 Preparing cutting data.................................................................................................................. 142

5.4 Settings, speed, quality................................................................................................................ 142

5.5 Recognising processing errors.....................................................................................................144

5.6 Oscillating cutting..........................................................................................................................154

5.7 Tips for increasing the rate of production.................................................................................... 156

5.8 Identifying and rectifying quality problems................................................................................... 156

6 Maintenance..................................................................................................................................159

6.1 Safe maintenance of the machine................................................................................................160

6.2 Tools, operating and auxiliary materials.......................................................................................160

6.3 Maintenance list for trained operating personnel......................................................................... 164

6.4 Maintenance list for authorized service technicians.....................................................................166

6.5 Cutter maintenance mode............................................................................................................ 168

6.6 Service flaps and covers..............................................................................................................169

6.7 Visually inspecting the machine for damage................................................................................174

6.8 EMERGENCY STOP control devices function test......................................................................174

6.9 Cleaning the machine...................................................................................................................175

6.10 Cleaning the inside of the beam................................................................................................ 175

6.11 Cleaning the X axis guide rails.................................................................................................. 177

6.12 X axis, oiling the guide carriage.................................................................................................178

6.13 Clean/oil Y axis guide rails.........................................................................................................181

6.14 Cleaning the feeding clamps/feed guide rail.............................................................................. 181

6.15 Draining the maintenance unit condensate water......................................................................183

6.16 Resetting 12.5/14.0 kW vacuum pump motor protection relay...................................................184

6.17 Reset 2.2/2.55 kW, 4.0/4.6 kW, 5.5/6.3 kW vacuum pump, motor protection relay....................185

6.18 Replacing the conveyor belt.......................................................................................................186

6.19 ICC camera, cleaning the lens (optional)...................................................................................204

6.20 Instructions for disposal..............................................................................................................205

6.21 Starting up after periods of standstill..........................................................................................206

7 Tools..............................................................................................................................................207

4

Page 5

Contents

8 Modules.........................................................................................................................................209

9 Material handling..........................................................................................................................211

10 Additional specifications...........................................................................................................213

5

Page 6

Contents

6

Page 7

1 Introduction

Introduction

Dear customer,

With your decision to purchase our product you are participating in the worldwide success of Zünd

cutter systems.

The modular design of our systems provides the following benefits, among others things:

• A system solution that meets your individual requirements in terms of speed and quality.

• The availability of the most up-to-date technology thanks to continuous development.

Our approach

Constant and intensive cooperation with experienced users is essential for developing innovative

and practical solutions. We are therefore grateful for any comments or suggestions on how we can

improve.

Contact

Zünd Systemtechnik AG

Industriestrasse 8

CH - 9450 Altstätten

Tel: +41 71 757 8181

info@zund.com

www.zund.com

7

Page 8

Introduction

1.1 Using the operating manual

The supplied operating manual is intended to enable you to operate the machine safely, perform

routine maintenance and use the machine optimally in every way.

To do this, you need to be able to find what you need in the documentation.

Scope of the operating manual

Volume 1 - Operating instructions

This volume contains information on engineering, commissioning, operation

and maintenance of the machine.

Volume 2 - Service manual

This volume contains information on the design of the machine and on

servicing by authorized service technicians. The service manual is not included

in the scope of delivery of the machine.

Spare parts catalog

The spare parts catalog is not included in the scope of delivery of the machine.

Structure of the operating instructions

The operating instructions consist of separate sections, which are numbered consecutively and

arranged according to the ring binder tabs.

The table of contents provides information on the structure of the individual sections.

Indication of optional accessories

There are many optional accessories available for the machine. Descriptions of optional additional

equipment are labeled in the operating manual with the wording (optional) .

Safekeeping of the documentation

Always keep Volume 1 of the "User manual" close at hand in the vicinity of the workstation.

Current status of the documentation

In order to ensure that the operating manual always remains complete and up to date, the following

must be observed:

• Do not remove individual documents.

• Request copies of missing or illegible pages from the manufacturer, or download them from the

Zünd homepage and print them out.

• If any new documentation is provided as a result of conversions, add it immediately.

• Replace changed documents and destroy the old version.

• If the documentation exists in more than one language, ensure that all languages are kept up to

date.

8

Page 9

Introduction

1.2 Points to note when reading this operating manual

Text references

Chapter headings are numbered consecutively in the chapters, with the first figure corresponding

to the chapter number. Where reference is made to sections outside the current chapter, note the

first figure and turn to the corresponding chapter, which contains the cited section. See chapter 2.4

Cutter; overview, for example, leads to chapter 2 Product description, which contains section 4 Cutter

overview.

Block diagrams and simplified representation

Note that all representations are provided for general information and do not necessarily correspond to

the latest version of the machine.

Dimensional information

Dimensional information is listed in the SI/US units, depending on the installation site.

1.3 Publishing details

Designation

Operating instructions for S3 series cutters.

Layout, illustration, and print

Zünd Systemtechnik AG - Technical Communications Department

©

Copyright

Zünd Systemtechnik AG

9

Page 10

Introduction

10

Page 11

Product description

2 Product description

This chapter contains information on the following:

• Representation conventions in the operating manual

• Usage possibilities of the machine

• Structure of the main components

• Important technical data

• General technical description of the machine

2.1 Important information about the product

Tip:

"Tip" refers to useful information which enhances the usability and prolongs the service life of the

machine or makes the work process significantly easier.

Tip:

With tips combined with the sheet we give you usage tips and useful information which can

improve the energy efficiency of the machine or optimize its environmental effects.

Important:

Usage tips and important machine operating information are labeled with Important.

11

Page 12

Product description

2.2 Orientation

Directions such as "right, left" or "front, back" relate to the operator's view of the machine during

operation.

1 front

2 rear

3 right

4 left

X X-axis

Y Y axis

12

Page 13

2.3 Product identification

2.3.1 Rating plate

Product description

1 Position of the signs 10 Year of manufacture

2 Rating plate 11 Serial number

3 Additional UL sign 12 UL mark of conformity

4 Additional connection values 13 Nominal voltage

5 Additional FCC sign 14 Rated current

6 CE mark of conformity 15 Frequency

7 UL functional safety 16 Nominal voltage

8 Product name 17 Current consumption

9 Type designation 18 Frequency

2.4 Intended use

The cutter system can be used for the following purposes:

• As an output station for CAD/CAM data.

• For processing and labeling of materials.

The intended use and the usage restrictions are also dependent on the available tool and material

transport system, which are described in the "Tools", "Modules" and "Material handling" chapters.

13

Page 14

Product description

2.5 Cutter overview

14

Page 15

1 Air supply to maintenance units

2 Beam

3 Tool/module power supply

4 Extractor

5 Workstation

6 Control panel with optional workstation

7 Vacuum pump

8 Working area

Product description

15

Page 16

Product description

2.6 Modules, tools

Zünd cutters are highly specialized and can be easily converted to process other materials through the

use of modules and tools.

Two modules can be attached to slots 1 and 2 on the module carriage as standard. Either an

electrically or pneumatically driven marking module can be installed in slot 3 (MAM-SP, MAM-SE).

Tip:

You can find detailed information in section Handling modules/tools on page 88 as well as in

the individual operating manuals of your modules and tools.

16

1 Module (e.g., KCM-S, UM-S)

2 Tool (e.g. CT, UCT, EOT, POT)

3 Tool insert: router, blade, pen

Page 17

2.6.1 Universal applications

Universal modules - UM-S

Universally applicable carrier module for a wide range of tools.

Product description

Tools for use in the UM

Electric Oscillating Tool - EOT

Cutting tool with high oscillation frequency for soft and medium hard

materials.

Electric Oscillating Tool - EOT-250

Robust tool with high-performance electric drive for processing thick

cardboard and leather materials.

Pneumatic Oscillating Tool - POT

Powerful cutting tool with large oscillation stroke for hard and tough

materials of up to 50 mm thickness.

Driven Rotary Tool - DRT

Tool for technically demanding textiles and textile materials. The powered

rotary knife enables a very high processing speed.

Universal Cutting Tool - UCT

Universally usable cutting tool for materials of up to 5 mm thickness.

17

Page 18

Product description

Scoring Cutting Tool - SCT

Combination tool for scoring and cutting cardboard and coating blankets of

up to 5 mm material thickness.

V-Cut Tool - VCT

Tool with five different cutting angles. Creation of complex 3D

constructions from high expansion foam or sandwich boards.

Passepartout Tool - PPT

Exact 45° oblique cuts in constantly high quality.

Perforating Tool - PTT1

Ideal tool for creating precise perforations in corrugated cardboard, solid

board, polypropylene, and foil.

Kiss Cutting Tool - KCT

Kiss-Cutting tool with adjustable pressing pressure for the processing of

numerous vinyl materials.

Universal Routing Tool - URT

Cost-effective routing and engraving tool.

Creasing Tools - CTT1/2

Creasing of various types of materials. The pressing pressure is

separately adjustable laterally and longitudinally along the shaft.

Universal Drawing Tool - UDT

Drawing tool for the use of standard commercial leads in various line

thicknesses.

Raster Braille Tool - RBT

Efficient procedure for the creation of tactile Braille markings (for the

blind).

18

Page 19

2.6.2 Routing, engraving:

Router modules - RM-S

Product description

Universally usable routing system, fitted with a powerful high

frequency spindle.

• Routing depth up to 25 mm

• Effective dust extraction, actively air-cooled

• Surface compensation for precise depth setting

• Optional Minimal Quantity Lubrication- MQL for

processing soft aluminum alloys

• 1 kW high-frequency spindle for very high processing

speeds

Tools for use in the RM-S

HF motor spindle 4040 DC-SZ

Motor spindle with 1000 W and manual roll pin.

2.6.3 Punching, perforating

Punch and Pricking Module - PPM-S: Combined high-performance

tool for perforating and punching leather, rubber and textile materials

with up to 8 holes per second. A punching spike is integrated.

19

Page 20

Product description

2.6.4 Kiss-cutting

Punch and Pricking Module - PPM-S: High-performance tool for

perforating leather, rubber and textile materials with up to 8 holes per

second. A marking tool is integrated.

Kiss-cut module - KCM-S

KCM-S: This module cuts films with the highest precision and processing

speed without damaging the carrier material.

20

Page 21

2.6.5 Drawing, marking, labeling

Marker modules - MAM

Marking and labeling of various types of materials. Use of standard

commercial leads.

• MAM-SE: 1 drawing tool, electric

• MAM-SP: 1 drawing tool, pneumatic

• MAM-SPS: 1 drawing tool, pneumatic

• MAM-SPD: 2 drawing tool, pneumatic

Product description

2.7 Material handling

Cutter with static work surface

Loading and removal of the processing material

on the working surface of the cutter. The working

surface is protected against damage using a cutting

board.

21

Page 22

Product description

Cutter with material transport

The material transport is used to pull the processing

materials onto the work surface. The conveyor belt

is used as a cutting base and conveyor belt at the

same time.

During processing, the material to be processed

is fixed in place using a vacuum. After cutting, the

beam moves backwards. The conveyor clamping

elements fix the conveyor belt and the feeding

clamps are pressed onto the material to be pushed

forward. The beam tightens the conveyor belt to the

set position.

The shape of the feeding clamps varies depending

on the material to be processed. An auxiliary drive

is used for larger tables or for transporting heavier

processing materials.

2.7.1 Collection tray

Cutter extensions allow streamlined working. The

material supply/removal is carried out while the

cutter is completing the jobs. Cutter extensions are

available in different sizes.

22

The collection tray is a practical device with which the

cutting waste and cut parts are collected. It ensures a

clean working environment. For emptying, the tray can

be removed from the cutter in just a few steps.

Page 23

2.8 Options

2.8.1 Laser pointer

Product description

The laser pointer is used as an aid for the precise

definition of the reference point. It also serves for

the connection of electrically driven tools.

2.8.2 ICC camera

The ICC camera allows perfect registration in

which the exact position of printed material on the

processing surface is determined.

The integrated laser pointer is used as an aid for

the precise determination of the reference point.

Electrically driven tools can also be connected to

the camera.

23

Page 24

Product description

2.9 Accessories box

The accessories box is delivered with the cutter. The accessories box contains the tools and

operating and auxiliary materials needed for maintaining the cutter. The contents are provided

appropriately for the cutter.

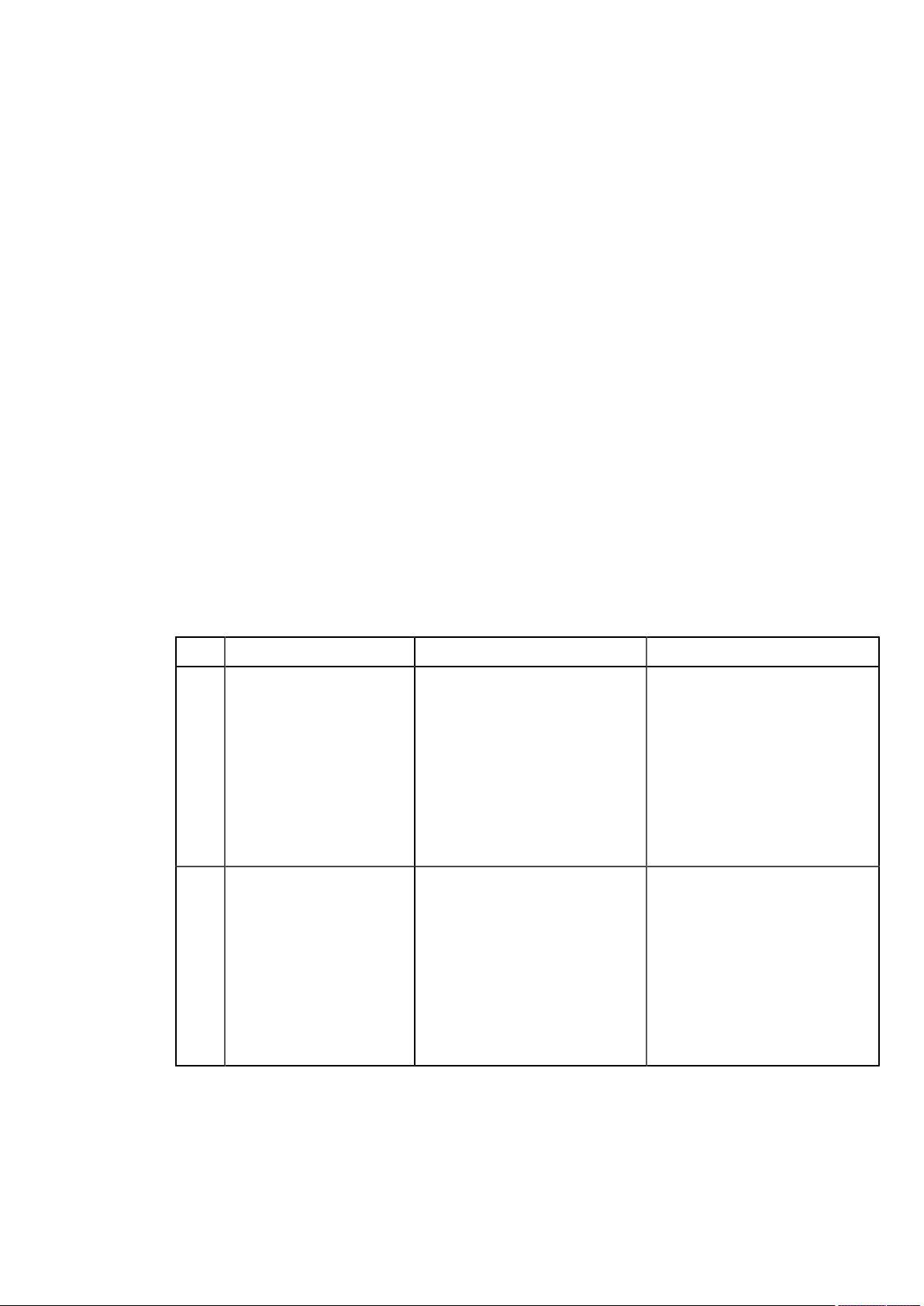

Contents (sample)

Accessories Quantity Task Conveyor Static PU

Allen screwdriver 4 x

170 mm

Torx screwdriver TX10 1 pc. Assembling/

Special guide rail oil 25 ml Oil for the X/Y axis

Lubrication set, X axis

guide rails

Staple gun 1 pc. Replacing the conveyor

Dosing gun KPM 250

ECON

19 mm tape, doublesided

Teflon grease 20 ml Service X X X

Soldering fluid brush 1 pc. Service X X X

Glass tube safety guards

(various)

1 pc. Assembling/

disassembling modules

disassembling covers

guide rails, carriage and

bearings

1 pc. Oil for the X/Y axis

guide rails, carriage and

bearings

belt

1 pc. Replacing the conveyor

belt

1 pc. Fixing the cutting board X

5 pcs. Service X X X

X X X

X X X

X X X

X X X

X

X

24

Page 25

Product description

2.10 Technical description

Zünd high performance cutters enable efficient and precise processing of the most varied of

materials. With the modular tool and material handling system, you can adapt your machine to your

individual requirements. Define the production requirements and put together your tailor-made cutter

configuration from the Zünd kit concept.

2.10.1 Base machine

Table design

The cutter consists of a base frame and a beam. Whereas the base frame is produced in the form of

a stable welded structure, the beam consists of a lightweight, torsionally rigid aluminum profile. The

cutter is mounted on vibration-dampening machine feet.

Working area / vacuum plate

The working area is made of stable plastic. The vacuum zones are arranged under the working area

and are controlled using a slider. The vacuum is built up using a powerful vacuum generator.

The vacuum is used for holding down and tightening the material to be processed.

Electronics unit / power box

The power box is housed in the front right-hand side of the cutter and is only accessible via a

removable cover. The power box contains the power supply of the complete cutter and is activated/

deactivated with the main switch. The connection of the individual consumers takes place using

software control, if required.

The electronics unit is arranged behind the power box. The electronics unit can only be accessed

using a special tool. The cutter control is housed in the electronics unit.

Pneumatics

The air pressure for the respective consumers is adjusted via a maintenance unit. The maintenance

unit is accessible via service doors for adjusting settings and carrying out maintenance work.

2.10.2 Movement system

The S3 series has four electronically driven axes:

Axis Function Movement system

Movement of the beam Driven via toothed belt

X

Material transport, material transport

extension

Feed clamping elements, feeding clamps

Y Movement of the module carriage Driven via toothed belt

Z Height adjustment of the module Example UM-S

T Rotary movement of the module Example UM-S

X axis - beam

The bar is driven via a toothed belt and a powerful electric motor. The design ensures that it works

without play and it also minimizes wear on the drive system. The beam is supplied with control

25

Page 26

Product description

signals and compressed air via an energy chain. All drive parts are protected against direct access or

contamination using covers.

X axis - material transport

Material transport takes place via conveyor clamp elements and feeding clamps on the bar. Feed

takes place via the bar movement. The conveyor belt is gripped by the conveyor clamp elements and

the processing material is secured against displacement using the feeding clamps.

Y axis - module carriage

The module carriage is driven by a motor via a toothed belt / gear mechanism. The design ensures

that it works without play and it also minimizes wear on the drive system. The module carriage is

supplied with control signals and compressed air via an energy chain. All drive parts are protected

against direct access/contamination using covers.

Z axis - height adjustment of the module

Machine-controlled setting of the processing height (e.g. UM-S).

T axis - rotary movement of the module

Modules with integrated T axis (e.g. UM-S) align the tool insert to the cutting path.

26

Page 27

2.11 Technical data

2.11.1 Dimensions

2.11.1.1 Base cutter (mm)

Product description

The effectively usable working surface (D x E) depends on the tool or module.

Type (mm) A B B1 C D E

M-800

M-1200

M-1600

L-1200

L-1600

XL-1200

830

2086

520

2556

3026

1542

1942

2342

1942

2342

1942 1230 2270

830

1230

1630

1230

1630

1330

1800

27

Page 28

Product description

2.11.1.2 Base cutter (inch)

The effectively usable working surface (D x E) depends on the tool or module.

Type (in) A B B1 C D E

M-800

M-1200

M-1600

L-1200

L-1600

XL-1200

32.7

82.1

20.5

70.9

119.1

60.7

76.5

92.2

48.4

92.2

48.4 48.4 89.4

32.7

48.4

64.2

48.4

64.2

52.4

70.9

28

Page 29

2.11.1.3 Cutter extension - CE (mm)

Product description

Type

Length (mm)

M-800 x

M-1200 x

M-1600 x

L-1200 x

L-1600 x

XL-1200 x

CE0800

875

CE1200

1275

CE1600

1674

29

Page 30

Product description

2.11.1.4 Cutter extension - CE (inch)

30

Type

Length (in)

M-800 x

M-1200 x

M-1600 x

L-1200 x

L-1600 x

XL-1200 x

CE0800

34.4

CE1200

50.2

CE1600

65.9

Page 31

Product description

2.11.2 Weights

2.11.2.1 Base cutter (kg)

Type Weight (kg) max. floor load (kg/m)2)

M-800

M-1200

M-1600

L-1200

L-1600

XL-1200 620

2.11.2.2 Base cutter (lbs)

Type Weight (lbs) max. floor load (lbs/in)2)

M-800

M-1200

M-1600

L-1200

L-1600

XL-1200 1370

420

490

560

560

610

925

1080

1240

1240

1350

200

440

2.11.2.3 Material weight (kg)

Type max. material weight (kg) max. material weight (kg/m2)

M-800

M-1200

M-1600

L-1200

L-1600

XL-1200 27

2.11.2.4 Material weight (lbs)

Type max. material weight (lbs) max. material weight (lbs/in2)

M-800

M-1200

M-1600

L-1200

L-1600

11

16

21

22

29

24

35

46

49

64

10

22

31

Page 32

Product description

Type max. material weight (lbs) max. material weight (lbs/in2)

XL-1200 60

2.11.3 Electrical connection, power consumption

Electrical connection 400 V, 50/60 Hz

Voltage 3-phase, 400 VL1, L2, L3, N, PE

Mains frequency 50/60 Hz

Power input - 3 phases (without vacuum generator) 3.0 kW

Current consumption, 3 phases (without vacuum generator) max. 16 A

Mains fuse, min.

Value

1

16 A

Electrical connection 208 V, 50/60 Hz

Value

Voltage 3 phase, 208 V L1, L2, L3, N, PE

Mains frequency 50/60 Hz

Power input - 3 phases (without vacuum generator) 3.0 KW

Current input, 3 phases (without vacuum generator) max. 16 A

Mains fuse, min.

1)

Applies only to the basic unit. The minimum requirements for the mains fuse increase depending on

1

20 A

the vacuum generator

Vacuum generator

For additional data see rating plate/original operating manual in chapter "Additional specifications."

While the 1.1 kW vacuum pump is supplied with power via the cutter, the other vacuum generators are

connected to a separate power supply.

The vacuum generator is selected according to the following criteria:

• Cutter model

• Desired application

• local mains voltage and frequency

32

1.1 kW vacuum pump

Value

Voltage 3-phase, 400 V L1, L2, L3, N, PE

Mains frequency 50/60 Hz

Power input - 3 phases 1.1 KW

Page 33

Product description

Value

Mains fuse, min. 16 A

2.2 kW vacuum pump

Value

Voltage 3-phase, 400 V L1, L2, L3, PE

Mains frequency 50/60 Hz

Power input - 3 phases 2.2 KW

Mains fuse, min. 16 A

2.55 kW vacuum pump

Value

Voltage 3-phase, 208 V L1, L2, L3, PE

Mains frequency 50/60 Hz

Power input - 3 phases 2.55 KW

Mains fuse, min. 16 A

4 kW vacuum pump

Value

Voltage 3-phase, 400 V L1, L2, L3, PE

Mains frequency 50/60 Hz

Power input - 3 phases 4 KW

Mains fuse, min. 16 A

12.5/14.5 kW vacuum pump

Value

Voltage 3-phase, 400 V L1, L2, L3, N, PE

Mains frequency 50/60 Hz

Power input - 3 phases 12.5/14.5 KW

Mains fuse, min. 32 A

4.6 kW vacuum pump

Value

Voltage 3-phase, 208 V L1, L2, L3, PE

33

Page 34

Product description

Mains frequency 50/60 Hz

Power input - 3 phases 4.6 KW

Mains fuse, min. 20 A

Vacuum turbine 1 - 9 kW

Voltage 3-phase, 400 V L1, L2, L3, PE

Mains frequency 50/60 Hz

Power input - 3 phases 1 - 9 KW

Mains fuse, min. 32 A

Value

Value

Vacuum turbine 1 - 9 kW

Value

Voltage 3-phase, 208 V L1, L2, L3, PE

Mains frequency 50/60 Hz

Power input - 3 phases 1 - 9 KW

Mains fuse, min. 50 A

2.11.4 Environmental conditions

Value

Operating temperature +10 °C to +35 °C

Storage temperature -20 °C to +55 °C

Relative humidity 10 - 80%, non-condensing

2.11.5 Compressed air supply

34

2.11.5.1 Compressed air connection requirements

Important:

The compressed air connection must fulfill the following requirements:

• Air purity: class 2.4.1 according to ISO 8573-1

• Air pressure: 0.6 - 1.0 MPa depending on configuration

Page 35

Product description

• Air consumption: base machine 20 l/min. 20 - 400 l/min depending on configuration

2.11.5.2 Compressed air settings

Compressed air regulator P1

Air pressure [MPa]

Maintenance unit House

connection

Punch modules - PUM-S, PMM-S,

PPM-S

Compressed air regulator P2

Electric Oscillating Tool - EOT-250 70

Universal Routing Tool - URT 60

Marker modules - MAM-SP, MAMSPS, MAM-SPD

Router modules - RM-S 40

Sheet feeder feed 150

Sheet feeder removal 150

0.7 - 0.8 0.7 - 1.0 150

Air pressure [MPa]

Maintenance unit House

connection

0.6 0.6 - 1.0

max. air

consumption [l/min]

max. air

consumption [l/min]

20

Base machine (vacuum elements)

Compressed air regulator P3

Air pressure [MPa]

Maintenance unit House

connection

Minimal Quantity Lubrication - MQL 70

Material transport (transport

elements, conveyor clamping

elements)

Board loading device

0.45 0.6 - 1.0

covered with base

consumption

max. air

consumption [l/min]

covered with base

consumption

35

Page 36

Product description

Compressed air regulator P4

Air pressure [MPa]

Maintenance unit House

max. air

consumption [l/min]

connection

Pneumatic Oscillating Tool - POT 400

0.8 0.8 - 1.0

Scoring Cutting Tool - SCT

Passepartout Tool - PPT 0.6 - 0.8 0.6 - 1.0 20

2.11.6 Performance features

Accuracy

Value Unit

Resolution of measuring system 0.0050.0002 mmin

Positioning accuracy at a constant temperature ±0.10.004 mmin

Repeat accuracy ±0.030.0012 mmin

Evenness of the worktop 0.40.016 mmin

20

Cutting performance

Value Unit

Speed in vector direction 1 - 14140.04 - 55.67 mm/sin/s

Max. acceleration in vector direction

max. permissible printing force of the printhead

1

14.14556.9 m/s2in/s

100 N

(creasing)

1

depending on the module equipment and cutter size

2.11.7 Emissions

Noise emission

Cutter noise emission < 75 dB (A)

Depending on the cutting technology used,

the machined material, the vacuum generator

and the environmental conditions, the value

can vary between <75 dB and ~85 dB.

2

36

Electromagnetic emissions

The S3 series meets the requirements of the following technical standards:

• EN 61000-6-2 EMC, interference resistance in industrial environments

• EN 61000-6-4 EMC, emission standard for industrial environments

Page 37

Product description

Please ask the manufacturer if you wish to view to the test reports.

FCC approval

NOTE:

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference, in which case

the user will be required to correct the interference at its own expense.

NOTE:

Changes or modifications not expressly approved by the party responsible for compliance could void

the user’s authority to operate the equipment.

37

Page 38

Product description

38

Page 39

Safety

3 Safety

This chapter contains information on the following:

• Definition of the intended use of the machine

• Generally applicable safety instructions and safety regulations to be observed

• Explanation of the meaning of symbols and pictograms which are used in this manual and in signs

on the machine

• Overview of protective devices on the machine

• Listing of the required protective equipment

• Information on the applicable requirements for operating and maintenance personnel

Specific handling-related and situation-related safety instructions are given in the corresponding work

steps in the following chapters of this manual and in other parts of the documentation.

3.1 General

Your safety – as the operator, service engineer or otherwise – is the primary concern. Certain

situations, problems or faults that may occur on the machine could put your safety at risk if you are not

aware of the steps you should take to avoid the resulting dangers.

State-of-the-art technology

The supplied machine corresponds to the state-of-the-art at the time of delivery.

However, the equipment may pose dangers if the safety instructions in this guide are not observed and

implemented.

3.2 Proper use

Proper use of the machine is essential for its safe operation.

The equipment supplied is listed and labeled and indicates the usage possibilities of the machine.

The machine is intended for use as an output device for CAD/CAM data for labeling and processing

materials arranged on the table plate. Proper use and the usage restrictions are dependent on the

module and tool system used and the available material transport system. Any other or further use is

deemed improper. The user bears sole liability for any damage arising from improper use!

Use of the machine shall also be regarded as proper when:

• All nationally applicable safety regulations are complied with.

• The safety instructions in this operating manual are observed.

• The operating conditions are adhered to and the prescribed materials are used.

3.3 Examples of reasonably predictable unintended use

Unintended use of the machine can have the following consequences:

• serious injuries

• serious material damage to the machine

• loss of warranty

Examples of reasonably predictable unintended use of the machine include:

39

Page 40

Safety

• Use of materials that are not defined in the contract and in this operating manual.

• Failure to observe the applicable parameters for the processing of the relevant material.

• Maintenance work on an unsafe machine.

• Failure to follow the operating instructions.

• Placing objects on the work surface.

• Processing of materials that are too large or too heavy.

• Processing of materials that are not fixed or are not adequately fixed.

• Processing of unsuitable materials such as steel, for example.

• Usage of a tooling system that is not intended for use with the material or the machine.

• Operating the machine without the designated protective devices.

• Use of modified module and tooling systems.

• Installation of spare parts and use of accessories and resources not approved by the manufacturer.

• Constructional changes to the machine, without subsequent risk assessment.

• Failure to observe the maintenance requirements.

• Failure to react to signs of wear and damage.

• Servicing work performed by untrained or unauthorised personnel.

• Operating the machine even though the operating instructions are incomplete or unavailable in the

local language.

• Deliberate or careless interference with the machine during operation.

• Bridging or altering the protective equipment.

40

Page 41

3.4 Hazard warnings, important instructions

Explanation of the notes

Both in the operating manual and on the device itself, dangers and important instructions are

designated by special symbols and signal words as follows:

Danger:

The safety instruction Danger

• refers to imminent danger

• refers to operational and service risks

• warns of adverse health effects or even life-threatening injuries

Warning:

The safety instruction Warning

• refers to a dangerous situation

• refers to operational and service risks

• warns of adverse health effects or even life-threatening injuries

Safety

Caution:

The safety instruction Caution

• refers to a dangerous situation

• refers to operational and service risks

• warns of minor reversible injuries and other serious material damage and consequential

damage

Note:

The safety instruction Note

• refers to operational and service risks

• warns of serious damage to the machine and other property damage and consequential

damage

41

Page 42

Safety

Tip:

Tip in combination with the light bulb refers to user tips and useful information which enhance the

usability, prolong the service life of the machine and make the work significantly easier.

Tip:

With tips combined with the sheet, we provide usage tips and useful information which can

improve the energy efficiency of the machine or optimize its environmental effects.

Important:

Usage tips and important information

Structure of the hazard warnings

1 Hazard symbol with the corresponding signal color

2 Signal word corresponding to the danger resulting from the situation

3 Description of the danger

4 Description of the consequences which could result from this hazardous situation

5 Possible actions and codes of conduct to prevent the hazard from occurring or to avert possible

hazardous situations

42

Page 43

Safety

3.5 Areas of responsibility

Manufacturer's areas of responsibility

• The manufacturer is responsible for the safe condition of the machine on delivery, including

operating manual and accessories, according to the sales documentation.

Areas of responsibility of the owner or person authorised by them:

• Ensuring that only adequately trained personnel who have been properly instructed and have read

and understood the content of the safety instructions in this chapter will operate and maintain this

machine.

• Clearly defining the responsibility of the operating and service personnel as required in the

operating manual.

• Checking the personal protective equipment of the operating and service personnel.

• Ensuring a technically safe state of the machine.

• Ensuring that servicing and maintenance are carried out according to the maintenance schedule.

• Notifying the manufacturer of any accident involving the machine that results in serious injury or

substantial material damage.

• Decommissioning the machine immediately if defects arise that affect its operational safety.

Areas of responsibility of the operating and service personnel:

• Wearing the required personal protective equipment.

• Halting operation immediately in the event of faults.

• Reporting any changes which affect operational safety.

• Keeping the machine clean.

• Check the function of the EMERGENCY STOP control devices before starting work.

3.6 Personnel requirements

The operating and service personnel must

• be able to read and understand one of the languages on the command menu (e.g., German,

English, French, Spanish, Italian).

• Be physically and mentally suited.

• Be qualified in the use of the machine by means of thorough training.

• Have read and understood the operating instructions/service manual.

• Be over the age of 16.

• Have knowledge of first aid and the use of fire extinguishers.

43

Page 44

Safety

3.7 Personal protective equipment

The safety equipment required for operating the machine is dependent on the following factors:

• Module and tool system used

• Processing material used

When operating the machine or carrying out maintenance or servicing work, wear tight fitting clothing

and appropriate personal protective equipment.

Warning:

Risk of injury from being caught or trapped in moving machine parts.

• Do not wear loose clothing, scarves, open jackets or open shirt sleeves.

• Remove all jewelry before starting maintenance and servicing work.

Personal protective equipment comprises of:

• Work clothes (service personnel),

• protective goggles (operating and service personnel):

• To provide protection from particles during machining

• To protect the eyes from dangerous radiation

• To protect the eyes from chemicals

• Protective gloves where injury is possible due to:

• burns

• sharp or pointed objects.

• Chemical-resistant protective gloves where injury is possible due to:

• chemicals (cleaning agents)

• Breathing protection when working with poisonous substances

• Hearing protection if the continuous sound pressure level is above 80 dB

Note:

You are personally responsible for:

• wearing the required personal protective equipment

• regular cleaning and maintenance of personal protective equipment;

• replacing damaged and unusable items of protective equipment promptly

44

Page 45

Safety

3.8 Rules and occupational safety

• Operation of the machine is always subject to local regulations regarding work safety and accident

prevention.

• Make sure that there is adequate lighting during operation.

• Check protective devices every time before starting the machine.

• If a hazardous situation arises, activate an EMERGENCY STOP control device to shut down the

machine.

• You are not permitted to make unauthorised modifications or changes to the machine which might

affect the system's safety. Accessories or spare parts made by other manufacturers may only be

used with the machine with the written approval of the manufacturer.

• Only service technicians authorized by the manufacturer are permitted to install, commission,

maintain and repair the machine.

• Before carrying out any maintenance, repair and modification work:

• Switch off the machine using the main switch and secure it with a padlock.

• Prevent the machine being switched on inadvertently by removing the mains supply cables to

the power box (several mains connections available!).

3.9 Conduct in the event of malfunctions

As a matter of principle, all troubleshooting work or inspections on the machine should only be carried

out when it is switched off.

The following must never be bypassed or rendered ineffective:

• Light barriers on beams

• Monitoring sensors

• Safety and control switches of the machine

If malfunctions cannot be remedied by the operating personnel using simple means, inform the

responsible service center!

45

Page 46

Safety

3.10 Danger areas

3.10.1 General danger area

46

1 Danger area

The danger area is restricted to the working area or the active area of the drive system. Never reach

into this work area during processing.

3.10.2 Danger area during initialization

Caution:

Risk of injury during manual initialization of the tool!

The safety devices are not active during manual initialization

• Do not reach into the danger area during manual initialization

Page 47

• For initialization, use automatic AKI initialization, if the tool allows this.

Safety

1 Module (e.g., UM-S)

2 Tool (e.g., UCT)

3 Danger area

D Safety distance during initialization (25 cm)

The safety distance (d) for operating personnel during manual initialization is 25 cm. Do not reach into

the marked danger area during the initialization phase!

3.10.3 Danger area during cleaning

Caution:

Risk of injury when cleaning the machine!

Blades, router bits and punching inserts have very sharp edges which are sometimes hidden by

moving equipment (spring-loaded gliding disc).

• Before starting to clean, remove all modules and tools from the module carriage.

• Switch off the machine with the main switch and secure it against unauthorised switch-on

using a padlock.

• Disconnect the machine from the mains.

47

Page 48

Safety

• While cleaning work is being performed, attach a sign that says "DO NOT SWITCH ON" that is

prominently displayed on the main control panel of the machine.

1 Danger area

48

Page 49

3.11 Warnings on the product

The warnings on the modules and tools are illustrated in the respective operating instructions.

Safety

No. Description Variant 1 (CE) Variant 2 (ANSI)

1 Mandatory sign:

Wear protective gloves

Art. no.:

5800412 (50 mm)

Art. no.:

5801106 (65 mm)

2 Mandatory sign:

Wear eye protection

Art. no.:

5800467 (50 mm)

Art. no.:

5801058 (65 mm)

49

Page 50

Safety

No. Description Variant 1 (CE) Variant 2 (ANSI)

3 Warning sign:

Hand injuries due to

crushing

Art. no.:

5800342 (50 mm)

4 Warning sign:

Electrical hazard

Art. no.:

5801338 (50 mm)

Art. no.:

5801059 (65 mm)

Art. no.:

5802331 (95 mm)

5 Warning sign:

Electrical hazard

6 Warning sign:

Laser beam

Art. no.:

5200367 (110 mm)

Art. no.:

5811418 (50 mm)

Art. no.:

5200367 (110 mm)

Art. no.:

5811418 (50 mm)

50

Art. no.:

5800344 (25 mm)

Art. no.:

5801062 (40 mm)

Page 51

3.12 Protective devices

Safety

1 EMERGENCY STOP control device

2 Safety device (protective trip switch)

3 EMERGENCY STOP control device

4 Control panel

3.12.1 Safety device

Caution:

The beam may cause serious injuries in case of a collision.

Note that the high level of kinetic energy of the drive results in a significant braking distance.

Light barriers are no guarantee against injuries!

The protective system consists of light barriers on the bar ends and on the module carriage.

The machine is stopped automatically if the light barriers detect an obstacle.

51

Page 52

Safety

Effects for the cutter

• The drive motors (beams, module carriage) are slowed to a standstill.

• The Z-axis remains in the position where it is located when the safety device is triggered (e.g. lower

position).

• The cutter switches to STOPPED mode.

• Safety-relevant units (modules, tools, etc. ) are stopped and switched off.

• Units that are not safetyrelevant or important for the operation of the machine, such as the operating unit, remain switched on.

• An error message is displayed.

• A warning tone sounds.

Effects on the options connected to the cutter

• Synchornised movements are stopped.

• Units that are not safety-relevant or important for the operation of the machine remain switched on.

Recommissioning

• Restore operational safety.

• Free the light barriers of obstacles.

• Acknowledge the error message on the control panel.

Tip:

If the Z-axis is in the upper or lower position when the safety device is triggered, it is now raised to

the park position.

3.12.2 Control panel

Malfunctions are shown on the LCD display.

An acoustic signal sounds in the event of an error or light barrier interruption or activation of an

EMERGENCY STOP control device.

3.12.3 EMERGENCY STOP control devices

Activating an EMERGENCY STOP control device triggers a machine standstill in the event of an

emergency.

Danger:

Risk of injury due to inaccessible EMERGENCY STOP control device!

Machines with inaccessible EMERGENCY STOP control devices are not safe for operation. The

machine cannot be stopped promptly in hazardous situations.

• Ensure that all EMERGENCY STOP control devices are easy to access and not hidden.

52

Note:

Risk of damage to the cutter by activating EMERGENCY STOP control devices.

Page 53

Safety

Do not use EMERGENCY STOP control devices to switch off the machine under normal

circumstances.

Note:

To unlock an activated EMERGENCY STOP control device after restoring operational safety, turn

the switch clockwise (see Reset EMERGENCY STOP control devicesReset EMERGENCY STOP

control devices on page 82Reset EMERGENCY STOP control devicesReset EMERGENCY

STOP control devices).

53

Page 54

Safety

3.12.4 Shutdown in an emergency

An emergency shutdown allows the machine to be stopped quickly in case of emergency.

Effects for the cutter

• The drive motors (beams, module carriers) are braked to a standstill and are then disconnected

from the energy supply.

• The drive axes are free and can be moved by hand.

• The cutter switches to STOPPED mode.

• Safety-related units (modules, tools, auxiliary drive...) are isolated from the energy supply.

Safety-related units (modules, tools...) are disconnected from the energy supply.

• Units that are not safetyrelevant or important for the operation of the machine, such as the operating unit, remain switched on.

• An error message is displayed.

• A warning tone sounds.

• The EMERGENCY STOP control device remains locked in the off position.

Effects on the options connected to the cutter

• Synchornised movements are stopped.

• Units that are not safety-relevant or important for the operation of the machine remain switched on.

3.12.5 Shutdown in the event of overload

The machine automatically shuts down if an axis (X,Y, T, Z) becomes blocked or overloaded.

Effects for the cutter

• The drive motors (beams, module carriers) are braked to a standstill and are then disconnected

from the energy supply.

• The drive axes are free and can be moved by hand.

• Safety-relevant units (modules, tools, auxiliary drive, etc.) are stopped or switched off.

Safety-relevant units (modules, tools, etc.) are stopped or switched off.

• Units that are not safetyrelevant or important for the operation of the machine, such as the operating unit, remain switched on.

• The cutter switches to the STOPPED operating mode

• An error message is displayed.

• A warning tone sounds.

Effects on the options connected to the cutter

• Synchornised movements are stopped.

• Units that are not safety-relevant or important for the operation of the machine remain switched on.

54

Page 55

3.13 Mechanical hazards

3.13.1 Collection, retraction

Caution:

Risk of injury from entanglement, getting caught and being pulled in!

The machine and the tool system has moving parts.

Possible consequences

• Bruises, crushing, lacerations to fingers or hands

• Bruising to the head and arms

• Pulling out of hair

• Damage to clothing

• Damage to machine

Precautions during initialization and operation in ONLINE mode:

• Do not touch modules and beams

• Do not reach into the working and moving area

• Do not touch the table plate or the material lying on it

• Do not place hands on side covers

• Do not lean with the torso on the work surface

• Avoid untied long hair and loose clothing and ties

These precautions specifically apply if the cutter can be switched into ONLINE operating mode by

the CAD/CAM system.

Safety

3.13.2 Hazards from foreign bodies

Caution:

Injury risk due to objects being ejected!

Foreign bodies on the table plate are collected by the beam or the module/tool/module carriage

and pushed away!

Possible consequences

• Facial injuries and others

• Damage to the machine

Precautionary measures during initialization and operation in ONLINE/OFFLINE mode:

• Do not place any materials, tools, or other objects on the table plate or the side covers.

• Before operation, check whether there are any objects on the table plate or the side covers.

55

Page 56

Safety

3.13.3 Cut and puncture injuries

Caution:

Injury risk from sharp objects!

Blades, router bits and punching inserts have very sharp edges which are sometimes hidden by

moving equipment (spring-loaded gliding disc).

Possible consequences

• Cutting and stabbing injuries to the hands and arms

Precautionary measures

• Change the tool inserts with extreme caution.

• Do not enter the working area during initialization and during operation in ONLINE mode.

3.14 Risk of burns

Warning:

Risk of injury from burning!

Certain materials (metals) or tools (blade, router) reach very high temperatures during processing.

Possible consequences

• Burning injuries to the limbs

Precautionary measures

• Allow workpieces to cool down before removal

• Wear suitable protective gloves when removing freshly processed workpieces

• Allow tools (router, blade) to cool before removing them

3.15 Electrical hazard

Warning:

The machine is operated with a mains voltage of 400/208 V and a mains frequency of 50/60 Hz.

Possible consequences

• Risk of death or injury from electric shock.

Precautionary measures

• Only trained service personnel and authorized service technicians are allowed to open power

boxes, switch boxes and electronics units.

• Ensure that the mains cables are protected against mechanical loads and are laid so that they

are free from strain.

• Ensure damaged cables are replaced immediately.

56

Page 57

Safety

3.16 Risks arising from the emission of toxic dust

Warning:

Risk of poisoning from the emission of toxic dust!

Processing certain materials can lead to the creation of harmful toxic dust.

• Obtain information about the toxicity of the material to be processed from the manufacturer.

• Use a suitable extraction unit or implement other appropriate measures accordingly.

The operator of the system is responsible for making sure that all national regulations concerning

the maximum permissible dust concentrations in the workplace are complied with. When handling

hazardous types of dust, all local safety regulations as well as the manufacturer's instructions must be

observed. When routing or processing hazardous materials, always use dust extractors with special

dust filters designed for the purpose. As an optional accessory, Zünd offers extraction systems that

comply with the following regulations:

• the extraction of hazardous dusts with MAK values up to 0.1 mg/m3and wood dusts conforming to

dust class M

• the extraction of dusts conforming to dust class H

3.17 Risks arising from the processing of toxic materials/materials

hazardous to health

Warning:

Risk of poisoning from emissions when processing toxic materials!

Processing such a wide variety of materials can lead to toxic emissions (gases, dust etc.) that are

hazardous to your health.

• Never process toxic materials/materials hazardous to health!

• Obtain information from the manufacturer of the material to be processed about its toxicity.

Observe the following guidelines when handling toxic/hazardous materials:

• The operator of the system is responsible for determining which processing materials are toxic/

hazardous.

• It is forbidden to process toxic materials on Zünd cutters without appropriate additional safety

measures!

• The operator of the system is responsible for installing appropriate additional safety measures!

57

Page 58

Safety

3.18 Environmental hazards

Warning:

Processing residues, operating materials, cleaning agents etc. can cause damage and pollute the

environment if they enter the soil, waterbodies or the sewage system.

Explanation of the hazard label

Hazard label for substances that are harmful to the environment

Safety regulations and protective measures

• Dispose of waste materials in accordance with current national environmental protection

regulations. In case of doubt, check on the appropriate disposal methods with your local collection

point or recycling center.

• Collect different chemicals in separate containers.

3.19 Handling and storage of chemicals

Warning:

Cleaning agents and operating materials can cause skin irritation and can therefore be hazardous

to your health if handled carelessly.

58

Page 59

Always wear your personal protective gear (protective gloves, goggles, mouth guard etc.) when

handling chemicals.

Explanation of the hazard label

Hazard label for very toxic or toxic substances

Safety

Hazard label for hazardous substances or irritant materials

Hazard label for irritating substances

59

Page 60

Safety

Note:

Chemicals classified as irritants are used to operate and clean this machine (cleaning agents,

operating fluids). Safety datasheets for the substances in question can be downloaded from the

Zünd homepage (www.zund.com).

Safe handling of chemicals

Important:

Dispose of chemicals in accordance with national regulations. Follow the manufacturer's instructions

(MSDS).

• Store chemicals in tightly closed containers in a cool, dry place (between 5 °C and 30 °C).

• Protect the containers from heat and direct sunlight.

• Provide good ventilation, including at floor level.

• Store chemicals in accordance with local regulations.

• Keep containers tightly closed.

• Use chemicals as intended only.

60

Page 61

3.20 Risk of fire and explosion

Warning:

There is a risk of fire when routing and cutting flammable materials

Terminate the routing/cutting and leave the tool to cool off in case of

• smoke emission.

• Discolorations on the router/blade which point to increased heat development

Warning:

Risk of dust explosions

Flying sparks or electrostatic charges result in the risk of dust explosions during the extraction of

different materials.

• Find information about the risk of explosion when processing the type of material that you are

using and, if necessary, do not process it.

• If necessary, adjust the extraction to the required regulations.

Safety

Observe the following safety rules and countermeasures

• Find out the locations where fire extinguishers are kept and familiarize

yourself with their use and operation. The adjacent sign indicates the

location of a fire extinguisher.

• Do not use inflammable cleaning agents to clean the cutter.

• Store all processing materials in the proper manner in accordance with

local guidelines.

Classes of fire

Refer to the following table to find out which type of fire extinguisher is used for each fire class:

Solid materials, mainly organic in nature; e.g. wood, paper, textiles, etc.

Liquid and liquefiable substances; e.g. gasoline, oils, grease, paints etc.

61

Page 62

Safety

Combustible gases: e.g. methane, propane, etc.

Behaviour in the event of a fire

• Turn off the machine using the main switch

• Assess the situation: If there is danger, leave the area

immediately and call the fire department. Only try to extinguish

the fire if your personal safety is not at risk.

• Remove a suitable fire extinguisher (A, B, C) from its bracket

and prepare it for use.

• Locate the source of the fire. Attack the fire with repeated short

bursts from the extinguisher. Always spray the extinguishing

agent from underneath into the source of the fire. In other

words, always aim at the burning material and not at the

flames.

• After using the fire extinguisher, do not return it to its usual

place but have it refilled immediately.

3.21 Danger from laser beam

The optional ICC camera with laser pointer and the laser pointer use a visible laser beam. The laser

beam is considered to be harmless to the human eye in case of short-term exposure (<0.25 s) (class 2

laser).

The ICC camera with laser pointer or the laser pointer are switched on together with the cutter. By

design, the laser beam is directed down onto the material.

Safety instructions

• Do not look into laser beam.

• If a laser beam hits your eye, close your eyes or turn away immediately.

• Keep in mind that certain medications or consuming alcohol may cause a delayed blinking reflex.

3.22 Safety instructions for the operating personnel

This instruction manual cannot cover all possible situations and potential hazards.

It is therefore particularly important that operating personnel

• have been thoroughly trained and are aware of and able to correctly assess the hazards that can

arise from the machine.

• Knows all protective devices on the machine.

• Request information from the manufacturer without delay if an undocumented, hazardous situation

arises in connection with the machine.

In addition to these safety instructions, you must also observe the situation-related safety notes in the

chapters "Controls and operation" and "Maintenance and cleaning".

62

Page 63

Safety

3.23 Safety precautions for service personnel

The reliability, readiness and service life of the machine greatly depend on you carrying out your work

in a conscientious manner.

Note:

Specialist knowledge and expertise are required to service and maintain the machine. The

manufacturer provides this knowledge through training courses which are specially tailored for

service personnel. Only personnel with Zünd certification are permitted to carry out service work

on Zünd cutters.

3.24 Disposal

Information about proper disposal

The symbol has the following functions:

• Marking substances that are toxic and harmful to the environment

• Instructions for disposal of harmful substances

• Warning against disposal with domestic waste or environmental pollution caused by hazardous

substances and objects contaminated with such substances

Measures for disposal

Zünd cutters correspond with the requirements of the German Electrical and Electronic Equipment Act

and generally do not contain any poisonous substances or consumables.

Contact Zünd customer services or your service partner before you dispose of your cutter.

Dispose of cutting waste in accordance with current national environmental protection regulations.

In case of doubt, check the appropriate disposal methods with your local collection point or recycling

center.

63

Page 64

Safety

64

Page 65

Controls and operation

4 Controls and operation

This chapter familiarizes you with the controls, guides you through the operational procedures and

describes the following operating steps:

• Daily commissioning

• Operation of the main components

• Detailed information on the operation of the machine

• Safe switch-off of the machine

4.1 Safe working practices

Danger:

Operating errors or negligence can put human lives at risk as well as causing serious damage to

the machine!

The machine is fitted with safety devices to minimise risk. However, these safety devices cannot

guard against damage as a result of operating errors or negligent working practices.

Observe the safety requirements from Chapter Safety on page 39 and the situational safety

requirements of the appropriate working step.

Operator personnel are responsible for the safe use of the machine!

65

Page 66

Controls and operation

4.2 Controls

4.2.1 Overview

66

1 Rear EMERGENCY STOP control device

2 Control panel and workstation (optional)

3 Maintenance units (dependent on cutter configuration)

Page 67

4.2.2 Control panel

Controls and operation

1 Display 8 ONLINE key

2 Soft keys 9 STOP key

3 Navigation keys 10 VAC (vacuum) key

4 Number block and function keys 11 Router on/off key (optional)

5 Tool up/down key 12 Front processing approval (optional)

6 Travel keys 13 Switch on front vacuum (optional)

7 SHIFT key 14 EMERGENCY STOP control device

67

Page 68

Controls and operation

4.2.3 EMERGENCY STOP control devices

Activating an EMERGENCY STOP control device triggers a machine standstill in the event of an

emergency.

The cutter is fitted with two EMERGENCY STOP control devices as standard. They are located as

follows:

• 1 x on control panel

• 1 x on side support cover on left

68

Danger:

Risk of injury due to inaccessible EMERGENCY STOP control device!

Machines with inaccessible EMERGENCY STOP control devices are not safe for operation. The

machine cannot be stopped promptly in hazardous situations.

• Ensure that all EMERGENCY STOP control devices are easy to access and not hidden.

Page 69

Controls and operation

Note:

Risk of damage to the cutter by activating EMERGENCY STOP control devices.

Do not use EMERGENCY STOP control devices to switch off the machine under normal

circumstances.

Note:

The activated EMERGENCY STOP control device remains locked in the off position.

To unlock an activated EMERGENCY STOP control device after restoring operational safety, turn

the switch clockwise (see Reset EMERGENCY STOP control devices on page 82).

4.2.4 Maintenance unit

The maintenance unit adjusts the air pressure to the switching of the vacuum elements/various

modules and options.

1 Maintenance unit, POT*

2, 6 Air pressure setting

3, 5 Stopcock

4, 7 Water separator

8 Maintenance unit, basic machine

69

Page 70

Controls and operation

The maintenance unit is preset and adjusted.

Check the air pressure setting at regular intervals. The setting values can be found in the chapter

Basic unit compressed air supply.

70

Page 71

Controls and operation

4.2.5 Interfaces

The machine has data exchange interfaces. These are attached to the electronics unit.

1 LAN

2 not used

3 USB (host) - not used

4 Status and error display

5 COM 1

6 COM 2

71

Page 72

Controls and operation

4.3 Menu navigation

4.3.1 Navigation keys

Functions in the cutter menu

Key

Use these keys to navigate through the menu

• If submenus are available, use this key to change to the next menu level

• Select setting/function