Page 1

Identificazione: MD-AL-GI-00

Rev. 4.0 del 31.01.18 - Applicazione:

GID

Reg. Pile IT12110P00002965 - Capitale Sociale € 100.000,00 I.V.

Reg. Impr. AR n.03225010481 - REA AR - 94189

Azienda Certificata ISO 9001 - Certificato n. 9151 - CNS0 - IT-17778

Zucchetti Centro Sistemi S.p.A. - Green Innovation Division

Via Lungarno, 248 - 52028 Terranuova Bracciolini - Arezzo, Italy

tel. +39 055 91971 - fax. +39 055 9197515

innovation@zcscompany.com - zcs@pec.it – www.zcsazzurro.com

Grid-connected inverter

1.1K – 3K TL

User Manual

V2.1 (07-06-2019)

Page 2

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

Table of Contents

1. Preliminary safety instructions…...………………………………………….…………………………………………………………….6

1.1. Safety instructions……………………………………………………………..…………………………………………………………..6

1.2. Symbols and icons…..……..…………………………………………………….…………………………………………………………9

2. Product features……………….……………………………………………………….………….……………………………………………10

2.1. Product presentation………..…………………………………………………...……………………………………………………..10

2.2. Description of functions……………………………………………………………………………………….……………………....12

2.3. Efficiency curve…..……………………………………………………………………..…………………………………………………13

3. Installation………..………………………………………………………………………………………………………………………………14

3.1. Installation process……...………………………………………………………………...……………………………………………14

3.2. Checks before installation……………….……………………………………………………………………………………………14

3.3. Installation tools…………………………………………………………………………….……………………………………………16

3.4. Installation position………………………………………………………………………….….………………………………………18

3.5. Moving the ZCS 1.1-3K TL inverter………..……………………………………………….………...……………………………19

3.6. Installing the ZCS 1.1-3K TL inverter…….……………………………………………….………...……………………………20

4. Electrical connections………..………………………………………………………………………….……………………………….…..21

4.1. Electrical connections……………..…………………………………………………………………..……………………….……....22

4.2. Ground cable connections (PNGD).……………………………………………………..…………………………………….…..22

4.3. Connecting the DC input power cable………………………...…………………………………….…………………………...24

4.4. Connecting the AC output power cables…...………………………………………..………………………………………….27

4.5. Connecting the communication cables……………………...…………………………………………..………………………30

4.6. Communication systems....………………………………………………………………………………………...…………………33

5. Commissioning the inverter……………………………..………………………………..…………………………….………………....36

5.1. Safety inspection before commissioning………………..……………………………………………………….……………..36

5.2. Starting the inverter………………………………………………………………………………………………………………….….36

6. Operating interface…………………………………………………………………………………………………………………………….37

6.1. Operating interface and display….………………………………………………………………………….…………..………….37

6.2. Main interface………………………………………………………………..…………………..…………………………………..…….38

6.3. Main menu……….………………………………………………………………………………………………….……………………....40

2 / 61

Page 3

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

7. Troubleshooting and maintenance..………..……………………………………………………………………………..…………....54

7.1. Troubleshooting…………………………………………………………………………………….…………………………………….54

7.2. Maintenance……………………………………………………………………………………………...…………………………………59

8. Uninstalling…………………………………………………………………………………….……………...………………………………….59

8.1. Steps for uninstalling the inverter…..…………………………………………………………………..…………………………59

8.2. Packaging…………………………………………………………………………………………………………………………………….59

8.3. Storage…..………………………………………………………………………………………………………………….………………...59

8.4. Disposal…….………………………………………………………………………..…………………………………….…………………59

9. Technical specifications………………………………………………………………………………………………………..…………….60

10. Warranty.…………….………………………………………………………………………………………………………………..……………62

3 / 61

Page 4

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

General instructions

This manual contains important safety instructions that must be followed during installation and

maintenance of the equipment.

Please keep these instructions!

This manual must be considered an integral part of the equipment and must always be available to everyone

who interacts with this equipment. The manual must always accompany the equipment, even when it is

transferred to another user or plant.

Copyright statement

The copyright of this manual belongs to Zucchetti Centro Sistemi S.p.A. No part of this manual may be copied

(including the software), reproduced or distributed in any form or by any means without the permission of

Zucchetti Centro Sistemi S.p.A. All rights reserved. ZCS reserves the right to final interpretation. This manual

is subject to change based on feedback from users, installers or customers. Please check our website at

http://www.zcsazzurro.com for the latest version.

Zucchetti Centro Sistemi

Via Lungarno 305/A

52028, Terranuova Bracciolini (AR)

+39 055 91971

info@zcscompany.com

http://www.zcscompany.com

4 / 61

Page 5

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

Danger: indicates a hazardous situation which, if not resolved or

avoided, could result in serious injury or death.

Danger

Warning: indicates a hazardous situation which, if not resolved

or avoided, could result in serious injury or death.

Warning

Caution: indicates a hazardous situation which, if not resolved

or avoided, could result in minor or moderate injury.

Caution

Attention: indicates a potentially hazardous situation which, if

not resolved or avoided, could result in damage to the system, or

other property.

Attention

Note: provides important tips on the correct and optimal

operation of the product.

Note

Preface

General information

Please read this manual carefully before installation, operation or maintenance.

This manual contains important safety instructions that must be followed during installation and

maintenance of the system.

Scope

This manual describes the assembly, installation, electrical connections, commissioning, maintenance and

troubleshooting of the following inverters:

1100TL / 1600TL / 2200TL / 2700TL / 3000TL

Keep this manual so that it is accessible at all times.

Recipients

This manual is intended for qualified technical personnel (installers, technicians, electricians, technical

support personnel or anyone who is qualified and certified to operate a photovoltaic system), who are

responsible for installing and starting up the inverter in the photovoltaic energy system and for operators of

the photovoltaic system.

Symbols used

This manual provides information for safe operation and uses certain symbols to ensure the safety of

personnel and materials, and for efficient use of the equipment during normal operation.

It is important to understand this information to avoid accidents and damage to property. Please take note

of the following symbols used in this manual.

5 / 61

Page 6

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

If you have problems or questions regarding the reading and

understanding of the following information, please contact

Zucchetti Centro Sistemi S.p.A. through the appropriate

channels.

Note

1. Preliminary safety instructions

General information in this chapter

Safety instructions

It mainly highlights the safety instructions to be followed during installation and use of the equipment.

Symbols and icons

Introduces the main safety symbols on the inverter.

1.1. Safety instructions

Before installing and using the equipment, make sure you read and understand the instructions in this

manual and familiarise yourself with the relative safety symbols shown in this chapter.

Depending on national and local requirements, permission must be obtained from your local provider before

connecting to the electrical grid, making sure that the connections are carried out by a qualified electrician.

Contact the nearest authorised service centre for any repairs or maintenance. Contact your distributor for

information on the nearest authorised service centre. DO NOT carry out repairs yourself, as this may result

in injury or damage.

Qualified personnel

Ensure that the operator has the necessary skills and training to operate the equipment. Personnel

responsible for the use and maintenance of the equipment must be skilled and capable of performing the

activities described, and must also have appropriate knowledge on how to correctly interpret the contents of

this manual. For safety reasons, this inverter can only be installed by a qualified electrician with the

necessary training and/or skills and knowledge. Zucchetti Centro Sistemi S.p.A. declines all responsibility for

damage to property or personal injury caused by incorrect use or the device.

Installation requirements

Install and start the inverter according to the following instructions. Place the inverter on suitable loadbearing supports with sufficient load capacity (such as walls or photovoltaic racks) and make sure that the

inverter is positioned vertically. Choose a suitable location for the installation of the electrical equipment.

Make sure there is sufficient space for heat dispersion and to accommodate future maintenance. Maintain

adequate ventilation and ensure that there is enough air circulation for cooling.

6 / 61

Page 7

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

Before connecting the mains power, be sure to disconnect the photovoltaic

modules by disconnecting all the DC switches of the generator. When

exposed to the sun, the photovoltaic generator produces a voltage that can

be dangerous!

Danger

All installation operations must be carried out by a professional electrician, who

must:

be prepared.

carefully read this manual and understand its contents.

Warning

Before connecting the inverter to the grid, make sure that all the necessary

permits have been obtained from the local grid operator and that all the

electrical connections are made by a professional electrician.

Attention

Figure 1 – Do not lose or damage this manual

Transport requirements

If you have problems with the packaging that could cause damage to the inverter or if you find any visible

damage, immediately notify the transport company. If necessary, request assistance from an installer of

photovoltaic systems or from Zucchetti Centro Sistemi SpA. Transport of the equipment, especially by road,

must be carried out with vehicles suitable to protect the components (in particular, electronic components)

against violent knocks, humidity, vibrations, etc.

Electrical connections

Please comply with all the electrical regulations on the prevention of accidents related to photovoltaic

inverters.

7 / 61

Page 8

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

Do not remove the information label or open the inverter.

Otherwise, ZCS will not provide any warranty or maintenance.

Note

Contact with the electrical grid or the terminal of the equipment may cause

electrocution or fire!

•

Do not touch the terminal or the conductor connected to the electrical grid.

•

Follow all the instructions and safety requirements relating to the mains connection.

Danger

Some internal components reach very high temperatures when the

inverter is in operation. Wear protective gloves!

Attention

Before carrying out any repairs, disconnect the inverter from the mains network (AC

side) and from the photovoltaic system (DC side).

After switching off the AC and DC switches, wait 5 minutes before carrying out any

repairs or maintenance on the inverter!

Danger

The inverter should start working again after any faults have been fixed. For any

repairs, contact your local authorised service centre;

Do not disassemble the internal components of the inverter without permission. This

will void the warranty. Zucchetti Centro Sistemi S.p.A. shall not be responsible for any

damage or loss caused by these actions.

Attention

Operation

Maintenance and repair

8 / 61

Page 9

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

Pay attention to possible burns due to hot parts.

Only touch the screen or press the keys while the inverter is in

operation.

Caution

The PV strings should be connected to the ground in accordance

with the local regulations.

• To ensure the safety of the system and people, the inverter

and photovoltaic strings must be securely connected to

the ground.

Attention

Ensure the correct DC input voltage; this must be below the

maximum allowable DC voltage. Overvoltage can cause

permanent damage to the inverter that is not covered by the

warranty!

Warning

Residual voltage may be present on the inverter! Before opening the

inverter, wait 5 minutes to ensure that the capacitors are completely

discharged.

Be careful of high voltage

Be careful of high temperatures

Complies with the European Standards (CE)

Grounding point

1.2. Symbols and icons

Safety signals

Symbols on the inverter

Some safety symbols are located on the inverter. Read and understand the contents of the

symbols before installing the inverter.

9 / 61

Page 10

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

Read this manual before installing the inverter.

Indication of the allowable temperature range

Degree of protection of the equipment according to the IEC 70-1

standard (EN 60529 June 1997).

Positive pole and negative pole of the input voltage (DC).

2. Product features

General information in this chapter

Product dimensions

The field of use and overall dimensions of the 1.1K-3K TL inverters are indicated in this section.

Function description

It describes how the 1.1K-3K TL inverters and their internal operating modules work.

Efficiency curve

It describes the efficiency curves of the inverter.

2.1. Product presentation

Field of use

The 1.1K-3K TL inverters are grid-connected photovoltaic inverters equipped with a single MPPT channel, capable

of converting the direct current generated by the photovoltaic strings into single-phase sine wave alternating

current and feeding the energy to the public electricity grid. An AC circuit breaker (see chapter 4.4) and DC circuit

breaker must be used as disconnecting devices and must always be easily accessible.

10 / 61

Page 11

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

Figure 2 – Grid-connected photovoltaic system

The 1.1K-3K TL inverters can only be used with photovoltaic modules that do not require one of the poles to

be grounded. The input current and voltage of the PV strings must not exceed the limits specified in the

technical specifications. Only photovoltaic modules can be connected to the input of the inverter (do not

connect batteries or other power supply sources).

• Accessories and optional components of the inverter should be chosen by a qualified technician who is

familiar with the installation conditions.

• Overall dimensions: L x W x H = 405.5 mm x 314 mm x 135.5 mm

Figure 3 – Front, side and back view of the inverter and bracket

11 / 61

Page 12

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

Labels on the inverter

Figure 4 – Do not remove the label on the side of the inverter

2.2. Description of functions

The DC power generated by the PV modules is filtered through the input board before entering the power

board. The input board also has the function of detecting the insulation impedance and the DC input

voltage/current. The power board converts the DC power into AC power. The current converted into AC is

filtered through the output board and is then fed into the grid. The output board also has the function of

measuring the grid and GFCI voltage/current, and acts as an output insulation relay. The control provides

the auxiliary power supply, controls the operating status of the inverter and shows it on the display. The

display also shows the error codes when the inverter is not functioning properly. At the same time, the

control board can activate the protection relay in order to disconnect the inverter from the grid and protect

the internal components.

Inverter functions

A. Feeding reactive power into the grid

The inverter is able to produce reactive power and feed it into the grid through the setting of the Power

Factor. The feed-in management can be controlled directly by the grid company through a dedicated RS485

interface.

B. Limiting the active power fed into the grid

If enabled, the inverter can limit the amount of active power fed into the grid at the desired value (expressed

as a percentage).

C. Automatic power reduction when grid is over frequency

When the grid frequency is higher than the limit set, the inverter reduces the output power in order to

ensure the stability of the grid.

D. Data transmission

The inverter (or a group of inverters) can be monitored remotely via an advanced communication system

based on a RS485 interface or via Wi-Fi.

E. Software update

A microSD card is used to update the firmware.

12 / 61

Page 13

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

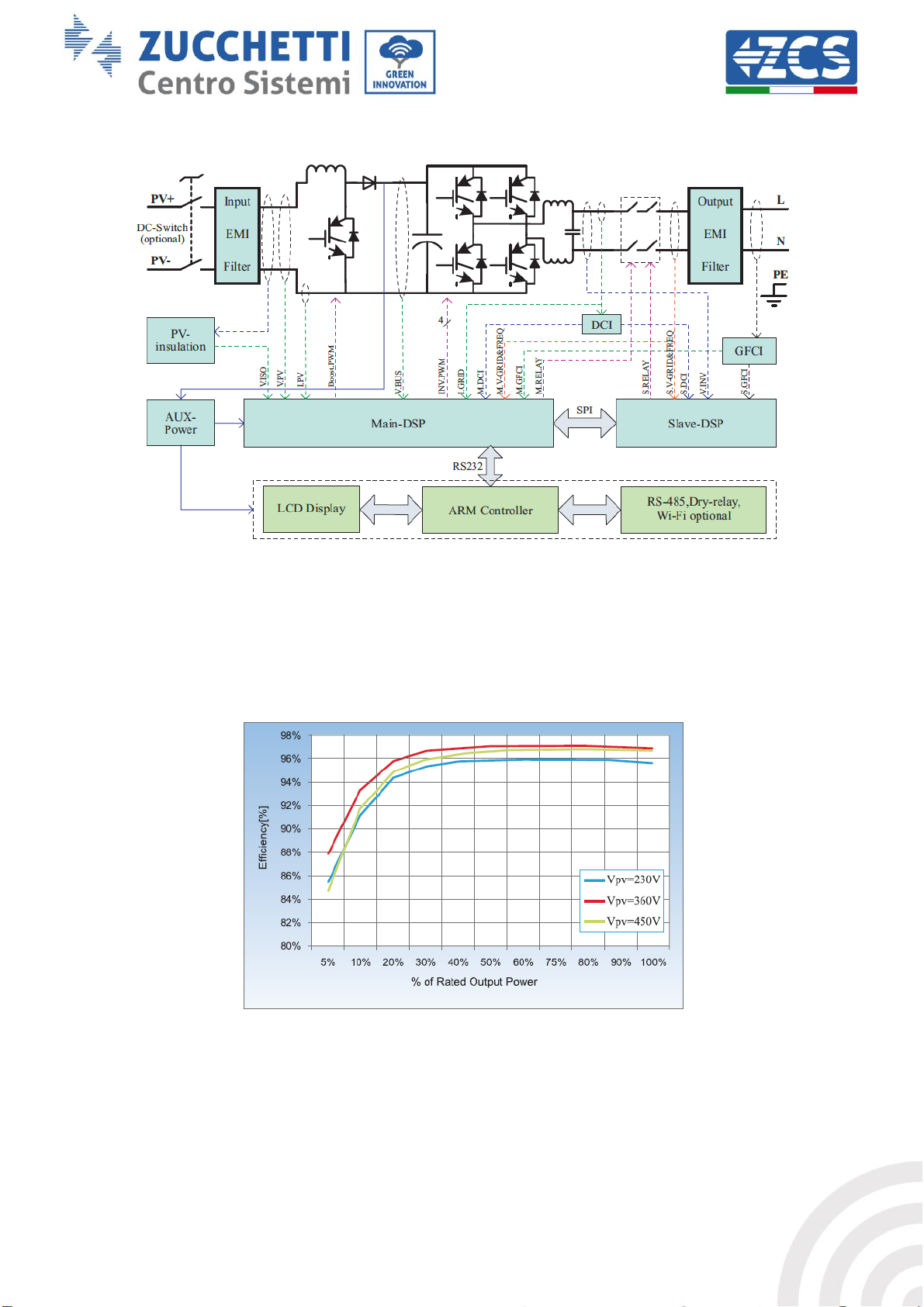

Wiring diagram

Figure 5 – Block diagram of the 1.1K-3K TL inverter

2.3. Efficiency curve

Efficiency curve for a Azzurro ZCS 3000 TL model

Figure 1 – Efficiency curve for an Azzurro ZCS 3000 TL inverter

13 / 61

Page 14

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

DO NOT install 1.1K-3K TL inverters near flammable materials.

DO NOT install 1.1K-3K TL inverters in an area where flammable or explosive

materials are stored.

Danger

The housing and heat sink may become very hot while the inverter is running, DO NOT

install the inverter in places where they may be touched inadvertently.

Warning

Consider the weight of the inverter during transportation and installation.

Choose an appropriate mounting position and surface.

Attention

3. Installation

General information in this chapter

This chapter describes how to install the 1.1K-3K TL inverter.

Installation notes:

3.1. Installation process

Figure 7 – Installation steps

3.2. Checks before installation

Checking the outer packaging

The packaging materials and components may be damaged during transportation. Therefore, please check

the materials of the outer packaging before installing the inverter. Check the surface of the box for external

damage such as holes or tears. If any kind of damage is detected, do not open the box containing the inverter

and contact the supplier and transport company as soon as possible.

It is recommended to remove the packaged materials from the box 24 hours before installing the inverter.

Checking the product

After removing the inverter from its packaging, check that the product is intact and complete. If any damage

is found or there are no components, contact the supplier and transport company.

14 / 61

Page 15

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

1 Photovoltaic inverter

1 mounting bracket

1 + input terminal

1 - input terminal

1 Metal terminal for + DC

power cables

1 Metal terminal for - DC

power cables

2 M5 hexagonal screws

10 M6 flat washers

7 expansion plugs (2

spares)

5 self-tapping screws

1 user manual

1 warranty

1 certificate

1 AC output connector

Contents of the packaging

Carefully check the contents of the packaging before installation, making sure that no element inside the

packaging is missing or damaged.

The package will contain the following components:

15 / 61

Page 16

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

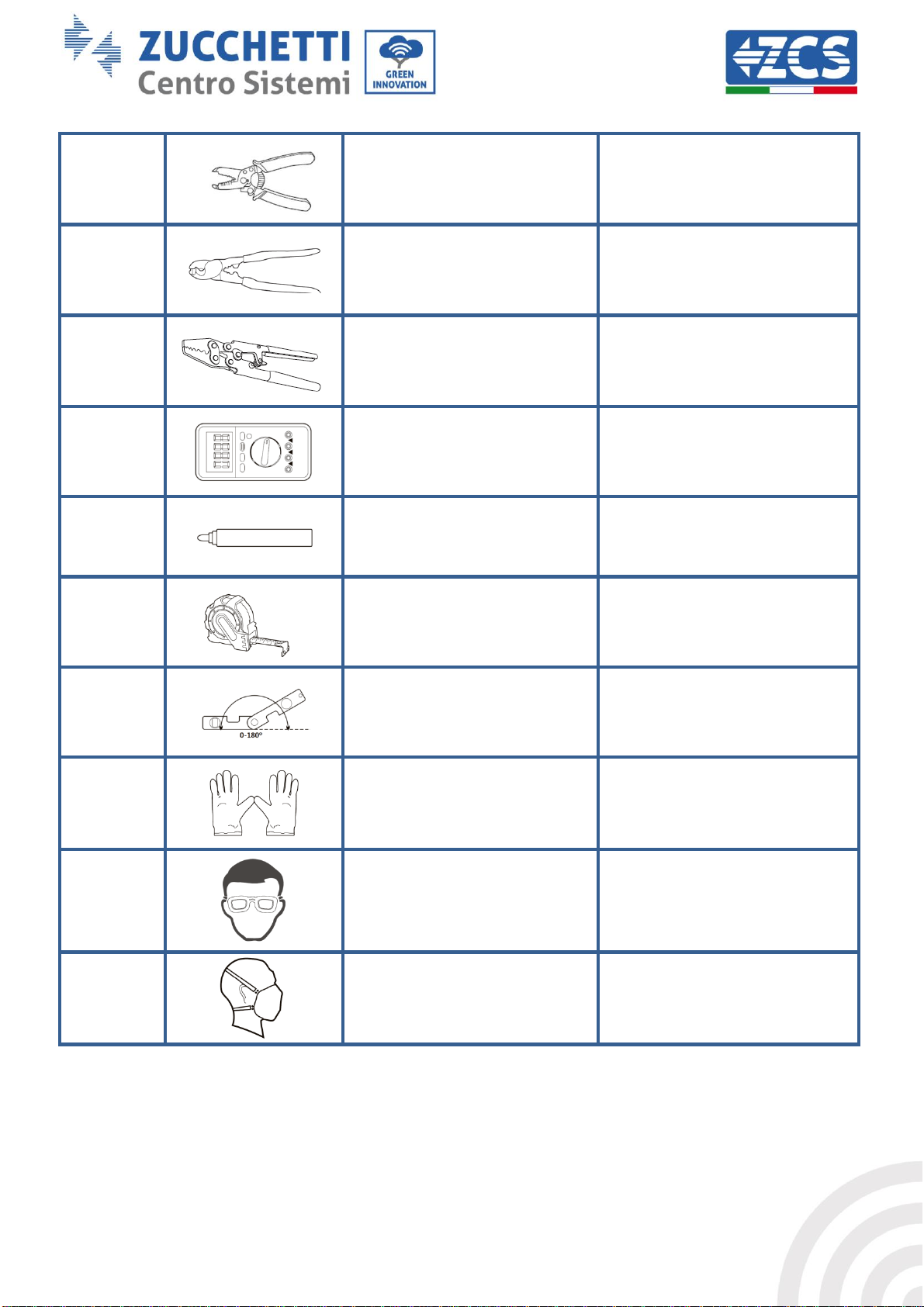

No.

Tool

Function

1

Drill

Recommended drill bit: 6 mm

To drill holes in the wall for

fixing the bracket

2 Screwdriver

To screw and unscrew screws for

the various connections

3 Wire stripping tool

To prepare the cables for wiring

4

Adjustable spanner (opening

greater than 32 mm)

To tighten the bolts

5 4 mm Allen key

To screw the inverter to the wall-

mounting bracket and to open

the front cover of the inverter

6 RJ45 crimping tool

To crimp the RJ45 connectors for

the communication cables

7 Rubber hammer

To insert the expansion plugs

into the wall holes

8 MC4 removal tool

To remove the DC connectors

from the inverter

9 Diagonal pliers

To cut and tighten the cable ends

3.3. Installation tools

The following tools are required for installation of the inverter and electrical connections; therefore, they

must be prepared before installation.

16 / 61

Page 17

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

10 Wire stripping tool

To remove the outer sheath of

the cables

11 Cable cutter

To cut the power cables

12 Crimping tool

To crimp the power cables

13 Multi-meter

To check the voltage and current

values

14 Marking pen

To mark the wall for better fixing

precision

15 Measuring tape

To measure the distances

16

Level

To make sure the bracket is level

17 ESD gloves

Protective clothing

18 Safety goggles

Protective clothing

19 Protection mask

Protective clothing

17 / 61

Page 18

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

3.4. Installation position

Choose an appropriate installation location for the inverter.

Follow the requirements below to determine the installation position.

Figure 8 – Requirements for installing a single inverter

18 / 61

Page 19

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

Figure 9 – Requirements for installing multiple inverters

For safety reasons, ZCS Spa and/or its partners may not carry out any technical repairs or maintenance

work, or move the inverter from and to the ground, if it is installed at a height of more than 180 cm from the

ground.

Inverters installed at higher heights must be moved to the ground before they can be repaired or serviced.

3.5. Moving the 1.1K-3K TL inverter

This section describes how to move the inverter correctly

1) Open the packaging and remove the protective cover in polystyrene, insert your hands into the slots on

both sides of the inverter and take a hold of it, as shown in figures 10 and 11.

Figure 10 – Removing the polystyrene protections

19 / 61

Page 20

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

To prevent damage and personal injury, hold the inverter firmly when moving, as

it is a heavy piece of equipment.

Do not position the inverter with the input/output terminals in contact with other

surfaces, as these are not designed to support the weight of the inverter. Always

position the inverter horizontally.

When placing the inverter on the floor, make sure to place a support under the

unit to protect its front door.

Attention

Figure 11 – Removing the inverter from its packaging

2) Lift the inverter from its packing box and move it to the installation position, then remove the

polystyrene protections.

3.6. Installing the 1.1K-3K TL inverter

1) Correctly position the mounting bracket on the wall, using a level to ensure that it is straight; mark the

five holes using a suitable marker pen. Keeping the hammer drill perpendicular to the wall and avoiding

any sudden movements when drilling, drill the five holes at the points marked on the wall using a 6 mm

drill bit. In case of errors during drilling, it is necessary to reposition the holes.

2) Insert the plugs horizontally into the holes made, paying attention to the force and depth with which

they are inserted (make sure the plug completely enters the hole).

3) Align the mounting bracket with the position of the holes and fix it to the wall using the screws and flat

washers supplied, tightening them properly.

4) Place the inverter on the mounting bracket

5) Secure the inverter to the mounting bracket with the M5 bolt to ensure stability.

6) (OPTIONAL) Depending on the customer’s requirements, the inverter can be locked to the mounting

bracket with a safety lock (not supplied with the kit).

20 / 61

Page 21

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

The inverter must be installed and serviced by professional technicians or electricians.

Attention

The PV modules generate electricity when exposed to sunlight, which can pose a risk

of electric shock. Before connecting the DC input power cord, be sure to disconnect

the strings via the appropriate disconnecting devices.

Danger

Figure 12 - Steps for installing the inverter on the wall

4. Electrical connections

General information in this chapter

This chapter describes the electrical connections of the 1.1K-3K TL inverter. Carefully read this section

before connecting the cables.

NOTE:

Before making any electrical connections, ensure that the DC circuit breaker is switched off. Please note that

the capacitors in the inverter may remain electrically charged after the DC circuit breaker has been switched

off. Therefore, it is necessary to wait at least 5 minutes to allow the capacitor to discharge completely.

21 / 61

Page 22

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

The maximum open-circuit voltage of the photovoltaic string must be less than 500 V.

The 1.1K-3K TL series has only one independent input channel (MPPT). All the

photovoltaic modules connected to it must be of the same model so as to have the

same rated electrical characteristics (Isc, Voc, Im, Vm, Pm and temperature

coefficients) and be positioned in the same orientation (solar azimuth and inclination

angle).

Note

The inverter does not have a transformer, therefore the positive pole and

negative pole of the photovoltaic string does NOT need to be grounded.

Otherwise, the inverter may fail. All non-current-carrying metal parts (such as

the PV module frame, PV rack, housing of the combiner box, and housing of the

inverter) in the PV power system must be connected to the ground.

Attention

4.1. Electrical connections

Figure 13 – Steps for connecting the cables

4.2. Ground cable connections (PGND)

Connect the 1.1K-3K TL inverter to the ground electrode using ground protection cables (PGND).

Prerequisites:

Prepare the PGND cables to be connected (outdoor power cables with a cross-section of 4 mm2 are

recommended for grounding purposes). It is recommended to use yellow-green cables for better

identification.

Procedure:

1) Remove an adequate length of the external insulation layers using a wire stripper, as shown in figure 14.

Note: L2 is approximately 2-3 mm longer than L1

22 / 61

Page 23

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

Figure 14 – Preparing the ground cable (1)

2) Insert the exposed wires in the OT terminal using a crimp tool, as shown in figure 15.

Note 1: L3 is the length between the insulation layer of the ground cable and the crimped part. L4 is the

distance between the crimped part and the conductor wires protruding from the crimped part.

Note 2: The cavity formed after the conductor has been crimp must completely wrap the conductor wires.

The core of the wire must be in close contact with the terminal.

Figure 15 – Preparing the ground cable (2)

3) Install the crimped OT terminal and flat washer using the M5 screw in the hole located on the

inverter heatsink, as shown in the figure; tighten the screw to a torque of 3 Nm using an Allen key.

Figure 16 – Connecting the ground terminal

23 / 61

Page 24

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

Make sure that the following information is observed. Otherwise, there is a risk of

fire.

The modules connected in series in each string must have the same

specifications.

The open-circuit voltage for each string must be less than 1000 VDC.

The output power for each PV string must be less than or equal to the

maximum input power allowable for 1.1K-3K TL inverters.

The positive and negative terminals of the PV strings must be connected

respectively to the positive and negative inputs of the input terminal block.

Attention

Before connecting the power supply, be sure to disconnect the generator’s

DC switch. When exposed to the sun, the photovoltaic generator produces a

voltage that can be dangerous!

Before connecting the power supply, make sure that the voltage of the DC

cables is within the permissible operating range and that the DC circuit

breaker switch is open. Otherwise, the high voltage may cause serious

damage.

Danger

Check the polarity of the PV string to ensure the correct connection of the cables

to the string.

Be sure not to connect the positive or negative pole of the PV string to the

ground.

Note

Cross-sectional area (mm2)

Outer diameter of cable (mm)

Range

Recommended value

4.0-6.0

4.0

4. 5 - 7. 8

4.3. Connecting the DC input power cables

Connect the 1.1K-3K TL inverter to the photovoltaic strings using DC input power cables.

Note

Depending on the type of inverter, select the appropriate inverter accessories (cables, fuse holder, fuse,

switch, etc). The inverter associated with the PV array must offer excellent performance and reliable quality.

The open-circuit voltage of the photovoltaic system must be lower than the maximum DC input voltage of

the inverter. The output voltage of the strings must be compatible with the MPPT voltage range.

The positive and negative poles of the panel on the inverter must be connected separately. The power cable

must be suitable for photovoltaic applications.

Table 1 – Recommended specifications for DC input cables

The DC input connectors (MC4) are classified into positive and negative connectors, as shown in the figures

below.

24 / 61

Page 25

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

Figure 17 – Positive (1) and Negative (2) MC4 connectors

Note

The positive and negative metal terminals are packed together with the positive and negative connectors

respectively. Separate the positive and negative metal terminals after unpacking the inverter so as to avoid

confusing the polarities.

Procedure

1) Remove the cable glands from the positive and negative connectors.

2) Remove an appropriate length of the insulation layer from the positive and negative power cables by

using a wire stripper, as shown in the figure.

Figure 18 - Connecting the DC input power cables (1)

25 / 61

Page 26

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

Before removing the positive and negative connectors, make sure that the

inverter’s circuit breaker is switched off. If not, the direct current may cause an

electric arc that could result in a fire

Warning

Note: L2 is approximately 2 or 3 mm longer than L1.

3) Insert the positive and negative power cables in the corresponding cable glands.

4) Insert the stripped positive and negative power cables into the positive and negative metal terminals

respectively, and crimp them using a suitable tool. Make sure that the cables are secured so that they

cannot be pulled out with a force of less than 400 N, as shown in figure 19

Figure 19 - Connecting the DC input power cables (2)

5) Insert the crimped power cables into the corresponding seats until you hear a “click” sound. At that

point, the power cables will be snapped into place.

6) Replace the cable glands on the positive and negative connectors and rotate them against the

insulation covers.

7) Insert the positive and negative connectors into the corresponding DC input terminals of the inverter

until you hear a “click” sound, as shown in the figure.

Figure 20 - Connecting the DC input power cables (3)

Removal procedure

To remove the positive and negative connectors from the inverter, insert a removal tool into the bayonet and

press the tool with an appropriate force, as shown in the figure below.

26 / 61

Page 27

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

Do not use the same AC circuit breaker for multiple inverters.

Do not install loads between the inverter and the AC circuit breaker

The circuit breaker used as a disconnection device should always be

operational and ready to operate.

Warning

Type

1100TL

1600TL

2200TL

2700TL

3000TL

Cable (mm2)

>4

>4

>4

>4

>4

Switch

16A/400V

16A/400V

25A/400V

25A/400V

25A/400V

Figure 21 – Removing the DC connector

4.4. Connecting the AC output power cables

Connect the inverter to the AC power distribution network or power grid using AC power cables.

Context

The AC power cables used for the inverter must be three-pole outdoor cables. For easier installation, use

flexible cables. The table lists the recommended specifications for cables and circuit breakers.

Table 2 – Recommended specifications for AC output cables

Note: For safety reasons, make sure to use correctly sized cables, otherwise the current may cause

excessive heating or overloading, which could result in a fire.

Figure 22 – Do not connect loads between the inverter and circuit breaker

27 / 61

Page 28

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

Figure 2 – Multi core copper wire

Multi-core copper cables

The cross-section of the power line must be sized in order to

prevent unwanted disconnections of the inverter from the grid

due to high impedance of the cable connecting the inverter to the

point of supply. In fact, excessive impedance could cause an

increase in the AC voltage, which in turn may cause the inverter

to disconnect from the grid. In addition, the AC cable must be

correctly sized to ensure that the loss of power on the cable is

less than 1% of the rated power and to ensure proper

functioning of the anti-islanding protection. The cable length

from the inverter to the grid should not exceed 150 meters.

The figure below shows the relationship between the power loss

in the cable, its length and the cross-section area.

Figure 25 – Relationship between power loss, length and cable cross-section

The 1.1K-3K TL inverters are single-phase output inverters that fully comply with the local grid connection

requirements and safety standards.

The inverters are equipped with AC output connectors with IP66 protection suitable for photovoltaic use;

the installer of the system is responsible for connecting the AC output cable; the figure of the AC connector is

shown below.

28 / 61

Page 29

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

Figure 26 - AC Output Connector

Cable connection procedure

1) Identify the suitable cables as shown in table 2 and remove an appropriate length of the protective

sheath, as shown in the figure (A: 30~50 mm B: 6~8 m).

Figure 27 – Connecting the AC output cables (1)

2) Disassemble the AC connector as shown in the figure below; insert the AC output cable (with its stripped

insulation layers as shown in step 1) through the PG waterproof cable gland.

Figure 28 – Connecting the AC output cables (2)

3) Connect the AC power cable according to the following criteria:

• Connect the ground wire (yellow-green) to the terminal labelled “PE”, and tighten the cable with an

Allen key;

• Connect the line wire (brown) to the terminal labelled “L”, and tighten the cable with an Allen key;

• Connect the neutral wire (blue) to the terminal labelled “N”, and tighten the cable with an Allen key;

29 / 61

Page 30

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

Communication port

RS485

I/O

CT

Cable cross-section

0.5-1.5 mm2

0.5-1.5 mm2

0.5-1.5 mm2

Outer diameter

2.5~6 mm

2.5~6 mm

2.5~6 mm

Figure 29 – Connecting the AC output cables (3)

4) Secure the clamping cable gland by turning it clockwise, as shown below; make sure that all the wires

are securely connected

5) Connect the AC output connector to the output terminal of the inverter; turn the AC connector in a

clockwise direction until the fixing device reaches its intended position, as shown below:

Figure 30 – Connecting the AC output cables (4)

4.5. Connecting the communication cables

Connecting the communication port

Note: The wiring procedure is the same for the RS485 input, I/O input and CT input. This chapter describes

the steps to be followed for connecting the communication cables.

Table 3 – Recommended specifications for communication cables

1) Remove the central waterproof cover of the communication terminal block using a star screwdriver;

30 / 61

Page 31

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

Figure 31 – Removing the central cover

2) Turn the waterproof cable gland; remove the cap in the waterproof cable gland;

Figure 32 – Removing the cable glands and stoppers

Note:

The waterproof connectors refer respectively to (from left to right): RS485, Input/Output, CT. Remove the

waterproof connectors according to the communication functions to be used. DO NOT remove the unused

connectors.

3) Choose a suitable cable according to Table 4-2 and remove the outer insulation part using a cable

stripping tool; insert the cable through the cable gland and the waterproof cable glands, as shown in

the figure below:

31 / 61

Page 32

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

Type

RS485

I/O

CT

Connector

Label

TX-

TX+

5V

GND

I4

I3

I2

I1

CT+

CT-

Function

RS485

differential

signal -

RS485

differential

signal +

Source

Ground

Input 4

Input 3

Input 2

Input 1

CT+

CT-

Figure 33 – Inserting the cables into the appropriate cable gland

4) Choose the terminal according to Table 4-4, connect the cables as shown in the labels and secure

them using a flat screwdriver.

Note: keep the unused terminals for future use.

Table 4 – Description of the communication terminals and their function

Figure 34 – Tightening the terminals on the cables

32 / 61

Page 33

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

5) Insert the terminal according to the printed label, then tighten the screws to secure the waterproof

cover; turn the cable glands clockwise to tighten.

Figure 35 – Closing the central door

• If multiple inverters need to be connected via the RS485 cable, refer to the following:

The RS485 cables are connected in parallel, so 4 cables are required to make the connection. First connect

the two 485+ cables (TX+) in parallel, then connect the two 485- cables (TX-) in parallel, finally insert them

into the terminal and tighten the screws using a slotted screwdriver.

Note: It is recommended to use two different wire colours to connect TX- (485-) and TX+ (485+). Wires of

the same colour can be connected together to avoid incorrect wire connections.

Figure 36 – Connecting multiple inverters

4.6. Communication systems

The 1.1K-3K TL inverters are equipped with RS485 (standard) and Wi-Fi (optional) communication systems.

These communication systems allow monitoring the main parameters of the inverter (energy generated,

alarms, operating status) through various channels, such as the ZCS AZZURRO portal, ZCS AZZURRO app or

your own monitoring system

33 / 61

Page 34

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

RS485

For a single inverter it is possible to connect the RS485 port to a terminal such as a PC, using a special RS485 / USB

converter. In this way, it is possible to create a personal system for data acquisition and monitoring of the inverter,

upon request of the Modbus RTU proprietary protocol to ZCS S.p.A.

Alternatively, the RS485 port can be connected to an external datalogger, which is not supplied with the inverter.

In turn, this datalogger can be connected to a router or a modem via Wi-Fi or ethernet cable to allow data to be

sent to the ZCS server.

Figure 36 – Connecting an inverter with RS485

It is possible to connect up to 31 inverters in a daisy chain via the RS485 port. The first in this series must

then be connected to a terminal in the manner described above.

Figure 38 – Connecting multiple inverters with RS485

Note 1: The RS485 communication cable must not be longer than 1000 m.

Note 2: When multiple inverters are connected via the RS485 cables, the Modbus address must be set

progressively as described in chapter 6.3.

WI-FI

For a single inverter, it is possible to connect the Wi-Fi adapter found on board the models – WS or integrated in

the basic models to a device capable of receiving wireless signals, such as routers, wi-fi modems and network

extenders. This allows the inverter data to be sent to the ZCS server and the inverter to be monitored remotely.

34 / 61

Page 35

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

Figure 39 – Connecting an inverter with wi-fi

For a group of inverters, it is possible to connect the different wi-fi cards to a single terminal (router, wi-fi

modem and network extenders). This procedure does not require the setting of a progressive Modbus address

on the various inverters.

Figure 40 – Connecting multiple inverters with Wi-Fi

To ensure proper transmission of the Wi-Fi signal, completely extract the Wi-Fi antenna by following the

procedure below.

1) Loosen the cable gland of the Wi-Fi antenna.

2) Pull out the Wi-Fi antenna for about 5 cm or until the cable gland prevents it from being pulled out

any further.

3) Tighten the cable gland of the Wi-Fi antenna.

Figure 41 – Extracting the Wi-Fi antenna

For more information and instructions on how to configure the communication system, refer to the relevant

technical notes available at www.azzurrozcs.com or contact the ZCS service centre.

35 / 61

Page 36

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

Make sure that the DC and AC voltage are within the range

permitted by the inverter.

Attention

5. Commissioning the inverter

5.1. Safety inspection before commissioning

Photovoltaic strings

Before turning on the inverter, the photovoltaic string must be examined. Check the open-circuit

voltage of each photovoltaic panel and compare it with the data in the technical datasheet.

- Make sure that the open-circuit voltage of each PV string corresponds to the technical data and that

it is lower than the maximum input voltage permitted by the inverter.

- Make sure that the positive and negative poles are correct.

DC connection

Use the multi-meter to check the voltage on the DC side; check the DC cable, make sure that the

positive and negative poles are not inverted, and are consistent with the positive and negative poles

of the photovoltaic string.

AC connection

Make sure that the AC switch of the inverter is off. Check that the inverter is properly connected to

the grid. Check that the phase voltage is within the correct range. If possible, measure the THD; if

there is too much distortion, the inverter may not operate properly.

5.2. Starting the inverter

1) Turn ON the DC switch on the field panel and on the photovoltaic inverter (if present); wait for the

screen to turn on.

2) Turn ON the AC switch installed on the wall.

When the photovoltaic string generates enough direct current, the inverter will start automatically.

The word “normal” shown on the screen indicates the correct functioning of the inverter.

3) Set the correct country code (refer to chapter 6.3 of this manual).

Note: Different grid operators in different countries require different specifications regarding the grid

connections of PV inverters. Therefore, it is very important to select the correct country code according to

the requirements of the local authorities.

If in doubt, consult the system engineer or a qualified electrician.

Zucchetti Centro Sistemi S.p.A. shall not be held responsible for any consequences resulting from the

incorrect selection of the country code.

If the inverter indicates the presence of any faults, refer to chapter 7.1 of this manual or contact the

Zucchetti Centro Sistemi S.p.A. technical support.

36 / 61

Page 37

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

6. Operating interface

General information in this chapter

This section describes the display and its operation, as well as the buttons and LED indicators of the 1.1K-3K

TL inverters.

6.1. Operating panel and display

Buttons and LED indicators

Figure 42 – LCD display with buttons and LED indicators

Main buttons:

Menu/Back: to go back or enter the main menu.

Up: to go up or increase the value by 1.

Down: to go down or decrease the value by 1.

OK/Enter: to confirm the selection and enter the menus

Indicator lights:

Status light (GREEN)

o Flashing: wait or status check

o Steady: normal operation

o Off: temporary or permanent error

Warning light (RED)

o Steady: temporary or permanent error

o Off: normal operation

GFCI warning light (RED)

o Steady: indicates GFCI fault

o Off: normal operation

37 / 61

Page 38

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

6.2. Main interface

The main LCD interface is used to display the statuses of the inverter, information, configuration of

parameters, etc.

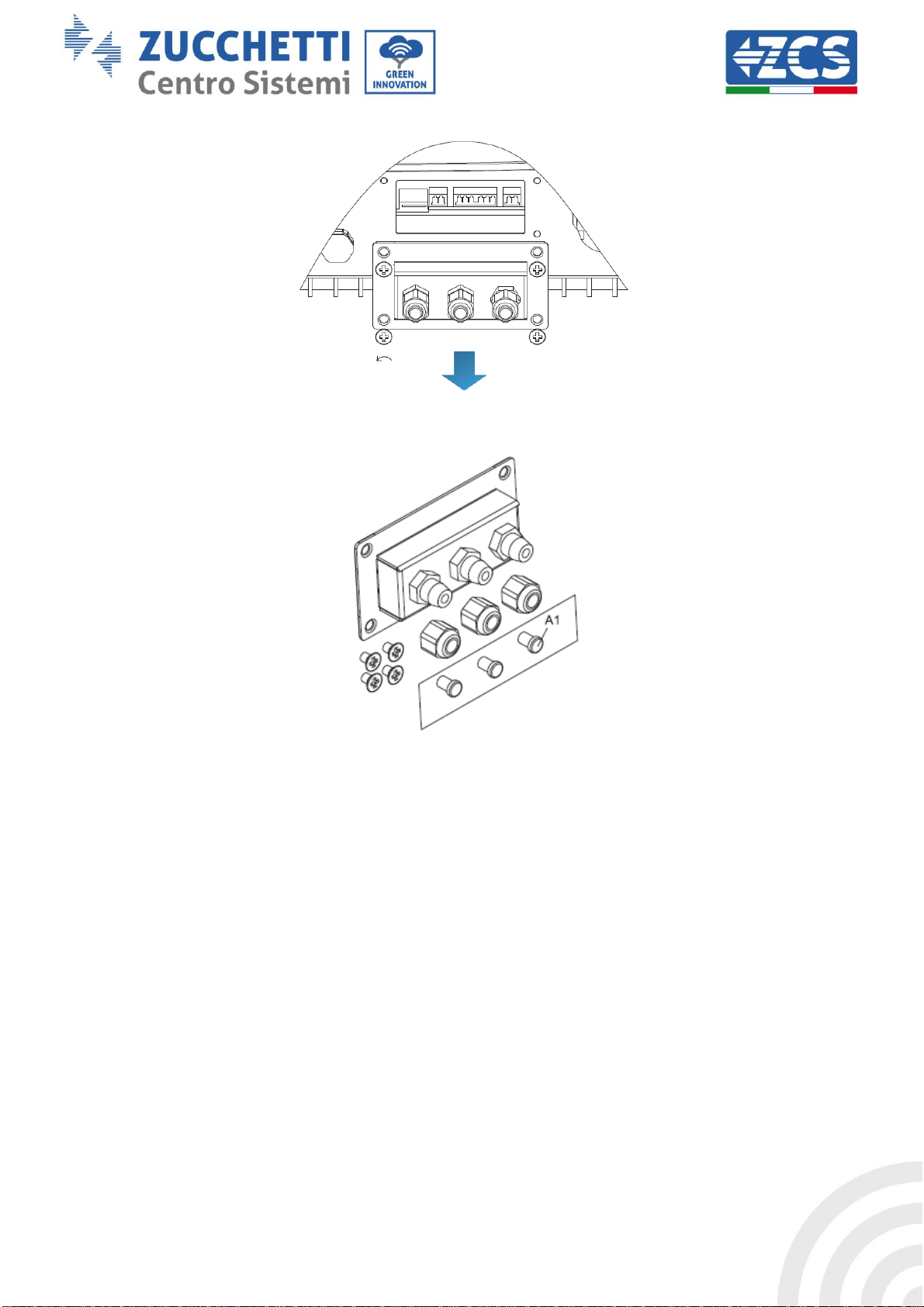

Figure 43 – Main interface of the LCD display

The LCD screen displays the power output of the inverter, the input information coming from the PV system,

information relating to errors, etc.

Figure 44 – Indicators in the main interface

A1 – Modbus communication address

A2 – RS485 Communication

A3 – Steady light for active RS485 communication

A4 – Wi-Fi Communication

A5 – Flashing light to indicate over-frequency and power derating status. Steady light to indicate remote

control

A6 – Indicates the energy produced today

A7 – Indicates the energy produced in total

A8 – Steady light to indicate the high temperature of the inverter

A9 – Output power in real time

A10 –Functioning of the MPPT SCAN option.

A11 – Steady light when the input voltage is higher than 100V

A12 –Real-time input voltage value

A13 – Input voltage and current of the string

A14 – Light is on when the state is normal

A15 – Grid voltage

38 / 61

Page 39

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

A16 – Grid current and frequency (shown alternatively every three seconds).

A17 – Energy produced from 3:00am to 9:00pm today

When the power is turned on, ZCS INNOVATION…. appears on the screen, as shown in the figure below

when the control board is correctly connected to the communication board, the LCD screen will display the

current status of the inverter, as shown in the figure below.

Inverter states include:

Wait: inverter is waiting to Check the state at the end of the reconnection time. In this state, the PV voltage

must be higher than 100 V, the grid voltage must be between the minimum and maximum permissible

limits, as should the other grid parameters; otherwise, the inverter will go into an error state.

Check: inverter is checking the insulation resistance, relays and other safety parameters. It also runs a selftest to ensure that the software and hardware of the inverter are functional. Inverter will go to an error state

if any faults or anomalies are found.

Normal: inverter is functioning properly and is feeding power into the grid. If any faults are found, the

inverter will go into an error state.

Error: inverter has encountered a temporary error. If the error disappears on its own, the inverter will

return to its normal state. If the error continues, please check the inverter according to the error code.

Permanent error: inverter has encountered a permanent error. The installer must debug this type of error

according to the code found in order to bring the inverter back to its proper functioning.

If the control board and communication board are not connected, the interface of the LCD display appears as

shown in the figure below.

39 / 61

Page 40

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

6.3. Main menu

Press the “Menu/Back” button in the main interface screen to enter the main menu, which will appear as

follows:

(A) Press the “OK” key to enter the “Settings” menu.

The “Settings” menu contains the following sub-menu:

Date and time

Select “1. Date and time” and press “OK” to enter the menu for setting the date/time. First set the date and

then the time using the “Up” and “Down” keys, then press “OK” to move to the next character and confirm.

The date and time are expressed in the format: 20YY – MM - DD HH:MM:SS.

The display will show “OK” if the setting is correct and “Error” in case of an error.

The date and time can be seen in the submenu “4. Time” inside the main menu.

40 / 61

Page 41

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

Code

country

Code

country

Code

country

00

Germany VDE AR-

N4105

12

Poland

24

Cyprus

01

CEI 0-21 Internal

13

Germany BDEW

25

India

02

Australia

14

Germany VDE

0126

26

Philippines

03

Spain RD1699

15

Italy CEI 0-16

27

New Zealand

04

Turkey

16

UK-G83

28

Brazil

05

Denmark

17

Greek - islands

29

Slovakia

06

Greece - mainland

18

EUEN50438

30

Slovakia SSE

07

Netherlands

19

IEC EN61727

31

Slovakia ZSD

08

Belgium

20

Korea

32

CEI 0-21 Areti

09

UK-G59

21

Sweden

33-49

Reserved

10

China

22

General Europe

11

France

23

CEI 0-21 External

Clear Energy

Select “2. Clear Energy” and press “OK” to enter the menu for deleting the energy data and in particular the

energy production daily and in total, which is shown in the main interface. Press “OK” to start the procedure;

the display will show “Enter PWD!”, press “OK” to enter the password. Enter the password “0001” using the

“Up” and “Down” keys to select the number and “OK” to move to the next one. Confirm. If the display shows

“Incorrect, try again,” press the “Back” key and enter the password again. When the password entered is

correct, the inverter will delete the data relating to the energy products and the display will show “OK” if the

setting is successful.

Clear Events

Select “3. Clear Events” and press “OK” to enter the menu for clearing historical events, i.e. to clear all error

warnings present in the “List of historical events” submenu. Press “OK” to start the procedure; the display

will show “OK” if the procedure is successful.

Set Country

Select “4. Set Country” and press “OK” to enter the menu for setting the national grid connection regulations.

If “Setting Disabled” appears on the display, go to step 7 “Enable Country” to enable this function. After

enabling the function, repeat the steps described above and set the code for the desired country using the

“Up” and “Down” keys, confirming with “OK”; the display will show “OK” if the setting is successful. The

current country code can be checked from the “System Info” menu.

Note: The change of the country code will take effect after the next start-up of the inverter.

For more information and to know the country regulations on board the inverter, refer to the following table.

Table 5 – Country Codes

41 / 61

Page 42

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

Enable country

Select 7 “Enable country” and press “OK” to enter the menu for enabling the selection of the country code. The

display will show “Enter PWD!”, press “OK” to enter the password. Enter the password “0001” using the “Up”

and “Down” keys to select the number and “OK” to move to the next one. Confirm. If the display shows

“Incorrect, try again,” press the “Back” key and enter the password again. When the password has been

entered correctly, you can enter the menu.

This operation must be carried out if you want to change the Country code and it has not been changed

during the last 24 hours of operation of the inverter.

Set Energy

Select 8 “Set Energy” and press “OK” to enter the menu for setting the energy already produced by the

photovoltaic system. The display will show “Enter PWD!.” Press “OK” to enter the password “0001” using the

“Up” and “Down” keys to select the number and “OK” to move to the next digit. If the display shows

“Incorrect, try again,” press the “Menu/Back” key and enter the password again. When the password has

been entered correctly, you can enter the menu. You can now set the amount of energy already produced by

the system before installing the current inverter, which is visible from the main interface.

Modbus address

Select 9 “ModBusAddress” and press “OK” to enter the menu for selecting the communication address.

Use the “Up” and “Down” keys to select the number and “OK” to move to the next one, and confirm.

After setting the address, press “OK.”

The Modbus address indicates the address with which the inverter sends its data to the monitoring

server. Address 01 is used for single inverters; if you want to extend the monitoring to multiple

inverters, progressive communication addresses will be used.

Note: make sure that the address entered is never 00, because this setting would exclude the

possibility of communication between the inverter and Wi-Fi network.

Language

Select 10 “Language” and press “OK” to enter the menu for selecting the language. Select the language

using the “Up” and “Down” keys; then press “OK” to confirm.

If the setting is successful, “OK” will be displayed; otherwise, “Error” will be displayed.

A faster way to change the language is to press the “Menu/Back” key and the “OK” key at the same time.

In the current firmware version (V5.00), the available languages are: Chinese, English, Italian, German,

French and Portuguese; future firmware updates may add additional languages.

Initial parameters

The user can change the start parameters directly from the LCD display. The user must first copy the TXT

files to the SD card. These files can be requested from Zucchetti Centro Sistemi Spa technical support.

Select 11 “InitParameters” and press “OK” to enter the menu for setting the start parameters. The display

will show “Enter PWD!”, press “OK” to enter the password. Enter the password “0001” using the “Up” and

“Down” keys to select the number and “OK” to move to the next one, and confirm. If the display shows

“Incorrect, try again,” press the “Back” key and enter the password again. When the password entered is

correct, you can enter the menu. The new start parameters will now be loaded onto the inverter

automatically.

If the setting is successful, “OK” will be displayed; otherwise, “Error” will be displayed.

Attention: do not enter this menu if the microSD card is not inserted in the appropriate slot of the inverter

or if the correct TXT files have not been copied to it.

42 / 61

Page 43

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

Safety Voltage

The user can change the value of the protection voltage directly from the LCD display. The user must first

copy the TXT files to the SD card. These files can be requested from Zucchetti Centro Sistemi Spa technical

support.

Select 12 “Safety V” and press “OK” to enter the menu for setting the protection voltage. The display will

show “Enter PWD!”, press “OK” to enter the password. Enter the password “0001” using the “Up” and

“Down” keys to select the number and “OK” to move to the next one, and confirm. If the display shows

“Incorrect, try again,” press the “Back” key and enter the password again. When the password has been

entered correctly, you can enter the menu. The new protection voltage will now be loaded on the inverter

automatically.

If the setting is successful, “OK” will be displayed; otherwise, “Error” will be displayed.

Attention: do not enter this menu if the microSD card is not inserted in the appropriate slot of the inverter

or if the correct TXT files have not been copied to it.

Safety Hz

The user can change the value of the protection frequency directly from the LCD display. The user must first

copy the TXT files to the SD card. These files can be requested from the Zucchetti Centro Sistemi Spa

technical support.

Select 13 “Safety Hz” and press “OK” to enter the menu for setting the protection frequency. The display will

show “Enter PWD!”, press “OK” to enter the password. Enter the password “0001” using the “Up” and

“Down” keys to select the number and “OK” to move to the next one, and confirm. If the display shows

“Incorrect, try again,” press the “Back” key and enter the password again. When the password entered is

correct, you can enter the menu. The new protection frequency will now be loaded on the inverter

automatically.

If the setting is successful, “OK” will be displayed; otherwise, “Error” will be displayed.

Attention: do not enter this menu if the microSD card is not inserted in the appropriate slot of the inverter

or if the correct TXT files have not been copied to it.

Insulation

The user can change the value of the insulation resistance directly from the LCD display. The user must first

copy the TXT files to the SD card. These files can be requested from Zucchetti Centro Sistemi Spa technical

support.

Select 14 “Insulation” and press “OK” to enter the menu for setting the insulation resistance. The display will

show “Enter PWD!”, press “OK” to enter the password. Enter the password “0001” using the “Up” and

“Down” keys to select the number and “OK” to move to the next one, and confirm. If the display shows

“Incorrect, try again,” press the “Back” key and enter the password again. When the password has been

entered correctly, you can enter the menu. The new insulation resistance will now be loaded on the inverter

automatically.

If the setting is successful, “OK” will be displayed; otherwise, “Error” will be displayed.

Attention: do not enter this menu if the microSD card is not inserted in the appropriate slot of the inverter

or if the correct TXT files have not been copied to it.

Reactive power setting

Select 16 “Reactive Set” and press “OK” to enter the menu for setting the reactive power produced. The

display will show “Enter PWD!”, press “OK” to enter the password. Enter the password “0001” using the “Up”

and “Down” keys to select the number and “OK” to move to the next one, and confirm. If the display shows

43 / 61

Page 44

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

“Incorrect, try again,” press the “Back” key and enter the password again. When the password has been

entered correctly, you can enter the menu. Now you can use the “Up” and “Down” keys to select the

“1.Enable” or “2.Disable” option and select it with the “OK” key. If the “1.Enable” option is selected, you can

use the “Up” and “Down” keys to select the options “Under-excited”, “Grid Manager”, and “Over-excited”, and

you can indicate the value of the reactive power produced for each of them. If the setting is successful, “OK”

will be displayed; otherwise, “Error” will be displayed.

Power derating

Select 17 “Derating P(W)” and press “OK” to enter the relative menu, from which you can enable the

“Derating” function, i.e. the possibility to set the power produced by the inverter. The display will show

“Enter PWD!”, press “OK” to enter the password. Enter the password “0001” using the “Up” and “Down” keys

to select the digit and “OK” to move to the next one, and confirm. If the display shows “Incorrect, try again,”

press the “Back” key and enter the password again. When the password entered is correct, you can enter the

menu. With the “Up” and “Down” keys you can set the “1. Enable” and “2. Disable” option, and select it with

the “OK” key. If the “1.Enable” option is selected, use the “Up”, “Down” and “OK” keys to select the percentage

value (between 0 and 100) of the maximum power that the inverter will produce; if the solar radiation

allows a greater amount of energy to be produced, the inverter will carry out the necessary operations to

limit the output power to the set value. If the setting is successful, “OK” will be displayed; otherwise, “Error”

will be displayed.

P(GRID) CHECK

Select “18. P(grid) Check” and press “OK” to enter the relative menu, from which you can enable the “Reflux

Power” function, i.e. the possibility to set the maximum power fed into the grid. The display will show “Enter

PWD!”, press “OK” to enter the password. Enter the password “0001” using the “Up” and “Down” keys to

select the number and “OK” to move to the next one, and confirm. If the display shows “Incorrect, try again,”

press the “Back” key and enter the password again. When the password has been entered correctly, you can

enter the menu. With the “Up” and “Down” keys you can set the “1. Enable” and “2. Disable” option, and

select it with the “OK” key. If the “1.Enable” option is selected, you can use the “Up”, “Down” and “OK” keys to

select the value (expressed in kW, up to two decimal places) of the maximum power that the inverter will

feed into the grid. In this way the inverter can feed a maximum power of between 0 kW and the rated power

of the inverter into the national grid, based on the solar radiation available and the domestic consumption. If

the setting is successful, “OK” will be displayed; otherwise, “Error” will be displayed.

Note: To activate the Reflux Power mode in single-phase inverters, it is necessary to install a CT current

sensor, as described in the appropriate procedure.

Fast self-test

1) During normal operation of the inverter, press the “Back” key to enter the main menu.

2) Press the “OK” key to enter the “Settings” menu.

3) Press the “Down” key several times until “19. Fast Self-test” is shown on the screen.

44 / 61

Page 45

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

4) Press “OK” to start the self-test.

5) The self-test will now start automatically; once completed, press “Down” to display the self-test

results, as shown in the figure.

45 / 61

Page 46

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

Standard Self-test

1) During normal operation of the inverter, press the “Back” key to enter the main menu.

2) Press the “OK” key to enter the “Settings” menu.

3) Press the “Down” key several times until “20. Standard Self-Test” is shown on the screen.

46 / 61

Page 47

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

4) Press “OK” to start the self-test.

5) The self-test will now start automatically; once completed, press “Down” to display the self-test

results, as shown in the figure below.

47 / 61

Page 48

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

P(f) Setting

Select 21 “Set P(f)” and press “OK” to enter the relative menu, from which you can change the active power

according to the grid frequency required by the local regulations. This function may be required by various

regulations for grid-connected inverters. Use the “Up”, “Down” and “OK” keys to set the time delay expressed

in seconds (*.***s) before the changed P active power will intervene.

48 / 61

Page 49

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

Q(v) Setting

Select 22 “Set Q(v)” and press “OK” to enter the relative menu, from which you can change the reactive

power according to the grid voltage required by the local regulations. This function may be required by

various regulations for grid-connected inverters. Use the “Up”, “Down” and “OK” keys to set the time delay

expressed in seconds (*.***s) before the changed Q reactive power will intervene.

81.S1 Check

Select 23. “81.S1Check” and press “OK” to enter the relative menu, from which it will be possible to enable

the frequency restriction thresholds required in special cases by local regulations. With the “Up” and “Down”

keys you can set the “1. Enable 81.S1” and “2. Disable 81.S1” option, and select it with the “OK” key. The

display will show “OK” if the setting is successful.

Disabled settings

The following functions:

- Remote Control, relating to item “5. Remote Control”

- Relay Command, relating to item “6. Relay Command”

- Relay test, relating to item “15. Relay Test”

cannot be used on this model of inverter; access to these submenus is not permitted either by the installer

or by the end user. ZCS S.p.A. accepts no responsibility deriving from the activation of one of the settings

described above.

(B) Press the “OK” key to enter the “Event List” menu.

The “Event List” menu is used to display the events recorded by the inverter, both historical and in

real time, showing the progressive number of the event, the identification code, the date and time of

its occurrence. The user can access this interface from the LCD display to check the details of the

alarms and alerts. Errors will be listed according to the date and time they occurred, so the most

recent events will be listed first. For more information, refer to the figure below.

Press the “Back” button in the main interface and then the “Up” button, then enter the “2. Event List”

menu. From here you can select the “1. Current Events” menu for the list of current events or “2.

Historical Events” for the list of historical events.

(C) Press the “OK” key to enter the “System Info” menu.

The “System Info” menu contains the following submenus:

49 / 61

Page 50

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

Inverter type

Use the “Up” and “Down” keys in the “System Info” menu to move, and the “OK” key to enter the “1. Inverter

type” menu. Here you can see the power of the inverter model

Serial number

Use the “Up” and “Down” keys in the “System Info” menu to move, and the “OK” key to enter the “2. Serial

Number” menu. Here you can see the serial number of the inverter.

SW version

Use the “Up” and “Down” keys in the “System Info” menu to move, and the “OK” key to enter the “3. SW

Version” menu. Here you can see the software version.

HW version

Use the “Up” and “Down” keys in the “System Info” menu to move, and the “OK” key to enter the “4. HW

Version” menu. Here you can see the hardware version.

Country

Use the “Up” and “Down” keys in the “System Info” menu to move, and the “OK” key to enter the “5. Country”

menu. Here you can see the country code that has been set.

Power factor

Use the “Up” and “Down” keys in the “System Info” menu to move, and the “OK” key to enter the “7. Power

Factor” menu. Here you can see the value of the power factor.

P(Grid) Feed-in

Use the “Up” and “Down” keys in the “System Info” menu to move, and the “OK” key to enter the “8. P(Grid)

Feed-in” menu. Here you can see the value of the set value of the power fed into the grid.

P(f)

Use the “Up” and “Down” keys in the “System Info” menu to move, and the “OK” key to enter the “9. P(f)”

menu. Here you can see the P(f) value that has been set.

Q(v)

Use the “Up” and “Down” keys in the “System Info” menu to move, and the “OK” key to enter the “10. Q(v)”

menu. Here you can see the Q(v) value that has been set.

Service Code

Use the “Up” and “Down” keys in the “System Info” menu to move, and the “OK” key to enter the “11.

ServiceCode” menu. Here you can see the currently installed firmware version.

(D) Press the “OK” key to enter the “Date and Time” menu.

Press the “Back” key in the main interface and the “Up” or “Down” keys to enter the submenu “4. Date and

Time”, then press “OK” to display the current date and time set on the inverter.

50 / 61

Page 51

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

(E) Press the “OK” key to enter the “Update Software” menu.

Press the “Back” key in the main interface and the “Up” or “Down” keys to enter the submenu “5. Software

Update”, then press “OK” to enter. The display will show “Enter PWD!.” Press “OK” to enter the password

“0715” using the “Up” and “Down” keys to select the number and “OK” to move to the next digit and confirm.

If the display shows “Incorrect, try again,” press the “Back” key and enter the password again. When the

password has been entered correctly, you can enter the menu and start updating the firmware.

Note: You can check the firmware version currently installed on the inverter from the “Service Code”

submenu found in the “System Info” menu.

IMPORTANT: Do not perform any update operation if there is no microSD card inside the inverter or if the

microSD card does not contain the appropriate update files. Always make sure that the correct update files

are loaded on the microSD card and that the card is correctly inserted in the appropriate slot.

Note: the microSD card is not supplied with the inverter and must be procured by the installer or customer.

The complete and detailed procedure for updating the firmware is described below.

Update requirements

- 4 Gb MicroSD card

- MicroSD to SD adapter or MicroSD to USB adapter for inserting the MicroSD card into the PC.

Firmware update procedure

1. Switch off the ZCS inverter by first disconnecting the AC power supply via the switch installed on the

system, and then disconnecting the DC power supply via the switch located on the side of the

inverter (if equipped) or switch off the system’s disconnecting switch. Wait for the display to turn off

completely.

2. Remove the central cover at the bottom of the inverter by unscrewing the four star screws, taking

care to have first loosened the four cable glands.

51 / 61

Page 52

Identification: MD-AL-GI-00

Rev. 4.0 of 31.01.18 - Application: GID

Manual of 07/06/2019 Rev. 2.1 “User Manual for 1.1K-3K TL”

Figure 45 – Removing the central cover

3. Extract (if PRESENT) the microSD card from its slot by pressing lightly on the card and pulling it out

of the inverter. Alternatively, obtain the microSD card yourself. Then insert it into the PC using the

appropriate adaptor.