Page 1

MBT-LA2

Operating Instructions

Page 2

Page 3

Product Description

The ZTS MBT-LA2 provides a comprehensive means of

testing the State of Charge and battery condition for 2V,

4V, 6V, 8V, and 12V lead acid battery types (SLA, AGM,

Gel, Wet). This microprocessor-controlled instrument

tests popular batteries using a patented, high accuracy

pulse load test. A fully automatic test cycle, indicated

by ‘running’ LEDs, begins when the TEST key is pressed.

After each pulse-load test, a single LED indicates percentage of remaining battery capacity. Batteries will

not be harmed by repeated testing or by maintaining

connection after a test cycle. This test set requires 4

AA batteries (not included).

Setup

1) Locate and open the battery compartment cover then

install 4 AA alkaline batteries, carefully noting the

proper orientation. Replace the battery cover.

2) Install test leads. Press the sheathed banana plugs

rmly into the appropriate jacks (note color), rotate

the plugs slightly to insure complete seating.

3) Turn on the power switch located on the right side of

the tester. One of the MODE LEDs should light.

NOTE: For proper operation, the MBT-LA2 must be

powered on before connecting the test leads to a

battery.

Testing Batteries

1) Use the MODE button to select the correct range for

the size and voltage of the battery to be tested.

- 1 -

Page 4

Note: There are four different 6V and 12V MODES and

two 8V MODE options depending on battery capacity.

Choose the MODE which corresponds to the battery

being tested.

2) Connect the test leads securely to the battery’s

terminals. Verify that the red test lead is connected to battery positive (+) and black to battery

negative (-).

3) Press the TEST button once. All display LEDs should

‘run’ for 15 seconds indicating a pulse load test in

progress. Next, a single LED will remain lighted

indicating the battery’s state of charge, or remaining

capacity. Make 2-3 tests to verify that the battery

has stabilized and is delivering consistent power

(especially if the battery is tested directly after being disconnected from a charger).

Understanding Test Results

The following are guidelines for correlating test results

to overall battery condition:

1) A battery which repeatedly tests 80% or higher is

nearly fully charged and is in good condition. Batteries that are tested directly after being disconnected

from oat charge should test 80% or greater for 2-3

consecutive tests. A test result of 60% or lower

indicates a failing battery.

- 2 -

Page 5

2) Batteries which test 60% or lower may be:

a. Not fully charged but otherwise in good condition

and still capable of taking a full charge, such as

a new/good battery not yet in service.

b. Fully charged but with diminished capacity due

to age or excessive charge-discharge cycles.

Note: Generally, a battery which has recently

been charged or has been on oat charge should

indicate 80-100% for 2-3 tests. Results of 60%

or lower indicate diminished battery capacity.

SLA batteries usually have diminished capacity

after 3-5 years of service depending on ambient

temperatures and the number of charge-discharge

cycles experienced by the battery. New batteries

or batteries that have been stored for an extended

period of time without use will usually not test

above 60-70% until they have been oat charged

(30 days) or put through several complete charge/

discharge cycles.

3) If LEDs ‘run’ during a test but no result is displayed:

a. The battery is completely discharged or defective.

b. The MODE is incorrect for that battery.

Techniques for Accurate Test Results

1) Clean connections are important. Verify that the

battery’s terminals are free of any visible contamination or corrosion.

2) Select the proper MODE for the battery. For example, select “6V 5-15AH” for a 6-volt, 12 AH battery.

Using the wrong MODE will not harm the tester, but

- 3 -

Page 6

the test results will be incorrect.

3) Make two tests, 5-10 seconds apart. This veries

that the battery is stabilized and capable of consistent power output under the pulse load.

4) Connect the tester’s clamps directly to the battery

terminals. Any extension or modication to the

tester’s lead wires can cause testing errors.

To insure accurate testing, use only ZTS lead

sets (clip or plier type).

5) Disconnect the battery from other circuits before

testing. A battery connected to a “oat” charging

system may test higher than it does out of circuit

(stand alone). The MBT-LA2 is designed to test

batteries out of circuit only.

Temperature Compensation

SLA batteries exhibit a direct relationship between

temperature and their ability to deliver current or

maintain voltage under load. The actual capacity of a

SLA battery is a function of temperature and the rate

of discharge. For example, a battery will indicate a

lower state of charge, or lower remaining capacity, as

temperature decreases, and will indicate a higher state

of charge (SOC) as temperature increases.

The MBT-LA2 is designed to test SLA batteries whose

ambient temperature is between 50° - 85°F (10°-30° C).

The following chart shows the effect of temperature

on the test result. Referring to the chart on page 5,

notice that a battery whose SOC is 100% will produce

a test result of 100% at 68°F. This same batttery will

produce a test result between 80% and 60% when its

- 4 -

Page 7

120°F

68°F

∆

•

0°F

∆

•

•

∆

•

∆

•

∆

•

∆

•

100

80

60

- 5 -

40

State of Charge or remaining battery capacity (%)

100 80 60 40 20 10

10

20

Test Result (LED Display)

Page 8

temperature is 0°F. Conversely, a battery whose SOC

+ ++ +

Series connection

+ + + +

Parallel connection

is 90% will produce a test result of 100% at 120°F.

In all cases, the MBT-LA will indicate the actual remaining battery capacity that is available at a given

temperature.

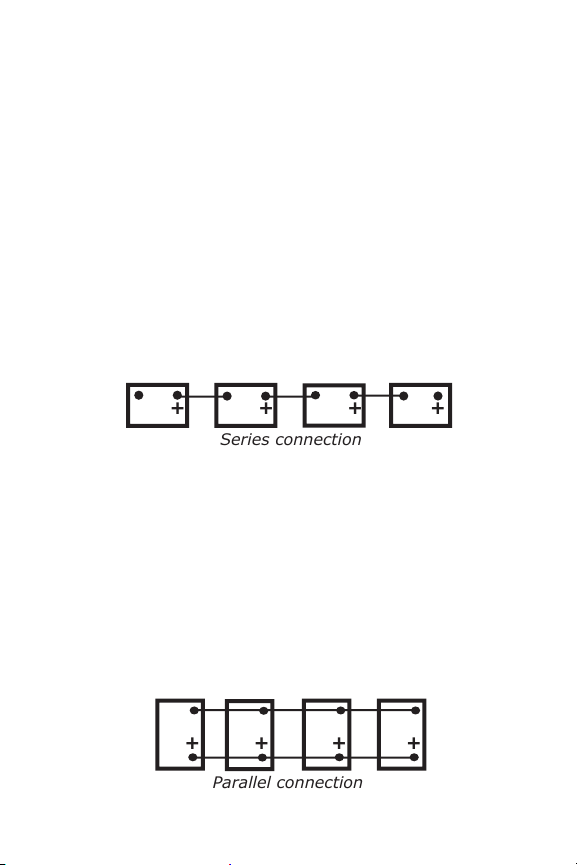

Testing Multiple Battery Systems

SLA battery cells are nominally 2.15 volts each and

are combined in groups to make batteries with 4V, 6V,

8V, and 12V at the terminals. In certain applications,

batteries of equal voltage and capacity are connected in

series or parallel to increase voltage, capacity or both.

For example, four 6v batteries may be connected in

series to produce a 24V strand.

When testing batteries which are connected in series,

there is no need to remove connections between batteries. Simply test each battery individually, by connecting directly to its terminals.

NOTE: Do not connect the MBT-LA2 to sources greater

than 12VDC, doing so may damage the tester.

Parallel Connection

In applications that have high power requirements, SLA

batteries are often wired in parallel.

- 6 -

Page 9

To test single batteries connected in parallel, it is necessary to disconnect one terminal to test the battery

accurately. Testing a group, as shown in the illustration,

takes into account all batteries and their inter-connections. This can be done with 6v and 12v systems,

where the total AH capacity does not exceed 200AH.

Verify that the tester is set to the proper MODE for total

amp-hour capacity. A reading below 70% indicates

one or more defective batteries or high resistance

inter-connections within the group.

Batteries under Charge

It is not recommended that batteries be tested when

connected to a charging system. Disconnect the charger for several minutes then test the battery three or

more times.

Operating Characteristics & Tips

1) When the power switch (ON/OFF) is turned on, the

MODE will be set to the last one used.

2) The internal cooling fan will run while test leads

are connected to a battery in the following three

MODES: 8V [20+AH] and 12v [16-50AH, 50+AH].

NOTE: To insure proper cooling, keep side and

bottom air vents unobstructed.

3) The MBT-LA2 will turn off automatically after 20

minutes of no test activity, provided it is NOT connected to a battery. To restart, simply cycle the

power switch OFF then back ON.

4) Over-voltage warnings occur when battery voltage is

- 7 -

Page 10

above the selected MODE. The MODE LED will blink

if the TEST button is pressed and no test cycle will

be initiated. For example, if 4v MODE is selected

and the leads are connected to a 12v battery, the

4V MODE LED will blink and the test button will not

function.

5) The leads should be left connected/plugged into the

tester when not in use. This minimizes contamination and helps insure good electrical connection.

Operating Problems / Troubleshooting

1) No operation and no LED activity.

a. Verify proper orientation of internal AA batteries

b. Clean the AA battery terminals.

2) Only the two red LEDs (10% & 20%) blink when

TEST button is pressed.

a. This indicates that the tester’s 4 AA batteries are

low. Replace with 4 new alkaline AA.

3) MODE button has no effect on battery selection or

TEST won’t begin.

a. Verify that the test leads are not connected to a

battery until after the unit is turned on.

b. Turn power switch off for 5 seconds, then restart.

c. Verify test lead polarity is correct.

About SLA Batteries

Capacity

This is the total amount of stored energy that is available from a fully charged cell or cells. A battery’s actual capacity is dependent upon the rate of discharge,

- 8 -

Page 11

temperature, and the specied cut-off voltage. Most

batteries have a rated capacity, expressed in amp-hours

(AH), that is based on a 20 hour constant discharge

to a cut-off voltage of 1.75v per cell. For example, a

6v battery with a rated capacity of 5AH should deliver

250mA for 20 hours before its voltage drops to 5.25v.

Capacity will decrease at higher rates of discharge and

increase with lower rates of discharge. A new battery

will achieve optimum capacity only after several com-

plete charge-discharge cycles, or by oat charging it

for at least 30 days.

Self Discharge

Batteries that are stored at room temperature will

lose, on average, about 3% of their charge per month

through self discharge. Thus a new, fully charged battery which has been stored for a year may test 60%

until it is recharged.

Battery Life

SLA batteries will lose capacity through aging. For

example, a battery on oat charge (stand-by use) will

fall to about 60% of its original rated capacity after

3-5 years of service. In cyclic use, a typical battery

will produce about 500 charge-discharge cycles before

falling to 60% of original rated capacity. Other factors

that affect capacity are the depth and rate of discharge,

ambient temperature, and charging method.

- 9 -

Page 12

Accessories

Suspension crown w/strap

Magnet

Soft case (tester not included)

Clip-type (P/N: LSC-MBTLA2)

Plier-type (P/N: LSP-MBTLA2)

MBT-LA2 Accessory Kit (P/N: K-MBTLA2)

This kit includes a protective soft case, suspension

crown/hanging strap, and strong magnet. The soft

case has a secure Velcro® ap and protects against

dirt and impact.

The hanging strap has a quick release buckle for easy

fastening to conduit, pipes, ladder rungs, etc. The

magnet, which secures to the strap, enables attachment

to steel surfaces such as battery cabinets.

Lead Sets

These exible 48” lead sets feature high strand count

18AWG rubber coated, kinkless lead wire with R/A

sheathed banana plugs. Two types of copper clamps

are available (Clip-type is standard on MBT-LA2).

- 10 -

Page 13

Specications

Testing capability (SLA battery):

2v [2-25AH]

4v [2-25AH]

6v [1-4AH, 5-15AH, 16-50AH, 51-200AH]

8v [2-20AH, 21-100AH]

12v [1-4AH, 5-15AH, 16-50AH, 51-200AH]

Power (internal): 4 x AA. Auto self test.

Auto shut-off: After 20 minutes w/o test activity

Pulse load: Varies according to battery type

Testing duration: approx. 15 seconds

Display: 8 LEDs - green, yellow, and red

Test leads: Solid copper clamps

R/A sheathed banana plugs

48”/122cm exible test lead wire

Dimensions: 9.25” x 6.25” x 2.00”

23.5cm x 15.9cm x 5.1cm

Weight: 32 oz. / 908g

UPC: 856777000206

Contact Information

ZTS, Inc.

6749 Bramble Avenue

Cincinnati, OH 45227

Toll-free: 888-796-2777

Tel: 513-271-2557

Fax: 513-272-1383

Email: testers@ztsinc.com

ztsinc.com

- 11 -

Page 14

NOTES:

© 2010 ZTS, Inc.

- 12 -

Page 15

MBT-LA2 Lead Acid Multi-Battery Tester

®

Features

• Computes State of Charge for lead acid

battery types (SLA, AGM, Gel, Flooded)

• Easy to use, fast test results (15 seconds)

• Patented, high accuracy Pulse Load test

• Test 2-volt, 4-volt, 6-volt, 8-volt, 12-volt

• Ideal for battery management - reduce

cost and increase reliability

Applications

• Fire/security • Battery management

• UPS • Telecom

• Medical • Safety

• Industrial • Auto/marine/RV

• Mobility • Inspection

• Emergency lighting • IT

• Manufacturing • Military

• Access control • Facility management

ZTS, Inc.

6749 Bramble Avenue

Cincinnati, OH 45227

www.ztsinc.com

Part No. MBT-LA2

U.S. Patents

6,823,274 - D611851

Made in U.S.A.

Requires 4 AA batteries (not included)

Loading...

Loading...