ZPA Pecky, a.s. MODACT MO EE 52 120, MODACT MO EE 52 124, MODACT MO EE 52 121, MODACT MO EE 52 123, MODACT MO EE 52 125 Mounting And Operating Instructions

...

Electric rotary multi-turn actuators

MOUNTING AND OPERATING

INSTRUCTIONS

Explosion-proof design

Type numbers 52 120 - 51 125

10/18

ZPA Pečky, a.s. is certified company in accordance with ISO 90001 as amended.

CONTENS

1. Application .................................................................................................................... 3

2. Operating conditions; Operating position ..............................................................................6

3. Operation mode; Service life of actuators ..............................................................................7

4. Technical data ................................................................................................................ 8

5. Actuator outfit ................................................................................................................9

6. Elektrical parameters ...................................................................................................... 10

7. Description .................................................................................................................. 12

8. Packing and storing ....................................................................................................... 20

9. Assembling and putting the electric actuator into operation ..................................................... 20

10. Adjustment of electric actuator with valve ........................................................................... 21

11. Operation and maintenance ............................................................................................. 22

12. Failures and their removal ............................................................................................... 23

Tables ..........................................................................................................................24–25

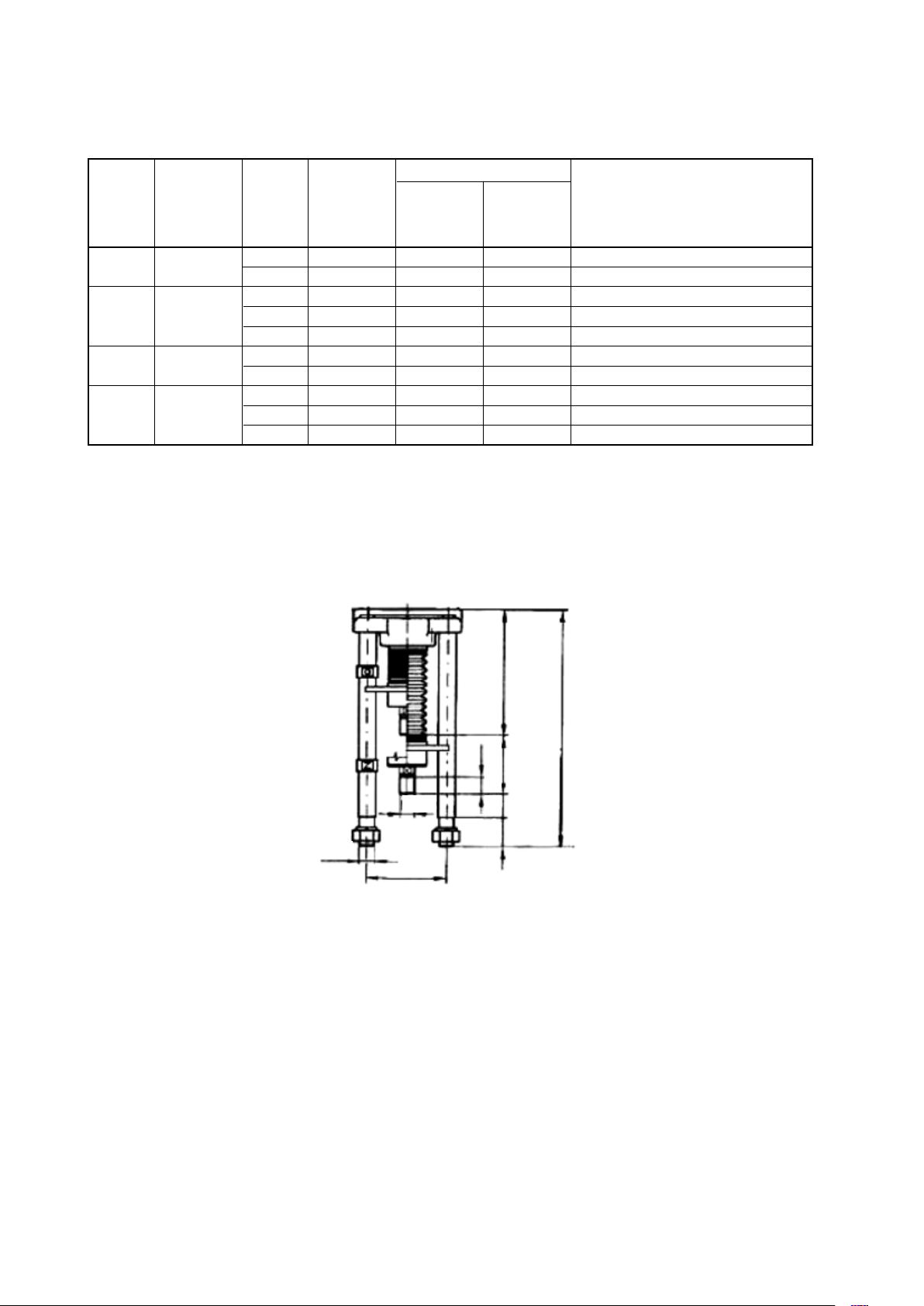

Dimensions of the actuators MODACT MO EEx .......................................................................26–31

Diagram of electric wiring ..................................................................................................32–38

List of spare parts ................................................................................................................ 39

The Mounting and Operating Instructions specify basic principles for mounting, connection, adjustment, operation,

maintenance, and repairs of electric explosion-proof actuators. A fundamental prerequisite is that assembly, operation,

maintenance, and revisions are performed by skilled technicians qualified for operation and works on explosion-proof

electric devices and the works are supervised by a professionally qualified expert instructed in a demonstrable way.

1. APPLICATION

The MODACT MO EEx electric rotary multi-turn actuators are specially intended for controlling devices by a reversing

rotary motion, e.g. slide valves and valves, and, in connection with an appropriate gearbox, also flap or ball valves,

and other devices for which they are suitable due to their properties.

They can be operated in an environment with a danger of explosion of explosive gaseous atmosphere in zone 1 and zone

2 according to ČSN EN 60079-10-1. The actuators are designed as a device of group II, category 2G in compliance with

standards ČSN EN 60 079-0:2013, ČSN EN 60 079-1:2015 and ČSN EN 60079-7:2017 for explosive gaseous atmosphere.

The actuators MODACT MO EEx are available for surrounding temperature from -25 °C to +55 °C.

The actuators MODACT MO EEx are available for surrounding temperature from -50 °C to +55 °C (in the version

without position transmitter or with current transmitter CPT 1AF). In the type designation, there are letters F

(52 12x.xxxxF) at the last places of their complementary type number.

The actuators marked

The actuators are marked with protection against explosion and symbols of the group and category of the device

II 2G and according to version for surrounding temperature from -25 °C to +55 °C with marking Ex db eb IIC T4 Gb

(type No. 52 125 with marking Ex de IIB T4 Gb) or for surrounding temperature from -50 °C to +55 °C or -60 °C to +55 °C

with marking Ex db eb IIB T4 Gb (see Data on actuators).

The actuators

Electric actuators MODACT MO EEx can be supplied in mining version marked I M2 Ex db eb I Mb.

Another modification of actuators is design for use in spark-safe control circuits. Certification of MO EEx actuators was

extended and the actuators defined as simple device according to Art. 5.7 ČSN EN 60079-11 with marking “II M2 Ex db ib I Mb”.

With their design, the actuators meet basic conditions of the level of spark safety protection “ib”. The control part of the

circuits (control of actuators) and the power part of the circuits (electric motors) are separated and each has its own switchboard.

MODACT MO EEx of mining version

The actuators marked

– label of protection against explosion and symbols of the group and category of the device II 2G or I M2

– and according to version for surrounding temperature

from -25 °C to +55 °C with marking Ex db eb IIC T4 Gb

(type No. 52125 marked Ex db eb IIB T4 Gb)

from -50 °C to +55 °C or from -60 °C to +55 °C with marking Ex db eb IIB T4 Gb

3

– as modification for use

in mines in group I, category M2 with marking Ex db eb I Mb

– as modification for use in spark-safe control

circuits in mines group I, category M2 with marking Ex db ib I Mb

Designation of explosion-proof properties

It consists of the following symbols:

Ex Electric device complies with the standard ČSN EN 60 079-0 and related standards for various types of protection

against explosion.

db

Designation of the type and level of protection against explosion, explosion-proof closure according to ČSN EN 60 079-1.

eb Designation of the type and level of protection against explosion, secured version according to ČSN EN 60 079-7.

II Designation of the group of explosion-proof electric device according to ČSN EN 60 079-0.

B, C Designation of the sub-group of the group of explosion-proof electric device according to ČSN EN 60 079-0.

T4 Designation of temperature class of explosion-proof electric device of the Group II according to ČSN EN 60 079-0.

Gb Designation of an explosion-proof electric device for explosive gas atmospheres with a “high” level of protection and

is not a source of ignition in normal operation or during expected malfunctions, according to ČSN EN 60079-0.

ib Designation of protection of spark safety according to ČSN EN 60 079-11.

Nomenclature

Environment with explosion danger

Explosive gaseous atmosphere – A mixture of flammable substances (in the form of gases, vapours or mist) with air

Maximum surface temperature – The highest temperature created during operation under the most unfavourable

Closure –

Explosion-proof closure “d” – Type of protection in which the parts capable of causing ignition of an explosive

Secured design “e” – Type of protection against explosion with additional measures adopted for

Spark safety “i” –

Spark-safe circuit – A circuit that, under testing conditions prescribed according to standard

Simple device – An electric component or combination of components of simple design with well defined

Zone 1 – A space where probability of occurrence of an explosive atmosphere of

Zone 2 – A space where occurrence of an explosive gaseous atmosphere formed of a

– Environment in which an explosive atmosphere can be created

under atmospheric conditions in which, after initialization, burning spreads out to

non-consumed mixture.

conditions (however within approved limits) on any surface part of the electric

device, which could induce ignition of surrounding atmosphere.

All walls, doors, covers, cable bushings, shafts, rods, pull-rods, etc. which contribute

to the type of protection against explosion and/or to the level of protection (IP) of the

electric device.

atmosphere are installed inside the closure; in case of internal explosion this

closure should withstand pressure of the explosion and prevent spreading of the

explosion into the surrounding atmosphere.

increased safety against non-permissible temperature increase and formation of

sparks or arcs inside and on external parts of the electric device which, under

normal operating conditions, does not form sparks or arcs.

Type of protection against explosion based on limited electric energy in the device and

the interconnecting line that is exposed to an environment with danger of explosion to

a level lower than the level that could cause ignition by sparkling or thermal effects.

ČSN EN 60079-11, produces neither sparks nor thermal effects that would be able

to cause ignition of a given explosive gaseous atmosphere.

electric parameters compatible with spark safety of the circuit in which they are used.

a mixture of flammable substances in the form of gas, vapour or mist with the air is

occasional under normal operation.

mixture of flammable substances in the form of gas, vapour or mist with the air is

improbable under normal operation; however, if this atmosphere is formed it will

only persist for a short period of time.

Standards

The following basic standards apply to explosion-proof actuators:

ČSN EN 60079-0 Electrical devices for explosive gaseous atmosphere. General requirements.

ČSN EN 60079-1 Electrical devices for explosive gaseous atmosphere. Explosion-proof closure “d”.

ČSN EN 60079-7 Electrical devices for explosive gaseous atmosphere. Secured version “e”.

ČSN EN 60079-10 Electrical devices for explosive gaseous atmosphere. Specification of dangerous areas.

4

ČSN EN 60079-14

nebo

4) Štítky na krytech skříní s označením použité ochrany proti výbuchu

a) pevný závěr „d“ ovládací skříně

b) zajištěné provedení „e“ svorkovnicové skříně

- bez přepínačů místního ovládání

nebo

4) Štítky na krytech skříní s označením použité ochrany proti výbuchu

a) pevný závěr „d“ ovládací skříně

b) zajištěné provedení „e“ svorkovnicové skříně

- bez přepínačů místního ovládání

nebo

- s přepínači místního ovládání

4) Štítky na krytech skříní s označením použité ochrany proti výbuchu

a) pevný závěr „d“ ovládací skříně

Regulations for electrical devices in areas with a danger of explosion of flammable gases and vapours.

ČSN IEC 60721 Types of environment for electrical devices.

ČSN 33 0371 Non-explosive mixtures. Classification and testing methods.

ČSN 34 3205 Operation of electric rotating machines and work with them.

ČSN EN 60079-11 Explosive atmospheres – Part 11: Protection of device by spark safety.

Data on actuators

The actuators are fitted with the following plates:

1) Plate with data of non-explosive closures:

or

or or for type no. 52 125

2) Rating and instrument plate contains:

– manufacture's name and address

– type designation of product (type number)

– serial number

– year of production

– rated value of tripping torgue Nm

– rated speed of shifting 1/min

– rated working stroke rev

– designation of protective enclosure of actuator IP

– weight of actuator kg

– mark of conformity CE

– electrical data of power circuits (voltage and frequency, current and output of electric motor);

– electrical data of control circuit of micro-switches (voltage, current);

– position transmitter (current)

3) Warning plate

4) Plates on covers with marking of used protection against explosion

a) explosion-proof closure “d” of control box

or

b) secured version “e” of terminal board box

– without change-over switches of local control

or

– with change-over switches of local control

or or

or

5

Electric actuators MODACT MO EEx of mining version marked I M2

4) Štítky na krytech skříní s označením použité ochrany proti výbuchu

a) pevný závěr „d“ ovládací skříně

b) zajištěné provedení „e“ svorkovnicové skříně

- bez přepínačů místního ovládání

nebo

- s přepínači místního ovládání

Štítek s daty nevýbušných závěrů

In an order, the customer shall state that the actuator is intended for using in spark-safe control circuits and, if possible,

specify its parameters. Based on this order, the delivered actuator will be fitted with particular anti-condensation heater

and marked with the following data.

Plate with data of non-explosive closures;

Rating plate

Plate on the cover of the switchboard box with pale blue surface finish.

2. OPERATING CONDITIONS, OPERATING POSITION

Operating conditions

The MODACT MO EEx actuators should withstand the effect of operating conditions and external influences, Classes

AC1, AD5, AE4, AE5, AF2, AG2, AH2, AK2, AL2, AM-2-2, AN2, AP3, BA4, BC3 a BE3 according to ČSN 33 2000-5-51 ed. 3.

When placed on an open area, the actuator is recommended to be fitted with a light shelter to protect it against direct

action of atmospheric effects. The shelter should overhang the actuator contour by at least 10 cm at the height of 20 – 30 cm.

If the actuator is used at a location with an ambient temperature under +10 °C and/or relative humidity above 80 %, at

a sheltered location, or in the tropical atmosphere, the anti-condensation heater built-in in all actuators, should always be

used. One or two heater elements should be connected, as required.

Installation of the actuators at a location with incombustible and non-conducting dust is only possible if this has

no adverse effect on their function. Herewith, the standard ČSN 34 3205 should strictly be adhered to. It is advisable to

remove dust whenever its layer becomes about 1 mm thick.

Notes: A sheltered location is considered a space where atmospheric precipitations are prevented from falling at

an angle of up to 60° from the vertical.

The location of the electric motor should be such that cooling air has free access to the motor and no heatedup blown-out air is drawn in the motor again. For air inlet, the minimum distance from the wall is 40 mm. Therefore,

the space in which the motor is located should be sufficiently large, clean and ventilated.

Classes of external influences – as extracted from ČSN Standard 33 2000-5-51 ed. 3.

Class:

1) Surrounding temperature from -25 to +55 °C or from -50 °C to +55 °C or from -60 °C to +55 °C

2) Surrounding temperature identical with point 1) and relative humidity from 10 % to 100 % with condensation

3) AC1 – elevation above sea level ≤ 2000 m

4) AD5 – splashing water in all directions

5) AE5 – small dust content in air; medium layers of dust; daily dust fall out more than 35 mg/m2, but not exceeding

6) AF2 – occurrence of corrosive or polluting substances from atmosphere Presence of corrosive polluting

7) AG2 – medium mechanical stress by impacts – common industrial processes

8) AH2 – medium mechanical stress by vibrations – common industrial processes

9) AK2 – serious risk of growth of vegetation and moulds

10) AL2 – Serious danger of occurance of animals (insects, birds, small animals)

11) AM2 – harmful effects of escaping stray currents

12) AN2 – medium sun radiation. Intensity from 500 to 700 W/m

350 mg/m2 per day

substances is significant

2

6

13) AP3 – medium seismic effects. Acceleration from 300 to 600 Gal

14) BA4 – staff capability. Instructed persons.

15) BC3 – frequent contact of persons with earth potential. Persons often touch foreign conductive parts or stand on

conductive base.

16) BE3N2 – danger of explosion of combustible gases and vapours. ČSN 33 2320 – ZONE 1.

Operating position

Working position of actuators MODACT® MO EEx actuators with plastic lubricant – any position.

The actuators with plastic lubricant are labelled “Filled: solid grease” on the power box at the side of the hand-wheel.

Actuators with oil charge – position limited only by slope of electric motor axis – max. 15° under the horizontal

level. In this way, reducing of service life of rubber sealing of the electric motor shaft by possible fragments

or impurities from the oil filling is prevented.

When the actuator is assembled with the electric motor above the horizontal plane the oil filling should be topped

up so that reliable lubrication of the motor pinion is ensured.

The actuators with oil filling are not labeled.

Corrosion protection

Actuators are standardly delivered with surface treatment corresponding to category of corrosion aggressiveness

C1, C2 and C3 according to ČSN EN ISO 12944-2.

On customer's request is possible to do surface treatment correcponding to category of corrosion aggressiveness

C4, C5-I and C5-M.

In following table is provided and overview of environment for each categories of corrosion aggressiveness according to ČSN EN ISO 12944-2.

Corrosion

aggressiveness

level

C1 Heated buildings with clean atmosphere

(very low) e.g. offices, shops, schools, hotels.

C2 Atmosphere with low level of pollution. Unheated buildings, in which may occur

(low) Mostly outdoor areas. condensation, e.g. stocks, sports halls.

(middle)

Seaside areas with middle salinity. factories, breweries.

C4 Industrial areas and seaside areas Chemical plants, swimming pools,

(high) with middle salinity. seaside shipyard.

C5-I

(very high

– industrial)

C5-M

(very high Seaside areas with high salinity.

– seaside)

Urban industrial atmospheres, Production areas with high humidity and low air

C3

mild pollution of sulfur dioxide. pollution, e.g. food industry, processing

Industrial areas with high humidity Buildings or areas with predominantly continuous

and aggressive atmosphere. condensation and high air pollution.

Outdoor Indoor

Example of typical environment

Buildings or areas with predominantly

continuous condensation and high air pollution.

3. OPERATION MODE, SERVICE LIFE OF ACTUATORS

Operation mode

According to ČSN EN 60 034-1, the electric actuators can be operated in the S2 load category. The run

time at temperature +50 °C is 10 min, the mean load torque is max. 60 % of the value of the maximum tripping

torque Mv.

According to ČSN EN 60 034-1, the electric actuators can also be operated in S4 load category (interrupted

operation with starting-up). The load factor N/N+R is max. 25 %; the longest operating cycle N+R is 10 min (the course

of load is shown in the picture).The maximum number of switching actions in automatic control mode is 1200 h-1. The

mean load torque with load factor 25 % and ambient temperature of 50 °C shall not exceed 40 % of the maximum

tripping torque Mv.

The highest mean load torque is equal to rated torque of the actuator.

7

Mz Starting torque ≥ 1.3 x M

M

Average load torque

stř

Mv Maximum tripping torque

v

Operating time

Course of operating cycle

N

Cycle period

Idling time

R

Service life

The actuator intended for shut-off valves must be able to perform at least 10,000 operating cycles (C - O - C).

The actuator intended for regulating purposes must be able to perform at least 1 million cycles with operation time

(during which the output shaft is moving) at least 250 hours. Service life in operating hours (h) depends on load and number

of switching. Not always, high frequency of switching influences positively accuracy of regulation. For attaining the longest

possible faultless period and service life, frequency of switching is recommended to be set to the lowest number of switching

necessary for the given process. Orientation data of service life derived from the set regulation parameters are shown in the

following table.

Service life [h] 830 1 000 2 000 4 000

Number of starts [1/h] Max. number of starts 1200 1 000 500 250

Service life of actuators for 1 million starts

4. TECHNICAL DATA

Supply voltage

The actuators MODACT MO EEx have been designed to operate at supply voltage of 3 AC 380 to 690 V, ±10 %,

50 Hz, ±2 %.

Within this supply voltage range, all parameters are kept up except the starting torque which varies with the square

of the supply voltage deviation from the rated value. This dependence is directly proportional to the supply voltage

variation; no larger supply voltage and frequency fluctuations are permitted.

Other supply voltage for electric actuators should be discussed with the manufacturer.

Protective enclosure

The type of protective enclosure MODACT MO EEx is IP 55, according to ČSN EN 60529.

Noise

Level of acoustic pressure A max. 85 dB (A)

Level of acoustic output A max. 95 dB (A)

Tripping torque

At the factory, the tripping torque has been adjusted as shown in Table 1 or 2, according to the customer’s requirements.

If no tripping torque adjustment has been specified by the customer the maximum tripping torque is adjusted.

Starting torque

The starting torque of the actuator is a calculated value determined by the starting torque of the electric motor and

the total gear ratio and efficiency of the actuator. After run reversation, the actuator can produce a starting torque for the

duration of 1 to 2 revolutions of the output shaft when torque-limit switching is locked. This can take place in either end

position or in any intermediate position.

Self-locking

The actuator is self-locking provided that the load is applied only in the opposite direction to the output shaft motion of

the actuator. Self-locking is provided by an arresting roller that stops the electric motor even in the manual control mode.

For safety reasons, it is strictly prohibited to use the actuators for driving lifting appliances that may be used

for the transport of persons or equipment in cases where people might be present under the lifted load.

8

Sense of rotation

When looking at the output shaft in the direction towards the control box, the CLOSE direction of rotation is identical

with the clockwise sense.

Working stroke

The ranges of working stroke are given in Table No. 1 or No. 2.

Rising spindle

In the design variants with connecting dimensions, Shapes A and C, the actuators can be adapted for mounting

to the valve with a rising spindle that projects over the upper end of the actuator output shaft in the end position

of the valve. The space reserved for the rising spindle is clearly shown in the dimensional sketches. The user should

mount a cylindrical guard of the rising spindle instead of the port cover at the control box top, if required. This guard

has not been included in the delivery of the actuator.

Manual control

Manual control is performed directly by a handwheel (without clutch). It can be used even when the electric motor

is running (the resulting motion of the output shaft is determined by the function of the differential gear). When the

handwheel is rotated clockwise the output shaft of the actuator also rotates clockwise (when looking at the shaft

towards the control box). On condition that the valve nut is provided with left-hand thread, the actuator closes the valve.

Torque-limit switches in the actuator are set and work when the actuator is under voltage.

When using the manual control, ie. actuator is controlled mechanically, the torque-limit switches doesn´t

work and the valve can be damaged.

5. ACTUATOR OUTFIT

Torque-limit switches

The actuator is fitted with two torque-limit switches (MO – OPEN, MZ – CLOSE) each of which acts only in

one direction of motion of the actuator output shaft. The torque-limit switches can be set to operate at any point of

the working stroke except the region in which they are locked (see Starting torque).

The tripping torque can be adjusted within the range shown in Table 1 or 2. The torque-limit switches are locked

if the load torque is lost after they have been brought into the OFF-position. This feature secures the actuator against

the so-called “pumping”.

Position-limit switches

The PO – OPEN and PZ – CLOSE position-limit switches limit the actuator working stroke, each being adjusted

to operate in either end position.

Position signalling

For signalling position of the actuator output shaft, two signalling switches, i.e. the SO – OPEN signalling switch and

the SZ – CLOSE signalling switch, are used. Each of these switches acts only in one direction of output shaft rotation. The

operating point of the microswitches can be set within the whole working stroke range except the narrow band before the

operating point of the microswitch used to switch off the electric motor.

Position transmitters

The MODACT MO EEx electric actuators can be supplied without position transmitter or can be fitted with position transmitter:

a) Resistance transmitter MEGATRON 1 x 100 Ω.

Technical parameters:

Position scanning resistance

Turning angle 0° – 320°

Non-linearity ≤ 1 %

Transition resistance max. 1.4 Ω

Permitted voltage 50 V DC

Maximum current 100 mA

b)

Type CPT 1Az passive current transmitter. Power supply to the current loop is not a part of the actuator. Recommended

feeding voltage is 18 – 28 V DC, at maximum loading resistance of the loop 500 Ω. The current loop should be earthed in one

point. Feeding voltage need not be stabilized; however, it must not exceed 30 V or else the transmitter could be damaged.

Range of CPT 1Az is set by a potentiometer on the transmitter body and its starting value by corresponding partial turning

of the transmitter.

9

Technical parameters of CPT 1Az:

Scanning of position capacity

Working stroke adjustable 0° – 40° to 0° – 120°

Non-linearity ≤ 1 %

Non-linearity, including gears ≤ 2.5 % (for a maximum stroke of 120°)

Hysteresis, including gears ≤ 5 % (for a maximum stroke of 120°)

(The non-linearity and hysteresis are related to a signal value of 20 mA).

Loading resistance 0 – 500 Ω

Output signal 4 – 20 mA or 20 – 4 mA

Supply voltage for R

for R

Maximum supply voltage ripple 5 %

Maximum transmitter power demand 560 mW

Insulation resistance 20 MΩ at 50 V DC

Insulation strength 50 V DC

Operational environment temperature -25 °C to +60 °C

Operational environment temperature – extended range -25 °C to +70 °C (additional on demand)

Dimensions ø 40 x 25 mm

For the transmitter CPT 1Az a two-wire connection is used, i.e., the transmitter, the power supply and the load are connected in

series. The user should secure that the two-wire circuit of the current transmitter is connected to the electric earth of the associated

regulator, computer, etc. This connection should only be made at a single point in any section of the circuit, outside the actuator.

= 0 – 100 Ω 10 to 20 V DC

load

= 400 – 500 Ω 18 to 28 V DC

load

Anti-condensation heater

The actuators are fitted with an anti-condensation heater preventing condensation of water vapour. It is connected to

the AC mains of voltage 230 V.

Local control

Local control serves for controlling the actuator from the site of its installation. It includes two change-over switches:

one with positions “Remote control - Off - Local control”, the other “Open - Stop - Close”. The former change-over switch

can be built-in as two-pole or four-pole. The change-over switches are installed in a terminal-board box and the control

elements on the lid of this terminal-board box.

6. ELECTRIC PARAMETERS

External electric connection

The electric actuator is equipped with a terminal board for connection to external circuits. This terminal board uses screw

terminals allowing conductors with a maximum cross-section 4 mm

after removal of the terminal box cover. All control circuits of the electric actuator are brought out to the terminal board. The

terminal box is fitted with cable bushings for connecting the electric actuator. The electric motor is fitted with an independent box

with a terminal board and a bushing.

When connecting external conductors strip the end to length of 8 mm and to each terminal insert the conductors that the

conductor insulation intervene to their metal parts. This will be observed surface and air insulation distances for increased safety “e”.

Actuator internal wiring

The internal wiring diagrams of the MODACT MO EEx actuators with terminal designation are shown in this Mounting and

operating instructions.

Each actuator is provided with its internal wiring diagram on the inner side of the terminal box. The terminals are marked on

a self-adhesive label attached to a carrying strip under the terminal block.

Current rating and maximum voltage of microswitches

Maximum voltage of mikroswitches is 250 V AC as well as DC, at these maximum levels of currents.

MO, MZ 250 V AC / 2 A; 250 V DC / 0,2 A

SO, SZ 250 V AC / 2 A; 250 V DC / 0,2 A

PO, PZ 250 V AC / 2 A; 250 V DC / 0,2 A

The microswitches can only be used as single-circuit devices. Two voltages of different values and phases cannot

be connected to the terminals of the same microswitch.

2

to be connected. Access to the terminal board is obtained

Isolation resistance

Isolation resistance of electric control circuits against the frame and against each other is min. 20 MΩ. After a dump test,

isolation resistance of control circuits is min. 2 MΩ. Isolation resistance of the electric motor is min. 1.9 MΩ. See Technical

specifications for more details.

10

Electric strength of electric circuits isolation

Circuit of resistance transmitter 500 V, 50 Hz

Circuit of current transmitter 50 V DC

Circuits of microswitches and anti-condensation heater 1 500 V, 50 Hz

Electric motor Un = 3 x 230/400 V 1 800 V, 50 Hz

Deviations of basic parameters

Tripping torque ±12 % of the maximum range value

Adjusting speed -10 % of the maximum range value

+15 % of the rated value (in no-load operation)

Setting of signalling switches ±2.5 % of the maximum range value

(for the ranges, refer to the Mounting instructions).

Hysteresis of signalling switches max. 4 % of the maximum range value

Setting of position-limit switches ±25° of the angle of output shaft

displacement (without the influence of running-down)

Hysteresis of position-limit switches max. 45° of the angle of output shaft displacement

Protection

For protection against electric shock to ČSN 33 2000-4-41 the actuators are provided with an internal protective

terminal in addition to an protective terminal, according to ČSN 18 6330. The electric motor is also fitted with a protective

terminal. The protective terminals are provided with a mark, according to ČSN EN 60417-1 and 2 (013 760).

If isn´t the actuator equipped with overcurrent protection when purchased is needed to ensure that

the protection is secured externally.

Electric actuators MODACT MO EEx of mining version I M2 for spark-safe control circuits

The actuator ensures the level of protection of spark safety “ib” as a simple device according to ČSN EN 60079-11.

Individual circuits of the actuator can be connected to various spark-safe circuits. However, no other than spark-safe

circuits may be connected.

The electric motor has its own separate switchboard. The electric motor circuit is not spark-safe.

Description of the electric control circuits

Components used

1. Actuator switchboard

The switchboard is formed of certified row terminals MXK4. Conductors of maximum cross-section 4 mm2 can be

connected to the switchboard. The conductors must insulated to metal parts of the terminal so that spark-safe surface

and air insulation distances would be observed. – rated voltage 400 V AC / DC

– rated current 27 A

2. Torque micro-switches XGK 12-88-J21 – rated voltage 250 V AC, 60 V DC

– rated current 26 A

3. Position-limit and signalling micro-switches D 433-B8LA

– rated voltage 250 V AC, 60 V DC

– rated current 6(2) A

4. Bushing D41V21x0,75 – rated voltage 300 V

– maximum constant current 8 A

5. Anti-condensation heater TRA25 – rated loading without cooling plate 12.5 W

– maximum permitted voltage 550 V AC / DC

– value of the anti-condensation heater is given by magnitude of

control voltage stated by the customer in the order.

For instance: for voltage 12 V 24 V 48 V

Value of anti-condensation heater 12 Ω 56 Ω 220 Ω

6. Position transmitter

The position transmitter is an optional accessory. For spark-safe circuits, resistance transmitter of the following

parameters is certified only: – rated power output 1 W

– acceptable voltage 50 V DC

– maximum current 100 mA

– electric strength 500 V

Actuators intended for using in spark-safe control circuits cannot be fitted with:

– current transmitter of position 4 – 20 mA

– block (change-over switches) of local control

11

Location of components

The switchboard is installed in the switchboard box with protective enclosure IP 67. Other components are installed

in the control box of the actuator in the version of firm closure “d”. The boxes are separated by certified bushing

D41V21 x 0.75 (thickness of insulation of bushing conductors is 0.5 – 0.6 mm).

Independent spark-safe circuits and their electric parameters.

Terminals Connected part Function Parameters of spark-safe circuit

10-11 XGK 12-88-J21 torque switch Ui = 60V, Ii = 1A, Li = 0 mH, Ci = 0 μF

12-13 XGK 12-88-J21 torque switch Ui = 60V, Ii = 1A, Li = 0 mH, Ci = 0 μF

14-15-16 D 433-B8LA position-limit switch Ui = 60V, Ii = 1A, Li = 0 mH, Ci = 0 μF

17-18-19 D 433-B8LA position-limit switch Ui = 60V, Ii = 1A, Li = 0 mH, Ci = 0 μF

20-21-22 D 433-B8LA signalling switch Ui = 60V, Ii = 1A, Li = 0 mH, Ci = 0 μF

23-24-25 D 433-B8LA signalling switch Ui = 60V, Ii = 1A, Li = 0 mH, Ci = 0 μF

50-51-52 resistance transmitter Position sensor 100 Ω Pi=1W, Ui = 50V, Ii =100mA, Li=0 mH, Ci=0 μF

60-61 TRA25 Anti-condensation heater Pi=12,5W, Ui = 60V, Ii = 1A, Li = 0 mH, Ci = 0 μF

7. DESCRIPTION

The electric actuators are designed for direct attachment on the controlled device. The actuators are

connected by means of a flange and a clutch according to ČSN 18 6314. The actuator flanges also comply with

ISO 5210. The following clutches are available for transmission of the output shaft motion to the valve:

Shape A (with adapter), according to ISO 5210 and DIN 3210

Shape B1 (with adapter), according to ISO 5210 (shape B according to DIN 3210)

Shape B3 (without adapter), according to ISO 5210 (shape E according to DIN 3210)

Shape D (without adapter), according to DIN 3210

Shape C (without adapter), according to DIN 3338

The adapters are mounted between the actuator and the valve.

The electric actuator configuration is shown in Fig. 1. The three-phase asynchronous motor 1 drives, via the countershaft

gearing 2, the sun gear of the differential gear unit installed in the actuator supporting box (power gearing) 3.

In the motor control mode, the crown gear of the planet differential unit is held in fixed position by a self-locking worm gearing.

The handwheel 4 connected with the worm allows manual control even when the motor is running. The output hollow shaft is fixedly

attached with the planet gear carrier. The output shaft is extended to the control box 5 where all elements of the electric actuator

are installed – position-limit, signalling and torque-limit switches, resistance or current position transmitters, and anti-condensation

heater. Operation of the position-limit and signalling switches is derived from rotation of the output shaft via special mechanisms.

11 10

1

5

6 7 8

2 3 4 9

Legend:

1 – Three-phase asynchronous motor

2 – Countershaft gear box

3 – Power gearing

4 – Control handwheel

5 – Control box

6 – Control box cover

7 – Terminal box

8 – Terminal box cover

9 – Cable bushings P 21 (for control)

10 – Terminal board of electric motor

11 – Explosion-proof cable bushing (for motor)

Fig. 1 – Electric actuator configuration

Operation of the torque-limit switches is derived from axial displacement of the “floating worm” of the manual control unit

which is scanned and transferred to the control box by means of a lever. The control box forms an explosion-proof closure “d” with

12

designation Ex db IIC T4 Gb. The terminal box in the secured design “e” has designation Ex eb II T4 Gb. The control elements are

accessible after removing the cover 6 of this box. Access to the terminal box is possible after removing the cover 8. The cable inlets

are protected by certified cable bushings. Three cable bushings are used on terminal board (see dimensional drawing).

1 piece M25 x 1,5 (cable diameter 10 – 16 mm)

1 piece M25 x 1,5 (cable diameter 13 – 18 mm)

1 piece M20 x 1,5 (cable diameter 7 – 12 mm)

The following control units are distinguished according to their function:

a) Torque-limit switching unit (12)

b) Signalling unit (13)

c) Position-limit switching unit (16)

d) Potentiometer shifting mechanism (14)

e) Position transmitters – resistance 1 x 100 Ω (15) or current transmitter CPT 1Az (19)

f) Anti-condensation heater (17)

All the above units are universal for all sizes of the electric actuators MO EEx.

Description and function of control units

a) Torque-limit switching unit (Fig. 3)

It is designed as an independent assembly unit and consists of the base plate 24 carrying micro-switches 25;

at the same time it acts as bearings for the torque control shaft 27 and the locking shaft 34.

18 21

13

17

15

22

12

21

20

12

21

21

Legend:

12 – Torque-limit switching unit

13 – Signalling unit

16

14 – Transmitter shifting mechanism

15 – Potentiometer MEGATRON 1 x 100 Ω

16 – Position-limit switching unit

18 – Driving gear

17 – Anti-condensation heater

21 – Fixing screws

22 – Basic control box

Fig. 2 – Control board – Design with potentiometer MEGATRON 1 x 100 Ω

19

A

18

21

13 22 17

Legend:

12 – Torque-limit switching unit

13 – Signalling unit

16 – Position-limit switching unit

17 – Anti-condensation heater

21

16

23

18 – Driving gear

19 – Current transmitter CPT 1Az (4 – 20 mA)

20 – Shim plates

21 – Fixing screws

22 – Basic control box

23 – Holder

For electric actuators type no. 52 120 the

plate of the transmitter CPT 1Az is turned round by 180 °

against the figure.

The encircled figures correspond to numbers of terminals

on the terminal board and apply also to the control board

with the current transmitter.

supporting

Fig. 2a – Control board – Design with current transmitter CPT 1Az (4 – 20 mA)

13

The torque control shaft transmits motion of the floating worm from the power gearing to CLOSE (MZ) or OPEN

(MO) micro-switches by means of segments 28 or 29 and levers 36 or 37. The tripping torque can be set by moving

round the segments with respect to the tripping levers. For readjusting the tripping torque outside the factory, the

segments 28, 29 are provided with a scale on which the points for setting the maximum and minimum torque are

marked as lines individually for each electric actuator. The set torque is indicated by slots in the segments 32 and 33.

However, numbers on this scale do not provide direct indication of the tripping torque setting. The divisions on this

scale serve only for finer dividing of the band between the points of maximum and minimum tripping torques and

thus for more accurate resetting of the tripping torque outside the factory in case that a loading stand is not available.

The segments 28 and 29 are intended for the direction “Close” and “Open”, respectively.

The torque-limit switching unit is also fitted with a locking mechanism which, after opening of the torque-limit switch,

provides for its locking. In this way closing of the switch and thus pulsing of the electric actuator is prevented. Moreover, the

locking mechanism prevents opening of the torque-limit switch after reversing the electric actuator run and thus enables

full utilization of starting torque of the electric actuator. The locking mechanism operates in either direction of motion of the

electric actuator output shaft in end positions as well as in intermediate position for the period of 1 – 2 turn of the output

shaft after reversing its motion.

With the output shaft of the electric actuator loaded with counteracting torque, the torque control shaft 27 and thus the

segments 28 or 29 are moved round. This displacement is transferred to the tripping lever 36 or 37. As the torque on the electric

output shaft reaches the value to which the torque-limit switching units has been adjusted, the tripping lever depresses the

button of respective micro-switch, the electric actuator is disconnected from the supply mains and the electric actuator stops.

24 25 34 26 37 28 30 32

36

27

35 29

31

33

Legend:

24 – Base plate

25 – CLOSE and OPEN torque-limit micro-switches

26 – Shifter

27 – Torque control shaft

28 – Upper CLOSE segment

29 – Upper OPEN segment

30 – CLOSE lock screw

31 – OPEN lock screw

32 – Lower CLOSE segment with slot

33 – Lower OPEN segment with slot

34 – Locking shaft

35 – Lock nut

36 – OPEN tripping lever

37 – CLOSE tripping lever

Diagram of micro-switches

Fig. 3 – Torque-limit switching unit

Adjustment of torque-limit switching unit

The tripping torque different from that to which the unit was set in the factory is adjusted as follows: Loosen the lock nut

35 (Fig. 3) and particular lock screw 30 (for direction CLOSE) or 31 (for direction OPEN). Insert a screwdriver into the slot

in the upper segment 28 or 29 and rotate the segment until the slot in the segment 32 or 33 tellies with the respective scale

division line. This point is determined in such a way that the difference between the maximum and minimum adjustable torques

in Nm is divided by the number of the scale divisions between the marks for the maximum and minimum torques. The figure

thus obtained indicates value in Nm of the tripping torque corresponding to one scale division. Interpolation is then used for

determining the scale division line with which the slot in the segment 32 or 33 should tally.

The colour scale division line nearer to the number 10 indicates the point of setting the maximum tripping torque.

The other division line indicates the point of setting the minimum tripping torque. The torque control unit must never

be set in such a way that the lower segment slot is outside the band marked out by colour division lines on the scale.

After setting the tripping torque, retighten the lock screw 30 or 31 and the lock nut 35.

The set tripping torque values must not exceed those corresponding to respective type designations in Tables 1 or 2.

b) Signalling unit (Fig. 4)

This unit transmits electric signal for signalling position of the electric actuator output shaft. The unit is driven

by the gear 46 from the output shaft via a multistage gearbox to the cams 38, 39 controlling the OPEN signalling

micro-switch 44 and CLOSE signalling micro-switch 45. The moment of operation of the signalling switches can

be chosen at any point of the working stroke of the electric actuator except the narrow band around the end

positions (the signalling switch should close earlier than the position-limit switch, while the output shaft is still

moving). The upper cam 38 and the lower cam 39 act in the CLOSE and OPEN direction, respectively.

14

38 41

40 39

42

43

44

45

46 47

Fig. 4 – Signalling unit

Diagram of micro-switches

Legend:

38 – CLOSE direction cams

39 – OPEN direction cams

40 – Screws for CLOSE direction cams

41 – Screws for OPEN direction cams

42 – OPEN direction lever

43 – CLOSE direction lever

44 – Micro-switch (lower) for direction OPEN

45 – Micro-switch (upper) for direction CLOSE

46 – Drive gear

47 – Supporting plate of the signalling unit

The signalling unit

the gearings fitted under it are arranged as shown in the kinematic diagram

so that, after loosening the lock screw 57, the sliding gear K3 can be moved to different levels

(Fig. 4)

is designed as an independent assembly. It is mounted on the supporting plate 47;

(Fig. 6).

The gearing is assembled

(I, II, III, IV, V).

Moving of the gear K3 changes the range of setting the signalling switches and the transmitter according to

the electric actuator working stroke. The tables at the Figs. 8 and 9 show the ranges of setting for respective

positions of the sliding gear K3.

Adjustment of signalling unit

If the ranges of setting the signalling switches and the transmitter are to be modified it is necessary to change the

position of the sliding gear K3. In resetting the gear K3 the signalling unit should be partially shifted out from the control

box (length of inlet cables to the micro-switches is sufficient to allow for that). This can be done after removing three

screws 21 (Fig. 2) which fix the unit to the base plate. After adjusting the signalling unit to the required range, the unit

is returned back. Before the screws 21 are retightened, correct meshing of the gears K1 and K2 should be checked

(Fig. 6). The pinion 59 (Fig. 6) is put on the lower end of the cam shaft 58 (Fig. 6) which is connected with the shaft 58

by an adjustable friction clutch. From this pinion the motion is scanned for driving the resistance or current transmitter.

Arrangement of the cams and micro-switches of the signalling unit is shown in Fig. 4. The shoulders of the cams 38,

39 deflect the levers 42 or 43 which control the signalling micro-switch OPEN (44) or CLOSE (45). In adjusting the

signalling and position-limit switches and the transmitter it is always necessary to reset the electric actuator output shaft

to the position where changing-over of the micro-switches should take place or required position of the transmitter is

to be reached.

In adjusting the signalling switches proceed as follows: loosen the screw 40 (for the CLOSE signalling switch SZ)

or 41 (for the OPEN signalling switch SO) – Fig. 4). Then, rotate the cam 38 or 39 in the arrow direction, i.e. in the

counter-clockwise sense and clockwise sense for the CLOSE signalling micro-switch and OPEN signalling microswitch, respectively, until the micro-switch closes. In this position hold the cams and retighten the lock screws.

Caution

After any manipulation with the lock screws in the electric actuator control section, the screws should be secured

against loosening during vibrations by a drop of quickly drying varnish. In case these screws were secured with varnish

earlier the old varnish should be removed during adjustment and the surface properly degreased.

c) Position-limit switching unit (Fig. 5)

This unit ensures tripping of the CLOSE or OPEN position-limit switches on reaching the preset number of turn

of the output shaft. Rotary motion of the unit is derived from motion of the output shaft by the driving gear 55. This gear

provides for a step-wise turning of the arranged gear wheels controlling the cam 50 (53). Turning of the cam against

the lever of the CLOSE or OPEN position-limit switch causes changing-over of the switches.

15

48

49

56 55 50 51 53 54

52

Diagram of micro-switches

Legend:

48 – Decadic transmission gearing

49 – CLOSE regulating screw

50 – CLOSE tripping cam

51 – Tripping rod

52 – OPEN regulating screw

53 – OPEN tripping cam

54 – OPEN position-limit micro-switch

55 – Driving gear

56 – CLOSE position-limit micro-switch

Fig. 5 – Step-wise position-limit switching unit

Adjustment of position-limit switching unit

The unit can be adjusted within the range according to Tables 1 or 2. The adjusting procedure is as follows:

–

After attaching the electric actuator on the valve, bring the valve into the CLOSE position by means of the electric actuator.

– In this position depress the tripping rod 51 in vertical direction and move it round by 90 ° to either side.

– Rotate the regulating screw 49 in the direction of the arrow “Z” (CLOSE) until the cam 50 depresses the spring of

the CLOSE position-limit micro-switch 56.

– Move the tripping rod 51 round by 90°, the rod is shifted out again. If this is not the case turn the screw 49 or 52 slightly.

– Readjust the valve by means of the electric actuator by a required number of turn into the OPEN position.

– Depress the tripping rod 51 again in the vertical direction and move it round by 90° to either side.

– Rotate the regulating screw 49 in the direction of the arrow “O” (OPEN) until the cam 53 depresses the spring of the

OPEN position-limit micro-switch 54.

– Move the tripping rod 51 round by 90°, the rod is shifted out again. If this is not the case turn the screw 49 or 52 slightly.

Note: Turning of the regulating screw 49, 52 should stop at the moment of changing-over!

If, before readjusting, the cams are in the position shown in Fig. 5 or the cam has already depressed the micro-switch

button, the following procedure of adjusting is preferred:

After depressing and positioning the tripping rod 51, turn the regulating screws 49 or 51 in the opposite direction of the

arrow until the cam top moves out from the micro-switch lever (in the direction towards the pertaining regulating screw) and

the micro-switch changes over (this can be checked by a suitable tester). By turning the regulating screw 49 or 52 in the arrow

direction move the cam top back onto the micro-switch lever until the micro-switch changes over again (the micro-switch

button is depressed). In this way the micro-switch is adjusted. Finally, shift out the tripping rod 51 as described above.

d) Position transmitters

Current position transmitter CPT 1Az (Fig. 7) - setting

First, it is necessary to set a suitable gear from the output

shaft actuator to the transmitter shaft according to the required

working lift of the servomotor. Adjustments are made by adjusting wheel K3 in the transmitter of the signaling unit according to

point b). Furthermore, it is necessary to insert the required wheel, which is mounted on the transmitter shaft. Wheel with smaller

diameter is marked A, the larger wheel is marked B (Figure 7).

The adjustment is performed by moving the oval pads with

two holes either under the beam of the transmitter (wheel A is

engaged) or above the transmitter beam (B is engaged).

This is done in the position where the beam of the transmitter is most distant from the transmission. Then, the screws securing the beam of the transmitter are slightly tightened so that

the transmitter beam can be moved to a position, when wheel

A or B engages with the drive wheel.

red

U UR

white

515152

CPT 1Az

red

white

52

mA V

R

CPT 1Az

16

Adjustment of working stroke of the signaling unit

Output

shaft

K1

K2

Gearbox

Cams

58

59

K3

Legend:

K1 – Gear

K2 – Driving gear

K3 – Sliding gear

57 – Lock screw of sliding gear

58 – Cam shaft

59 – Pinion with friction clutch

57

Fig. 6 – Kinematic diagram of gears

Note:

For electric actuators, type no. 52 120, position of the sliding gear K3 for respective gear stages is shown on the left,

for remaining type nos. on the right.

Adjustment of working stroke –

68

69

design variant with current position transmitter

70 71 72

73

K3

Gear

stage

I

II

III

IV

V

Fig. 7 –

Adjustment ranges of working stroke

Gear

on

transmitter

A

B

A

B

A

B

A

B

A

B

Legend:

60 – Current transmitter CPT 1Az

61 – Transmitter supporting plate

62 – Spacing shims

63 – Oval shims

64 – Lock screw

65 – Shim plate

66 – Double gear

K3 – Sliding gear

B

74

Gears on current transmitter – gears

A

Type number

52 120 52 121, 52 122 52 123 – 125

0,9 -1,8

1,6 -3,3

2,1 - 4,2

3,4 - 6,9

6,7 - 13,4

11,6 - 23,3

21,4 - 42,9

39,2 - 78,5

75 - 144

131 - 263

1,3 - 2,6

2,4 - 4,8

4,4 - 8,8

8 - 16

14,8 - 29,6

27 - 54

49 - 99

90 - 181

167 -334

304 -609

1 - 2

1,8 - 3,7

3,4 - 6,8

6,1 - 12,3

11,4 - 22,8

20,8 - 41,7

37,8 - 76,5

69,5 - 139

129 - 258

234 - 470

17

Operating diagram of position-limit and signalling switches

Open Closed Numbers of terminals

on terminal board

PO

15-16

14-15

PZ

Open Closed

SO

SZ

Contact closed Contact open

Fig. 8 – Operating diagram of position-limit and signalling switches

In this position, check the wheel and, if necessary, adjust the height of the double wheel with the washers on the

transmitter shaft wheel drive. There must be a slight clearance between the wheel A (or B) and the drive wheel, so

that the transmitter shaft is not stressed in a direction perpendicular to its axis. Then tighten the transmitter beam

fastening screws securely and secure with a varnish. The gear selection of the wheels K3 and wheels A, B is carried

out according to the table. If the required stroke is overlapped two bands, it is preferable to choose a lower band.

After adjusting the appropriate gear, adjust the current transmitter according to the following procedure:

Before starting setting the current transmitter it is necessary to set the end-limit positions (torque or position switches)

of the actuator and connect them into the tripping circuit of the electric motor. In case of an external source of feeding

voltage, verification must be carried out that it does not exceed the maximum value 30 V DC (limit value when CPT 1Az is

still not damaged). Recommended value is 18 – 28 V DC.

Positive pole of the source is connected to the positive pole of the transmitter CPT 1Az; a milli-ammeter of

precision at least 0.5 % connected into the circuit. The current loop must be earthed in one point. The figure does not

show the earthing that can be made at any point of the circuit.

1. Shift the output shaft into the position Closed. During closing, the current signal value should decrease. If it increases

release the transmitter body and, by turning of about 180°, shift to the descending part of the outputcharacteristics.

Set 4 mA by fine turning. Tighten the shim plates to secure the transmitter against spontaneousturning.

2. Shift the output shaft to the position Open and set 20 mA using a potentiometer on the transmitter body. The

potentiometer has a range of 12 revolutions and it has no stops so that it cannot be damaged by furtherturning.

3. Once again verify the current value in the position Closed. If it has changed too much repeat the points 1. and 2.

If the required corrections are large this procedure should be repeated several times. After the setting, secure the

transmitter against turning and drip the screws with varnish.

4. Use a voltmeter to check the voltage on the CPT1 terminals. In order to keep linearity of the output signal the

voltage must not drop below 9 V, not even with off-take 20 mA. If this condition is not met it is necessary to increase

the feeding voltage (within the range of recommend values) or to decrease total resistance of the current loop R.

18-19

17-18

21-22

20-21

24-25

23-24

Caution!

The transmitter CPT 1Az must not be connected without checking the supply voltage. The transmitter outlet

conductors must neither be connected to the electric actuator frame nor to the earth, not even accidentally.

1. Before the supply voltage is checked, it is first necessary to disconnect the transmitter from the supply mains. Measure

the voltage on terminals of the electric actuator to which the transmitter is connected – this can best be done using

a digital voltmeter of input resistance at least 1 MΩ. This voltage should fall within the range of 18 – 25 V DC; in no case

may it exceed 30 V (otherwise the transmitter can be damaged). Then, connect the transmitter so that the positive pole

of the power source is connected to the positive pole of the transmitter, i.e. to the pin with red insulator (r) + (nearer to

the transmitter centre). The terminal with white coating (wired to the terminal 52) is connected to the negative pole of the

transmitter (white insulator). In the latest design variants the red conductor is plus and the black one is minus.

18

A milli-ammeter, preferentially a digital one with accuracy at least 0.5 %, is temporarily connected in series with the transmitter.

The output shaft is moved to the position CLOSE. The signal value should decrease. If this is not the case, the output shaft should

be rotated in the CLOSE direction until the signal starts decreasing and the output shaft reaches the CLOSE position.

Then, loosen the screws of the transmitter shim plates so that the whole transmitter can be turned to set the current

to 4 mA, and retighten the screws of the shim plates. Thereafter, move the output shaft of the electric actuator to

the position OPEN. Using the resistance trimmer on the transmitter face (nearer to the edge) set the current to

20 mA. The trimmer has 12 turn and no stops. Hence, it cannot be damaged.

In case the correction of the current 20 mA was considerable repeat adjustment for 4 mA and 20 mA once again.

Disconnect the milli-ammeter. The screw secured by a drop of varnish situated nearer to the centre must not be turned.

Retighten the countershafts fixing the transmitter shim plates and secure with a drop of varnish against loosening.

After completing the adjusting procedure, check voltage on the transmitter terminals using a voltmeter. The voltage

should fall within the range of 9 – 16 V with current 20 mA.

Note:

The transmitter characteristics has two branches: the descending one and the ascending one with respect to the

CLOSE position. The characteristics is selected by turning the transmitter body.

MEGATRON resistance transmitter

The MO EEx actuators can alternatively be equipped with a MEGATRON resistive transmitter. This transmitter is

unilaterally the driven shaft and at its end a bicycle 73 consisting of gears A and B is mounted. Drive principle and

adjusting the MEGATRON transmitter is the same as the CPT 1Az current transmitter. The difference is only in the

toothed dimensions wheel A and B bin 73 and hence in the working stroke table.

68

69

70

K3

71

72

B

A

Gear on current transmitter – gears

73

Legend:

68 – Potentiometer MEGATRON

69 –

Transmitter supporting plate

70 –

Lock screw

71 –

Shim plate

72 – Spacer

73 –

Double gear

Setting up the MEGATRON resistance transmitter

First, it is necessary to set a suitable gear from the actuator output shaft to the transmitter shaft, according

to the required working stroke of the servomotor, see the following table.

Working stroke ranges for the MEGATRON resistive transmitter

Gear

stage

A 0,5 - 1,0 1,2 - 2,5 0,9 - 1,8

I

B 0,9 - 1,9 2,3 - 4,6 1,7 - 3,4

A 1,7 - 3,5 4,0 - 8,2 3,1 - 6,4

II

B 3,2 - 6,4 7,7 - 15,4 5,9 - 11,7

A 5,8 - 11,7 13,8 - 27,7 10,6 - 21,4

III

B 10,4 - 20,8 25,6 - 51,3 19 - 38

B 37,4 - 74,8 86 - 172,2 68,5 - 137

B 122,5 - 245,3 292 - 584,5 224,3 - 450

A 20 - 39,9 46,8 - 93,8 36,4 - 73

IV

A 67,1 - 134,2 155,4 - 311,1 122,9 - 245,7

V

Gear

on

transmitter

52 120

Type number

52 121 – 52 122

52 123 – 52 125

19

The adjustment is made by means of the adjusting wheel K3 in the signaling unit gearbox according to the previous

point b). It is also necessary to insert the required wheel, which is attached to the transmitter shaft. Wheel with smaller

diameter is marked A, the larger wheel is marked B. The displacement is accomplished by moving the washer 72 either

under the transmitter beam (the wheel A is in motion) or above the transmitter beam (wheel B is engaged). This is

done in the position where the beam of the transmitter is most distant from the gearbox. Then, the screws attaching the

transmitter beam shall be slightly tilted to the extent possible move the transmitter beam to the position where the

wheel A or B engages the drive wheel. We will review this position shot of wheels. There must be a slight clearance

between the wheel A (or B) and the drive wheel, so that the transmitter shaft is not direction perpendicular to its axis.

Then tighten the transmitter beam fastening screws securely and secure with a varnish.

If the desired working stroke is in the overlap of two bands, it is preferable to choose a lower band. After adjusting the

appropriate gear, adjust the transmitter according to the following procedure: Due to the graduated the gear ratio of the

signaling unit with the potentiometer running does not always move over the entire resistance range but only in a certain

part. When setting the signaling unit to the "open" and "closed" according to point b), certain resistance transmitter settings

are automatically set. Final tuning of the transmitter is done as follows: Move the actuator output shaft to the "closed"

position. Then loosen the tab bolts transmitter so that the whole transmitter can be rotated (the transmitter is in the form of

stops and can be rotated only in the range 320 °). Then rotate the transmitter to the lowest resistance value (approx. 4 Ω,

less not) and tighten the tab bolts. When turning on the actuator turning the handwheel to "open", the resistance starts to

rise to the resistance value corresponding to the "open" end position (50 Ω to max. 98 Ω). This translates the transmitter.

8. PACKING AND STORING

For deliveries to domestic customers, the electric actuators remain unpacked. The actuators are transported by

covered conveyances or in transport containers. For deliveries to foreign customers, the electric actuators should

be packed. Type and design of packing should be adapted to transport conditions and distance to the place

of destination. Upon receipt of electric actuators from the manufacturer, the customer should check them for any

possible damage during transport. Data on the actuator rating plate should be compared with those stated in the order

and accompanying documentation. Any possible discrepancies, defects or damages should immediately be reported to

the supplier. In such case, the commissioning is impossible.

If the non-packed electric actuator is not installed outright it should be stored in a dust-free room with temperature ranging

between -25 to +50 °C and relative humidity up to 80 %. The room should be free of caustic gases and vapours, and protected

against detrimental climatic effects. If the electric actuator is to be stored for a period longer that 3 years it is necessary, prior

to commissioning, to replace the oil filling. Any manipulation at temperatures below -25 °C is forbidden. The electric actuators

must not be stored outdoors or in rooms not protected against rain, snow and ice accretions. Excessive slushing grease

should be removed before the actuator is put into operation. If the unpacked electric actuators are to be stored for a period

longer than 3 months it is recommended to put a bag with silica gel or another suitable desiccant into the terminal box.

9.

ASSEMBLING AND PUTTING THE ELECTRIC ACTUATOR

INTO OPERATION

After receiving the actuators from the manufacturer, the customer should check whether they have not been damaged during

transportation. Check should be made whether data on the plates of the actuator agree with the order and with the accompanying

documentation. Possible discrepancies, defects and damages should be immediately reported to the supplier. In this case, the

actuator cannot be put into operation. If the unpacked actuator is not mounted immediately, it should be stored in a dust-free

room with temperature ranging between -25 °C and +50 °C and relative humidity up to 80 %; the room should be free of caustic

gases and vapours and protected against harmful climatic effects. Any manipulation at temperatures below -25 °C is prohibited.

The actuators must not be stored in the open area or in rooms not protected against rain, snow and frost. Surplus conserving

grease should be removed just before putting the actuator into operation. When unpacked actuators are to be stored for a period

longer than 3 months, it is recommended to insert a sachet with silicagel or another suitable desiccant under the actuator cover.

The user can only put into operation the electric devices in satisfactory conditions documented by a report on initial

revision. Before fitting, the actuator should be carefully inspected, particularly in case it has been stored for a longer time; the

following check should be made:

– conditions of parts and connections forming explosion-proof closure,

– insulation resistance of motor winding,

– absence of any damage to the actuator during storage.

It should again be verified whether placement corresponds to provisions of the paragraph “Working conditions”.

If different way of assembly is necessary due to local conditions, an agreement with the manufacturer is required.

The protective conductor must be connected to the protection terminal marked according to ČSN IEC 417. The actuator

is fitted with protection terminals on the frame and inside the actuator on the control panel at the terminal board.

Note: Before connecting and adjusting MODACT MO EEx servo motors in potentially explosive atmospheres

explosive gaseous atmosphere, it is necessary to pre-ventilate the installation of the actuator.

20

Insulation resistance

Before putting into operation or starting an actuator that has not been used for a longer period of time, it is necessary

to check whether insulation conditions have not been deteriorated and whether this cannot cause any risk of damaging to

the winding or an electric shock. Insulation conditions should also be checked during inspections in compliance with

provisions of ČSN 34 3205 and standards valid for explosion-proof electric devices. Insulation resistance of electric

control circuits against frame as well as against each other is min. 20 MΩ. Insulation resistance of the electric motor is

min 1.9 MΩ. Insulation resistance of the transmitter CPT 1Az is min. 20 MΩ with 50 V DC.

The actuators of lower insulation resistance must not be put into operation. The reason can be in a damaged winding

or excess humidity. Moist motors, the insulation resistance of which is lower than the specified value, must be carefully

dried before being put into operation. The purpose of drying the winding is to get rid of moisture from the insulation and

thus increase insulation resistance to the prescribed value. Drying can be carried out in various ways. Directives for

drying are laid down in the standard ČSN 35 0010 or local recommended methods can be used.

Přívod a zapojení

The inlet to the actuator and connection to its switching, protection and securing instruments can only be installed by

technicians with particular qualification who must follow pertaining standards and wiring diagrams as provided in these

Instructions for Use.

Inspect the completeness and functionality of the bushings before installation. The gland must be mounted without

any in the state in which it was delivered. Use lock nuts or securing glue against accidental clearance. For tightening

moments depending on the cables used, is in every case a fully responsible user. Both parts - sealing clutch and nut

- must be properly tightened. Insufficient or excessive tightening may affect the type of protection, leakage or power

characteristics of the bushing.

The actuator is connected according to the wiring diagram placed inside the enclosure so that the mains supply is

permanently connected good contact with connection terminals. The grid voltage must correspond to the voltage indicated on

theactuator performance label. The inside of the cover must be clean and dry. The wires connected must not have loose

wires.

After connecting the inlet cables, all screws of the connecting terminals should be checked for tightness so that they

do not get warm during operation due to increased transition resistance. The connecting terminals must not be under

tension or bending stress from the connected conductors. In case of connection with aluminium conductors the following

measures are recommended. One-step before connecting the conductor, the oxidized layer should be removed from the

conductor and new oxidation should be prevented by smearing the connection with a neutral vaseline.

After the connection, make sure, by short starting of the actuator in the intermediate position of the working stroke,

that the output shaft of the actuator rotates in a proper direction.

V, W terminals of the motor (actuator).

actuator is fitted to the valve and adjusted according to the paragraph Actuator Setting. The adjustment is best carried

out using the manual control mode.

Then, repeat the functional check. After verifying correct electric connection, the

If it is not, then we will transfer some two wires on the U,

Important warning!

During adjusting, repair, and maintenance, secure the actuator in the prescribed way in order to rule out its conne-

ction to the power supply and thus to prevent possibility of an injury due to electric shock or the actuator rotation.

After adjusting the actuator check its function by means of the control circuit. Especially check whether the servo

actuator correctly starts up and whether the electric motor after turning off the respective relay is not energized. If not,

switch off the actuator power supply off immediately to prevent damage to the electric motor, and find the case of the fault.

10. ADJUSTMENT OF ELECTRIC ACTUATOR WITH VALVE

After fitting the electric actuator on the valve and checking its mechanical connection, the setting and adjusting is

carried out as follows:

1) Bring the electric actuator manually into an intermediate position.

2) Connect the actuator to the supply mains and check a correct sense of rotation of the output shaft by a short start

in the middle of the working stroke. When viewing into the control box the output shaft should rotate clockwise

in the CLOSE direction.

3) Bring the actuator electrically near to the CLOSE position and complete adjustment to the CLOSE position by

means of the handwheel. In this CLOSE position set the position-limit switching unit (CLOSE position-limit switch

PZ) according to Point 7c and the potentiometer or current transmitter according to Point 7e.

4)

Bring the output shaft into the position where the signalling switch SZ should change over. Adjustment of the CLOSE

signalling switch SZ is carried out according to Point 7b.

21

5) Move the output shaft round by a required number of turn and adjust the OPEN position-limit switch PO according

to Point 7c and the potentiometer according to Point 7e. Adjustment of the position-limit and signalling switches, and

the position transmitter should be checked repeatedly.

6)

Bring the output shaft into the position where the signalling switch SO should change over. Adjustment of the OPEN

signalling switch SO is carried out according to Point 7b.

Caution!

When fitting the valve into piping, the valve should be set into its intermediate position using the electric actuator

handwheel. By short starting of the electric motor make sure that the actuator rotates in correct direction. If this is not

the case, reverse mutually two phase conductors in the electric motor terminal board.

11. OPERATION AND MAINTENANCE

Operation of rotary electric actuators is based on working conditions and is usually limited to transmission of pulses to respective functions. In case of a power supply failure, readjust the controlled device by the handwheel. If the electric actuator is

connected into the automatic circuit (which does not imply the regulating mode) it is recommend to install devices for manual

remote control into the circuit so that the electric actuator can be controlled even in case of a failure of the automatic device.

The operator should ensure that the electric actuator receives a prescribed maintenance, that it is protected against detrimental

effects of the environment and climatic conditions which are not specifiedin the paragraph “Operating conditions”. Moreover, care

should be taken to ensure that excessive heating-up of the surface of the explosion-proof closure of the motor and control box

is prevented. It is necessary to make sure that rated values are not exceeded and excessive actuator vibrations are prevented.

Furthermore, care should be taken not to overheat the surface of the electric motor, the power gear and the fixed

engine breech and control cabinets. Be careful not to exceed the label values and excessive vibration of the actuator.

The safe working life of the bearings is 25,000 hours of operation, after which it has to be replaced. Unwanted and the

damaged gearbox may be the source of a hot surface with a risk of ignition. Therefore, it is necessary once weekly check

the noise, oil leakage from the gearbox, or even the surface temperature of the cabinet.

Lubrication

The actuators are lubricated with plastic consistent lubricants or gearbox oil PP 80 (see Table 1 or 2).

Lubricants

Type number

of actuator

52 120, 52 121, 52 122

52 123, 52 124

52 125

Note: M – plastic lubricant; O – gearbox oil

of output shaft

above 40 O O

Adjusting speed

[min-1]

up to 40 M M

applies to all speeds

Surrounding temperature

-25 -50

O O

+60 +60

[°C]

Actuators with plastic lubricant

The types of lubricant and amounts are listed in the table.

Lubricants in the drive units supplied are designed to last the entire useful life of the unit.

During the time when the drive units are in use, it is not necessary to change or monitor the amount of the lubricant.

The actuators with plastic lubricant are labelled “Filled: solid grease” on the power box at the side of

the hand-wheel.

Type of lubricant for specific climatic conditions and temperature

Type number

of drive unit

Amount of lubricant

(kg)

T1

(-25 – +75 °C)

U1

(-40 – +55 °C)

UCHL1

(-50 – +55 °C)

CHL1

(-60 – +40 °C)

52 120 0,30

52 121, 52 122 0,50

52 123, 52 124 0,70

Note: The Ciatim 221 lubricant is designed for the friction points of rubber bushings against metal surfaces, roller brake, the hub

of an outer cogged wheel of a planetary-gear differential (for locations of friction between the shaft and other surfaces).

CIATIM – 201 GOST 6267-74