Page 1

EC-EX10/I

Eclipse 10 Zone Expander

Installation Instructions

1. Introduction

The EC-EX10/I is supplied in a stylish plastic enclosure and is

connected to the 4-wire control panel network to provide an

additional 10 zones.

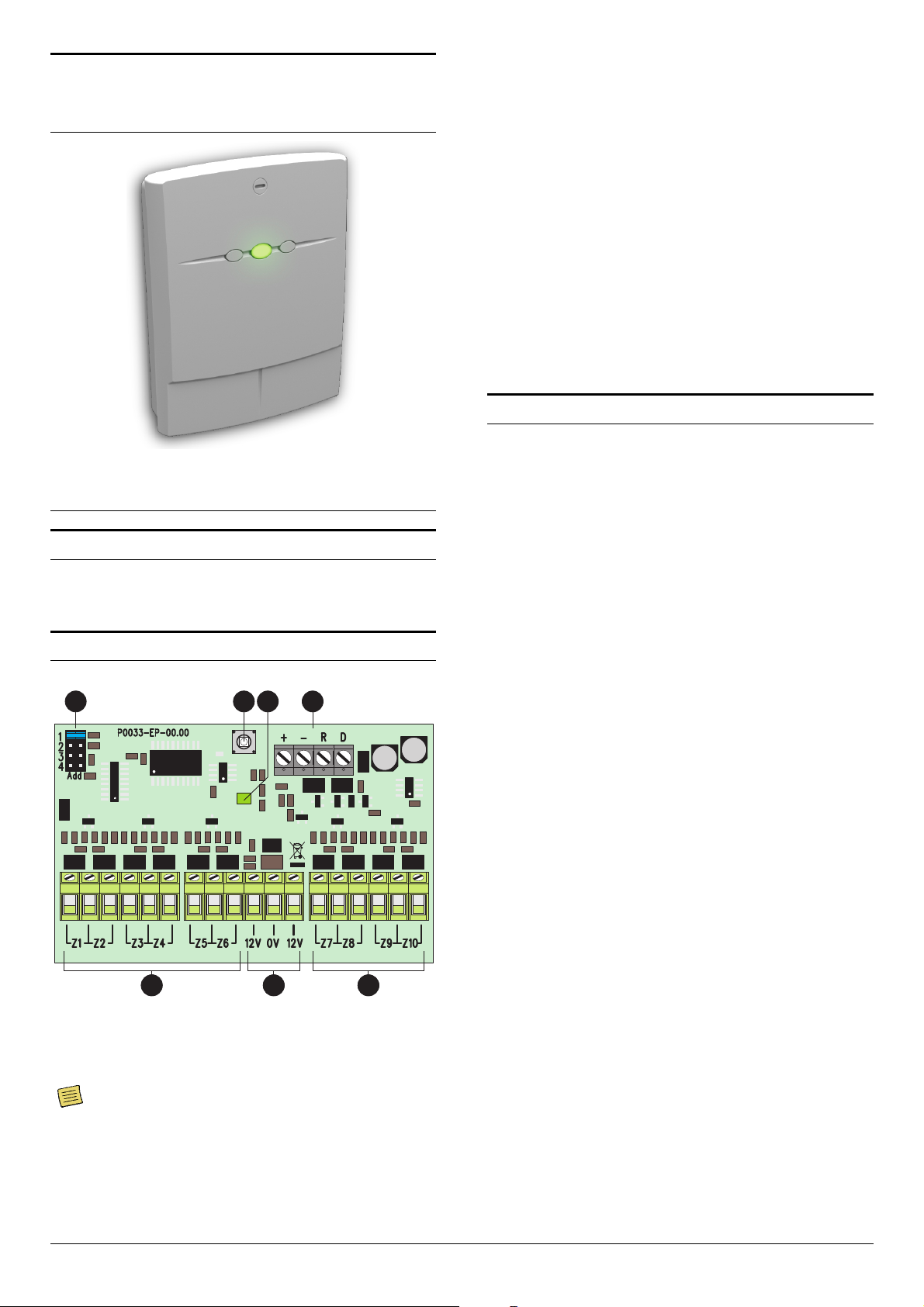

2. PCB Layout & Connections

The figure below shows the PCB layout for the EC-EX10/I:

3

2

75 7576

1. Address Selector

Each expander must be assigned a different address using the

address selector. Move the jumper to the required position 1, 2,

3 or 4.

Zone Expanders and Zone & Output Expanders use the

same address slot. Therefore, each zone expander,

which ever type must be assigned a unique address.

2. Lid Tamper

The lid tamper detection switch. The tamper protection can be

disabled at the control panel, please refer to the control panel

installation manual.

41

3. Status Indicator

This LED normally indicates the power status of the system and

is lit green when the power is healthy. The indicator will also

flash the expander address when the system is in engineer’s

mode.

4. Network

These four connections must be connected to the control panel

network, or the “Network Out” of another Zone & Output

expander.

5. Zone Inputs

These terminals provide the zone inputs for detection devices.

Both the zone type and the wiring configuration are

programmable by the control panel. Please refer to the control

panel installation manual. The power for detection devices

should be taken from the auxiliary 12V terminals.

6. Auxiliary 12V

These terminals provide auxiliary power for powering detection

devices.

3. Installation

Please follow the installation sequence below:

1. Remove the screw cap by using a large flat blade screw

driver, then undo the cover screw using a suitable pozi-drive

screwdriver and remove the cover.

2. Position the expander in the require position and mark the

four securing holes in each corner.

3. Drill and plug the holes then secure the expander with

suitable fixings.

4. Route the network and zone cables into the housing

through the cable entries provided.

5. Connect the detection devices to the Zone Inputs and

Auxiliary 12V.

6. Connect the network cable to the Network terminals.

7. Set the Address Selector to the required position.

8. Apply power to system and confirm the new expander is

being recognised by the control panel. See “Confirm

Devices” in the control panel installation manual.

9. Test the operation of the zones then finally replace cover.

P0033-LI-01.00 1

Page 2

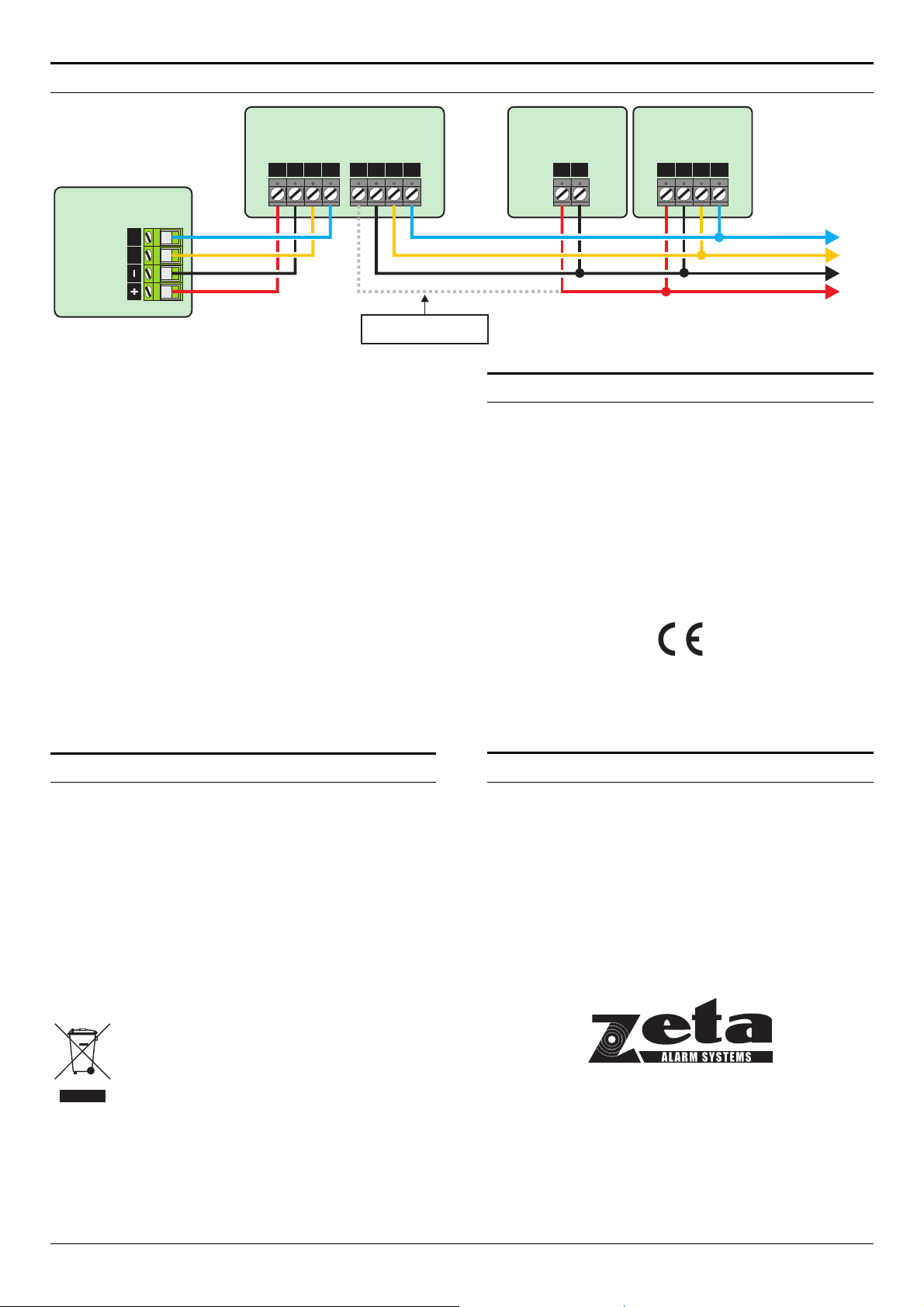

4. Network Wiring

Zone & Output Expander

Address = 1

IN OUT

12V

0V

RD

12V

0V

RD

Control Panel

RD

Network

Disconnect +12V

Remote keypads and expanders are all connected to the same

network terminals located at the bottom left hand corner of the

control panel and may be connected serially (daisy chain), in

parallel (star) or any combination of the two.

Network Voltage Drop

When devices are on long cable runs or the current being drawn

from the network is high, the voltage at the expander or keypad

will drop due to the impedance of the cable. There are several

ways to reduce the level of voltage drop in a network:

f Use thicker lower resistance cable. Standard 7/0.2 alarm

cable has a resistance of 8Ω per 100m

f Double up on the power connections – this will require

using a 6 or 8-core cable rather than a 4-core cable

f Install a power supply to power the device locally

12V Power

Supply

0V

12V

Zone Expander

Address = 2

0V

RD

12V

To additional devices

6. Standards

Safety

Conforms to European Union (EU) Low Voltage Directive (LVD)

2006/95/EC.

EMC

Conforms to European Union (EU) Electro-Magnetic Compatibility

(EMC) Directive 2004/108/EC.

Security

Conforms to EN 50131-1 and EN 50131-3 Grade 2,

Environmental Class IV.

Installing a Power Supply

When a power supply is installed, the 0V connections on the

power supply must be connected through to 0V on the control

panel and the +12V connection between the control panel or

previous device must be disconnected, see figure above.

5. Specifications

Electrical

Voltage: 10 - 16VDC.

Current: 30mA

Zone Inputs: 10 fully programmable

Auxiliary 12V: Protected by 1Amp electronic fuse (PTC)

Environmental

Operating Temp.: -25°C to +55°C (-13°F to +131°F).

Storage Temp.: -25°C to +60°C (-13°F to +140°F).

Max. Humidity: 95% non-condensing.

EMC: Residential, commercial and light

industrial.

Do not throw away the product with the

normal household waste at the end of its

life, but hand it in at an official collection

point for recycling.

Physical

Dimensions: 136.0mm x 174.0mm x 35.0mm.

Packed Weight: 250g.

The CE mark indicates that the EC-EX10/I complies with the

European requirements for safety, health, environment and

customer protection.

7. Warranty

Zeta Alarm Systems by GLT Exports Ltd products are carefully

designed to provide reliable problem-free operation. Product

quality is carefully controlled during all manufacturing

processes. The EC-EX10/I is covered against defects in material

or faulty workmanship for a period of 2 years from the date of

purchase. Due to our policy of continuous product

improvement, Zeta Alarm Systems by GLT Exports Ltd reserves

the right to change specification without prior notice.

As the EC-EX10/I is not a complete intruder alarm systems, but

only part of it, Zeta Alarm Systems by GLT Exports Ltd does not

accept responsibility or liability for any damages whatsoever

based on any claim that the unit failed to function correctly.

Technical Support

Email: support@zetaalarmsystems.com

2 P0033-LI-01.00

Loading...

Loading...