DigiTract 4

Two Stage Heat/Cool

Comfort Control System

Installation Guide

Part #DT4MAN

Zoning Systems

That’s all we do.

Rev. October 2013

TABLE OF CONTENTS...................................................................................................................................................................Page

INTRODUCTION.......................................................................................................................................................................................................1

SYSTEM DESCRIPTION...........................................................................................................................................................................................1

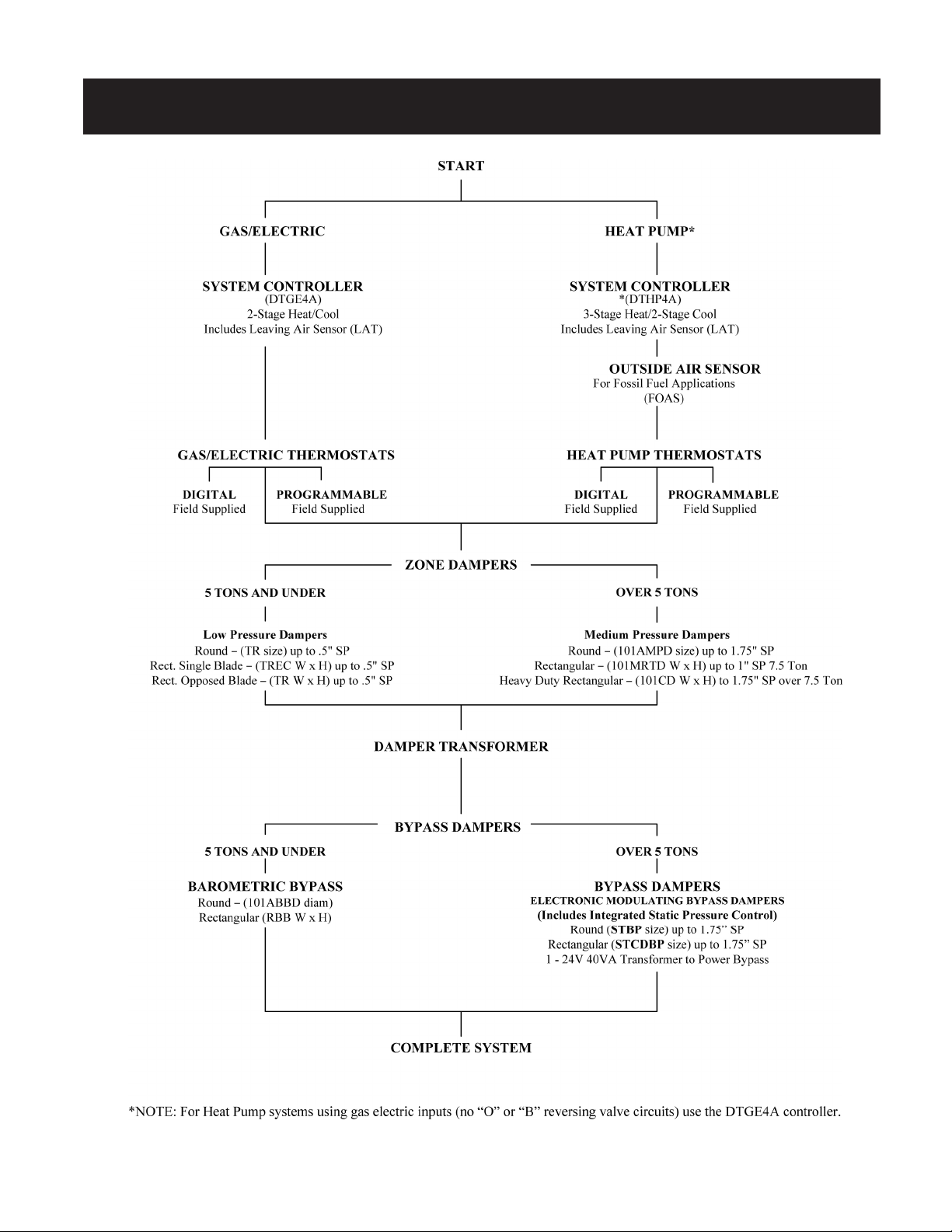

COMPONENT SELECTION GUIDE ..........................................................................................................................................................................2

WIRING

Gas/Electric DTGE4A ..........................................................................................................................................................................................3

Heat Pump DTHP4A ...........................................................................................................................................................................................4

Zone Dampers....................................................................................................................................................................................................5

SYSTEM CONTROLLERS

Gas/Electric DTGE4A

Operation...........................................................................................................................................................................................6

Status Lights .......................................................................................................................................................................................6

Components.......................................................................................................................................................................................7

Heat Pump DTHP4A

Operation...........................................................................................................................................................................................8

Status Lights .......................................................................................................................................................................................9

Components..................................................................................................................................................................................9-10

Fossil Fuel Application .....................................................................................................................................................................11

CAPACITY CONTROLLERS

Gas/Electric DTGE4A........................................................................................................................................................................11

Heat Pump DTHP4A.........................................................................................................................................................................11

Capacity Control and Staging............................................................................................................................................................11

ZONE DAMPERS

Round.........................................................................................................................................................................................................13-14

Rectangular.................................................................................................................................................................................................15-16

Installation Notes..............................................................................................................................................................................................17

BYPASS DAMPERS

Barometric..................................................................................................................................................................................................17-18

Electronic ...................................................................................................................................................................................................19-20

SYSTEM STARTUP

LAT and OAS Installation ..................................................................................................................................................................12

Bypass Damper with Integrated Pressure Control.........................................................................................................................................21-22

DAMPER TRANSFORMER .....................................................................................................................................................................................23

Gas/Electric DTGE4A...................................................................................................................................................................................23-24

Heat Pump DTHP4A .........................................................................................................................................................................................24

Troubleshooting / Service Checks.....................................................................................................................................................................25

LAT Voltage – Temperature Conversion Chart..................................................................................................................................................25

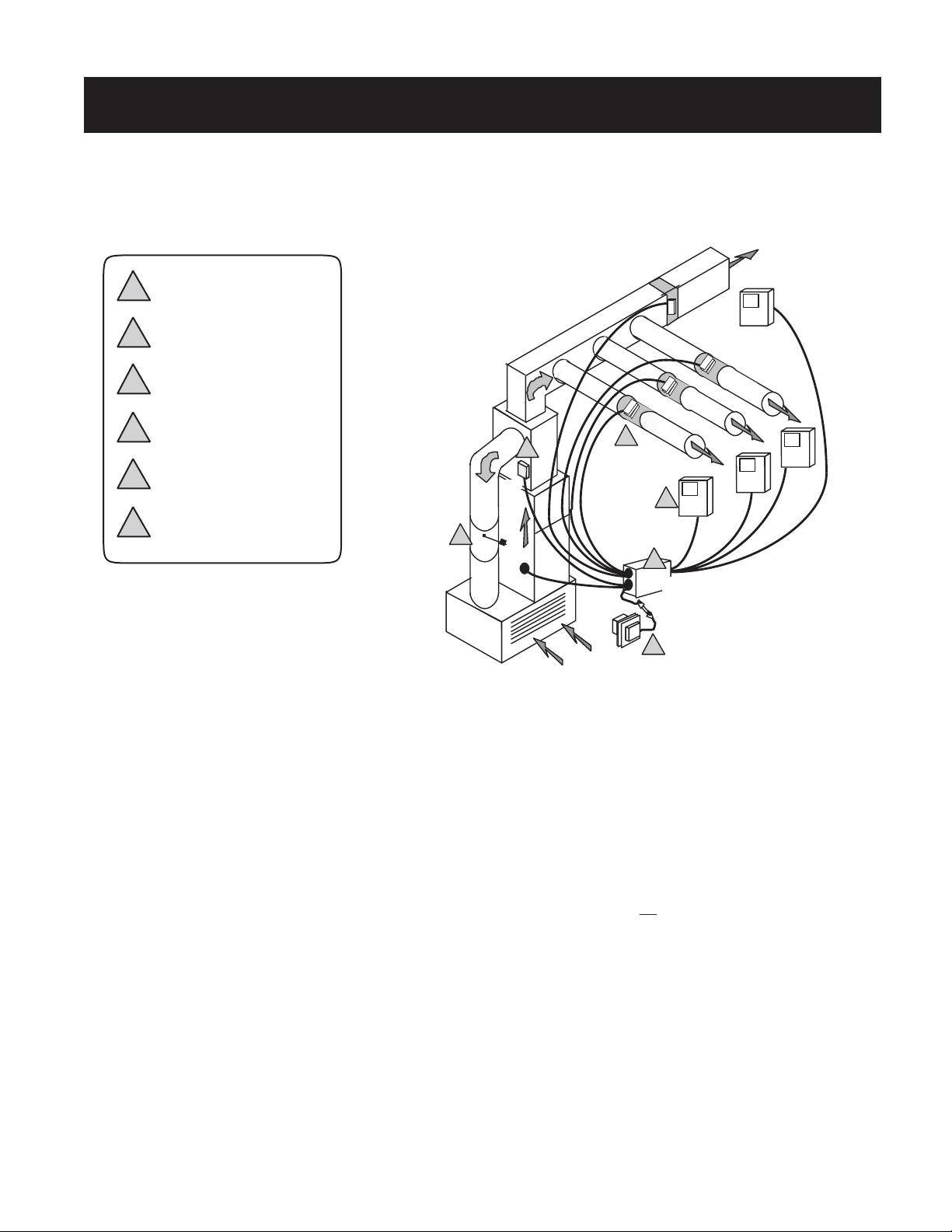

The Digitract 4 zoning system enables up to four room thermostats to control a single HVAC system. This permits superior building temperature control

over a standard single thermostat. Any generic thermostat may be used on this control system. When using digital thermostats, they must have “C”

terminal for common or be battery powered. Both Programmable and Non-Programmable thermostats can be used. This system is designed to be

installed and serviced by qualified licensed professionals.

INTRODUCTION

SYSTEM DESCRIPTION

The Digitract 4 zoning system consists of a 2-stage System Controller

with built-in Capacity Control (leaving air sensor), Zone Dampers, Zone

Thermostats, Bypass Damper and Damper Transformer.

The System Controller is the heart of the Digitract 4 zoning system. It

monitors the leaving air temperature, zone thermostats and controls the

HVAC System and zone dampers. See pages 6 to 10 for further information.

trol feature of the System Controller. It is a sensor placed in the supply

air of the HVAC system. The sensor monitors the supply air temperature of the HVAC system and sends this information to the System

Controller. The System Controller uses this information to stage and temporarily cycle the HVAC system off if the leaving air gets too hot in heat

mode or too cold in cool mode. For heat pumps, this input is also

used to control the auxiliary heat. See Capacity Controller section, page

Balance Point is used for fossil fuel applications when an FOAS is

applied. The balance point feature will lock out compressor and enable

gas furnace when outside air temperature drops below BP (balance

point) setting.

The Zone Dampers are air valves placed in the forced air duct work

for each zone. They are controlled by the System Controller. While the

HVAC system is running, the zone dampers for any zone thermostats not

calling will close and zone dampers for the zones calling will remain

open. Conditioned air is only directed to the zones needing it. See pages

13 to 17 for further information.

The Zone Thermostats monitor the room temperature of each zone

and compare it to the heat and cool setpoints stored in them. If the room

temperature drops below the heat setpoint, the zone thermostat makes

a heat call telling the System Controller that zone needs heating. If the

room temperature rises above the cool setpoint, that thermostat makes

a cool call telling the System Controller that zone needs cooling.

Two-stage thermostats are not required with the Digitract 4 System. The

System Controller will cycle staging and auxiliary strip heat based on

The Bypass Damper is a pressure relief valve placed between the

supply and return ducts of the forced air duct work. As zone dampers

start closing, the bypass damper will open and divert some of the supply

air to the return. This prevents a pressure buildup in the supply duct

which can cause fan cavitation, excessive air velocities, and excessive

Damper Transformer. Wired to TR1 and TR2 on the System Controller.

Powers the zone dampers only. Requires an in-line fuse. See Damper

*The Digitract 4 was designed for both residential and

commercial applications of 4 or less zones. The full

spectrum of supply dampers can be applied, from low

pressure; medium pressure; and heavy duty; round and

rectangular.

System Controller

1

Leaving Air Sensor

2

ZONE 4

73

Zone Damper

3

Zone Thermostat

4

Bypass Damper

5

Damper

6

Transformer

The Leaving Air Sensor (LAT) is part of the staging and capacity con-

11, for further information.

ZONE 3

ZONE 2

ZONE 1

2

LAT

5

3

73

4

1

73

73

DIGITRACT 4

System Controller

6

Fused 24V Transformer

leaving air temperature and time.

zone damper blow-by. See pages 17 to 22 for further information.

Transformer section, page 23.

1

Digitract 4 COMPONENT SELECTION GUIDE

2

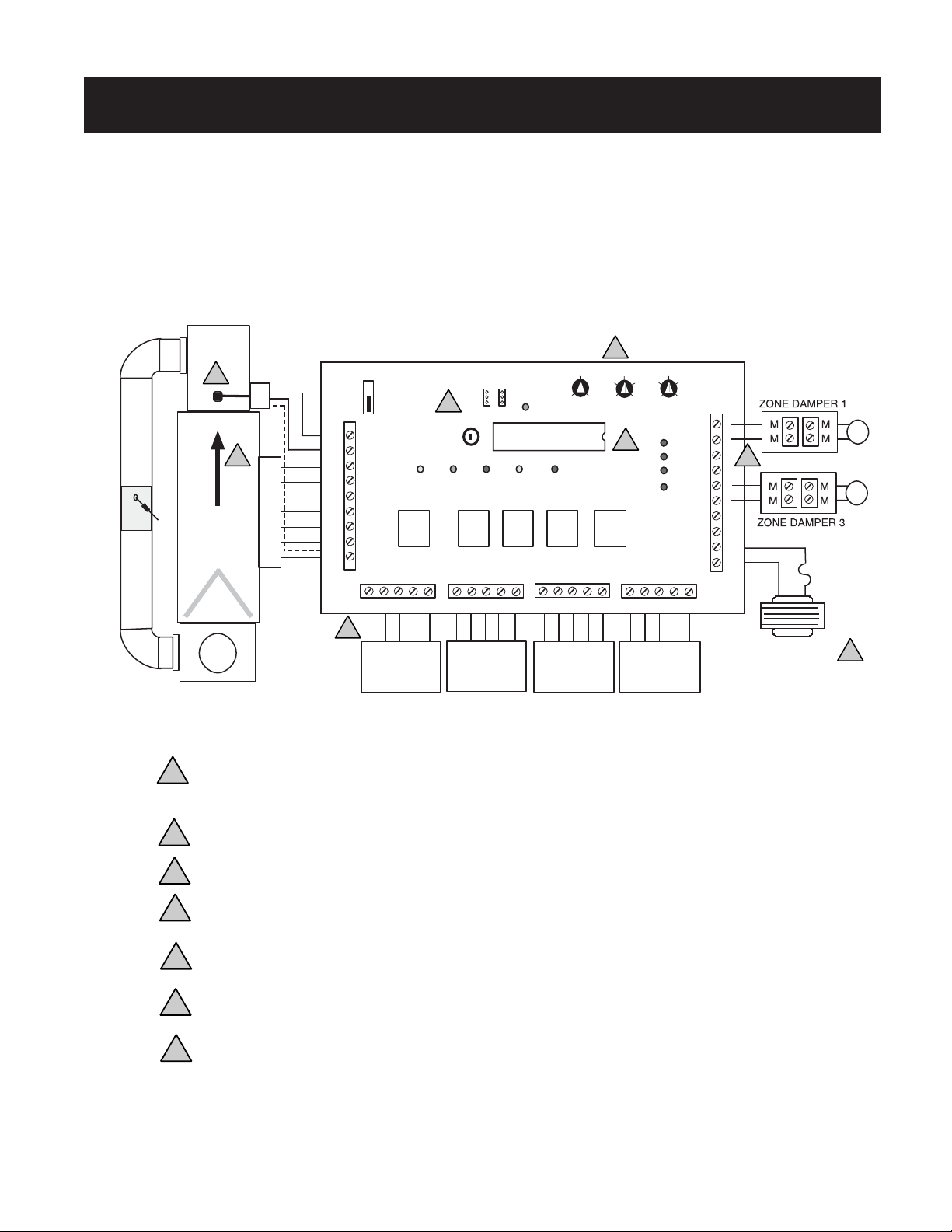

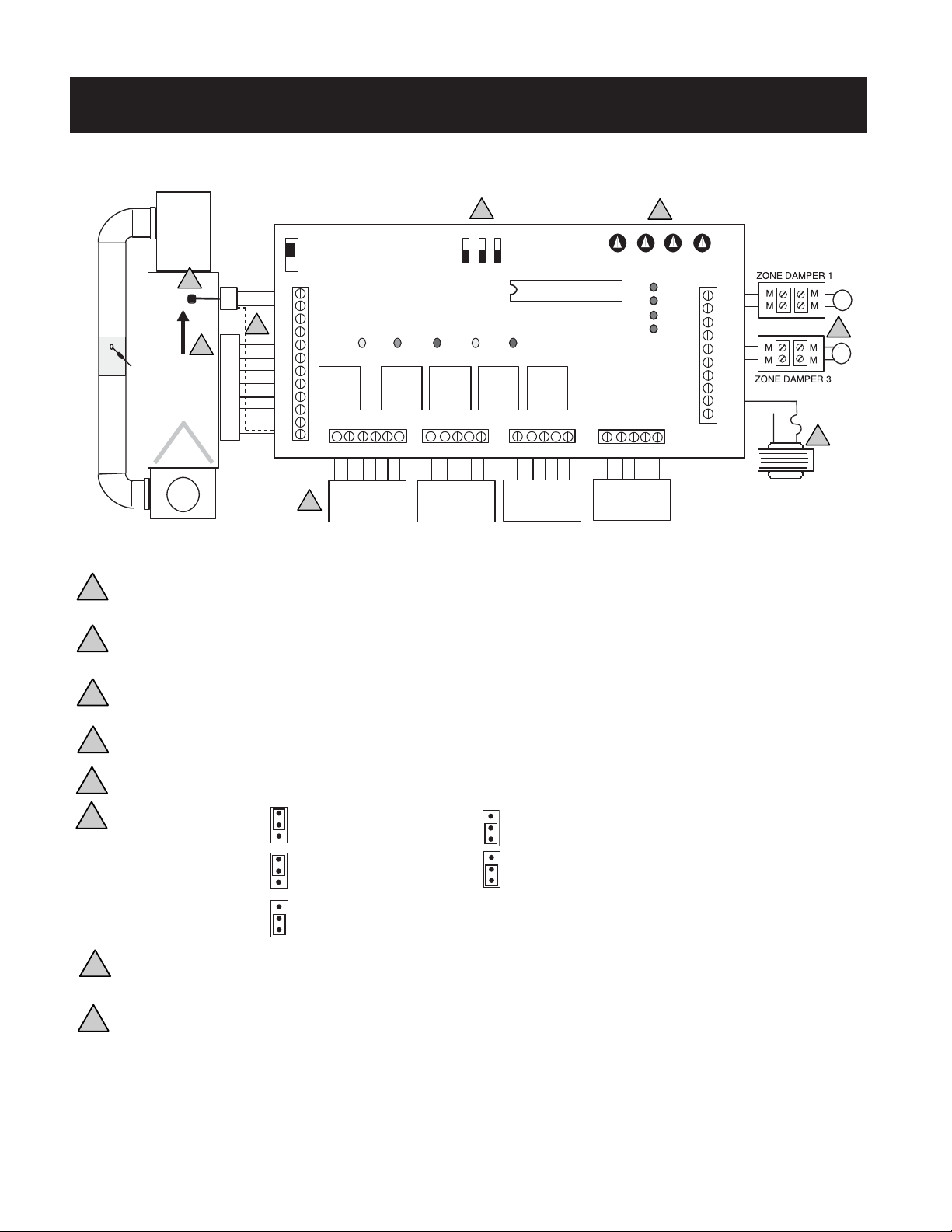

WIRING – GAS/ELECTRIC DTGE4A

Use minimum 18 gauge for all wiring.

All wiring must meet state and local codes.

Zone damper terminals. Refer to “Wiring – Zone Dampers” section, page 5.

Connect W2 and Y2 of the DTGE4A only if there are two heat and/or two cool stages.

Most thermostats are compatible with the DigiTract 4.

Zone damper terminals. Refer to “WIRING – ZONE DAMPERS” on page 5.

Install one 24V AC transformer, sized and fused for the total number of zone dampers. See “DAMPER

Fan cycling jumper: Bottom position = FAU fan control; Upper position = energized fan on heat call (JPI not used)

Adjustable potentiometers:

• HI – To establish HI cutout for furnace protection and staging temperatures – must be field adjusted to 120°

for HP applications.

• LO – To establish LO cutout, to protect freezing of coil, to set up staging for compressors

• TIME – To establish changeover time when opposite calls will be recognized by controller

Digitract 4 Gas/Electric 2-Stage Heat/Cool

HVAC unit and LAT terminals. Do not connect Y2 or W2 for single stage heat/cool systems.

BYPASS

DAMPER

LAT

SENSOR

1

ON

OFF

S

LAT

}

S

Y2

W1

G

W2

Y1

R

C

UNIT TERMINALS

AIRFLOW

2

Y2

W1

G

W2

Y1

R

C

W R Y G C

3

ZONE 1

THERMOSTAT

LAT. Locate the leaving air sensor in the supply air stream, as far from the coil/heat exchanger as possible

1

before the bypass takeoff. Do not locate the LAT downstream of the bypass takeoff. Refer to "CAPACITY

Zonex DigiTract GE

6

JP1

R11

Y1 G W1 Y2 W2

STAT 1 STAT 2

W R Y G C W R Y G C W R Y G C

W R Y G C

ZONE 2

THERMOSTAT

JP2

PWR

DTGE4A

W R Y G C

ZONE 3

THERMOSTAT

40

STAT 3

7

135

45

125

50

115

LO HI

15

10

145

25

155

5

TIME

3

DPR 1

DPR 2

DPR 3

DPR 4

STAT 4

W R Y G CW R Y G C

ZONE 4

THERMOSTAT

20

CONTROLLER-LAT INSTALLATION” on page 12 for further information.

DAMPER

1

1

2

2

3

3

4

4

TR1

TR2

4

24V AC Transformer

to Power Dampers

5

2

3

4

5

TRANSFORMER” on page 23.

6

7

3

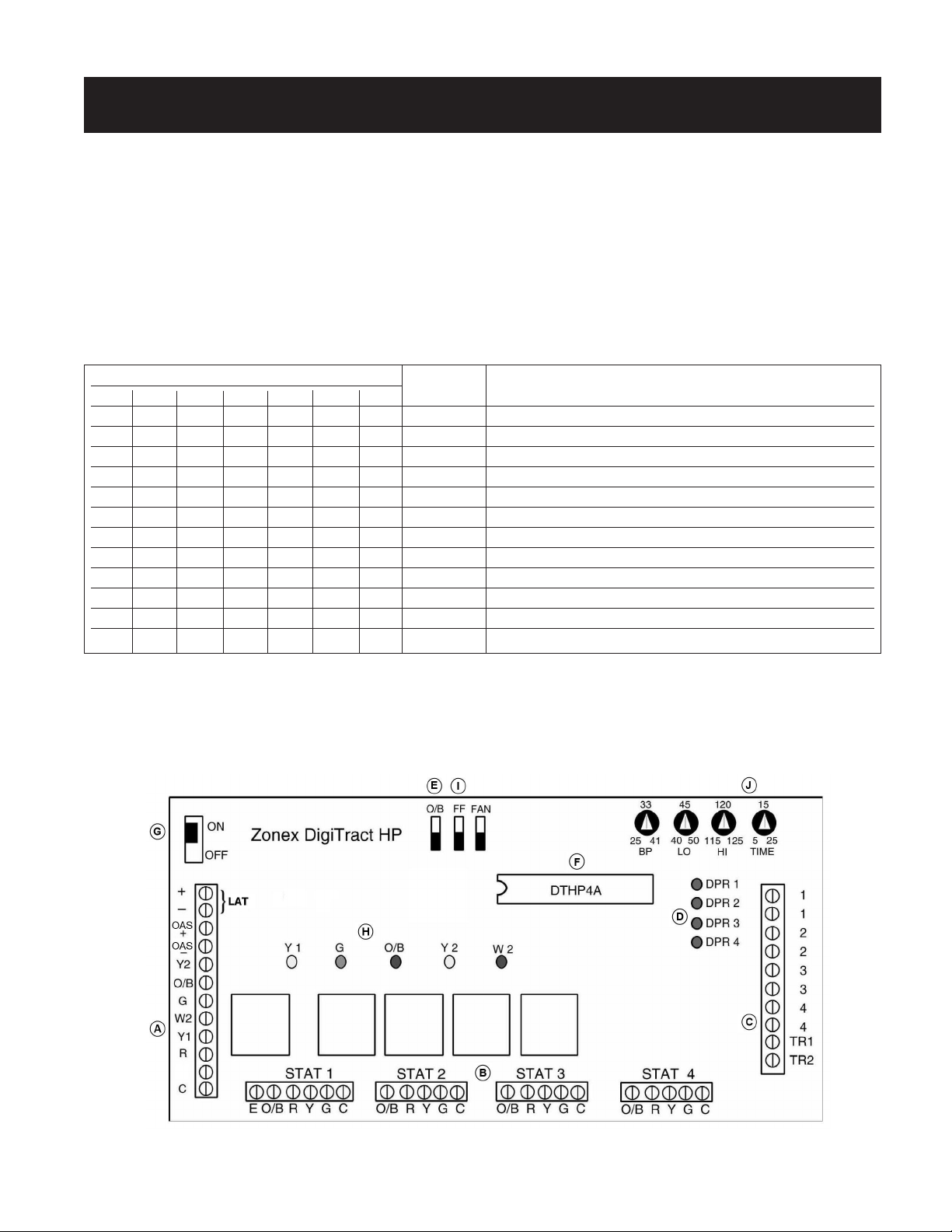

WIRING – HEAT PUMP DTHP4A

1

2

3

4

5

6

7

8

Digitract 4 HP 3-Stage Heat/2-Stage Cool

Connect W2 from the controller to the unit’s electric heat stage terminal designation. It is recommended to install an outdoor thermostat

for non-fossil fuel applications.

Most heat pump thermostats are compatible; 1C/2H.

NOTE: Some combination thermostats do not have an E terminal. Connect W2 of the thermostat to the E terminal of STAT 1 terminal block.

Zone damper terminals. Refer to “WIRING – ZONE DAMPERS” on page 5.

Reversing valve jumper:

Fossil fuel jumper:

Fan jumper:

FOAS – Outdoor Air Sensor used to sense Balance Point temperature for auto-changeover, fossil fuel application only. Use FOAS only; not

HP outdoor thermostat.

Adjustable potentiometers:

• BP – To establish temperature that locks out heat pump and energizes fossil fuel furnace

• HI – To establish HI cutout for furnace protection and staging temperatures

• LO – To establish LO cutout, to protect freezing of coil, to set up staging for compressors

• TIME – To establish changeover time when opposite calls will be recognized by controller

B-Mode –

energize for heat

O Mode –

energize for cool

Fossil Fuel Application

Not Used

Normal HP Operation

ON

Zonex DigiTract HP

OFF

LAT

}

Y 1 G O/B Y 2

STAT 1

E O/B R Y G C

BYPASS

DAMPER

AIRFLOW

LAT

SENSOR

Y2

O/B

G

W2

Y1

R

C

OAS

OAS

O/B

W2

+

–

+

–

Y2

G

Y1

R

C

S TAT 2

O/B FF

FAN

W 2

O/B R Y G CO/B R Y G C

S TAT 3

DTHP4A

33

45

40 50

25 41

LOBP

STAT 4

O/B R Y G C

120

115 125

HI

DPR 1

DPR 2

DPR 3

DPR 4

5 25

TIME

15

1

1

2

2

3

3

4

4

TR1

TR2

E O/B R Y G C

ZONE 1

THERMOSTAT

O/B R Y G C

ZONE 2

THERMOSTAT

O/B R Y G C

ZONE 3

THERMOSTAT

O/B R Y G C

ZONE 4

THERMOSTAT

24V AC Transformer

to Power Dampers

LAT. Locate the leaving air sensor between the refrigerant coil and the electric heat coil(s) or other auxiliary heat source. Refer to

“CAPACITY CONTROLLER – LAT INSTALLATION” page 12, for further information.

2

3

4

Install one 24V AC transformer, sized and fused for the total number of zone dampers. See “DAMPER TRANSFORMER” on page 23.

5

6

7

8

4

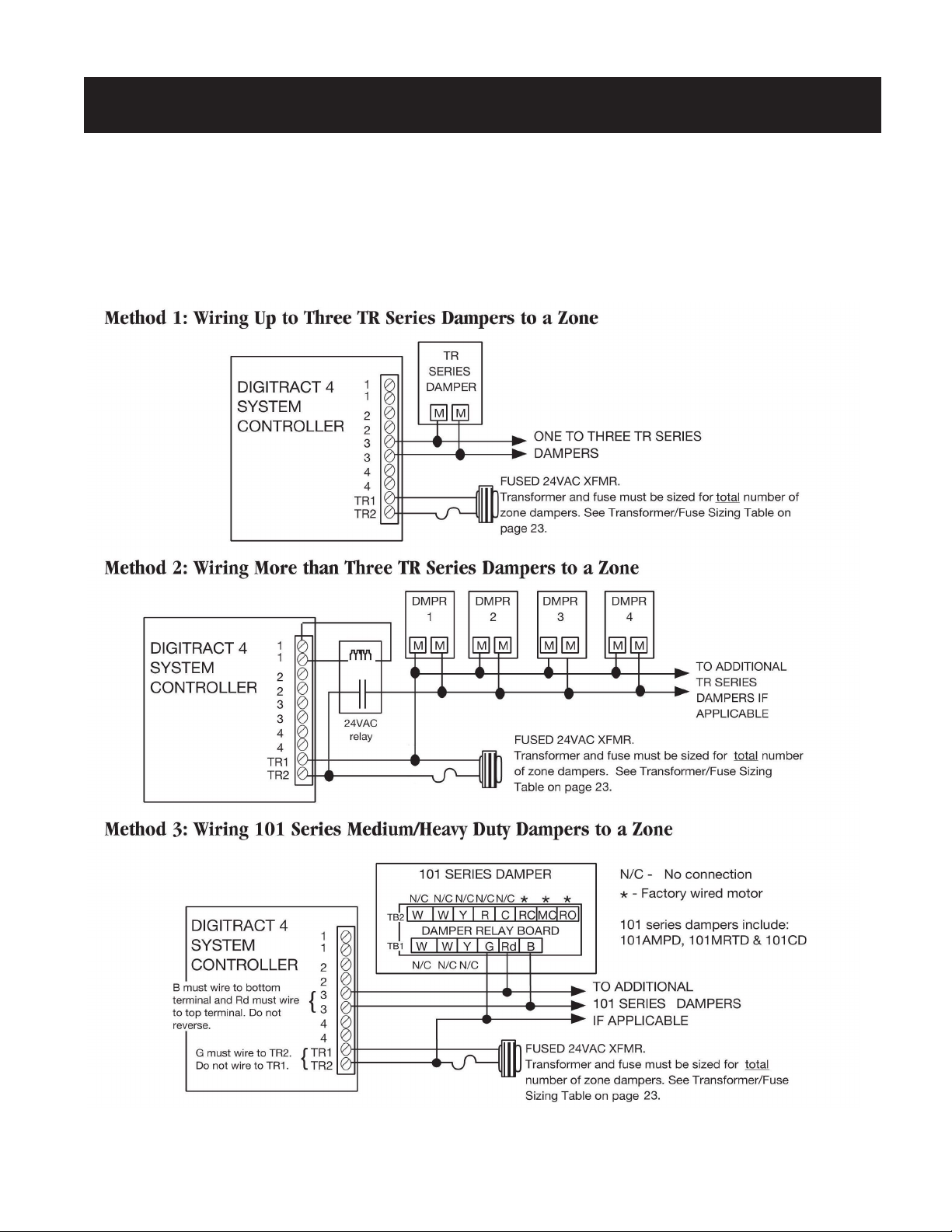

WIRING – ZONE DAMPERS

There are three methods of wiring the zone dampers. If necessary, you

can mix wiring methods on different zones to suit your application.

Method 1: When wiring one to three TR/TREC series dampers to

a zone.

Method 2: When wiring more than three TR/TREC series dampers to a

zone, use a 24V ac, SPNO relay.

Method 3: When using 101AMPD or 101CD series dampers with a

DigiTract controller. Note: 101 series medium pressure dampers are

required for all systems over 5 tons. Refer to Parts Selection Table,

page 13.

5

The DigiTract Controller is the heart of the DigiTract zoning system. It

is an auto changeover, home run system with a built in staging and

capacity controller. The function of the system controller is to receive

calls from the zone thermostats, operate the HVAC system in either heat

or cool mode and close the damper(s)of zones not calling for the operating mode. The mode of operation is determined by the first call

received. If the thermostats are calling for opposite modes, a

changeover sequence will start. Based on the Time Setpoint setting, a

changeover will occur after time delay. Changeover will continue as long

as there are opposing calls. The built in Capacity Controller maintains

the supply air temperature within an operation range to prevent freeze

ups and overheating. For Heat Pumps, the DTHP4A System Controller

will also control the auxiliary heat.

The Digitract 4 controller is not to be subjected to temperatures below

33°F or above 160°F. The controllers must not be installed in atmospheres that could create condensation or corrosion. Warranty is voided

on controllers that fail due to moisture or corrosion evidenced on the

circuit board. The operating voltage range on the Digitract 4 controllers

is 24 vac to 28 vac.

The DigiTract 4 is available in two models, Gas Electric 2-Stage

Heat/Cool and Heat Pump 3 stage Heat/2 Stage Cool with integrated fossil

fuel control.

NOTE: For Heat Pump systems using gas electric inputs (no “O” or “B”

reversing valve circuits) use the DTGE4A controller.

SYSTEM CONTROLLERS

SYSTEM CONTROLLER – GAS/ELECTRIC DTGE4A

OPERATION

The System Controller will initially run in the mode requested by the first

calling zone thermostat.

Cool mode – When running in the cool mode, the System Controller

energizes the compressor(s) and indoor blower. This is indicated by the

corresponding Y and G LEDs illuminating. Dampers for the zones not

calling for cool are powered closed and the dampers for the zones calling

for cool are left open. This is indicated by the DPR LEDs. If the DPR LED

is illuminated on the damper terminal strip and damper terminal board, the

corresponding damper is closed. The system will continue to run in the

cool mode until all calls are satisfied or changeover occurs. When all calls

are satisfied or prior to changeover, the system will go into a purge mode.

Heat mode – When running in the heat mode, the System Controller

energizes the heat stage (s), indicated by the W LEDs illuminating. If the

a call for heat, indicated by the G LED illuminating. Dampers for the

zones not calling for heat are powered closed and the dampers for the

zones calling for heat are left open. This is indicated by the DPR LEDs.

If a DPR LED is on, the corresponding damper to the LED is being

powered closed. The system will continue to run in the heat mode until

all calls are satisfied or changeover occurs. When all calls are satisfied

or prior to changeover, the system will go into purge mode.

Changeover – While the system is operating in one mode, and the

System Controller receives a call for the opposite mode, the System

Controller will continue to run in the current mode until the changeover

TIME limit has been reached, or all current calls have been satisfied.

Then the System Controller will go into a purge mode for 4 minutes,

then change over to the new mode

Purge mode – Purge mode is initiated after the last calling zone is

satisfied, or when the controller goes into a forced changeover. All HVAC

output LEDs on the controller go off during this cycle. When the last calling

zone thermostat satisfies, the Digitract controller goes into a four-minute

purge cycle. During this time delay all controller outputs to the HVAC

system and dampers are terminated. All dampers go to a full openp osition

and the HVAC system fan delay control runs the blower for a time. This

time delay with no control outputs allows the supply duct to return to

ambient temperature before the next call is initiated.

When the controller goes into a force mode changeover, and the initial call

drops out to the purge cycle, the HVAC outputs are terminated, and the initial zone damper remains open for a 4-minute delay with the other dampers

closing. The HVAC system fan control allows the blower to run for a time,

and the initial calling zone supply duct returns to ambient temperature.

Ventilation– When no zones are calling, all zone dampers are open.

During this time, if any thermostat has the fan switch ON then the indoor

blower is energized (G made to R) and the G LED is on. This provides

ventilation to all zones.

Fan Control Jumper is in the JP2 position, the blower will energize with

6

W1: First stage heat. When energized (W1 made to R),

energizes first-stage heat.

W2: Second stage heat. When energized (W2 made to R),

energizes second-stage heat.

G: Blower. When energized (G made to R),

energizes the indoor blower.

Y1: First stage cool. When energized (Y1 made to R),

energizes first stage cooling.

Y2: Second stage cool. When energized (Y2 made to R),

energizes second stage cooling.

R: HVAC unit 24V power. Powers the Digitract 4 board

and zone thermostats.

C: HVAC unit 24V power return.

B. Thermostat Terminals – Connects up to four zone

thermostats.

W: Heat call. When energized (W made to R),

requests the Digitract 4 to run in heat mode.

R: HVAC unit 24V power.

Y: Cool call. When energized (Y made to R),

requests the Digitract 4 to run in cool mode.

G: Blower Fan- When energized (G made to R), requests the

DigiTract 4 to turn on the indoor blower fan.

C: HVAC unit 24V common.

C. Damper Terminals – Connects dampers for up to four zones and

damper power supply.

TR1/TR2: 24V AC transformer terminals. This transformer powers

only the zone dampers.

1 1: Zone damper 1.

When energized, powers zone damper 1 closed.

2 2: Zone damper 2.

When energized, powers zone damper 2 closed.

3 3: Zone damper 3.

When energized, powers zone damper 3 closed.

4 4: Zone damper 4.

When energized, powers zone damper 4 closed.

D. Damper Status LEDs – On when corresponding zone damper is

being powered closed.

E. Board Number – This number indicates the circuit board number

and revision. You must know this number if conferring with technical support.

F. Special Function Jumpers

JP1 – Not used.

place the jumper over the top and middle jumper pins. Controller is shipped

with the jumper on the middle and lower pin for furnace fan control.

G. Microcontroller – Responsible for activation and control of the

unit based upon thermostat input.

H. HVAC System Status LEDs – Indicates what the DTGE4A is

energizing on the HVAC system.

Y1: Compressor, yellow. On when the first-stage cool is energized.

Y2: Compressor, yellow. On when the second-stage cool is energized.

G: Blower, green. On when the indoor blower is energized.

W1: Heat, red. On when first stage heat is energized.

W2: Heat, red. On when second stage heat is energized.

PWR: Power, orange. On when power at R and C and the Power

Switch is on. Flashing when in Capacity Control cut out mode.

See Status Lights section, page 6, for further information.

I. Power Switch – When OFF, power from the HVAC unit transformer is

disconnected from the Digitract 4 and thermostats. When ON, power

from the HVAC unit transformer is supplied to the Digitract 4 and the

zone thermostats.

J. Adjustable Potentiometers – For HIGH limit, LO limit and TIME

changeover. Use these potentiometers to adjust limits for a customized

job. From factory the settings are 145° high, 45° low and 15-minute

changeover.

SYSTEM CONTROLLER – GAS/ELECTRIC DTGE4A

COMPONENTS

A. HVAC Unit/LAT Terminals – Connects to HVAC unit

and Leaving Air Sensor (LAT).

S S: LAT terminals. The LAT monitors the leaving

air temperature.

J

15

135

Zonex DigiTract GE

ON

OFF

S

A

LAT

}

S

UNIT TERMINALS

Y2

W1

G

W2

Y1

R

C

STAT 1 STAT 2

W R Y G C

ZONE 1

THERMOSTAT

JP2 – Electric Heat – To energize the system blower on a call for heat,

R11

Y1 G W1 Y2 W2

W R Y G C W R Y G C W R Y G C

B

JP1

PWR

JP2

DTGE4A

H

F

45

E

50

40

LO

G

STAT 3

W R Y G CW R Y G C

ZONE 3

THERMOSTAT

125

115

HI

155

5

TIME

D

STAT 4

25

DPR 1

DPR 2

DPR 3

DPR 4

DAMPER

20

10

145

1

1

2

2

3

3

4

4

TR1

TR2

C

7

The System Controller will initially run in the mode requested by the first

calling zone thermostat.

Cool mode – When running in the cool mode, the System

Controller energizes the compressor(s), indoor blower

and energizes the reversing valve (O made to R) if the reversing valve selection jumper is in the O position. This is indicated

by the corresponding Y, G and O/B (if jumper in O position)

LEDs illuminating. Also, the dampers for the zones not calling

for cool are closed and the dampers for the zones calling for

cool are left open. This is indicated by the DPR LEDs. If the DPR

LED is illuminated, the damper terminal strip and damper terminal board, the corresponding damper is closed. The system

will continue to run in the cool mode until all calls are satisfied

or changeover occurs. When all calls are satisfied or prior to

changeover, the system will go into a purge mode.

Heat mode – When running in the heat mode, the System Controller

energizes the compressor(s), indoor blower and energizes the

reversing valve if the reversing valve selection jumper is in the B

position. This is indicated by the corresponding Y, G and O/B (if

jumper in B position) LEDs illuminating. Also, the dampers for the

zones not calling for heat are closed and the dampers for the zones

calling for heat are left open. This is indicated by the DPR LEDs. If the

DPR LED is on the damper terminal strip and damper terminal board,

the corresponding damper is closed. After running in heat mode for 8

minutes, the System Controller will energize the auxiliary heat if the coil

leaving air temperature drops below 90° and will de-energize when the

coil leaving air temperature rises above 100°. The W2 LED is on when the

auxiliary heat is energized. The system will continue to run in the heat

mode until all calls are satisfied or changeover occurs. When all calls

are satisfied or prior to changeover, the system will go into a purge mode.

Changeover – While the system is operating in one mode, if the System

Controller receives a call for the opposite mode, the System Controller

will continue to run in the current mode until the changeover time has

been reached or all current calls are satisfied. The System controller

will then go into a 4-minute purge, then change over to the opposite

mode.

Purge mode – Purge mode is initiated after the last calling zone is

satisfied, or when the controller goes into a forced changeover. All HVAC

output LEDs on the controller go off during this cycle. When the last

calling zone thermostat satisfies, the Digitract controller goes into a four

minute purge cycle. During this time delay all controller outputs to the

HVAC system and dampers are terminated. All dampers go to a full open

position and the HVAC system fan delay control runs the blower for a

time. This time delay with no control outputs allows the supply duct to

return to ambient temperature before the next call is initiated.

When the controller goes into a force mode changeover, and the initial

call drops out to the purge cycle, the HVAC outputs are terminated, and

the initial zone damper remains open for 4 minute delay with the other

dampers closing. The HVAC system fan control allows the blower to run

for a time, and the initial calling zone supply duct returns to ambient

temperature.

Auxiliary heat – 8 minutes after the System Controller has run in heat

mode, if the coil leaving air temperature is below 90°, the auxiliary heat

is energized and the W2 LED illuminates. When the coil leaving air

temperature rises above 100°, the auxiliary heat is de-energized and the

W2 LED cycles off.

Ventilation – When no zones are calling, all zone dampers are open.

During this time, if any thermostat has the fan switch ON then the

indoor blower is energized and the G LED is on. This provides

ventilation to all zones.

Emergency heat – Emergency Mode is selected from STAT1 position

only. To make an emergency heat call, STAT1 must be in the emergency

heat mode and make a heat call. When STAT1 places the call for heat, all

thermostats will then be able to place a call for emergency heat

independently. Compressors will be locked out of operation until STAT1

places a cool or heat call. When a call for emergency heat is placed the

blower and electric strip heat will energize. Zones that are not calling

for heat will close their dampers; those that are calling will remain open.

Fossil Fuel Operation – The DTHP4A provides a selectable integrated

Fossil Fuel operation. Applying this controller to Fossil Fuel systems

eliminates the need for a “Fossil Fuel Kit,” additional capacity control,

auxiliary relays and complicated control wiring. The controller offers

balance point control when the optional FOAS outdoor air sensor is used.

This enables the heat pump compressor to be locked out and the Furnace

to be energized on a call for heat, when the outdoor temperature is below

the BP setpoint on the DTHP4A controller. When the FOAS is not used, the

controller will stage up to the furnace based on time and temperature.

By placing the controller jumper in the FF position the controller is

configured for Fossil Fuel operation. When there is no Outside Air

Sensor applied, a call for heat from any zone energizes Y1 compressor

output and G blower output (“B” mode energizes rev valve also). With

the factory POT settings: LO 45° and HI 120°, the controller will stage up

from Y1 to Y2 after four minutes, if the supply air temperature is below

95°. After 8 minutes run time if the supply air temperature is 90° or

below, W2 LED will illuminate energizing the furnace; Y1 and Y2 will

drop out leaving the fan circuit energized. When the controller energizes

W2 for the furnace, the capacity control automatically implements a fixed

cutout temperature of approximately 135°. When this temperature is

exceeded, W2 drops out and the system goes into a 4-minute purge cycle

to reduce supply air temperature.

When using the optional FOAS Outdoor Air Sensor, the Balance Point “BP”

POT should be checked and adjusted as required; factory setting is 33°. On

call for heat, if the OA temp is above the BP setting, Y1 will be energized

on the Heat Pump. When the OA is below the BP, call for heat will

energize W2 gas furnace directly.

SYSTEM CONTROLLER – HEAT PUMP DTHP4A

OPERATION

8

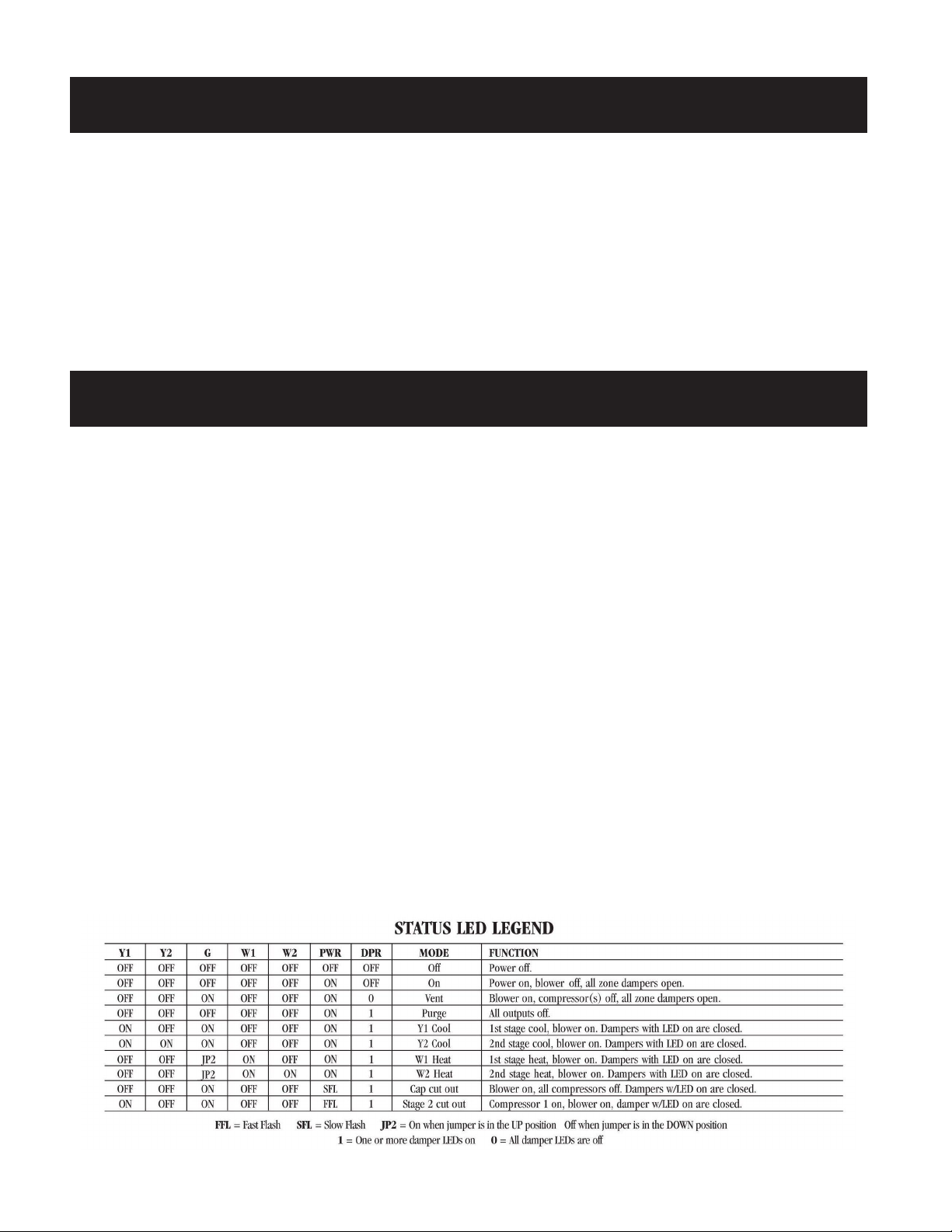

STATUS LED LEGEND

COMPONENTS DTHP4A

SYSTEM CONTROLLER – HEAT PUMP DTHP4A

O/B Reversing valve LED, yellow. On when the reversing valve is energized.

Y1 Compressor LED, yellow. On when the first compressor stage is energized.

Y2 Compressor LED, yellow. On when the second compressor stage is energized.

G Indoor blower LED, green. On when the indoor blower is energized by the DTHP4A Controller.

W2 Auxiliary heat LED, red. On when the auxiliary heat is energized.

PWR Power LED, orange. On when DTHP4A is powered. Flashing during capacity control cutout.

DPR Damper status LED, red. One per damper. On when damper is closed.

STATUS LEDs

O/B Y1 Y2 G W2 PWR DPR MODE FUNCTION

OFF OFF OFF OFF OFF OFF OFF Off Power off.

OFF OFF OFF OFF OFF ON OFF On Power on, blower off, all zones satisfied.

ON/OFF OFF OFF ON OFF ON 0 Vent Blower on, compressor(s) off, all zone dampers open.

ON/OFF OFF OFF OFF OFF ON 1 Purge Blower off, compressor(s) off. Dampers with LED on are closed.

A ON OFF ON OFF ON 1 Y1 Cool 1st stage cool, blower on. Dampers with LED on are closed.

A ON ON ON OFF ON 1 Y2 Cool 2nd stage cool, blower on. Dampers with LED on are closed.

B ON OFF ON OFF ON 1 Y1 Heat 1st stage heat, blower on. Dampers with LED on are closed.

B ON ON ON C ON 1 Y2 Heat 2nd stage heat, blower on. Dampers with LED on are closed.

ON/OFF OFF OFF ON ON ON 1 Em. Heat Auxiliary and emergency heat on.

OFF OFF OFF ON OFF FL 1 Cap Cut out Blower on, all compressors off. Dampers with LED on are closed.

ON/OFF ON ON ON ON ON 1 Em. Heat If below 90°, stages up to Y1, Y2 and W2

ON/OFF OFF OFF ON ON ON 1 Em. Heat Fossil fuel mode, stages up to W2 only

FL = Flashing A = On when reversing valve jumper is in O position B = On when reversing valve jumper is in B position

C = On when auxiliary heat is energized 1 = One or more damper LEDs on 0 = All damper LEDs are off

9

leaving air temperature.

±: OAS Optional Outside Air Sensor for use in Fossil Fuel /

Dual Fuel applications

W2: Auxiliary Heat. When energized (W2 made to R), turns on the

heat pump auxiliary heat.

G: Blower. When energized (G made to R), turns on the

indoor blower.

Y1: Compressor. When energized (Y1 made to R), turns on the heat

pump first stage compressor.

Y2: Compressor. When energized, (Y2 made to R), turns on the

heat pump second stage compressor.

O/B: Reversing Valve. When energized (O/B made to R), engages

the heat pump reversing valve.

R: Heat pump unit 24V power. Powers Digitract 4 and thermostats.

C: Heat pump unit 24V common.

B. Thermostat Terminals – Connects up to four zone heat pump

thermostats.

E: Emergency Heat. On STAT 1 only. Connected to E terminal on

STAT 1.

0/B: Reversing valve signal. “O” energizes reversing valve in the Cool

mode. “B” energizes reversing valve in the Heat mode.

R: Heat pump unit 24V power. See A.

Y: Compressor.

G: Blower.

C: Heat pump unit 24V common.

C. Damper Terminals – Connects dampers for up to four zones and

damper power supply.

TR1/TR2: 24V AC transformer terminals. This transformer powers

only the zone dampers.

1 1: Zone damper 1. When energized, powers zone damper 1 closed.

2 2: Zone damper 2. When energized, powers zone damper 2 closed.

3 3: Zone damper 3. When energized, powers zone damper 3 closed.

4 4: Zone damper 4. When energized, powers zone damper 4 closed.

D. Damper Status Lights – Light on when corresponding zone

damper is closed.

E. Reversing Valve Selection Jumper – Configures Digitract 4 to

energize reversing valve in cool mode or heat mode. Place on O and

center pin to energize reversing valve in cool mode. Place on B and

center pin to energize in heat mode.

F. Microcontroller – Responsible for activation and control of the

unit and dampers based upon thermostat input.

G. Power Switch – When OFF, power from the heat pump transformer

is disconnected from the Digitract 4 and thermostats. When ON, power

from the heat pump transformer is supplied to the Digitract 4 and

the zone thermostats.

H. Heat Pump Status LEDs – Indicates what the DTHP4A is

energizing on the heat pump.

O/B: Reversing valve, yellow. On when the reversing valve is

energized.

Y1: Compressor, yellow. On when the first stage compressor is

energized.

Y2: Compressor, yellow. On when the second stage compressor is

energized.

G: Blower, green. On when the indoor blower is energized.

W2: Auxiliary heat, red. On when the auxiliary heat is energized.

PWR: Power, orange. On when power at R and C and the Power

Switch is on. Flashing when in Capacity Control cut out mode.

See Status Lights section, page 9, for further information.

I. FF fossil fuel jumper – Place jumper in FF position to use fossil

fuel features.

J. Adjustable potentiometer for balance point (BP), LO limit, HI limit

and changeover time.

SYSTEM CONTROLLER – HEAT PUMP DTHP4A

COMPONENTS

A. Heat Pump Unit/LAT Terminals – Connects to Heat Pump and

Leaving Air Sensor (LAT).

± LAT terminals. The LAT monitors the heat pump coil

10

The HVAC system is sized to handle the load of the entire home

or building. Because of this, when all the zones are not calling, the load

to the HVAC system can diminish below its designed capacity. Left

unchecked, the HVAC unit could freeze up or overheat. To compensate

for this, the Digitract 4 is furnished with a built in Capacity Controller.

The basic function of the Capacity Controller is to monitor the leaving air

temperature and cycle the unit off when the air is out of operating range

and, after a minimum four minute time delay, turn the unit back on when

the air temperature has returned within operating range. Additionally, for

heat pumps the Capacity Controller will turn on the heat pump auxiliary

heat if the coil leaving air temperature is not hot enough in heat mode.

Upon a heat call, the controller will energize W1 LED if the leaving air

temperature is less than High Limit Setpoint. This setpoint is determined by

adjusting the potentiometer located in the upper right corner of the controller,

HI. W1 will de-energize if LAT exceeds the HI setpoint, W1 LED will de-energize and the PWR LED will flash slowly indicating a stage 1 capacity cutout.

If the LAT is below the High limit, W1 will energize, W1 LED will illuminate.

W2 Heat operations – After W1 has operated continuously for 4 minutes

and LAT is less than High Limit minus 25°(if HI of 145° – 25°=120°),

then W2 will energize indicated by the W2 LED. If LAT rises to High

Limit minus 5°, then W2 will de-energize indicted by W2 LED off and

PWR LED flashing quickly. If all heat calls are satisfied both W1 and

W2 will de-energize and controller will go into a 4-minute purge

cycle.

Y1 Heat Operation – Upon a call for heat, the controller will energize

Y1 LED, if the LAT rises above the High Limit (potentiometer located on

controller top right corner, marked HI), then Y1 LED will de-energize

and PWR LED will flash indicating a stage 1 capacity cutout. After a

4-minute time delay the LAT will be checked; if LAT is less than HI

cutout, then Y1 LED will reenergize and PWR LED will stop flashing. If

the O/B jumper is in the B position, the O/B LED will illuminate with Y1.

Y2 Heat Operation – After 4 minutes of continuous Y1 operation, the

leaving air temperature will be checked. If the LAT is less than High

Limit (HI) minus 25° (HI of 120-25 = 95°), then Y2 will energize,

indicated by the Y2 LED. Y2 will cycle off when LAT is HI minus 5°

(120 – 5 = 115) or when all heat calls are satisfied.

Fossil Fuel Operation – For Fossil Fuel operation, FF jumper must be

placed in the FF position.

• For greater efficiency and comfort, an Outdoor Air Sensor, Part

# FOAS, should be used in the Fossil Fuel application. The FOAS is

used to lock out compressor operation when outside air temperature

has dropped below Balance Point setpoint, the temperature at which

that heat pump is no longer efficient. When the outside temperature

is less than Balance Point setpoint and there is a call for heat, Y1 and

Y2 will be locked out; and W2 will energize indicated by W2 LED

illuminating. The HI limit will be reset automatically to 135° to

provide HI limit protection for furnace. Calls for heat are recognized

from all thermostats; dampers for zones calling for heat will open,

indicated by DPR LEDs off, while zones not calling will close,

indicated by illuminated DPR LEDs. The Balance Point setpoint is

adjustable from 25° to 41° by moving Balance Point potentiometer to

desired setpoint. Refer to page 9 for potentiometer location on DTHP4A.

• Applications without FOAS will stage on time and temperature. With

the Fossil Fuel jumper in the FF position, after 8 minutes of continuous

heat operation, if leaving air is less than 90°, then W2 will energize.

Y1 and Y2 will de-energize indicated by LEDs off; W2 LED will

illuminate and furnace will start. The HI limit will be reset automatically

to 135° to protect furnace heat exchanger. DPR LED for calling zones

will be off, while DPR LEDs for non-calling zones will illuminate. All

thermostats are able to make calls for heat.

Auxiliary Heat (Electric Strip Heat) – After 8 minutes of continuous

operation the leaving air temperature is checked. If LAT is below 90°,

W2 will energize and W2 LED will illuminate. W2 will cycle off above

100°, or when all calls are satisfied.

Y1 Cool Operation – Upon a cool call, the controller will energize

Y1 and G. If the leaving air temperature drops below the low limit

setpoint, Y1 will be de-energized, the PWR led will flash indicating a stage

1 capacity cutout. After 4 minutes the leaving air temperature will be

checked again; if the leaving air temperature has risen above the cutout

set point, then Y1 will reenergize and PWR LED will stop flashing. If

controller is for a Heat Pump, and the reversing valve is in the O

position, the O/B output will be energized simultaneously with the Y1,

indicated by the O/B LED.

After 8 minutes of continuous Y1 run time, LAT (leaving air temperature)

will be checked. If LAT is greater than low limit (LO) plus 12° (LO of

45° + 12° = 57°), then Y2 will energize and Y2 LED will illuminate.

Y2 will cycle off when LAT drops below 5° plus low limit (45°+ 5° = 50°).

Y2 and G will de-energize when all calls are satisfied, and the controller

will go into a 4-minute purge cycle.

CAPACITY CONTROL AND STAGING

COOLING OPERATION – DTGE4A AND DTHP4A

HEAT OPERATION – GAS/ELECTRIC DTGE4A

HEAT OPERATION – HEAT PUMP DTHP4A

11

+

-

Y2

W1

G

W2

R

Y1

C

Red

Black

1.Drill a 3/8” hole in the supply air, ahead of the bypass tap.

A. GAS/Electric application – install sensor as far as possible from the FAU heat exchanger but still before

the bypass tap.

B. Heat Pump application – install the sensor after the indoor coil but before the electric strip heat

assembly.

2.Secure the sensor-mounting base to the duct or AHU cabinet (HP) with the self-tapping screws provided.

3.Run the shielded sensor cable back to the controller location; trim off any excess cable.

OAS INSTALLATION FOR FOSSIL FUEL

OAS, outdoor air sensor (Optional for Fossil Fuel applications), Sensor Installation

1. Install the OAS outside of the building, away from direct sun exposure, and above the snow line.

2. Run the sensor cable to the Digitract controller location; trim off any excess cable.

NOTE: Use of OAS with fossil fuel

creates a more efficient

system, providing greater

comfort control.

See page 11.

SHIELD

LAT AND OAS INSTALLATION

CAPACITY CONTROLLER – LAT INSTALLATION

Capacity control installation, LAT installation

4. The LAT requires no calibration.

3. The OAS does not require calibration.

4. Check the Balance Point (BP) POT on the controller. It is factory set at 33°.

Wiring Diagram for Fossil Fuel Applications

LAT

COIL

W1

Y1

Furnace

Shield

Red

Black

G

R

C

Shield

Red

Black

.

.

.

+

LAT

–

+

OAS

–

Y2

O/B

G

W2

Y1

R

E

.

C

DTHP4A

Controller

OAS (Outdoor Air Sensor)

Optional

R W Y1 O/B C

Outdoor Unit

12

Use the table below to determine which zone dampers to use.

Maximum Differential Pressure refers to the maximum static pressure drop in inches of water column between the

input (upstream) of the zone damper and the output (downstream) when the damper is closed.

There are two styles of round zone dampers, low pressure or medium

pressure. For systems 5 tons or under with a maximum differential static

pressure of 0.5”, use low pressure dampers. Otherwise use medium

pressure for up to 1.75” differential pressure on any system over 5 tons.

ROUND LOW PRESSURE ZONE DAMPERS (TR diam)

Zonex Systems round low pressure zone dampers can be used for systems up to 5 tons

with a maximum differential static pressure of 0.5”. These are two position, spring

open, power close dampers for very simple operation. Round damper sizes 9

inches and under are manufactured from 24 gauge galvanized steel. Sizes 10”, 12”,

14” and 16” are made from 20 - 22 gauge steel. All sizes are designed with rolled-in

stiffening beads for superior rigidity. The damper pipe is furnished with one crimped end

and one straight end for easy installation. A hat section supports a synchronous 24V

AC 60Hz 12VA motor and terminal board. The motor is designed for continuous full stall

operation. Special winding and heavy duty gearing provide for long motor life and

easy spring open operation. A cross pin on the motor shaft provides positive direct drive

to the damper blade shaft without a coupling or set screws, allowing for a quick and easy

motor change if required. Motor drive time from full open to full close is 30 seconds.

A red LED will be illuminated on the damper terminal board to indicate when the

damper is being powered closed. The LED will remain on when the damper is fully closed

and cycle off when the damper is opening or in the full opened position. Since this is a

spring open damper, in the event of power failure, the damper fails to the full open position.

ROUND MEDIUM PRESSURE ZONE DAMPERS

(101AMPD series)

The Zonex Systems round medium pressure zone dampers are recommended for any size

system above 5 ton, 2000 CFM, and are rated for a maximum of 1.75” SP. These dampers

are constructed from 20-22 gauge galvanized steel, with an elliptical damper disc. The

damper shell is manufactured with the supply end crimped and an air flow direction arrow.

The damper is driven by a 24-volt power open / power close, direct coupled actuator rated

at 2VA. The actuator assembly includes manual open and close stop adjustments and

mechanical drive release. The actuator is designed for full stall operation in the open and

close positions and requires no end switches.

MEDIUM PRESSURE (101AMPD diam)

LOW PRESSURE (TR diam)

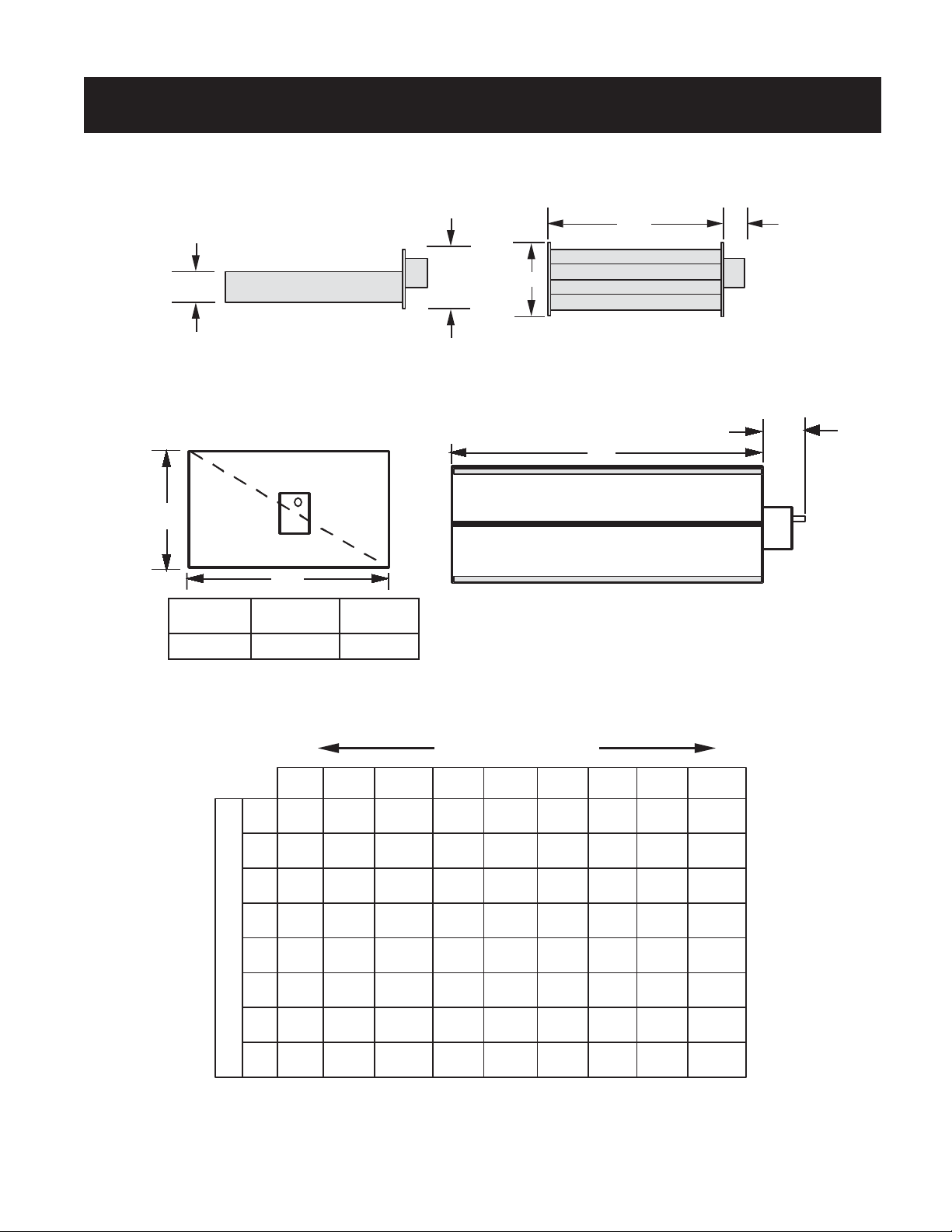

ZONE DAMPERS

ROUND ZONE DAMPERS

SYSTEM SIZE

MAXIMUM

DIFFERENTIAL

PRESSURE

ROUND

DAMPER

RECTANGULAR

DAMPER

5 TONS OR UNDER

UNDER 7.5 TONS

7.5 TONS OF LARGER

0.5"

1"

1.75"

LOW PRESSURE

MEDIUM PRESSURE

MEDIUM PRESSURE

LOW PRESSURE

MEDIUM PRESSURE

HEAVY DUTY

13

ZONE DAMPERS

TYPICAL ROUND CAPACITIES*

* These air quantities were derived from a duct sizing chart .1” friction loss per 100’ of duct. All CFMs listed are approximate. For accurate selection

use duct sizing table or device.

ROUND LOW & MEDIUM PRESSURE DAMPER SIZES

ROUND LOW PRESSURE DAMPER

PAR T #

TR06

TR07

TR08

TR09

TR10

TR12

TR14

TR16

ROUND MEDIUM PRESSURE DAMPER

PAR T #

101AMPD06

101AMPD08

101AMPD10

101AMPD12

101AMPD14

101AMPD16

101AMPD18

SIZE DIAMETER (D) LENGTH (L)

6"

7"

8"

9"

10"

12"

14"

16"

SIZE DIAMETER (D) LENGTH (L)

6"

8"

10"

12"

14"

16"

18"

6"

7"

8"

9"

10"

12"

14"

16"

6"

8"

10"

12"

14"

16"

18"

10"

10"

10"

11"

12"

14"

16"

18"

10"

10"

12"

14"

16"

18"

20"

WIDTH (W)

9"

10"

11"

12"

13"

15"

17"

18 1/2"

WIDTH (W)

9"

11"

13"

15"

17"

19"

21"

W

D

L

Duct

Diameter

6"

7"

8"

9"

10"

12"

14"

16"

Nominal

CFM

110

160

250

320

410

660

1000

1450

Duct Velocity

FPM

540

600

700

725

750

850

925

1070

18" 2000 1100 .036

Damper

P " WC

Δ

.014

.014

.015

.015

.015

.022

.035

.036

14

ZONE DAMPERS

Rectangular zone dampers are available for the DigiTract 4 controllers in three (3) styles:

TREC WxH for low pressure applications (5 tons or less) rated at .5” SP;

101MRTD WxH for medium pressure application up to 7.5 tons, rated at 1” SP;

101CD WxH for heavy duty applications over 7.5 tons, rated at 1.75” SP.

RECTANGULAR LOW PRESSURE ZONE DAMPERS

(TREC W x H)

Zonex Systems rectangular low pressure dampers can be used for systems up

to 5 tons with a maximum differential static pressure of 0.5”. These are two

position, spring open, power close dampers. They are constructed from heavy

duty galvanized steel. The damper is a single blade type that slips into a 2-1/2”

wide cutout in the existing duct and attaches with screws via a duct mounting

plate. The duct mounting plate is 5” wide. The drive assembly supports a

synchronous 24V AC 60Hz 12VA motor and terminal board. The motor is

designed for continuous full stall operation. Special winding and heavy duty

gearing provide for long motor life and easy spring open operation. A cross pin

on the motor shaft provides positive direct drive to the damper shaft without

a coupling or set screws. Motor drive time from full open to full close is 30

seconds. A red LED will be illuminated on the damper terminal board to

indicate when the damper is being powered closed. The LED will remain on

when the damper is fully closed and cycle off when the damper is opening or

in the full opened position. Since this is a spring open damper, in the event of

power failure the damper fails to the full open position.

RECTANGULAR MEDIUM PRESSURE ZONE DAMPERS (101MRTD W x H)

Zonex Systems rectangular medium pressure dampers are recommended for systems under 7.5 tons with a maximum differential static pressure of 1”.

These are power open, power close dampers. They are constructed from heavy duty aluminum and stainless steel. The damper is an opposed blade

type that slips into a 3-1/4” wide cutout in the existing duct and attaches with screws via a duct mounting plate. The duct mounting plate is 5” wide.

Power consumption is 6VA. The motors are designed for continuous full stall operation. Special winding and heavy duty gearing provide for long

motor life.

RECTANGULAR HEAVY DUTY ZONE DAMPERS

(101CD W x H)

Zonex Systems rectangular heavy duty dampers are recommended for systems

7.5 tons or larger with a maximum differential static pressure of 1.75”. These are

power open, power close dampers made of 20 gauge “snap-lock” steel frame

with S and Drive duct connections. Allow a 16” gap in the duct for the damper.

Formed steel blade stops incorporate a gasket for quiet operation and improved

structural rigidity. Rectangular dampers under 10” in height incorporate a

single blade design. Dampers 10” or over use opposed blade design. A full stall

motor, drawing 2 VA and a relay board control the damper position.

MEDIUM PRESSURE (101MRTD W x H) AND

HEAVY DUTY (101CD W x H) RECTANGULAR DAMPERS

LOW PRESSURE (TREC W x H) RECTANGULAR DAMPER

RECTANGULAR ZONE DAMPERS

15

ZONE DAMPERS

LOW AND MEDIUM PRESSURE RECTANGULAR DAMPER DIMENSIONS

HEAVY DUTY RECTANGULAR DAMPER DIMENSIONS

Motors on low and medium pressure dampers will be mounted on the Height (H) side. Bottom mount motors will be located on the Width (W)

side. *These air quantities were derived from a duct sizing chart .1” friction loss per 100’ of duct. All CFMs listed are approximate. For accurate selection

use duct sizing table or device.

Part Number 101CD W x H

Sizes available from 8” x 8” up to 48” x 48”

Part Number TREC W x H and 101MRTD W x H

Sizes available from 8” x 6” up to 24” x 20”.

RECTANGULAR DAMPER CAPACITIES*

Dampers listed below are standard sizes. For larger sizes and capacities, contact the factory.

2-1/2"

MOTOR

B

16

WIDTH HEIGHT

A

B 16"

DEPTH

2-1/4"

W

5"

H

48" MAXIMUM WIDTH

4"

A

Rectangular heavy duty dampers should operate at 1500 FPM.

E.G. A 24" x 12" damper = 2 square feet.

2 square feet X 1500FPM = 3000 CFM.

8 1012 1416 18202224

200

6

280

8

390

10

490

12

14

HEIGHT IN INCHES

16

18

20

250

390

510

650

310

490

650

850

1000

1200

1400

WIDTH IN INCHES

390

590

800

1000

1250

1500

1750

16

440

680

950

1200

1500

1800

2100

500

770

1100

1400

1750

2100

2500

570

900

1220

1600

2000

2450

2850

630

960

1400

1850

2250

2300

3080

700

1090

1500

2000

2500

3000

3600

4000

The barometric bypass damper is for systems 5 tons or under. It utilizes

a weighted damper blade to maintain constant duct pressure. This

allows for easy installation without the need for electrical power or

wiring. The round barometric damper can be installed in any position.

The RBB rectangular damper must be installed with horizontal air

flow only.

SIZING: When only the smallest zone is calling, the maximum

amount of excess supply air will flow through the bypass damper. To

determine the proper size bypass damper to use, do the following steps:

Step 1: Calculate bypass air volume as follows.

A) Calculate total air volume at 400 CFM

per ton.

B) Calculate air volume of smallest zone in

CFM.

C) Calculate bypass air volume by subtract-

ing the smallest zone air volume from

the total.

(A - B = C)

Step 2: Select damper from sizing table.

Once you have calculated the bypass air volume from Step 1, use the

BAROMETRIC BYPASS SELECTION TABLE. From the table, select the

bypass damper with the CFM rating equal to or greater than the value

calculated in Step 1. For rectangular barometric dampers, use a

ductulator to convert from round to rectangular.

If bypassing more than 2000 CFM, use electronic bypass damper.

Example: You have a 4 ton system. Your smallest zone will use 500

CFM. The total CFM is 1600 CFM (400 * 4). Your bypass CFM is 1100

(1600 - 500). From the table, you determine that a 12” bypass damper

is needed.

Do not use the barometric bypass in any system over 5 tons.

For systems over 5 tons, or to bypass more than 2000 CFM, use the

electronic bypass.

RECTANGULAR & ROUND

BAROMETRIC BYPASS

BYPASS DAMPERS

BYPASS DAMPERS – BAROMETRIC

Diameter CFM

9” 650

10” 800

12” 1200

14” 1600

16” 2000

ZONE DAMPERS

SIZING ZONE DAMPERS

If the ductwork already exists, simply size the damper to fit the ductwork.

For new systems or retrofit jobs:

a) Determine CFM from heat gain or loss calculations.

b) Select damper size by using a duct sizing table or calculator.

c) Select a Zonex Systems damper to fit the duct size selected for

that zone.

DAMPER INSTALLATION NOTES

1. Do not exceed 700 FPM in a register/diffuser branch duct.

2. If a damper is installed within 3 feet of register/diffuser, install sound

attenuating flex duct between damper and outlet.

3. Zone dampers should be preceded by 2’-4’ of straight pipe where

possible.

4. In attic installations and high humidity areas, the Zonex Systems

damper should be insulated along with the ductwork. The hat section

on the damper is delivered with insulation between the hat section

and pipe. Therefore, insulation should be applied to the round pipe

and be butted against the hat section, (do not insulate the motor terminal board or relay board). Both motor and the relay board generate enough heat so no condensation will develop on the hat section.

5. Remember to allow a 16” gap in the duct for Heavy Duty rectangular

CD dampers.

6. Low and medium pressure rectangular dampers slide into a 3” wide

cutout in the ductwork.

7. Install TR round dampers to the motor in the 9 to 3 o’clock position.

Do not install damper so the motor is in the 4 to 8 o’clock position.

BAROMETRIC BYPASS

SELECTION TABLE

Bypass dampers are used to provide constant air delivery through the air

handling unit. This is done by bypassing excess air from the supply duct

back to the return duct. As a zone is satisfied, its zone damper closes.

When this happens, the bypass damper opens just enough to bypass the

excess air. This will control static pressure and noise at the diffusers.

Zonex Systems offers two types of bypass dampers, Barometric and

Electronic. Each is available in round or rectangular configuration.

Barometric bypass dampers are limited to systems of 5 tons. Electronic

dampers can be used on any size system. For residential HVAC systems

with variable speed blowers, the barometric or electric bypass dampers

can be used. NOTE: When using the electric bypass (STBP/STCDBP), see

the Bypass Dampers - Electronic Section, Pages 19-22; or contact

Technical Support.

17

BAROMETRIC BYPASS

DAMPER

AIRFLOW

1

2

1. Damper Shaft

2. Lock Nut

3. Lever Arm

4. Counter Weight

3

4

INSTALLATION

The round barometric bypass damper can be installed in any position.

This damper is factory set for horizontal installation and can be field

modified for vertical installation. Do not run speed screws into damper

housing. Screws may interfere with damper travel. Make sure counter

weight is not obstructed in any way.

a) Install the bypass damper between the supply and return

plenums of the unit. It must be the first tap off the supply plenum.

b) Be sure the air flows through the damper in the proper direction

as indicated by the arrow on the damper. Airflow is always

from supply to return plenum. Be certain the damper shaft

is horizontal.

c) Loosen counter weight with allen wrench.

d) Loosen lever arm from damper shaft and allow to hang straight

down.

e) Fully close damper by grabbing damper shaft on side attached

to lever arm and turning clockwise until it stops.

f) While holding the damper fully closed, rotate the lever arm a

little to the right (facing the damper) and then screw in to

tighten to the damper shaft. Then tighten lock nut.

g) Be sure the damper is being held closed by the counter weight.

Proceed to setup.

BAROMETRIC BYPASS SETUP

a) Turn off all thermostats.

b) Turn on Switching Center/Controller and set fan switch to “ON”

position. Allow fan to run for 5 minutes to equalize pressure.

Then make sure all dampers are open by checking for air flow

out of each damper.

c) By moving counter weight up or down the lever arm, adjust it

so that the damper just wants to start opening.

d) If the damper cannot be held closed with the counter weight

all the way to the bottom of the lever arm, then hold the

damper shaft, loosen the lever arm from the damper shaft, and

rotate the lever arm farther to the right and retighten. Repeat

Step C.

e) The barometric bypass damper is now calibrated.

BAROMETRIC BYPASS STARTUP TEST

a) Have at least half of the zones call for either heating or cooling.

b) Check to be sure the calling zone dampers are open, (air is

flowing).

c) Verify the bypass damper is open. Note, the damper may not

fully open.

d) If the open zones are not noisy, the bypass damper is set.

BYPASS DAMPERS – BAROMETRIC

AIRFLOW

SHEET METAL

PIPE

AIRFLOW

BAROMETRIC

BYPASS

HORIZONTAL APPLICATION

A/C UNIT

RETURN

VERTICAL APPLICATION

OR

FURNACE

BAROMETRIC

BYPASS

SUPPLY

PLENUM

A/C UNIT

OR

FURNACE

RETURN AIR GRILLE

RETURN

AIR

PLATFORM

SUPPLY

PLENUM

AIRFLOW

ROOFTOP INSTALLATION Down Discharge Application

SUPPLY

PLENUM

OPEN RETURN PLENUM BYPASS APPLICATION

To prevent bypass air from

flowing out the return grill,

use a short open ended

return air plenum to

connect the bypass

damper to the unit.

RETURN AIR

GRILLE

SHEET METAL

PIPE

BYPASS DAMPER

AIR CONDITIONING

UNIT

A/C UNIT

OR

FURNACE

BAROMETRIC

BYPASS

AIRFLOW

RETURN

PLENUM

SUPPLY

DUCT

ROOF LINE

18

Diameter

CFM

8”

560

10”

900

12”

1250

14”

1700

16”

2200

18”

2600

PART #

SIZE D L

W

STBP08

8

8”

10”

11”

STBP10

10

10”

12”

13”

STBP12

12

12”

14”

15”

STBP14

14

14”

16”

17”

STBP16

16

16”

18”

19”

STBP18

18

18”

20”

21”

ROUND BYPASS SELECTION TABLE

RECTANGULAR BYPASS DAMPERS

SELECT FROM 8 x 8 thru 48 x 48

D

L

W

H

D

4”

W

48” MAXIMUM WIDTH

BYPASS DAMPERS – ELECTRONIC

ELECTRONIC BYPASS DAMPERS

Bypass dampers are used to provide constant air delivery through the air handling unit. This is done by bypassing excess air

from the supply duct back to the return duct. As a zone is satisfied, its zone damper closes. When this happens, the bypass

damper opens just enough to bypass the excess air. This will control static pressure and noise at the diffusers.

The Electronic Bypass Damper is used on any size system over 5 tons. The damper can be round (STBP) or rectangular

(STCDBP) with integrated static pressure control; and multiple dampers can be slaved together.

SIZING ELECTRONIC BYPASS DAMPERS

The bypass damper is to be sized for the total system CFM

@ 1500 FPM. System CFM should be calculated at 400

CFM per ton.

Example: A 5-ton system is rated at 2000 CFM (5x400 =

2000). When calculated at 1500 FPM, the bypass damper

should be 16”. Never undersize the bypass damper.

ROUND BYPASS DAMPER SELECTION

The Zonex Systems STBP damper is used for round

bypass applications. When you know the bypass CFM

requirements, use the ROUND BYPASS SELECTION

TABLE to confirm the round damper size.

NOTE: Multiple round dampers can be slaved from one

static pressure control to provide the correct capacity. One

large rectangular bypass damper may be used instead of

multiple round dampers. See below.

RECTANGULAR BYPASS DAMPER SELECTION

The Zonex Systems STCDBP WxH damper is used for

rectangular bypass applications. These dampers are also

sized for the total system CFM rated at 1500 FPM.

Multiple dampers can be slaved from a single static

pressure control.

19

Bypass air in CFM. Calculated at 1500 FPM.

Formula used: B = W X H / 144 X 1500, where B = Bypass air in CFM, W = damper width in inches, H= damper height in inches, 144 = 144

sq. inches per sq. ft., 1500 = 1500 FPM.

SLAVING BYPASS DAMPERS

Use only one Pressure Sensor when slaving two or more Bypass Dampers together. Connect the Pressure Sensor to one damper as described above.

Connect the slave dampers in parallel as shown. Up to 4 dampers can be slaved to one Sensor. The slaved dampers will self synchronize each time

the dampers reach full open or full close.

24 28 32 36 40 44 48

8 2000 2333 2667 3000 3333 3667 4000

10 2500 2917 3333 3750 4167 4583 5000

12 3000 3500 4000 4500 5000 5500 6000

14 3500 4083 4667 5250 5833 6417 7000

16 4000 4667 5333 6000 6667 7333 8000

18 4500 5250 6000 6750 7500 8250 9000

20 5000 5833 6667 7500 8333 9167 10000

22 5500 6417 7333 8250 9167 10083 11000

24 6000 7000 8000 9000 10000 11000 12000

28 7000 8167 9333 10500 11667 12833 14000

32 8000 9333 10667 12000 13333 14667 16000

36 9000 10500 12000 13500 15000 16500 18000

40 10000 11667 13333 15000 16667 18333 20000

44 11000 12833 14667 16500 18333 20167 22000

48 12000 14000 16000 18000 20000 22000 24000

8 10 12 14 16 18 20 22

8 667 833 1000 1167 1333 1500 1667 1833

10 833 1042 1250 1458 1667 1875 2083 2292

12 1000 1250 1500 1750 2000 2250 2500 2750

14 1167 1458 1750 2042 2333 2625 2917 3208

16 1333 1667 2000 2333 2667 3000 3333 3667

18 1500 1875 2250 2625 3000 3375 3750 4125

20 1667 2083 2500 2917 3333 3750 4167 4583

22 1833 2292 2750 3208 3667 4125 4583 5042

24 2000 2500 3000 3500 4000 4500 5000 5500

28 2333 2917 3500 4083 4667 5250 5833 6417

32 2667 3333 4000 4667 5333 6000 6667 7333

36 3000 3750 4500 5250 6000 6750 7500 8250

40 3333 4167 5000 5833 6667 7500 8333 9167

44 3667 4583 5500 6417 7333 8250 9167 10083

48 4000 5000 6000 7000 8000 9000 10000 11000

WIDTH IN INCHES

HEIGHT IN INCHES

BYPASS DAMPERS – ELECTRONIC

RECTANGULAR BYPASS SELECTION TABLE

DAMPER

ACTUATOR

To Static Pressure Controller As Shown On The Bypass Wiring Diagram On Page 22.

**

RC RO MC

***

*

20

SLAVE

DAMPER

ACTUATOR

RC RO MC

TO NEXT SLAVE

BYPASS DAMPER

IF APPLICABLE

RC

RO

MC

BYPASS DAMPERS with INTEGRATED PRESSURE CONTROL

Part # STBP or STCDBP

Bypass Damper with Integrated Pressure Control is used to control bypass operations. The bypass damper modulates

to maintain static pressure as zone dampers open and close. The bypass system reduces air noise from the supply

registers caused by excessive air velocity. If the system is configured for intermittent fan mode and the system satisfies,

there will be a 3-minute delay to allow for system purge, after which the bypass damper will open to 25%, preventing

noisy rush of air through supply registers when fan starts up on a call for heat or cool. If the system is configured for

fan continuous operation, the STBP (Round) or STCDBP (Rectangular) Electronic Bypass will monitor static pressure

continuously, providing constant control of system static.

INTEGRATED PRESSURE CONTROL

DESCRIPTION

A. Supply air tube

B. 24vac R and C

C. Damper Terminal RO, RC, MC

D. LED lights

E. Adjustable Potentiometer

F. TP1 Test Point

Fig. 1

BYPASS DAMPER INSTALLATION

1. Verify the bypass damper is sized properly to the

system and not undersized. (Bypass damper

sizing is recommended for 100% of system

CFM.)

2. Bypass damper and controller are powered by a

dedicated 24vac 40VA transformer.

3. Do not install the bypass damper outside.

4. Locate the Integrated Pressure Control (IPC)

and air tube on the bypass damper.

5. Drill ¼” hole into the side of the supply duct 2’

after the bypass and before the 1st supply takeoff. Mount pressure supporting block over ¼”

hole, align hole in block with hole in duct. Use

provided sheet metal screws.

6. Install air tube into supply air duct by slipping

supplied plastic tubing into holes in support

block and duct. Slip tube 3” into the duct.

Pickup tubing fits snugly into provided hole.

7. Connect pressure tube from static air pickup to

Integrated Pressure Control.

Fig. 2

21

BYPASS DAMPER WITH INTEGRATED

BYPBYPASS DAMPERS with INTEGRATED PRESSURE CONTROLASS DAMPERS with INTEGRATED PRESSURE CONTROL

BYPASS CONTROL SETUP

1. Run all supply dampers to the full open position and

have blower motor running at 100% fan speed. (See

Note #1)

2. Manually close the bypass damper by pressing in the

release lever on the motor side of the actuator. With

the release lever pressed, rotate the damper actuator

collar to close the damper and release the lever to lock

the damper closed.

3. Quick Set Option: Turn the potentiometer on the

damper control board to the full left position and slowly

rotate RIGHT, until the “RC” RED LED turns on.

Now rotate LEFT just slightly, until RC LED turns off.

The IPC is ready for operation.

“RC” RED LED means damper closing.

“RO” GREEN LED means damper opening.

4. Static Pressure Option: The Integrated Pressure

Control Board can be field configured for specified

static pressure using a multi meter and the static

pressure – voltage chart. (Exhibit A). This chart shows

voltage (DC) to inches of W.C. (static pressure)

relationship. Use a multi meter set on VDC and place

the leads on the “C” terminal and “TP1” (test point

one) next to the potentiometer. The Voltage reading

translates to inches of W.C.

BYPASS CHECKOUT FOR STATIC

PRESSURE CONTROLLER

1. Make cool call at the zone thermostat of the smallest

zone.

2. Verify all zone dampers are closed except for calling

zone.

3. Verify noise at zone registers is not excessive. Adjust

the Integrated Pressure Control LEFT to lower noise

(airflow) or RIGHT to increase airflow until too

noisy.

BYPASS DAMPER WIRING DIAGRAM

WITH INTEGRATED BYPASS CONTROL

Note # 1: To open all dampers, it may be necessary to

remove Y outputs to unit on the zone control board and to

make full cool calls on all thermostats. This will modulate

dampers fully open and lock out compressor.

22

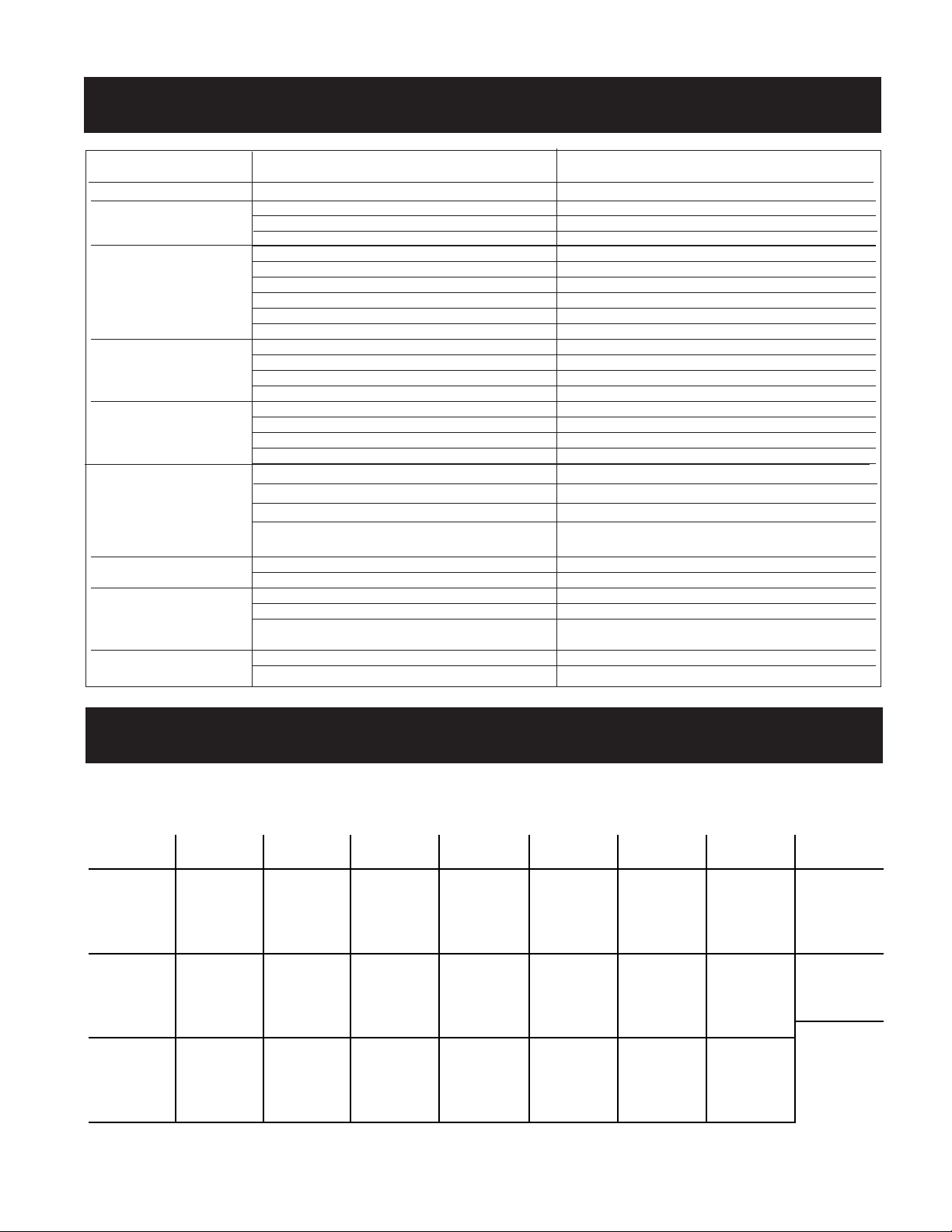

DAMPER TRANSFORMER

The 24V transformer connected to TR1 and TR2 of the Digitract 4

System Controller powers the zone dampers. The power rating of the

transformer must be sufficient to power the number of dampers used.

Also, a properly rated in line fuse must be used on the secondary of

the transformer. To determine the power rating of the transformer and

the amperage rating of the fuse, use the table below. If using a

combination of spring open and power open dampers, size as if all

dampers are spring open.

Note: The System Controller and thermostats are powered by the

HVAC unit transformer via terminals R and C.

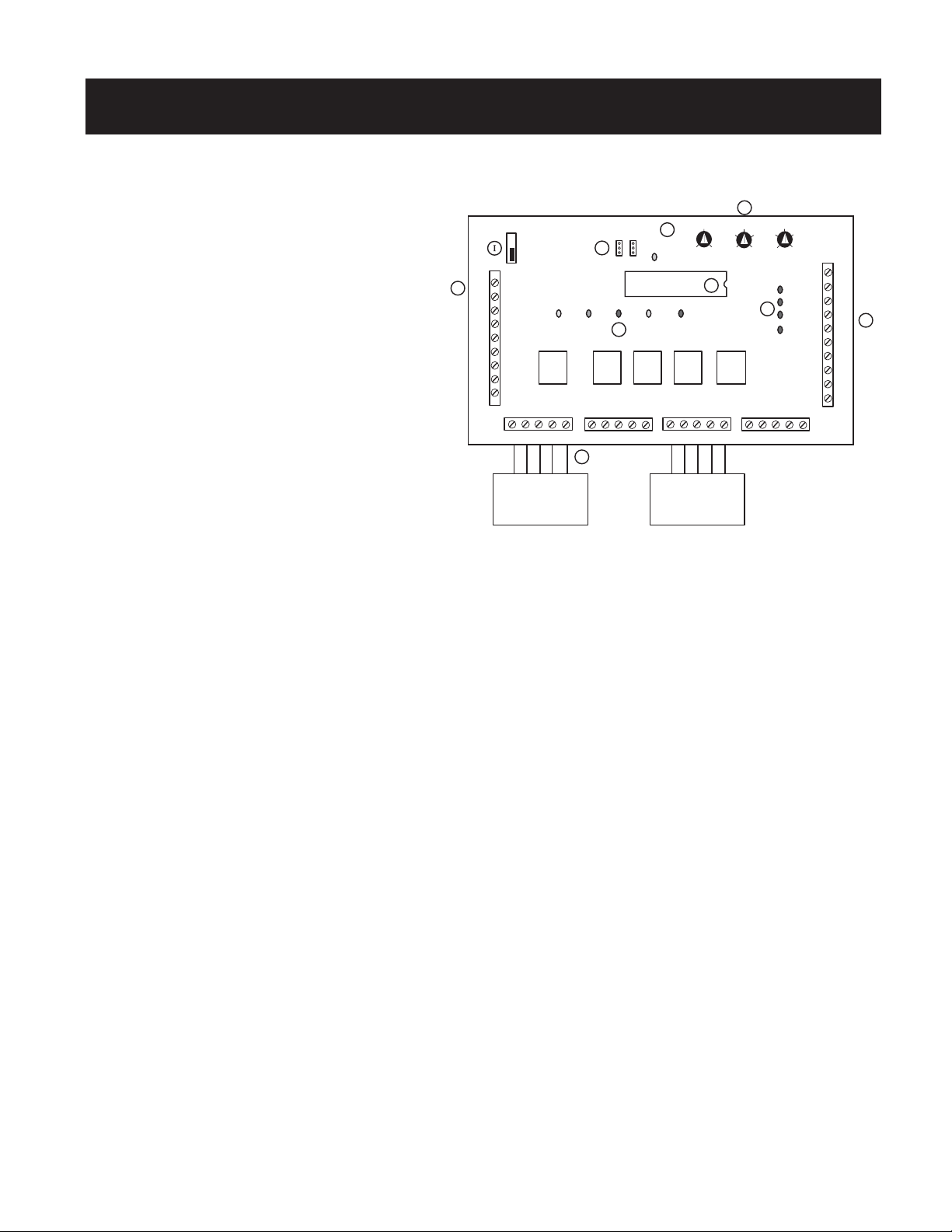

STARTUP TEST, GAS/ELECTRIC DTGE4A

1. If there is no heating system, go to step 12

2. At System Controller:

a. Turn power switch to ON. Verify power LED is illuminated.

3. Turn off all thermostats except thermostat 1.

4. At zone 1 thermostat:

a. Set power switch to ON, if applicable.

b. Set to Heat mode.

c. Set fan switch to AUTO mode.

d. Set heat setpoint 4° above room temperature.

5. At System Controller:

a. Verify W1 and PWR LEDs are ON. If not, cycle System Controller

power switch OFF and then ON and recheck.

b. If fan jumper is across middle and top pin, verify that G is

energized for fan operation in Heat mode.

c. Verify that DPR 1 LED is OFF and DPR 2 through DPR 4 are ON.

6. At furnace, verify that furnace is on and blower fan is running. If the

G LED on System Controller is not on, the blower fan is controlled

by the furnace and there will be a delay before it turns on.

7. At zone 1, verify that air is coming out of register.

verify that W2 LED energizes and, if 2nd stage heat is available, 2nd

stage starts.

9. At next zone:

a. Verify that no air is coming out of register.

b. At thermostat:

1. Set power switch to ON, if applicable.

2. Set to Heat mode.

3. Set fan switch to AUTO mode

4. Set heat setpoint 4° above room temperature.

c. Verify that air is now coming out of register.

10. At previous zone, turn off thermostat, and verify there is no airflow.

Verify that DPR 2 is OFF and DPR 1, 3 and 4 are ON.

11. Repeat steps 9 and 10 for remaining zones.

12. Turn off all thermostats except zone 1.

13. At zone 1 thermostat:

a. Set power to ON, if applicable.

b. Set to Cool mode.

c. Set fan switch to AUTO mode.

d. Set cool setpoint 4° below room temperature.

14. At System Controller:

a. Verify Y1, G and PWR LEDs are on. If not, cycle System Controller

power switch OFF and ON and recheck.

b. Verify that DPR 1 LED is OFF and DPR 2 through 4 are ON.

15. At HVAC unit, verify air conditioner and blower are running.

16. Verify that air is coming out of registers.

NUMBER TR SERIES TR SERIES TR SERIES TR SERIES MED. PRESSURE/HEAVY DUTYMED. PRESSURE/HEAVY DUTYMED. PRESSURE/HEAVY DUTYMED. PRESSURE/HEAVY DUTY

OF (SPRING OPEN) DAMPERS (SPRING OPEN) DAMPERS (SPRING OPEN) DAMPERS (SPRING OPEN) DAMPERS (POWER OPEN) DAMPERS (POWER OPEN) DAMPERS (POWER OPEN) DAMPERS (POWER OPEN) DAMPERS

DAMPERS XFMR PWR XFMR PWR FUSE SIZE FUSE SIZE

1 40 VA 1 AMP 40 VA 1 AMP

2 40 VA 2 AMP 40 VA 1 AMP

3 40 VA 2 AMP 40 VA 1 AMP

4 40 VA 3 AMP 40 VA 2 AMP

5 48 VA 3 AMP 40 VA 2 AMP

6 60 VA 4 AMP 40 VA 2 AMP

7 72 VA 5 AMP 40 VA 3 AMP

8 84 VA 5 AMP 42 VA 3 AMP

9 96 VA 6 AMP 48 VA 3 AMP

10 108 VA 6 AMP 54 VA 3 AMP

11 120 VA 7 AMP 60 VA 4 AMP

12 132 VA 7 AMP 66 VA 4 AMP

Notice:

All wiring must meet state and local codes.

TRANSFORMER/FUSE SIZING

XFMR PWR

FUSE SIZE

8. After 4 minutes of W1 run time, check LAT. If LAT is less that

HI limit minus 25°, then W2 will energize. If LAT is greater than

HI limit minus 25°, remove LAT from supply plenum and

17. After 8 minutes, check LAT. If LAT is above LO cutout plus

23

23

12°, verify that Y2 energizes. If LAT is less than LO cutout plus

12°, remove LAT from supply plenum and verify Y2 operation.

STARTUP TEST, GAS/ELECTRIC DTGE4A (Continued)

18. At next thermostat:

a. Verify that air is not coming out of register.

b. At thermostat:

1. Set power switch to ON, if applicable

2. Set to Cool mode.

3. Set fan to AUTO mode.

4. Set cool setpoint 4° below room temperature.

c. Verify that there is airflow from register.

19. At previous zone, turn off thermostat and verify that there is no

airflow from register.

20. Repeat steps 18 and 19 for remaining zones.

Test complete.

1. Disconnect Y1, Y2, O/B, W2 and G wires between controller and air

handler. This will allow controller to cycle all stages of heat and cool

without energizing compressors, fans or heat strips.

2. Turn off all thermostats except zone 1.

3. At zone 1 thermostat:

a. Set power switch to ON, if applicable.

b. Set to Heat mode.

c. Set fan to AUTO mode.

d. Set heat setpoint 4° above room temperature.

4. At System Controller: