Installation and Applica tions Manual

System 2000

GEN II

A MODULATING SYSTEM

Vote Based Auto Changeover VAV

Part #GENIIMAN

June 2014

GEN II

QUICK START AND COMMISSIONING

Follow these Quick steps for a successful job

If you need additional information, please read the GEN II Manual

1. Install GEN II Controller in an easily accessible location for your customer.

2. Install an Independent 24 Volt 40 VA tr ansfor m er, and connec t to th e T R1 and T R2 ter m inals

on the GEN II controller.

3. Install the LAT sensor in the supply air, ahead of any bypass takeoffs. Wire sensor to the S S

terminals on the GEN II controller.

4. Install Dampers and Bypass Dampers.

5. Install all thermostat sub-bases.

6. Wire R & C Terminals from the GEN II Controller to the

Thermostat wire).

7. Wire RX & TX Term inals from the GEN II Controller using Belden 8740 t wisted pair w ire to

first thermostat sub-base – only.

the

8. Damper wiring – connect RO, RC, MC wires from each therm ostat to its dam per with 18 GA

thermostat wire.

9. Plug 1 MODSTAT into that sub-base.

10. Address that therm ostat to #1 – see Pages 10-13 f or MODSTAT installation, add ressing and

operation.

11. Turn on GEN II Controller s witch “E”. Power light s h ou ld light up and then look at t he D ispl ay

"O" on the GEN II Controller, and t he num ber 01 ap pears on the Dis play. T his indicat es you

are communicating with the first thermostat.

12. If you don’t see the #1 and a 0 is displa yed, check the address . If the address is #01, t hen

check wires for R&C polarity and RX TX for correct connections.

13. If #1 is displayed on the GEN II Controller, then daisy chain wires from Stat 01 to the next stat

and address it #2; the n repeat the ON – Off switch operatio n and c onf ir m the #2 shows up on

the display indicating the system is now communicating with 2 thermostats.

14. Continue adding MODSTATS, and conf irm communicatio n by repeating the O N – Off switch

operation until all stats are wired and the total number of thermostats on your job shows up

on the display on the GEN II Controller. (If you are adding stan d-alone units to the GEN II

Controller, see #15. If not, skip to #16)

15. If there are any stand-alone units that are going to be managed by the GEN II Controller,

install DIGICOM / DIGIHP stats at this tim e. Continue the RX & TX daisy chain from the last

MODSTAT to the DIGICOM / DIGIHP and wire in the stand-alone unit at this time and

address the DIGICOM / DIGIHP (see Pages 14-17 for installation, addressing and

operation). Confirm communication by repeating the On – Off switch operation u ntil all stats

are wired and the total nu mber of thermostats on your job shows up o n the display on the

GEN II Controller.

16. Go to any MODSTAT and make a Cool Cal l. Look at the GEN II Co ntroller and conf irm Y1

(yellow LED) and G (green LED) lights are on.

17. Turn off the Cool Call to be sure Y1 and G turn off at GEN II Controller.

18. Repeat with Heat Call for W1 (red LED).

19. Wire GEN II Controller to A/C unit.

20. Set stat to ca ll for cool, and c heck r egister to be sure each dam per op ens and closes as you

make and satisfy calls.

For Advanced Feature Configuration or additional operating information, review the attached

GEN II Manual.

first sub-base – only (18 ga.

GEN II

QUICK START AND COMMISSIONING

The GEN II is equipped with a Digital Display (O) on the GEN II controller that constantly

displays Leaving Air Temperature from the unit. At startup, this dis p lay also reports the num ber

of thermostats communicating with the GEN II controller. The display and 3 buttons (N) beneath the

display provide the installing contractor the ability to tailor the system to your specific application.

The GEN II controller is shipped from the factory configured for basic Gas/Electric operation.

However, the following should be checked as part of the initial installation setup procedures:

1. EH jumper (A) is installed b y the fac tory on one pin for normal gas hea t operation where the fan

is controlled by the HVAC system fan control. When a f an output is required from the GEN II

controller on a call for heat, place the EH j umper over both pins for several seconds and then

remove. Place the jumper tab on one pin.

2. O/B and HP jumpers (B&C) should both be on one pin or removed for GE operation.

3. PRIORITY jumper (D) should be on one pin.

Note: If the Priority opp osing zone strateg y is to be used, this jumper pos ition will be changed

after the initial system start-up is completed.

See Advanced Feature Configuration.

4. Set the power switch (E) to ON.

5. Set the NIGHT DAY switch (L) to the DAY position.

6. Set the fan jumper (M) to AUTO for interm ittent operation or ON for c onstant ON operation in

the Occupied mode.

7. Place the LOCK – UNLOCK switch (P) in the UNLOCK position.

8. Place the TIME/TEMP jumper (Q) on the middle and upper pins to control Y2 and W 2 staging

on run time and supply air temperature.

Table of Contents

Page

System Overview

General Sequence

Gas Electric Operation

4

5

Heat Pump Operation

7

8

8

Zone Therm

12

.....13

Zone Thermostats

Advanced Feature Configuration

Zone Dampers

Bypass Dampers

System Overview Diagram ..................................................................................................................1

Controller ID Diagram ..........................................................................................................................3

Installation Controller ...........................................................................................................................3

GE Controller Configuration .................................................................................................................

GE Advanced Configuration ................................................................................................................5

H&C Cut-out Temperature ...................................................................................................................

Electric Heat Fan .................................................................................................................................5

2nd Stage cut in ....................................................................................................................................5

Controller ID Diagram ..........................................................................................................................6

Heat Pump Installation .........................................................................................................................

Basic Configuration ..............................................................................................................................

Heat Pump Advanced Configuration ...................................................................................................8

H&C Cut-out Temperature ...................................................................................................................

2nd Stage Cut-in ...................................................................................................................................9

ostat – ModStat

ModStat Installation ...........................................................................................................................10

Wiring Diagram ..................................................................................................................................10

ModStat Configuration ..................................................................................................................11-

Supplemental Heat Applications ...................................................................................................

DIGICOM / DIGIHP Installation ....................................................................................................14-15

DIGICOM / DIGIHP Configuration ................................................................................................16-17

Voltage Polarity .................................................................................................................................17

System Start and Test .........................................................................................................................18

Troubleshooting ...................................................................................................................................18

Gas Electric and Heat Pump .............................................................................................................19

Occupied/Unoccupied Fan ................................................................................................................19

Opposing Call Changeover ...............................................................................................................19

Priority Demand ................................................................................................................................19

Thermostat Security – LOCK ............................................................................................................20

Air Balance ........................................................................................................................................20

Default Thermostat Set Points ..........................................................................................................21

Time Clock (GCLK) ...........................................................................................................................21

Round Dampers ................................................................................................................................22

Rectangular Dampers .......................................................................................................................23

D-Fuser .............................................................................................................................................24

Sizing ................................................................................................................................................25

Slaving Zone Dampers .....................................................................................................................25

Bypass Dampers ...............................................................................................................................26

Slaving Bypass Dampers ..................................................................................................................27

Bypass Damper with Integrated Pressure Control........................................................................28-29

....................................................................................................................................1

of Operation ............................................................................................................2

...........................................................................................................................3

.............................................................................................................................6

– DIGICOM / DIGIHP

– Electronic

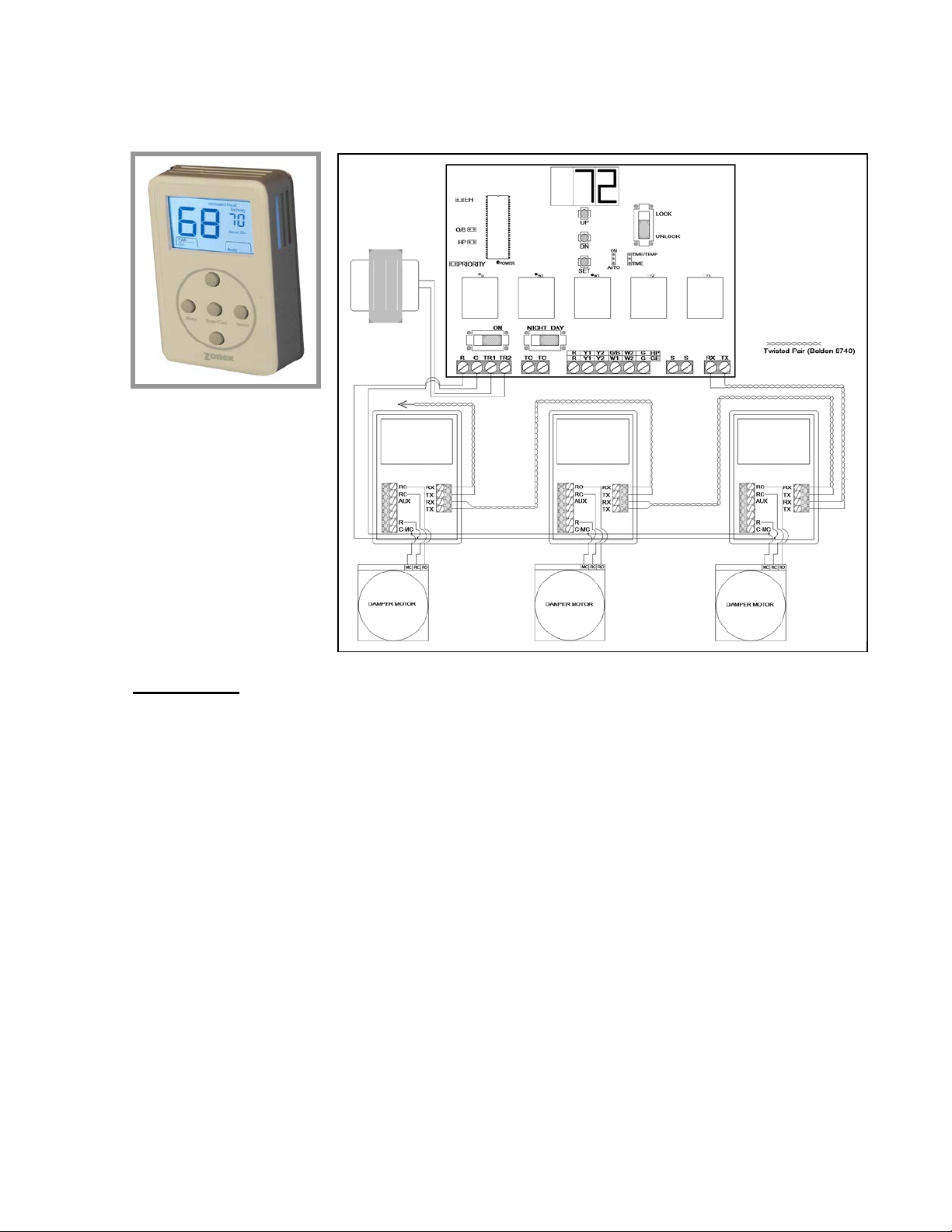

SYSTEM OVERVIEW

The SYSTEM 2000 GEN II is a commercial modulating or 2-p os iti on zone co ntr o l s ystem controlling

2-17 independent zones per unit. The G EN II controller is designed for Auto Change- over , multistage Heat Pump (2C/3H) and Gas Electric (2C/2H) applications.

For modulating applicat ions, the GEN II s ystem uses the Zonex ModStat, which controls the “ST”

series, 3-wire, 24-volt, po wer open / power close round and rectan gular dampers. For 2-position

damper applications, the GEN II system uses the Zonex MODS2 thermostat. The MODS2

thermostats control the T R round or TREC rectangular series, 2-wire, power close / spring open,

low pressure dampers . The TR / TREC series dampers are designed f or systems 5 tons or less

(2000 CFM).

Sophisticated, integrated software allows for a wide range of system control and changeover

strategies, allowing the contractor to tailor the GEN II system to your specific application.

Additional features i nclude LED status indication of all system functions, digital LAT display, fully

adjustable capacity control with on-board limit settings, and optional staging strategies. Night

setback operation is standard, with selectable 2-hour override at each stat, along with a unique

feature to remotely lock thermostats in the system.

The system provides the installing contractor with a simple startup diagnostic to minimize wiring

errors and speed installation.

GEN II is rec ognized as the Industry's easi est zone control system to install and wire. The GEN II

System operates over an unshielded two-wire data link, along w ith two 24 V power wires a ll daisy

chained from st at to stat with no home run wiring required. Three wires from the s tat to actuator

control a modulating damper in each zone.

The GEN II system does not require a computer to set up or operate.

1

System 2000 GEN II offers the following additional control features:

1. Set Cooling and Heating capacity cut-out set points

2. Adjustable timing to initiate 2

nd

stage operation

3. Adjustable opposing call changeover timing

4. Priority demand votes on a stat-by-stat basis

5. Provide default occupied and unoccupied set points on every stat

6. Open all dampers for air balancing

System 2000 GEN II components:

• GEN II controller (includes integrated capacity control)

• Zone thermostats

• Power open / power close 24vac supply dampers

• Power open / power close 24vac bypass damper with static pressure control

• Communication cable (Belden 8740) twisted pair

• Time Clock (optional)

• 24vac 40va transformers: 1 to control system and dampers

1 for bypass damper and static pressure control

• Stand-alone thermostat – non-zoned system

GENERAL SEQUENCE OF OPERATION

When the GEN II controllers are po wered up, the t otal num ber of addressed ther m ostats (ModStat ,

MODS2, DIGICOM, DIGIHP) are determined and verified on the display. This confirms the

controller is communic ating with all thermostats in the system. If there are no activ e heat or cool

calls detected, the sup ply dampers will modulate to 5 0% open (ModStat) or full open (MODS 2) for

ventilation mode. Ad ditional thermostats ma y be utilized to control stand-alone rooftop units with

DIGICOM / DIGIHP thermostats. The system blower operat ion can be configured for constant ON

or intermittent Auto. The controllers are shipped from the factory for Auto fan.

The System 2000 GEN II systems can be f ield configured for adjustable t ime based opposite cal l

changeover, vote based majority changeover, or priority vote changeover by thermostat

assignment. The GEN II controllers are shipped from the factory for 10-minute opposing call

changeover. The GEN II controllers “poll” the thermostats once per minute to determine the

thermostat demand s tatus for heat and cool. T he heat and cool chang eover functions wil l operate

by the type of changeov er selected on t he controller. When the G EN II controllers change m odes,

a 5-minute purge cycle is initiated before the changeover is completed.

On active heat or cool calls, the non-calling zones will modulate to the close position, or close 100%

depending on the therm ostat being used. When the last calling zone is satisf ied in either heat or

cool mode, the GEN II controllers will terminate the HVAC outputs after the next “poll”; and the

blower output will be de-energized (unless contr oller is configured for cons tant fan) for a 5-minute

purge cycle. During the purge cycle no heat or cool calls are recognized.

When the system is in the heat ing mode and calls for coolin g are received, an opposing c all timer

strategy operates. T his timer is adjus table from 5–30 m inutes. The factory d efault is 10 minutes .

At the end of the selected t i me period, if the oppos ing c all is 3 de grees a way from set point, heating

is turned off. After a 5-m inute purge cycle, Cooling is turned on until the c ool call is satisfied. If

necessary, GEN II will return to the heating mode. If all calls have been satisfied, dampers will

modulate to the 50% open position for vent ilation. If th e opposing zone str ategy is not des ired, this

feature may be disabled.

This mode may be enhanc ed by adding Priority votes to each thermostat in t he system, thereb y

weighting certain zones more than others. This Priority mode allows you to select 0, 1, or 2

additional votes for a thermostat that has unusual loads, like a conference room.

2

LEGEND

TERMINAL FUNCTIONS / CONNECTIONS

GAS ELECTRIC OPERATION

TX / RX – Data Transmit / Receive

S S – Leaving / Supply Air Sensor Input

G – Fan Output

W2 – Auxiliary / Emergency Heat

O/B – Reversing Valve Output

Y2 – Stage 2 Cool Output

Y1 – Stage 1 Cool Output

R – 24vac from Unit Transformer

TC / TC – Time Clock Input for Occupied /

Unoccupied Operation

TR1 / TR2 – 24vac Power Input / Common

R / C – Stat Power Daisy Chain Stat to Stat

(18 ga. Thermostat wire)

A EH Jumper (Set Up Fan Operation for

Electric Heat)

B O/B Jumper (Heat Pump Only –

Reversing Valve Operation)

C H/P Jumper (Jump for Heat Pump

Operation)

D Priority Jumper (Allows for Priority Vote

Setup)

E On / Off Switch

F R C Power to ModStats (18 ga.

Thermostat wire)

G 24-Volt Transformer

H TC – TC Time Clock Terminals

I Unit Terminals

J S S Terminals – Leaving Air Sensor

(LAT)

K RX – TX Communications Wire

L Day / Night Switch

M Fan Jumper (Continuous or Auto)

N Up / Down / Set Buttons (High Limit,

Low Limit, Set)

O Digital Display (Leaving Air Temperature

and configuration)

P Lock / Unlock (Lock Thermostats)

Q Staging Strategy (Time / Temperature or

Time Only)

General Installation Instructions

GEN II Controller

1. Install the GEN II controller on a n interior wall wher e the ambient tem perature is between 32°120°F (0°- 48°C) non-condensing. This controller is to be installed in an accessible interior

area; not in attics or above ceilings.

2. The controller is to be powered by a dedicated 24vac 40va transformer.

The transformer secondary is wired to TR1 TR2 on the controller (G).

The secondary

voltage to the controller must be 24 to 28vac.

3

3. Install the leavi ng air s ensor (LAT ) in the s upp ly air , ahead of t he b ypass tak e-off. Sensor wires

are connected to the S S terminals on the controller (J). The LAT sensor leads may be

extended using standard 18/2 thermostat wire.

4. The leaving air sensor (LAT) is calibrated to the controller at the factory. However, the

calibration should be checked as part of the system setup procedures. If adjustments are

required, use the Blue potentiometer labeled R4 4 located in the upper lef t hand corner of the

GEN II controller. Screw the pot clockwise to lower the display temperature and counter clockwise to raise the temperature. NOTE: The display will update every 10 seconds.

5. Confirm you have connected the RX TX communication wires and R and C from the

thermostats to the con trolle r ( F&K), F = (R C), K = (TX RX). (Communication wire m axim um is

4,000 ft. from the Command Center to the farthest ModStat, DIGICOM or DIGIHP.)

6. Connect the output wires from the controller to the HVAC system using standard 18 ga.

thermostat wire.

The LAT sensor leads may be extended using standard 18/2 thermostat wire.

Gas Electric - Basic GEN II Controller Configuration

The GEN II is equipped with a Digital Display (O) on the GEN II controller that constantly

displays Leaving Air Temperature from the unit. The display and 3 buttons benea th the displa y

provide the installing contractor the ability to tailor the system to your specific application.

The GEN II controller is shipped from the factory configured for basic Gas/Electric operation.

However, the following should be checked as part of the initial installation setup procedures:

1. EH jumper (A) is installed b y the fac tory on one pin for normal gas hea t operation where the fan

is controlled by the HVAC system fan control. When a f an output is required from the G EN II

controller on a call for heat, place the EH j umper over both pins for several seconds and then

remove. Place the jumper tab on one pin.

4

2. O/B and HP jumpers (B&C) should both be on one pin or removed, for GE operation.

3. PRIORITY jumper (D) should be on one pin.

Note: If the Priority oppos ing zone strateg y is to be used, this jumper positi on will be changed

after the initial system start-up is completed.

See Advanced Feature Configuration.

4. Set the power switch (E) to ON.

5. Set the NIGHT DAY switch (L) to the DAY position.

6. Set the fan jum per (M) to AUTO for inter mittent operation or ON for constant ON o peration in

the Occupied mode.

7. Place the LOCK – UNLOCK switch (P) in the UNLOCK position.

8. Place the TIME/TEMP jumper (Q) on the m iddle and upper pins to c ontrol Y2 and W2 staging

on run time and supply air temperature.

GEN II Gas Electric Advanced Feature Configuration

Gas Electric Capacity Control - Cool and Heat cut-out temperature adjust

The factory setting for the Cool and Heat cut-out temper atures is 45°- 145°F (7°- 62°C). T his can

be easily changed with the following proced ur e:

1. Cool cut-out temp – Press the DN button (N); “C” will be displayed and then the cut-out

temperature.

2. LOWER – Press the DN button; after the “ C” is displayed, continue to h old the DN button unti l

the desired temperature is displayed; then release.

NOTE: The controller will not change the Cool cut-out lower than 40°F (4°C).

3. RAISE – Press the DN but ton; after “C” is displayed, immediately release the DN button a nd

press the UP button. Hold until the desired temperature reading is displayed, and release.

4. Press the DN button to verify the new cool cut-out temperature.

Heat cut-out temperature - Press and hold the UP button; after the “H” is displayed, use the same

procedure as above to raise or lower the displayed temperature.

Electric Heat - Fan Configuration

EH jumper (A) is insta lled by the fac tory on one pin f or normal gas heat o peration wher e the fan is

controlled by the HVAC system fan control. When a fan output is required from the GEN II

controller on a call for heat, place the EH jumper over both pins for several seconds and then

remove. Place the jumper tab on one pin.

2nd Stage Heat and Cool Cut-in Configuration

The GEN II controller is set up at the fac tory to stage Y2 and W2 cut-in operation based on a 3minute time delay and

middle and upper pins on TIME/TEMP (Q), and the c ut-in delay set at 03 (3 m in) in the controller

program. The cut -in temperatur es are fix ed in the con troller progr am at 57°F (13°C) and hig her for

Y2 and 120°F (48°C) and lower for W2. The Y2 and W2 cut-in delay sequence can be field

adjusted (see below).

supply air tem perature. This is done wit h a jumper which is place d on the

Adjust 2nd Stage Cut-in Time Delay

1. To increase the Y2 and W2 cut-in delay, press and hold the SET and DN buttons (N)

simultaneously. W hen 03 appears in the display, release the buttons and immediately press

the UP button and hold until the desired de lay time is displayed, and r elease. The time delay

is fully adjustable from 3 - 20 minutes . To verify the change, press and hold the SET and DN

buttons simultaneously until the delay time is shown, and release.

5

2. To decrease the Y2 and W2 cut-in delay, press and hold the SET and DN buttons (N)

TERMINAL FUNCTIONS / CONNECTIONS

(18 ga. Thermostat wire)

LEGEND

simultaneously. W hen delay time appear s in the displa y, release the butt ons and imm ediately

press the DN button and hold u ntil the desired dela y time is displayed, and rele ase. To verify

the change, press and hold the SET and DN buttons until the delay time is shown, and release.

Configure 2nd Stage Cut-in For Time Delay and Thermostat Demand Only

1. Place the 2nd stage configuration jumper (Q) on the middle and lower pins - TIME.

2. If the cut-in time del a y must be ch anged f rom the f actor y settin g of 03 (3 m in), f ollow the above

procedures to raise or lower the time delay value.

3. Verify time delay value by pressing the SET and DN buttons simultaneously.

HEAT PUMP OPERATION

TX / RX – Data Transmit / Receive

S S – Leaving / Supply Air Sensor Input

G – Fan Output

W2 – Auxiliary / Emergency Heat

O/B – Reversing Valve Output

Y2 – Stage 2 Cool Output

Y1 – Stage 1 Cool Output

R – 24vac from Unit Transformer

TC / TC – Time Clock Input for Occupied /

Unoccupied Operation

TR1 / TR2 – 24vac Power Input / Common

R / C – Stat Power Daisy Chain Stat to Stat

A EH Jumper (Set Up Fan Operation for

Electric Heat)

B O/B Jumper (Heat Pump Only –

Reversing Valve Operation)

C H/P Jumper (Jump for Heat Pump

Operation)

D Priority Jumper (Allows for Priority Vote

Setup)

E On / Off Switch

F R C Power to ModStats (18 ga.

Thermostat wire)

G 24-Volt Transformer

H TC – TC Time Clock Terminals

I Unit Terminals

J S S Terminals – Leaving Air Sensor

(LAT)

K RX – TX Communications Wire

L Day / Night Switch

M Fan Jumper (Continuous or Auto)

N Up / Down / Set Buttons (High Limit,

Low Limit, Set)

O Digital Display (Leaving Air Temperature

and configuration)

P Lock / Unlock (Lock Thermostats)

Q Staging Strategy (Time / Temperature or

Time Only)

6

General Installation Instructions

GEN II Controller

1. Install the GEN II controller on a n interior wall wh ere the ambient tem perature is between 32°120°F (0°- 48°C) non-condensing. This controller is to be installed in an accessible interior

area; not in attics or above ceilings.

2. The controller is to be powered by a dedicated 24vac 40va transformer.

The transformer secondary is wired to TR1 TR2 on the controller (G).

The secondary voltage to the controller must be 24 to 28vac.

3. Install the LAT air sensor in the supply air between the indoor coil and electric strip heat

elements.

4. The leaving air sensor (LAT) is calibrated to the controller at the factory. However, the

calibration should be checked as part of the system setup procedures. If adjustments are

required, use the Blue potentiometer labeled R44 l ocated in the upper left hand c orner of the

GEN II controller. Screw the pot clockwise to lower the display temperature and counter clockwise to raise the temperature. NOTE: The display will update every 10 seconds.

5. Confirm you have connected the RX TX communication wires and R and C from the

thermostats to the con trolle r ( F&K), F = (R C), K = (TX RX). (Communication wire m axim um is

4,000 ft. from the Command Center to the farthest ModStat, DIGICOM or DIGIHP.)

6. Connect the output wires from the controller to the HVAC system using standard 18 ga.

thermostat wire.

The LAT sensor leads may be extended using standard 18/2 thermostat wire.

Heat Pump operation “O” reversing valve

Cool Call – W hen a majority active cool call is received b y the GEN II controller, Y1, O /B and G

LEDs are illuminated; and the out puts are energized (within 1.5 to 3 minutes ). After 3 minutes, if

the leaving air tem perature is 58°F (14°C) or above, Y2 will e nergize for 2-stage system s. If the

supply air temperature dro ps one degree below the Cool cut-out tem perature, Y1 and Y2 will deenergize for 4 minutes.

“B” reversing valve – Sequence of operation is the same: O/B is energized in the heat mode.

Heat Call - When a majority active heat call is received by the GEN II controller, Y1 and G LEDs are

illuminated; and the out puts are energized (w ithin 1.5 to 3 minutes). If after 3 minutes the leaving

air temperature is 94°F (34°C) or less, Y2 will en er gi ze. If after 6 minutes of run time the leaving air

temperature is 91°F (32°C) or less, W 2 will energi ze. If the sup ply air tem perature ex ceeds 126°F

(52°C), Y1, Y2 and W2 ( if energized) will drop ou t; and Y1 can then energ ize after a 4-minute time

delay. NOTE: If the system fan is configured for “AUTO” on the GEN II c ontroller, the “G” output

will be de-energ i zed in the t emperature cut-out mode.

When the last active call satis fies, the GEN II control ler goes into a 5-minute purge cycle with a ll

supply dampers closing; then all dampers modulate open for ventilation.

Emergency Heat - The GEN I I emergency heat oper ation can be selected from any ModStat f or

the entire control system . When the system operation mode is c hanged to Emergency Heat on a

given ModStat, the GEN II controller will recognize the mode change on the next s ystem poll. The

thermostat which was us ed to select Emergency Heat does not ha ve to make a heat call for the

GEN II controller to respond to the change. Once the GEN II controller changes the mode to

Emergency Heat, any ModStat in the system can make an emergency heat call. When the

controller receives a heat c all in t his mode, the com pressor (s) are lock ed out a nd W 2 is energi zed.

The G EN II controller will continue to make c onsecutive Emer gency Heat calls un til the ModStat(s )

have been changed back to the AUTO or HEAT mode.

7

To select Emergency Heat on any ModStat:

1. Press and hold the ModStat Menu button

2. When the mode disp lay indicates Emg, releas e the Menu button; and immediately press and

hold the Select button to set the mode.

Heat Pump operation “B” reversing valve

By placing the O/B jum per (B) on both pins, the GEN II controller is c onfigured for “B” reversing

valve operation. The operation and setup procedures are the s ame as with “O” mode reversing

valve, except the reversing valve will be energized for heat operation.

GEN II Heat Pump Basic Configuration

The GEN II controller is shipped from the factory

for Gas Electric operation.

The controller must be field configured for Heat

Pump operation.

Heat Pump configuration:

1. Switch controller to OFF (E).

2. Set the O/B jumper (B) on one pin for “O”

reversing valve (energizes for cool) or

set the O/B jumper (B) on both pins for “B”

reversing valve (energizes for heat).

3. Set the HP jumper (C) on both pins for Heat

Pump operation.

4. Set the Priority jumper (D) on one pin.

5. Set the TIME / TEMP jumper (Q) on the

middle and upper pins.

6. Set NIGHT / DAY switch (L) for DAY position.

7. Set LOCK / UNLOCK switch (P) to UNLOCK.

8. Switch the controller to ON (E).

9. Press the UP button (N), and verify the “H”

(cut-out) temperature reads 126°F (52°C) on the controller display (O).

NOTE: The heat cut-out temperature must not be changed from the factory setting.

GEN II Heat Pump Advanced Feature Configuration

Heat Pump Capacity Control - Cool and Heat cut-out tempera tu re adjustment

When the GEN II controller is configured f or H e at P um p (H P jumper (C) on both pins ), the Cool and

Heat cut-out temperatur es are 45°- 126°F (7°- 52°C). The cut-out tem peratures can be changed

with the following procedure:

Heat cut-out temp – To eliminate the possibility of the Heat Pump tripping out on high head

pressure or short cycling in the heat mode, the heat cut -out temperature shou ld never

from the factory setting of 126°F (52°C).

1. Cool cut-out temp – Press the DN button (N); “C” will be displayed, then the cut-out

temperature.

2. LOWER – Press the DN button. After the “C ” is displa yed, contin ue to hold t he DN butto n until

the desired temperature is displayed; then release.

NOTE: The controller will not change the Cool cut-out lower than 40°F (4°C).

8

be chang ed

3. RAISE – Press the DN button. Af ter “C” is displa yed, immediatel y release the DN button, and

press the UP button. Hold until the desired temperature reading is displayed; then release.

4. Press the DN button to verify the new cool cut-out temperature.

2nd Stage Heat and Cool Cut-in Configuration

The GEN II controller is set up at the fac tory to stage Y2 and W2 cut-in operation based on a 3minute time delay and

middle and upper pins on TIME/TEMP (Q), and the c ut-in delay set at 03 (3 m in) in the controller

program. The cut -in temperatur es are fix ed in the con troller progr am at 57°F (13°C) and hig her for

Y2 and 120°F (48°C) and lower for W2. The Y2 and W2 cut-in delay sequence can be field

adjusted (see below).

Adjust 2nd Stage Cut-in Time Delay

1. To increase the Y2 and W2 cut-in delay, press and hold the SET and DN buttons (N)

simultaneously. W hen 03 appears in the display, release the buttons and immediately press

the UP button and hold until the desired de lay time is displayed, and r elease. The time delay

is fully adjustable from 3 - 20 minutes . To verify the change, press and hold the SET and DN

buttons simultaneously until the delay time is shown, and release.

2. To decrease the Y2 and W2 cut-in delay, press and hold the SET and DN buttons (N)

simultaneously. W hen delay time appear s in the displa y, release the butt ons and imm ediately

press the DN button and hold u ntil the desired dela y time is displayed, and rele ase. To verify

the change, press and hold the SET and DN buttons until the delay time is shown, and release.

supply air tem perature. This is done wit h a jumper which is place d on the

Configure Y2 and W2 cut-in for time delay and thermostat demand only

1. Place the 2

2. If the Y2 cut-in tim e delay must be changed from the factory setting of 03 (3 min), f ollow the

above procedures to raise or lower the time delay value.

NOTE: The cut-in delay timing for W2 (Aux Heat) is set for approximately 3 minutes in the

control program and cannot be manually changed.

3. Verify time delay value by pressing the SET and DN buttons simultaneously.

nd

stage configuration jumper (Q) on the middle and lower pins - TIME.

9

Zone Thermostat - ModStat

Installation

Wiring

All 24-volt and comm unication wiring connections are made to term inal blocks on the thermostat

sub-base. The com munication terminal b lock (RX TX/RX TX) is des i gne d as a j unc tion for two sets

of 22 ga. solid cop per , t wist ed p air c om munications cable. The c a ble s ho uld b e d ais y c ha ine d f rom

thermostat to thermostat (use Belden 8740).

1. Install the therm os tat s ub-bas e on an int er ior wal l a wa y fr om direct sunlight, suppl y a ir c urr ents ,

or any heat generating source. Mounting screws and anchors are provided. The sub-base

may be installed on a vertical 2x4 electrical box.

2. Connect the control wires from the ModStat' s R & C, to the GEN I I controller (F). Verif y R & C

polarity is the same on each thermostat (18 ga. Thermostat wire).

3. On the ModStat, connect the damper output wires from C-MC, RC and RO to the actuator

motor terminals. NOTE: For MODS2, terminal RO is not used.

4. Connect the RX TX communicat ion wires on the right hand term inal block; there are 2 sets of

RX TX terminals to make the daisy chain wiring easier.

NOTE: The communication wire must be twisted pair Belden 8740, 8450 (shielded) or

82442 (plenum rated).

10

Configuration

Addressing

Each thermostat must have a unique address from 1-17.

1. Press and hold the Menu button unti l you see the system mode displa y on the lo wer right beg in

to change modes; then press and hold the Heat/Cool button with the Menu button.

2. When the displa y shows “address,” releas e t he Menu and Heat/Cool buttons, and pr ess th e UP

or DN button until the correct address is displayed in the upper right of the display.

3. After setting the addr ess , th e ther mostat will automatic ally go back to norm al oper atio n; a nd the

set point temperature will replace the address number just programmed.

Display Temperature Calibration

Thermostats are calibrate d at the factory and shoul d require no further adjustm ent. However, the

display space temperature may be field calibrated by the following procedure:

1. Press and hold the Heat/Cool and Select buttons together; then press and release the UP

button to increase the display temperature by one degree.

2. To lower the tem perature displa y, press the DN b utton once, af ter pressing the Heat/Cool and

Select buttons. This makes a 1-degree change.

Adjusting Set Points

The Heat or Cool set po ints can be displayed b y pres si ng th e Heat/Cool butto n; t h e s et p oi nt w ill b e

indicated on the upper right of the display.

The Heat and Cool set points can be individually set for the Occupied and Unoccupied modes.

Occupied Mode: H & C settings - Function switch (L) in the D AY position, or time clock in

Occupied.

Unoccupied Mode: H & C settings – Function s witch (L) in the NIGHT pos ition, or time clock

in Unoccupied.

11

Heat - If “Heat Setting” is displayed on the top right of the display, simply press the UP or DN button

to change the heat set point. If “Cool Sett ing” is displayed and you want to change the Heat set

point, press the Heat/Cool button twic e to c han ge f r om “Cool Setting” to “Heat S etti ng”. Then press

the UP or DN button to change the set point.

Cool - If “Cool Setting” is displayed on the top right of the display, simply press the UP or DN button

to change the cool set p oint. If “Heat Setting” is displa yed and you want to change the Coo l set

point, press the Heat/Cool button t wic e to c han ge f r om “Heat Setting” to “Cool S etti ng”. Then press

the UP or DN button to change the set point.

Changing Mode

The thermostats are auto changeover, but specific modes may be selected. Auto mode is the

default.

Heat only – Press and hold the Menu button and note the mode display begin to change. Press

the Select button when Heat is displayed.

Emergency Heat - Press and hold the Menu button and note the mode displ ay begin to change.

Press the Select button when Emg is displayed.

Cool only - Press and hold the Menu button and note the mode display begin to change. Press the

Select button when Cool is displayed.

System Off - Press and hold the Menu button and note the mode displ ay begin to change. Pres s

the Select button when Off is displayed.

Auto mode – Press and release the Menu button.

Override

When the thermostat displ ays “Unoccupied” (top of display), a 2-hour temporary overri de may be

initiated by pressing the O verride/Select button. W hen additional override time is required, press

the Override/Select button again.

Reheat

The ModStat can be field c onfigured for reheat operatio n, including Fan Powered Box es. To set

the ModStat for Reheat, pr ess and hold the Heat/Cool

and Select b uttons together and then press

the Menu button; release all three buttons and the ° symbol will appear next to the heat and cool set

point temperature display.

NOTE: An air proving switch must be wired into the AUX output to protect the electric heating

devices.

Heat Call – The ModStat will send a sig nal for dem and heating when the spac e tem perat ure drops

1° below the heat set point temperature. If the temperature drops 2° below the heat set point

temperature, the AUX output will energi ze for auxiliar y heat. The therm ostat will end the active c all

when the space temperature meets the heat set point.

When configured for R eheat, if the spac e temper ature drops below the hea t set point, the ModStat

will modulate th e damper to 40% open. W hen the tem perature drops one more degre e, the AUX

terminal energizes the duct heat strip. The heat call will terminate when the space temperature

reaches the heat s et point temperature. The “AUX” output will de-energize, and the dam per will

modulate closed. If the system goes into the ventilation mode, the damper will then modulate open.

12

SUPPLEMENTAL HEAT APPLICATIONS MODSTAT

SUBBASE

{twisted pair}

{18 ga. stat wire}

ModStat Terminal Designations

TX – Data transmit

RX – Data receive

AUX – Reheat/AUX Heat Fan

RO – Run Open, damper

RC – Run Closed, damper

R – 24vac power input

C-MC – 24vac power common

NOTE: A larger transformer may be needed to power fan relay and/or heat strip relay.

13

DIGICOM / DIGIHP THERMOST ATS

DESCRIPTION

The Zonex Systems DIGICOM (2H, 2C) and DIGIHP (3H, 2C) are

microprocessor bas ed, auto changeover, stand-alone ther mostats used to

control stand alone units with no dampers in the system . The DIGICOM is

the Gas Electric version and has two-stage heat / cool outputs with

selectable fan operat ion. The DIGIHP Heat Pum p thermostats have twostage cool and three-s tage heat outputs with selectabl e fan. The D IGICOM

and DIGIHP thermostats have a large, easy-to-read LCD display with a

distinctive grey back light. The display backlight is continuous ly illuminated

in the Occupied mode and goes off in the Unoccupied mode.

The DIGICOM and DIGIHP are very easy to configure through the system program or to make

manual adjustments using the buttons located on the front cover.

These thermostats feature an onboard thermistor for precise temperature measurement. In the

event of power loss, the H eat and Cool set point s are stored in a non-volatile memor y, without the

need for battery backup.

The space ambient temperature is continually displayed with large, easy-to-read numbers. The

DIGICOM temperature displa y range is 45° - 95°F (7°- 35°C) and the DIGIHP t emperature displa y

range is 55°- 95°F (12°- 35°C). Fan Mode, H eat or Cool set points and operation m odes are all

indicated on the display.

Programmed set points can be manuall y adjust ed at t he ther m ostat or elec tron icall y locked thr ough

the system program to provi de limited manual s et point adjustment. Two-hour o verride is provided

for after-hours temporary operation with a touch of a button.

INSTALLATION

Thermostat and terminal base

1. The thermostat is to be ins talled on the interior wall, away from drafts , supply air currents and

direct sunlight or any heat generating source.

2. To remove the thermos tat cover, gras p t he c over at the top and p ul l s traigh t of f; do not pivot the

cover from the base.

3. Install the thermos tat terminal base to the wall using the pro vided anchors and screws. The

thermostat can also be mounted on a 2x4 electrical box using two #6-32” screws.

Wiring

The Zonex System s DIGICOM and DIGIHP t hermostats have been specif ically designed to make

wall mounting and wire connections very eas y. The thermostat terminal base has two separate

terminal blocks: the left side terminal block is for the 24vac control circuits, and the right side

terminal block is for the RX TX comm unication circuits. Ther e are two sets of RX TX terminals on

the base to make daisy chain wiring from device to device straightforward and simple.

14

Wiring (Continued)

1. Use minimum 18-gauge AWG thermostat wire for the 24v ac contr ol cir cuits. T he load o n thes e

circuits must not exceed 1 amp. The voltage range on R and C must not exceed 28vac. Check

Polarity before appl ying the transform er wire to R and C. Ref er to the Polarit y Check diagram

on Page 17.

2. Connect the comm unicatio n wires to the RX TX terminals. There are 2 sets of RX TX terminals

for “daisy chain” installatio n of th is circuit. The comm unication wire spec ification is twiste d pair

(Belden 8740) or shielded twisted pair wire (Belden 8450).

NOTE: When using s hielded twisted pair wire ( Belden 8450), just connect t he shield conductors

together, as there is no electrical connection on the thermostat base ter minals. The shield will be

landed on the GEN II controller on the G or TR2 terminal.

Blower Fan Relay

For electrical heat applications, which require a fan output on a call for heat, see Fig. 3.

DIGICOM

Fig. 1

DIGIHP

Fig. 2

Fig. 3

15

Configuration

1. Set the unique address for each thermostat from 01 to 20.

2. Press and hold the Menu button until you see th e system mode displa y on the lo wer r ight beg in

to scroll and change modes; then press and hold the Heat/Cool button with the Menu button.

3. When the display shows “address” and the set point temperature changes to the address

number, press the UP or DN button to raise or lower the number.

MAN UAL AD J U S T MEN T S

Heat and Cool Set point Display

Press the Heat/Cool button to display the Heat or Cool set point temperatures.

Temperature Set points

COOL Set point

1. Press the Heat/Cool button to display the Cool set point on the upper right.

2. Press the UP or DN buttons to change the Cool set point.

HEAT Set point

1. Press the Heat/Cool button to display the Heat set point on the upper right.

2. Press the UP or DN buttons to change the Heat set point temperature.

FAN Mode

To change the FAN operation to AUTO or On, press the UP and DN buttons together once to

toggle fan operation.

HVAC System Mode

To select Heat, Cool, Auto, Emergency Heat (HP only) or OFF, press and hold the Menu

button; and when the desired m ode is displayed, press and ho ld the Select button; th en release

both to confirm mode.

Override

When the system is in the Unoc cupied mode, the thermostat provides a 2-hour override for after hours system operat ion. T o s elect the 2-hour override, press the Select button a nd n ote “Override”

indicated on the displa y, along with the b acklight com ing on. When additi onal override is required,

press the Select button again.

Calibration

When re-calibration is required, press and hold the Heat/Cool and Select butt ons simultaneously

(the screen will flash) . Then pr ess the UP button once to incre ase tem peratur e 1° , or pres s the DN

button once to decrease the temperature 1°. If additional calibration is required, repeat this step.

Reversing Valve Mode – Heating

DIGIHP (O&B) is factory set at “O” and ca n be field configured for “B” re versing valve operation.

For “B” mode reversing valve (reversing valve energized in the heat mode), press and hold the

Heat/Cool and Select buttons; then press and release the Menu button once. Release the

Heat/Cool and Select buttons. The ° symbol next to the set point display should disappear.

(To set from “B” to “O”, reverse the procedure.)

THERMOSTAT OPERATION

Display

The grey displa y backlight is constantly i lluminated in the Occupied m ode. The display backlight

goes off when in the Unoc cupied mode. When in the Unoccupied mode, if an y button is pressed,

the backlight will illum inate for 5 seconds. If the thermostat is placed in the override mode, the

backlight will illum inate until the 2 hours times out. T o terminate overri de, press the Select button

again.

COOL – DIGICOM / D IGIHP: The therm ostat will m ake a Y1 cool call when the s pace tem per ature

rises 1° above the cool se t point. Y2 will energize wh en the space tem perature ris es 2° above the

cool set point. When the room temperature is less than 2° above the cool set point, Y2 de-

16

energizes. Y1 de-energizes at set point. O or B is energized for the reversing valve circuit,

depending on configuration. The G circuit is energized for fan.

HEAT – DIGICOM: The thermostat will make a W1 heat call when the space temperature is 1

degree below t he heat set point. W 2 will ener gize when t he sp ace t em perature i s 2 degrees below

the heat set point. When the room temperature rises to within 2 degrees of the heat set point, W 2

de-energizes. W1 de-energizes at set point.

NOTE: The “G” fan circuit on the DIG ICOM thermostat is not energized in the Heat mode unles s

the fan is set for ON operation.

HEAT − DIGIHP: The ther m ostat will mak e a Y1 heat call when th e space tem perature is 1 d egree

below the heat set p oi nt. Y 2 will energize when the spac e temperature is 2 degrees bel o w the hea t

set point. E (aux heat) will energize when the space temperature is 3 degrees below set point .

When the room temperature rises to within 2 degrees of the heat set point, E (aux heat) deenergizes. When the room temperature rises to within 1 degree , Y2 de-energizes. Y1 deenergizes at set point.

Emergency Heat – DIGIHP: When Emergenc y Heat is selected on the DIGIHP thermostat on a

call for heat, there is an output signal o n “E” for backup heat and “G” f or the fan. The compressor

circuits “Y1” and “Y2” are lock ed out during heat calls until Auto, Heat or Cool mode is selected.

The thermostat display will indicate when Emergency Heat has been selected.

DIGICOM – FAN op eration f or electric heat app lications : A pilot relay m ay be re quired to e nergize

the fan for heat operation on electr ic heat applications. This relay is a 24vac coil – SPST and is

field supplied. The coil is energized from W1 and C from the DIGICOM thermostat terminal base.

VOLTAGE POLARITY CHECK ON DIGICOM / DIGIHP

17

System Start and Test

1. Plug all thermostats into sub-bases. Turn GEN II power switch (E) to ON.

2. Choose any Thermostat and change its address from 25 to 1.

(See ModStat installation instructions – Configuration – Addressing).

3. Turn GEN II power switch OFF and the n ON. The Display sh ould flash 01 and the n show the

leaving air temperature. This confirms your successful wiring and communication with that

thermostat.

4. If 01 is displa yed, change the next thermost at’s address from 25 to 2. Turn the GEN II power

switch OFF and then ON. The display should flas h 02 and then show the tem perature. Readdress thermostats one at a time.

5. After each stat is re-addressed, turn th e power switch off and then on. This will verify that the

re-addressed stat has been found by the GEN II Controller.

This procedure will sim plif y your instal lation a nd wil l confirm your wiring is cor rect and th at the GEN

II controller can communicate over the 2-wire twis ted pair data link with every therm ostat in your

system.

Troubleshooting

When stat #1 is not found:

1. Check remaining stats to verify that all addresses are 25.

2. Check all R & C wiring for proper color-to-color connections. Even if the stats lighted, all R

wires at the thermostat must be connected to the GEN II R terminal. All C wires must be

connected to the GEN II C terminal. Confirm the daisy chain wiring is correct at this time.

3. Check RX & TX wires for proper color code and connections; polarity is imperative. All RX

connections must land on R X term inal o n the f ol lo win g thermostat, and all TX c onnecti ons must

connect to TX terminal on each thermostat.

4. Check R & C wires for opens or shorts.

Checking the Daisy Chain for opens o r shorts:

Start from the GEN II board, and follo w RX & TX wires to the f irst sub-base. Remove the RX & TX

wires going to the nex t s ub -bas e in th e l ink . Plug a s ta t int o th e first sub-base, and ad dr ess it as #1.

Turn the GEN II power switch off, then on, to see if the display flashes.

1. If 01 is displayed, the first link of the daisy chain is OK. Reconnect the wires going to sub-

base.

2. Repeat these steps with a stat numbered 02. If the number 02 is displayed, then

Communication is confirmed.

When the correct number does not ap pear f or a link , that link is either shorted or open. A link of the

daisy chain, which is open or shorted, must be repaired before the next thermostat is checked.

When the thermos tats are correctly addres sed, wired and linked, the total number of stats on your

job connected to the GEN II Control board wi ll be disp layed when the board is turned on.

After the correct num ber of connected therm ostats is displayed, complete the wiring of AC unit or

heat pump connections; then make heat and cool calls to the GEN II Controller.

18

Advanced Feature Confi guration - Gas Electric and Heat Pump

Occupied / Unoccupied fan operation

The factory setting for F AN operation is AUTO, with the F AN jumper (M) on the middle and lower

pins. In this setting, the fan circuit on “G” is only energized on an acti ve cool call in Gas /Electric

mode or on an activ e heat c all or cool call in He at Pum p mode. T his applies to both Oc cupied and

Unoccupied modes. When the FAN jumper is in AUT O, there is no output on “G” with a n active

heat call in Gas/Electric mode.

• Constant Fan in the Occupied (DAY) mode – Place the FAN jumper (M) on the center and

upper pins on ON. T he fan output on “G” will be constant in the Occupie d (DAY) m ode and will

revert to auto in the Unoccupied (NIGHT) mode.

Opposing Call Changeover

The GEN II controllers are configured at the factory for Opposing Call Changeover with a time delay

setting of 10 minutes. W ith this configuration, any number of therm ostats can make a like active

call (heat or cool). Dur ing this tim e, if a single th erm ostat m ak es an opposit e call, a

at the next poll. This tim er starts a time delay operation to allow the initial calling therm ostats to

satisfy. If the initia l active therm ostats do not completel y satisfy after 10 m inutes, the dam pers all

close and the controller dro ps out the HVAC outputs and goes into a 3-minute pur ge cycle. When

the purge cycle times out, the opposing thermostat call is initiated; and the appropriate HVAC

outputs are energized, an d the supply dam per opens. The therm ostat with the opposing c all must

now satisfy before the GEN II controller will recognize any of the initially calling thermostats.

The opposing call timer is factory adjusted for 10 minutes. However, the delay time can be field

adjusted from 5 to 30 minutes.

To increase the opposing call time delay:

1. Press the SET and UP buttons.

2. Release the SET button when the display changes, and continue to hold down the UP

button.

3. Release the UP button when the desired time is displayed.

To lower the time delay:

4. Press the SET and UP buttons.

5. Release the SET button, and immediately press and hold the DN (down) button until

the desired time is indicated; then release.

The Opposing Call feature can be disabled by performing steps 1 through 3 and then releasing the

UP button when the display indicates 32. With this feature disabled, the GEN II c o n tr ol le rs wi ll

operate changeover by majority vote from the zone thermostats.

timer is s tarted

Priority active Heat and Cool call operation

The GEN II controllers m ay be configure d in the field for major ity vote changeover but also assign

multiple votes for selected thermostats to enhance the changeover operation for special

requirements. Each thermostat repr esents one vo te for heat or c ool operati on; a m ajority of active

calls will determine which mode the controller will operate in. With the Priority feature, any

thermostat may be assigne d one or more additional votes to allo w it to ha ve priority to bring a mode

changeover more quickly. To keep proper overall temperature control, this priority vote change

should be limited to as few zones as possible.

Follow the procedure to implement Priority vote operation:

1. Determine which thermostat address is to have an additional one or two votes.

2. Place the PRIORITY jumper (D) on both pins.

19

3. Press and ho ld t he SET and UP buttons (N), and the L ED disp lay will scroll through t h e number

of zones starting with 01.

4. W hen the display indicates the addr ess (01 to 17) of the thermostat you want to add votes to,

release both buttons and pres s the DN button. The display will scroll thr ough 00, 01, 02. To

add one additiona l vote, release the DN button when the display indicates 01 (this assigns a

total of 2 votes). To increase the votes b y two, press the DN button and wait unt il the

indicates 02 and then release the DN button (this assigns a total of 3 votes maximum).

5. T o change the votes back to a single vote, press the DN button on the selected address an d

release when the display indicates 00.

6. To review the vote status of all of the thermostats in the system, pres s the UP button; and the

display will first i ndicate the address number starting with 01and then th e vote status for that

address. 00 = 1 vote 01 = 2 votes 02 = 3 votes. Upon r eview, if stat #1 has 2 votes , the

display will show Stat 01 followed by 02 signifying the number of Priority votes assigned to

Stat 1. Stat 02 will appear followed b y a blank display, indicating onl y 1 vote; and Stat 03 will

appear followed b y a blank scr een, indicating n o priorit y votes have been a dded to Stats 02 or

03.

7. Be certain to Place the PRIORITY jumper on one pin to put the contro ller back into normal

operation with the changes that were made.

Thermostat security - Set Point LOCK

display

The GEN II system provides the a bility to electronically lock all of the zone thermostats (global).

When the thermostats are in the LOCK mode, there will be a padlock icon on each thermostat

display. The LOCK m ode lim its the m anual chang ing of the heat and c ool set po int s to a m ax imum

of 2° above or below the initial heat and cool set point temperatures.

To set the thermostats for the LOCK mode, simply change the switch position (P) from UNLOCK to

LOCK. All of the thermostats will change to LOCK on the next system poll. To unlock, set the

switch to the UNLOCK position; and the thermostats will drop the icon after the next system poll

and revert to normal operation.

Air Balance - Force Dampers Open

When performing an air ba lance on the supply air outlets, the GE N II controller provides a uniq ue

feature to simplif y this proc edure. T he GEN II controller will put all therm ostats in a cool ca ll whic h

will open the dampers 100% and bring on the system blower.

1. Place the EH jumper (A) over both pins

2. Press the SET and UP buttons (N) simultaneously – T his puts a global cool set point of 58°F

(14°C) on all of the zone ther mostats, and the controller ener gizes th e “ G” fan out put on l y; Y1 is

not energized.

3. When the air balance proc edure is completed, pres s the SET and DN buttons sim ultaneously,

which will assign 70°F (21°C) Heat and 75°F (23°C) Cool set points on all of the zone

thermostats.

4. Press and hold the SET and DN buttons; and while holding these buttons, remove the EH

jumper tab and plac e it o n one pin. Rele ase the SET and DN buttons. This proc edure r eturns

the GEN II controller to normal operation. For Electric Heat fan configuration, see Page 5.

20

Default Thermostat Set Point Programming

Global default set points can be established from the GEN II controller.

The following procedure will provide a 75°F (23°C) Cool and 70°F (21°C) Heat occupied set point

along with Unoccup ied 58°F (14°C) Heat a nd 85°F (29°C) Cool set point for every thermostat in th e

system. This handy feature minimizes visits to the thermostats. To establish these default set

points:

1. EH jumper (A) - place the jumper over both pins.

2. Press the SET and DN button (N) simultaneously to engage default set points.

3. Remove the EH jumper, and place on one pin to put controller back into normal operation.

4. To view the unoccupied set points place the Night / Day switch (L) to the NIGHT position.

Following a poll, the t hermostat backlights will turn off ; and the unoccupied set points will be

displayed.

Time Clock

The GCLK is a 24vac 7-Da y programmable time clock off ered by Zonex Systems, exclusivel y for

the GEN II control s ys tem. This digital time clock will enable the c ontrol system to operate with

“Global” Occupied and Un occupied schedules in a 7-day form at. The GCLK is powered from the

GEN II c ontroller p ower suppl y, and there is a bac kup batter y to protect the tim e clock program for

up to 100 hours.

Installation

The GCLK must be installed on an interior wall next to the GEN II controller. Both the GEN II

controller and GCLK t ime clock must be easil y accessible to monitor stat us and to make program

and function changes.

1. Remove the clear dust cover lens and loosen two screws on opposite corners of the clock

module.

2. Remove the housing that surrounds the time clock and the wire terminal cover.

3. Remove the clock m odule b y pulling stra ight out f rom the b ase. Instal l the bac king plat e to the

wall with 3 screws (provided).

4. The GCLK is powered from TR1 and TR2 on the GEN II c ontroller to terminals 1 and 2 on the

time clock terminal base.

5. The Normally Open s witch c ontacts on the tim e clock 3 an d 5 are wired to the TC term inals on

the GEN II controller.

6. Press the clock module back into place in the base, making certain that it is seated correctly.

7. Install the wire terminal cover and the clock housing with the 2 screws.

8. Install the clear dust cover lens in place.

Programming

See Programming and Conf iguratio n inclu ded with the G CLK.

21

ZONE DAMPERS

DAMPER MODEL

MAXIMUM

PRESSURE

SYSTEM SIZE

DUCT SIZE

STMPD Round Med. Pressure

1.75”

Any Size

18”

STMRTD Rect. Med. Press ure

1”

7.5 Tons

24”W x 20”H

STCD Rect. Heavy Duty

1.75”

Any Size

48”W x 48”H

D-FUSER

0.1”

Any Size

10”

DIAMETER

CFM

FPM

∆P “ WC

6”

110

540

.014

8”

250

700

.015

10”

410

750

.015

12”

660

850

.022

14”

1000

925

.035

16”

1450

1070

.036

18”

2000

1100

.036

L

W

D

ROUND DIM ENSION AL DATA

STMPD06

6

6”

10”

9”

STMPD08

8

8”

10”

11”

STMPD10

10

10”

12”

13”

STMPD12

12

12”

14”

15”

STMPD14

14

14”

16”

17”

STMPD16

16

16”

18”

19”

STMPD18

18

18”

20”

21”

MEDIUM PRESSURE (STMPD)

DAMPER TO

MODSTAT

WIRING

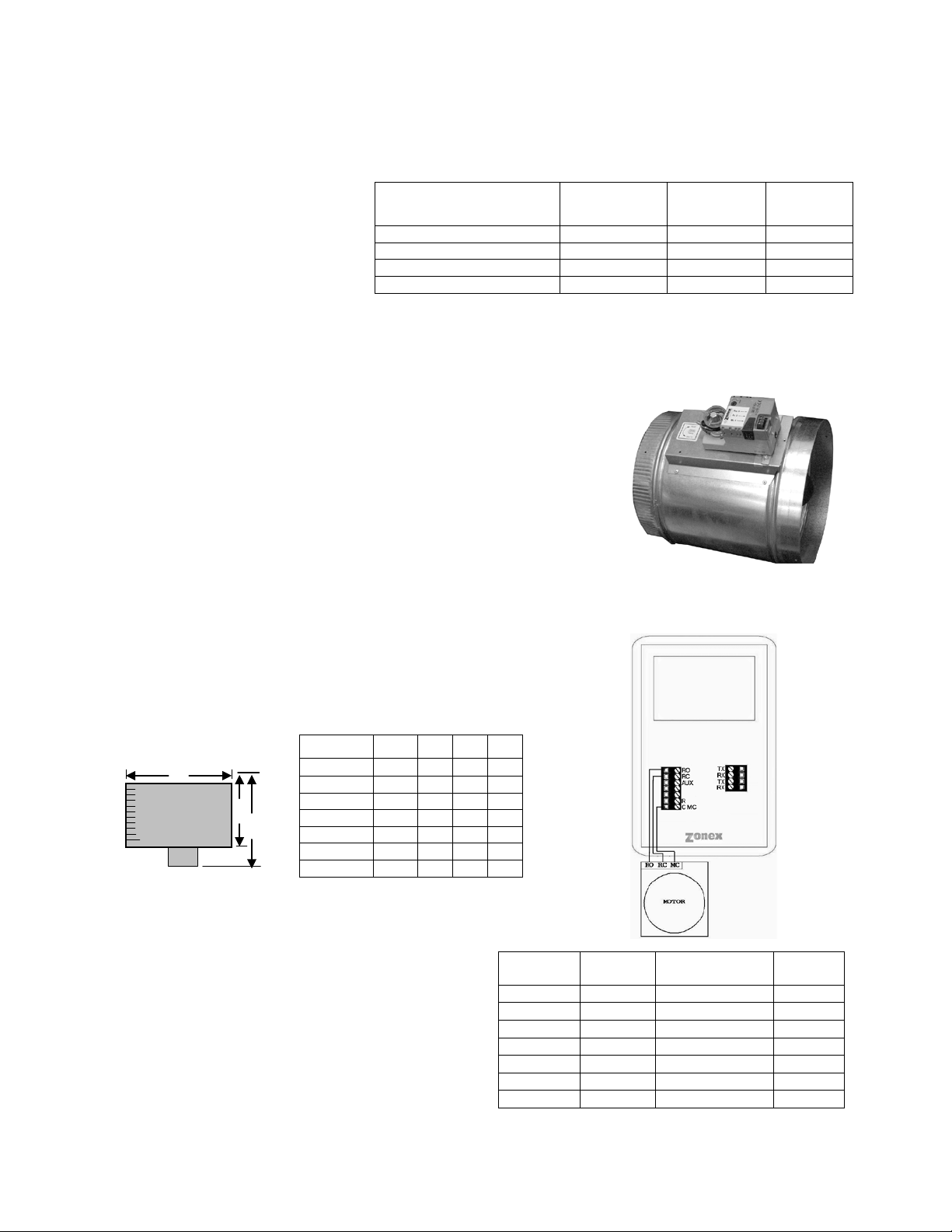

Zonex Systems zone dam pers are

used in cooling/heating systems to

provide room by room zone

control. The damper is provided

with a factory mounted actuator.

Each zone damper is controlled

by a zone thermostat. Mo re than

one damper can be controlled by

one zone thermostat. Use this

table to determine which zone

Maximum Differential Pressure refers to the maximum static pressure drop in inches

of water column between the input (upstream) of the zone damper and the output

(downstream) when the damper is closed.

dampers to use.

ROUND MEDIUM PRESSURE ZONE DAMPERS

Zonex Systems round medium pressure zone dampers are

recommended for systems with a maximum differential static

pressure up to 1.75”. This modulating power open/power close

damper is manufactured from 20-22 gauge galvanized steel with

rolled-in stiff ening beads for superior rigidity. Mechanica l minimum

and maximum s et stops are pr ovide d and are easil y adj ustable. T he

damper is elliptical, which allows the airflow to be tracked linearly.

The damper pipe is f urnished with one c rimped end and one s traight

end for easy installation. Do not install damper in an inverted

position. A hat section supports a reversing 24vac, 60Hz, 2 VA

motor. A magnetic c lutch allows for continu ous power to the motor

and longer motor life. Motor drive time from full open to full close is

90 seconds.

ROUND MEDIUM PRESSURE DAMPER

PART NUMBERS AND SIZES

PAR T # SIZE D L W

TYPICAL ROUND CAPACITIES

These air quantities were derived from a duct s izing

chart 0.1” friction loss per 100’ of duct. All CFMs

listed are approxim ate. For accurate selection, use

duct sizing table or device.

DIFFERENTIAL

DUCT

NOMINAL

MAXIMUM

DUCT VELOCITY

MAXIMUM

DAMPER

22

D

H

MOTOR

D

2 ½”

48” MAXIMUM WIDTH

MEDIUM PRESSURE RECTANGULAR DIMENSIONAL DATA

Part Number

Sizes available from 8” x 6” up to 24” x 20”

2½”

5”

H

RECTANGULAR ZONE DAMPERS

The rectangular zone dampers are available in either medium pressure or heavy dut y. For systems under 7.5

tons, use medium pressure dampers . For systems 7.5 tons or over, use heav y duty dampers. Motor dr ive

time open and close is 90 seconds.

RECTANGULAR MEDIUM PRESSURE ZONE DAMPERS (STMRTD)

Zonex Systems rectangular medium pressure dampers are recommended for

systems under 7.5 tons with a m aximum differ ential static pressur e of 1”. These

are fully m odulating, power open, power close damper s. They are constructed

from heavy duty alum inum and sta inless stee l. The d am per is an op posed blade

type that slips into a 3¼-inch wid e cutout in the existing d uct and attaches with

screws via a duct mountin g plate. The duct mountin g plate is 5 inches wide. A

hat section supports a r eversing 24vac, 60Hz, 2 VA motor. A magnet ic clutch

allows for continuous po wer to the motor and longer m otor life. Two set screws

connect the motor to the damper shaft, allowing quick motor replacement if

necessary. Motor drive time from full open to full close is 90 seconds.

W

HEAVY DUTY RECTANGULAR DIMENSIONAL DATA

Part Number STCD W x H

Sizes available from 8” x 8” up to 48” x 48”

RECTANGULAR HEAVY DUTY ZONE DAMPERS (STCD)

Zonex Systems rectangul ar heavy duty dampers ar e recommended for systems 7.5

tons or larger with a m aximum differential static pres sure of 1.75”. These are fully

modulating, po wer open / power close dam pers made of 20 gauge “s naplock” steel

frame with S & Drive duc t connections. Allo w a 16” gap in the duct for the damper.

Formed steel blade stops incorporate a gasket for quiet operation and improved

structural rigidity. Rectangular dampers under 10” in height incorporate a single

blade design. Dampers 10” or over use opposed blade design. A full stall

motor, drawing 2 VA, drives the motor from full open to full close in 90 seconds.

STMRTD W x H 2¼”

23

RECTANGULAR DAMPER SELECTION

Rectangular Damper Capacities*

WIDTH IN INCHES

8 10

12

14

16

18

20

22

24

26

28

30

32

8

300

400

500

610

710

820

925

1050

1175

1250

1400

1500

1600

10

400

540

680

825

975

1125

1300

1400

1590

1750

1975

2100

2175

12

500

680

850

1000

1200

1400

1600

1850

2000

2300

2550

2700

2850

14

610

825

1000

1250

1500

1750

2000

2250

2500

2900

3150

3425

3625

16

710

975

1200

1500

1800

2100

2450

2700

3000

3600

3950

4200

4425

18

820

1125

1400

1750

2100

2500

2850

3080

3600

4400

4600

4950

5100

20

925

1300

1600

2000

2450

2850

3400

3775

4000

4800

5500

5700

6000

22

1050

1400

1850

2250

2700

3080

3775

4300

4800

5100

6000

6350

6800

24

1175

1590

2000

2500

3000

3600

4000

4800

5400

6100

7000

7150

7600

26

1250

1750

2300

2900

3600

4400

4800

5100

6100

6700

7800

8400

8900

28

1400

1975

2550

3150

3950

4600

5500

6000

7000

7800

8400

9150

10000

30

1500

2100

2700

3425

4200

4950

5700

6350

7150

8400

9150

10000

11000

32

1600

2175

2850

3625

4425

5100

6000

6800

7600

8900

10000

11000

11250

* These air quantities were derived from duct sizing chart .1" friction loss per 100' of duct.

All CFMs listed are approximate.

For accurate selection use duct sizing table or device.

6”

Neck Vel

Throw 50 FPM

400

500

600

700

800

900 0.011

0.016

0.023

0.035

0.04

0.055 80

98

120

135

157

176

4’

4’

5’

6’

6’

7’

8”

Neck Vel

Throw 50 PM

400

500

600

700

800

900

0.019

0.03

0.045

0.056

0.041

0.093 140

170

207

247

280

315 5’

6’

7’

8’

9’

10’

10”

Neck Vel

400

500

600

700

800

900

0.029

0.045

0.066

0.09

0.12

0.146 218

273

330

382

438

497

6’

8’

9’

10’

11’

12’

24”

2”

12”

COLLAR:

PLACE ON SIDE

PLACE ON TOP

12”

AT NECK VELOCITIES UP TO 700 FPM

HEIGHT IN INCHES

D-FUSER ZONE DAMPER

Zonex Systems D-Fus er is a combination zone damper and diffuser. It mounts in a st andard 2’ x 2’ T-bar

ceiling opening, providing for simple installation and easy maintenance access. The D-Fuser is a cone

shaped fluidic nozzl e with a platen that m odulates up and do wn to control air f low. As the platen m oves up,

the air volume is r educed; but the air velocity and throw rem ain constant. This keeps the air hugging the

ceiling, which maximizes room air mixing and minimizes the “waterfall” effect. The D-Fuser is a fully

modulating power open / power c lose damper using a 24vac 60Hz 2 VA motor. Motor drive tim e from full

open to full close is 90 seconds . The D-Fuser connects to rou nd duct either on the side or top. Collars ar e

available for 6”, 7”, 8”, 9” and 10” duct.

NC LESS THAN 30

∆P

CFM

∆P

CFM

∆P

CFM

Throw 50 FPM

24

SIZING ZONE DAMPERS

If the ductwork already exists, simply size the damper to fit the ductwork. For new systems or retrofit jobs:

A. Determine CFM from heat gain or loss calculations.

B. Select damper size using either the round capacities chart, the rectangular capacities chart or by

using a duct sizing table or calculator.

C. Select a Zonex Systems damper to fit the duct size selected for that zone.

Make sure your zone dampers match the type specified in the table showing Maximum Differential Pressure.

INSTALLATION NOTES

1. Do not exceed 700 FPM in a register/diffuser branch duct.

2. If a damper is installed within 3 feet of a register/diffuser, install sound attenuating flex duct between

damper and outlet.

3. Zone dampers should be preceded by 2’ − 4’ of straight pipe where possible.

4. In attic installations and hi gh humidity areas, the Zone x Systems damper s hould be insulated along with

the ductwork. The hat sec tion on the round damper is delivered with insulation between the hat section

and pipe. Therefore, i nsul ation should be app lied t o the r ound p ipe and be but ted aga inst the h at sec tion

(do not insulate the motor). The motor generates enough heat so that no condensation will develop on it.

5. Remember to allow a 16” gap in the duct for heavy duty rectangular dampers.

6. Medium pressure rectangular dampers slide into a 3¼” wide cutout in the side of the preexisting

ductwork.

7. Minimum open and close p ositioning is field adjustabl e on the actuator. T he dam per is shipped from the

factory to close 100%.

NOTE: Dampers should not be installed with motor upside down in the 6:00 position.

SLAVING UP TO THREE ZONE DAMPERS

Up to three dampers can be direc tly controlle d by one therm ostat. T o wire two to three zone dam pers to one

thermostat, use the follo wing diagram shown. Rem ember to size the damper power tr ansformer for the total

number of zone dampers. Each actuator draws 2 VA.

ZONE DAMPER ZONE DAMPER ZONE DAMPER

Mc Ro Rc Mc Ro Rc Mc Ro Rc

Mc Ro Rc

MODSTAT

SLAVING MORE THAN

THREE ZONE DAMPERS

Use the following diagram

when a thermostat will be

controlling more than three

zone dampers. Use an

additional 24V transformer

sized at 2VA per damper to

power the slaved dampers.

25

BYPASS DAMPERS – ELECTRONIC

8”

560

10”

900

12”

1250

14”

1700

16”

2200

18”

2600

STBP08

8

8”

10”

11”

STBP10

10

10”

12”

13”

STBP12

12

12”

14”

15”

STBP14

14

14”

16”

17”

STBP16

16

16”

18”

19”

STBP18

18

18”

20”

21”

ROUND BYPASS SELECTION TABLE

4”

H

D

W

48” MAXIMUM WIDTH

RECTANGULAR BYPASS DAMPERS

D

L

W

ELECTRONIC BYPASS DAMPERS

Bypass dampers are used to provide constant air delivery through the air handling unit. This is done by

bypassing excess air f rom the supply duct back to th e return duct. As a zone is sat isfied, its zone damper

closes. When this happe ns , the bypass damper opens j ust enoug h t o b ypass the ex ces s air. This will control

static pressure and noise at the diffusers.

The Electronic Bypas s Da mper is used on any size s yst em over 5 tons. The da mper can be round (STBP) or

rectangular (STCDBP) with integrated static pressure control; and multiple dampers can be slaved together.

SIZING ELECTRONIC BYPASS DAMPERS

The bypass damper is to be sized for the total

system CFM @ 1500 F PM. System CFM should

be calculated at 400 CFM per ton.

Example: A 5-ton system is rated at 2000 CFM

(5x400 = 2000). When calculated at 1500 FPM,

the bypass damper should be 16”. Never

undersize the bypass damper.

ROUND BYPASS DAMPER SELECTION

The Zonex Systems STBP damper is used for

round bypass applications. When you know the

bypass CFM requirements, use the ROUND

BYPASS SELECTION TABLE to confirm the

round damper size.