GEN II-R

Residential / Light Commercial

Zoning utilizing 2-postion zone dampers

Installation and Applications Manual

Control 2-10 Zones

with 2 or 3 Wire Dampers

using Standard Thermostats

with only 1 Gen II-R per System

58

QUICK START AND COMMISSIONING

GEN II-R

QUICK START AND COMMISSIONING

Follow these Quick steps for a successful job

If you need additional information, please read the GEN II-R Manual

1. Install GEN II-R controller in an easily accessible location for your customer.

2. Install an independent 24 volt 40 VA transformer if using 3 wire (run open-run closed damper), and connect to the TR1

and TR2 (next to TC/TC) terminals on the GEN II-R controller. When using a TR series 2 position / spring return damper

the transformer VA needs to be sized based on damper quantity. See page 19 for transformer sizing.

3. Install the LAT sensor in the supply air, ahead of any bypass takeoffs. Wire sensor to the S S terminals on the

GEN II-R controller.

4. Install Dampers and Bypass Damper.

5. Install all field supplied programmable thermostats sub-bases and pull 18/4 thermostat wire to the damper

control board that it will control. For Heat Pump operation with emergency heat, install one Heat Pump thermostat

with emergency heat operation on any zone using 18/5 thermostat wire to that one thermostat.

6. Wire TR1 and TR2 terminals from the GEN II-R controller to the first damper control board R and C - only (18 ga

thermostat wire).

7. Wire A & B terminals from GEN II-R controller using Belden 8740 twisted pair wire or Zonex supplied equal to

the first damper control board A & B - only.

8. Damper wiring is factory per wired to the damper control board.

9. Wire the first thermostat to it’s damper control board R, C, Y, W/OB and E if using emergancy heat in Heat Pump

operation.

10. Address the the first damper control board jumper as #1- see pages 10 and 11 for thermostat installation and

addressing. Note: Each damper will have a unique address 1-10.

11. Turn on GEN II-R controller switch “E”. Power light should light up and look at the display “G” on the GEN II-R

controller, and the #01 should appear on the display. This indicates you are communicating with the first zone

damper / thermostat.

12. If you don’t see the #01 and 00 is displayed, check the address jumper on damper control board. If the

address is #01, then check wires for TR1 & TR2 or R & C polarity and A & B for correct connections.

13. If #01 is displayed on the GEN II-R controller, then daisy chain wires from damper control board #1 to the next

damper control board and address it #2; then repeat the ON-OFF switch operation and confirm the #02 shows

up on the display indicating the system is now communicating with 2 thermostats.

14. Continue adding damper control boards; and confirm communication by repeating the ON-OFF switch opera tion until all thermostats are wired and the total number of thermostats on the job show up on the display on

the GEN II-R controller.

15. Go to any thermostat and make a Cool Call. Look at the GEN II-R controller and confirm Y1 (yellow LED) and

G (green LED) lights are ON.

16. Satisfy the Cool Call at the thermostat to be sure Y1 and G turn OFF at the GEN II-R controller.

17. Repeat with a Heat Call for W1 (red LED).

18. Wire GEN II-R controller to the A/C unit.

19. Set thermostat to call for cooling, and check register to be sure each damper opens and closes as you make

and satisfy the call

.

A

C

D

QUICK START AND COMMISSIONING

GEN II-R

QUICK START AND COMMISSIONING

GEN II-R-Zoning

OFF ON

TR1

OUT IN

TR2

E

B

TR1TR2

TC TC

F

EH

O/BHPPRI

TIME/TMP

O/B RY1Y2G W2

Y1

Y1Y2W1W2G

Y2

TIME

SET

ON

AUTO

H

G

W1

7 2

NIGHT DAY

UNLOCK LOCK

UP

K

DN

I

W2

J

A

G

GND B

L

R

GE

HP

The GEN II-R is equipped with a Digital Display (G) that constantly displays Leaving Air Tem-

perature from the unit. At startup, this display also reports the number of thermostats communicating with the GEN II-R controller. The display and 3 buttons (H) beneath the display provide the installing contractor the ability to tailor the system to your specific application.

The GEN II-R controller is shipped from the factory configured fo

However, the following should be checked as part of the initial installation setup procedures:

1. EH jumper (F) is installed by the factory on one pin for normal gas heat operation where the fan

is controlled by the HVAC system fan control. When a fan output is required from the GEN II-R

controller on a call for heat, place the EH jumper over both pins for several seconds and then

remove. Place the jumper tab on one pin.

2. O/B and HP jumpers (F) should both be on one pin or removed for GE operation.

3. Set the Power Switch (E) to ON.

4. Set the fan jumper (I) to AUTO for intermittent operation or ON for constant ON operation in the

Occupied mode.

5. Place the TIME/TEMP jumper (I) on the middle and upper pins to control Y2 and W2 staging on

run time and supply air temperature.

r basic Gas/Electric operation.

S S

M

TABLE OF CONTENTS

SYSTEM OVERVIEW

1

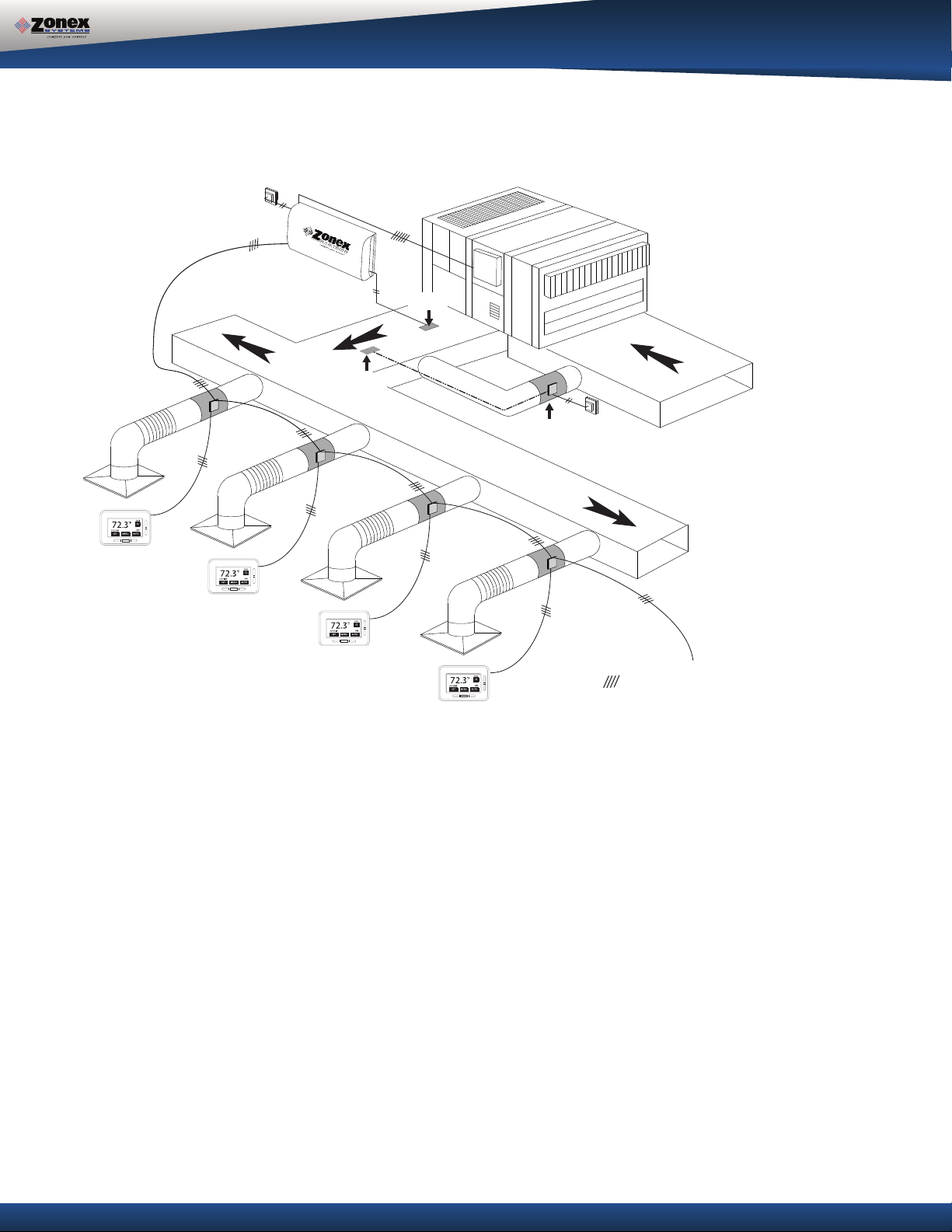

System Overview Diagram

Component Selection Guide

General Sequence of Operation

GAS ELECTRIC OPERATION

2

Controller ID Diagram

Installation Controller

GE Controller Configuration

GE Advanced Configuration

Heat and Cool Cut-out Temperatures

Electric Heat Fan

2nd Stage Operation

HEAT PUMP OPERATION

3

Controller ID Diagram

Heat Pump Installation

Basic Configuration

Heat Pump Advanced Configuration

Heat and Cool Cut-out Temperatures

2nd Stage Operation

DAMPER CONTROL BOARD / THERMOSTAT SELECTION

4

Damper Control Board Call Out

Damper Control Board Addressing and Configuration

Thermostat Selection Based on System Operation

Thermostat Wiring Schematic

1

1

2

3

4

4

4

4

5

5

5

6

7

7

7

8

9

9

9

10

10

10

11

11

GEN II-R WIRING SCHEMATIC

5

Wiring Schematic with Power Closed / Spring Open Dampers

Wiring Schematic with Power Closed / Power Open Dampers

SYSTEM START UP AND TESTING

7

TROUBLESHOOTING

8

ADVANCED CONFIGURATION

9

Fan Operation

Opposing Call Changeover

ZONE DAMPERS - 2 OR 3 WIRE SELECTION

10

11

Round and Rectangular Damper Selection

Sizing

Sizing Transformer Based on Damper Count

Slaving Zone Dampers

BYPASS DAMPERS

Bypass Dampers Barometric and Electronic

Slaving Bypass Dampers

IPC – Static Pressure Controller

12

12

13

14

14

15

15

15

16

16-18

18

19

19-20

21

21-24

24

25-26

1

ZONE

DAMPER

24VAC / 40VA

TRANSFORMER

2

ZONE

DAMPER

STATIC

PRESSURE

SENSOR

GEN II-R-Zoning

LEAVING

AIR SENSOR

BYPASS DAMPER

3

ZONE

DAMPER

4

ZONE

DAMPER

24VAC / 40VA

TRANSFORMER

SYSTEM OVERVIEW

System Features

- Universal for G/E or H/P Units

- 2 or 3 Wire Zone Dampers

- Up to 10 Zones Per Unit

- Auto- Changeover Operation

- On-board Capacity Control

- Start Up Diagnostic

- 2 Data Wires

- 2 Power Wires

- 4 Wire Stat to Damper Board

- No Home Run Wiring

- No Computer Required For Setup

UP TO 10 DAMPERS

PULL 24V POWER AND UNSHIELDED TWISTED PAIR

DAISY CHAINED FROM DAMPER TO DAMPER

SYSTEM OVERVIEW

The GEN II-R is a residential / light commercial zone control system controlling 2-10 independent

zones per unit. The GEN II-R controller is designed for auto changeover, multi-stage Heat Pump

(2C/3H) and Gas Electric (2C/2H) applications.

The GEN II-R system uses field supplied programmable thermostats, which power and control the

24-volt, power open / power closed or power closed / spring open round and rectangular dampers.

Additional features include LED status indication of all system functions, digital LAT display, fully

adjustable capacity control with on-board limit settings, and optional staging strategies.

The system provides the installing contractor with a simple startup diagnostic to minimize wiring errors

and speed installation.

1

COMPONENT SELECTION GUIDE

GEN II -R

Universal Controller for

Gas/Electric - 2-Stage Heat/Cool

or

Heat Pump 3- Stage Heat/2-Stage Cool

Includes Leaving Air Sensor (LAT)

GAS/ELECTRIC

PROGRAMMABLE

Field Supplied

5 TONS AND UNDER

Low Pressure Dampers (12VA)

Round - (TRX size) up to .5” SP

Rect. Single Blade - (TREX W x H) up to .5” SP

Rect. Opposed Blade - (TREX W x H) up to .5” SP

DAMPER TRANSFORMER***

ZONE DAMPERS

Heavy Duty Rectangular - (**STCRX W x H) up to 1.75” SP

HEAT PUMP*

HEAT PUMP THERMOSTATSGAS/ELECTRIC THERMOSTATS

PROGRAMMABLE

Field Supplied

OVER 5 TONS

Medium Pressure Dampers (2VA)

Round - (**STMRX size) up to 1.75” SP

**

BYPASS DAMPERS

5 TONS AND UNDER

BAROMETRIC BYPASS

Round - (101ABBD diam)

Rectangular ( RBB W x H)

ELECTRONIC MODULATING BYPASS DAMPER

(Includes Integrated Static Pressure Control)

Rectangular ( STCDBP size) up to 1.75” SP

1-24 40VA Transformer Powers Bypass

OVER 5 TONS

BYPASS DAMPER

Round - (STBP size) up to 1.75” SP

COMPLETE SYSTEM

*Note: For Heat Pump systems using Gas/Electric inputs ( no “O” or “B” reversing value circuits) use the Gas/Electric set up.

** Note: For Heat Pump operation with emergency heat, install one Heat Pump thermostat with emergency heat operation on any zone.

*** Note: Damper transformer needs to be sized based on the VA of the style and quantity of the dampers. See page 19 for transformer sizing.

2

GENERAL SEQUENCE OF OPERATION

GENERAL SEQUENCE OF OPERATION

When the GEN II-R controller is powered up, the total number of addressed dampers are determined and

verified on the display. This confirms the controller is communicating with all dampers in the system. If

there are no active heat or cool calls detected, the supply dampers will open in ventilation mode. The

system blower operation can be configured for constant ON or intermittent Auto.

The GEN II-R systems can be field configured for adjustable time based opposing call changeover or vote

based majority changeover. The GEN II-R controller is shipped from the factory for 10-minute opposing

call changeover. The GEN II-R controller “polls” the damper control boards once per minute to determine

the thermostat demand status for heat and cool. The heat and cool changeover functions will operate

according to changeover strategy selected. When the GEN II-R controller changes modes, a 5-minute

purge cycle is initiated before the changeover is completed.

On active heat or cool calls, the non-calling zones will close. When the last calling zone is satisfied in

either heat or cool mode, the GEN II-R controller terminates the HVAC outputs after the next “poll” and

the blower output will be de-energized (unless controller is configured for constant fan) for a 5-minute

purge cycle. During the purge cycle no heat or cool calls are recognized.

When the system is in the heating mode and calls for cooling are received, an opposing call timer strategy

operates. This timer is adjustable from 5 - 30 minutes. The factory default is 10 minutes. At the end of the

selected time period, if the opposing call is 3° away from set point, heating is turned off. After a 5-minute

purge mode, Cooling is turned on until the cool call is satisfied. If necessary, GEN II-R will return to the

heating mode, If all calls have been satisfied, dampers will open for ventilation. If the opposing zone strategy is not desired, this feature may be disabled.

3

LEGEND

TERMINAL FUNCTIONS / CONNECTIONS

GAS ELECTRIC OPERATION

D

GEN II-R

OFF ON

TR1

OUT IN

A

B

C

TR2

TR1TR2

TC TC

Y1Y2W1W2G

R

GE

O/B RY1Y2G W2

HP

G

E

F

EH

O/BHPPRI

SET

TIME/TMP

TIME

ON

AUTO

H

UP

DN

7 2

I

Y1

A / B - Data Transmit / Receive

S S – Leaving / Supply Air Sensor Input

G – Fan Output

W2 –

W1 –

Y2 – Stage 2 Cool Output

Y1 – Stage 1 Cool Output

R – 24vac from Unit Transformer

TC / TC – Not Used

TR1 / TR2 – 24vac Power Input / Common

Y2

Stage 2 Heat Input

Stage 1 Heat Input

TR1 / TR2 - Damper Power Daisy Chain

Damper to Damper (18GA Thermostat wire)

W1

W2

NIGHT DAY

UNLOCK LOCK

K

J

A

G

GND B

S S

L

M

TR1 & TR2 Power out to Dampers R & C

A

(18 ga thermostat wire)

B TR1 & TR2 24-Volt Transformer

C Not Used

D Unit Terminals

E On / Off Switch

F Priority Jumper (Not Used)

H/P Jumper (Jump for Heat Pump

Operation)

O/B Jumper (Heat Pump Only –

Reversing Valve Operation)

EH Jumper (Set Up Fan Operation for

Electric Heat)

G Digital Display (Leaving Air Temperature

and configuration)

H Up / Down / Set Buttons (High Limit, Low

Limit, Set)

I Fan Jumper (Continuous or Auto)

Staging Strategy (Time / Temperature or

nly)

Time O

J Not Used

K Not Used

A / B / GND Communications Wire

L

M S S Terminals – Leaving Air Sensor (LAT)

General Installation Instructions

GEN II-R Controller

1. Install the GEN II-R controller on an interior wall where the ambient temperature is between 32°120°F (0°- 48°C) non-condensing. This controller is to be installed in an accessible interior

area; not in attics or above ceilings.

2. The controller is to be powered by a dedicated

style and quantity.

The secondary voltage to the controller must be 24 to 28vac.

3. Install the leaving air sensor (LAT) in the supply air, ahead of the bypass take-off. Sensor wires

are connected to the S S terminals on the controller (M). The LAT sensor leads may be

extended using standard 18/2 thermostat wire.

4. The leaving air sensor (LAT) is calibrated to the controller at the factory. However, the

calibration should be checked as part of the system setup procedure. If adjustments are

required, use the Blue potenti

GEN II-R controller. Screw the pot clockwise to lower the display temperature and counter clockwise to raise the temperature. NOTE: The display will update every 10 seconds.

5. Confirm you have daisy chained the A and B communication wires and R and C from the

damper control boards to the GEN II-R controller (A & L), A=(TR1, TR2), L=(A, B). (Communi cation wire maximum is 4,000 ft. from the GEN II-R controller to the farthest damper).

6. Connect the output wires from the controller to the HVAC system using standard 18 GA

thermostat wire.

24vac 40va transformer. VA based on damper

The transformer secondary is wired to TR1 TR2 on the controller (B).

ometer labeled R44 located in the upper right hand corner of the

4

GAS ELECTRIC BASIC CONTROLLER CONFIGURATION

The GEN II-R is equipped with a Digital Display (G) that constantly displays Leaving

Air Temperature from the unit. The display and 3 buttons beneath the display provide the

installing contractor the ability to tailor the system to your specific application.

The GEN II-R controller is shipped from the factory configured for basic Gas/Electric operation.

However, the following should be checked as part of the initial installation setup procedures:

1. EH jumper (F) is i

is controlled by the HVAC system fan control. When a fan output is required from the GEN II-R

controller on a call for heat, place the EH jumper over both pins for several seconds and then

remove. Place the jumper tab on one pin.

2. O/B and HP jumpers (F) should both be on one pin or removed, for GE operation.

3. PRIORITY jumper (F) should be on one pin.

4. Set the power switch (E) to ON

5. Set the NIGHT DAY switch (J) to the DAY position.

6. Set the fan jumper (I) to AUTO for intermittent operation or ON for constant ON operation in the

Occupied mode.

7. Place the LOCK – UNLOCK switch (K) in the UNLOCK position.

8. Place the TIME/TEMP jumper (I) on the middle and upper pins to control Y2 and W2 staging on

run time and supply air temperature.

nstalled by the factory on one pin for normal gas heat operation where the fan

.

GEN II-R Gas Electric Advanced Feature Configuration

Gas Electric Capacity Control - Cool and Heat cut-out temperature adjust

The factory setting for the Cool and Heat cut-out temperatures is 45°- 145°F (7°- 62°C). This can

be easily changed with the following procedure:

1. Cool cut-out temp – Press the DN button (H); “C” will be displayed and then the cut-out

temperature.

2. LOWER – Press the DN button; after the “C” is displayed, continue to hold the DN button until

the desired temperature is displayed; then

NOTE: The controller will not change the Cool cut-out lower than 40°F (4°C).

3. RAISE–Press the DN button; after “C” is displayed, immediately release the DN button and

press the UP button. Hold until the desired temperature reading is displayed and release.

4. Press the DN button to verify the new cool cut-out temperature.

release.

Heat cut-out temperature - Press and hold the UP button; after the “H” is displayed, use the

same procedure as above to raise

or lower the displayed temperature.

Electric Heat - Fan Configuration

EH jumper (F) is installed by the factory on one pin for normal gas heat operation where the fan is

controlled by the HVAC system fan control. When a fan output is required from the GEN II

controller on a call for heat, place the EH jumper over both pins for several seconds and then

remove. Place the jumper tab on one pin.

2nd Stage Heat and Cool Cut-in / Cut-out Configuration

The GEN II-R controller is set up at the factory to stage Y2 and W2 cut-in operation based on a 3-minute time delay and supply air temperature. This is done using the TIME/TEMP (I) jumper. Time may

be field configured from 3-20 minutes by the contractor during system configuration. The cut-in

temperatures are fixed in the controller program at 58°F (14°C) and higher for Y2 and 120°F (48°C)

and lower for W2. The GEN II-R controller second stage cut-out temperature is fixed in the controller

program at 50°F (10°C). Y2 will de-energize when it drops below 50°F and re-energize when it rises

above 58°F. If the air temperature drops below the low cut-out (45°F) Y1 and Y2 are de-energized and

the controller will go into a 5 minute purge mode. After 5 minute purge, if the temperature has risen

above the low cut-out Y1 is re-energized. Heat W1 and W2 will de-energize if leaving air temperature

rises above heat cutout and will be locked out for 5 minutes. After 5 minute lockout, if a heat call

remains and leaving air temperature is lower than heat cutout, W1 will re-energize. By placing jumper

on bottom two pins, a time only strategy may be configured into the system. ( see below);

5

GAS ELECTRIC ADVANCED FEATURE CONFIGURATION

Adjust 2ndStage Cut-in Time Delay

1. To increase the Y2 and W2 cut-in delay, press and hold the SET and DN buttons (H)

simultaneously. When 03 appears in the display, release the buttons and immediately press

the UP button and hold until the desired delay time is displayed, and release. The time delay

is fully adjustable from 3 - 20 minutes. To verify the change, press and hold the SET and DN

buttons simultaneously until the delay time is shown, and relea

2. To decrease the Y2 and W2 cut-in delay, press and hold the SET and DN buttons (H)

simultaneously. When delay time appears in the display, release the buttons and immediately

press the DN button and hold until the desired delay time is displayed, and release. To verify

the change, press and hold the SET and DN buttons until the delay time is shown, and release.

Configure 2ndStage Cut-in for Time Delay and Thermostat Demand Only

1. Place the 2ndstage configuration jumper (I) on the middle and lower pins - TIME.

2. If the cut-in time delay must be changed from the factory setting of 03 (3 min), follow the above

procedures to raise or lower the time delay value.

3. Verify time delay value by pressing the SET and DN buttons simultaneously.

se.

6

LEGEND

HEAT PUMP OPERATION

TERMINAL FUNCTIONS / CONNECTIONS

HEAT PUMP OPERATION

GEN II-R

OFF ON

TR1

OUT IN

A

B

C

D

TR2

TR1TR2

TC TC

Y1Y2W1W2G

R

GE

G

E

F

EH

O/BHPPRI

O/B RY1Y2G W2

Y1

HP

A / B - Data Transmit / Receive

S S – Leaving / Supply Air Sensor Input

G – Fan Output

W2 – Auxiliary / Emergency Heat

O/B – Reversing Valve Output

Y2 – Stage 2 Cool Output

Y1 – Stage 1 Cool Output

R – 24vac from Unit Transformer

TC / TC – Not Used

TR1 / TR2 – 24vac Power Input / Common

TR1 / TR2 - Damper Power Daisy Chain

Damper to Damper (18GA Thermostat wire)

Y2

SET

TIME/TMP

TIME

AUTO

H

UP

DN

ON

I

W1

W2

7 2

NIGHT DAY

UNLOCK LOCK

K

J

A

G

GND B

S S

A

TR1 & TR2 Power out to Dampers R & C

(18 ga thermostat wire)

B TR1 & TR2 24-Volt Transformer

C Not Used

D Unit Terminals

E On / Off Switch

F Priority Jumper (Not used)

H/P Jumper (Jump for Heat Pump

Operation)

O/B Jumper (Heat Pump Only –

Reversing Valve Operation)

L

EH Jumper (Set Up Fan Operation for

Electric Heat)

G Digital Display (Leaving Air Temperature

M

and configuration)

H Up / Down / Set Buttons (High Limit,

Low Limit, Set)

I Fan Jumper (Continuous or Auto)

Staging Strategy (Time / Temperature or

Time Only)

J Not Used

K Not Used

L A / B / GND Communications Wire

M S S T

erminals – Leaving Air Sensor

(LAT)

General Installation Instructions

GEN II-R Controller

1. Install the GEN II-R controller on an interior wall where the ambient temperature is between 32°120°F (0°- 48°C) non-condensing. This controller is to be installed in an accessible interior

area; not in attics or above ceilings.

2. The controller is to be powered by a dedicated

style and quantity. The transformer secondary is wired to TR1 TR2 on the controller (B).

The secondary voltage to the controller must be 24 to 28vac.

3. Install the LAT air sensor in the supply air between

elements. The LAT sensor leads may be extended using standard 18/2 thermostat wire.

4. The leaving air sensor (LAT) is calibrated to the controller at the factory. However, the

calibration should be checked as part of the system setup procedures. If adjustments are

required, use the Blue potentiometer labeled R44 located in the upper left hand corner of the

GEN II-R controller. Screw the pot clockwise to lower the display temperature and counter clockwise to raise the temperature.

5. Confirm you have daisy chained the A and B communication wires and R and C from the

Damper control boards to the GEN II-R controller (A & L), A=(TR1, TR2), L=(A, B). (Communi cation wire maximum is 4,000 ft. from the GEN II-R controller to the farthest damper).

6. On each damper board place the HP jumper on both pins for Heat Pump operation.

7. Connect the output wires from the controller to the HVAC system using standard 18 GA

thermostat wire.

24vac 40va transformer. VA based on damper

the indoor coil and electric strip heat

NOTE: The display will update every 10 seconds.

7

GENERAL INSTALLATION INSTRUCTIONS

Heat Pump operation “O” reversing valve

Cool Call – When a majority active cool call is received by the GEN II controller, Y1, O/B and G

LEDs are illuminated; and the outputs are energized (within 1.5 to 3 minutes). After 3 minutes, if

the leaving air temperature is 58°F (14°C) or above, Y2 will energize for 2-stage systems. Y2 will

de-energize when it drops below 50°F and re-energize when it rises above 58°F. If the supply air

temperature drops one degree below the Cool cut

for 5 minutes.

“B” reversing valve –

Sequence of operation is the

Heat Call - When a majority active heat call is received by the GEN II controller, Y1 and G LEDs are

illuminated; and the outputs are energized (within 1.5 to 3 minutes). If after 3 minutes the leaving

air temperature is 94°F (34°C) or less, Y2 will energize. If after 6 minutes of run time the leaving air

temperature is 91°F (32°C) or less, W2 will energize. If the supply air temperature exceeds 126°F

(52

°C), Y1, Y2 and W2 (if energized) will drop out; and Y1 can then energize after a 5-minute time

delay. NOTE: If the system fan is configured for “AUTO” on the GEN II controller, the “G” output

will be de-energized in the temperature cut-out mode.

When the last active call satisfies, the GEN II controller goes into a 5-minute purge cycle with all

supply dampers closing; then all dampers modulate open for ventilation.

Heat Pump operation “B” reversing valve

-out temperature, Y1 and Y2 will de-energize

same: O/B is energized in the heat mode.

By placing the O/B jumper (B) on both pins, the GEN II controller is configured for “B” reversing

valve operation. The operation and setup procedures are the same as with “O” mode reversing

valve, except the reversing valve will be energized for heat operation.

GEN II-R Heat Pump Basic Configuration

The GEN II-R controller is shipped from the

factory for Gas Electric operation.

The controller must be field configured for

Heat Pump operation.

Heat Pump configuration:

1. Switch controller to OFF (E).

2. Set the O/B jumper (F) on one pin for “O”

reversing valve (energizes for cool) or

A

B

C

TR1

TR2

TR1TR2

TC TC

OFF ON

OUT IN

E

F

Set the O/B jumper (F) on both pins for “B”

reversing valve (energizes for heat).

Y1Y2W1W2G

R

GE

O/B RY1Y2G W2

Y1

HP

3. Set the HP jumper (F) on both pins for Heat

Pump operation.

4. Set the Priority jumper (F) on one pin.

5. Set the TIME / TEMP jumper (I) on the

middle and upper pins.

D

6. Set NIGHT / DAY switch (J) for DAY position.

7. Set LOCK / UNLOCK switch (K) to UNLOCK.

8. Swi

tch the controller to ON (E).

9. Press the UP button (H), and verify the “H” (cut-out) temperature reads 126°F (52°C) on the

controller display (G).

NOTE: The heat cut-out temperature

must not be changed from the factory setting.

GEN II-R

SET

EH

O/BHPPRI

TIME/TMP

TIME

Y2

AUTO

G

H

UP

DN

ON

7 2

I

W1

W2

NIGHT DAY

UNLOCK LOCK

K

J

A

G

GND B

S S

L

M

8

HEAT PUMP ADVANCED FEATURE CONFIGURATION

GEN II-R Heat Pump Advanced Feature Configuration

Heat Pump Capacity Control - Cool and Heat cut-out temperature adjustment

When the GEN II-R controller is configured for Heat Pump (HP jumper (F) on both pins), the Cool /

Heat cut-out temperatures are 45°- 126°F (7°- 52°C). The cut-out temperatures can be changed

with the following procedure:

Heat cut-out temp – To eliminate the possibility of the Heat Pump tripping out on high head

pressure or short cycling in the heat mode, the heat cut-out temperature should never

from the factory setting of 126°F (52°C).

1. Cool cut-out temp – Press the DN button (H); “C” will be displayed, then the cut-out

temperature.

2. LOWER – Press the DN button. After the “C” is displayed, continue to hold the DN button until

the desired temperature is displayed; then release.

NOTE: The controller will not change the Cool cut-out lower than 40°F (4°C).

3. RAISE – Press the DN button. After “C” is displayed, immediately release the DN button, and

press the UP button. Hold until the desired temperature reading is displayed; then release.

4. Press the DN button to verify the new cool cut-out temperature.

2nd Stage Heat and Cool Cut-in / Cut-out Configuration

The GEN II-R controller is set up at the factory to stage Y2 and W2 cut-in operation based on a 3-minute time delay and supply air temperature. This is done using the TIME/TEMP (I) jumper. Time may

be field configured from 3-20 minutes by the contractor during system configuration. The cut-in

temperatures are fixed in the controller program at 58°F (14°C) and higher for Y2 and 120°F (48°C)

and lower for W2. The GEN II-R controller second stage cut-out temperature is fixed in the controller

program at 50°F (10°C). Y2 will de-energize when it drops below 50°F and re-energize when it rises

above 58°F. If the air temperature drops below the low cut-out (45°F) Y1 and Y2 are de-energized and

the controller will go into a 5 minute purge mode. After 5 minute purge, if the temperature has risen

above the low cut-out Y1 is re-energized. Heat W1 and W2 will de-energize if leaving air temperature

rises above heat cutout and will be locked out for 5 minutes. After 5 minute lockout, if a heat call

remains and leaving air temperature is lower than heat cutout, W1 will re-energize. By placing jumper

on bottom two pins, a time only strategy may be configured into the system. ( see below);

be changed

Adjust 2ndStage Cut-in Time Delay

1. To increase the Y2 and W2 cut-in delay, press and hold the SET and DN buttons (H)

simultaneously. When 03 appears in the display, release the buttons and immediately press

the

UP button and hold until the desired delay time is displayed, and release. The time delay

is fully adjustable from 3 - 20 minutes. To verify the change, press and hold the SET and DN

buttons simultaneously until the delay time is shown, and release.

2. To decrease the Y2 and W2 cut-in delay, press and hold the SET and DN buttons (H)

simultaneously. When delay time appears in the display, release the buttons and immediately

press the DN button and hold until the desired

the change, press and hold the SET and DN buttons until the delay time is shown, and release.

delay time is displayed, and release. To verify

Configure Y2 and W2 Cut-in for Time Delay and Thermostat Demand Only

nd

1. Place the 2

2. If the Y2 cut-in time delay must be changed from the factory setting of 03 (3 min), follow the

above procedures to raise or lower the time delay value.

NOTE: The cutcontrol program and cannot be manually changed.

3. Verify time delay value by pressing the SET and DN buttons simultaneously.

stage configuration jumper (I) on the middle and lower pins - TIME.

in delay timing for W2 (Aux Heat) is set for approximately 3 minutes in the

9

DAMPER CONTROL BOARD CALL OUT AND CONFIGURATION

A

A

B

B

RC

MC

RO

HP

A

A

B

B

RC

MC

RO

ZN1

ZN2

ZN3

ZN4

ZN5

ZN6

ZN7

ZN8

ZN9

ZN10

RUN OPEN

RUN CLOSED

HP

DAMPER CONTROL BOARD LEGEND

A R & C 24 volt Power Daisy Chained IN and OUT

B Thermostat Terminals

C Damper Board ID

D Jumper for Heat Pump Operation

E Damper Motor Terminals

F Data Transmit / Receive IN

G Date Transmit / Receive OUT

TERMINAL FUNCTIONS / CONNECTIONS

R / C - 24 volt Power IN and OUT

R - 24 volt Hot to Thermostat

C - 24 volt Common to Thermostat

W/OB - Heating Input / Reversing Valve Input

Y - Cooling Input

E - Emergency Heat Input (Heat Pump Only)

MC - Motor Common

RO - Run Open

RC - Run Closed

A / B - Data Transmit / Receive IN and OUT

A

B

R

C

R

C

W/OB

Y

C

E

ZN1

ZN2

ZN3

ZN4

ZN5

ZN6

RUN OPEN

RUN CLOSED

ZN7

ZN8

ZN9

ZN10

D

HP

MC

RO

RC

B

A

A

E

F

B

G

DAMPER CONTROL BOARD ADDRESSING / CONFIGURATION

Each damper control board must have a unique address from 1-10. To set the damper control board address there is a

jumper on the board. Find the first damper in the daisy chain and place the jumper on ZN1 for address #1. Go to the

second damper in the daisy chain and place the jumper on ZN2 for address #2. Continue addressing the damper control

boards in numerical order of the daisy chain wiring.

HP

MC

RO

RC

B

A

B

A

R

C

Setting Damper Boards for Heat Pump Operation

When the GEN II-R controller is set up for Heat Pump operation, every damper board in the system needs to be

placed in heat pump mode. This allows the dampers boards to work with heat pump thermostats. Place the HP

jumper on both pins.

R

C

W/OB

Y

E

ZN1

ZN2

ZN3

ZN4

ZN5

ZN6

RUN OPEN

RUN CLOSED

ZN7

ZN8

ZN9

ZN10

10

THERMOSTAT WIRING SCHEMATIC

THERMOSTAT SELECTION BASED ON SYSTEM OPERATION

All thermostats are field selected, make sure to choose a programmable thermostat for each zone based on the system

parameters below. Programmable thermostats allow multiple schedules on a zone by zone basis.

GAS / ELECTRIC - Use any standard gas / electric single stage Heat / Cool 7 day programable thermostat.

HEAT PUMP - Use any standard heat pump single stage Heat / Cool 7 day programable thermostat.

Note: For heat pump operation with emergency heat, install one heat pump thermostat with emergency

heat operation on any zone.

WIRING TO A GAS / ELECTRIC THERMOSTAT

R

C

W

Y

70.9

°F

71

WIRING TO A HEAT PUMP THERMOSTAT

R

C

OB

Y

E

70.9

°F

71

R

C

R

C

W/OB

Y

E

ZN1

ZN2

RUN OPEN

RUN CLOSED

ZN5

ZN6

ZN7

ZN8

ZN3

ZN4

DAMPER CONTROL BOARD

R

C

R

C

W/OB

Y

E

ZN1

ZN2

RUN OPEN

RUN CLOSED

ZN5

ZN6

ZN7

ZN8

ZN3

ZN4

DAMPER CONTROL BOARD

MC

RO

RC

B

A

B

HP

ZN10

ZN10

A

MC

RO

RC

B

A

B

HP

A

ZN9

ZN9

Note: For heat pump operation with emergency heat, install one heat pump thermostat with emergency

heat operation on any zone.

11

DESCRIPTION

A

A

B

B

ZN1

ZN2

ZN3

ZN4

ZN5

ZN6

ZN7

ZN8

ZN9

ZN10

HP

GEN II-R WIRING SCHEMATIC WITH PC / SO DAMPERS

PER RTU OR SPLIT SYSTEM

GEN II CONTROLLER CONTROLS 2-10 ZONE DAMPERS

ONLY 1 24VAC 40VA TRANSFORMER POWERS ALL SUPPLY

ID

DAMPERS AND THERMOSTATS

C1

FIELD SUPPLIED 7 DAY PROGRAMMABLE THERMOSTATS

24VAC/40VA TRANSFORMER SIZED @ (12VA PER ZONE DAMPER)

DM POWER CLOSED, SPRING OPEN DAMPER (FACTORY PRE-WIRED)

TR1

DEVICE

THERMOSTAT T1 -T10

ZONE DAMPER

CONTROL BOARD

SYSTEM TRANSFORMER

GEN II-R

WITH POWER CLOSED / SPRING OPEN DAMPERS

RESIDENTIAL / LIGHT COMMERCIAL ZONING - CONTROL 2-10 ZONES

DAISY CHAIN DAMPER TO DAMPER

SUPPLY LAT LOCATED BEFORE THE BYPASS

LAT

SUPPLY LAT DISCHARGE SENSORS

UNLOCK LOCK

NIGHT DAY

JUMPER ON BOTH PINS FOR HEAT PUMP OPERATION

BAROMETRIC BYPASS USED ON SYSTEMS 5 TONS OR LESS

HP

BP-DM

HEAT PUMP OPERATION

BYPASS DAMPER

24V POWER IN AND OUT USE 18/2 THERMOSTAT WIRE

A

TWISTED PAIR WIRING -BELDEN 8740 DAISY CHAIN

RS485 COMMUNICATION LINK

DAMPER TO DAMPER

GND B

FOR APPLICATIONS ASSISTANCE CALL 800-228-2966

VISIT OUR ON-LINE CATALOG AT ZONEXPRODUCTS.COM

S S

ZONE ID ADDRESS JUMPERS

AND HEAT PUMP OPERATION JUMPER

MC

R

MC

R

RO

RUN OPEN

RUN CLOSED

C

RO

RUN OPEN

RUN CLOSED

C

C

C

C

C

FIELD SUPPLIED THERMOSTATS

DAISY CHAIN 24VAC AND DATA LINK CABLE (BELDEN 8740)

TO ALL ZONE DAMPER BOARDS - EXPANDABLE TO 10 ZONES

B

B

A

A

RC

HP

ZN10

ZN9

ZN8

ZN7

ZN6

ZN5

DM-3

ZN4

ZN3

ZN2

ZN1

R

C

W/OB

B

A

RC

R

C

W/OB

ZONE DAMPER

Y

E

B

A

HP

ZN10

ZN9

ZN8

ZN7

ZN6

ZN5

DM-2

ZN4

ZN3

ZN2

ZN1

ZONE DAMPER

Y

E

GAS / ELECTRIC OR HEAT PUMP OPERATION.

USE 7 DAY PROGRAMMABLE THERMOSTATS FOR

FOR HEAT PUMP OPERATION WITH EMERGENCY HEAT,

70

°F

69.3

74

°F

74.6

INSTALL ONE HEAT PUMP THERMOSTAT

WITH EMERGENCY HEAT OPERATION ON ANY ZONE.

T3

T2

G

7 2

DN

UP

ON

SET

TIME/TMP

EH

O/BHPPRI

R = TR1 C = TR2

Power Terminals

OFF ON

TR2

TR1

24V POWER OUT

24V POWER IN

TR1TR2

TC TC

C1

W2

W1

AUTO

TIME

Y2

Y1

O/B RY1Y2G W2

HP

GE

Y1Y2W1W2G

R

MC

R

RO

RUN OPEN

RUN CLOSED

C

B

B

A

A

RC

HP

HP

ZN10

ZN9

ZN8

ZN7

ZN6

ZN5

DM-1

ZN4

ZN3

ZN2

ZN1

R

C

W/OB

ZONE DAMPER

Y

E

71

°F

C

C

T1

70.9

12

A

A

B

B

ZN1

ZN2

ZN3

ZN4

ZN5

ZN6

ZN7

ZN8

ZN9

ZN10

HP

GEN II-R WIRING SCHEMATIC WITH PC / PO DAMPERS

DESCRIPTION

IND. 24VAC/40VA TRANSFORMER

GEN II CONTROLLER

CONTROLS 2-10 ZONE DAMPERS

ONLY 1 24VAC 40VA TRANSFORMER*

POWERS ALL SUPPLY DAMPERS

AND THERMOSTATS

TO POWER THE BYPASS DAMPER

SUPPLY LAT LOCATED BEFORE

POWER CLOSED, POWER OPEN

DAMPER (FACTORY PRE-WIRED)

24VAC/40VA TRANSFORMER

SIZED @ (2VA PER ZONE DAMPER)

FIELD SUPPLIED THERMOSTAT

DAISY CHAIN DAMPER TO DAMPER

THE BYPASS. RETURN LAT

LOCATED AFTER THE BYPASS

LOCATED AFTER THE BYPASS

BEFORE THE FIRST SUPPLY TAKEOFF

JUMPER IN PLACE FOR HEAT PUMP

OPERATION

TWISTED PAIR WIRING -BELDEN 8740

SUPPLIED WITH BYPASS

SUPPLIED WITH THE BYPASS

DAMPER (FACTORY PRE-WIRED)

DAMPER (FACTORY PRE-WIRED)

DAISY CHAIN DAMPER TO DAMPER

ID

DEVICE

CONTROL BOARD C1

THERMOSTAT T1 -T10

DM

ZONE DAMPER

TR1

SYSTEM TRANSFORMER

BYPASS TRANSFORMER TR2

IPC

LAT

SPT

INTEGRATED

SUPPLY / RETURN AIR

STATIC PRESSURE CONTROL

LAT DISCHARGE SENSORS

STATIC PRESSURE TUBE

HP

BP-DM

DAISY CHAIN 24VAC AND

EXPANDABLE TO 10 ZONES

DM-3

ZONE DAMPER

DATALINK CABLE (BELDEN 8740)

TO ALL ZONE DAMPER BOARDS -

C

C

FIELD SUPPLIED THERMOSTATS

USE 7 DAY PROGRAMMABLE THERMOSTATS FOR

70

°F

INSTALL ONE HEAT PUMP THERMOSTAT

GAS / ELECTRIC OR HEAT PUMP OPERATION.

WITH EMERGENCY HEAT OPERATION ON ANY ZONE.

FOR HEAT PUMP OPERATION WITH EMERGENCY HEAT,

T3

69.3

ZONE ID ADDRESS JUMPERS

FOR APPLICATIONS ASSISTANCE CALL 800-228-2966

HEAT PUMP OPERATION

BYPASS DAMPER ACTUATOR

24V POWER IN AND OUT USE 18/2 THERMOSTAT WIRE

VISIT OUR ON-LINE CATALOG AT ZONEXPRODUCTS.COM

RS485 COMMUNICATION LINK

AND HEAT PUMP OPERATION JUMPER

ACTUATOR

B

B

A

A

RC

RO

MC

HP

ZN10

ZN9

RC

RO

MC

R

RUN OPEN

RUN CLOSED

C

ZN8

ZN7

ZN6

ZN5

ZN4

ZN3

ZN2

ZN1

R

Y

C

W/OB

E

T2

C

C

74

°F

C

74.6

T1

71

°F

C

70.9

13

B

B

A

A

RC

RO

MC

HP

ZN10

ZN9

RC

RO

GEN II-R

WITH POWER CLOSED / POWER OPEN DAMPERS -3 WIRE

UNLOCK LOCK

NIGHT DAY

A

RESIDENTIAL / LIGHT COMMERCIAL ZONING - CONTROL 2-10 ZONES

7 2

DN

UP

ON

TC TC

TIME/TMP

EH

O/BHPPRI

AUTO

TIME

O/B RY1Y2G W2

SET

R = TR1 C = TR2

Power Terminals

OFF ON

TR2

TR1

24V POWER OUT

24V POWER IN

TR1TR2

S S

GND B

G

W2

W1

Y2

Y1

HP

GE

Y1Y2W1W2G

R

ACTUATOR

ACTUATOR

MC

R

MC

RC

RO

MC

R

RUN OPEN

RUN CLOSED

C

RO

RUN OPEN

RUN CLOSED

C

ZN8

ZN7

ZN6

ZN5

DM-2

ZN4

ZN3

ZN2

ZN1

R

C

W/OB

B

A

RC

R

C

W/OB

ZONE DAMPER

Y

E

B

A

HP

HP

ZN10

ZN9

ZN8

ZN7

ZN6

ZN5

DM-1

ZN4

ZN3

ZN2

ZN1

ZONE DAMPER

Y

E

SYSTEM START UP AND TEST

System Start Up and Test

1. Plug all thermostats into sub-bases. Turn GEN II-R power switch (E) to ON.

2. Find the first damper control board in the Daisy chain and set its address to 01.

3. Turn GEN II-R power switch OFF and then ON. The Display should flash 01 and then show the

leaving air temperature. This confirms your successful wiring and communication with that

thermostat.

4. If 01 is displayed, change the next damper control board address to 02. Turn the GEN II-R

switch OFF and then ON. Th e display should flash 02 and then show the tem

address damper control boards one at a time.

5. After each damper board is re-addressed, turn the power switch OFF and then ON. This will

verify that the re-addressed damper board has been found by the GEN II-R Controller.

This procedure will simplify your installation and will confirm your wiring is correct and that the GEN

controller can communicate over the 2-wire twisted pair data link with every thermostat in your

II-R

system.

Troubleshooting

When stat #1 is not found:

perature. Re -

1. Check damper control board to verify that it is addressed as 01.

2. Check all TR1 and TR2 wiring for proper color-to-color connections. Even if the stats are powered

all R wires at the damper control board must be connected to the GEN II-R TR1 terminal. All C wires

must be connected to the GEN II-R TR2 terminal. Confirm the daisy chain wiring is correct at this

time.

3. Check A, B wires for proper color code and connections; polarity is imperative. All A connec tions must land on A terminal on each of damper control board, and all B connections must connect

to B terminal on each damper control board.

4. Check TR1 and TR2 wires for opens or shorts.

Checking the Daisy Chain for opens or shorts:

Start from the GEN II-R board, and follow A, B wires to the first damper control board. Remove the A,

B wires going to the next damper control board in the link and address the first damper control board

as #1. Turn the GEN II-R power switch Off, then On, to see if the display flashes 01, at the GEN II-R

controller.

1. If 01 is displayed, the first link of the daisy chain is OK. Reconnect the wires going to sub-base.

2. Repeat these steps with a stat numbered 02. If the number 02 is displayed, then communication is

confirmed.

When the correct number does not appear for a link, that link is either shorted or open. A link of the

daisy chain, which is open or shorted, must be repaired before the next damper is checked.

When the damper control boards are correctly addressed, wired and linked, the total number of stats

on your job connected to the GEN II-R control board will be displayed when the board is turned on.

After the correct number of connected damper control boards is displayed, complete the wiring of the

AC unit or heat pump connections, next make heat and cool calls to the GEN II-R controller.

14

ADVANCED FEATURE CONFIGURATION

Fan operation

The factory setting for FAN operation is AUTO, with the FAN jumper (I) on the middle and lower

pins. In this setting, the fan circuit on “G” is only energized on an active cool call in Gas/Electric

mode or on an active heat call or cool call in Heat Pump mode.

When the FAN jumper is in AUTO, there is no output on “G” with an active heat call in Gas/Elec-

tric mode. For constant fan operation place the FAN jumper (I) on the center and upper pins on ON.

Opposing Call Changeover

The GEN II-R controllers are configured at the factory for Opposing Call Changeover with a time delay

setting of 10 minutes. With this configuration, any number of thermostats can make a like active

call (heat or cool). During this time, if a single thermostat makes an opposite call, a

at the next poll. This timer starts a time delay operation to allow the initial calling thermostats to

satisfy. If the initial active thermosta

close and the controller drops out the HVAC outputs and goes into a 5 minute purge cycle. When

the purge cycle times out, the opposing thermostat call is initiated; and the appropriate HVAC

outputs are energized, and the supply damper opens. The thermostat with the opposing call must

now satisfy before the GEN II-R controller will recognize any of the initially calling thermostats.

ts do not completely satisfy after 10 minutes, the dampers all

timer is started

The opposing call t

adjusted from 5 to 30 minutes, or disabled.

To increase

1. Press the SET and UP buttons.

2. Release the SET button when the display changes, and continue to hold down the UP

button.

3. Release the UP button when the desired time is displayed.

To lower

4. Press the SET and UP buttons.

5. Release the SET button, and immediately press and hold the DN (down) button until

The Opposing Call feature can be disabled by performing steps 1 through 3 and then releasing the

UP button when the display indicates 32. With this feature disabled, the GEN II-R controller will

operate changeover by majority vote from the zone thermostats.

the time delay:

the desired time is indicated; then release.

imer is factory adjusted for 10 minutes. However, the delay time can be field

the opposing call time delay:

15

2 WIRE ZONE DAMPERS

Zonex Systems zone dampers are used in cooling / heating systems to provide room by room zone control. The

damper is provided with a zone actuator. Each zone damper is controlled by a zone thermostat. More than one

damper can be controlled by one zone thermostat.

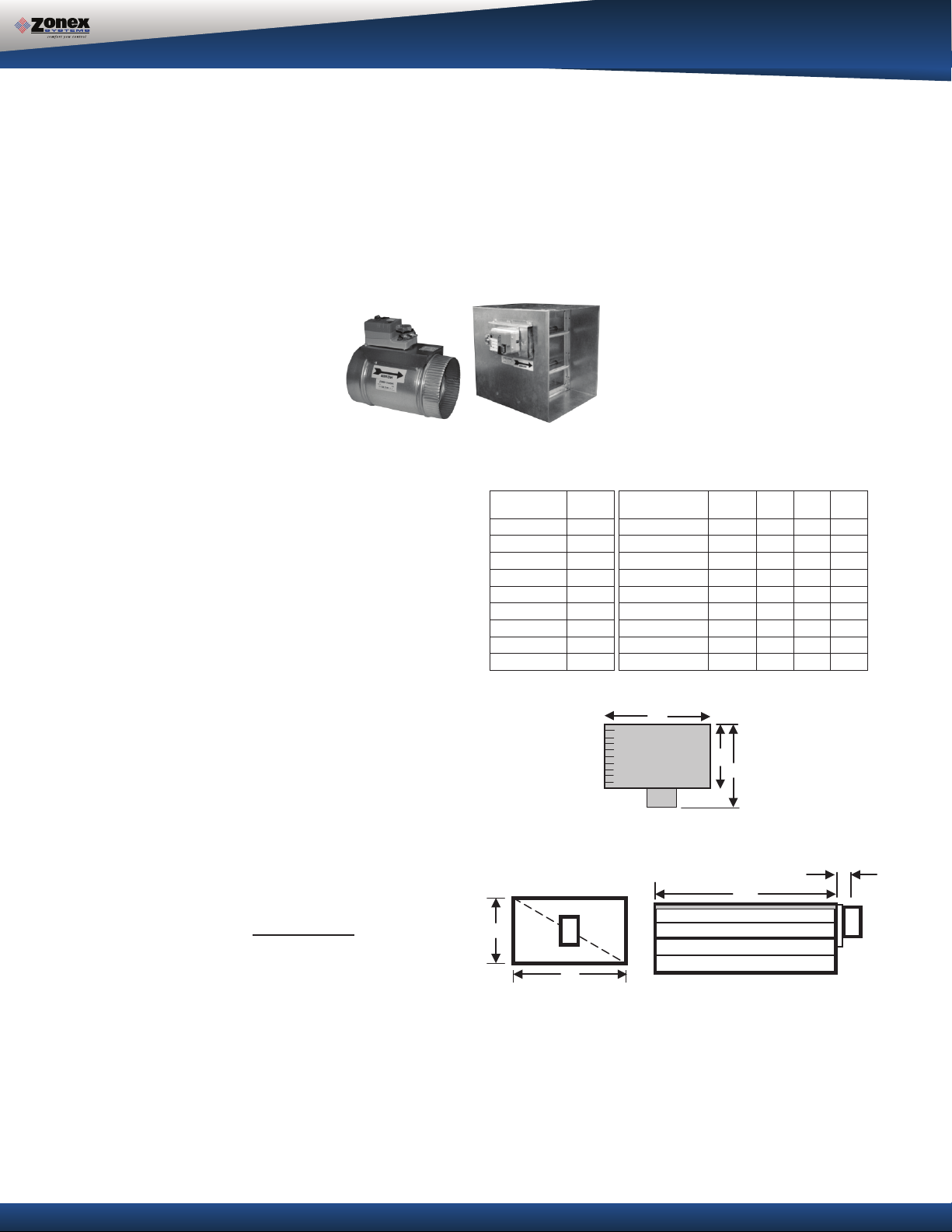

ROUND LOW PRESSURE ZONE DAMPERS (TRX diam)

Zonex Systems round low pressure zone dampers can be used for

systems up to 5 tons with a maximum differential static pressure of 0.5”.

These are two position, spring open, power close dampers for very simple

operation. All sizes are designed with rolled-in stiffening beads for easy

installation. A hat section supports a synchronous 24V AC 60Hz 12VA

motor and terminal board. A red LED will be illuminated on the damper

terminal board to indicate when the damper is being powered closed. The

LED will remain on when the damper is fully closed and cycle off when the

damper is opening or in the full opened position. Since this is a spring

open damper, in the event of power failure, the damper fails to the full

open position.

LOW PRESSURE (TRX diam)

RECTANGULAR LOW PRESSURE ZONE DAMPERS (TREX W x H)

Zonex Systems rectangular low pressure zone dampers can be used for

systems up to 5 tons with a maximum differential static pressure of 0.5”.

These are two position, spring open, power close dampers. The damper

is a single blade type that slips into a 2-1/2” wide cutout in the existing

duct and attaches with screws via a duct mounting plate. The duct mounting plate is 5” wide. A red LED will be illuminated on the damper terminal

board to indicate when the damper is being powered closed. The LED will

remain on when the damper is fully closed and cycle off when the damper

is opening or in the full opened position. Since this is a spring open

damper, in the event of power failure, the damper fails to the full open

position.

LOW PRESSURE (TREX W x H) RECTANGULAR

DAMPER

SIZING ZONE DAMPERS

If the ductwork already exists, simply size the damper to fit the ductwork. For new systems or retrofit jobs:

A. Determine CFM from heat gain or loss calculations.

B. Select damper size using either the round capacities chart, the rectangul ar capacities chart or

by using a duct sizing table or calculator.

C. Select a Zonex Systems damper to fit the duct size selected for that zone.

Make sure your zone dampers match the type specified in the table showing Maximum Differential Pr

essure.

INSTALLATION NOTES

1. Do not exceed 700 FPM in a register/diffuser branch duct.

2. If a damper is installed within 3 feet of a register/diffuser, install sound attenuating flex duct between

damper and outlet.

3. Zone dampers should be preceded by 2’−4’ of straight pipe where possible.

4. In attic installations and high humidity areas, the Zonex Systems damper should be insulated along with

the ductwork. The hat section on the round damper is delivere

d with insulation between the hat section

and pipe. Therefore, insulation should be applied to the round pipe and be butted against the hat section

(do not insulate the motor). The motor generates enough heat so that no condensation will develop on it.

5. Remember to allow a 16” gap in the duct for heavy duty rectangular CD dampers.

6. Low pressure rectangular dampers slide into a 3” wide cutout in the side of the pre-existing duct

work.

7. Minimum open and close positioni

ng is field adjustable on the actuator. The damper is shipped from the

factory to close 100%.

NOTE: Dampers should not be installed with motor upside down in the 6:00 position.

16

Zonex Systems zone dampers are

DAMPER MODEL

MAXIMUM

PRESSURE

SYSTEM SIZE

DUCT SIZE

STMRX Round Med. Pressure

1.75”

Any Size

18”

STCRX Rect. Heavy Duty

1.75”

Any Size

48”W x 48”H

DIAMETER

CFM

FPM

∆P “ WC

6”

110

540

.014

8”

250

700

.015

10”

410

750

.015

12”

660

850

.022

14”

1000

925

.035

16”

1450

1070

.036

18”

2000

1100

.036

L

W

D

ROUND DI M E N S I O N A L D A T A

STMRX06

66”10”

9”

STMRX08

88”10”

11”

STMRX10

10

10”

12”

13”

STMRX12

12

12”

14”

15”

STMRX14

14

14”

16”

17”

STMRX16

16

16”

18”

19”

STMRX18

18

18”

23”

21”

MEDIUM PRESSURE (STMRX)

used in cooling/heating systems to

provide room by room zone

DIFFERENTIAL

control. The damper is provided

with a factory mounted actuator.

Each zone damper is controlled

by a zone thermostat. More than

one damper can be controlled by

one zone thermostat. Use this

Maximum Differential Pressure refers to the maximum static pressure drop in inches

of water column between the input (upstream) of the zone damper and the output

(downstream) when the damper is closed.

table to determine which zone

dampers to use.

ROUND MEDIUM PRESSURE ZONE DAMPERS

Zonex Systems round medium pressure zone dampers are recommended for systems with a maximum differantial static pressure up to

1.75”. This power open / power closed damper is manufactured from

20-22 gauge galvanized steel with rolled-in stiffening beads for superior

rigidity. Mechanical minimum and maximum set stops are provided and

are easily adjustable. Do not install damper in an inverted position. A

hat section supports a reversing 24vac, 60Hz, 2 VA motor. Motor drive

time from full open to full close is 90 seconds.

3 WIRE ZONE DAMPERS

MAXIMUM

MAXIMUM

ROUND MEDIUM PRESSURE DAMPER

PART NUMBERS AND SIZES

TYPICAL ROUND CAPACITIES

These air qua

ntities were derived from a duct sizing

chart 0.1” friction loss per 100’ of duct. All CFMs

listed are approximate. For accurate selection, use

duct sizing table or device.

PART # SIZE D L W

DUCT

NOMINAL

DUCT VELOCITY

DAMPER

17

D

H

MOTOR

D

2 ½”

48” MAXIMUM WIDTH

ZONE DAMPERS

RECTANGULAR ZONE DAMPERS

The rectangular zone dampers are available in either low pressure or heavy duty. For systems under 5 tons,

use low pressure dampers. For systems 5 tons or over, use heavy duty dampers. Motor drive time open

and close is 90 seconds.

HEAVY DUTY RECTANGULAR DIMENSIONAL DATA

Part Number STCRX W x H

Sizes available from 8” x 8” up to 48” x 48”

RECTANGULAR HEAVY DUTY ZONE DAMPERS (STCRX)

Zonex Systems rectangular heavy duty dampers are recommended for systems 5 tons

or larger with a maximum differential static psure of 1.75”. These are power open /

power closed dampers made of 20 gauge “snaplock” steel frame with S & Drive duct

connections. Allow a 16” gap in the duct for the damper. A full stall motor, drawing 2 VA,

drives the motor from full open to full close in 90 seconds.

Rectangular Damper Capacities*

8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 40 42 44 46 48

8

300 400 500 610 710 820 925 1050 1175 1250 1400 1500 1600 1725 1825 2000 2100 2200 2275 2400 2525

10

400 540 680 825 975 1125 1300 1400 1590 1750 1975 2 100 2175 2400 2600 2775 2900 3000 3200 3400 3600

12

500 680 850 1000 1200 1400 1600 1850 2000 2300 2550 2700 2850 3100 3400 3600 3800 3975 4200 4450 5775

14

610 825 1000 1250 1500 1750 2000 2250 2500 2900 3150 3425 3625 3825 4200 4600 4800 5000 5300 5750 6000

16

710 975 1200 1500 1800 2100 2450 2700 3000 3600 3950 4200 4425 4650 5100 5600 5780 6025 6500 7000 7400

18

820 1125 1400 1750 2100 2500 2850 3080 3600 4400 4600 4950 5100 5600 6000 6500 7000 7150 7600 8100 8600

20

925 1300 1600 2000 2450 2850 3400 3775 4000 4800 5500 5700 6000 6600 7100 7900 8025 8500 9000 9600 100 75

22

1050 1400 1850 2250 2700 3080 3775 4300 4800 5100 6000 6350 6800 7200 7800 8600 9000 9600 10000 11500 12500

24

1175 1590 2000 2500 3000 3600 4000 4800 5400 6100 7000 7150 7600 8600 9100 10000 10700 11500 12000 13050 14700

26

1250 1750 2300 2900 3600 4400 4800 5100 6100 6700 7800 8400 8900 10000 10900 11075 12050 13000 14000 15000 15900

28

1400 1975 2550 3150 3950 4600 5500 6000 7000 7800 8400 9150 10000 10700 11900 13000 13800 14900 15200 16500 17500

30

1500 2100 2700 3425 4200 4950 5700 6350 7150 8400 9150 10000 11000 11800 12400 13800 14200 15000 16000 17400 18500

32

1600 2175 2850 3625 4425 5100 6000 6800 7600 8900 10000 11000 11250 12700 13900 14900 15200 16900 1730 0 19000 20500

HEIGHT IN INCHES

34

1725 2400 3100 3825 4650 5600 6600 7200 8600 10000 10700 11800 12700 14100 15000 16500 17200 18100 19200 20500 21900

36

1825 2600 3400 4200 5100 6000 7100 7800 9100 10900 11900 12400 13900 15000 16100 17400 18500 20000 21500 22900 24200

38

2000 2775 3600 4600 5600 6500 7900 8600 10000 11075 13000 13800 14900 16500 17400 17800 20000 21900 22600 24000 25100

40

2100 2900 3800 4800 5780 7000 8025 9000 10700 12050 13800 14200 15200 17200 18500 20000 21000 22200 24900 25000 27000

42

2200 3000 3975 5000 6025 7150 8500 9600 11500 13000 14900 15000 16900 18100 20000 21900 22200 22800 25100 26900 30000

44

2275 3200 4200 5300 6500 7600 9000 10000 12000 1400 0 15200 16000 17300 19200 21500 22600 24900 25100 26500 30000 32000

46

2400 3400 4450 5750 7000 8100 9600 11500 13050 1500 0 16500 17400 19000 20500 22900 24000 25000 26900 30000 30500 32800

48

2525 3600 5775 6000 7400 8600 1075 12500 14700 1590 0 17500 18500 20500 21900 24200 25100 27000 30000 32000 32800 35600

WIDTH IN INCHES

* These air quantities were derived from duct sizing chart .1" friction loss per 100' of duct. All CF .etamixorppa era detsil sM

For accurate selection use duct sizing table or

18

DAMPER TRANSFORMER SIZING

DAMPER TRANSFORMER SIZING

The 24V transformer connected to TR1 and TR2 of the GEN II-R System Controller powers the zone dampers. The power

rating of the transformer must be sufficient to power the number of dampers used. Also, a properly rated in line fuse must be

used on the secondary of the transformer. To determine the power rating of the transformer and the amperage rating of the

fuse, use the table below. If using a combination of spring open and power open dampers, size as if all dampers are spring

open.

TRANSFORMER/FUSE SIZING

NUMBER

OF

DAMPERS

1 40 VA 1 AMP 40 VA 1 AMP

2 40 VA 2 AMP 40 VA 1 AMP

3 40 VA 2 AMP 40 VA 1 AMP

4 40 VA 3 AMP 40 VA 2 AMP

5 48 VA 3 AMP 40 VA 2 AMP

6 60 VA 4 AMP 40 VA 2 AMP

7 72 VA 5 AMP 40 VA 3 AMP

8 84 VA 5 AMP 40 VA 3 AMP

9 96 VA 6 AMP 40 VA 3 AMP

10 108 VA 6 AMP 40 VA 3 AMP

11 120 VA 7 AMP 40 VA 4 AMP

12 132 VA 7 AMP 40 VA 4 AMP

Notice:

All wiring must meet state and local codes.

TR SERIES (12va)

(SPRING OPEN) DAMPERS

XFMR PWR

FUSE SIZE

MED. PRESSURE/HEAVY DUTY(2va)

(POWER OPEN) DAMPERS

XFMR PWR

FUSE SIZE

SLAVING ZONE DAMPERS

SLAVING UP TO THREE 2-WIRE ZONE DAMPERS

Up to three dampers can be directly controlled by one zone damper control board. To wire two or three dampers for a zone,

use the following wiring diagram. Remember to size the power transformer for the total number of zone dampers in the system,

12va per damper.

RUN CLOSED

ZN6

ZN7

RUN OPEN

ZN8

MC

RO

RC

B

A

B

HP

A

ZN9

ZN10

M

ZONE DAMPER 2

TR or TREC damper

M

M

ZONE DAMPER 3

TR or TREC damper

M

R

C

R

C

W/OB

Y

E

ZN1

ZN2

ZN3

ZN4

ZN5

TRX or TREX damper

19

SLAVING ZONE DAMPERS

SLAVING MORE THAN THREE 2-WIRE ZONE DAMPERS

When slaving more than three zone dampers, use the following diagram. An additional 24-volt transformer and control relays are

needed for these applications. Note: All slave dampers need to be model TR / TREC and are 12va per damper.

M

R

C

R

C

W/OB

Y

E

M

M

ZONE DAMPER 1

CONTROL

RELAY

MC

RUN OPEN

RO

RUN CLOSED

RC

B

A

B

HP

ZN1

ZN2

ZN3

ZN4

ZN5

ZN6

A

ZN7

ZN8

ZN9

ZN10

SPST

TR or TREC damper TR or TREC damper

24 VOLT

TRANSFORMER

M

ZONE DAMPER 2

M

M

ZONE DAMPER 3

TR or TREC damper

TRX or TREX damper

SLAVING UP TO THREE ST SERIES 3-WIRE ZONE DAMPERS

Up to three dampers can be directly controlled by one zone damper control board. To wire two or three dampers for a zone,

use the following wiring diagram. Remember to size the power transformer for the total number of zone dampers in the system,

2va per damper.

ACTUATOR

RC

RO

MC

RUN CLOSED

ZN6

RUN OPEN

ZN7

MC

RO

RC

B

A

B

HP

A

ZN8

ZN9

ZN10

RC

ZONE DAMPER 2

STMPD or STCD damper

MCRO

STMPD or STCD damper

RC

ZONE DAMPER 3

MCRO

R

C

R

C

W/OB

Y

E

ZN1

STMRX or STCRX damper

ZN2

ZN3

ZN4

ZN5

SLAVING MORE THAN THREE ST SERIES 3-WIRE ZONE DAMPERS

When slaving more than three zone dampers, use the following diagram. An additional 24-volt transformer and control relays are

needed for these applications. Note: All slave dampers need to be model STMPD / STCD

ACTUATOR

RC

R

C

R

C

W/OB

Y

E

ZN1

STMRX or STCRX damper

RC

RO

RC

RO

MC

MC

RUN OPEN

RO

RUN CLOSED

RC

B

A

B

HP

ZN2

ZN3

ZN4

ZN5

ZN6

A

ZN7

ZN8

ZN9

ZN10

CONTROL

RELAY

SPST

CONTROL

RELAY

SPST

MC

ZONE DAMPER 1

STMPD or STCD damper STMPD or STCD damper

24 VOLT

TRANSFORMER

MC

ZONE DAMPER 2

RC

RO

MC RO

ZONE DAMPER 3

STMPD or STCD damper

20

BYPASS DAMPERS

Bypass dampers are used to provide constant air delivery

through the air handling unit. This is done by bypassing excess

air from the supply duct back to the return duct. As a zone is

satisfied, its zone damper closes. When this happens, the

bypass damper opens just enough to bypass the excess air.

This will control static pressure and noise at the diffusers.

Zonex Systems offers two types of bypass dampers, Barome-

BYPASS DAMPERS – BAROMETRIC

The barometric bypass damper is for systems 5 tons or under.

It utilizes a weighted damper blade to maintain constant duct

pressure. This allows for easy installation without the need for

electrical power or wiring. The round barometric damper can

be installed in any position. The RBB rectangular damper must

be installed with horizontal air flow only.

SIZING: When only the smallest zone is calling, the maximum

amount of excess supply air flow through the bypass damper.

To determine the proper size bypass damper to use, do the

following steps:

Step 1: Calculate bypass air volume as

follows:

A) Calculate total air volume at 400

CFM per ton.

B) Calculate air volume of smallest

zone in CFM.

C) Calculate bypass air volume by

subtracting the smallest zone air

volume from the total. (A - B = C)

BAROMETRIC BYPASS

SELECTION TABLE

Diameter CFM

9” 650

10” 800

12” 1200

14” 1600

16” 2000

BYPASS DAMPERS

tric and electronic. Each is available in round or rectangular

configuration. Barometric bypass dampers are limited to

systems of 5 tons. Electronic bypass dampers can be used on

any size system. For residential HVAC systems with variable

speed blowers, the barometric or electric bypass dampers can

be used. NOTE: When using the electronic bypass (STBP/ST-

CDBP), see the Bypass Dampers - Electronic Section, Pages

23-26; or contact Technical Support at 800-228-2966.

If bypassing more than 2000 CFM, use the electronic bypass.

Example: You have a 4 ton system. Your smallest zone will use

500 CFM. The total CFM is 1600 CFM (400*4). Your bypass

CFM is 1100 (1600-500). From the table, you determine that a

12” bypass damper is needed.

Do not use the barometric bypass in any system over 5 tons,

for systems over 5 tons, or to bypass more than 2000 CFM,

use the electronic bypass.

BAROMETRIC BYPASS

DAMPER

AIRFLOW

3

4

RECTANGULAR & ROUND

BAROMETRIC BYPASS

1

2

1. Damper Shaft

2. Lock Nut

3. Lever Arm

4. Counter Weight

Step 2: Select damper from sizing table. Once you have calcu-

lated the bypass air volume from Step 1, use the

BAROMET-

RIC BYPASS SELECTION TABLE. From the table, select the

bypass damper with CFM rating equal to or greater than the

value calculated in Step 1. For rectangular barometric dampers,

use a ductulator to convert from round to rectangular.

21

BYPASS DAMPERS- BAROMETRIC

INSTALLATION

The round barometric bypass damper can be installed in any

position. This damper is factory set for horizontal installation

and can be field modified for vertical installation. Do not run

speed screws into damper housing. Screws may interfere with

damper travel. Make sure counterweight is not obstructed in any

way.

a) Install the bypass damper between the supply and return

plenums of the unit. It must be the first tap off the supply plenum.

b) Be sure the air flows through the damper in the proper

direction as indicated by the arrow on the damper. Airflow

is always from supply to return plenum. Be certain the

damper shaft is horizontal.

c) Loosen counter weight with allen wrench.

d) Loosen lever arm from damper shaft and allow to hang

straight down.

e) Fully close damper by grabbing damper shaft on side

attached to lever arm and turning clockwise until it stops.

f) While holding the damper fully closed, rotate the lever

arm a little to the right (facing the damper) and then

screw into tighten to the damper shaft. Then tighten lock

nut.

BAROMETRIC BYPASS SETUP

a) Turn off all thermostats.

b

) Turn on Controller and set fan switch to “ON” position.

Allow fan to run for 5 minutes to equalize pressure.

Then make sure all dampers are open by checking

for air flow out of each damper.

c) By moving counter weight up or down the lever arm,

adjust it so the damper just wants to start opening.

d) If the damper cannot be held closed with the counter

weight all the way to the bottom of the lever arm, then

hold the damper shaft, loosen the lever arm from the

damper shaft, and rotate the lever arm farther to the

right and retighten. Repeat Step C.

e) The barometric bypass damper is now calibrated.

BAROMETRIC BYPASS STARTUP TEST

a) Have at least half of the zones call for either heating or

cooling.

b) Check to be sure the calling zone dampers are open,

(air is flowing).

c) Verify the bypass damper is open. Note, the damper

may not fully open.

g) Be sure the damper is being held closed by the counter

weight. Proceed to setup.

HORIZONTAL APPLICATION

AIRFLOW

SHEET METAL

PIPE

AIRFLOW

BAROMETRIC

BYPASS

RETURN

VERTICAL APPLICATION

A/C UNIT

OR

FURNACE

BAROMETRIC

BYPASS

SUPPLY

PLENUM

A/C UNIT

OR

FURNACE

RETURN AIR GRILLE

RETURN

AIR

PLATFORM

SUPPLY

PLENUM

AIRFLOW

OPEN RETURN PLENUM BYPASS APPLICATION

To prevent bypass air from

flowing out the return grill,

use a short open ended

return air plenum to

connect the bypass

damper to the unit.

RETURN AIR

d) If the open zones are not noisy, the bypass damper is

set.

ROOFTOP INSTALLATION Down Discharge Application

A/C UNIT

OR

FURNACE

BAROMETRIC

BYPASS

PIPE

AIRFLOW

UNIT

SUPPLY

DUCT

GRILLE

SUPPLY

PLENUM

SHEET METAL

BYPASS DAMPER

AIR CONDITIONING

ROOF LINE

RETURN

PLENUM

22

8”

560

10”

900

12”

1250

14”

1700

16”

2200

18”

2600

20”

3300

22”

4000

24”

4700

STBP08

88”10”

11”

STBP10

10

10”

12”

13”

STBP12

12

12”

14”

15”

STBP14

14

14”

16”

17”

STBP16

16

16”

18”

19”

STBP18

18

18”

23”

21”

STRDBP20

20

20”

24”

27”

STRDBP22

22

22”

24”

27”

STRDBP24

24

24”

24”

27”

ROUND BYPASS SELECTION TABLE

4”

H

D

W

48” MAXIMUM WIDTH

RECTANGULAR BYPASS DAMPERS

D

L

W

BYPASS DAMPERS- ELECTRONIC

ELECTRONIC BYPASS DAMPERS

Bypass dampers are used to provide constant air delivery through the air handling unit. This is done by

bypassing excess air from the supply duct back to the return duct. As a zone is satisfied, its zone damper

closes. When this happens, the bypass damper opens just enough to bypass the excess air. This will control

static pressure and noise at the diffusers.

The Electronic Bypass Damper is used on any size system over 5 tons.

The damper can be round (STBP) or

rectangular (STCDBP) with integrated static pressure control; and multiple dampers can be slaved together.

SIZING ELECTRONIC BYPASS DAMPERS

The bypass damper is to be sized for the total

system CFM @ 1500 FPM. System CFM should

Diameter CFM

PART # SIZE D L W

be calculated at 400 CFM per ton.

Example: A 5-ton system is rated at 2000 CFM

(5x400 = 2000). When calculated at 1500 FPM,

the bypass damper should be 16”. Never

undersize the bypass damper.

ROUND BYPASS DAMPER SE

LECTION

The Zonex Systems STBP damper is used for

round bypass applications. When you know the

bypass CFM requirements, use the ROUND

BYPASS SELECTION TABLE to confirm the

round damper size.

NOTE: Multiple round dampers can be slaved

from one static pressure control to provide the

correct capacity. One large rectangular bypass

damper may be used instead of multiple round

dampers. See below.

RECTANGULAR BYPASS DAMPER

SELECTION

The Zonex Systems STCDBP WxH

used for rectangular bypass applications. These

dampers are also sized for the total system CFM

rated at 1500 FPM. Multiple dampers can be

slaved from a single static pressure control.

damper is

SELECT FROM 8 x 8 thru 48 x 48

23

WIDTH IN INCHES

81012141618202224283236404448

8

667

833

1000

1167

1333

1500

1667

1833

2000

2333

2667

3000

3333

3667

4000

10

833

1042

1250

1458

1667

1875

2083

2292

2500

2917

3333

3750

4167

4583

5000

12

1000

1250

1500

1750

2000

2250

2500

2750

3000

3500

4000

4500

5000

5500

6000

14

1167

1458

1750

2042

2333

2625

2917

3208

3500

4083

4667

5250

5833

6417

7000

16

1333

1667

2000

2333

2667

3000

3333

3667

4000

4667

5333

6000

6667

7333

8000

18

1500

1875

2250

2625

3000

3375

3750

4125

4500

5250

6000

6750

7500

8250

9000

20

1667

2083

2500

2917

3333

3750

4167

4583

5000

5833

6667

7500

8333

9167

10000

22

1833

2292

2750

3208

3667

4125

4583

5042

5500

6417

7333

8250

9167

10083

11000

24

2000

2500

3000

3500

4000

4500

5000

5500

6000

7000

8000

9000

10000

11000

12000

28

2333

2917

3500

4083

4667

5250

5833

6417

7000

8167

9333

10500

11667

12833

14000

32

2667

3333

4000

4667

5333

6000

6667

7333

8000

9333

10667

12000

13333

14667

16000

36

3000

3750

4500

5250

6000

6750

7500

8250

9000

10500

12000

13500

15000

16500

18000

40

3333

4167

5000

5833

6667

7500

8333

9167

10000

11667

13333

15000

16667

18333

20000

44

3667

4583

5500

6417

7333

8250

9167

10083

11000

12833

14667

16500

18333

20167

22000

48

4000

5000

6000

7000

8000

9000

10000

11000

12000

14000

16000

18000

20000

22000

24000

HEIGHT IN INCHES

DAMPER

SLAVE

TO NEXT SLAVE

B

I

RC

R

M

RECTANGULAR BYPASS SELECTION TABLE

RECTANGULAR BYPASS SELECTION TABLE

Bypass air in CFM. Calculated at 1500 FPM.

Formula used: B = W x H / 144 x 1500, where B = Bypass air in CFM, W = damper width in inches, H = damper height in inches,

144 = 144 sq. inches per sq. ft., 1500 = 1500 FPM.

ROUND AND RECTANGULAR

BYPASS DAMPER MOTORS

SLAVING BYPASS DAMPERS

Use only one Pressure Sensor when slaving two or more

Bypass Dampers together. Connect the Pressure Sensor

to one damper as described above. Connect the slave

dampers in parallel as shown. Up to 4 dampers can be

slaved to one Sensor. The slaved dampers will selfsynchronize each time the dampers reach full open or full

close.

ACTUATOR

RC RO MC RC RO MC

To Static Pressure Control, as shown on the Bypass

Wiring Diagram on the next page.

DAMPER

ACTUATOR

YPASS DAMPER

F APPLICABLE

O

C

24

INTEGRATED PRESSURE CONTROL SETUP

BYPASS DAMPER with INTEGRATED PRESSURE CONTROL

(Part # STBP or STCDBP)

Bypass Damper with Integrated Pressure Control is used to control bypass operations. The bypass damper

modulates to maintain static pressure as zone dampers open and close. The bypass system reduces air noise