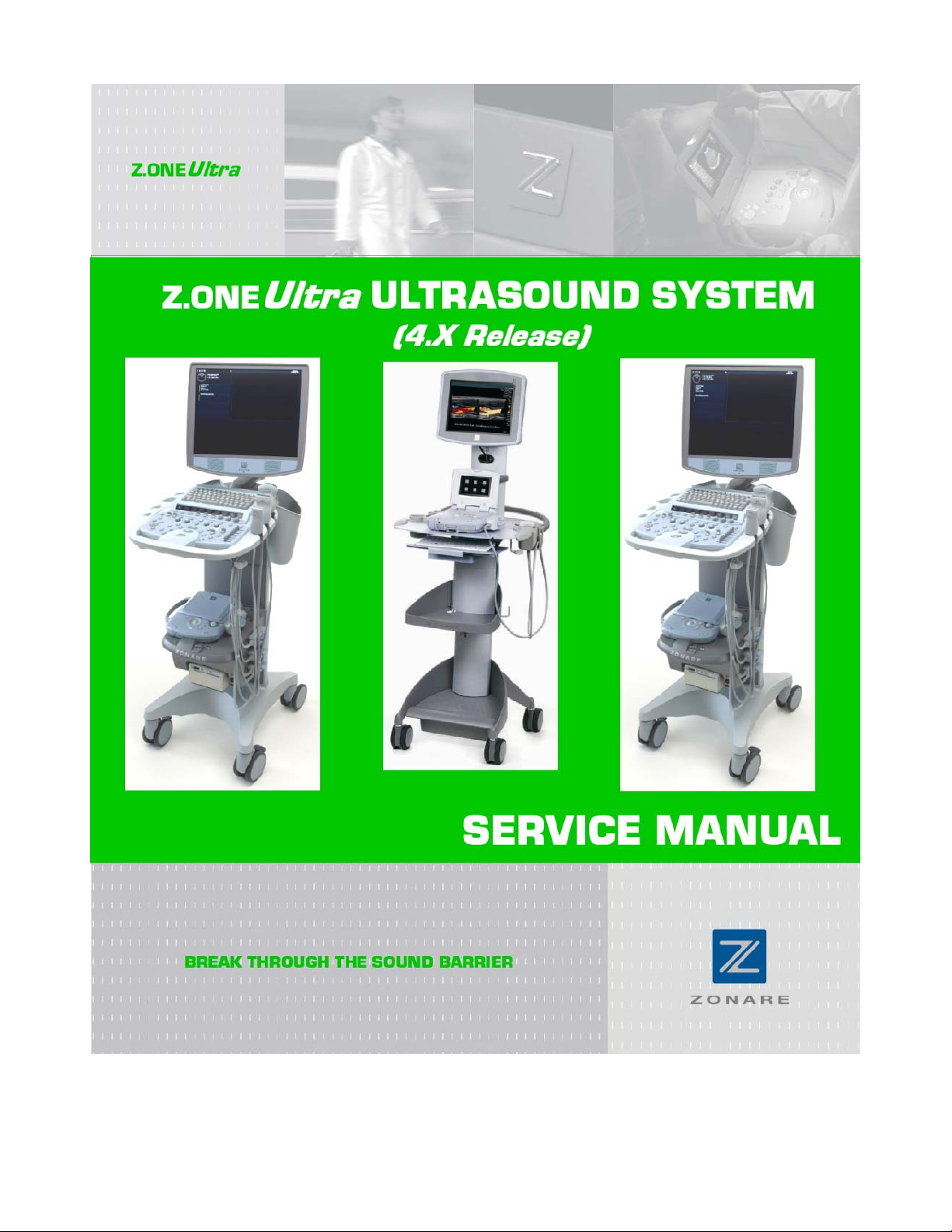

Page 1

Page 2

REVISION HISTORY

REV DESCRIPTION DATE

A Initial Release to support Version 4.0 Software/Hardware 1/09

B Updated software release and Scan Module support 4/09

C Updated to 4.1/4.2 software releases 9/09

D Updated Release to Support 4.7 SW & Product Changes 7/11

Q00169 Rev D Page 2 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 3

TABLE OF CONTENTS

1 INTRODUCTION.........................................................................................................................................10

1.1 Purpose.................................................................................................................................................11

1.2 Product Overview ................................................................................................................................11

1.3 Product Features.................................................................................................................................12

1.4 Definitions/Acronyms ..........................................................................................................................13

1.5 Documentation Conventions..............................................................................................................15

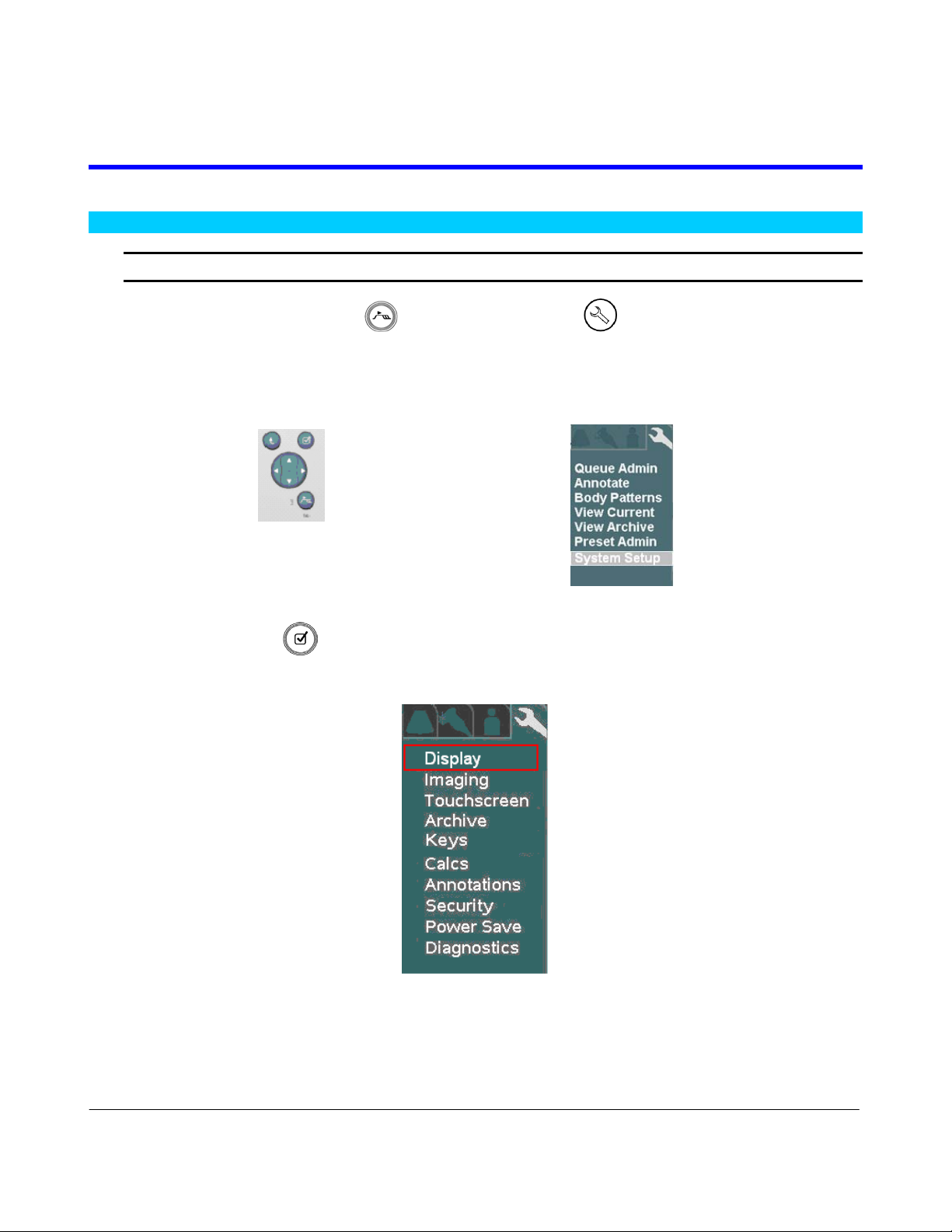

2 SAFETY .......................................................................................................................................................17

2.1 CAUTIONs and WARNINGs During Service/Operation................................................................17

2.2 Battery WARNINGs.............................................................................................................................18

2.3 CAUTIONs During Service.................................................................................................................18

2.4 Battery CAUTIONs..............................................................................................................................19

2.5 USB Memory Stick CAUTIONs .........................................................................................................19

2.6 Networking CAUTION.........................................................................................................................19

3 SYSTEM SPECIFICATIONS ....................................................................................................................20

3.1 System Dimensions................................................................................................................................20

3.2 Displays.................................................................................................................................................21

3.3 Image Archive or Export Storage......................................................................................................22

3.4 Transducers..........................................................................................................................................22

3.5 Accessories/Options...............................................................................................................................26

3.6 Peripherals............................................................................................................................................26

3.7 Site Requirements...............................................................................................................................26

3.8 System Power......................................................................................................................................27

3.9 System Power Protection...................................................................................................................27

3.10 Electrical Specifications..................................................................................................................27

3.11 Temperature, Humidity, Pressure Limits......................................................................................29

3.12 Device Classification .......................................................................................................................30

3.13 Safety Standards..............................................................................................................................30

3.14 DICOM Standard..............................................................................................................................30

3.15 Product Labeling..............................................................................................................................30

4 TOP-LEVEL PRODUCT OVERVIEW......................................................................................................35

4.1 Major Assembly Identification............................................................................................................35

4.2 Transducers..........................................................................................................................................35

Q00169 Rev D Page 3 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 4

4.3 Accessory Components......................................................................................................................36

4.4 SmartCart Major Assemblies (shown with MTP Multi- probe Option).........................................37

4.5 miniCart Major Assemblies ................................................................................................................38

4.6 SmartCart User Interface Controls (Overview)...............................................................................39

4.7 Scan Engine User Interface Controls (Overview)...........................................................................41

4.8 SmartCart User Interface Controls (Detailed) – Version 1............................................................42

4.9 SmartCart User Interface Controls (Detailed) – “Enhanced” Version (2)....................................47

4.10 SmartCart & miniCart Keyboard Controls (Detailed)..................................................................52

4.11 Scan Engine User Interface Controls (Detailed).........................................................................55

4.12 SmartCart Rear I/O Panel: Layout & Functional Definitions ....................................................58

4.13 miniCart I/O Connections: Layout & Functional Definitions .....................................................58

4.14 Scan Engine/Scan Module Rear I/O Ports: Layout & Functional Definitions ........................59

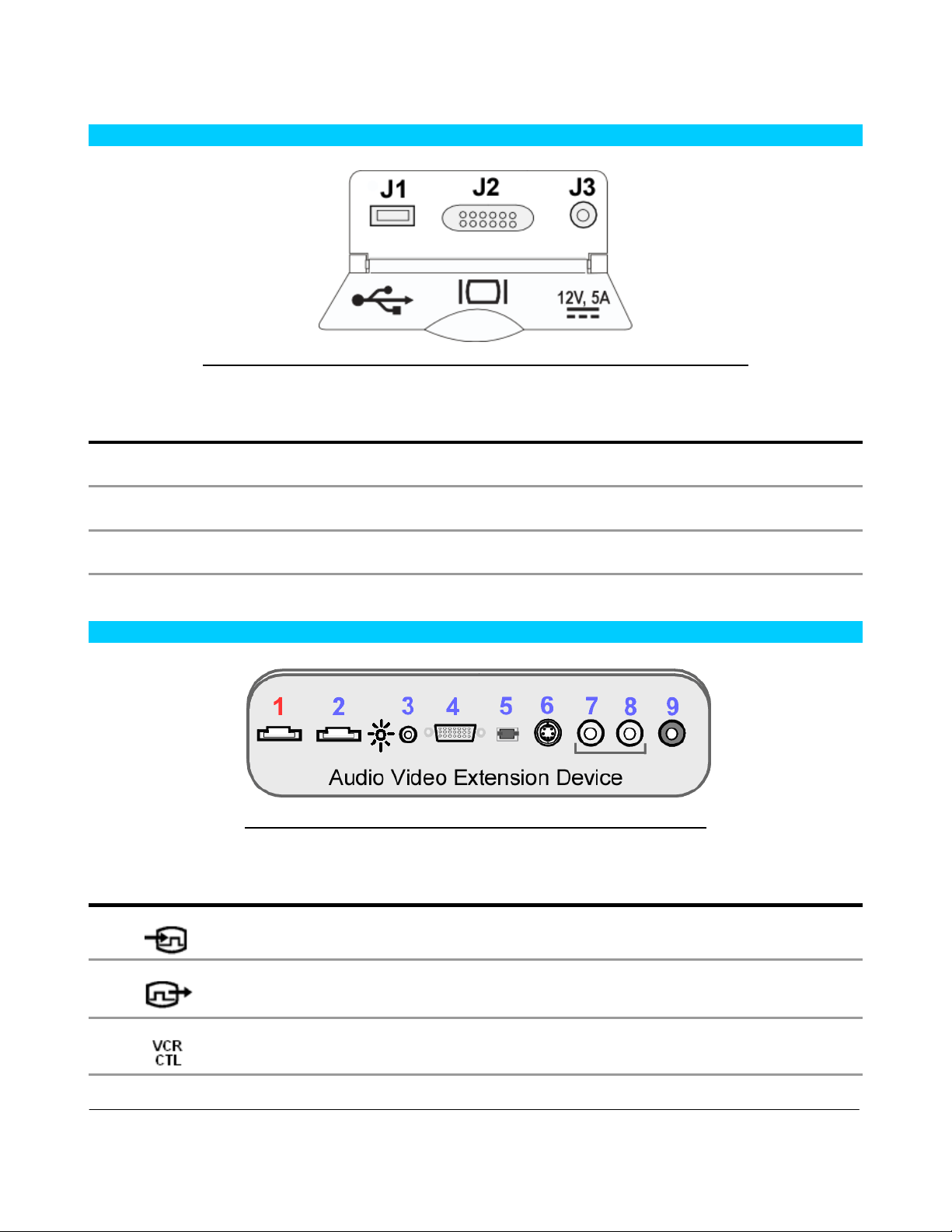

4.15 AVED: Audio-Video Extension Device - I/O Panel: (Option)...................................................59

5 SYSTEM UNCRATING & INSTALLATION PROCEDURES ..............................................................61

5.1 Product Shipment................................................................................................................................61

5.2 Electrical Requirements......................................................................................................................61

5.3 Environmental and Space Requirements........................................................................................61

5.4 Uncrating...............................................................................................................................................61

5.5 Mechanical Verification.......................................................................................................................65

5.6 System Installation:.............................................................................................................................65

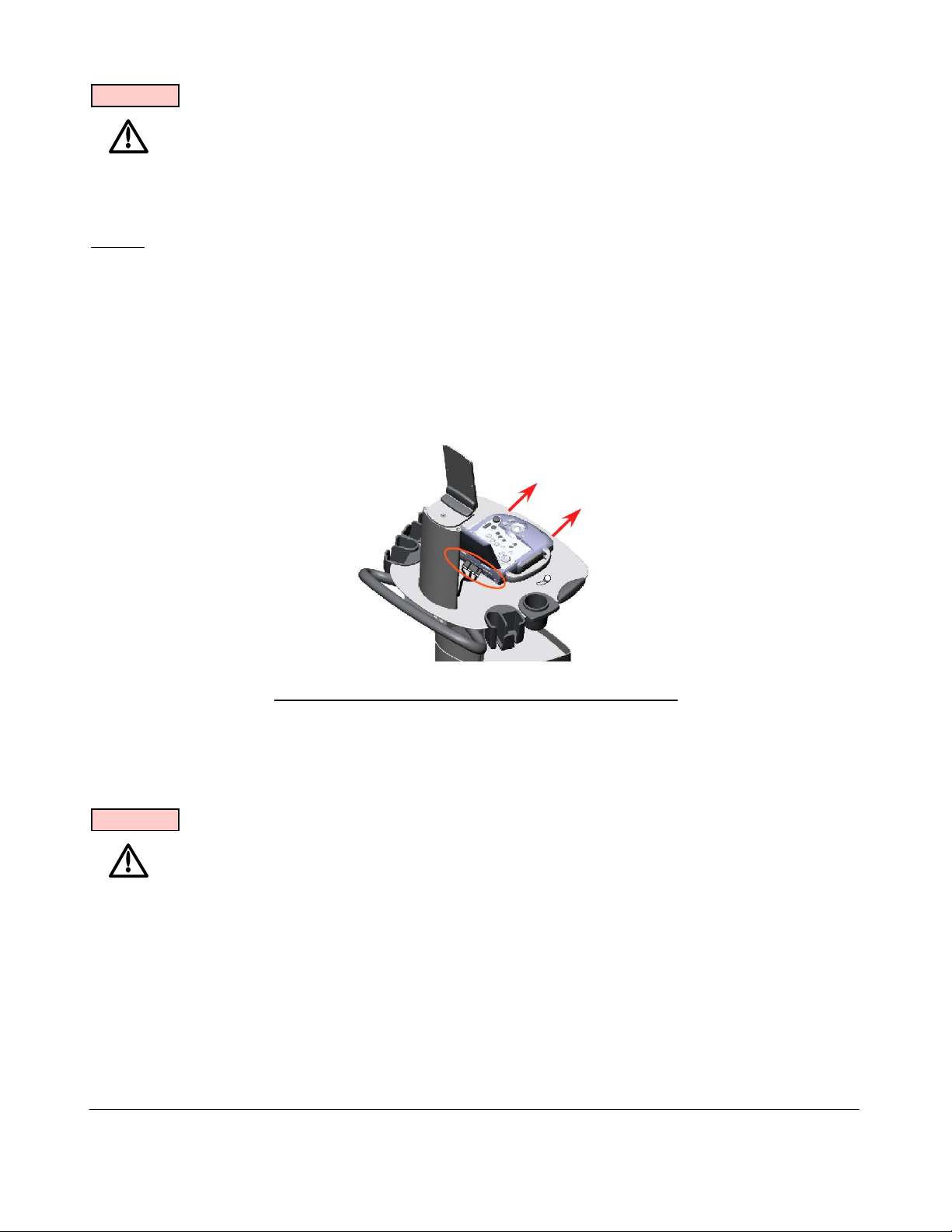

5.7 Transporting - Shipping the Scan Engine/Scan Module................................................................74

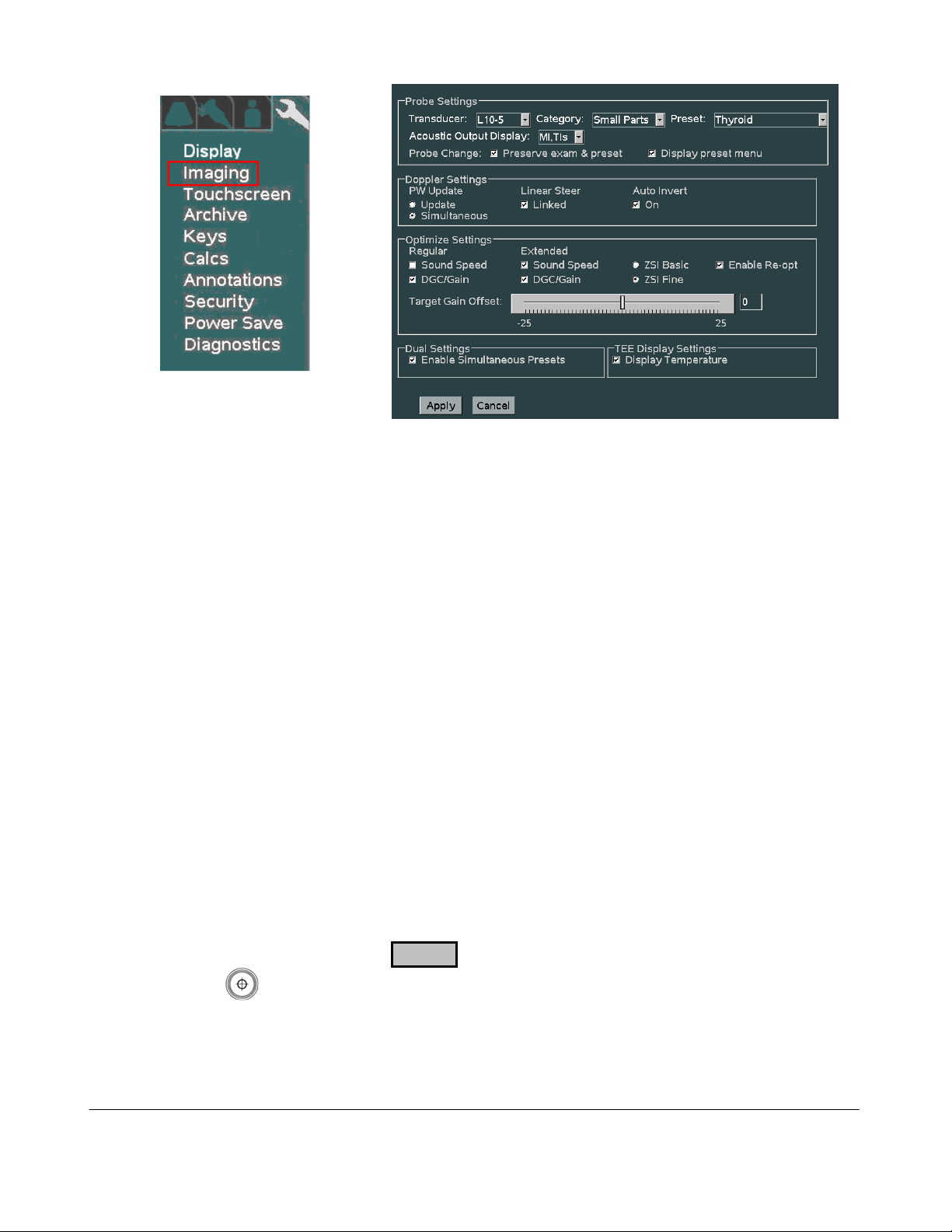

6 BASIC SYSTEM CONFIGURATION.......................................................................................................75

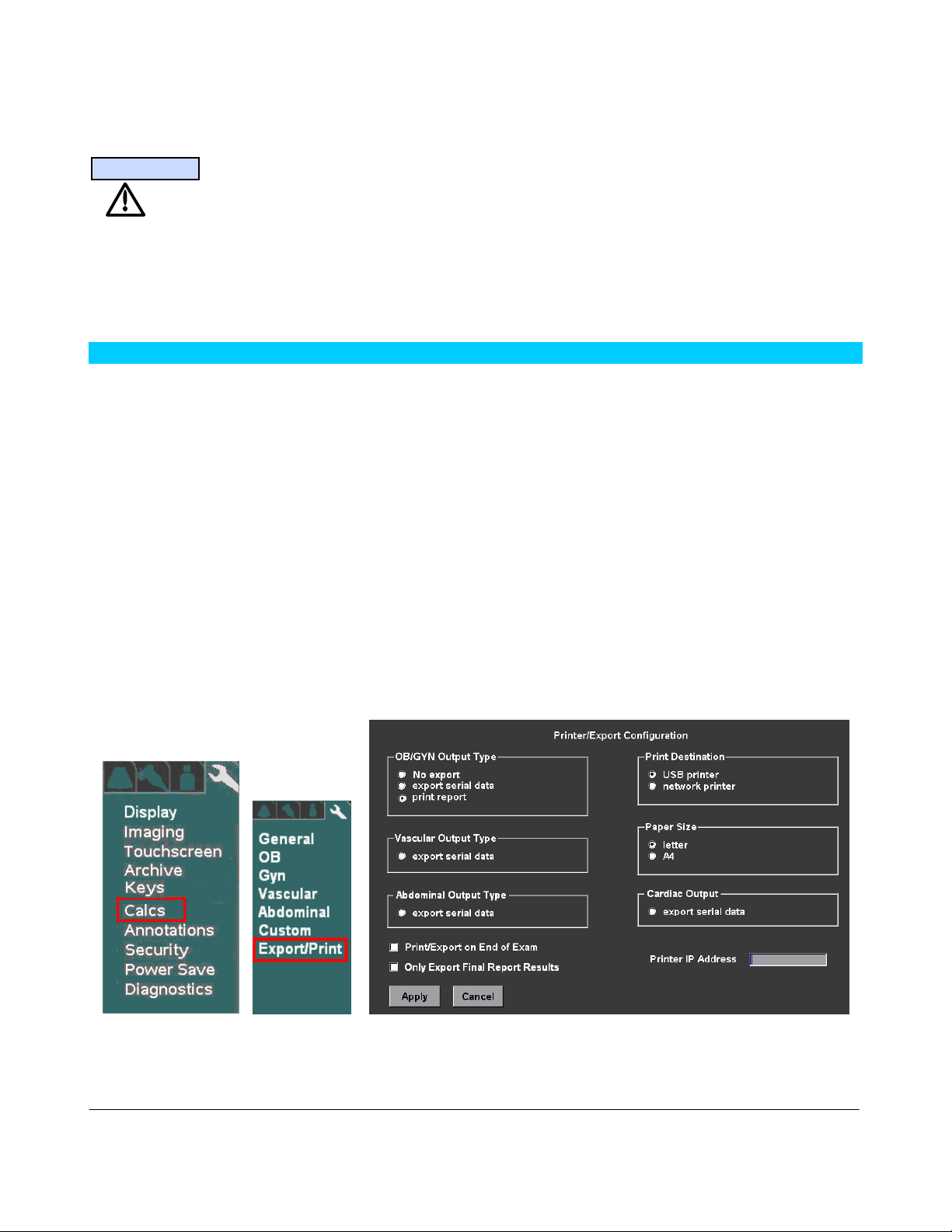

6.1 Basic System Configuration Procedures .........................................................................................75

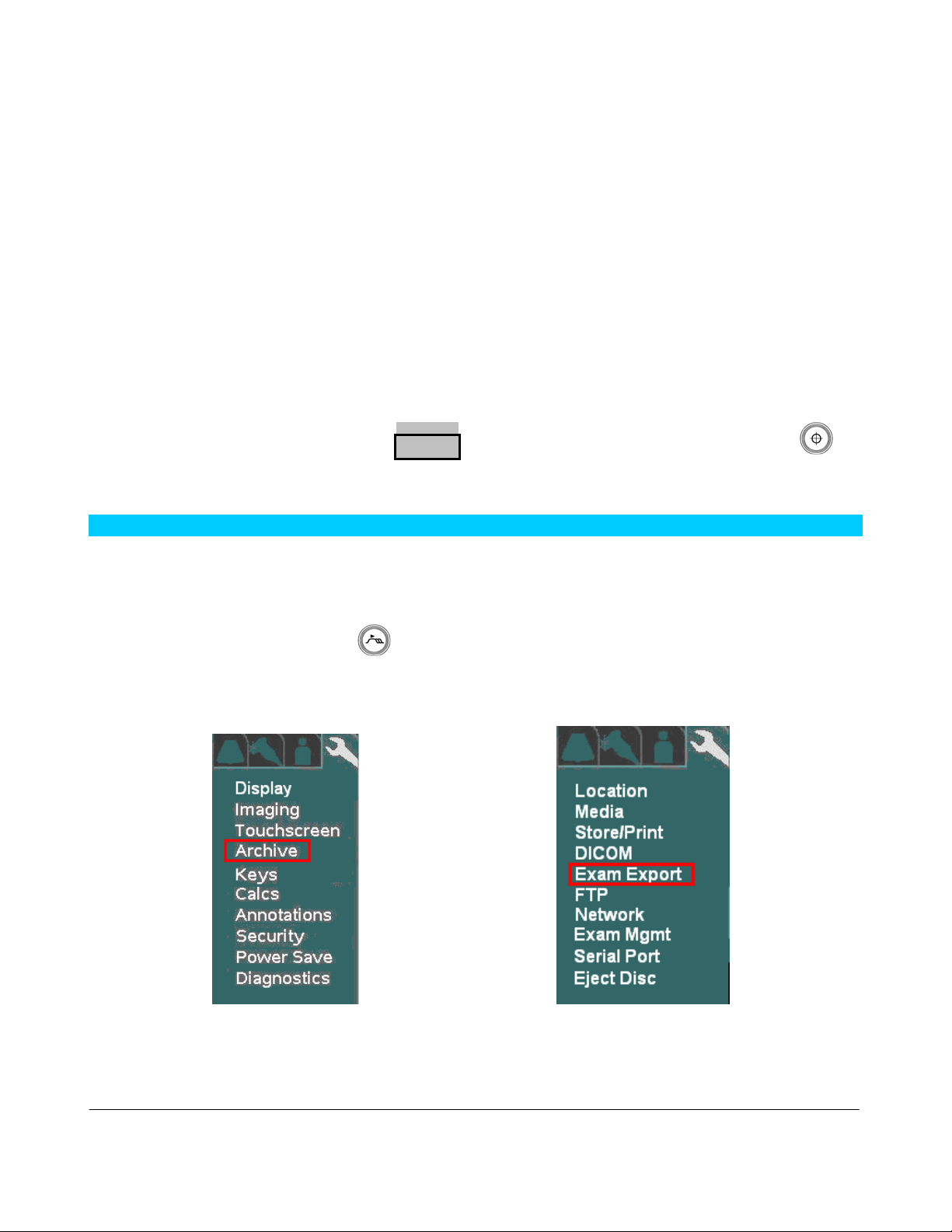

7 ARCHIVE MENU FUNCTIONS................................................................................................................83

7.1 “Media” & “Store/Print” Button Configuration...................................................................................83

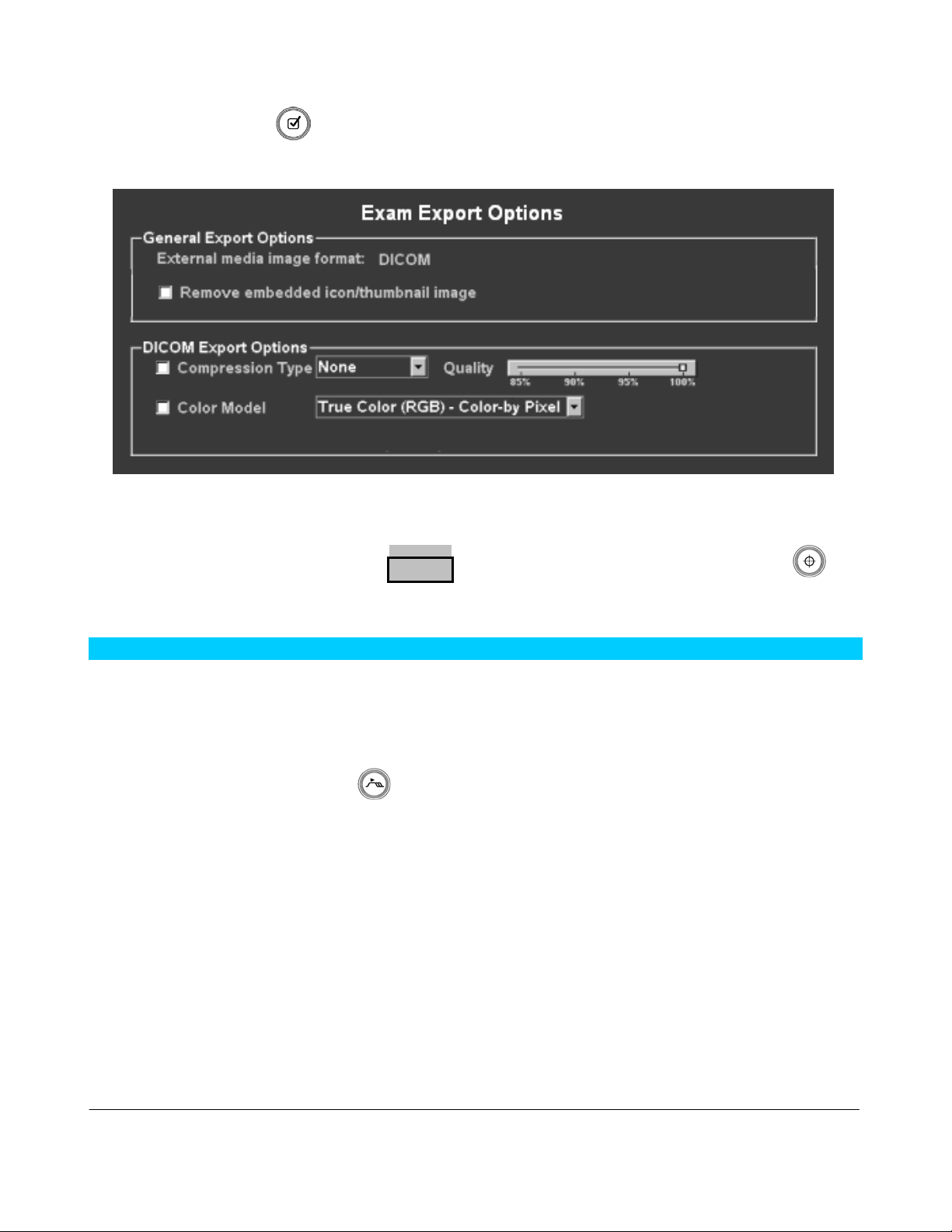

7.2 “Exam Export” Menu ...........................................................................................................................86

7.3 “Exam Management” Menu................................................................................................................87

7.4 Archive “Export” – OPTION menu.....................................................................................................93

7.5 “Serial Port” Setup - (Export Calc Report Data)..............................................................................95

8 DICOM CONFIGURATION.......................................................................................................................98

8.1 “DICOM” Configuration Overview .....................................................................................................98

8.2 “DICOM” Configuration Parameter Definitions:...............................................................................99

8.3 Z.ONEUltra Pre-Install Survey Form (Sample Only)....................................................................102

Q00169 Rev D Page 4 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 5

8.4 “DICOM” Configuration Procedure - Menus..................................................................................106

8.5 “Network” Setup.................................................................................................................................114

8.6 “FTP” Setup........................................................................................................................................116

9 ADVANCED SYSTEM SETUP CONFIGURATION............................................................................118

9.1 “Security” Setup Menus....................................................................................................................118

9.2 “Power Save” Setup Menu...............................................................................................................120

10 GENERAL PROCEDURES................................................................................................................122

10.1 Installing USB Memory Stick, into the Scan Engine/Scan Module.........................................122

11 FUNCTIONAL DESCRIPTIONS.........................................................................................................123

11.1 Overall System...............................................................................................................................123

11.2 SmartCart........................................................................................................................................125

12 POWER & SIGNAL DISTRIBUTION DIAGRAMS..........................................................................129

12.1 SmartCart Power Module Block Diagram (Basic).....................................................................130

12.2 SmartCart Power Module Block Diagram (Detailed)................................................................131

12.3 SmartCart Main Board Cable Connect Diagram (Original DVD Config) ...............................132

12.4 SmartCart Main Board Cable Connect Diagram (IDE/SATA Adapter DVD Config)............133

12.5 SmartCart Main Board Cable Connection Diagram (USB Style DVD Configuration) .........134

12.6 miniCart AC/DC Power Distribution Diagram ............................................................................135

13 FUNCTIONAL BLOCK DIAGRAMS..................................................................................................136

13.1 Z.ONEUltra Overall System Block Diagram (SmartCart w/Cardiac-Option Configuration) 137

13.2 miniCart Configuration: Overall System Block Diagram.............................................................138

13.3 Z.ONEUltra SmartCart - Cardiac Module (CW/ECG) Option - Block Diagram....................139

14 ASSEMBLY DIAGRAMS.....................................................................................................................140

14.1 SmartCart: Power Module Functional Identification .................................................................140

15 PERIPHERALS & ACCESSORIES...................................................................................................141

15.1 DVD/CD Burner - (Internal)"........................................................................................................141

15.2 AVED – Audio Video Extension Device Box - (Option)"..........................................................142

15.3 SONY UP-D897 USB Digital Printer...........................................................................................148

15.4 SONY UP-D25MD Color Printer..................................................................................................154

15.5 HP LaserJet Network (REPORT) Printer ...................................................................................156

15.6 2- Pedal Footswitch.......................................................................................................................160

16 SOFTWARE PROCEDURES..............................................................................................................161

Q00169 Rev D Page 5 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 6

16.1 SCAN ENGINE: Standard Software Installation/Upgrade Procedure....................................161

16.2 SCAN ENGINE (Only) “Advanced” Software Installation Procedure.....................................163

16.3 SCAN MODULE: Standard Software Installation/Upgrade Procedure..................................167

16.4 SCAN MODULE: “Clean” Software Install Procedure (“SERVICE” key)..............................169

16.5 SCAN MODULE: “Clean” Software Install Procedure (Undocked or Auto-Load)...............170

16.6 FTP Site Access: Software/File Downloads from Zonare .....................................................172

16.7 “DIAGNOSTIC” Panel Operations...............................................................................................172

17 CLEANING AND DISINFECTING PROCEDURES.........................................................................183

17.1 SmartCart........................................................................................................................................183

17.2 Scan Engine....................................................................................................................................184

17.3 Transducers....................................................................................................................................185

18 MAINTENANCE – CALIBRATION PROCEDURES.......................................................................189

18.1 Foreword .........................................................................................................................................189

18.2 List: Maintenance Procedures......................................................................................................189

18.3 List: Calibration Procedures.........................................................................................................189

18.4 PIC Reset (Power Supply) Procedure.......................................................................................190

18.5 Z-PAK “RECONDITION” Procedure - (SmartCart)...................................................................190

18.6 UI Lift (Gas spring) Release Cable Adjustment - (SmartCart)................................................192

18.7 Touchscreen Calibration - (Scan Engine)..................................................................................193

18.8 Display Monitor Adjustment – User Settings .............................................................................195

19 SYSTEM TROUBLESHOOTING........................................................................................................197

19.1 Foreword .........................................................................................................................................197

19.2 Technical Support Contact Information......................................................................................197

19.3 Troubleshooting..............................................................................................................................199

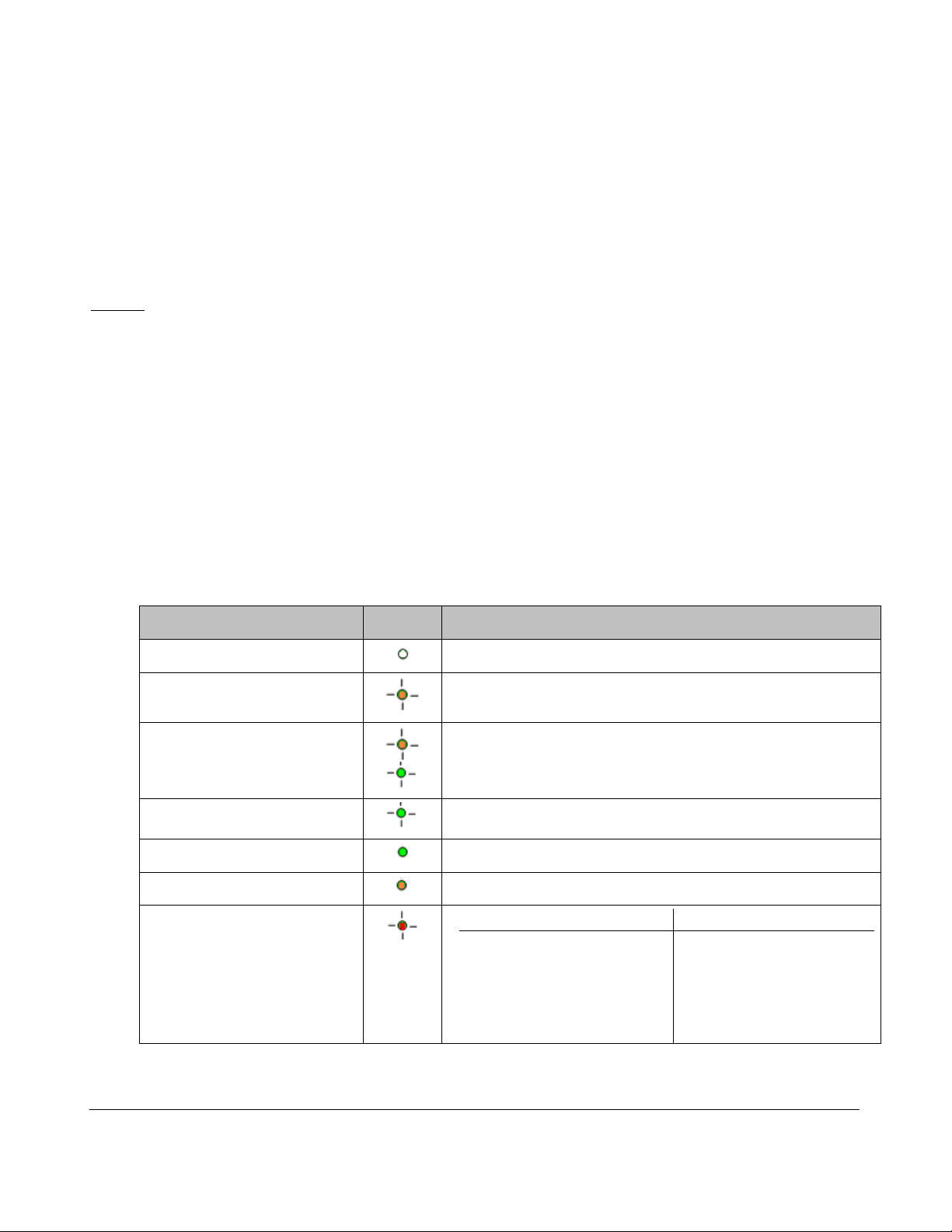

19.4 System Status LED & Error Code Definitions............................................................................206

19.5 Scan Engine Fan Operation.........................................................................................................214

19.6 SmartCart LCD Display Troubleshooting...................................................................................214

19.7 Battery Performance – Charge Times - Reconditioning ..........................................................215

20 REPAIR PROCEDURES .....................................................................................................................217

20.1 Foreword .........................................................................................................................................217

20.2 Recommended Tools ....................................................................................................................217

20.3 Hardware Service/Replacement Procedures (SmartCart).......................................................217

20.4 Hardware Service/Replacement Procedures (miniCart)..........................................................277

Q00169 Rev D Page 6 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 7

20.5 Hardware Service/Replacement Procedures (Scan Engine)..................................................287

20.6 Hardware Service/Replacement Procedures (Transducers)...................................................288

20.7 Service Software Procedures.......................................................................................................291

21 PART NUMBER INFORMATION.......................................................................................................293

21.1 SmartCart........................................................................................................................................293

21.2 miniCart ...........................................................................................................................................296

21.3 Scan Engine....................................................................................................................................298

21.4 Scan Module...................................................................................................................................299

21.5 Transducers....................................................................................................................................300

21.6 Peripherals......................................................................................................................................302

22 INDEX .....................................................................................................................................................303

Q00169 Rev D Page 7 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 8

TABLE OF FIGURES

FIGURE 1: LABEL, SCAN ENGINE – SERIAL/PART NO..........................................................................................................31

FIGURE 2: LABEL, SCAN MODULE – SERIAL/PART NO........................................................................................................31

FIGURE 3: LABEL, SCAN ENGINE BATTERY (VERSION 1) - SERIAL/PART NO.....................................................................31

FIGURE 4: LABEL, SCAN ENGINE BATTERY (VERSION 2) - SERIAL/PART NO.....................................................................31

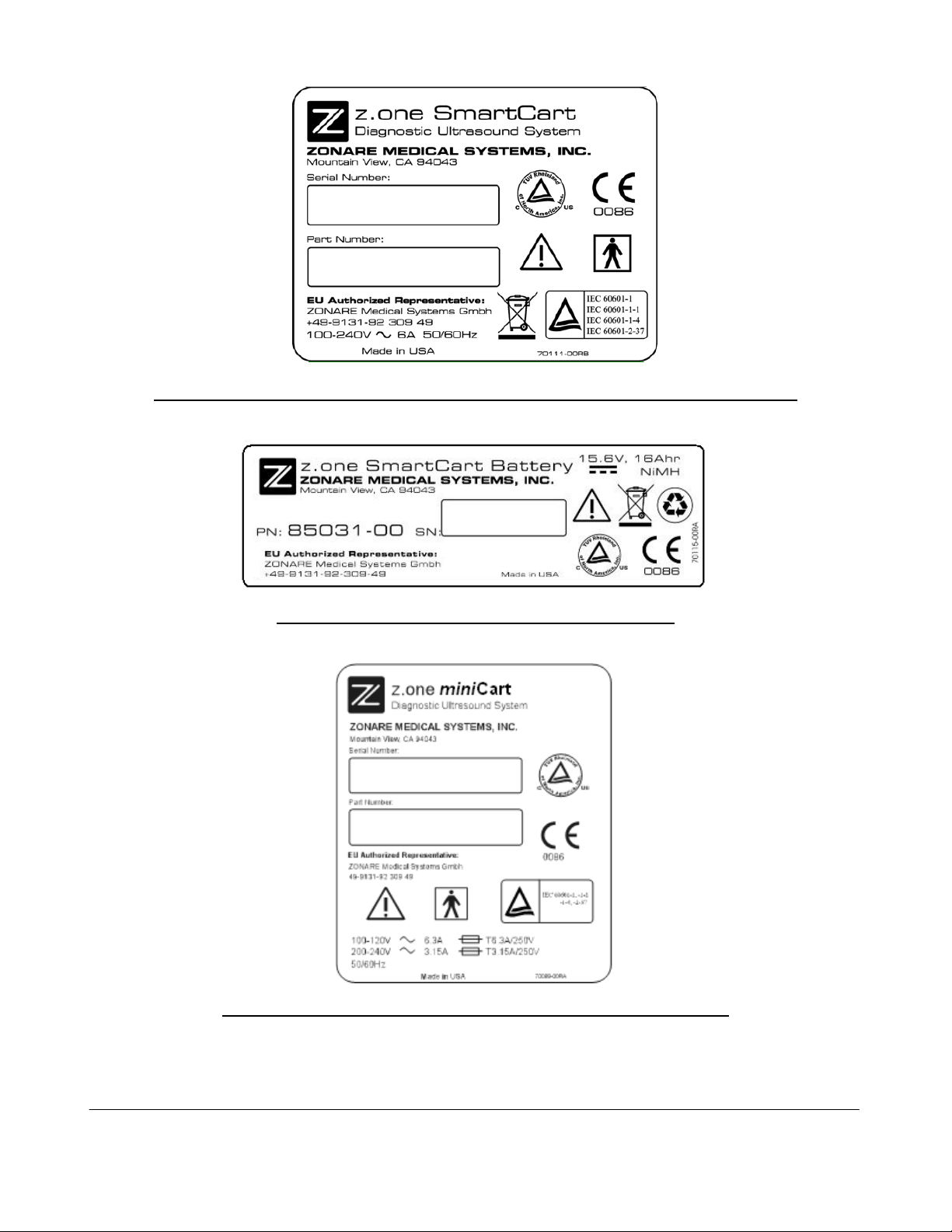

FIGURE 5: LABEL, 100V-240V SMARTCART REAR PANEL - SERIAL/PART NO..................................................................32

FIGURE 6: LABEL, SMARTCART Z-PAK BATTERY ................................................................................................................32

FIGURE 7: LABEL, MINICART REAR PANEL - SERIAL/PART NO.............................................................................................32

FIGURE 8: LABEL, LINEAR ARRAY TRANSDUCERS - SERIAL/PART NO................................................................................33

FIGURE 9: LABEL, CURVED ARRAY TRANSDUCERS - SERIAL/PART NO..............................................................................33

FIGURE 10: LABEL, ENDO CAVITY TRANSDUCER - SERIAL/PART NO.................................................................................33

FIGURE 11: LABEL, PHASED TRANSDUCERS - SERIAL/PART NO........................................................................................33

FIGURE 12: LABEL, SPECIALTY TRANSDUCERS - SERIAL/PART NO....................................................................................33

FIGURE 13: LABEL, AC POWER BATTERY ADAPTER...........................................................................................................34

FIGURE 14: LABEL, AC POWER ADAPTER POWER SUPPLY................................................................................................34

FIGURE 15: Z.ONEULTRA MAJOR ASSEMBLY ILLUSTRATIONS............................................................................................ 35

FIGURE 16: TRANSDUCER ILLUSTRATIONS .......................................................................................................................... 35

FIGURE 17: ACCESSORIES ...................................................................................................................................................36

FIGURE 18: SMARTCART KEYBOARD CONTROLS (OVERVIEW)...........................................................................................39

FIGURE 19: SMARTCART USER INTERFACE (VERSION 1) CONTROLS (OVERVIEW)...........................................................39

FIGURE 20: SMARTCART USER INTERFACE (“ENHANCED” VERSION) CONTROLS (OVERVIEW).........................................40

FIGURE 21: SCAN ENGINE USER INTERFACE CONTROLS (OVERVIEW)............................................................................... 41

FIGURE 22: SMARTCART USER INTERFACE LAYOUT – VERSION 1......................................................................................42

FIGURE 23: SMARTCART USER INTERFACE LAYOUT – “ENHANCED” VERSION (2).............................................................47

FIGURE 24: SMARTCART KEYBOARD LAYOUT......................................................................................................................52

FIGURE 25: MINICART KEYBOARD LAYOUT........................................................................................................................... 52

FIGURE 26: SCAN ENGINE USER INTERFACE LAYOUT (DETAILED).....................................................................................55

FIGURE 27: SMARTCART REAR I/O PANEL..........................................................................................................................58

FIGURE 28: MINICART USB HUB CONNECTIONS.................................................................................................................58

FIGURE 29: SCAN ENGINE/SCAN MODULE REAR I/O CONNECTIONS.................................................................................59

FIGURE 30: AVED OPTION - I/O PANEL (SMARTCART)...................................................................................................... 59

FIGURE 31: MAIN SHIPPING CONTAINER REMOVAL ..............................................................................................................62

FIGURE 32: LOADING RAMP LOWERING................................................................................................................................62

FIGURE 33: REMOVABLE SECTION OF SHIPPING BASE......................................................................................................... 62

FIGURE 34: REMOVING PROTECTIVE STORAGE BAG............................................................................................................ 63

FIGURE 35: BRAKE RELEASE OF WHEELS.............................................................................................................................63

FIGURE 36: BATTERY PACK INSTALLATION..........................................................................................................................66

FIGURE 37: SCANNER DOCKING IN SMARTCART.................................................................................................................66

FIGURE 38: SCAN ENGINE TO MINICART DOCKING..............................................................................................................67

FIGURE 39: AC POWER ADAPTER .......................................................................................................................................70

FIGURE 40: 2-BAY BATTERY CHARGER...............................................................................................................................72

FIGURE 41: INSTALLING USB MEMORY STICK...................................................................................................................122

FIGURE 42: SMARTCART: BRAKE MECHANISM..................................................................................................................127

FIGURE 43: SMARTCART: HEIGHT ADJUSTMENT MECHANISM.......................................................................................... 128

FIGURE 44: SMARTCART: POWER MODULE BLOCK DIAGRAM (BASIC)............................................................................ 130

FIGURE 45: SMARTCART: POWER MODULE BLOCK DIAGRAM (DETAILED) .....................................................................131

FIGURE 46: SMARTCART: MAIN BOARD CABLE CONNECTION DIAGRAMS (ORIGINAL DVD)...........................................132

FIGURE 47: SMARTCART: MAIN BOARD CABLE CONNECTION DIAGRAMS (IDE/USB ADAPTER STYLE DVD)............... 133

FIGURE 48: SMARTCART: MAIN BOARD CABLE CONNECTION DIAGRAMS (USB STYLE DVD DRIVE)............................134

FIGURE 49: MINICART: AC/DC POWER DISTRIBUTION DIAGRAM.....................................................................................135

FIGURE 50: OVERALL SYSTEM BLOCK DIAGRAM (ADVHDWE SCAN ENGINE & SMARTCART W/CARDIAC OPTION) .......137

FIGURE 51: OVERALL SYSTEM BLOCK DIAGRAM (ADVHDWE SCAN ENGINE & MINICART)..............................................138

FIGURE 52: SMARTCART: CARDIAC OPTION (CW/ECG) MODULE BLOCK DIAGRAM.......................................................139

Q00169 Rev D Page 8 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 9

FIGURE 53: SMARTCART: POWER MODULE FUNCTIONS DIAGRAM ..................................................................................140

FIGURE 54: AVED: AUDIO VIDEO EXTENSION DEVICE I/O PANEL DIAGRAM...................................................................144

FIGURE 55: MENU SETTINGS (UP-D897)..........................................................................................................................150

FIGURE 56: OPERATOR CONTROLS (UP-D897) ............................................................................................................... 152

FIGURE 57: APPROVED DISINFECTANTS TABLE (IMMERSION-METHOD)...........................................................................185

FIGURE 58: APPROVED DISINFECTANTS TABLE (WIPE-METHOD).................................................................................... 186

FIGURE 59: TRANSDUCER IMMERSION LIMITS....................................................................................................................187

FIGURE 60: MINICART 13” DISPLAY: RECOMMENDED SETTINGS -....................................................................................195

FIGURE 61: SMARTCART 19” DISPLAY: RECOMMENDED SETTINGS................................................................................. 195

FIGURE 62: TRANSDUCER CONNECTOR PIN DAMAGE – (EXAMPLE)................................................................................199

Q00169 Rev D Page 9 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 10

1 INTRODUCTION

USA, Canada, Asia

ZONARE Medical Systems, Inc.

420 N. Bernardo

Mountain View, CA 94043

Toll-free line (in USA only) live-voice support: ................................................. 1-877-913-9663

Standard line (USA & International) live-voice support: ................................... 1-650-316-3199

Tech Support fax line ........................................................................................... 1-650-230-2817

Customer Support E-Mail: .......................techsupport@zonare.com or salessupport@zonare.com

Web site..................................................www.zonare.com

FTP site (Service) ..................................ftp://12.40.200.87

Toll-free live-phone support: ............. 1-877-913-9663 (5:00AM – 5:00PM, Pacific Standard Time)

Tech Support FAX line ...................... 1-650-230-2817

Tech Support e-mail........................... techsupport@zonare.com

Corporate web site.............................. www.zonare.com

FTP site (Tech Support Window):

URL............................................ftp://12.40.200.87

Enter the following User Name and Password information:

User Name: (call Tech Support for current login information)

Password: (call Tech Support for current login information)

Q00169 Rev D Page 10 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 11

Europe

ZONARE Medical Systems GmbH

Henkestrasse 91

91052 Erlangen, Germany

Tech Support Phone .......................... (+49) 9131-974 94-0 (8:00AM – 5:00PM)

Tech Support e-mail........................... info@zonare.de

Corporate web site.............................. www.zonare.com

1.1 Purpose

This manual’s purpose is to provide information to assist service personnel in performing the service,

maintenance, and repair procedures that may be required to support ZONARE’s Z.ONEUltra

Diagnostic Ultrasound System product.

1.2 Product Overview

ZONARE’s Z.ONEUltra Convertible Ultrasound System provides a combination of a full-featured,

cart-based ultrasound system, with the versatility of a compact, easily transportable to the patient, selfcontained portable unit.

The Z.ONEUltra Convertible Ultrasound System is offered in two different models, utilizing two

different configurations of Carts. The sub-systems that comprise the Z.ONEUltra product are listed

below:

Full-Feature SmartCart or

Portable “Scan Engine” (or docked “Scan Module”

Ultrasound transducer(s)

The portable Scan Engine consists of a limited number of field replaceable units (FRU’s). The FRU’s

for this unit are:

Lithium-Ion battery pack

USB Memory Stick

Scan Engine (complete)

lightweight miniCart

The SmartCart consists of a limited number of field replaceable units (FRU’s). The FRU’s for this

unit are:

Q00169 Rev D Page 11 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 12

19” Display Monitor

User Interface Assembly

OLED Sub-Assembly (part of UI)

Main Board Assembly

Power Supply Module

Z-PAK Battery Pack

Scanner Deck (w/MTP)

MTP Bolster Plate (or MTP w/CW)

ECG Module

Misc cables and mechanical assemblies

The miniCart consists of a limited number of field replaceable units (FRU’s). The FRU’s for this unit

are:

AC Fuses

Main Power Supply (DC)

USB Hub

LCD Display

Remote Keyboard

Wheels

In addition to the two different Cart offerings, the Z.ONEUltra Ultrasound System is offered with two

different configurations of scanner electronics.

One version being a standalone portable use “Scan Engine” (with local LCD display and user

interface controls), and the other being a “brains only” (non-portable) “Scan Module”.

Scan Engine Scan Module

The ultrasound transducers are replaced as a single FRU, with no field-serviceable parts.

1.3 Product Features

The Z.ONEUltra ultrasound system includes the following key features:

Q00169 Rev D Page 12 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 13

Full function scanning modalities (B-Scan, M-Mode, Color Flow, Power Doppler, PW Dopper)

Remote portability for patient scanning

1.4 Definitions/Acronyms

2D: ................. Two dimensional (B-Mode, Color mode)

BMP: ............. Bit MaP

C: ................... Color Flow Mode (Doppler)

D:................... Doppler (Pulsed Wave) Mode

DICOM:........ Digital Imaging and COmmunication in Medicine

DSP:............... Digital Signal Processing

ESD:............... Electro Static Discharge

EV:................. Endo Vaginal

FPGA: ........... Field Programmable Gate Array

FRU:.............. Field Replaceable Unit

HSSL:............ High Speed Serial Link

LCD:.............. Liquid Crystal Display

LED:.............. Light Emitting Diode

M:................... M-Mode (Motion Mode - Tissue)

NTSC:............

National Television Standards Committee (video standard)

PAL: .............. Phase Alternation by Line (video standard)

PRF:............... Pulse Repetition Frequency

PW:................ Pulsed Wave Mode (Doppler)

Retrospective:.. Post-processing performed on frozen images from memory

SVGA: ........... Super Video Graphics Array

DGC: ............. Depth Gain Compensation

USB:............... Universal Serial Bus

Q00169 Rev D Page 13 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 14

VKB:.............. Virtual KeyBoard

Q00169 Rev D Page 14 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 15

1.5 Documentation Conventions

This following alert conventions are used in this manual:

1.5.1 Alert Messages

1. A WARNING indicates that PERSONAL INJURY OR DEATH may occur to patient and/or

user if the user does not observe the provided information.

WARNING

2. A CAUTION indicates that DAMAGE TO EQUIPMENT may occur if the user does not

observe the provided information.

CAUTION

3. A PRECAUTION indicates that INCONVENIENCE TO THE USER (such as loss of text

entries or saved settings) may result if the user does not observe the provided information.

PRECAUTION

4. Common terms that have a special meaning for the Z.ONEUltra (e.g. Menu Control or

Trackball) are capitalized to distinguish their special usage (as opposed to a person who does

navigation).

5. Control and function names (e.g. Print Button, Image Display) are capitalized for recognition.

6. Items to be acted upon are underlined (e.g. press the Store Button

). Items needing emphasis

are in boldface type.

1.5.2 Symbols

The following symbol conventions are used in this manual, and/or on the Z.ONEUltra product:

This symbol is used to draw attention to information that may relate to safety of the

patient, the operator, or the equipment.

Q00169 Rev D Page 15 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 16

Caution: ESD sensitive

This symbol indicates that the equipment is not Category AP, and therefore must not

be used in the presence of flammable liquids or gasses.

.

Type BF patient applied part (B= body, F= floating applied part).

This symbol indicates that the equipment does not utilize a floating double insulated

isolation connection, and therefore must not be connected to external equipment that

is not protectively earthed (DO NOT connect to class II equipment).

Storage/Operating Temperature conditions

Alternating Current (AC)

Direct Current (DC)

Date of manufacture

Q00169 Rev D Page 16 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 17

2 SAFETY

It is extremely important to read the following definitions of WARNING information, prior to

beginning any service on any sub-system within the Z.ONEUltra product. As you see applicability

of each of these noted WARNINGs, during the course of the servicing process, be prepared to

avoid harm to persons and equipment by proper adherence.

2.1 CAUTIONs and WARNINGs During Service/Operation

CAUTION

On the miniCart, to prevent possible damage to the 13” display monitor during system

transport (or moving for relocation within the facility) the monitor should first be folded down

to horizontal, rotated to a center position, and “locked” into place using the provided retaining

pin located on the bottom of the display arm.

CAUTION

To prevent possible damage to the electronics of the system from condensation, the following

warning must be observed:

Anytime that any Zonare equipment (Scan Engine, SmartCart or minCart) is being moved from

an environment that differs greatly in temperature and/or humidity, from the environment

where it has been moved for intended operation, (as a result of shipping or transport) the unit

should be allowed to stand for a period of no less than 30 minutes

powering on.

, prior to inserting battery or

WARNING

WARNING

WARNING

Inspect all cables and power cords BEFORE powering-on the Z.ONEUltra system; or

connecting the transducer. Do not use the system if visual signs of external damage are

observed.

To achieve proper grounding reliability, the Z.ONEUltra SmartCart or miniCart power plug

must be fully inserted into a receptacle marked 'Hospital Grade". Do not remove the

grounding wire. If there is any question of power outlet or power cord integrity, do not

proceed. Obtain qualified technical assistance

.

The ZONARE Z.ONEUltra contains no operator-serviceable components within the enclosures.

To avoid electrical shock, the no covers should be removed except by ZONARE factory trained

personnel. Failure to do so may void the system warranty or service contract coverage

Warnings.

Q00169 Rev D Page 17 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 18

WARNING

Do not operate the Z.ONEUltra system in the presence of flammable anesthetics or in a room

recently washed with flammable cleaning and disinfecting agents. Cleaners can produce

explosive vapors. Check labels of original containers of cleaners and disinfectants for warnings

about vapors. Thoroughly ventilate the room, if such vapors may potentially be present, prior

to activating any of the

Z.ONEUltra components.

2.2 Battery WARNINGs

WARNINGS.

The battery has a safe smart device. Do not disassemble or alter the battery in any

way.

Charge the battery at room temperature.

Do not short-circuit battery by directly connecting the positive and negative terminals

with metal objects.

Do not heat or discard battery in a fire.

Do not expose the battery to temperatures above 150 degree F.

Do not charge the battery near a heat source

Do not leave battery in direct sunlight

Recharge battery only using Scan Engine in a docked condition in Z.ONEUltra

SuperCar or miniCartt, or remotely using ZONARE Z.ONE battery charger.

Do not use a damaged battery.

Inspect the battery for damage before charging or placing the battery in the

Z.ONEUltra.

Do not connect battery to an electrical power outlet.

Do not continue to recharge the battery if it does not recharge fully after 4 hours

Battery MUST be REMOVED from Scan Engine, during shipping/transport of the

Z.ONEUltra

2.3 CAUTIONs During Service

CAUTIONS

Apply proper line voltage. Verify that the Z.ONEUltra system is compatible to match

the AC voltage of site receptacle. Also verify that all plugs match the receptacle type.

Mismatched voltage or plug configuration can damage system components.

Protect the system from water or other liquids that could drip into the electronic

components.

Do not drop the transducer(s), or allow them to impact any hard surfaces.

Q00169 Rev D Page 18 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 19

Avoid allowing metal contact pins on connector-end of transducers to come in

contact with foreign surfaces (potential for bending pins).

Perform no unauthorized modification to any of the Z.ONEUltra sub-systems.

Unauthorized modification can introduce additional hazards to the product.

2.4 Battery CAUTIONs

CAUTIONS

To protect the battery from potential thermal damage, the system monitors the

temperature of the battery at all times. If the battery is detected as exceeding the

maximum safe operating temperature, a warning message will appear on the display of

the Z.ONEUltra.

To prevent possible damage to the unit, the battery should be REMOVED from the

Scan Engine prior to transport or shipment.

Do not immerse battery in water or allow it to get wet.

Do not put the battery into a microwave oven or pressurized container.

Use only batteries provided by ZONARE

Store the battery between -20 to 60o Celsius (-4 o to 158

o

F).

If the battery leaks, emits orders, emits heat, is deformed or discolored in any way

immediately remove it and stop using it.

2.5 USB Memory Stick CAUTIONs

CAUTIONS

USB Memory Sticks that are purchased from outside sources (besides Zonare) may not be

compatible for use in the Z.ONEUltra. USB Memory Sticks which are labeled as “U3

Smart Technology” on their label or packaging, will NOT be recognized (or function) in

the Z.ONEUltra.

In the case of having one of these incompatible format USB Memory Sticks. There are

freeware U3 Smart Technology “Removal” programs available on the internet, that can

be downloaded and run to make the USB Memory Sticks useable on the Z.ONEUltra

2.6 Networking CAUTION

CAUTIONS

In order to comply with Electro-Magnetic Compliance it is necessary that the

Z.ONEUltra be connected to available Ethernet resources using a high quality, shielded

CAT-5 cable.

Q00169 Rev D Page 19 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 20

3 SYSTEM SPECIFICATIONS

This section contains Z.ONEUltra system and accessory specifications. For information on the

specifications for ZONARE authorized peripherals, refer to the manufacturers’ documentation.

3.1 System Dimensions

SmartCart (with Scan Engine installed)

Height:

- Max operational: 157.5 cm (62 in)

- Min operational: 128 cm (50.5 in)

- Display lowered for transport: 104 cm (41 in)

Width: 51 cm (20.1 in)

Depth: 72 cm (28.2 in)

Weight: 57 kg (125lb.)

miniCart (with Scan Engine installed)

Height:

- Max operational: 160 cm (63 in)

- Min operational: 134 cm (53 in)

- Display lowered for transport: 104 cm (41.5 in.)

Width: 57.2 cm (22.5 in)

Depth: 56.1 cm (22.0 in)

Weight: 55 kg (132 lbs.)

Scan Engine

Height: 7.3 cm (2.9 in)

Width: 18.7 cm (7.4 in)

Depth: 25 cm (9.8 in)

Weight: 2.5 kg (5.6 lb) – with battery, no probe

Scan Module

Height: 5.3 cm (2.1 in)

Width: 22.3 cm (8.8 in)

Depth: 25 cm (10.0 in)

Weight: 1.6 kg (3.5 lb)

Q00169 Rev D Page 20 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 21

3.2 Displays

SmartCart

19” high resolution color LCD display

1280 x 1024 display format (internal)

1280 x 1024 / 800 x 600 video format - configurable (HDMI output)

0.41 mm pixel pitch

Viewing angle (H/V): 170 degrees typical

Minimum 10:1 contrast

+/- 90o rotation

30o backward tilt

Full 90o forward tilt into secure transport position

Advanced setup parameters via on-screen menu

Integrated system programmed video settings

Multi-Transducer Port (3 Connectors) - Option

miniCart

13” high resolution color LCD display

640x480 display format (internal)

0.41 mm pixel pitch

Viewing angle (H/V): 170 degrees typical

Minimum 10:1 contrast

+/- 90o rotation

30o backward tilt

Full 90o forward tilt into secure transport position

Integrated system programmed video settings

Scan Engine

5.8” high resolution color LCD display

800x480 display format (internal)

640x480 video format (HDMI output port)

0.16 mm pitch

Manual Brightness and Contrast controls

USB 2.0 I/O port (one)

DC power (+12V) input port

Scan Module

640x480 video format (HDMI port)

USB 2.0 port (one)

Q00169 Rev D Page 21 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 22

DC power (+12V) input port

3.3 Image Archive or Export Storage

Scan Engine - Internal:

IMPORTANT

The image storage capacity numbers listed below apply ONLY to standalone

(undocked) Scan Engine use, or use when docked in a miniCart. In these applications

resolution of the individual image is 640 x 480.

The image storage capactiy numbers, when a Scan Engine is being used while docked

in a SmartCart, will be approximately 1/3 less. This is due to the higher image

resolution of 800 x 600 that is used in the Z.ONEUltra application.

- 512MB Internal CompactFlash Storage (Standard)

DICOM uncompressed: 1280 images

DICOM RLE: 4060 images

BMP: 1700 images

- 2GB Internal CompactFlash Storage (Option)

DICOM uncompressed: 5000 images

DICOM RLE: 15,900 images

BMP: 6650 images

SmartCart - Internal:

- Internal Hard Drive (120GB version specs referenced below)

DICOM uncompressed: 300,000 images

DICOM RLE: 944,000 images

BMP: 399,0000 images

- Slimline Internal DVD+RW / CD-RW Drive

Cart S/N 3xxx and below:

ATAPI (Parallel) Interface

24X speed writing for CD-R, DVD+R, or DVD+RW discs

Cart S/N 4xxx and above:

USB (Serial) Interface

24X speed writing for CD-R, DVD+R, or DVD+RW discs

3.4 Transducers

C10-3 ........................................................ (I.D. 3)

Penetration Depth 13 CM

Q00169 Rev D Page 22 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 23

Number of Elements 64

Field of View 80 degrees

Radius of Curvature 16 mm

Ultrasound Bandwidth 10-3 MHz

C9-4T Convex ...........................................(I.D. 146)

Penetration Depth 14 CM

Number of Elements 128

Field of View 135 degrees

Radius of Curvature 11.5 mm

Ultrasound Bandwidth 9-4 MHz

C9-3 Convex..............................................(I.D. 130)

Penetration Depth 18 CM

Number of Elements 128

Field of View 67 degrees

Radius of Curvature 33 mm

Ultrasound Bandwidth 9-3 MHz

C8-33D 3-D .............................................. (I.D. 140)

Penetration Depth 24 CM

Number of Elements 128

Field of View 79 degrees

Radius of Curvature 40 mm

Ultrasound Bandwidth 8-3 MHz

C6-2 Convex..............................................(I.D. 129)

Penetration Depth 24 CM

Number of Elements 128

Field of View 65 degrees

Radius of Curvature 50 mm

Ultrasound Bandwidth 6-2 MHz

C5-2 Convex

............................................ (I.D. 128)

Penetration Depth 24 CM

Number of Elements 128

Field of View 65 degrees

Radius of Curvature 50 mm

Ultrasound Bandwidth 4-1 MHz

C4-1 Convex

Q00169 Rev D Page 23 of 304

..............................................(I.D. 2)

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 24

Penetration Depth 30 CM

Number of Elements 64

Field of View 80 degrees

Ultrasound Bandwidth 4-1 MHz

L14-5sp Linear........................................ (I.D. 70)

Penetration Depth 6 CM

Number of Elements 128

Field of View 26 mm

Ultrasound Bandwidth 14-5 MHz

L14-5W Wide Aperture Linear............. (I.D. 66 or 71)

Penetration Depth 10 CM

Number of Elements 192

Field of View 55 mm

Ultrasound Bandwidth 14-5 MHz

L12-4V Veterinary.................................. (I.D. 67)

Penetration Depth 10 CM

Number of Elements 128

Field of View 63 degrees

Ultrasound Bandwidth 12-4 MHz

L10-5 Linear............................................ (I.D. 64)

Penetration Depth 10 CM

Number of Elements 128

Field of View 38 mm

Ultrasound Bandwidth 10-5 MHz

L8-3 Linear

.............................................. (I.D. 65)

Penetration Depth 10 CM

Number of Elements 128

Field of View 38 mm

Ultrasound Bandwidth 8-3 MHz

E9-3 3-D

................................................... (I.D. 141)

Penetration Depth 14 CM

Number of Elements 128

Field of View 135 degrees

Radius of Curvature 10.0 mm

Q00169 Rev D Page 24 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 25

Ultrasound Bandwidth 9-3 MHz

EV9-4 Transvaginal................................ (I.D. 144)

Penetration Depth 14 CM

Number of Elements 128

Field of View 135 degrees

Radius of Curvature 12 mm

Ultrasound Bandwidth 9-4 MHz

P10-4 Phased (version 1)........................ (I.D. 7)

Penetration Depth 14 CM

Number of Elements 128

Field of View 80 degrees

Ultrasound Bandwidth 10-4 MHz

P10-4 Phased (version 2)........................ (I.D. 14)

Penetration Depth 12 CM

Number of Elements 128

Field of View 79.6 degrees

Ultrasound Bandwidth 10-4 MHz

P8-3 TEE ...................................................(I.D. 8)

Penetration Depth 18 CM

Number of Elements 64

Ultrasound Bandwidth 7.5-2.7 MHz

P4-1 Phased ............................................ (I.D. 4)

Penetration Depth 30 CM

Number of Elements 128

Field of View 84 degrees

Ultrasound Bandwidth 4-1 MHz

P4-1c Phased

.............................................(I.D. 5 or 6)

Penetration Depth 30 CM

Number of Elements 64

Field of View 84 degrees

Ultrasound Bandwidth 4-1 MHz

A2CW Doppler-Only

(CW Option Required) – I.D. 514)

Q00169 Rev D Page 25 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 26

Number of Elements 2

Ultrasound Frequency 2.0 MHz

Ultrasound Bandwidth n/a

A5CW Doppler-Only (CW Option Required) – I.D. 513)

Number of Elements 2

Ultrasound Frequency 5.0 MHz

Ultrasound Bandwidth n/a

3.5 Accessories/Options

2-Pedal Footswitch (Freeze/Store)

2-Bay Battery Charger

AC Power Adapter

USB Memory Stick

AVED (Audio Video Extension Device) Box

o NTSC output:

Horizontal frequency:...........................15.733 KHz

Vertical frequency:...............................59.94 Hz.

o PAL output:

Horizontal frequency:...........................15.625 KHz

Vertical frequency:...............................50.0 Hz.

3.6 Peripherals

SmartCart:

On-Board (Mounted) – Local Image Printing

Sony UP-D897 USB Digital B/W Printer

Off-Board (Un-mounted)

Sony UP-D25MD Color Printer

HP LaserJet (PostScript-3 style) Network Printer -------------------- (Report printing only)

miniCart:

Sony UP-D897 Digital B/W Printer

3.7 Site Requirements

Power

100 – 120VAC, 50-60Hz or 200 – 240VAC, 50-60Hz (Factory Configurable)

Q00169 Rev D Page 26 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 27

Environmental

Cooling consistent with 1024 BTU / hour system output (Scan Engine + SmartCart/miniCart)

o

Ambient air temperature of 0

– 35o Celsius (32 o - 95 o F)

Ambient relative humidity of up to 80%, non-condensing

3.8 System Power

SmartCart

- 90 – 120V @ 6A (max)

- 200 – 240V @3A (max)

- Line Frequency: 50 – 60Hz

- 250 W-h - Nickel Metal Hydride (NiMH) battery pack - (Option)

miniCart

- 100 – 120V @ 6A (max)

- 200 – 240V @3A (max)

- Line Frequency: 50 – 60Hz

3.9 System Power Protection

SmartCart

- Re-settable AC circuit breaker

miniCart

- User-replaceable fuses:

T6.3A/250V ..................................................... (100-120V Systems)

T3.15A/250V ................................................... (200-240V Systems)

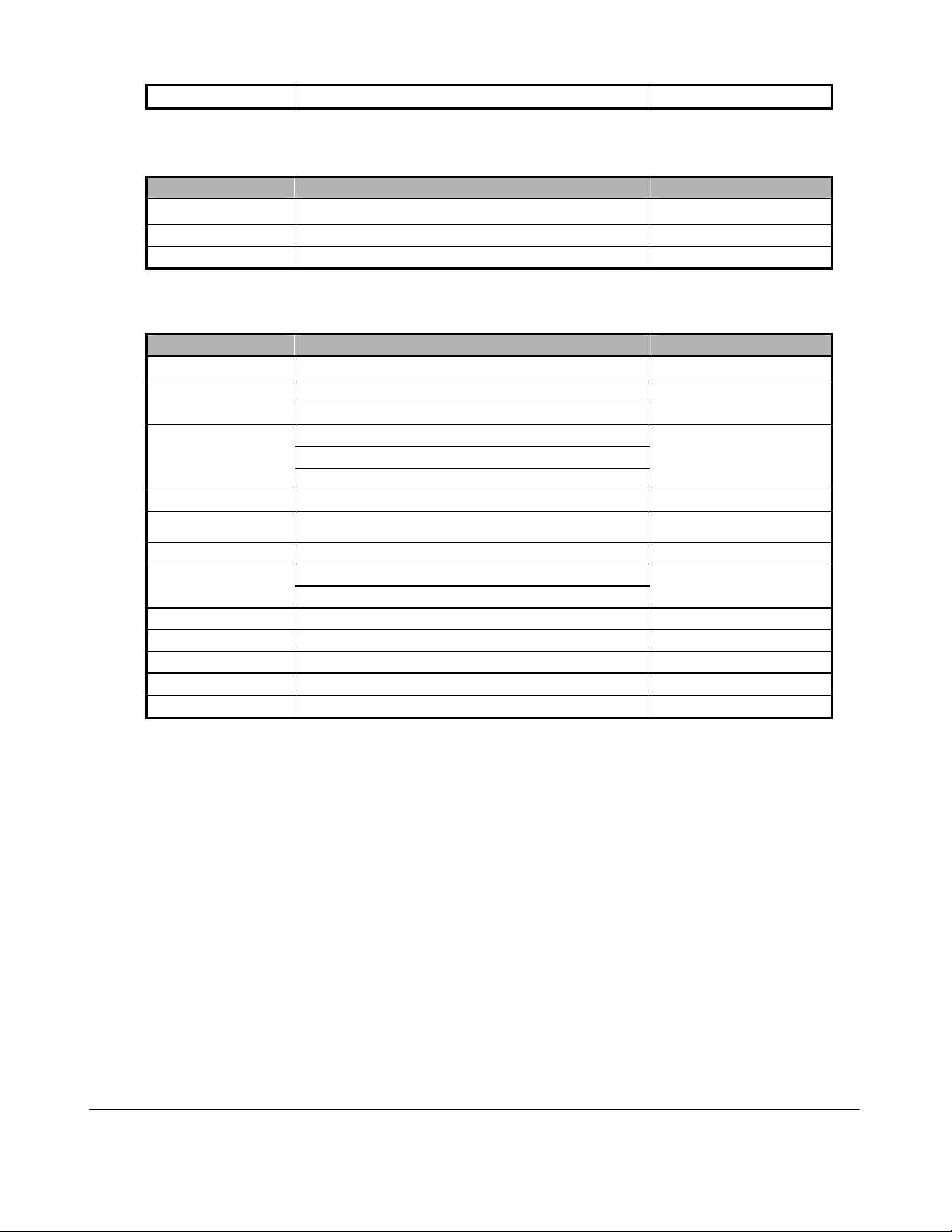

3.10 Electrical Specifications

DC Voltages:

SmartCart DC Power Supplies

Voltage Purpose Max Current Rating

+12V

+12V

+7 to +14V

VMain Logic Power 12 A

VScanner Power 8 A

VFan Power

variable

Q00169 Rev D Page 27 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 28

+12 to +25V

miniCart DC Power Supplies

Voltage Purpose Max Current Rating

+12V

+12V

+5V

Scanner Power Board DC Supplies

Voltage Purpose Total Current

+1.2V

+1.5V

+2.5V

+3.3V

Vfan

+5.0V

V5.0RTC

+12V

HV1

HV2

HV3

VAux Power (Peripherals)

Scan Engine Power 20 A

LCD Display Source Power 6 A

USB Hub Power

DSP Power 2.3 A

Digital FPGA (Digital Board)

Striker (Analog Board)

FPGA busses

ADC’s +1.8V

ADC’s and AFE’s

DDR SDRAM 0.30 A

CPU, FPGA’s, etc. 2.5 A

Cooling fans 0.25A

Power Supply monitoring

Levels shifters, muxes, eeprom.

Local power for PIC, etc. 25 mA

Pulsers 170 mA

Probe Mux Bias Power Transducer dependent

Transmit Power (Tissue) User variable

Transmit Power (Doppler) User variable

Future use

8 A

11.2 A

7.4 A

10 mA

“Z-Pack” Battery (SmartCart) – (Option)

Battery, 13-cell, 15.6 VDC, 16 A-hours, rechargeable Nickel Metal Hydride battery pack

Weight: 7.7 lbs.

Operating range: (values listed are approximations)

- Active use......................................At least 1 hour (mode/display brightness dependent)

- Storage mode.................................Less then 50% loss - 1 month

Battery (Scan Engine)

Battery, 4-cell, 7.4 VDC, 4.4 amp-hours, rechargeable lithium ion battery pack

Operating range: (values listed are approximations)

Q00169 Rev D Page 28 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 29

- Active use......................................30-40 minutes (mode & display brightness

dependent)

- Standby mode................................2.0-3.0 hours

- Storage mode (in Scan Engine).....3 weeks

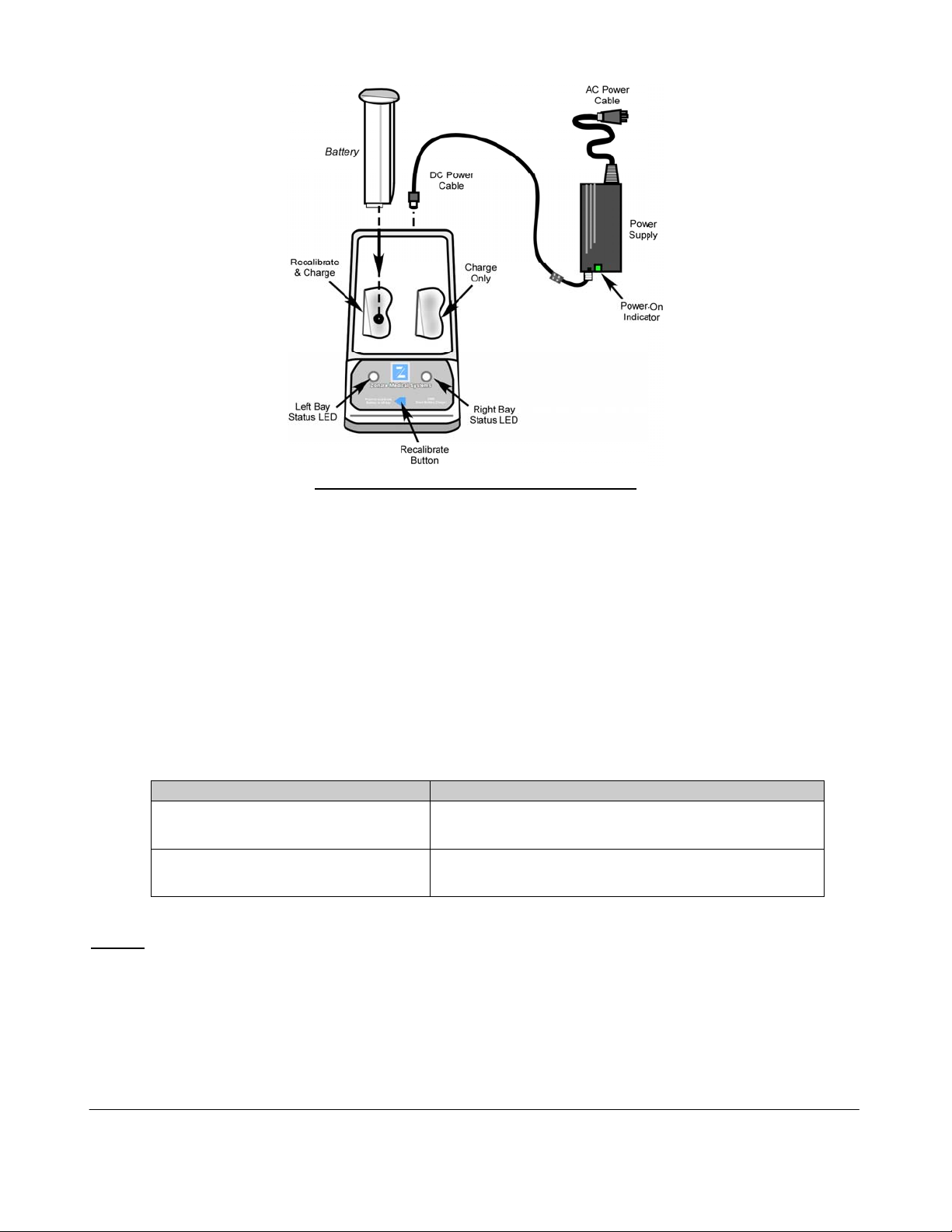

(Scan Engine) Battery Charger, 2-Bay

Models:

- Z311: Domestic Version...............110 VAC power cord

- Z312 : International Version .......220VAC power cord

Operating Modes:

- CHARGE Mode ...........................1.0 hour (dependent current charge state)

- RECALIBRATE Mode................14 hours (discharge->charge->discharge-fully charge)

Bays:

- Left Bay.........................................Recalibrate or Charge operation

- Right Bay.......................................Charge operation only

AC Power Adapter (Advanced Hardware Scan Engine)

Models:

- Z316 : Domestic Version..............110 VAC power cord

- Z317 : International Version .......220 VAC power cord

Voltage Output

- +9V to +12V..................................+/- 5% over loading

3.11 Temperature, Humidity, Pressure Limits

System: (During Operation):

Temperature 0o to 35o Celsius | (32

o

to 95

o

F)

Relative Humidity 15–80%

Elevation 3,100 to (-116) Meters | 10,200 to (-1,250) Feet

System: (During Shipping/Storage): Battery MUST

Temperature -20 to 60o Celsius | (-4 o to 158

be REMOVED from Scan Engine!

o

F)

Relative Humidity 15–90%

Elevation 5,944 to (-116) Meters | 19,500 to (-1,250) Feet

Q00169 Rev D Page 29 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 30

3.12 Device Classification

FDA Class II Device Classification

CE / MDD Class IIa-rule 10 active device intended for diagnosis

3.13 Safety Standards

All ZONARE instruments, cables, and diagnostic ultrasound imaging transducers have been designed

to meet the essential requirements contained in:

93/42/EEC (Medical Device Directive).

In addition, all the above listed equipment meets the following appropriate requirements:

UL 60601-1 (Standard for Medical Electrical Equipment Part 1: General Requirements for

Safety)

IEC 60601- (Medical Electrical Equipment Part 1: General Requirements for Safety)

JIS-T-1001 (General Requirements of Medical Electrical Equipment), including limits for

current leakage and isolation from a primary power line

Testing for compliance with the essential requirements of the Medical Device Directive has

been performed.

The Z.ONEUltra meets the acoustic output emission guidelines established by the U.S. Food and Drug

Administration (FDA). Acoustic output quantities have been measured, and are displayed, in

accordance with the standards listed under “Guidance Documents”.

3.14 DICOM Standard

NEMA PS 3.15: 2000, Digital Imaging and Communications in Medicine (DICOM)-Part 15:

Security Profiles

3.15 Product Labeling

The following figures depict the labeling that is required by various regulatory authorities, and

describe their location.

Contact ZONARE if any of these labels are missing or damaged beyond legibility. The Z.ONEUltra

labels herein are for reference only and are not shown to scale.

Q00169 Rev D Page 30 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 31

Figure 1: Label, Scan Engine – Serial/Part No.

Figure 2: Label, Scan Module – Serial/Part No.

Figure 3: Label, Scan Engine Battery (Version 1) - Serial/Part No.

Figure 4: Label, Scan Engine Battery (Version 2) - Serial/Part No.

Q00169 Rev D Page 31 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 32

Figure 5: Label, 100V-240V SmartCart Rear Panel - Serial/Part No.

Figure 6: Label, SmartCart Z-Pak Battery

Figure 7: Label,

Q00169 Rev D Page 32 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

mini

Cart rear panel - Serial/Part No.

Page 33

Figure 8: Label, Linear Array Transducers - Serial/Part No.

Figure 9: Label, Curved Array Transducers - Serial/Part No.

Figure 10: Label, Endo Cavity Transducer - Serial/Part No.

Figure 11: Label, Phased Transducers - Serial/Part No.

Figure 12: Label, Specialty Transducers - Serial/Part No.

Q00169 Rev D Page 33 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 34

Figure 13: Label, AC Power Battery Adapter

Figure 14: Label, AC Power Adapter Power Supply

Q00169 Rev D Page 34 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 35

4 TOP-LEVEL PRODUCT OVERVIEW

4.1 Major Assembly Identification

SmartCart miniCart

Scan Engine Scan Module

Figure 15: Z.ONEUltra Major Assembly Illustrations

4.2 Transducers

Linear Curved Phased Endo-Cavity CW Aux TEE

Figure 16: Transducer Illustrations

Q00169 Rev D Page 35 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 36

4.3 Accessory Components

USB Memory Stick Lithium-Ion Battery Pack 2-Pedal Footswitch

AC Power Adapter Battery Charger, 2-Bay

Figure 17: Accessories

Q00169 Rev D Page 36 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 37

4.4 SmartCart Major Assemblies (shown with MTP Multi- probe Option)

Q00169 Rev D Page 37 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 38

4.5 miniCart Major Assemblies

Q00169 Rev D Page 38 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 39

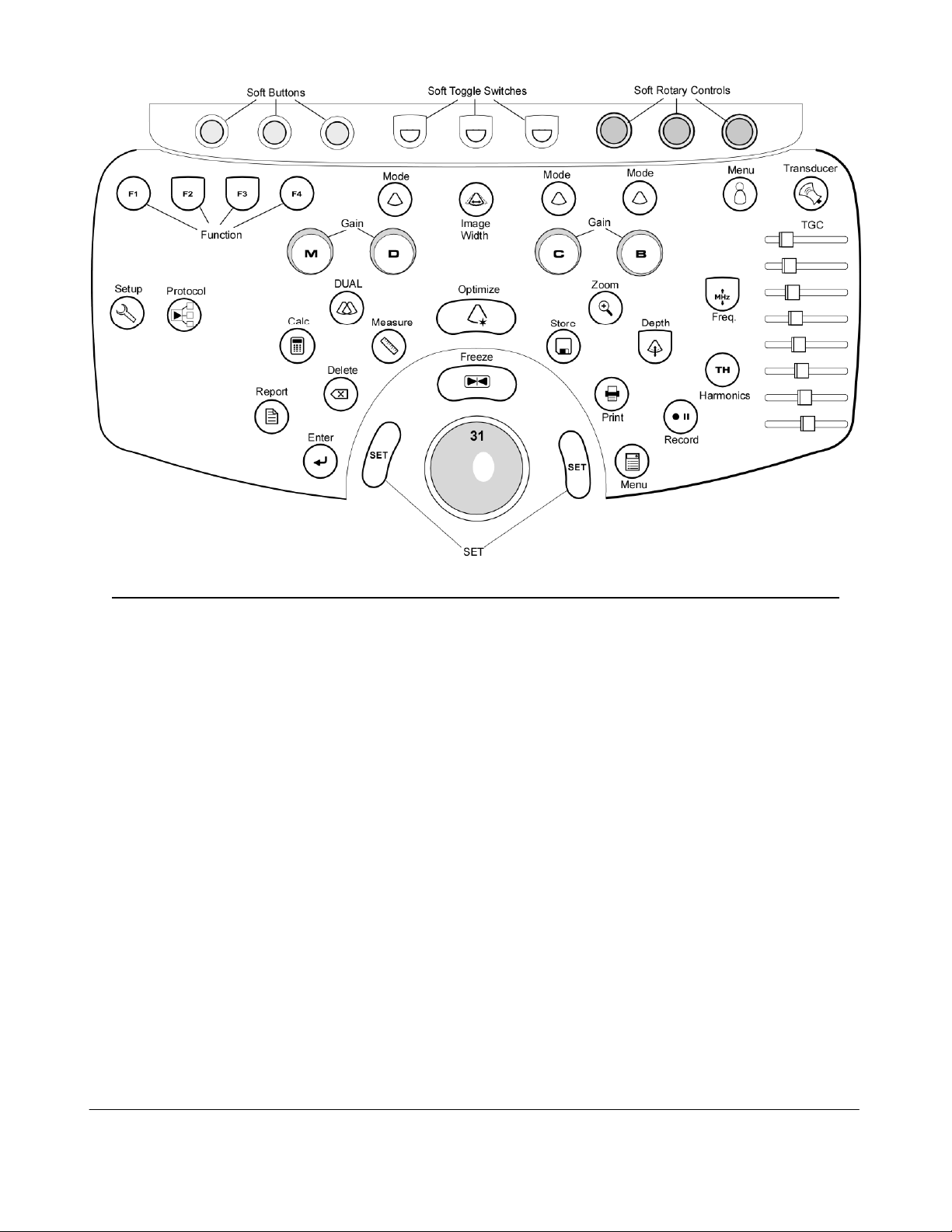

4.6 SmartCart User Interface Controls (Overview)

Figure 18: SmartCart Keyboard Controls (Overview)

Figure 19: SmartCart User Interface (Version 1) Controls (Overview)

Q00169 Rev D Page 39 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 40

Figure 20: SmartCart User Interface (“Enhanced” version) Controls (Overview)

Q00169 Rev D Page 40 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 41

4.7 Scan Engine User Interface Controls (Overview)

Figure 21: Scan Engine User Interface Controls (Overview)

Q00169 Rev D Page 41 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 42

4.8 SmartCart User Interface Controls (Detailed) – Version 1

Figure 22: SmartCart User Interface Layout – Version 1

Q00169 Rev D Page 42 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 43

4.8.1 SmartCart User Interface Functions (Version 1)

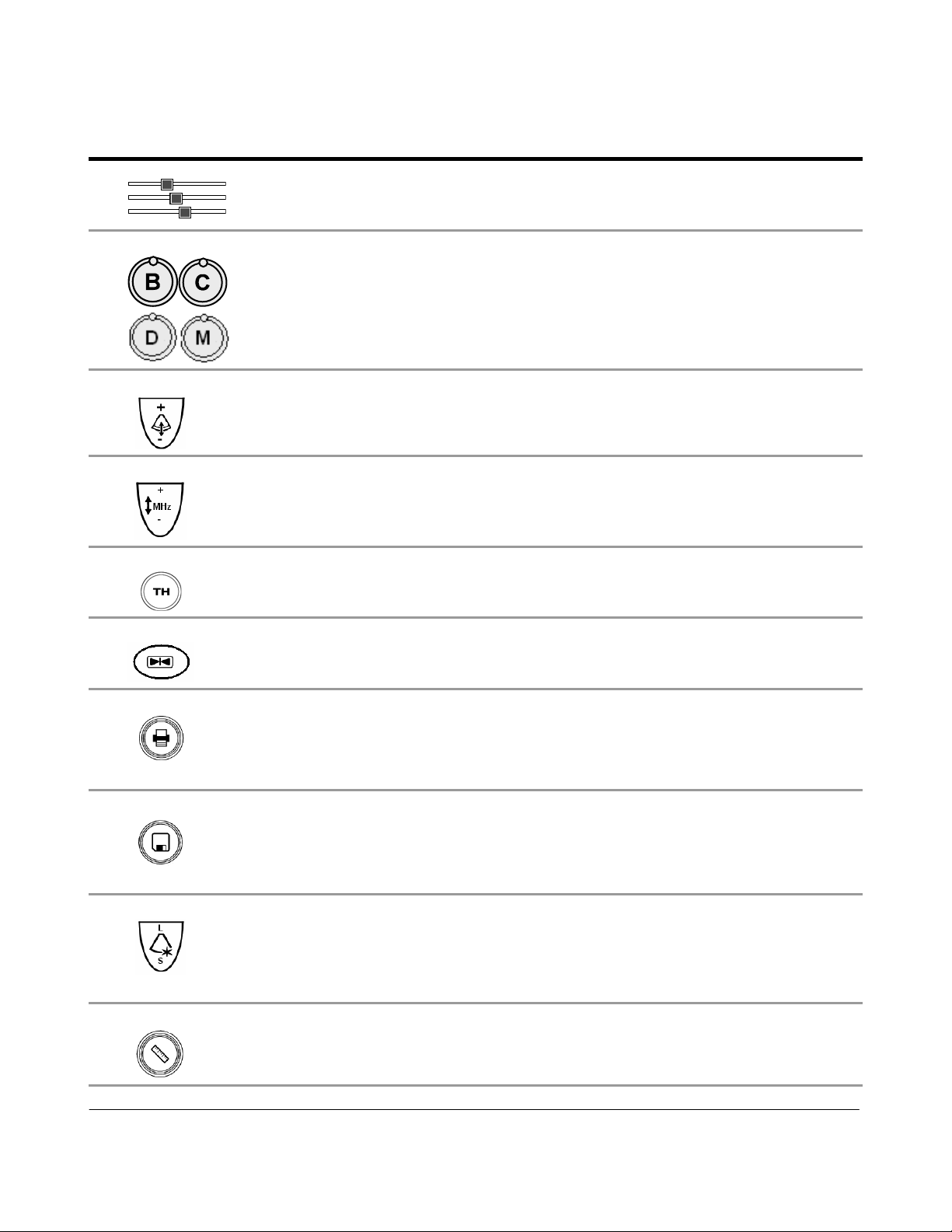

Number System Control Description

1 DGC Slidepots Changes gain of image at discrete depths

2

GAIN Changes overall gain for applicable modality (outer ring)

3 DEPTH Adjusts (Up/Down) the imaging depth of the display

4 FREQUENCY Enables increasing/decreasing transmit frequency

5 HARMONICS Activates tissue harmonics imaging mode

6 FREEZE Halts or re-starts active imaging on the display

7 PRINT Sends current image to device(s) previously specified in System

Setup menu (Local Printer, DICOM printer, DICOM store).

8 STORE 1/2 Sends current image to device(s) previously specified in System

Setup menu (Local Printer, DICOM printer, DICOM store).

9 OPTIMIZE Dual function: “ZST” Sound Speed Correction and/or

“AutoOpt” (DGC)

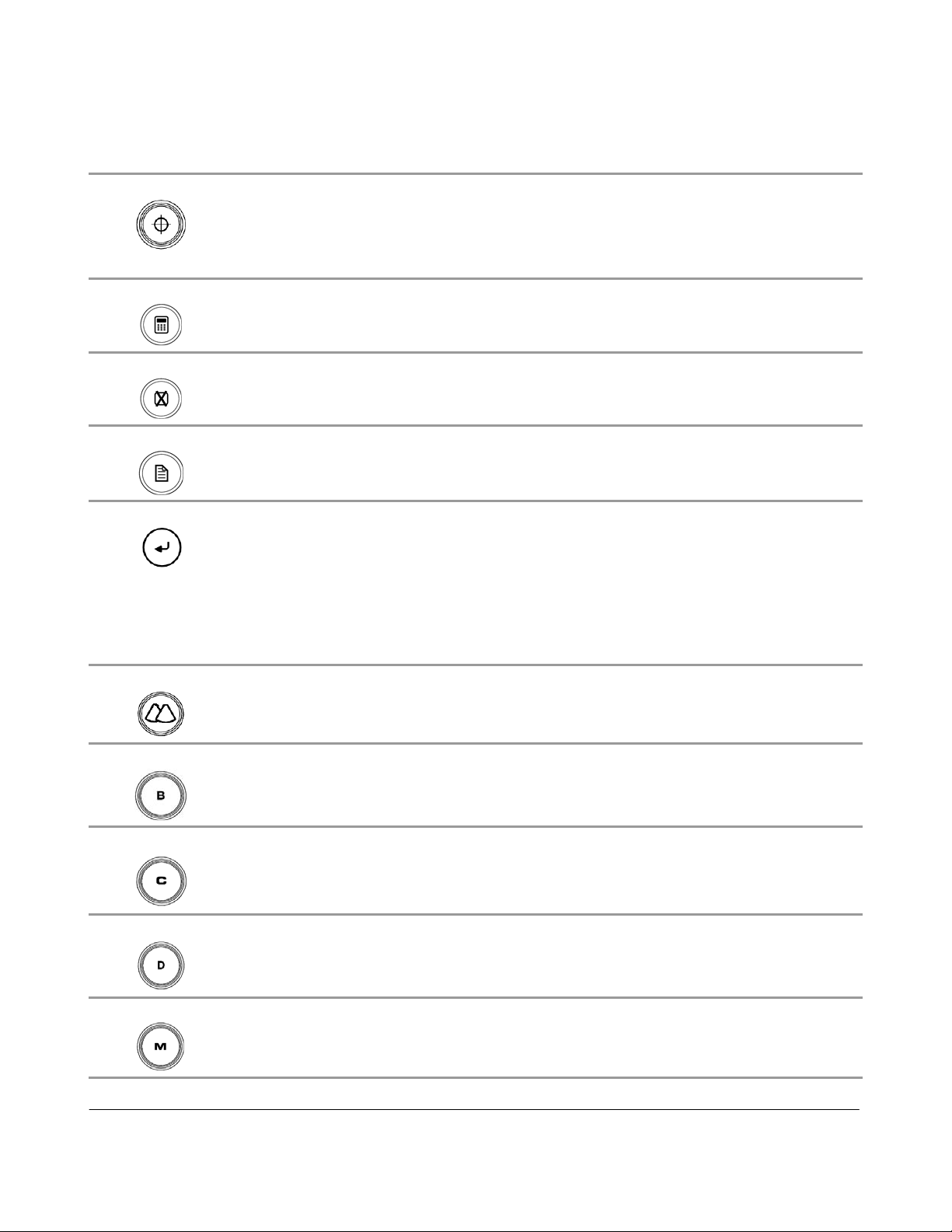

10 MEASURE Multi function key:

Q00169 Rev D Page 43 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 44

1) Brings up dynamic caliper (live) or Calc menu (frozen)

2) Toggles on/off the Auto-Dop Trace function, in PW Doppler

mode

11 “SET” Used to toggle the function of active items on display (equivalent

to a “mouse click”)

12 CALC Brings up Calculation tools on the display

13 DELETE (Calc) Deletes active Calculation tool from the display

14 REPORT (Calc) Initiates a Calculation report

15 ENTER (Calc) / Shared function key:

1) Ends the current Calculation process, and produces a result

2) Toggles between the (A) or (B) image, as the “Active”

(selected) image, in DUAL mode

16 DUAL Mode Activates/deactivates DUAL imaging mode

17 B B- Mode (Tissue mode)

18 C Color (Doppler) Mode, toggle activates/de-activates

19 D Doppler (Pulsed Wave), toggle activates/de-activates

20 M M-Mode (tissue motion), toggle activates/de-activates

Q00169 Rev D Page 44 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 45

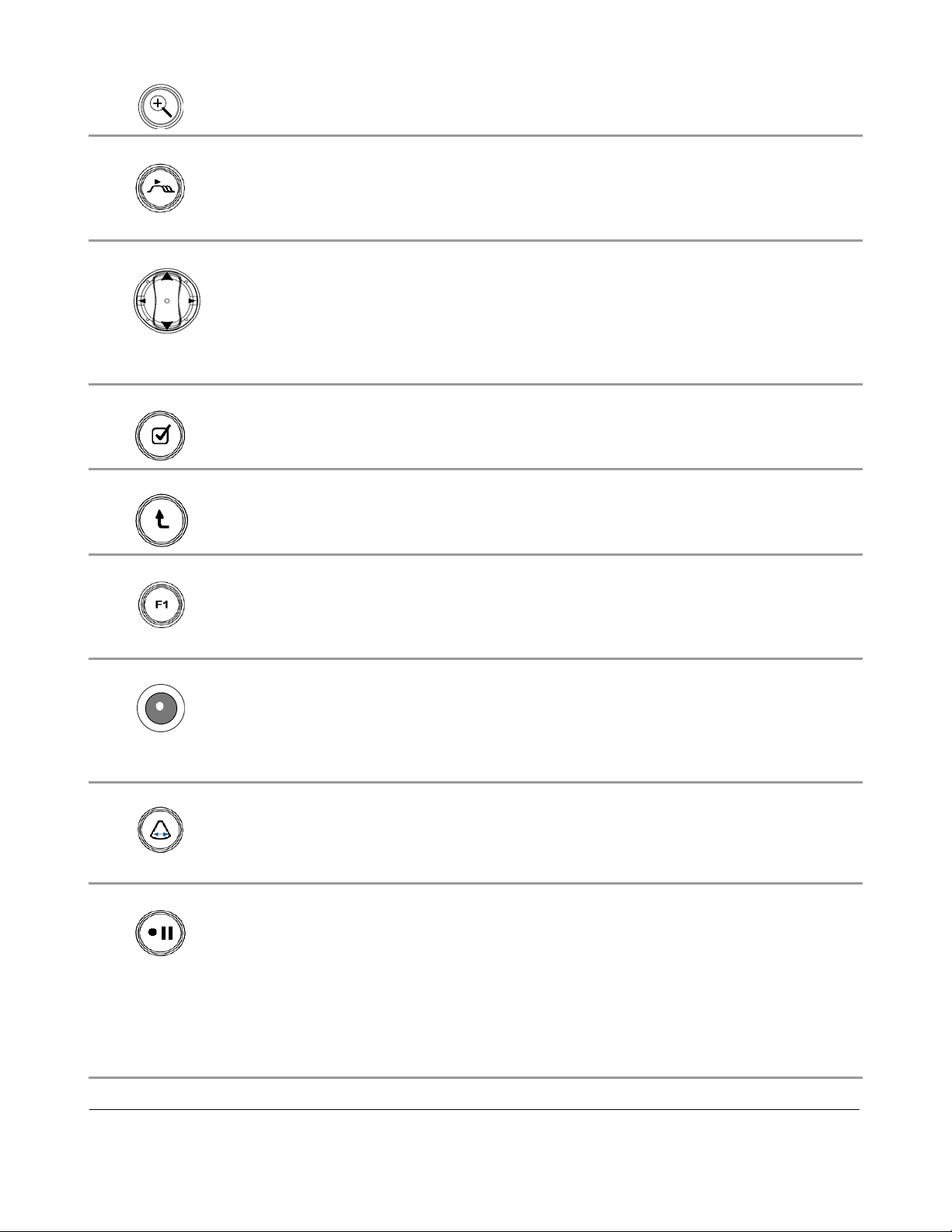

21 ZOOM Initiates the variable image magnification process

22 TAB Advances through four (4) on-screen menus (Imaging, Presets,

Patient Info, Tools)

23 Menu Control Functions like a computer mouse or joystick, for scrolling through

on-screen menu selections (up/down), and modifying settings for

selected on-screen functions (left/right)

24 SELECT Activates currently highlighted selection in the on-screen menu.

25 BACK Returns back one window, in the on-screen display menu

26 F1 –F4 Function keys, user configurable in System Setup menu

27 Trackball Used for positioning the cursor, defining size/position of ROI in

color mode, positioning measurement tools, reviewing cine-loop

images and navigating form/tables/worksheets/reports

28 Image Width Enables changing the width (angle) of the active scanning area of

the B-Mode sector, to maximize frame rate

29 Record Shared function key:

1) Momentary Press: Generates the remote print/record trigger

signal out of the optional AVED box

2) Extended Press: Ejects the DVD/CD from the internal DVD

drive in the SmartCart

Q00169 Rev D Page 45 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 46

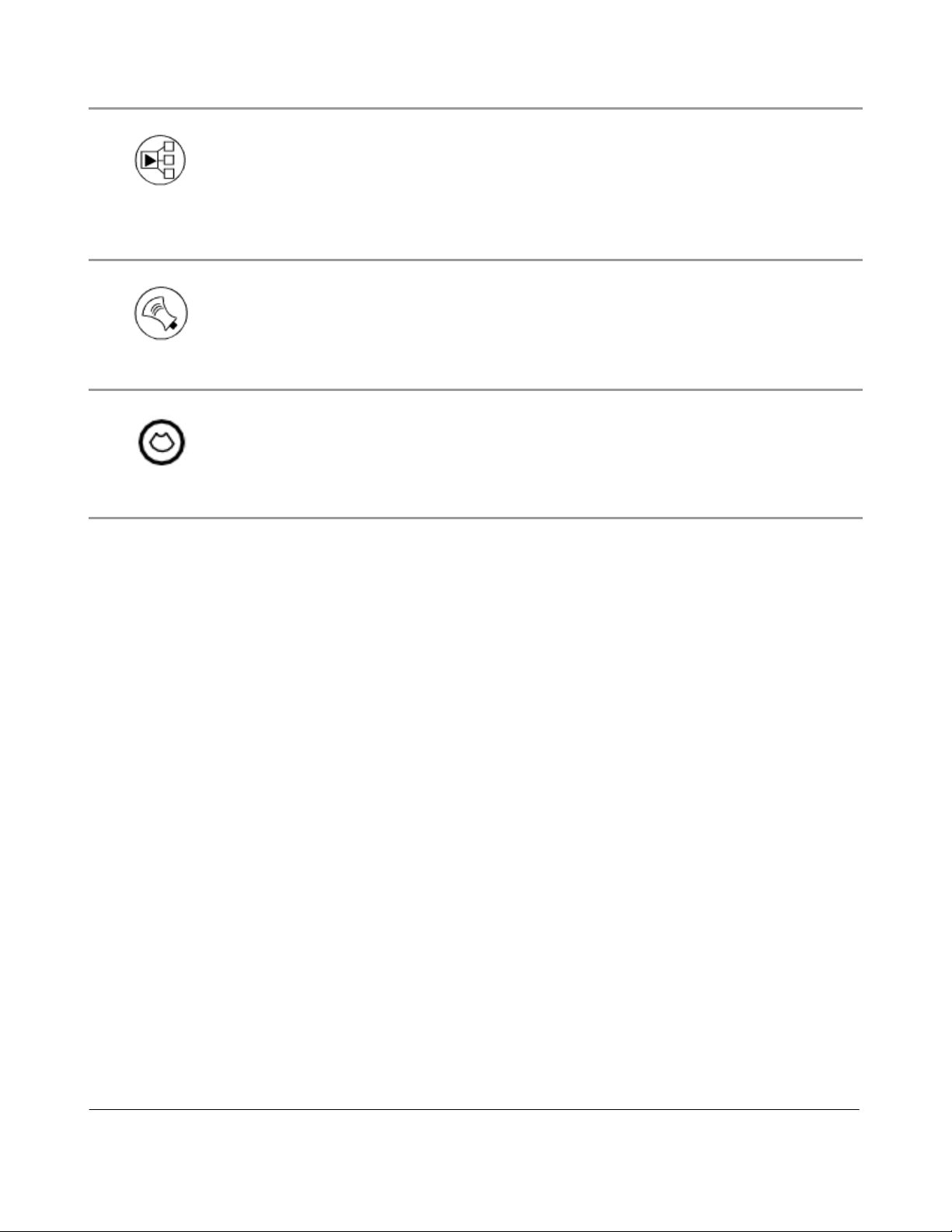

30 Protocol Used to enable controls for selecting timing (time or cardiac

cycle) for Cine Clip stores.

31 Transducer (MTP) Used to bring the available transducers to the OLED display

windows, for selection of a desired transducer from the 3-Port

MTP panel.

32 Mode Keys (4) Mode functional assignment keys, User configurable in System

Setup menu

Q00169 Rev D Page 46 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 47

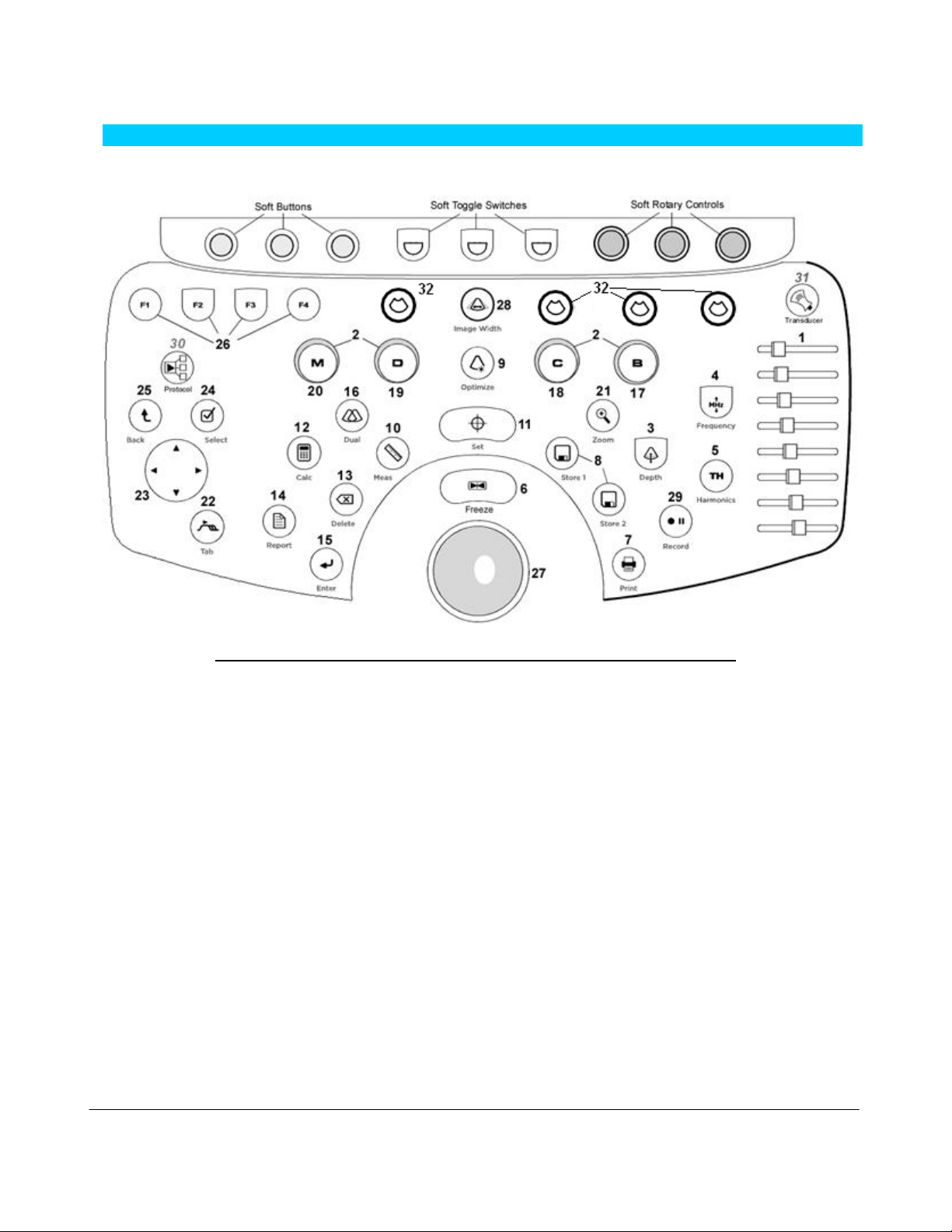

4.9 SmartCart User Interface Controls (Detailed) – “Enhanced” Version (2)

Figure 23: SmartCart User Interface Layout – “Enhanced” Version (2)

Q00169 Rev D Page 47 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 48

4.9.1 SmartCart User Interface Functions (Enhanced Version)

Number System Control Description

1 F1 –F4 Function keys, user configurable in System Setup menu

2 Mode Keys (3) Mode functional assignment keys, User configurable in System

Setup menu

3 Image Width Enables changing the width (angle) of the active scanning area of

the B-Mode sector, to maximize frame rate

4 Exam Type Brings up Exam Type/Presets configuration menu, and 6 user

Preset setting to OLED display windows

5 Transducer (MTP) Used to bring the available transducers to the OLED display

windows, for selection of a desired transducer from the 3-Port

MTP panel.

6

GAIN Changes overall gain for applicable modality (outer ring)

7 M M-Mode (tissue motion), toggle activates/de-activates

8 D Doppler (Pulsed Wave), toggle activates/de-activates

9 C Color (Doppler) Mode, toggle activates/de-activates

Q00169 Rev D Page 48 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 49

10 B B- Mode (Tissue mode)

11 DGC Slidepots Changes gain of image at discrete depths

12 SETUP Used to bring up the SYSTEM SETUP configuration menu.

13 Protocol Used to enable controls for selecting timing (time or cardiac

cycle) for Cine Clip stores.

14 REPORT (Calc) Brings up the Calculation report page

15 CALC Brings up the Calculations menu page.

16 DUAL Mode Activates/deactivates DUAL imaging mode

17 ZOOM Initiates the variable image magnification process

18 DEPTH Adjusts (Up/Down) the imaging depth of the display

19 Record Shared function key:

1) Momentary Press: Generates the remote print/record trigger

signal out of the optional AVED box

2) Extended Press: Ejects the DVD/CD from the internal DVD

drive in the SmartCart

20 HARMONICS Activates tissue harmonics imaging mode

Q00169 Rev D Page 49 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 50

21 FREQUENCY Enables increasing/decreasing transmit frequency

22 ENTER (Calc) / Shared function key:

1) Ends the current Calculation process, and produces a result

2) Toggles between the (A) or (B) image, as the “Active”

(selected) image, in DUAL mode

23 DELETE (Calc) Deletes active Calculation tool from the display

24 MEASURE Multi function key:

1) Brings up dynamic caliper (live) or Calc menu (frozen)

2) Toggles on/off the Auto-Dop Trace function, in PW Doppler

mode

25 OPTIMIZE Dual function: “ZST” Sound Speed Correction and/or

“AutoOpt” (DGC)

26 STORE Sends current image to device(s) previously specified in System

Setup menu (Local Printer, DICOM printer, DICOM store).

27 PRINT Sends current image to device(s) previously specified in System

Setup menu (Local Printer, DICOM printer, DICOM store).

28 MENU Brings up access to four (4) on-screen menus (Imaging, Presets,

Patient Info, Tools)

29 “SET” Used to toggle the function of active items on display

(equivalent to a “mouse click”)

Q00169 Rev D Page 50 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 51

30 FREEZE Halts or re-starts active imaging on the display

31 Trackball Used for positioning the cursor, defining size/position of ROI in

color mode, positioning measurement tools, reviewing cine-loop

images and navigating form/tables/worksheets/reports

Q00169 Rev D Page 51 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 52

4.10 SmartCart & miniCart Keyboard Controls (Detailed)

Figure 24: SmartCart Keyboard Layout

Figure 25:

mini

Cart Keyboard Layout

Q00169 Rev D Page 52 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 53

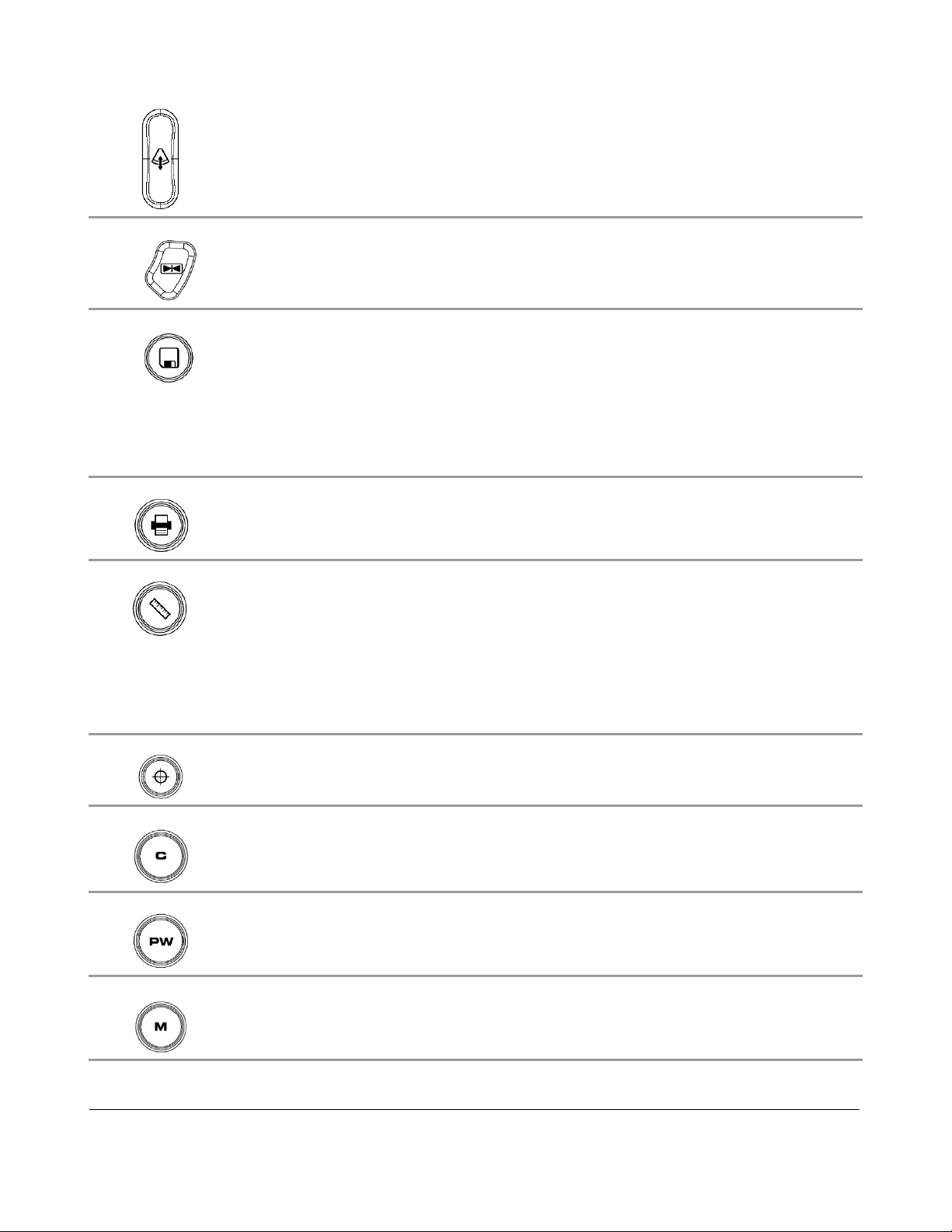

KEYBOARD: SPECIAL FUNCTION CONTROLS

Key System Control Description

NEW PATIENT

CURRENT EXAM

PG BACK

PG FWD

FIRST LAST

DELETE

FORMAT

ARCHIVE

END EXAM

DICOM QUEUE

ECG

SERVICE

BX GUIDE

(Arrow)

BODY PATTERN

This is a toggle key. The first press will display the Patient Information page.

The second press will return to the imaging display.

If there is an exam in progress, pressing this key will display the in-progress

exam's images, most recently stored image displayed first. If there is no exam

in progress, pressing this key will have no effect.

This key only works when in in-progress exam review or archived exam review.

Pressing this key will display the previous image, or page of images if in a

multi-image display format. Once the first page is reached, the key press will

have no effect.

This key only works when in in-progress exam review or archived exam review.

Pressing this key will display the next image, or page of images if in a multiimage display format. Once the last page is reached, the key press will have

no effect.

This key only works when in in-progress exam review or archived exam review.

Pressing this key will toggle between the first stored image (or first page of

images in a multi-image display format) and the last stored image (or last page

of images in a multi-image display format).

This key only works when in in-progress exam review or archived exam review.

When an image has been selected, pressing the Delete key will tag the image

for deletion by drawing a red X through it. If the selected image already has

been tagged for deletion (red X) pressing the Delete key will remove the red X,

untagging the image.

This key only works when in in-progress exam review or archived exam review.

Pressing this key will toggle between the following image formats: 2 x 2,

displaying 2 rows of 2 images (4 images); 3 x 2, displaying 2 rows of 3 images

(6 images); and a full-size image.

This is a toggle key. The first press will display the Patient Selection Table.

The second press will return to imaging.

When an exam is in progress, pressing the End Exam key will close the exam.

If no exam is in progress, pressing this key will have no effect.

This is a toggle key. The first press will display the DICOM queue. The

second press will return to imaging.

CARDIAC Option Systems ONLY: This is a toggle key. The pressing of this

key will activate ECG operation and display the ECG trace on the monitor. A

repeat press will turn off this function.

This is a dual-function key. A “quick” momentary press is a shortcut to bring

up the USER DIAGNOSTIC PANEL screen. An “extended” press will trigger a

capture of a set of current LOG files to the internal archive

This is a toggle key. The first press will display the biopsy needle path guide.

The second press will remove the biopsy needle path guide.

This is a toggle key. It will only work when the image is frozen. Pressing the

key when the image is frozen will display an arrow graphic in the middle of the

display.

This is a cycling key. Pressing the Body Pattern key will display a Body Pattern

for the Exam Type in use. Pressing the key will cycle through available Body

Patterns, including a blank.

Q00169 Rev D Page 53 of 304

"Note: Copies are uncontrolled documents - For revision verification see the Master Docum e ntation List"

Page 54

DEL WORD | DEL TEXT

SET | HOME

Pressing Del Text will remove all text annotations and arrow graphics

displayed. Pressing Shift+Del Word will delete the most recently entered text

annotation, whether it be free text, POT, or List entry.

Pressing Home will move the text annotation cursor to its default home

position. Pressing Shift+Set Home will set the current cursor position as the

new Home position.

TEXT

ALT GR

LONG TRANS SAG

COR

RT LT

PROX MID DIST

LIST 1

LIST 2

Pressing Text will display the text annotation cursor. Pressing Text again will

remove the text annotation cursor.