Page 1

,,._<,-.-

HIGH

WSb2

SPEED

STRETCH

SEWING

MACHINE

ij@JD}jlBJJ~

OPERATION

MANUAL

*i~EJ=.flft

PARTS

BOOK

ttl Ill· ttJJI

ZOJE

SEWING

~ill!TI

mn

~~

MACHINE

ftt

'l5i

ae

CO.,

~

EI

LTD.

Page 2

I§

~

CONTENTS

$0~lli'M!iN.i:E~$J]lf(Safety

g;.~;§ii¥Jffl.~(Assembling

~Wltltft-.lg;.~(Sewing

Bi:ffi'~t?Jl1lft-J3>:~(1nstalling

i@~JJtlll¥.i:!i'Eft'J1iaJ(Operating

precautions and notes

for

procedure)···············:············································1-7

the machine rest board)····················································································8

machine installation)·····························································································8

the belt

cover)·····························································································S

direction

of

machine pulley)···········································································B

;)<Cf1!tilll(Lubrication)···························································································································9

!kHR~'iil!tilll(Silicone

Jif~fj{J::fj$(Th

reading)················································································································· ·11-12

ffJjj;jlff:IJft-JiJ!J'!I"(Adjusting

;"¥:

liJJ

tt

ll'liJ!J

'!~"(Adjusting

<tJ!liH~

!ltft-JiJ!J'!I"(Adjusting

~>!Xitll'liJ!J'!I"(Adjusting

~!>JJtllft-Jil!ff::J(Cieaning

tlt

<tl¥.l:!!!~(Replacing

tltfllii¥J:!!!~(Oil

Jjfiflift-J::tJi*(To

illlm~iili

··

..

iJ!Ji'i>l!i;il&ftl<t%x;J-!ffi

replacement)·············································································································· ·15

drain the

lli.lft-.lf&'!!tEi111"t::J(Checking

(Adjustment dimensions/Comparison table

'l"~%1Ji!;fi!l;jl<(Subclass

~f~-¥-IIIHParts

1

JJt'i\:~tZ/(1)

2JJt5\:~tZ/(2)

3.J-Jt5\:~tZ/(3)

list)·····················································································································19-60

(Machine bed frame(1) )·····················································································:·······20-21

(Machine bed frame(2) )········

(Machine bed frame(3)

4.1'3::!111il'O'liJJVl*Z!(Crank

s.J:3::!11111'!l;;IJ<Jt*ZI(Arm

6.<Hf~tZ/(Needle

·

7.1JHt~tZJ(Needle

8.

'11

Htlt*Z!

(Looper

9.~1\JVltZ/(Feed

O.~;;!JiJ!J'!I";fJ!tZ/(Differential

1

11.llil!!iltJt*Z!(Presser

12.!Jlll<tVl*Z!(Spreader

13.li!~N.~~w(Thread

14.Jit~tJttZ/(Needle

15.:fT~C.~VltZ/(Looper

16.i!iliiHJttZ/(1

17.~'lJil'HJttZ/(2)(Lubrication

)(Lubrication mechanism(1

18.'ffifli:<O:g;<j;fl;J(HR

.19.~!/,g(Thread

stand) ........ · .. ··· ........ · ........ ·· ............ · .. ·· .................. · .... · ..... · ......... ·· ... · ................... 57

20. i'itlli.:&llltf'f(Parts tor semi-submerged installation)

oil

tor

H.R.

device)·····························································································10

presser

foot

pressure)···················································································

the differential feed ratio)························:·························································· ·13

stitch length)····················································································· ···········13

the thread

tension)··························································································14

the machine)·········································:·························································14

the

needle)······································································································15

oil)···············································································································15

;jl</;f;J<;lJll

<t

and cleaning the

for

oil

filter)·····································································16

equivalent sizes/standard

needle)·······································

specifications)···································································································18

·····················································································22-23

)·····························································································24-25

shaft

drive

mechanism)··············································································26-27

shaft mechanism)······················································································· ···28-29

bar mechanism)··································································.-·····························30-31

guard mechanism)···································································· ... -..................... 32-33

drive

mechanism)· .... · .. ···· ...... · · · ...... · · ...... · ...... · · ...... ·

........

· · · ...... · .. · .. · .. · ........ · ...... 34-35

mechanism)······················································································- .................. 36-38

feed mechanism)

foot

mechanism)·· .. · .. ·· .. ·· .............. · ........................... ·· .......... ·

.................................................................................

........................

mechanism)···············································································'················43-44

tension mechanism)··· ................ · ..... ·· ........ · .. · .......

& spreader thread handling)··

............................................................................

·····

........ · ........................ 45-46

thread handling)·· ........................................................................................ 49-50

))

... · · ... · · · · · · · · · · ·

mechanism(2))·········

device)

........................ , ...................................................................................

................................................. , ............................

.......

:·

· · ..... · .. · .... · · ........ · .. · ..... · .... · .. · .... · .... · ...... 51-52

........................................................................

·13

···17

39-40

·41-42

47-48

53-54

55-56

-58

59-60

Page 3

1 ,

Wi

~

Introduction

·~~~~7~~~*~£®~m~~o

This

is

the instruction manual that describes how to use this product sately.

etE~~~&~illl,

Read

this instruction manual

~£the

prOcedures.

:%-&Hlil~Jit~,

and

tEJ't:JHlllNI*t!.!~Wm®liMt,

learn

very carefully how to operate,adjust

~'l!t,

ii!Ji!:,

and

service

this

sewing machine before heginning any

!l~~::lrti<~Fo,

:pj:Jttrrf<!!JIL

•~m~wm~tE~~~~.~~*~m#~ill~#®~Wm$#~~Jtt~~~®o

~~~*~~~~wm~~$#®~~tt.~~~?BAW,o

~Jit.~T~*~~.~~~~~~~~®F£,~*~~~~®~~oMr~~m~-~~~®~~~~~

Jl<o

~W:fJLf<!!ffl®~Mli\:%-~'ll'l!w;>f;:~~!ffi'~~li®~iJI.~~.

You should realize first that there

blank

range to them when you

For

safety it

is

essential that we

There may

Therefore, you should read

take

2,

Jllll>!\

>f<:0~

be

some safety measures that you yourself must take.

necessary safety measures

:ti:-:i:n\':6§

• §ti'J Applications, purpose I

Safety precautions

®~~m,

'!!!'~o

Our

industrial sewing machines

industry.Accordingly

never

is

always the

are

operating

supply

and

understand very carefully this instruction manual together with that

in

order

risk

of

contacting moving parts,such

industrial

safe products and you

to

use

sewing machines.

this

machine

use

them correctly

efficiently

~~~il!!iBIBIIi~®J.9t:i!:.fllot~$~

have

been

use

our

products for

developed

other

in

order

to increase quality and/or production

than

intended

tE"kti,~®~x1i!I'ZFc,

as

needles because you have to work

and

sately.

of

and

effectively.

13

®ilifliJf5/:0if£®Jilf

use

described

above.

£ o

~Jitl!l\~..tffl:iai~;VJ-,

:pj:J't:7J-bhmo

the

driving equipment

in

the

sewing

at

point-

and

~M;r;

::g)f~Jll'q;JJ');

~~~®~~:fJL,

The

environment

':h

T'l<:~tF',

I.;ff:fi;J!ii'l!i!l3i!i!f.~;f!L~~ot'fflt®;f!L~tl!:~#lfto

Do not use the machine

2.N;:lJJ,~i,?l!€"'1:"'1:3lt®lll!/J,

Do not

3.IDJ-,

Do not leave

4.ii'i!ll>l®lli\!JI.\

Do

S.ijlJ!r<l!,tt#ill!:JJt

Do

Circumstances

in

which our industrial sewing machines

i;\'iiJ:;'ETJt>F:tft~'fzT~o

near

use

or store

the

machine

i'l!illi\i'l!il<L

1i:~llilil'illfl:l'6®lll!/J

the

machine outside,in

lli\Lt1Itk,

not use the machine in

±

10%~

not

use

the

machine

on

*~®>F;ttt,

objects which make noise

lk~lE,\1,

in

the

~l!filMI'i~Wt!L®~,

are

used

may seriously affect their lives,functions,pertormance and/or satety.

For

safety,do not

such

as a high-frequency welder,etc.

~if&~lll!/J~~*'l!l'

air which

has

vapor from chemicals,

ttmll>t'l<::¥.1HIH~P)i;jo

use

the

machine

o.

or

do

not

expose

under

the

circumstances below.

the

device

to

chemicals.

o

high

temperatures

il:~W:fJL'IIl'*:I;F;l!>PJlJ®:lt!!/J

the

places of high

l:®Jttt~~ru11'8®:lt!!/J

the

condition

that

ambient

the

or

the direct sun.

o

temperature and humidity

that

seriously aftects sewing machines.

o

voltage fluctuation range is more than±

!0%

of

the

rated

voltage.

6.<1!.lli\W:I:7Gli<fli*i'l1t<J1b:i:i;;!ljl,tlf..tM~'!!!'®W:i!:~"

Do not use

::ID:ti:~tfilit

(1)

ilt~flE~*~'

the

machine

Safety measures

in

the

place

~®:~®'l<~*tp

where the

supply

voltage specified for

Safety precautions when you

the

penorm

control motor cannot

maintenance

on

the

he

properly obtained.

machine.

tE~~mJtt~~~,~~,~E~fttp~~~.ii!'~<l!.lli\~3C.~<I!.lli\~~~~L~T,#~~:fJL~~m

;r:{l;tWiJbzFo,

®'l<:~li!kftttJi!U

Always

tum

performing any maintenance,such as checking,repairing,cleaning,etc-However,if you need to pe:rfonn these procedures with

on. to prevent

follow them.

1'EuHT~T~.ill'.B;J',

Always

tum

1'filt11'~fto

,

Mt<'f-W~~I!OtF'JWi!U

off

the

power,unplug the machine

accident<; due

%-&,*:llli<l!.lli\~3<,

off the power and nnplug the machine betore performing the procedures shown below.

{§Jl',,

1i~,'!!!'~lm<l!.ll!!i!t11'ft.ill'.~,

to

the unexpected start

ftl>EI!Oll:~t!L~Wff~~~Mt~mi"l'~~

o

and

then

make sure

of

the machine and users misoperation.estabish your oun procedurf'.s

~<l!.iW~'Ii.M.~~..t~T:GFoilt~o

that

the

machine

does

not

run

by pressing

the

treadle before

for

the

safety

power

and

-1-

Page 4

•

i:JD:itiJ

Lubrication

•

Jl'iiJO

Threading

· trEU111. Cleaning

·

h#

Replacing

·

:i1Hr1Jiilill5iWt(i<JliU'lifll:i!!]~li1

·

:l!!~111.lilf

.

Urrtl r f!;.ill-.111,

•

i/lill\'#JlliJI!t

·

i/lill\';&ij/J

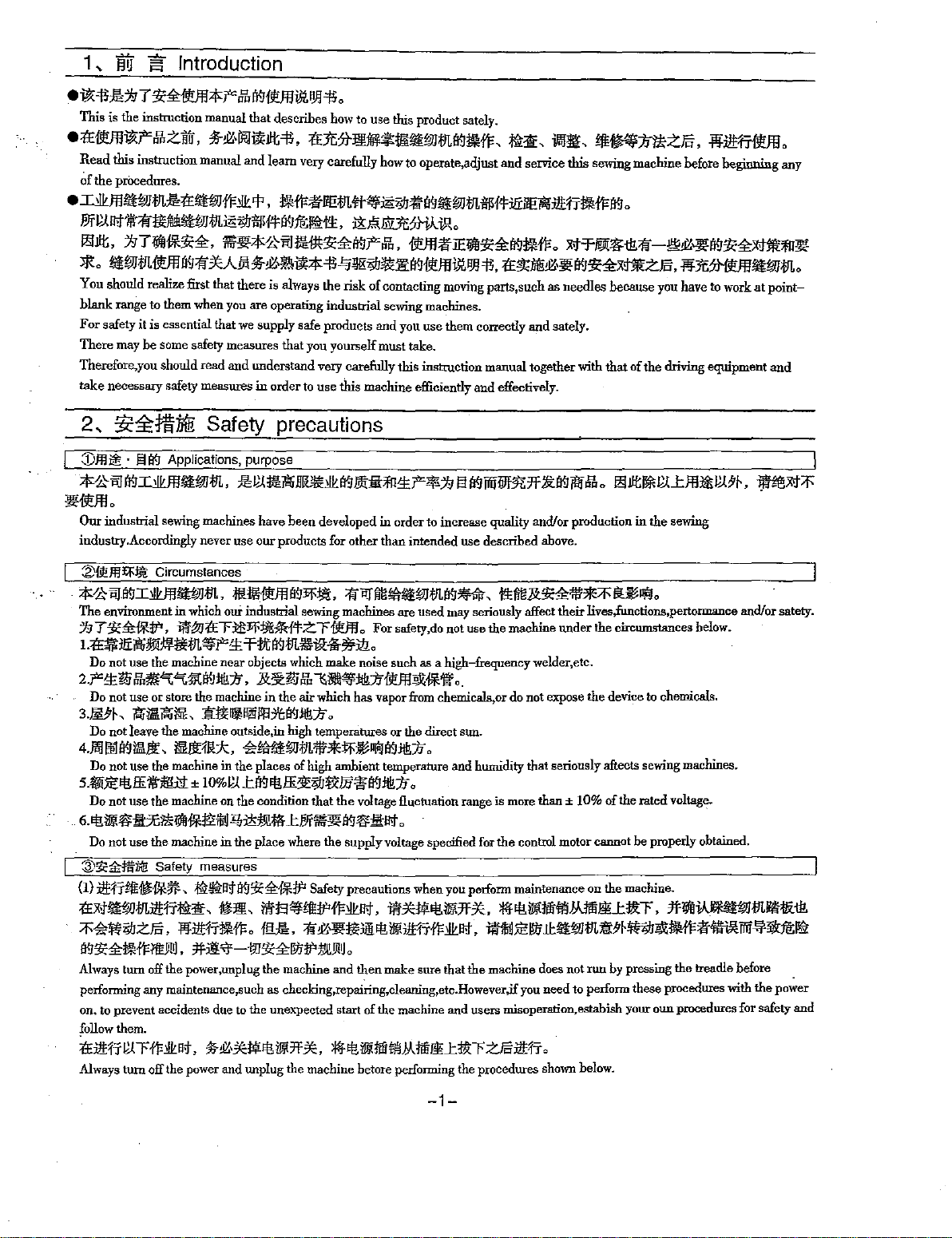

(2)

7f~~Jiij(i<J~~·J]J!

o~7f~~~~mliii.*~~~~m~*~$*,$~~m~.~~~~~~Ho

~-~~~~llt.@~L~~~~~~~m~o

Check

H

there

O%-liQJll'P!JlUlifliiJ..

>~<iWti::lK#~Ji!;~o

O~iVl'JDm;GJiii,

(

illHM£~ij/J'f'~,

Before

positioned correctly

see

if

the needle point is centered in the needle

presser

the

needle

Replacing the cil

i!f§!-J051(:jlj!<I!!Jl;:7f51(:;G!i"fi!J:rr

ltllt

the

machine

should

starting the

foot}.

head

he

something

machine,make

(tum

o Checking/replacing

Before

opern.ting

and

unit

wrong

#41!~1il!~

Be

careful of the needle point.

the machine

for

any

damage

with

the machine,im.mediately

o Check by hand

oil

element

o

Always

turn

off

the

power

Adjusting the stitch iength

Adjusting the differential feed ratio

and/or

taulty

function

at

the

petform

repairs

to

see

if

the needle holder is secured.

before performing the procedures

start

of

each

day.

and/or

other

neeessazy procedmes.

%-~>Jiflii.UfB!IJ:JH'tEiEJifli~fJtl!o

iJ..#~hM~#1L<P•C')

sure

that

the

presser

foot

is

the

machine

pulley slowly

drop

by

hole

hand

on

to

the

shown

below.

o%-liQ~~ffiJlliJ~*Iill~lill~o

M.!ll'Pliii!i"f~~ij/J,~~M~~~ij/J)

Check

to

see

if

the presser

the

foot

lifter and press it by hand front to back and left to right).

(3)

:flli/1/

.

~Training

O~T~k·~.D~~D*~(I<J~f!;A&~~~~~m.@*~~~~~iiii~**~·~~If!;~~~o

~Jlt.

iWJI!I'!=FfllJ'i!f~ijifft~:lli!l1tJ~jjl;:flliJJ/~,

To

prevent accidents,operators

To

ensure

so,managers

I

:)}If

m Unpacking

t.umm~~wrllt-!!!U!i"flltNIJ;~JEtll

The

machine

is

packaged

Side up

by

referring

2.Qfi!Jtll.111.~.Y.!JI!JIPM~#.m*tllllt,

Never hold

Otherwise

3.~~tllft~llt,

Take

4.7f~Jll:li(i<J!IJ;~:!4t~f!,(Ji"fJEJllJi9Ji'i'

Keep the

§ilil;~J/SIIi9~lllt

eM~ii"J.'i!!t.'i;f<~,

The

Responsibility

it

out

the

ea:rdhoard

packaging

to

the

area

near the needle and/or

may

cause

machine

box

Disposal of the packaging

material

of

the

foot

must design

in

a

cardboard

the lndications,such as logo ,etc

injury

and/or

iirl£lK:i:•L'Ii9fft:ilt,

very

carefully

and

packing carefully in case secondary

ll!;%:,

li!;~,

of

the

machine

customer.

<bmM~~

is

secured (raise the presser

and

service/maintenance personnel should have

and

conduct

training

Ji9

0

».fl!.!ili~~LfllJ~*:fil\lJlRJ:

box

before shipping.

~XH~ll*.Ei111.#$fft~~n51(:fllJ$#o

thread

guide related

damage

to the machine.

t),,t,Jljji;Ji9~tll

while checking the position of

foot

by

llii~*(I<JiJJI~o

for

these

people.

Unpack

your machine in orderly sequence while checking

printed

on

the boxes.

parts

when

o

the

center of

i#!Jf!£ff¥.fl'ttdffo

transport

VCE!!f~o

consists of

,\it.i!f!i!ii!l'!=fli.~"i!N:rfllJ~#J/SIIElifliJ!Ml(!<}i!J:ff~~o

wood,

paper,

cardboard

proper

taking

out

the

gravity.

is

needed in the

and

VCE

the

fiber.

knowledge

r

Fo,

machine

future.

The

proper

and

skills

for

safe operation.

iit.bU:~fFi'l<Xil!¥fflli

'6'9UlilcMJ11;~~~11l.Ho

from

the cushion.

disposal

of

the packaging is

them

o

right-

the

-2-

Page 5

!il!ill<!Jlll!V!I/Jti':J~!I

l.~!iJJ<!Jla<JJ£'11o,

2.ii!JJi!t~!iJJ<IJLEJi*JIIa<J#:tsf1H'Ji,

plastics.

3

-~~)J<!Jla<J

The machine waste is

commissioned

il!:flll!i¥51l!Jll!l#9H6~,1!li~:li!!>f:!!l:l¥o:IJ"ti':J:fl~r,

The

parts contaminated with

:ff®i'§:®i:li!!f':J:riilll!il!ill<IJL

•

~r:ffJ®!'i'r®i:li!!f':J:rilJIJ~!iJJm,

The

manufacturer assumes no

upright position avoiding it from dropping or

~~Transportation

L~<IJLWka<J~~-"'J!jl)Ji"-

1)'~

~o

;)l;fl!!~%-&;•{j!JIIIj'~~Jl!'fl

The

machine should

a

hand

truck.Be

z.:§7YJ!J!!iJJ:IIL:III!kllt.

Disposal

of

machine

Jil'\!rjilj:flt)i\'f±J!t1-TJIJ:llllo

J£'11o

Jjlz~J!l!

~

:li!!>f~J¥,JF

to

be disposed of

if

necessary.

lubricants

Transport

liability

Jcl;(..tJ!!'fl

he

carried by

sure

to

use a hand

Jll:t"'¥-JIJ\1±~~,

at

truck

waste

The

proper disposal

fl'L

f¥.&AI·#i!l!:tsfo

a<J:fl

~:\IDEJ!t1-TJ1l:!l

in

accordance with the locally valld environmental protection regulations. A specialist should

of

The

materials

0

&·~II&

machine waste is

used

on

the

if<j'f;"'lf

n

a<J r li<J!t1-TJIJ:!Io

the

responsibility

machines

of

the

customer.

am

steel,alwninum,brass

:)t;l;Ui!t1-TJIJ:llllo

should

be

disposed off separately according to

within

the

customers

premises

:<l<ii!Jli!trlilltl!::fl'OfiE o :riiil.illt:k

for transport within

falling

o

~~·,

the

customer's premises. Care should

down

to

the ground when

fllA11'~.RJ!Il.r~tt~m

T>ifMW.J<IILJ>I:fil1m,

it

is moved.

the

locally valid environmental protection regulations.

Jil'tt;f;:FJ!f~!J!!iJJ~o

he

taken

to transport

the

~;;li;

o

least

more

than

two people when

for other fransportation.

li:'FlWiE:IIL~dlL

it

is

moWlted

on

the

'lt'll;¢11i!ti':JJIIU!i!o

~m_rr,s;a

table

and/or

and

various

machine

in

be

an

lllir5~lJIJI!t~£mM!1m,~nu~~~~m*_rll!lll!i~o

To

carry

the

machine,hold

Your

left

upper

arm. H

Slip

out

of

your hands and fall to

3.1'Ett!:i!W:IJL~;!IU;;Ii;1]'~~

Care should

ransferred using a

be

taken

4.im*~m=l?dEi5!iWHIIJMHl!ll!illt,

Wipe

off the oil from

or

the

bottom

of

the

the

the

machine

to

avoid excessive

hand

truck. Otherwise

the

machine

box may come

machine

pulley

tightl:r

and/or

your

the

floor. Therefore, wipe off

_t~~at,

iii'I'E~:F~:t:J::B-lll'i!rU;;Ir,

shock

and

the

machine

i'R-"'l!l!'Flt<IIL*ka<llll!~o

before

packaging

off

while

in

with your right

hands

are

shake

may fall down.

stained

when

with oil,tlie

the

oil carefully.

the

machine

hane

and

the

machine

machine

l;(fMW.J<IJL~*!Ji!tlitl!fto

is

mounted

1!i!i!tl~llt~II\'Jil!l1m<IIL*;;Ii;ll!i~{j!-B!llli#JI'!8>:!l!tlili!io

it again for secondary transport. Otherwise

transiL

may

on

arm

with

be

e.asy

to

the

table

and/or

the

machine may easily slip

t

out

of

your

hands

::ID$:~

·

:i.~

Installation preparation

!ilmm~t!i

Machine

table

Lw*JII~:J'E:B-*Sl':!:i!W<IJL<IIL*ll<:i!:.&.lilliilltFota<J&fl'JII;iJa<J!J!!iJJ<IJL~i&C~i&,~lo

Use

the

machine table (table

running.

2.1Jil:Jt;:)}~

IJI.I<Ilt:r

Arrange the working environment for easy operation

H

~!lWJ:IILll!iJ!!!ll!l#OII!~fl':J'G~

0

the

illumination

is

3.~~U<IJLII>t,

AHach a

non-slip

pad

4.1'£~-fF~l&'~tl':llitrt!!r.

Adjust

the

height

of

!3!1&

Cables

J.i'il'¢ilillj{]Ji~~mm*Ei<ll<llli!J3!~1j{]Jill:*o

IT~fl'o

When

connecting

z.iEAAIJ>iW:F~!;';J!n!~:i:J:$a<J;iJ

Do not

strain

the

the

cables

board--.

metallegs)that

insufficient, control

or

:klllf.!l:~fj;~q;j;'iiJ;jJl!li/1\'MJi!t~*$:,

to

the

treadle(foot switch). Otherwise

*"'~i&Wij{j/.16!Jl

the

table

cables

according

between

to a working posture of

the

machine

ti':J

IJil

change

'l'ii!Jl

and

completely carries

, U

:ff~ffi\fl;l&a<J>f~

by

cosidering where to

lighting

as

required.

the

machine

place

the

and

is

fully resistant to warping while

'I' o

~o*:l'G~:F:l!-Ht

machine

and

the

IJil'l\':11&

•

1Jili!Uiil1/il~J<ii!i,lff{

brightness around

the

machine

the

working area.

-~iE!J!!iJJ<IJLJiili;ffU'l8!1illlfll:~Jil!ti':Jm-To

the

operator may

c

Itl'llta<J/.16ll!:

the

operator.

!:i!!iJJ:IIL<IIL*Ei<ll<IILJII:i!n!~l!Mfitn!llt.

t.l}e

motor,

be

sure

l o

to

slip

tum

off

off

the

the

treadle

power

while

mnning

the

machine,causing trouble.

%-&•1'E1if<ll~7f~ffla<J>Iki!i<ri!t

and

connect

each

cable

connectors securely.

o

in use.-

is

3.Jii':F~iliit~III!J!Jt~o

Do not

bend

the

cables

excessively.

4.!3!J/i:€l9lllfl#

.

When

connecting

5.!J<:"Jl:'il'f;t;'Jl\(J3;1Jl;{i';"'l!':;;Ji;bUiil:JF!;'!?fc{JjljFJ3;Jit~o

Protect

6.11i!~ltlt~ll>t~:XHJ!AA"'45*,

Never

use

(

~O~;;IJ~,

the

each

cable

using a cover

staples to fasten

cables

V3f%'<'.il'!il')

that

are

close to

or

adjusting its position

the

cables,

ti':Ji!n!~,

the

moving parts ,such

jjizjl1NI!~1'E25mmJIJ:i!t1-T:l<ll!io

if

necessary.

ill*'lltotlli<!l;;ii;)<.)l{o

Otherwise

it

causes

a short

as

circuit

pulley or V

and/or

a fire.

beit,keep

a distance of

25mm

at

least

between

them.

-3-

Page 6

Jt:fll.

Motor

I.!iiW:fll.Jt:tJ!.Ii'J'i<~il!f.ili:J!!I

Install the machine motor correctly by reterring to the instruction manual supplied by

z.'b T

lliJ

.!l:1N~

.Alt1iH1ili'Jfli;~,

Select the machine motor

Jt:t1LI*i¥1fle11ii#.llil

Dl'll1li:flll!J

equipped

with the pulley cover so that

~,

iEl!IDii'J.it!:rr'i<~o

the

manufacturer.

.!l:~

Ali'JliiWJ:tJI.Jt:tJ!.o

any

part

of your

body

etc,is not caught

in

the belt.

~'1ll!/ll!il!~Jlfllilll

L1EiJ!Iil!:P3ll!:

Never start

2.:tJ!.iJ!I

i1!:A~IIit4lifti1Ut

If

machine oil gets in your eyes,it

protective glasses.

l!Of-ii!:Ai!Hii',

Should machine oil gets in your eyes, wash

3.:tJ!.iJlltil'i!!FlJl.tFo,

A void

skin

4.~X>J')f:J?fJ!!:tJ!.iJlli1f:A

Never

swallow

5

:tJ!.iJ!I~i!i!~1E:Wllt)f:?@J

*JJ

-ii!:A

Keep machine oil out

*H

swallowed,do not

6.~iJll,

~-'&'~li'JM:ll!!tt:fl&:,ffl:il!!l!~li'JJ<.%-,

Handling machine

1l

B:A

ill!

!!.(

lltrftX>J"

the

machine with

:&~

ilil'll'f'ltt7J<.liFmis?»P*ili~~i1!:rr#l~

ili'!'1..l:.ffl7J<.lll!mM'f'ltt

contact, immediately wash contacted areas completely

P~o

machine oil.

li'J:It!!/J

P

~,

;r--:J?~tt;PJi[l!±.,

of

the

reach

induce

oil

)f:J?.it!:D

no

oil

in

,

}jlj'

!!.(

may

0

of children.

vomiting immediately

)6~

the reservoir.

1Eftl'll

ll>J'ilii\1\Jil.r:t?

cause eye irritation.To prevent the machine oil

them

with

1li

..tili~~il!:rr#l~

o

IIJH!t

fresh water

o

o

go

to

see

a doctor.

i#~Jl!l~iEli.IDM:ll!!o

!!.(

fo

M:Jl!!o

Dispose

of

the waste oil and/or containers properly

or

shop at which you purchased it.

7.'fl

Tll!J.!l::IR~,

Mter opening the

direct sunlight.

7J<.?.tli'JffilA,

oil

container,be

fle11i%Ji"ii!i!~:tJ!.ill!ll>J'ilUfl~iJll*lili,

sure

to

seal it to prevent

as

demanded

dust

by

and water

:!lil:tJ!.iJll

.it!:A

~~lito

from

getting

in

your eyes.wear a pair of

0

15 minutes

with

law.H you have further questions on its disposal.consult the store

and

then

go to

see

a doctor.

water

and

soap.

:!m)f:%Jill:Q~Jli,J~ll\lf1li*~Ji"i,

Jil::tEll!::flJlS~J¥JJ!Ilm;:M:{!i!~

from

getting into the

oil

and

leep

o

it

in

the dark to avoid

iEli.ID.it!:rr

H:tJ!.

~of&

Machine table

Ll'T3fltlw.Ji!,

Before turning the power on, visually

and/or loosening.

2.1'EJ'T3fJtlJ!\Il>J',

Never bring your banes close to the

3.:l!t:W3f:!l€tJ6~H:tJ!.Il>J',

When the machine

The machine pulley should

4.~f);!iiW:tJL1!fJ.i!Z'b3t:!Vli~iJIIi.*,

i#li.IDt\.til'~~til'~:!Bl':fl~{%,

check

ilf)f:J!'>I'¥J'.$:1'E:fJL#Jllf:i

-.IDE*!if;.JJfllt:Jllr-Jit:~$I!Q

Lt£1fi:i!Jffi?DIH&,

Do not run

the

i?f.i$1!1,

machine with the safety devices removed,such

2.!.lW1JL:tEJE~'ft~11llfe;ll&i¥.J,

Never bring your

3.-IY.!JllJllfil-lm'I'\;~11!.11t~~l!!\ZFc1~11LiJ3?&~~.JiiE~~JLo

hands

Precautions while you are running the machine

#'i#J~t?.\11'.~:'lt~l!ti¥.JJ!:Ri$r,

t&x.t:or::J:O>I{F.P

'lUlder the needle while running

iiJl.A.11!.#

r;

the

ma~e.

il!FF!l'JE~~JJ11!.o

as

eye guard,linger guard,pulley cover,etc.

~llt~11Ll\M&ii'f011L~i#J~11ffl:W!i¥.J,

if~

:lJtlJj\'L'o

A clutch motor keeps

the machine could start running

4.!.l@J1JL:t£JE~'ft:J1Hil[J'O;iJ&i¥.J,

~llt.~:or::*'ilf~n,~r,I~~~:tE~k$m"

To prevent accidents,never brir.g any hart

up

and

needle

5.t£:or::MU11J.IIt~j!fj;!hfl'j!f)llf;Jf011J.IIt,

Always

tum

off the power while the machine is not

6.~~11t3}lll:''ilf~lJ!l~o

In

the event of a power failure,be

7.dfl'!.tW11LIIt,

While

opemtin~

I

CV!IH/',

L~iJ",

Well

lnstruction

2.~

m~~~1JJ.~:or::~~i#Jzii'i,lll'~tiYhil'o

If

press the treadle to make

~,.,,

~:lit,

trained people should

manual carefully.

T~t?,

it

~:l!f,

is

necessary to lay the machine backward for maintenance,check

3.:tE1t*llWfi!PVIDEi:11l'llt,

~i#JZ!i'i,

Before installing/removing the V belt,always turn off the power,unplug the machine

does not operate.

4.Mr011!.11LM9

Carry out daily maintenance work

s.~JJ11!.1¥.J~>ll!~'l!ll1'tl¥.i~il!f1VI!;;f<0i'!JI¥.J;!l;3i;$f'to

·

;;f<0i'!J'ilf~:flt-"W'iJf{fo

Employ Pegasus genuine harts when repairing

by any Improper repair/adjustment and substituting other harts for thoes manufactured

6.i#:or::'!l'i!t=lliiliJ!t:

Do not attempt to modify

7.rli\illtllil~>ll!,

Be

sure

to

replace

8.~!?,

~:lit,

After perlorming maintenance,check and repair,make

on

running for a while after the power

by

pressing the machine treadle.

J!ii't;lt@X;j:;r;~'ilf'f-J'!1,

of

your fingers,hair

bar.Also never leave scissors, tweezers, tools,etc,around these areas.

-JE~'ilf~l!!\Jf~o

used

sure

to

tum

off

the

is

turned off.Therefore,he careful

~2L

'I<:HJl~jft'f-~,

and

clothes

near

or

before leaving the machine table.

power.

even

VJfl'JSl11!''

the machine pulley

~1JL-IWJ~,

after

the

power is

,v

helt,motor pulley,thread take-

tumed

off as

Ji~lm,

#$o

i#'5i'ff~~1Jt11Lit'ffi.A.i¥.JHil*"

the

machine,wear clothes that cannot

il!il!

Maintenance,Chcek,Repair

~I¥.Jil'.ill0]\HlisH1~:lJUilll~i¥.J.Mt-tEJ'E~~~-fY.!JlliJI,I!fl~i¥.Jii>$2Ji'i,

pertorm

maintenance,check

~'ilf~JJmm~~fiiJIIt,

sure

that the machine dose not operate before beginning any of the procedures.

%&:''ilf~l!!\7f~l*".

be

caught

in

the machine.

l'l'liHJ'il'.!lko

and

repair

of

the

machine after studying these precautions

%-&:;'ilfll!.ll!i7foX:~.

and

ifl<l!ll!lllli~.!Allli.RIU::J;H,

Jell!.ll!lffi~»Jml!llk=t&rF,

repair,always

turn

off

the

power,unplug the machirie

Jtl9bil...llll~Q~1JL~:or::~

and

the

JtlffQV...RP~

and

Wlt!::frlll<fl'o

and

1'1'/it~:l!t~JEJ!Il~lt,

and

Jf>Ztl<!lll;;f<~~MiJI.I!fl~l¥.!f.i.iK,

periodical inspections properly

by

following these precautions

xHHl·~i¥.J~J11L

the

machine and/or replacing

§ B

i¥.J!J'UiiliWJtW11Llt!:=ITilli::li!t.

the

1113chine

at

your

j,iijJ!!:jijj'IJFf!PTWJ<-3>:!111l!t,

the safety devices and/or safety covers

~>11!1¥.Jfl'~'J\liitlii,

i#~:l!t~li1!~l!!\Zii'ffi'oi'i'lffQ3i;l!t;ff1tW!o

i'i'IJitlllililli::li!tW~i¥.1¥$:,

own

discretion.

:'tt-3>:!?>1<,

We

are not responsible for accidents caused by

i'tffl'~'J\lii'f

that

are

sure

that

%-&,l'I<W'*I¥.JJ!:RiMCU"

temporarily removed for maintenance and/or adjustment.

twning

on

the

press the treadle to make

"W3i;iUti¥.Jlt!:=IT.

and

j,iijJ!!:~iV!IiN'iilfh~'lillf'tft~l¥.!¥$:,

the

parts.

We

are

not responsible for accidents caused

by

Pegasus.

:;$:0

i'!J'ilf:;=f'

:fit

-"W'i!fffo

power does not pose any

danger

sure

the

machine

the instruction manuaL

the

mooiflcation.

to you.

-5-

Page 8

ii:

~

~

m ll!l;tf'HIIl

4,

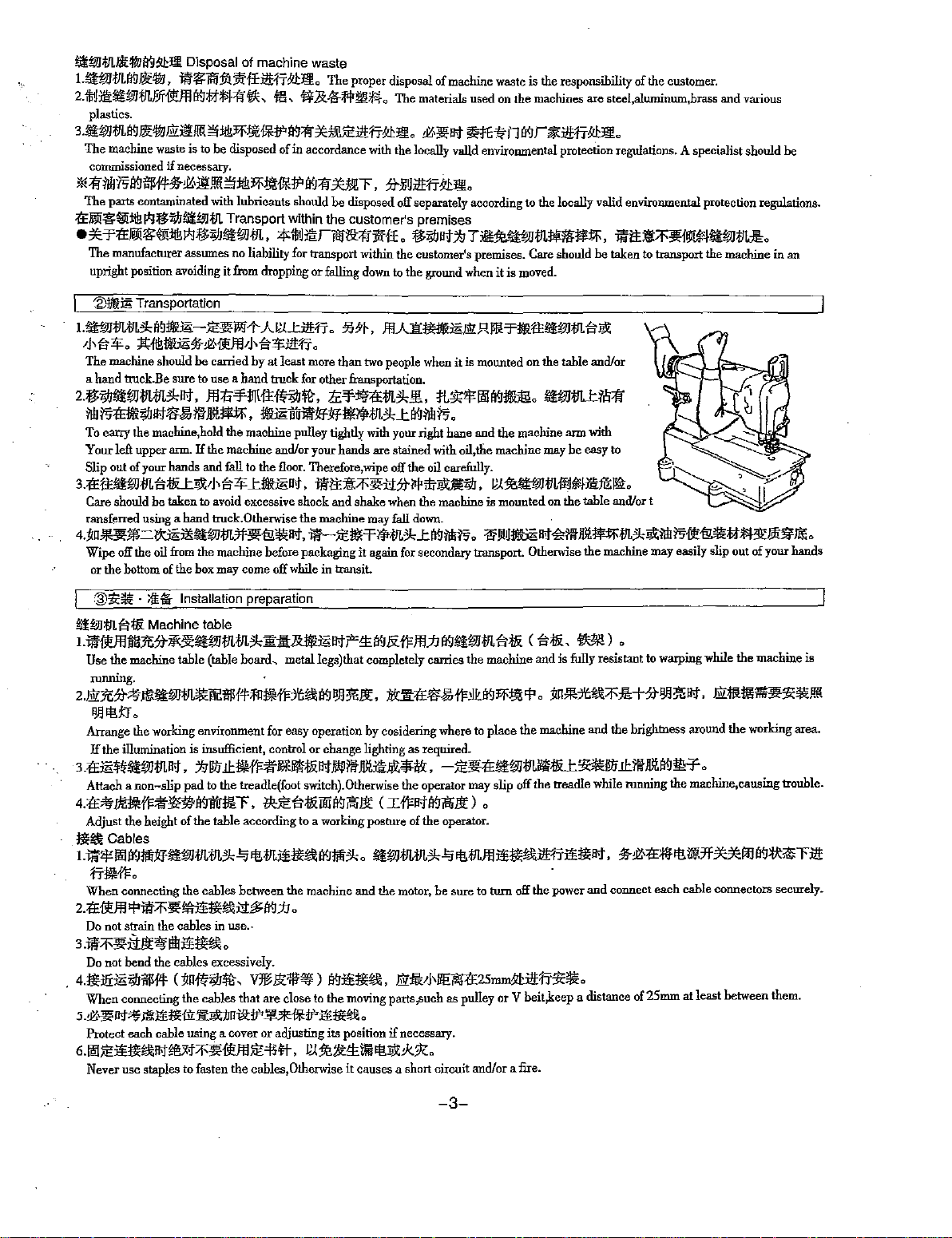

1'1\rtFiff~ijJ~I¥Jf:iit~~:i-·GiH?~it

mJii);

Be

sure

to

study

very

carefully

Location of warning labels and safety devices

for

safety.

ll"ll!!i&

Eye

guard

Sliding plate Front cover

-6-

Page 9

5,

~::£1:!H?~li[

Protectors for safety

This chapter describes each protector

(l)

:IPDJll:/.&.

Eye

guard

717

~~~i¥.1'1<:£:,

~jijj

1<~

i¥.J:IP

For

the

safety of eyes,do not

fM.t::r;J!:tEJT:tf:IPH~<&i¥.J~iffi;T~fF!itli1Jiit

DU!.

o

operate

for

safety.Therefore,read and study the

the

machine

with

the

eye guard open.

follov..-ing

o

:IPD~1&~71

The

carefully.

71'E!it*'JJ

eye guard will prevent any

.P#-t!li

TH<.t,

~t!li#-

pieces

of

the

::r;{lo

I!.

broken

AD~

needle from getting into your eyes if the needle shoul break during sewing.

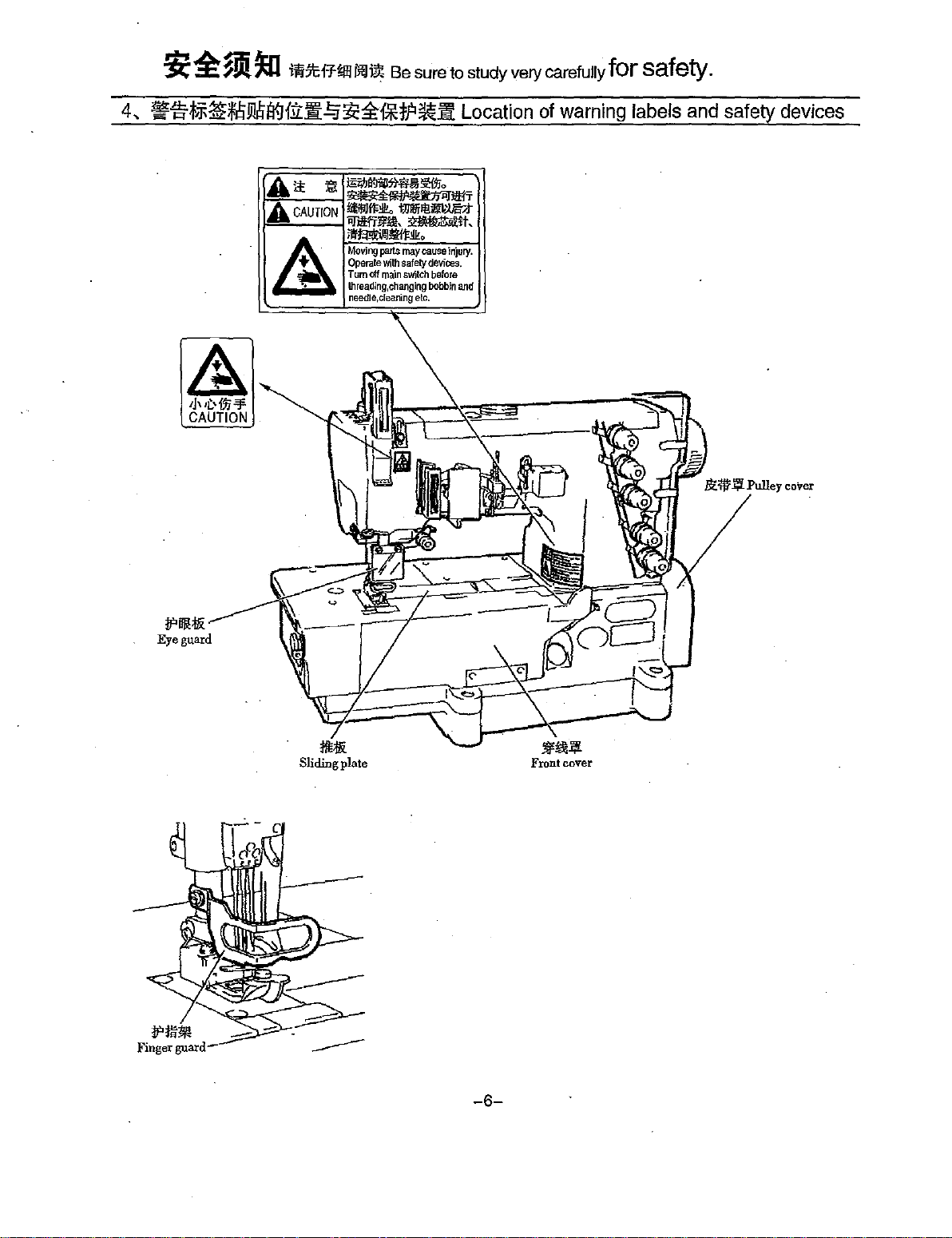

(2)

:!Pf.l~

Finger

guard

717~~Lr~~i¥.Jiit#-~A~MW~~~®,1'Eiit#-mili'1<~7:1Pt!l~o~,1'E:!Pt!l~L~717~r~~Wmfl

fBJimto

:!m*Jil.f'f-11:1JAfBJ!li!{$A,

To prevent

needle.However,there is clearance ahove the finger guard for easy threa.ding.Be careful that

finiers

(3)

it'll!'

the

needle

that moves up and down from contacting any of

if

you insert it into this clearance.

'ill.

Pulley

cover

!itli1Jiiti¥.Jf!f~~;fnv:*Jt'lll'H1JI:JJ1'Elt'lll'llP3,

iJT.#flliJ6~{lo)jjljj1j'f-f.lJi!i)jjl;~®o

your

'i'EH'I'

body,the finger guard is

(

!Jil'JJIJ1'EJ1;;Jt~**)

installed

the

needle

~A~Ji!k:JiH!ffl;®i¥.Jo

close to

the

may

penetrate any of your

717Mfit

·®,~~*~~:IP~~r'J<~i¥.J~iffi;o

The

machine

sewing.

prevent

To

(4)

~~Pulley

~l!fiji/JiiWJiJT.f/f~~(p'JJUi*~(oj'

Check

(5)

~

JA#i:M<WffB!Jii¥.JL71-:11~5mmi!U,

pulley

accidents,operate

the

direction

Presser

foot

and V belt

in

which

are

cov~ed

the

machine

the

machine

with

the

pulley

cover.

The

with the

pulley

cover installed in place.

machine

pulley

and

the V belt

rotate

at

high

speed

during

JEl!fij(p'JJUiff~(oj1'£{~~~1)!tl~~(oj;tJ*I¥.Jo

puliey

rotates.It should rotate clockwise as

J!

-t-fBJ

imtfl!i<:'¥-t!li¥.Jfil;®o

:tEJllh:tf:ktil:fJ-JDii~Ji\\Jllll/1:1&

seen

from

the

pulley.

§

~til:fJ-

ID!iJ

~,

ilH'!l!:#t'¥-t!lf<!IAJDiir~

There

is a

clearance

fingers

are

caught

knee

switch

(6)

~~.\JFomt

of

more

in

this clearance.Never

or

automatically raising

cover

than

5mm between

o

it

with

insert

the

the

top surface

any

of

treadle.

of

your fingers

the needle

under

the

plate

presser

and

the

foot

presser

wP,en

foot.Be careful

raising

the

presser

that

none

foot with

of

the

your

~#i¥.J~~JAHiitiEW~~,~~rr~ti~~i¥.J~~E~o~7~~rr~~ill~i¥.J~#~A~Ji!k,~~w~~

.\Jffliri¥.J~;m;-r~tF!iiWm,

The

looper travels left

part

of

your

body

(7)

Jtili(

Sliding plate

r~Jii!;J&~tEH~~

Jt:!Jiffliri¥.J~iffi;r~fF!itWiito

The

looper

thread

thread

take-up

to

right while drawing

,he

sure

to operate

TJiitfl-

take-up

from contacting any of your hody,be

the

J£JI!:i¥.Jr~1'Ei;I!:IUi*ill~,

rotates

in

machine

order to

an

are

with

supply

as

seen

from

the

front of

the

front cover closed securely.

71

T~:!Mr1TIUi~~i¥.Jr~liW!~Atii!M,

the

required

sure

to operate

amount of looper

the

the

machine.To prevent

thread

machine with the

during

sewing. To prevent

sliding

plate

the

closed

looper

from contacting any

securely.

~&>wt£

the

looper

-7-

Page 10

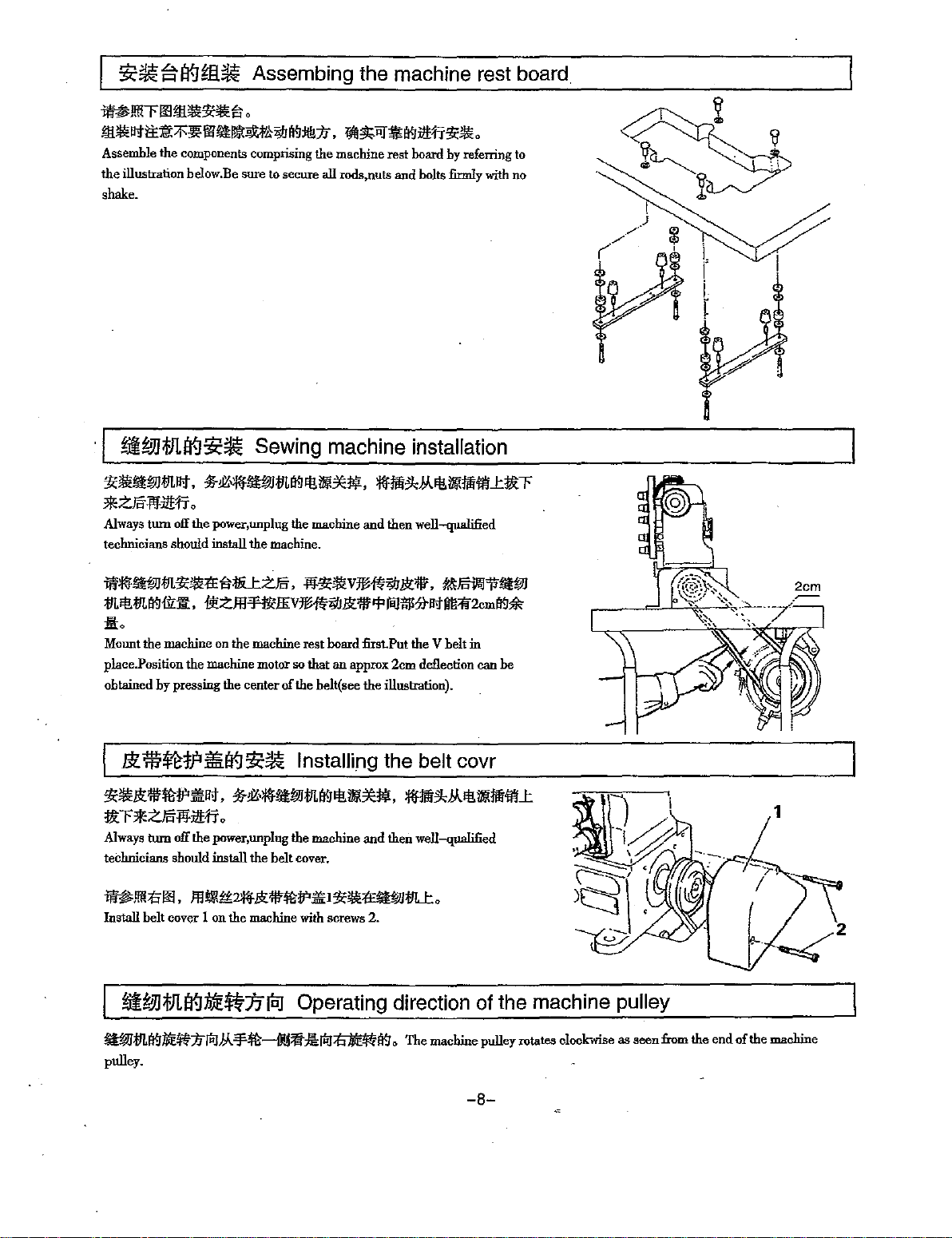

~~@;1¥-.Jffi.~

Assembing the machine rest board

u!!llTOOmi!li't<JIO'~

m!!li~~~~~m~~~*~~~».~~~#~~~'tt!!lio

Assemble the

the illustration below.Be sure

shake.

· I

fig,Mlla9~~

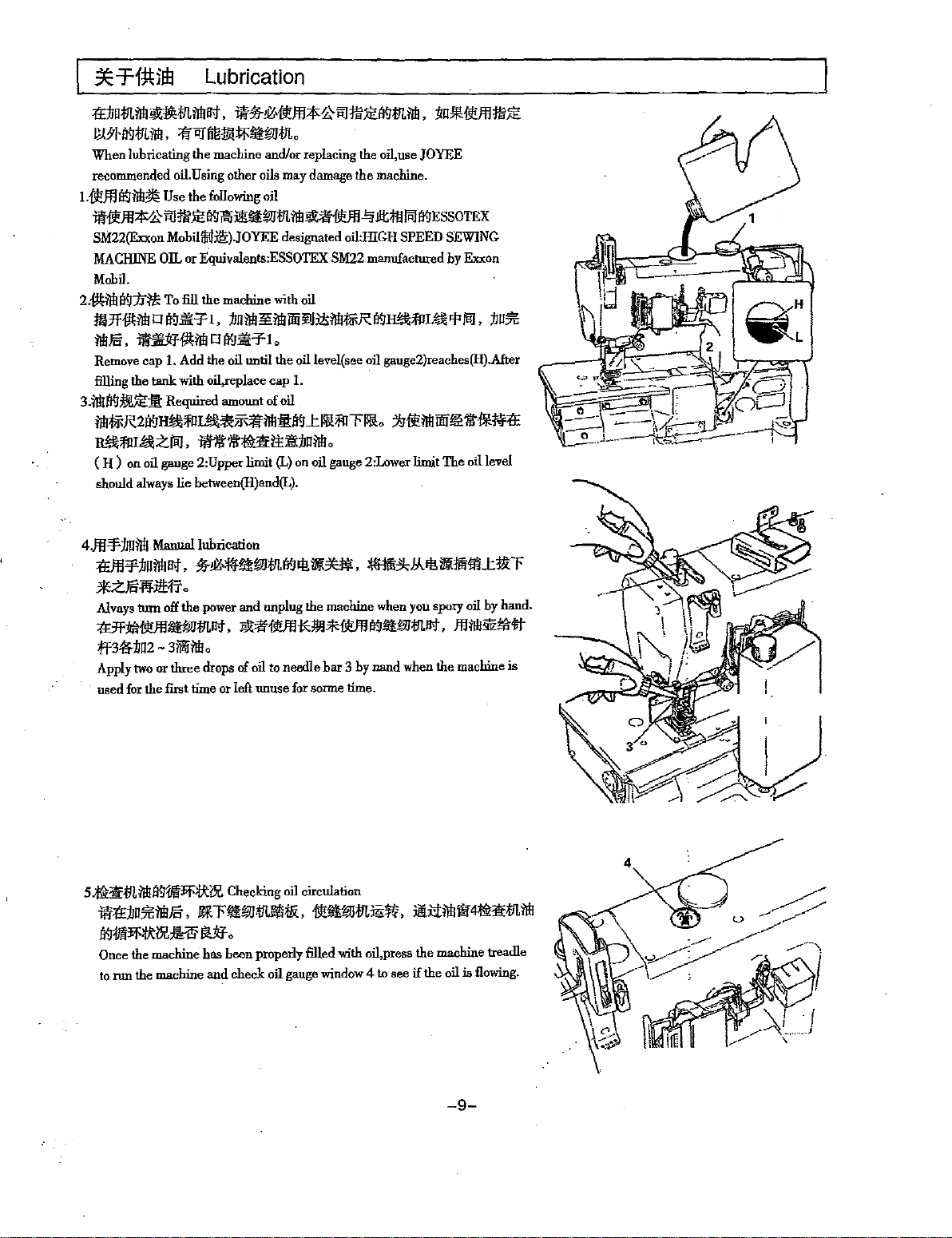

'tt~m~.~~~awm~~~~.~~~~~~~ML~T

*Z.Ji'i

Always tum

technicians shotdd

components

{!i:i1/:tr

0

off

the

o

comprising the machine rest

to

secure

all

rods,nuts

and

Sewing machine installation

power,unplug

install

the

the machine.

machine

and

then well-qualified

hoard

holts

by

refening

firmly

with

to

no

~~~m'tt!!li~~~Zfo"i,{!i:$:!!11V~~~~*·~~~~~

m~m~~~.~zm~Kv~~*~~$*~~fl~m~~

lil:o

Mount

the

machine

place.Position the machine

obtained by pressing the center

El"l'iHit.P~tr-.1~~

**~*~~~~.~~~~wm~~~~.~~~~~~~ML

~T*Zfo"i:pj:~~

Always

turn

technicians should

~.lfflti'OO,

Install belt cover 1

~g,Mlli¥-J»fE~jj"lcJ

um~~!WfiJlil~

pulley.

on

the

machine

rest

board

first.Put

motor

so

that

an

approx

of

the belt(see the illustration).

the

V belt

in

2cm deflection can

he

Installing the belt covr

o

off

the power,unplug the machine and

install

the belt cover.

fflli!lft~~ft!P~I't<J!O'~mLo

on

the machine

with

screws 2.

then

well-qualified

Operating direction of the machine pulley

'f~~'ll-:li!"lu~l¥.1

0 The machine pulley rotates clockwise as seen from the end of the machine

-8-

Page 11

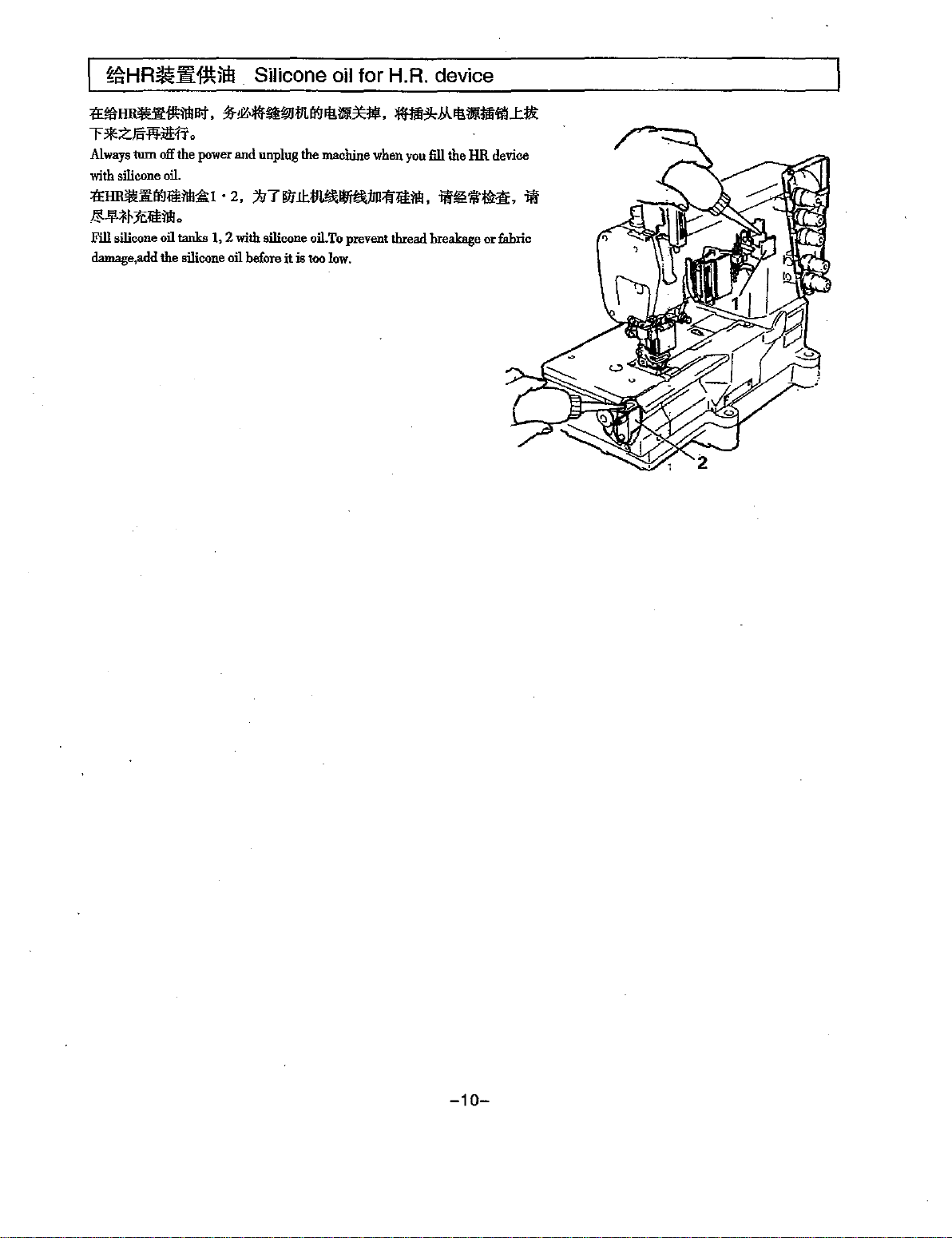

Lubrication

l'E:tm:IJT.iii!JiiG~tllilllllt.

I~H'rll{]:IJT.ii!J.

When lubricating the machine

recommended

L1VIJB{]ii!J~

iliVIl~~"-lill~ll{]~~W:IJT.iii!JiiG~~~~~il{]E~OrnX

SM22(Exxon

MACHINE

:{;fliJfmlll!tt;llWtllo

oil

Use

Mobiijj;IJJI!i:)JOYEE

Oil.

or

il%-&Hl!!ffl2f<0"-lil1~1l{]tllii!J.

and/or

Using

other

oils

may

the

following

oil

designated

Equivalents:ESSOrnx

replacing

damage the machine.

the

oil:HIGH

SM22

mannfactured

oil, use

:!m*Uill~

JOYEE

SPEED

SEWING

by

Exxon

Mobil.

2.-(jf;ii!Jil{]::iJ*

!S3ffAA!IOB{]llit-'FI,

iii!Fc.

Remove cap

filling

3.ii!Jil{]~~:lit

illlf-'FR21l{]~fn~~r,;gii!JJitll{]J:II!!fnl'"ll!!.

illil&fn~ziiil.

(H)

should

4JlFf-:fJRilll

l'Effl'f:builllut.

>ftt];'i:J't:l!t1T

Alvays

~~u~m~.~~~*~*~ll{]!lwm~.milll~~~

ff34f:IJU2-

Apply

used

To

fill

the

machine

:hUill!:?!':ii!Jiiiij;IJJ;!;ii!J:fli<Ril{]~;ftl~rpiBJ,

ilt""~illl

the

tank

on

oil

gange

always

0

ll{]lli(-'fl

1.

Add the

oil

with

oil,replace

Required

amonnt

ft~tl:~:builll

2:Upper

lie

hetween(H)and(L).

Mannallnbrication

%-&.:f{fll!Wtllll{]J!!l.!J!~l*.

0

tum

off the

power

and

3ii2Jii!Jo

two

or

three

drops

of

for

the first time

or

left unuse

with

0

until the

cap

of

oil

limit

(L)

unplug

oil

to

needle

oil

oillevel(see

!.

o

on

oil

gauge

the machine

bar 3 by

for

sorme

:/JU%

oil

gauge2)reaches(H).After

:*M!illlllif~iltf¥~

2:I.ower

limit

The

oil

level

o~»..l!!l.!l!'lfflmJ:*l'"

when

you

spory

oil

by

hand.

nand

when

the machine is

time.

s.tHr:!ll.illliltr'~l'Fitl:ll.

il1'E:IJU%iii!Fc.

ll{]1JQ:I'Fitl:li.Hii!f

Once the machine has

to

run the machine

Checking

oil

0!tl'"!JfWMiOC.

~

0

been

properly filled with oil,press the machine treadle

an~

check

oil

gauge window 4 to

circulation

HWtlllii~,

J!:liilll*<®1ttllilll

see

if

the

oil

is flowing.

-9-

Page 12

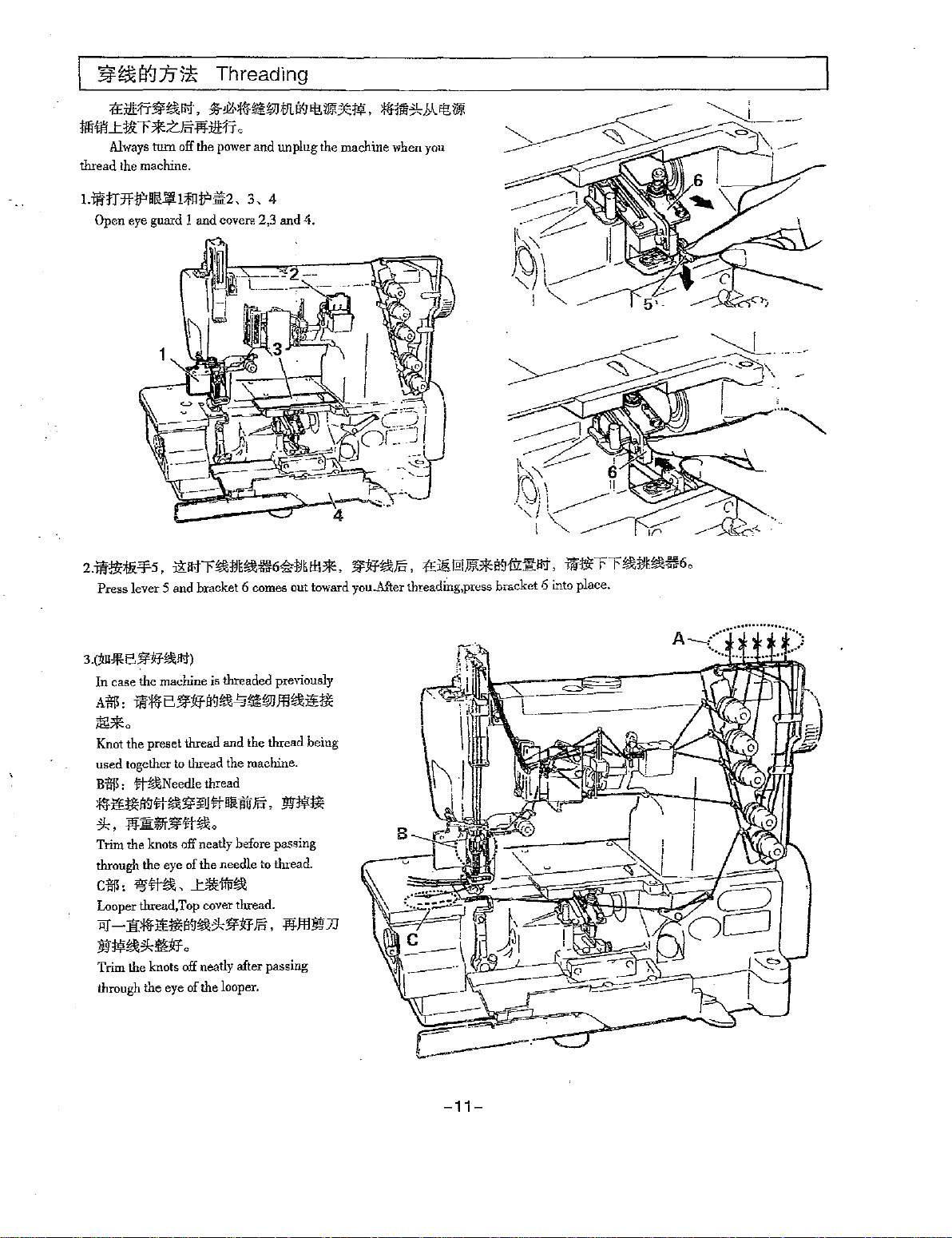

~HR~'i':milll

~~~~M~.~~~~m~~~~.~~R~~ffi~£~

""F*zll'fW::lll::ff

Always

tum

with

silicone oil.

~l!RJt!lit~li£M:iU

~:W1Eli£Mo

Fill silicone oil

damage,add

o

off

the

power

tanks

the

silicone oil before

Silicone oil for H.R. device

and

unplug

the

machine

·

2,

::h7~11:M-!m1ili£M,

1,

2

with

silicone oil.

it

is too

To

low.

when

prevent

you

thread

fill

ft"ii!"*1!t·

breakage

the

HR

device

or

fabric

if

-10-

Page 13

~&:lHF-r:1:J5*

Threading

:tEittfi3J'~IP:I

li!Hi'L.tl'&r*Zfcf

Always

thread

the machine.

L'ii!fJTJHJ'Dii.\Jl;f!!i?Jlir2,

Open eye guard 1

z.w!'!<;f!i.-¥5.

Press lever 5 and bracket 6 comes out toward you.After threading,press bracket 6

,

%&•¥J-litW-lllfl9et\IJ!(*1J1:,

~:l!Hl',

turn

off the power

and

unplug

the

>!!fJlil*Aet\IJ!(

machine

when you

3, 4

and

coven'. 2,3

i!a-.tr~:1Jt~~64?:1Jttll*.

and

4.

3J':!<f~Fo

•

.fEit@ljJl<*fBi!I~a-.t.

-m~rf~:IJt~~6,

l."l.to

place.

3.(JlnJ!I,B3J':!<f~Bt)

In

case the machine is threaded previously

A$:w¥fB3J':!<ffl9~~litWffl~~~

JB!*,

Knot the preset thread and the thread being

used

together to thread the machine.

B$:

j;j-~Needle

¥J-~~Ji<Jj;f-~3J'i!J#!Iilltrfcf,

~'

~]l:;ilf3J'#~,

Trim

the knots off neatly before passing

through

the

C$:i'?;#~._t!ll'ftflj~

Looper thread,Top cover thread.

~-~¥J-~~Ii'l~*3¥:!<ffci.~m~n

~W~M!:I!f,

Trim

the knots off neatly after passing

through

the

eye

of

eye of

thread

the

needle to thread.

the

looper.

:®11(;:~

-11-

Page 14

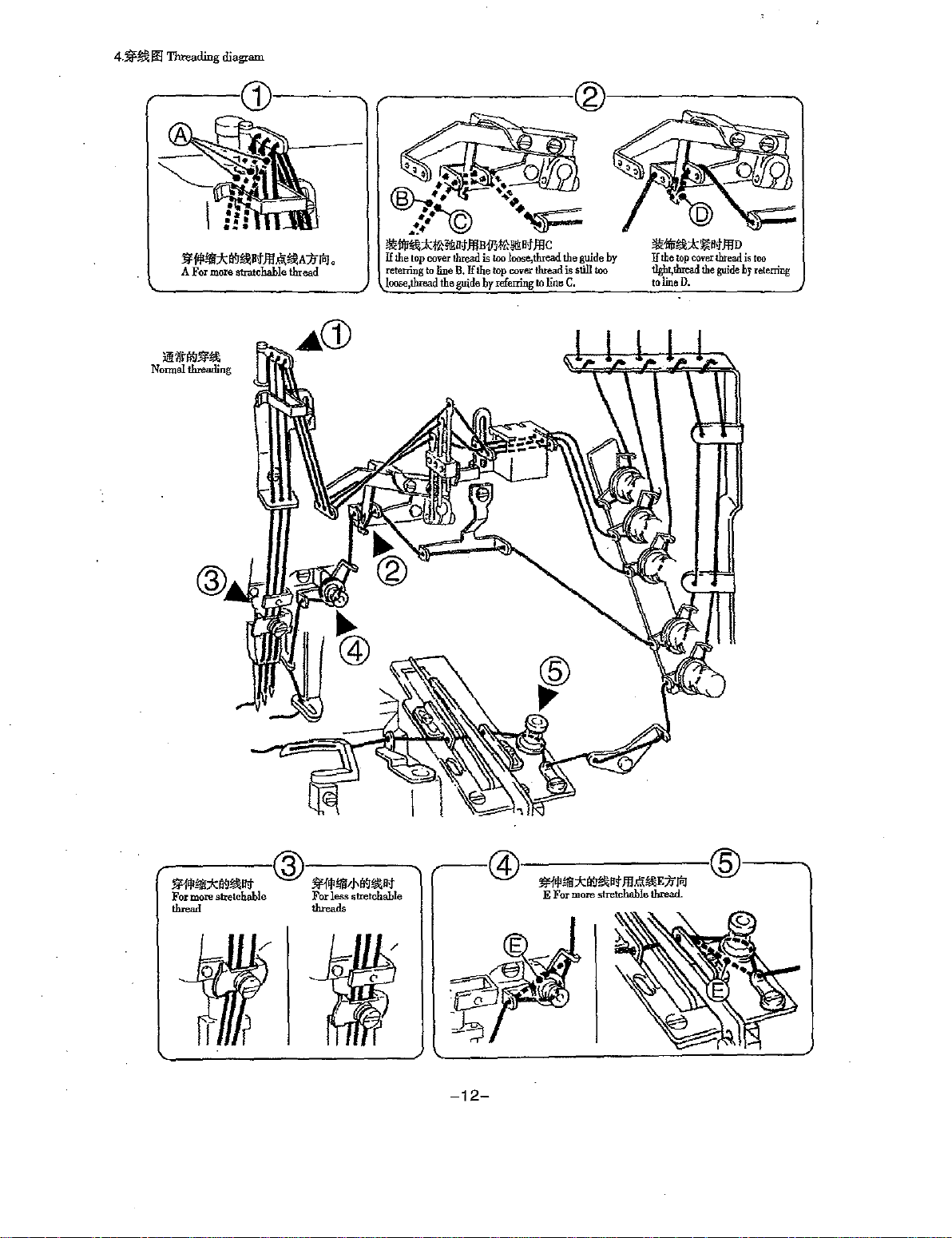

4.:lf~l'l'l

Threading diag<am

lii'fifl!iiH<:il'JAAP>t

A

For

more

stratchable

Jll.<\ii1!<A:tiill

thread

o

~---------~----------~

ll!;it;!11<;t~ll<tJllD

II

the

top

cover

thread

is

tlght,tbread

to

line

D.

the

guide

too

hy

retening

-12-

Page 15

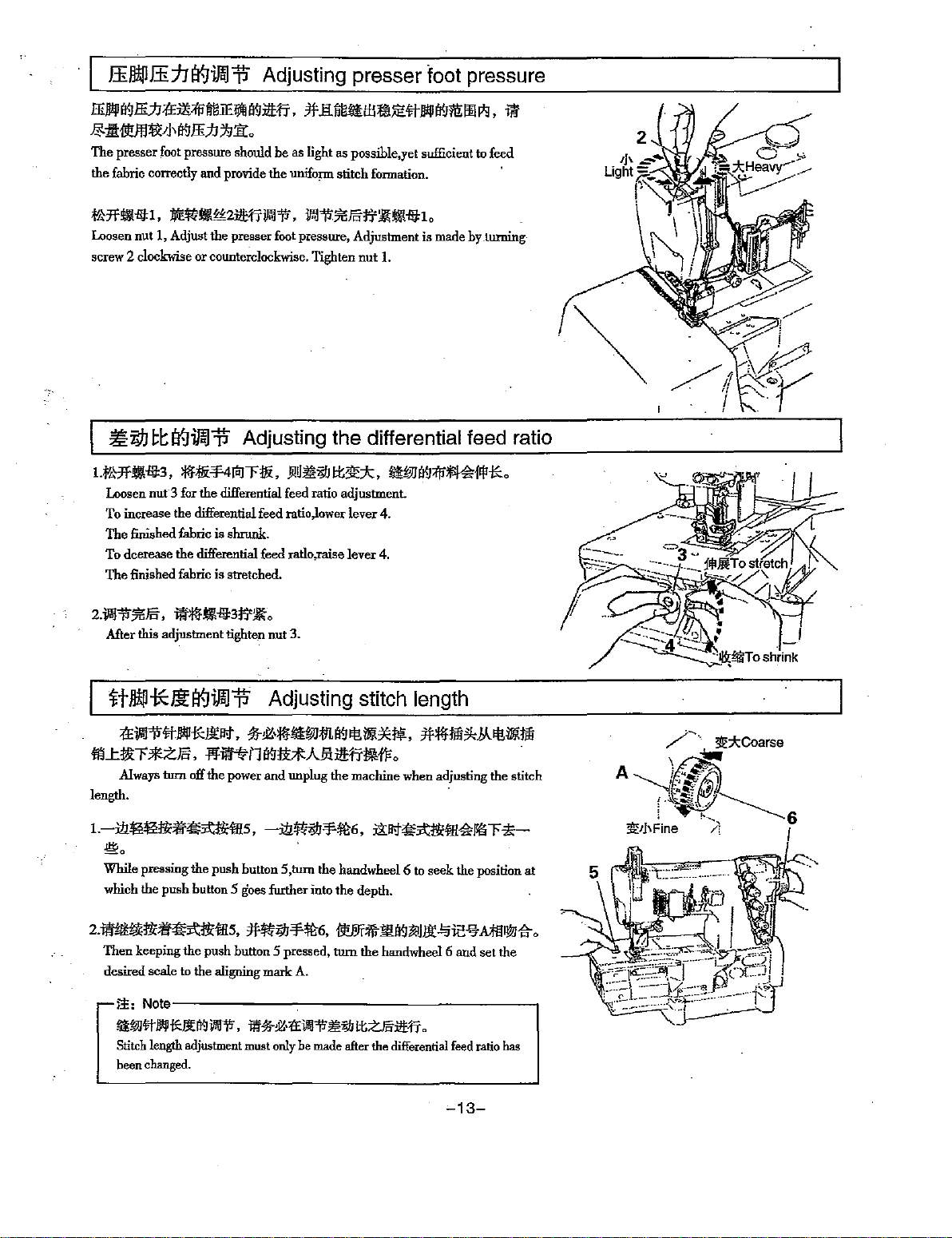

EE)l!;f!EE::fJI¥-Ji?ol:P

Adjusting presser foot pressure

ffi~~ffh~~~~~~~~~.*~~m~~~~~~oo~.~

..ey.

:l:fV!Jti(;j\

The

presser

the

fabric correctly

~

ffij:)

;h1!:.

foot pressure should

and

provide

he

as light

the

unifo~

as

possible,yet sufficient to

stitch

formation. '

feed

..

,.

tk7f!li1llol'

Loosen

screw 2 clockwise

~il!J

r.tk7f!ll1lio3,

Loosen

To

The

To

The

2.illl"'\'i%ii'f'

After this adjustment tighte.n

:M!~~~2JI!:~i/lill'i'

nut

1,

Adjust the presser foot pressure, Adjustment is made

or

counterclockwise. Tighten

tti¥-Ji?ol'P

Adjusting the differential feed ratio

:JIH1i-'¥4torFJ!i,

nut3

for

the

differential feed ratio adjustment.

i/lill'i%ii'f1'5'~'11!1!Jol,

Ji!tl£iill

increase the differential feed ratio ,lower lever 4.

finished fabric is shrunk.

dcerease

the

differential feed ratlo,.raise

finished fabric

is

stretched.

if:flf'll(1!Jo3j'j<~,

nut

3.

nut

1.

tt>Je:fc,

lever

4.

by

.turning

~w~~JIOI4l.'fljl*·

H)l!;fl*l!ti¥-Ji?ol"'W

~lll!l'i~~*jj;ilt,

m..t~r*Zii'f,

Always

length.

r.

-i11~~tl<31'~:<~:ruus,

.Jll.~i'1~'1tl:MJ£fflll'f!;.

tum

off

the

Adjusting stitch length

:%-~·:flfUi!L~I'!!M::X:l*,

power

and

unplug

the

machine

---iii~iill'¥~6,

*:flflm~.M..I'!!lllilm

when

adjusting

i:kllt~~4l.'JIIIr

®.

While pressing

which

the

2.ft~ti<31'~~W.5,

Then

keeping

desired

~:

Note-------,-------------,

~W$J"JI!Iiif:lli'l'J~l'",

Stitch length adjustment must only he made after the differential feed ratio has

been changed.

the

push

push

button 5 goes further into

the

push

button 5 pressed,

scale

to

the

aligning

button

5,tum

the

handwheel6

the

depth.

*~iill'¥~6,

mark

i!I':Jl-,g.:fE~l'"i!f!iJIJit:Ui~ff"

{iti!Jf~!I!~~Jjj;

tum

the

A.

to

seek

.!;;ie%Mil1Pi.Jii-

handwheel 6

the position

and

~13-

the

stitch

o~i:-

set

the

at

0

Page 16

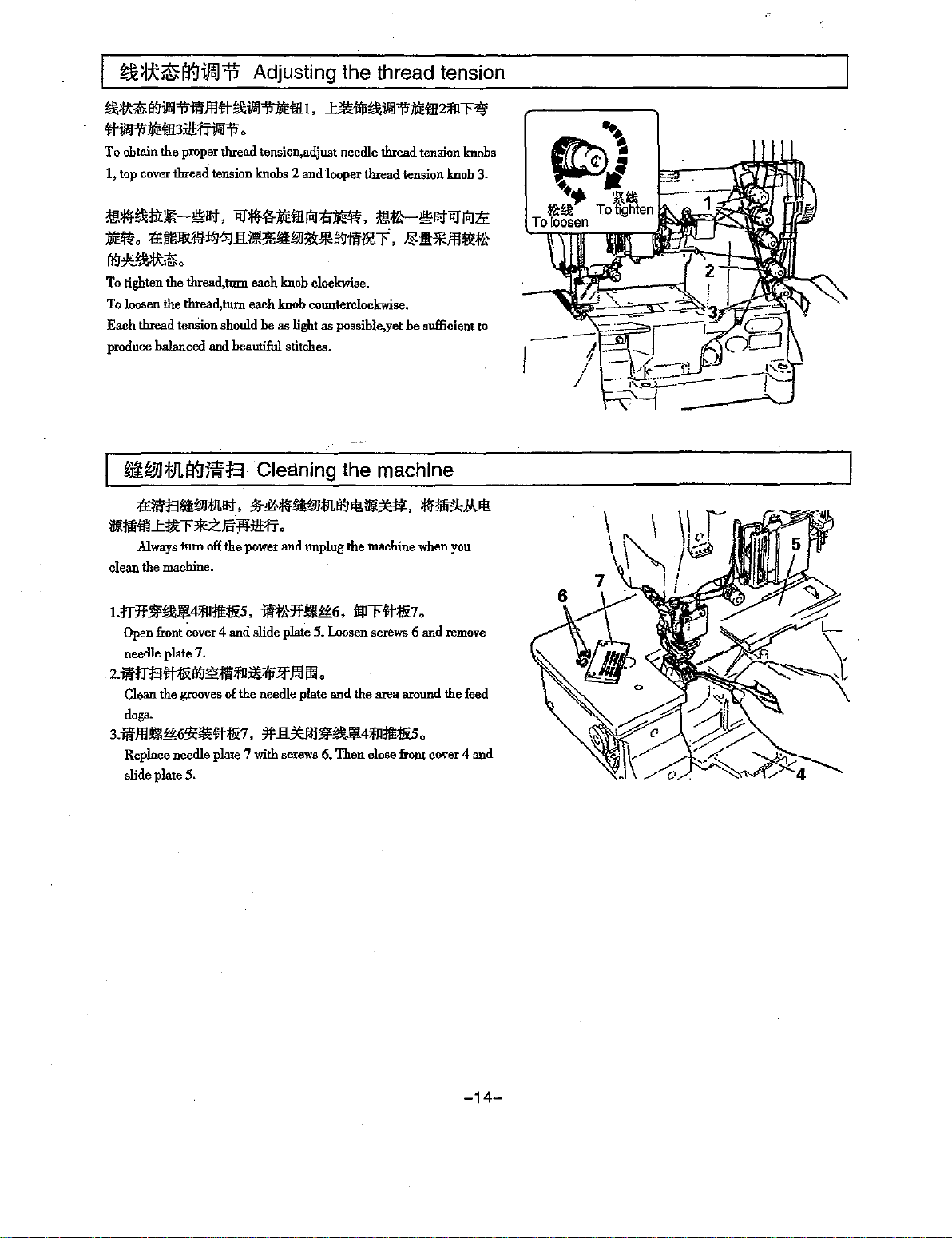

~~J;:~i'f.Jifol'P

Adjusting the thread tension

~>I!:~(I{Jilllll>ii!fll#~illll~ffil,

#illli1J~ffi3it!:ffi\\11J

To

obtain

the

proper

1, top cover

~*~~~-~~.~~~m~~~.~~~~~~~ft

thread

0

thread

tension

tension,adjust needle

knobs 2 and

L!ll'l1ili~illll~ffi2;IICF*

thread

tension

looper

thread

tension

knobs

knob

3.

~:.:-

~~

~

••

r.t!!

To

loosen

~~.~~~~~~~~~~(I{J~~T.~t*fll~~

(I{J~>Ii:~o

To

tighten the thread,turn each

To

loosen the

Each

produce balanced and beautiful stitches.

thread

thread,tum

tenSion

should

~~;f:JLI'f.J)Wt=l

~~~~~m~,*~*~m(I{J~~~w.~~R~

~JifimJ:tltf*Zii'f:jlj:1zH'f,

Always

turn

off the

clean

the

machine.

knob

cloekwise.

each

knob

counterclockwise.

he

as

light

as possihle,yet he sufficient

Cleaning the machine

power

and

unplug

the

machine

when-you

to

---

~I!

To

tighten

I.fl"'Jf~~·4fpf&;fi5'

Open

front

~ver

needle plate

2.

if/lTJ3#;f&(i{J'!i!li!lfll:i;lHfi

Clean

dogs.

3.Jff!l-~6'!i;ili€#;!&7,

Replace needle plate 7

slide plate

the

7.

grooves

5.

iilf'k'Jf!l~6,

4

and

slide

plate

Jf

)l!:l

Ill!

of

the

needle

plate

'If

l'!lkffl~~.\J4fp1!£;ji5o

with

screws 6. Then close

5.

Loosen

o

and

l!lff#;fi7 0

the

screws 6 and

area

around

front

remove

the

cover 4

feed

and

-14-

Page 17

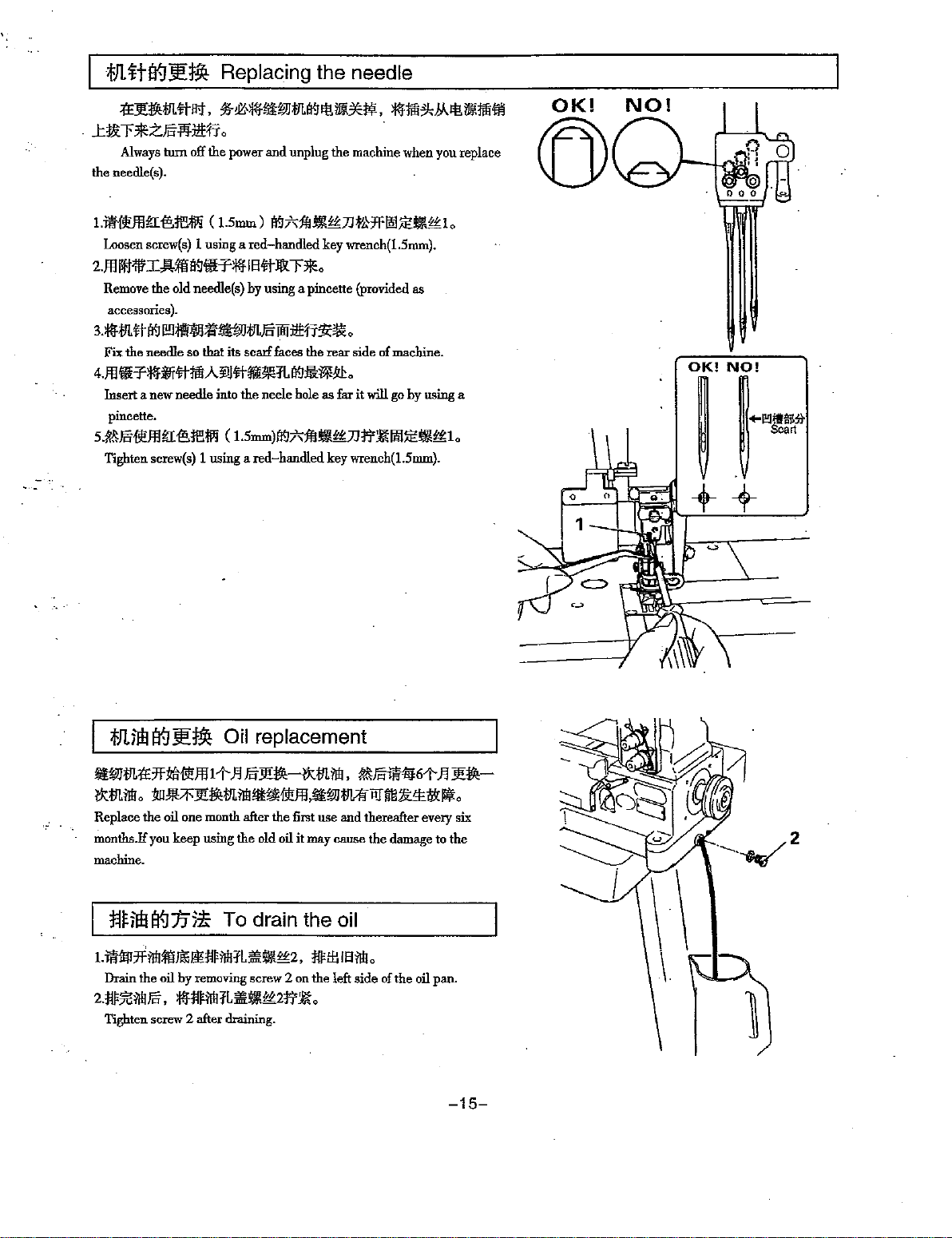

fMtW-J~~

Replacing the needle

:tE!l!l!RJJL<fta1'

J:~T*Z.FP:pj:J1t:il'

Always

tum

the needle(s).

J.~g[il\.1fi:flli

Loosen

screw(s) I using a red-handled

:%-1X,JW!ii~tll.(!9Jtl.ll!(:)'d>j1'

o

off the

power

and

unplug

the machine when

(

!.Smm)

(!9:t;Jfi.tll*JJ~Hf~iE~*Io

key

wrench(l.Smm).

JWl!ll:li;J,I.J{I.lJ!(l!llii!J

you

replace

OK!

CD

2.fflllft'I!'IJUfla9llii"lWIB#.llilT*o

Remove

3.lWtll.#a91!!lU.'I~MW:l1tfi':ti:illeo

Fix

Insert

s.~FPU~il\.1e:flli

Tighten

the

old

needle(s)

accessories).

the

needle

so

that

its scarl' faces the rear side

a

new

needle

into the

pincette.

(

l.Smm)l¥.J;>';ffdll!*JJJ'i'~~i£lill(*lo

screw(s) I using a red-handled

by

using a pincette

neele

hole as far

(provided

of

machine.

it

will go

key

wreoch(!.Smm).

as

by

using a

*ll111lW-J~~

l.iWtll.:tE7f:l!itill!ffli1-

l?ztll.lillo~~~tll.liii~U~~ey~~~-o

Replace the oil one

you

months.If

machine.

keep using the old oil

:t.I~1J:Ilf(.J:h5*

Ll#il1J7flill~miR!ti4Plill'fLlli<~*2,

Drain

the

oil

2JJp%li!IFP,

Tighten screw 2 after draining.

lW:II~illl1Llli<~*2ri'~o

Oil replacement

Jl

FP£~-l?ztll.lill,

month

after

the

To drain the

by

removing screw 2 on the

first

use

it

may

cause the

:liPlliiBlill

left

~~61-

and

thereafter every six

damage

oil

o

side

of

the oil pan.

Jl

to

£~

the

-15-

]

Page 18

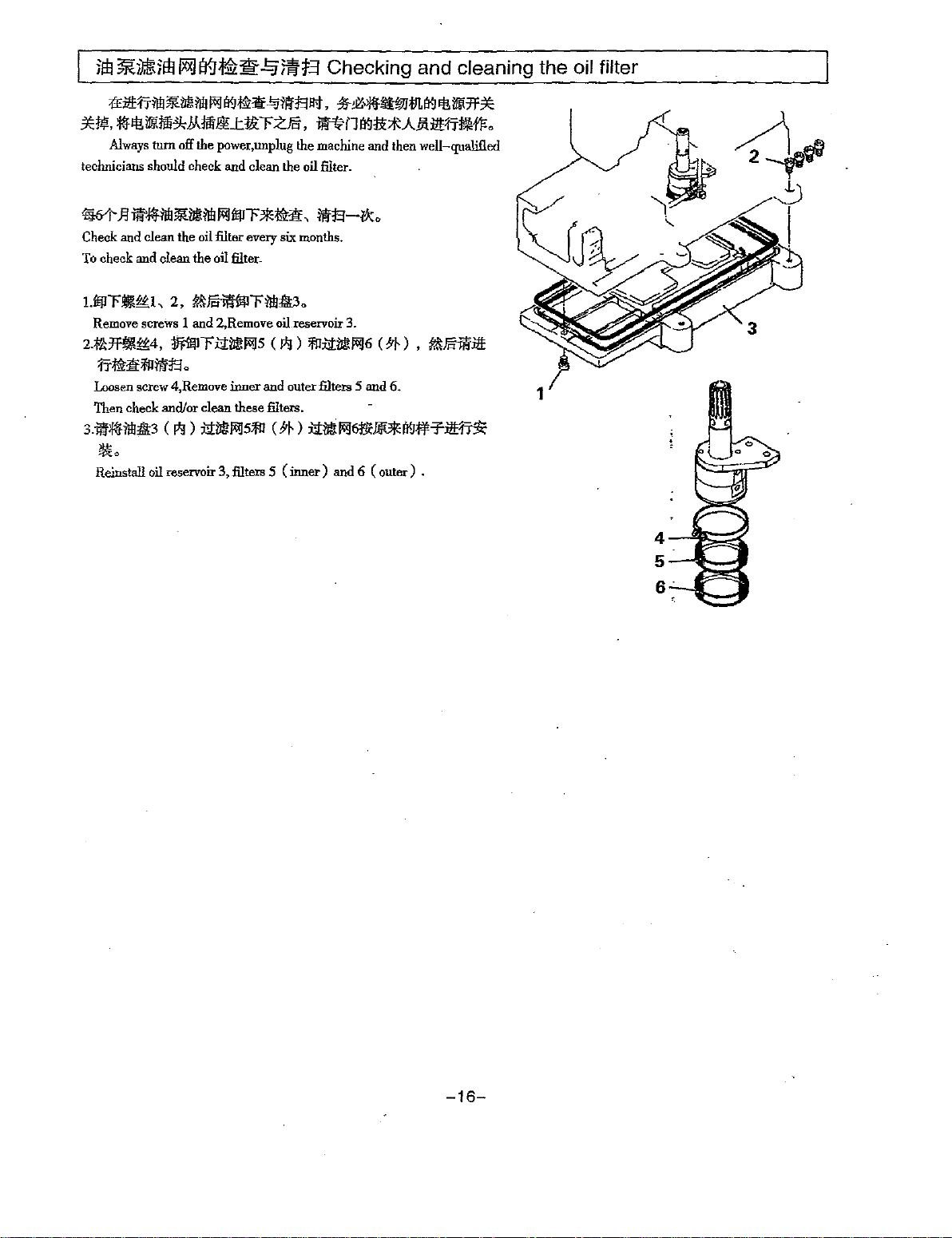

1fll*il:!R1flliXX.li¥JtiLi!l-~)W1.::J

~*fl$*~$~~&~~~E~.~~~~wm~~~*~

~;'ll!,

~~~li~l>UliELtt.ltrW,

Always

turn

off

the

power,unplug

technicians

should

check

and

clean

Checking

ftf1ii{J11i*A9l.it!:IT;flkfl'.

the

the

machine

oil

filter.

and

then

and

cleaning

well-qualified

the

oil filter

~~~*~*~~~~r*&~,~E-~.

Check

and

clean the oil filter every six

To

check and clean the oil filter-

months.

L~r'l!!££1,

Remove screws 1 and 2,Remove oil reservoir 3.

2-'**~££4,

rr~~ifll~E.

Loosen

Then check and/or clean these filters.

Hf*illtll3

2,

il:~r~:ll3.

jjf!ljlru~~s

screw

4,Remove inner

(

1*1)

J;;til!i~sifl!

and

<

I*J

>

ifl!uil!i~6

outer

filters 5

(

~~)

J;;tiJ!i~Gl'i<W-*ii{J:l'f-T~'ti:

!!!<.

Reinstall oil reservoir 3, filtenJ 5

(inner)

<

~~

> ,

and

6.

and 6 ( outer) -

il:~*

-16-

Page 19

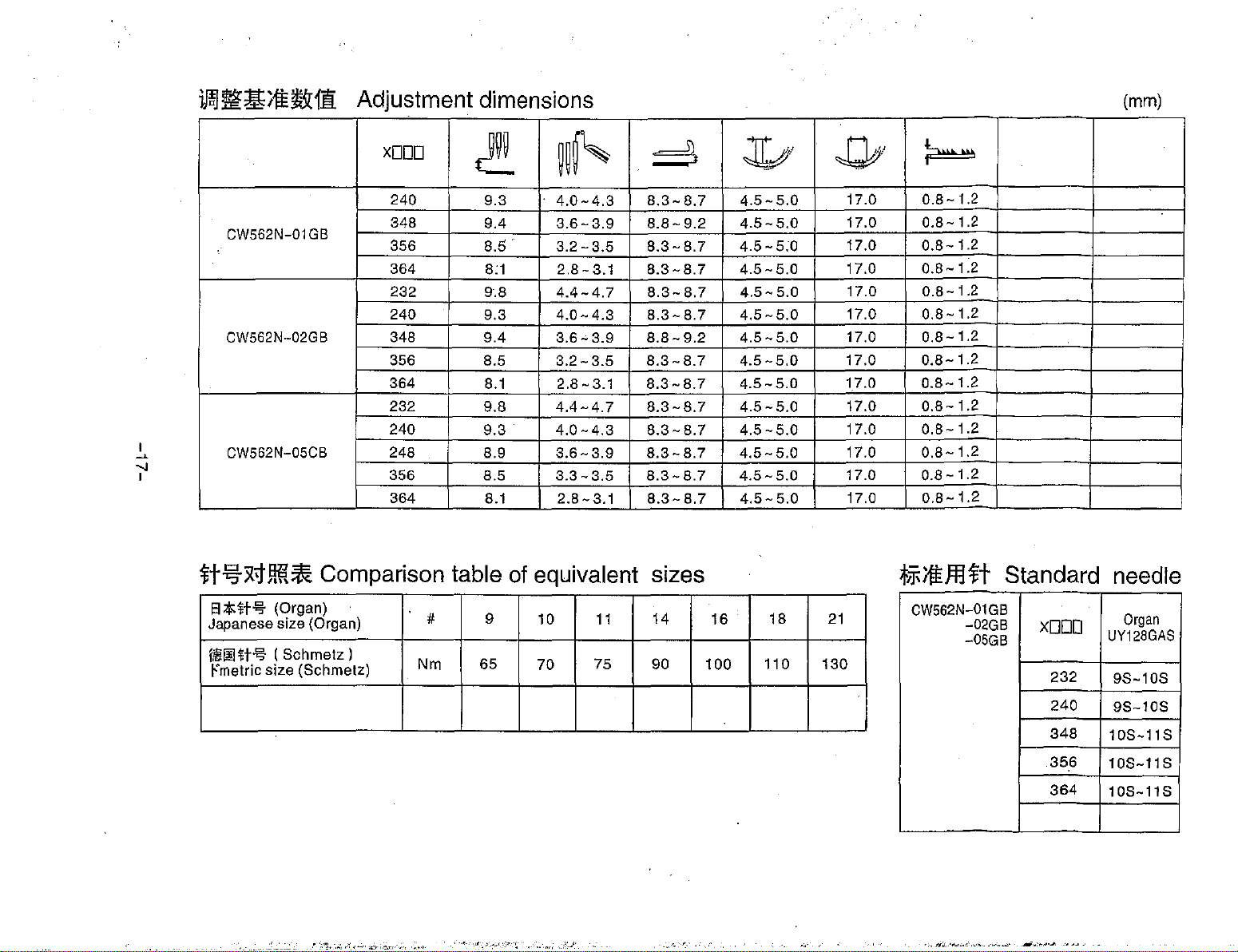

ilol!Jil¥1i~ii

Adjustment

dimensions

(mm)

~

-..j

xooo

t!

240

CW562N-01

CW562N-02GB

I

I

CW562N-05CB

H-9x;ffffi*

13:<is:*t-i%

Japanese size (Organ)

!ill~

tt-l%

rmetric size (Schmelz)

GB

Comparison

(Organ)

(Schmelz)

348

356

364

232

240

348

356

364

232

240

248

356

364

-

# 9

Nm

9.3

9.4

8.5

8:1

9.8

9.3

9.4

8.5

8.1

9.8

9.3

8.9

8.5

8.1

table

65

of

~i~

4.0-4.3

3.6-3.9

3.2-3.5

2.8-3.1

4.4-4.7

4.0-4.3

3.6-3.9

3.2-3.5

2.8-3.1

4.4-4.7

4.0-4.3

3.6-3.9

3.3-3.5

2.8-3.1

equivalent

10

70

_c__

11

75

___

~

8.3-8.7

8.8-9.2

8.3-8.7

8.3-8.7

8.3-8.7

8.3-8.7

8.8-9.2

8.3-8.7

8.3-8.7

8.3-8.7

8.3-8.7

8.3-8.7

8.3-8.7

8.3-8.7

sizes

14

90

.

16

100

~'

4.5-5.0

4.5-5.0

4.5-5.0

4.5-5.0

4.5-5.0

4.5-5.0

4.5-5.0

4.5-5.0

4.5-5.0

4.5-5.0

4.5-5.0

4.5-5.0

4.5-5.0

4.5-5.0

18

110

'

JJ;;!

17.0

17.0

17.0

17.0

17.0

17.0

17.0

17.0

17.0

17.0

17.0

17.0

17.0

17.0

21

130

.

~

0.8-1.2

0.8-

1.2

0.8-1.2

0.8-1.2

0.8-1.2

0.8-

1.2

0.8-1.2

0.8-1.2

0.8-1.2

0.8-

1.2

0.8-1.2

0.8-1.2

0.8-1.2

0.8-1.2

~li.ffilt

CW562N-01

Standard

GB

-02GB

-05GB

xooo

232

240

348

356

364

-

needle

Organ

UY128GAS

98-108

98-108

108-118

108-118

108-118

I

.,_._.,

__ , .,.

;o--_-~

•

'"""

·

..

·~

,;,.~.--

-"-~'-~~-·--

i;'j

·"n;v

.... -.•

'

·.·.·~---~*·-·

..r~o~,,_.

-••~

·

Page 20

CW500N

CWSOON

~~U

W\~IJTru~m*i~

CWSOON

CWSOON

Series

Series

subclass

specifications

~

00

........

~

Jll

~

.

Application

ili!;.<js;!ii

Versatile

I

I

~ill!ll

Binding

!I

:t:t<ill

:Ya

Aouching

elastic lace

*

~iW

tl:lil!Jll1 :1.3tLI:1!1,

It

you

use the machine

tape

'II€

*

- - - -

~

'l"m!~

Subclass

CW562N-01

CW562N-02GB

CW562N~05CB

with

GB

-·

i\1i1~

::titS1P3fmiiiJ:IIiltiE'I±3.2mm>;(

a differential feed ratio of more than 1:1.3 the main feed

I

tm

(:fl)

Number

of

needies

2

3

2

3

2

3

0

Mlll:

(;fl)

Number

of

threads

4

5

4

5

4

5

tHe(mm)

Needle

4.8

3.2.

4.8

3.2.

5.6.

H

space(mm)

• 5.6 •

• 5.6 • 6.4

4 4.4

6.4

4

4.

4.8

6.4

1',

~

!1:*:

ttJl!i!¥:

(mm)

Maxstilch

length

(mm)

4.4

4.4

4.4

4.4

4.4

dog

movement amount should

Ob

~ii!J~~

Diff feed tatio

0.5-1.3

0.5-

1.3

0.5-1.3

0.5-1.3

0.5-1.0

0.5-1.0

~

..L

ffiJI!i!11i7f-:ll

(mm)

Presser

foot

lift

(mm)

6.3

5

6.3

5

5.3

5

be

less than 3.2mm.

0

-~M£~ll:

(rpm)

Max

speed

(rpm)

6,000

6,000

6,000

6,000

5,500

5,500

~

1i

Remarks

tt/l!ilm:ot

Stitch type Net weight(head only)

lil!Jllfllltt

Needle size

!i!Hilfi!

-t(W

x D x H)

Machines

size(W x D x

H)

602, 605

UY128GAS

W:495mm

#98-#11

0:280mm H:414mm

S

'F:t.lll!1m:ll

.(;).a

:II

Gross

weight(with accessories)

llj~

Working noise level

41.5Kg

47.5Kg

n=5.400mm;

DIN 45635

LpA.;82.0dB

4BA-1

llllli

Page 21

•

itt:

..

flf}

PARTS LIST

-19-

. I

Page 22

-,

tJL~~t1;!(1)

MACHINE BED FRAME

(1)

-20-

-):)~·

(...

1

19

Page 23

,

*Jl.7'l:~#il(1)

1¥-liJ-

REF.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

.

16

17

18

19

{'t

%

PART

NO

50010001

50010002

50010003

50010004

50010005

50010006

50010007

50010008

50010009

50010010

35.1-23

10.1-40

50010011

50010012

50010013

50010014

50010015

50010016

MACHINE BED FRAME (1)

m~~fJ"

lill:l!U~:iKll

fflffi4l!l!i'ilill~

t!L:!klill~

1f!ll!lill~

#;ffll!i~~fLlill~

Jl;jfL~I!!I

:l:tilt1WJ

Jffi~i!i

Jffiililli.~fJ

.==::ifl%i1;lil::jij<~

~fJ

tf;R:jij<~

~#~;/J~i!i

~#H~lill'!&

#Be~

#JI€ifirui<Wit'l&

#JI€ifirui<~fJ

ll'!%.1!$

11

DESCRIPTION

SHOULDER

OIL

LEVE

PLUG

PLUG

PLUG

PLUG

RETAINING

FILTER

COVER

SCREW

CAUTION

PIN

STICKER

TOP

COVETR

GASKET

TOP

CPVER

GASKET

BOLT

$

PIN

LGAUGE

RING

LABEL

(RIGHT)

PLATE

(LEFT)

f<:ll:

QTY

4

I

I

5

3

I

3

3

I

2

I

2

1

I

I

1

I

8

I

-21-

Page 24

::.,

*ll7le~#i!(2)

4

MACHINE BED FRAME (2)

\@

-22-

Page 25

_,

1JL~Hi1iti;J(2)

MACHINE BED FRAME

(2)

!¥%

REF.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

%

14

PART

NO

50020001

50020002

50020003

50020004

50020005

50020006

50020007

50020008

50020009

50020010

50020011

50020012

50020013

50020014

50020015

50020016

50020017

50020018

50020019

50020020

50020021

50020022

50020023

50020024

50020025

50020026

50020027

50020028

50020029

50020030

50021000

-'~';

DESCRIPTION

Jlii;fli.

llii11i.il!!#~tr

Jlii;fli.\ll'#l!>l

l::l'it~tr

llii11i.il!!#~tr\ll'#i!

J::l'i[;fli.

l::l'itf/.3:Jk

ll!lfl!lr&

J::l'it\ll'#l!>l

jj~Jll:flP

l:J!KAA.\:Il~tr

iiAAill:flP

J!KAA

Ji.\;J1AA.\ll-11i.

J!l'ii?J:Il

J!l'ii?J:Il~tr

Jil;;l;ttllli~tt

~AAJ:Il~'lil:

~AAJ:Il~'lil:~tr

§ltll-'ll:'l<ll!t~fr

~AAJ:Illilf~llll

lilf:IP.\1!1.

lilf:IPJ;~tr

lilfJFl:llml!>l

lilfJFJ:IlU

lilfJF.\1!!.Y.:~Umlf!l

lilf:IPJ:Il~~~tr

lilfJF~~

lilfJFl;'ltll!t~tr

llli:IPJ:Il'ltll!t~trml!>l

~AA';11&.#

J:ll

~

lilf:IP

.!ll~fr

ARM

SCREW

0

RlNG

SCREW

WASHER

AR1v!

PLUG

OIL

SIGHT

0

RlNG

NEEDLE

SCREW

BARCKET

SCREW

LOOPER

PULLER

SCREW

SCREW

FLAT

SCREW

SCREW

CUSHION

EYE

GUARD

SCREW

WASHER

BRACKET

WASHER

SCREW

BRACKET

SCREW

WASHER

FRONT

COVER

COVER

BAR

TIIREAD

COVER

SPRING

COVER

f'-"

(LEFI')

(TOP)

WlNDOW

GUARD

GUIDE

COVER

~:lit

QTY

1

1

1

11

1

1

1

1

1

1

3

1

1

1

1

2

1

1

2

2

2

1

2

2

1

1

1

1

2

2

1

-23-

Page 26

=.,

1Jl~~1~(3)

MACHINE BED FRAME

(3)

-24-

Page 27

_,

*J1.?1Hi1it1il(3)

1¥%

REF.

1'1'

PART

-!}

NO

MACHINE BED FRAME

-

4;

DESCRIPTION

(3)

f}j;

~:li!:

Q1Y

50020004

I

50030001

2

3

10

11

12

13

14

15

16

17

18

19

20

50030002

50030003

4

50030004

5

50031000

6

50031001

7

8 50021006

9 50031002

50031003

50020029

50020021

50030005

50030006

50020011

50030007

50020019

50020017

50031004

50031005

!rHnlil~~~

!iiil'llil~iff.*~~

!iiil'Li:~

!iiil'ti'a

Jt~W.f'l'

Li:fl!~.\fi.W.

Li:1l!~~'i!<~J!J'lU.~~

Li:1l!~JJ'i!C~..t~~!l;F/ll

Li:1l!JJ-'I<~l£Hl~~

li!<iili*~~

'i!<M~

1'1'

llil-'1<1!40

~-l!j:

llli~~

llliJ!I<~~~

llillli~lli!-

llillli~lli!·~~

1ltrJli}Ej}[~~

Li:1l!JJ-'Il'i!<iii~

Li:-'11~

SCREW

SCREW

BFD

COVER(LEIT)

BFD

COVER(RIGIIT)

COVER

SIDE

COVER

SCREW

SPRING

PIN

SCREW

SCREW

CUSHON

NUT

BRACKLT

SCREW·

FLAT

SPRING

SCREW

SCREW

LINK

COVER

COVER(LEIT)

ASSY

6

I

I

I

I

I

1

4

I

2

3

2

1

I

2

1

2

1

1

1

-25-

Page 28

lm,

l'::E.~-ffl"i>!JtJHt.l

CRANK SHAFT DRIVE MECHANISM

-26-

Page 29

ll!l,

l'::E$1111~7JJ~M~

0

!¥-'%

REF.

1

2 50041000

3 50020004

4

5 50040003

6 50040004

7

8 50040006

9

10 50042000

11

12 50043000

13

14 50045000

15 50040008

16 50040009

17

18 50040011

19

20

21 50040014

22

23 50040016

24

25 50040018

26 50040019

27 50040020

#

7

PART

NO

50040001

50040002

50040005

50040007

50042002

50044000

50040010

50040012

50040013

50040015

50040017

CRANK SHAFT DRIVE MECHANISM

"f;llli~Ul'~

~#:i!i'FW.#

~#Ji;f'fj!~~tr

JOJ<d!i;Ji'j

JOJ<d!i;Ji'J~tr

JOJ<d!i;Ji'l~;;E~tr

*~~

li*~~;;E{]l~tf

~tr

"F~<P=WEim#

Om'

!II

lll!1iUili'fm1't

.:t;tJJjlj~'IIH&m#

r1ll!m:f<t~m#

lli~ml

lli~J;f~tf

J!l'lll'~

J,I..;IJ~~:<E~tr

J,I..;IJ~;;E{]l~tf

J>'..iW~!I!Illl

RiW~mm~m:<E~tr

Hlimll"1ll!

Jjlj~'lJl'

"F1ll!lll!:li!:lftlll"ilr#

J(_(:J

J(_(:J~tf

tf(:Jmm~

~

DESCRIPTION

1'$

CRANK

SHAFf

CONNECTION

SCREW

CRANK

BOLT

SCREW

JOINT

SCREW

SCREW

BUSHING

0

RING

BUSHING

GEAR

(LOWER)

BUSHING

COVER

SCREW

MACHINE

PULLER

SCREW

SCREW

WASHER

BOLT

SHAFf

T!MlNG

ADJUSTING

BELT

BAR

GUIDE

SCREW

WASHER

ASSY

ASSY

~:!i!:

QTY

1

1

4

1

1

1

1

2

12

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

-27-

Page 30

-28-

Page 31

Ji,

...t.:E~ill1t7;JJ*M~

fi'-1}

REF.

I 50051000

2 50051002

3 50051003

4

5

6

7 50050004

8

9

10 50050005

11

12

13 50040006

14

15

16 50050007

17

18

19

20

21

22

23

24

25

26

f'f

%

PART

NO

50050001

50050002

50050003

50052000

50020004.

50040003

50040005

50040007

50050006

50053000

50050009

50054000

50050010

50040011

50040012

50050011

I. 50050012

50050008

50050013

ARM

SHAFT MECHANISM

1'J

tr:ffilli1Wmf'f

#:ffilli1W'k'tm!lmu

#:ffilllm~'k't!lmu

iEill!lmu

.!l:.i#J!lmu

-LH!E~Em~u

..t1llni1rililll~

..t~ii:ffmf'f

li:ffJiMJ

..tjj];~:£Jtilli1W

:£Jtilli1W!lmu

Jl)(~~

~~iEill~u

~-n

-'1'-fl

..t-'f-~:!jl;!lmU

..t1l!nru=Wfl.:m

f'f

./A.i#JI!;J"!JMt

~#;f!;m.f'f

'¥4t

..t4t'k't~u

..t4l!JEifi:J:I(-B

..t4tlilll"'

..t~•-n

..t~~l>

..t~'Pl>

DESCRIPI'ION

MOTION

SCREW

SCREW

SCREW

SCREW

SCREW

CRANK

CONNECTION

SCREW

CRANK

BOLT

JOINT

SCREW

SCREW

BALANCE

SCREW

BUSHING

GEAR

BUSHING

HAND

SCREW

SCREW

WASHER

SCREW

SHAFT

SHAFT

ASSY

SHAFT

ASSY

(UPPER)

WHEEL

:m:

ASSY

WEIGHT

~:i:

QTY

I

I

2

I

I

I

1

1

4

1

1

1

2

10

1

2

1

1

1

1

1

1

1

1

I

1

-29-

Page 32

/,,

H*'f~j!jfj;_J

NEEDLE BAR MECHANISM

-30-

Page 33

H:ff~Ei:ft.l

!¥'-'%

REF.

I 5006000I

2

3

4

5

6

7

8

9

10 50020029

11

I2

13

I4

I5

16

17

18

I9

20

2I

22

23

{'/'

PART

50060002

50060003

50060004

50060005

50060006

50060007

50060008

50060009

50020004

50060011

50060012

50060013

500600I4

500600I5

50060016

500600I7

50020011

50040009

500600I8

500600I9

50060020

NEEDLE BAR MECHANISM

-'%

NO

~:f'f

~~9<

~:f'fruk~w

~:f'fi!:f'f

~:f'fi!mm

/!!~ill!~

#1'fl!:f'fml!

#:f'fl!\'~

#:f'fl!i'M

•u

#:f'fl!i'~&!imu

ilflfBJE{ii:[ij

ilfl'§;

#~

#~!!miT

~:I&

#Uu

#:!&~:!&

~:!&MIT

#Umr!imu

ll!iii¥

#:f'filfl~

#:f'f.l:~ilfl~~9<

~

DESCRIPTION

NEEDLE

NEEDLE

SCREW

LINK/NEEDLE

PIN

NEEDLE

WASHER

BWCK

SCREW

SCREW

LATCH

SPONGE

NEEDLE

SCREW

NEEDLE

SCREW

BRACKET

SCREW

SCREW

GUIDE

BWCKINEEDLE

CUSHION

OIL

WICK

OIL

WICK

$

BAR·

BAR

CLAMP

BAR

BEARING

HOLDER

PLATE

RUBBER

RETAINER

DRIVE

BAR

M

QTY

I

I

I

I

I

I

I

I

I

I

2

I

I

I

3

I

2

I

2

I

I

I

I

-31-

Page 34

--t,

{:ii!Jtffl.;f:tj

.NEEDLE GUARD MECHANISM

-32-

Page 35

-t,

!¥%

REF.

I

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

f*iHJLtt.l

{'f

%

PART

NO

50071000

50070001

50072000

50020004

50031004

50070003

50070004

50070005

50070006

50070007

50070008

50070009

50070010

50070011

50070012

50040014

50070013

50070014

50070015

50070016

50070017

50070018

50070019

50042002

NEEDLE GUARD MECHANISM

1'i

DESCRIPTION

Ffdrtmftm#

r~ooort~~~

1Jilfl-lt:ff@.{'f

i'il~lt:ff~~

i'ilfl-lt:ff~~~~

i'ilfl-il!Jil'l

i'il~il!Jil'l~~

i'il~il!!il'lfW

i'ilfl-~

i'ilfl-~i!l!~

ill!~

*~~fill!'ll

i'il~~Jfr:JJ~I!'ll

*~~1t$'il/ltii!l!l!'ll

i'il~lli

1Jil~lli~~

1Jil~lliflll!'ll

pgjJjlfl-~~

Foi'il~

iltri'il~

?'HJil~~~

*~~2!:~

*~~tl~

Ol!1il!'ll

ECCENTIUC

SCREW

CONNECTION

SCREW

SCREW

CRANK

SCREW

PIN

SHAFf

FELT

OIL

WICK

WASHER

RING

OIL

SEAL

LEVER

BOLT

WASHER

SCREW

NEEDLE

NEEDLE

SCREW

BUSHING

BUSHING

ORING

f;l:

ASS¥

ASSY

(REAR)

(FRON1)

(LEFT)

(RIGHT)

ASSY

ti

QTY

1

2

1

2

1

1

2

1

I

3

I

I

I

I

I

I

I

I

I

I

I

I

I

1

-33-

Page 36

J\.,

~Htll#il

LOOPER DRIVE MECHANISM

15

-34-

1

Page 37

J\.,

~iHJl#il

)¥-!;}

REF.

I

2

3

4

5

6

7

8

9

10

II

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

-!;}

#

PART

NO

50080001

50080002

50080003

50050012

50070013

50080004

50080005

50080006

50080007

50070001

50081000

50020004

50080008

50080009

50080010

50080011

50080012

50080013

50080014

50080015

50080016

50070004

50080017

50080018

50070010

50070009

LOOPER DRIVE MECHANISM

,g

DESCRIPTION

')f#

'llf#illlifi

'lftt~-rr

'lf#illlifi~-rr

.!1:11EmJt

~#!l!l:jfljillif1H~-rr

~#~JlJii!l!ll

i!lf#~

i!iH.'6~

6~~-rr

i!lf#Jt:f'H!I.

Jtff~-rr

T~M:!ik:

T~"'"~:!ik:~-rr

~#ifflllrm:ff

~#i!lillrtt

~#ifflllrttmll

~-llF

i!)f#JlJj.J!::f!j~

l'lf#ifflllr~ll

-!!M,,~Jm

~~m~-rr

illillrtt~-llF

'llf#ifflllrm~

m~JFo11'!mJ

#

l'li'#il!llrm:ffmil

LOOPER

LOOPER

SCREW

BOLT

WASHER

SCREW

OIL

SEAL

SHAFT

ECCENTRIC

SCREW

CONNECTION

SCREW

BALANCE

SCREW

CRANK

SCREW

WASHER

NUT

BLOCK

WASHER

COLLAR

SCREW

NUT

SHAFT

RING

WASHER

:fil;

HOLDER

ASSY

ASSY

WEIGHT

PIN

ASSY

u

./

QTY

I

I

I

I

I

I

I

I

I

3

I

2

. I

2

I

I

I

I

I

I

I

I

I

I

I

1

-35-

Page 38

11..,

~:(j];j;JH~

FEED MECHANISM

-36-

Page 39

n, *:filfMi.J FEED MECHANISM

rt~

REF.

1

2

3

4

5

6

7

8

9

!0

11

12

.

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

~

f'l'

PART

NO

50090001

50090002

50090003

50090004

50090005

50090006

50070001

50090007

50090008

50090009

500900!0

50090011

50090012

50090013

50090014

50090015

50090016

50090017

50020029

50090018

50090019

50090020

50090021

50090022

50090023

50090024

50090025

50090026

50090027

50090028

50090029

50050007

50090030

50090031

50090032

50090033

50090034

50090035

50090036

50090037

50090038

50090039

*0$>-f$1:!

:3:=:*0$>-f

>-F$\:!~tr

£lSIJ3.F$1:!

£lSIJ*'$>-F

i\1;{.-~'i:

:t~lllm~~tr

>.f$1:!{\l;,r,,m

1\l;,t_,~'i:~tr

>-F~~~

ill;,t.,mllm

1\l;'(}~~tr

>-F$\:!:tli!N.m~

>-f$\:!J:i!N.{JL~

i!N.{JL~~tr

IDC!I!Jf

m~

li:i!N.Ul~

li:i!N.ilLUtr

~#~~

>.F$\:!llfi~~

*'"'~;ffmll!l

*'"'·~;ff

~#~~

8~

:l!O$i!.!.ll>8$R

#lll!i!.!J'i:

fifJ~tr

IDI!ll'ii'lll~llm

ili!Mli

8~~1li!~~

ili!Mli~~~tr

*'"'~~~~~tr

*'"'~~

*'"'~~

~§.it

~~

~~~tr

:l!O$~;ffM'i:

:JfPJ§Il!l

£lSil*O$~;ff

#JIP::ft<!BI

~

DESCRIPTION

1$

MAIN

FEED

BAR

MAIN

FEED

DOG

SCREW

DIFFERNTIAL

DIFFERNTIAL

BUSIDNG

SCREW

ECCENTillC

SCREW

BLOCK/FEED

WASHER

SCREW

GUIDE(RIGHT)

GUIDE(LEFI')

SCREW

OIL

SHIEW

COVER

PLATE(LEFI')

SCREW

NEEDLE

BLOCK

WASHER

UNKIMAIN

NEEDLE

ECCENTillC

REGULATOR

ECCENTillC

SCREW

SPRll'IG

SPACER

NUT

SCREW

SCREW

BUSIDNG

GUIDE

WASHER

NUT

SCREW

BUSIDNG

Rll'IG

UNK/DIFFERENTIAL

Pll'l

FEED

FEED

Pll'l

BAR

BEARING

FEED

BEARING

RETAINER

BLOCK

BAR

DOG

GUIDE

FEED

.l&:il:

QTY

I

I

2

1

I

I

4

I

1

1

I

1

1

I

2

2

I

I

2

I

I

I

1

1

1

1

1

1

5

1

1

1

1

1

1

2

2

1

1

1

1

1

-37-

Page 40

Jr.,

~1'i11Mt)

!¥%

REF.

I

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

{'/'

-'%

PART

NO

50090040

50090041

50050011

50090042

50090043

50090044

50091000

50070017

50090045

50090046

50090047

50090048