Page 1

~.JIE!I:

dl

IITGH

SPEED CYLINDER

OPERATION MANUAL

BED

INTERLOCK SEWING MACHINE

PARTS

woo

ZOJE

·

WJ

SEWING

r

mmnmtRJ§iBI~61

BOOK

MACHINE

CO

., L TO

.

Page 2

:*~m~~~~·~~m~~.

:

The

description

:

commodity

covered

without

notice.

~7~~1-~m~a~~~~.

in

this

operation

manual

and

. I .

parts

~~~~~.

book

is

subject

to

change

for

improvement

of

the

Page 3

General Safety Instructions

Warning

1

risk of fire, electric shock and personal injury, including the following.

1

Read

1.

Keep work

2.

Consider work area environment.

3.

Guard against electric shock. ·

4.

Keep

5.

Dress properly.

6,

Do

7.

Maintain machine

a.

Disconnect machine

9.

Avoid

1

10.

Check damaged

11.

Warning.

!

When

using this machine, basic safety

precautl~ns

all these instructions before operating this product

area

clean.

Cluttered areas

Do

not expose power to

well

lit. Dot not

Avoid boby contact

and

benches invite Injuries.

rain.

Do

not

use

power tools where there

with

earthed or grounded surfaces {e.g.plpes, radiators,

use

machine tools

Is

risk

children away

Do not

Do

corering

let visitors touch the tool or extension

not wear loose clothing or jewelry, they

to

contain

long

hair.

code.

can

not abuse the cord.

by

cord

or

Never carry the machine

from heat, oil

and

sharp edges.

with

care.

Follow instructions for lubrication

damaged have it repaired by

When

not

in

use,

before servicing and

yank it to disconnect it from

and

changing accessories. Inspect tool cord periodically

an

authorized serviced facility.

when

changing accessories.

unintentional starting.

Do

not carry a plugged -

in

tool

with

a finger

on

parts.

Before further

determine that it will operate properly

The

use

use

of the

tool,

a guard

or

other part that is

and

perform its Intended function.

of any accessory or attachment, other than thosa

and

save thesa instructions.

to

be

caught

the

switch.

may present a risk of personal Injury.

should always

In

damp

or

be

followed

wet locations,

Keep

cause fire or explosion.

ranges

In

moving parts. Wear protecting hair.

the

socket,

Ensure

damaged

switch

should

recommended

In

Is

be

this

Keep

off

when

carefully

Instruction

to

reduce

work

area

refrigerators).

the

cord

away

and

plugging

checked

manual,

the

if

in.

to

'

12.

Have your tool repaired by qualified person.

.out

Repairs should only be carried

by qualified persons using original spare

• Special Waning For Electric Connection I

1.1ncorporate

1 2.Follow the instruction manual device to install controc device.

3.Aiways

4.Before adjustment, parts change or

this machine only

earth

machine appropriately during operation.

with

"CE"

certificate

servicing must

hold-

be

sure

to-

run

control device.

to pull out the plug

hazard of unintentionally start of machine.

.

II

.

from

parts.

socket to

prevent

the

Page 4

.•

..;

·,::--;

I •

-;

..

•' . ',•

•'

• I

," • ..,·

r:,,

. . - -

'

1

I

~~-

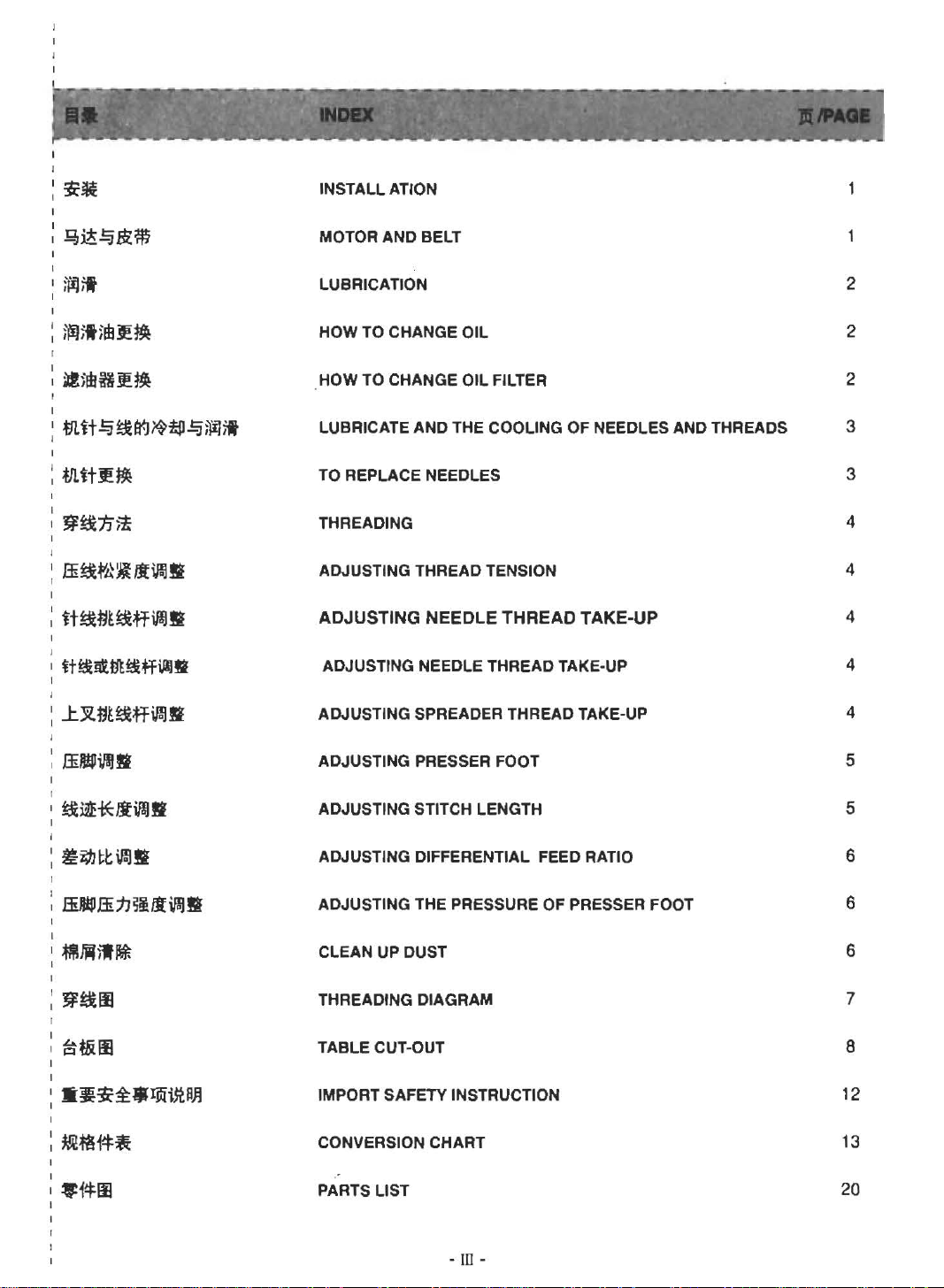

:!?li!~Bi::m

I

I

)IIJ;j

I

:

)lil;fjfBJ!~

I

l~j!bft£~

I

mtt~~a9~~~illlii

I

:

Vl.ttJ!~

I

~~'1J1"!

I

I

I

ffi~f'a~

I

I

:

tt~n~~ffVll!!l

I

l

ttt£~t1tt!ff\fllf!

I

JlVIl!!l

INSTALLATION

MOTOR AND BELT

LUBRICATION

HOW TO CHANGE

HOW TO CHANGE OIL FILTER

LUBRICATE

TO REPLACE NEEDLES

THREADING

ADJUSTING THREAD TENSION

ADJUSTING

ADJUSTING NEEDLE THREAD TAKE-UP

OIL

AND

THE COOLING OF NEEDLES AND THREADS

NEEDLE

THREAD

TAKE-UP

2

2

2

3

3

4

4

4

4

:

J:.>Z.n~~ff\P.l!!l

:

ffiii!P~!!l

I

~~~*llVll!!l

I

I

:

~~~t\P.l!t

:

lUll

ffi

jJ

~!!

Jl

I

I

~-~iJ~

I

:

~t£11J

I

I

~

~t&IIJ

I

:

•~~i:•~·u~aJJ

:

~t~H*Jt

I

l•t-t!IJ

I

VI).

ADJUSTING SPREADER THREAD TAKE-UP

ADJUSTING PRESSER FOOT

ADJUSTING STITCH LENGTH

ADJUSTING DIFFERENTIAL FEED RATIO

ADJUSTING THE PRESSURE OF PRESSER FOOT

CLEAN

THREADING DIAGRAM

TABLE CUT-OUT

IMPORT SAFETY INSTRUCTION

CONVERSION CHART

PARTS LIST

UP

DUST

4

5

5

6

6

6

7

8

12

13

20

- Ill -

Page 5

I

~.~*~HIIff~~tltl~J[I)&•#ta~l:llJiJT?JJzJR

i!J:.

~"':ti~~-tJ!.Ji.

~~-

.

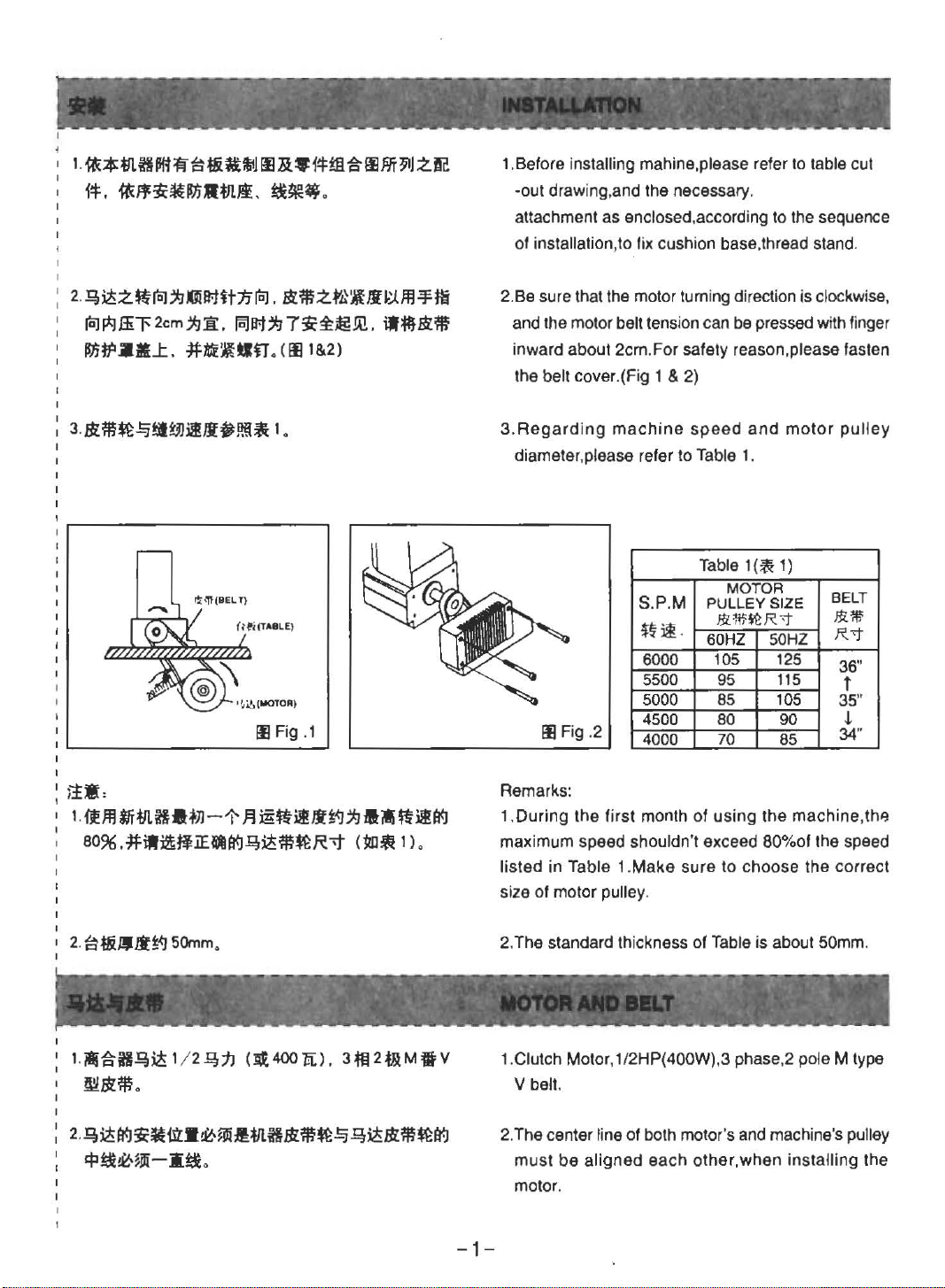

1.Before installing mahine,please refer to table cut

-out drawing,and the necessary.

attachment as enclosed,according to the sequence

installation, to fix cushion base,thread stand.

of

I

2.:£6~z~r'DI~o~t-ttt1iicl.

ial~ffi~~m~R.~IM~7:ti~~m.~~m:m

~~~M..t.

~UUUifT.

m:mzt'J}~JI~~FI'I"¥tti

Clllt&2)

[I)

Fig

.1

2.Be sure that the motor turning direction is clockwise,

3.Regarding

Remarks:

1.During

maximum speed shouldn't exceed 80%of the speed

listed

size

and the motor

inward about 2cm. For safety reason

the

belt cover.(Fig 1 & 2)

diameter,ptease refer to Table

bell tension can be pressed with finger

machine

S.P.M

nl.f.

speed

and

1.

Table

1(~

MOTOR

PULLEY

J:ti'ffH~R.'t

60HZ

SIZE

50HZ

6000 105

5500 95

Ill Fig .2

the

in Table

of

motor pulley.

first

month

1.Make

5000

4500

4000

of

sure

85

80

70

using

to

choose

the

,please fasten

motor

1)

pulley

BELT

J:ti'lll'

R.'t

125

115

105

90

85

36"

t

35"

J.

34"

machine,thP.

the correct

1 2.

~tl~li!-<J

I.J!~il:f6~1/2:£6:h

50mm.

Mm:m.

2.

:£6

~

a<J:ti•Ut•!0~~m

'fl~!0~:M-

-~.

(~400a).

H&m~~

3.f02tHM.V

~~&m~a<J

2.The standard thickness

1.Ciutch

Motor, 1/2HP(400W),3 phase,2 pole M type

V belt.

2.The center line

must

be

aligned

motor.

-1

-

of

of

Table is about 50mm.

both motor's and machine's pulley

each

other,when

installing the

Page 6

~

- -

-

~

-

---

- - - - - - - - -

:

..

,.

I

1-------------------

I

2.1!1-rMTma.n:~mM

ilJfi'fiaH~HiAIIridl

;..ma~.m~•~~~~mffi..t~~~~~~

(II)

3.

4)

c:mimfJIJ~.

.

ttff

-....--

- - -

--

- - - - - - - - - ----

~dtflrtn.a.t£

..tM~idll'ifCA>:midlfi

.

--.

---

_,..,.-..--~-

--

- -r-- - - - - - - -

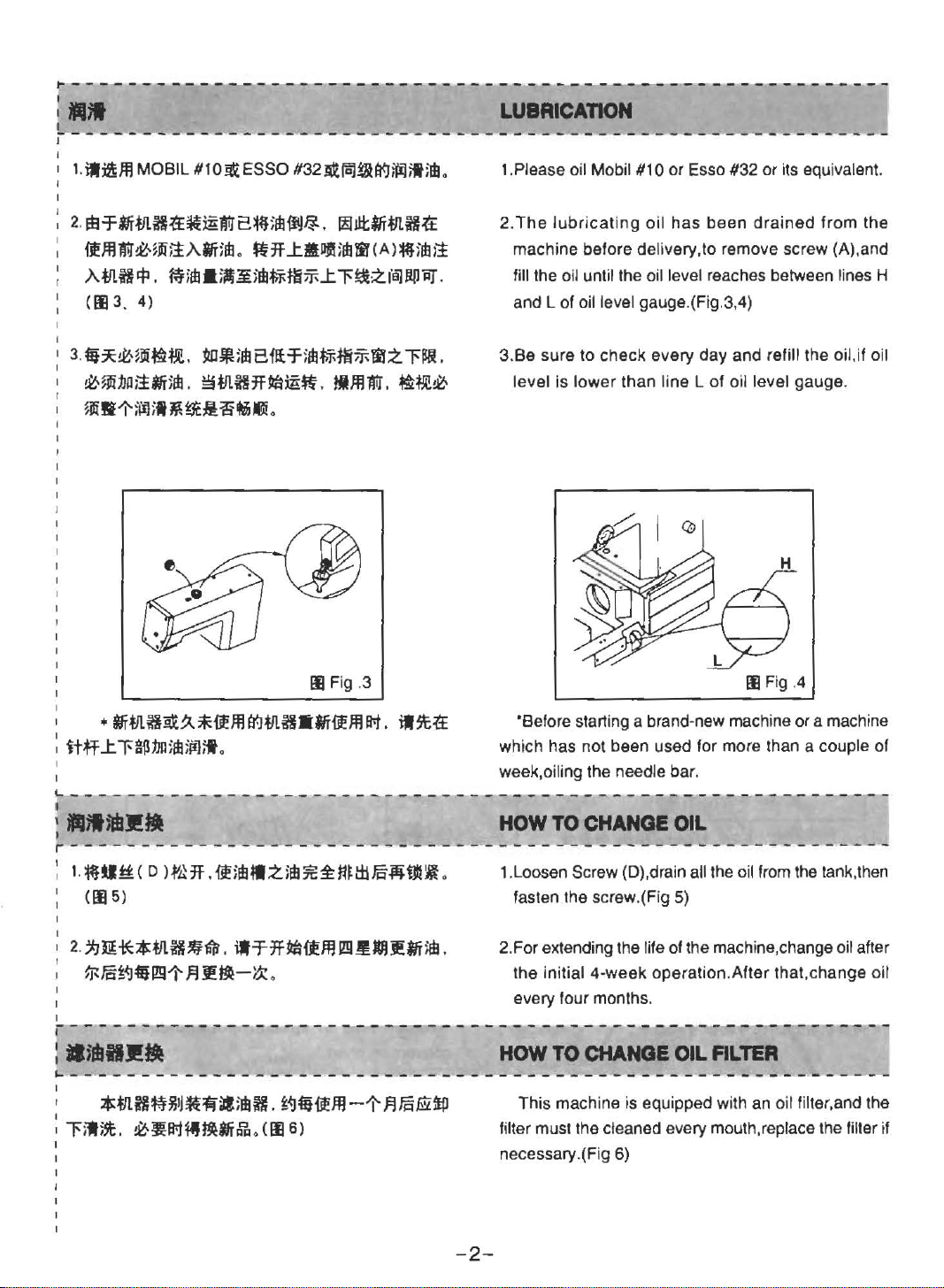

WBRICATION

1.Piease oil Mobil #10 or Esso #32 or its equivalent.

2.

The

lubricating

machine before delivery,to remove screw (A),and

fill the oil until the oil level reaches between lines H

and

Lor

oil level gauge.(Fig.3,4)

oil

has

been

drained

from

the

I

3.fe7dH~*~·

~~~~MT~.~tltB1f~~-

~R-1-fiili•~~,l!e~~.

~

--

--

-------------------

'

: -'IJJIIIJ!.

r---------

I ,

~tl*

co

(II)

5)

~*imcflt-Fim~tiff-mz~~.

.

~m~.~~~

II) Fig

----

>f~ff. ifimMzi!fl1f~~nfi~:pjm~

---------------------

.3

3.Be sure

level is lower than line L

*Before starting a brand-new machine or a machine

which has not been used for

week,oiling the needle bar.

-

-------------------------------

HOW

.

1.Loosen Screw (D),drain all the oil from the tank, then

fasten the screw.(Fig 5)

to

check every

TO

CHANGE

-------------~-------

day

and refill the oil,if oil

of

oil level gauge.

II)

more than a couple of

OIL

Fig

.4

I

2.~Ji:**tltH~~

~f.Si-t.JIJI!91-

I

~--~~---------

~---------------------------~-----------------------

...

-Fff~illlJ2!1~JIJlJ!flr)$.

fl

)!~-(}.:

.

-----

~

~-

----~~;~~~-~~~L~-;

2.For extending the life of the machine,change

the initial 4-week operation.After that,change

every four months.

This machine is equipped with an oil filter,and the

filter must the cleaned every mouth,replace the filter if

necessary.(Fig 6)

-2-

oil after

-~

----

--

-

oil

--

Page 7

I

I

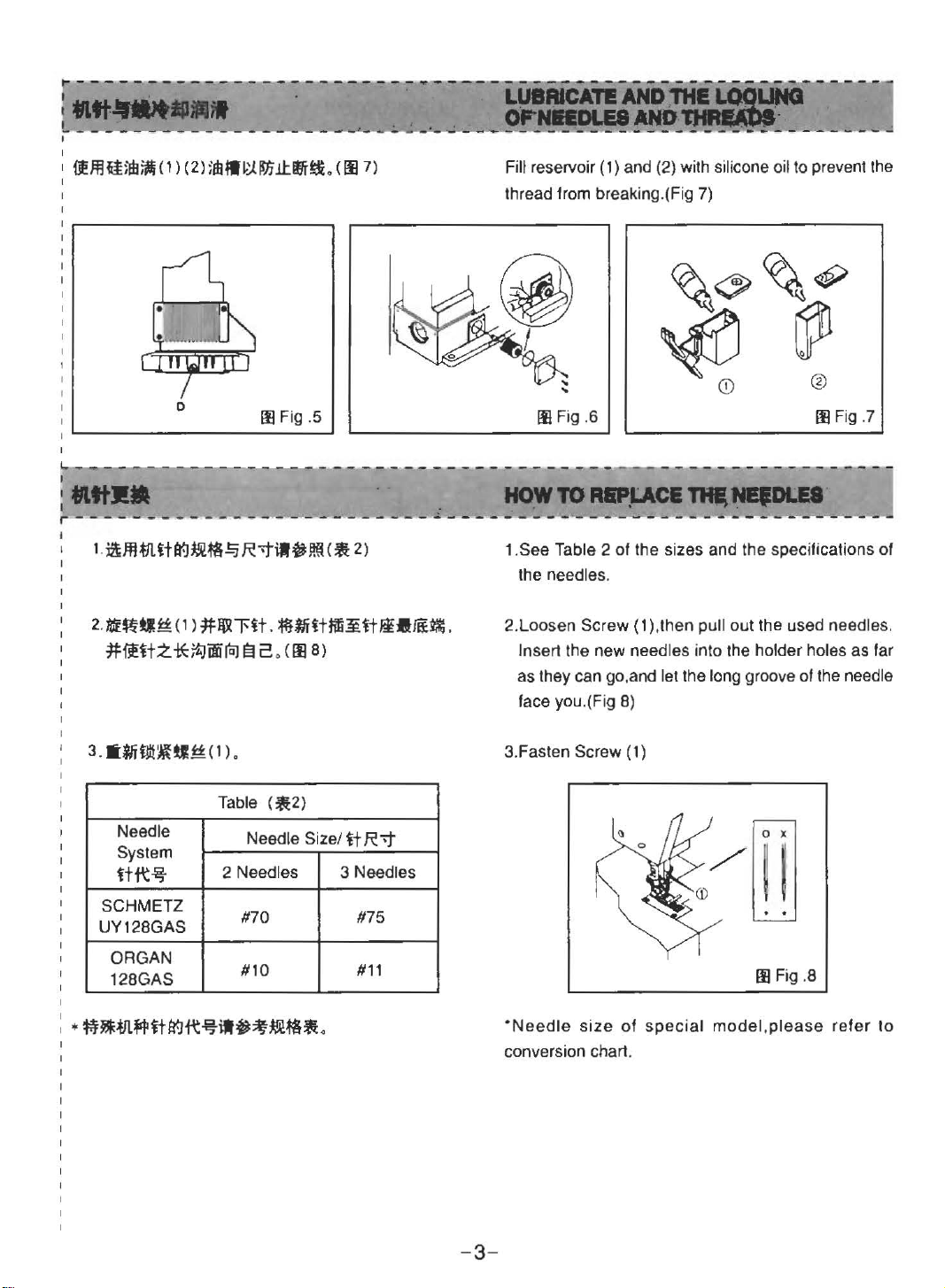

if,EijU)IB~(l)

(2);fbM~~Ifli.itlffitl.

(IIJ7)

Fill reservoir

thread from breaking.(Fig

(l)

and (2) with silicone oil to prevent the

7)

0

'

......

I

Ill Fig .5

,------------

2.1tfE~*I*

#fittz.-*~iiitaJ

3.

atJTU!WUI*

Needle

System

tttt~

SCHMETZ

UY128GAS

< 1 l

#ltlll'H.

m 2 .

C

1).

Table

Needle

2 Needles 3 Needles

#70

--------

~fliHJI~tt

ems>

(:\\2)

Size/

li·li!~.

tt

R>t

#75

Ill

Fig .6 Ill Fig .7

-~-

----

1.See Table 2

the needles.

2.Loosen Screw (1),then pull out the used needles.

Insert

as they can go.and let the long groove of the needle

face you.(Fig

3.Fasten Screw (1)

--

---------------

of

the sizes and the specifications

the new needles into the holder holes as tar

8)

of

ORGAN

128GAS

#10

#11

•Needle

conversion chart.

size

of

-3-

special

Ill Fig .8

model,please

refer

to

Page 8

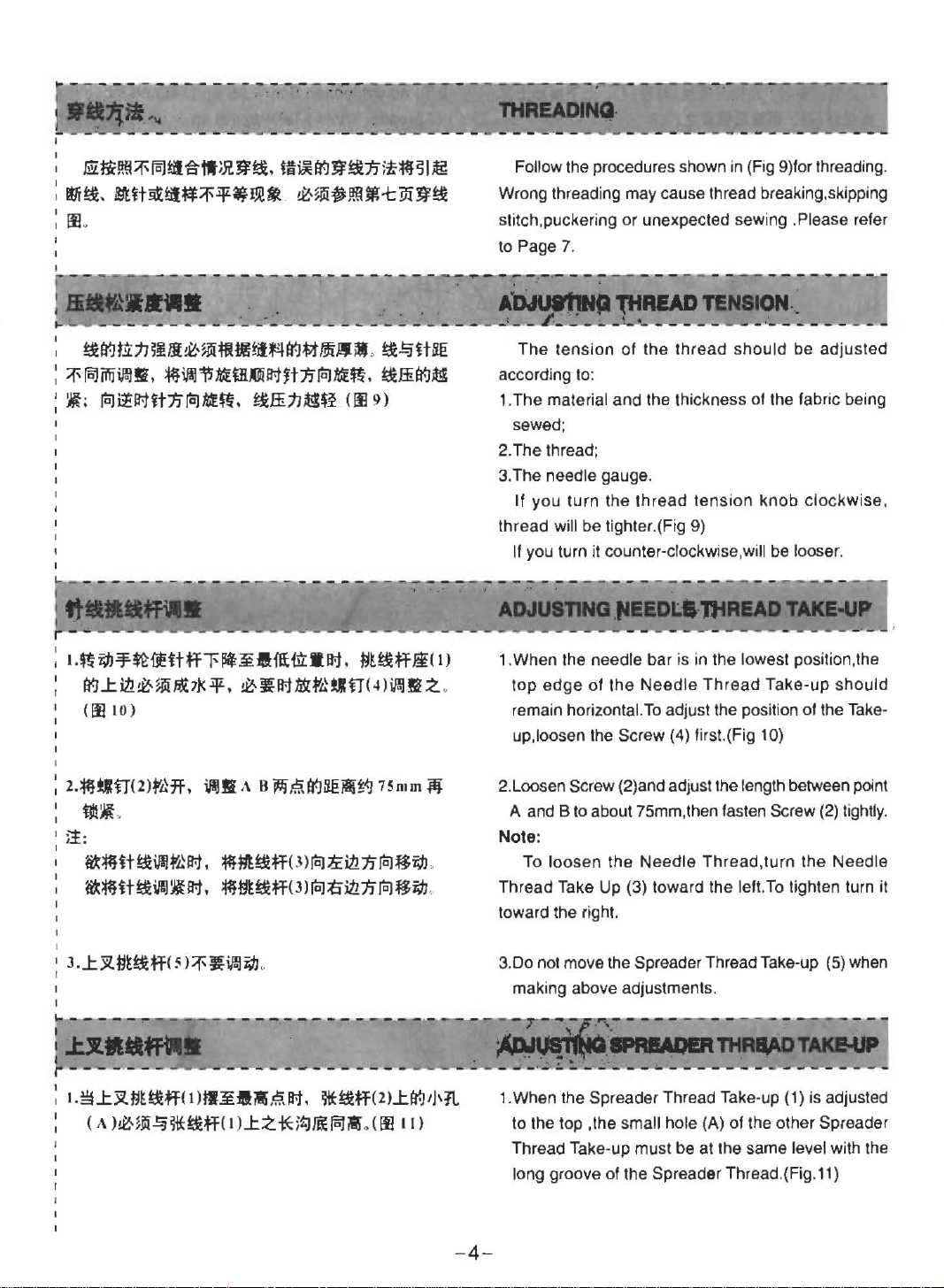

m:nc!ffi~!El~-8-•;JIJr~.

I

~

~~.~H~~~~·~--

ttt~I¥1Jr~:t;;i;:t4sl~

~~*lffi~~~Jr~

: 00.

~~tt~~M~~mW~M~~~-~-~~H~

:

~~~~m.:t4~~~mG~t-tH1l~~R.~ffi~~

: ~

;

~i$B1H1lJal.tU~.

I

I

~ffi::h~*£

(fll9)

Follow the procedures shown in (Fig 9)for threading.

Wrong threading may cause

stitch,puckering or unexpected sewing .Please refer

to Page

according to:

1.

2.The thread;

3.The needle gauge.

thread

7.

The

tension

The

material and the thickness of the fabric being

sewed;

If

you turn the

will be tighter.(Fig 9)

If you turn it counter-clockwise,will be looser.

of

the

thread

thread

th

read breaking.skipping

should be

tension

knob

clockwise

adjusted

,

I

LRTJJ~~iittff"FI!it3UtflHU:•~t-t'

~...till~~~*•·

<00

10)

: 2.:f4tlfT(2lt'Mf,

I

~~

<

I

;!

•

I I •

m:::t4tt~~*'~",

W:::t4tt~if.l~B1'

I

I J •

...t

)2J}~~

ff(

I

I

I

l.~...c:st~t~*<tHt~••

(A

)~~~~*~ff(

5 )

~~~t-tntt~u:n<o~>if.Jmz

Vllfl

,, B

~~Loa~~~~J.J

~m~ff<3>~tr:ill1l~3TJJ

:t4!1~~ff(J)fal:fi'it11l~3TJJ

~ ~

if.J

TJJ

,,

·

.a~t-t,

I

)_tz

* )

1;)/!faJ

~t~ff.ri(

I)

.

75mm M

.

.

*~ff<z>...tif.l,Mt

• • (

00

II)

1.When the needle bar

top

edge

remain horizontal.

up,loosen the Screw (4) first.(Fig 10)

2.Loosen Screw (2)and adjust the length between point

A and B to about 75mm,then fasten

Note:

To

loosen

Thread Take Up (3) toward the left.

toward the right.

3.Do not move the Spreader Thread Take-up (5) when

making above adjustments.

1.When the Spreader Thread Take-up (1) is adjusted

to the top ,the

Thread Take-up must be

long groove of the Spreader Thread.(Fig.

is

in the lowest position,the

of

the

Needle

To

the Needle Thread,turn t

small hole (A)

Thread

adjust the position of the Take-

of

the other Spreader

at

the same level with the

Take-up

Screw (2) tightly.

To

should

he

Needle

tighten turn it

11)

-4-

Page 9

2.~~VIJ!la:t.

~t

~*T<2>.

stt'Mfti~C3l&C4>.

\llfl/iS"~~z.

..tl'tl~..t.Jl.

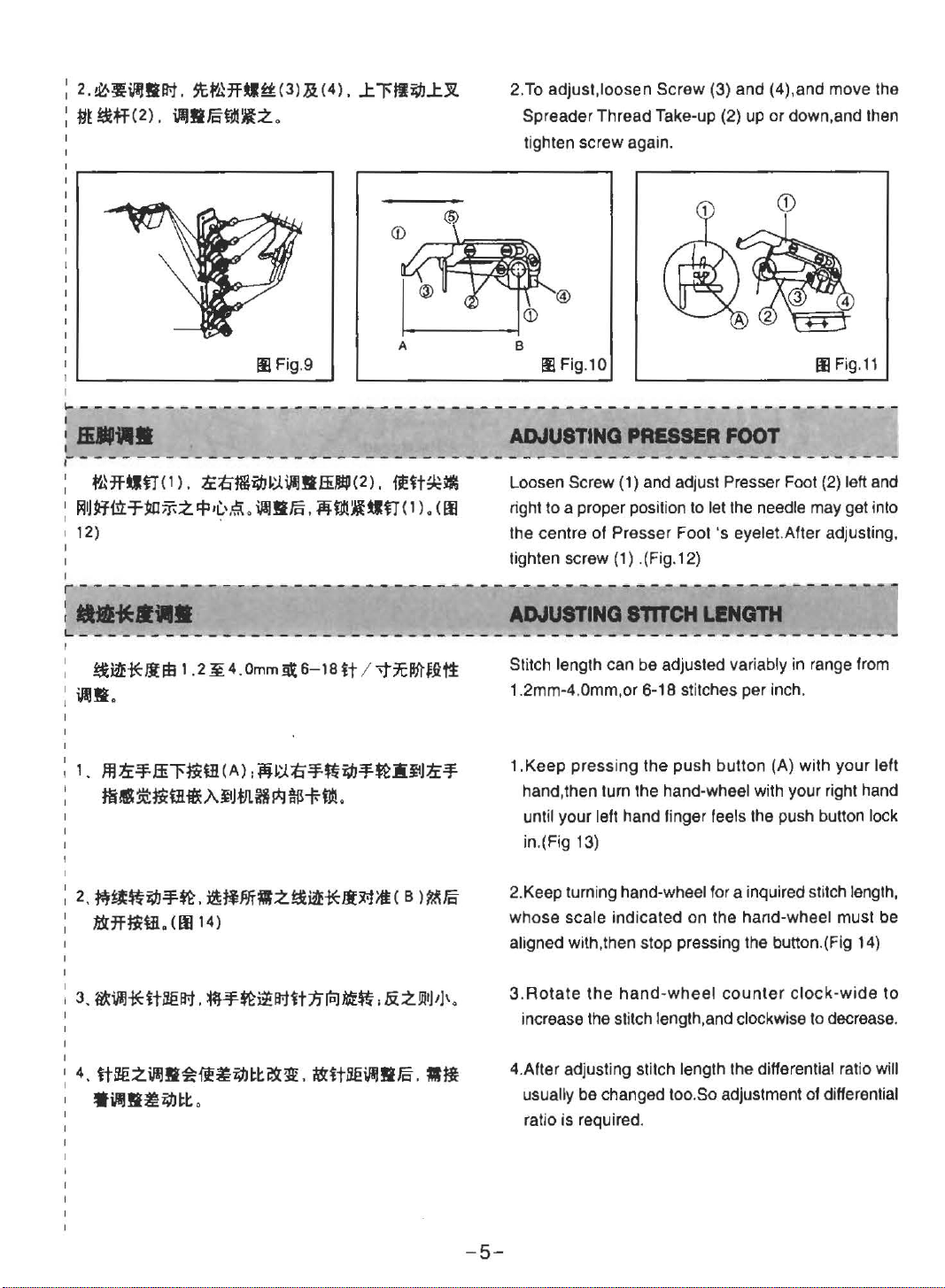

2.To adjust,loosen

Spreader Thread Take-up (2) up

tighten screw again.

Screw

(3) and (4),and move the

or

down,and then

A

!11

Fig.9

~---------------------~------~-----

1

:

a.a

.--

-

---

--

--

-

----

- - - - -_ ...._....

;

t'~fftJJI(1)

:

li.jiJ~tl!-T~ff.Ztpl~'.~.

1 12) the centre

I

I

r---------~--~----

r

••*n•

L

_______

~l!t*I.IIB

:

Vll!l.

Jfl

ti.'fffil'ltiUl

m~~ltiUlfftAiiJtn.HI*J$-Fnl.

.

.titlni~tJ.VIl!lffi_,(2),

\111!1/i'i,

_._

-~~

1

.2

~

4.0mm~

(A):

Ji:tJ.tl.'f~~.'f~IIiltr:Ef

__

- -

ftU~W&

Ji:m~tlfT(

~

------

6-ts

HI

1).

------

_._

-------------------------------~--

>t9CIIft¥itt

--

---

(Ill

B

!11

Fig. 10

-

ADJU&nNG

---

- -

---

Loosen Screw (1) and adjust Presser Foot (2) left and

right to a proper position to let the needle may get into

tighten screw (1) .(Fig.12)

----~---~---------------------

ADJUSTING

Stitch length can be adjusted variably in range from

1.2mm-4.0mm,or 6-18 stitches per inch.

1.Keep

pressing

hand,then turn the hand-wheel with your right hand

until your left hand finger feels the push button lock

in.(Fig 13)

Ill

Fig.11

-----------

PREISER

..--

--

--

------

of

Presser Foot ·s eyelet.After adjusting.

I'MCH

the

LINGTH

push button (A) with your left

----------

FOOT

-

---

_

_..__

--

_..

_

:

2,

~~$t~.'f~,

1it1f~tH.

I

I

3.

W:VIl*ttiielt-1.

I

I

:

4.

tt:u!:ZVIJ!I~ft~~~t~~.

•

Vll

·~

~~li/T·Z~l!t*Jljifift(

(1:1)14)

M~~a:tttnliiJfdftt:

t&ttlieVIIflliS".

fdJ

~t.

B

)~/iS"

&z!ilrJ,J\.

att

2.Keep turning hand-wheel for a inquired

whose scale indicated on the hand-wheel must be

aligned with,then stop pressing the button.(Fig 14)

3.Rotate

increase the stitch length,and clockwise to decrease.

4.After adjusting stitch length the differential ratio

usually be changed too.So adjustment of differential

ratio is required.

the

hand-wheel

-5-

counter

stitch length,

clock-wide

to

wlll

Page 10

t-

---

- -

t

utt••

,

r--~--

---

-

·

------~--

Ill

Fig.

12

------

-

Pwss

-----

Dn..t

cken

Appuye

A

l

r Opri

mtr

Ill Fig.13 Ill Fig.

14

Jti:ffl.B:Z.~M~I:iiTM

c1

> •

..tr~MiiTVAJR

r-~

----

1

Dii1J••••

~

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

~~~m~~~H~~~~z~~~.ff~ffin~

:

·~J!t

.

--

-

1 ,0.3iffl!lf3§: 1

.

c!llts)

......--

----

,2.9f~7ftl~

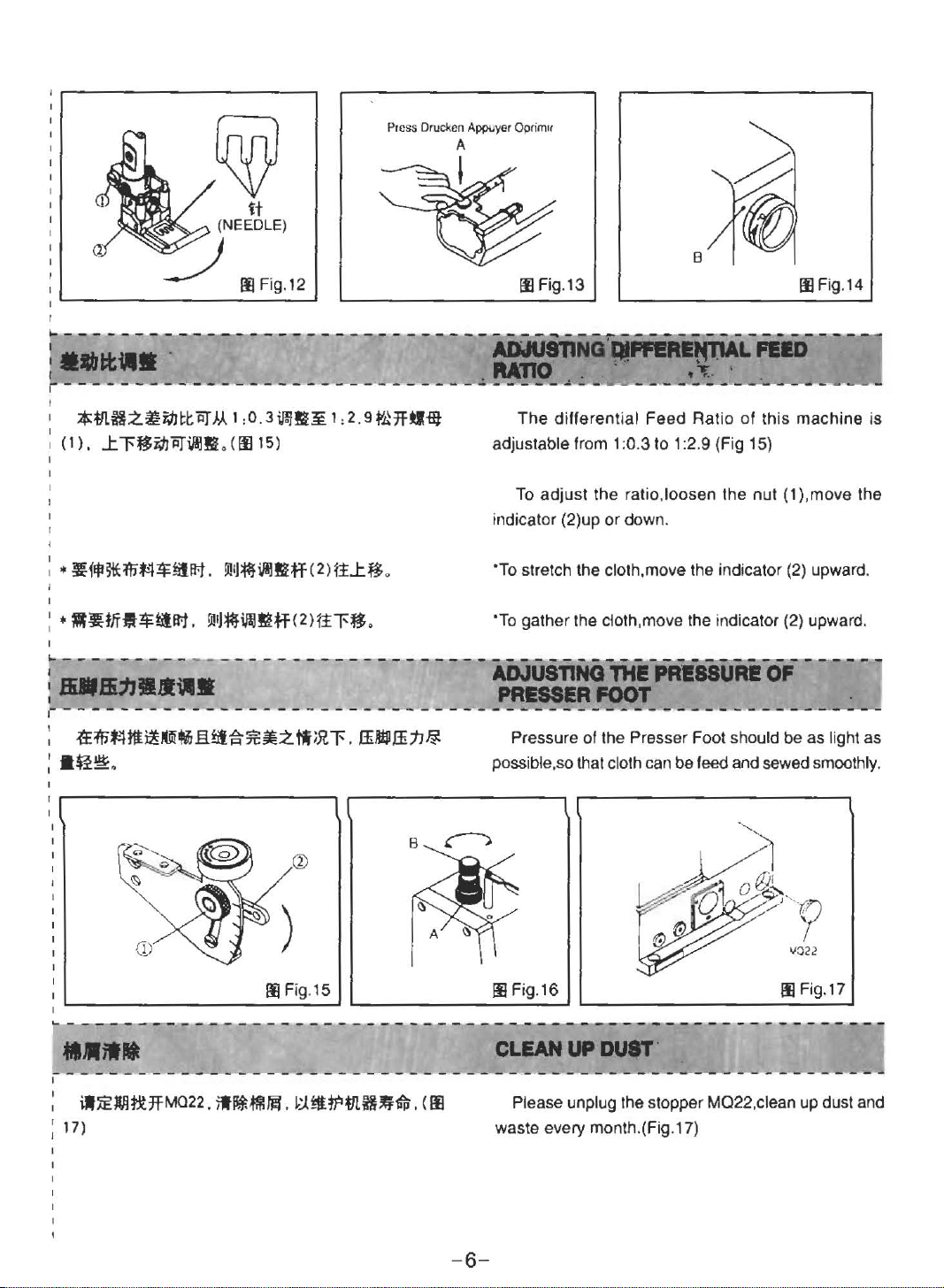

adjustable from 1:0.3 to 1:2.9 (Fig 15)

indicator (2)up or down .

·To stretch the cloth,move the indicator (2) upward.

'To gather the cloth,move the indicator (2) upward.

-...--....-

-

---------------------

~PRIISURIOP

possible,so that

B

~

The

differential

To

adjust the ratio ,loosen the

Pressure of the Presser Foot should be as light as

Feed

~--

cloth can be feed and sewed smoothly.

Ratio of this machine

nut

(1),move the

-

~----~

-.s

--

....-.

-~

is

I

)

Ill Fig.15

••••

1

---------

i·~

JfJj

I 17)

I

tl

7f

~

M022

.

51

--

M;

.fM

!iii

------

.

tH1HPffl.

--------------

WI~$

. ( Ill

m Fig.16

CLEANUP~

- --

Please unplug the stopper MQ22,clean up dust and

waste every month.(Fig. 17)

- 6-

Ill Fig.17

-

__

_::~!!.-

____

__

_

Page 11

I-

- -

I

~---

-7-

.J

Page 12

r--

- ,

1 I

I I

-----

l

l

·-----

!)lfft

i UNIT :

Ji.li~R'fi}~

--

- - - -

MM

I DIFFERENCE : + 2

--

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - l

~

3-·9

<C)

"'

"'

I.

9,

I.

""'

~

l

1\8

0

I~

I

I

30

lz:;

I

5

~

(.)

i i e

: l

' I I

I I I

l I

I

: --l ------------------------------------------------------:

I I

I !l!f.il:I UNIT : MM

I

I

' I

I

I

!

io;'l

A- A M iii

pJT~

R-;-J-1.}~

5-

ll

~

I DIFFERENCE :

<J}

r

I

2

90

__._.

--+--

- -

R20

:+:

2

:2

L

H--_____;;~+-...:..:.._----"1

jjl·

~§

m I

0

-

3~

Y-----

--~-

----

----r m

-----+ m

385

460

1

::

'

:c

~

1

Is

~

2

C;)

s·

~

~

m

t$

I I

~

- - J - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - J

j;

B-8

8ll

li

228

8

N

-8-

~

0

Page 13

~

-- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

FOR

~~t)Jti

!;.UZ

/ UNIT : MM

~JT~iR'f~~

/

DIFFERENCE: ± 2

N

~

- - - - - - - - - - - - - - - - - - - - l

~

rr

cO

I

I

i

-------------

fl

p

B-B

8'1

i1l

FOR

~~t)Jti

!;.f.li:

/ UNIT :

~JTJi R 'f~~

433

290

200

1

50

80

0

--

--

--

- -

MM

/

DIFFERENCE : ± 2

I

0

---

-

----

- - I - - - - - - - - - - - - - - - - - - - - - - -

0

,._

"'

Slll7

540

465

450

400

385

325

296

115

61

~

200

B- B

~

ill

~

---- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

., §

,_

N

-9-

465

4CO

385

325

296

250

11

5

61

0

~

Page 14

FOR CRL.CRUUTP.Q

!llf.!t/ UNIT: MM

Ji]fl!f

R-t~~

/

DIFFERENCE : ± 2

;;;

N

<D

~

15;

~

eo

:l

N

I

I

_J?

I

-

.}0

J-t9

\

~~

-~

-

226

A-A 8'1

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ,

FOR

n ;

~Jrl!f

iii

~TJ]t}]~

uNIT

R-t~~

MM

/

DIFFERENCE : ± 2

r----r-______.:.,.._

J

-~

9

C)

N

or.

0

..

"'

__

I

I

illS I

~~

A I

!

,___

..

~

M

"'

~

i i

1

~

I

.--.--

' '

f

20

n:..-

A-A

8ll

iii

0

....

~~

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

-----.

or.

~-I ~

~-~-

226

- 10-

I

1

....

•

"'

-

-

5J5

C)

I

~

Page 15

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - l

FOR CFE

tf!i.!LI

,6Jf:Ji

UNIT: MM

R-10~/

DIFFERENCE: ± 2

.,i

433

290

465

400

3a5

325

296

-n-

80

p

0

8-8

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

FOR CFE

$-i.!L

I UNIT:

,6Jf:Ji

R-10~/

63

0

I!IJ

iii

MM

DIFFERENCE :

433

290

±2

~

~B

o()

....

0

0

\15

6\

lll

i

540

465

400

385

J25

296

270

~

ft-

~

-lG

8-8

811

-- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

0 0

m

li

-11-

...

....

N

\\5

61

0

I

~

Page 16

1.

limf1=~

( 1) .

ff,Eij

1. Transportation

(1

~.a=Jt"it~i*FJflit~tJI.H@.ill!fi#l.

). The machine packed with two piece

covers that made of expanded polystyrene to

protest i

(2). Put the machine into a carton .

t.

I

1 2,

fllr=f'{f~

(1).

mu;r-tem~t-t.

I 4

tlfiS'

I

.r±J.HitliS'.$Fi'F

1.

m•i-t=~tufft.

eml!fi.a~:Jt.aJ:.

Z~il

i!

a

ili'!M~J:i*J?!l•.

(3). Use a cart

2.Storage

( 1 ). The machine must use duster -cover to cover it

when it did not work.

(2). The machine avoid to storage in the temperature

or

by

two men's hands to move it.

more than 45°C.

3.

Working

The machine doesn't work over

4.

Warming

Pay

attention to th is warning advice as follow .

a. Working

b.

Never touch the needle if the machine is still

running .

c. Be

d. Do not insert your finger between

roller for transportation on fabric.

area

is dangerous.

careful if you infeed fabric.

40°

C.

needle and

Pay attention to the warning s

a.

Movable parts must be enclsed with guard when

you operate.

b.

Pull out the plug from socket when you adjust,

thead, change bobbin and

-

12-

li

cker.

needle clean.

Page 17

...

~

.....

r

·~-

-.--.-

"'i•

.•.

-1

. ' .

.

~'

~-

•.

~

~flit•

~.

....

:

4

·:: •••

-.

0

MODEL

flL

I ZJW122/CH-C1

I

I

I

_.

I

w

I

I

I ZJU 122/CH-C1

I

I

I

I

I ZJW122

I

I CH/UTP(UTR)-C1

Jt~

~

SUB-CLASS

~

tiS

240 I M5240 I E3524P I D4206 I H4258 P0024

248 I M5248 I E3525P I

256 I M5356 I E3826S I D4206 I H4258 I P0216

356 I M5356 I E3826P I D4206 I H4258 I P0216

364 I M5364 I E3827P I D4207 I H4259 I P0217

240

248 I M5248 I E3525P I D4206 I H4258 I P0315

256 I M5356 I E3826S I D4206 I H4258 I P0416

356 I M5356 I E3826P I D4206 I H4258 I p0416

364 I M5364 I E3827P I D4207 I H4259 I P0417

24

0 I M5240 I E3524P I D4206 I H4258 I P0024

248 I M5248 I E3525P I D4206 I H4258 I P0025

256 M5356 E3826S D4206 H4258 P0216

~~FJ~_j~

NEEDLE I NEEDLE

I CLAMP

I H

!ft.

PLATE

I H

I M5240 I E3524P I D4206 I H4258 I P0314

MAINFEED I DIFF.FEED

I

DOG

fi

I

t=.~tH

f

D4206

I

DOG

I !J4Ji1ifHf

I H4258 P0025

: I 356 M5356 E3826P D4206 H4258 P0216

I I 364 M5364 E3827P D4207 H4259 P0217

ZJU122

: CH/UTQ(UTS)-C

240

I M5240 I E3524P I

248 I M5248 I E3525P I D4206 I H4258 I P0315

256 M5356 E3826S D4206 H4258 P0416

1

1

l 356 M5356 E3826P D4206 H4258 p0416

04206

I H4258 I P0314

PRESSER !SPREADER

FOOT

JJi

!141

I

!1M

H

MH41E

MH41E

LOOPER

1>J

H

MT01

MT01

MT01

MT01

NEEDLE

H

~o:-

UY128GAS#11 I

UY128GAS#11 I

UY128GAS#11 I

UY128GAS#11 I

:

I

I

I

I

I

I I 364 M5364 E3827P D4207 H4259 P0417

:_

?J_~,?~~~A.::~1_1_-

_3~~--L-~~3~~-

E3826Q I D4206 I H4258 I p0216

MH41E

MT01

~Y!2~<!~S!

!,_

~

Page 18

-r-- -·--- -- ---

I • .

--

c . -

-

...

·-·-~-·-

•

- -..-----

~

-----~---

-

0

MODEL I

ZJW123/CHE-C1

I

I

I

ZJW132

I

I

1

/CHEIU

.......

~

I ZJW152

I

: /CZ/UTP/RL0-C1 I

ZJU152

I /CZ/UTQ/RLO-C1

: ZJW

1/

CZJCLA/UTP/R'

ZJU152

:

/

CZJCLAIUTP/RLO

ZJW152

/

CZP

/RLQ-

ZJU152

/CZP/RLQ-

ZJW152 I

: /

CZP

/CLAIRLQ-C1

ZJU152

I /

CZP

/CLA/RLQ-

L------

~

SUB-GLASS

248 M5248 E2325P D2109 H2219

356 M5356 E2326P

364

356

---

--.

v;;JO

I

·~~

I"'L-

-d

C1

C1

C1

- - -- --- - ---

woJV

I

---

oJ-'U

I

~

....

I

...,._,...,

oJ.JU

364 M5364 E4327

...,

iiU$·

-.

;;J

JV

O

--

~

I

I

I

l

I

I

I

I

-

~

·;..7::;r:-

I

M5364

M5356 E2326P

···----

-

__

I

I

I

I

I

I

I

....

fVJ;.Jv

I'FI..JW'VV

···----

l'f'I...JoJ"""'-1

,

..

,....,....,....,_

,.,...,..,....,\J

IYI

...J~

- - - -

-

If"

NEEDLE MAINFEED DIFF.FEED

PLATE

H

tu

E3826Q D4206 H4258 P0416

E2324P D2109 H2219 P2904

E2327P

- ·---·

·

--

~::<+v.::or

1-.,.W''-VI

-

----·

'-.,.V'-U

--u-.-

L-_...,

__

'-.....V'-U

----

DOG DOG FOOT

L

itiH~

·

D2110

D2110

D21

10

---

I I I MH41E

1

I

I

I

I

I

-

·-

- .

UWC..IU

V..J'-

I

\J

----.-

V..J'-

I

\J

----

·-

IW'~IV

U~IV

D3217 H3263

----

- -

...

J

J.~rJJ~~~

H2220 P2906

H2220 P2907

H2220 P2906

.

·----

. ·- -

nv.::o.c

I

I

IW"'-UC..

I

.

·----

I

I

IV'-U'-

I

••--v-

I

I

JV-V6.

I

I

h.I'-V'-

--

----

~

~.

~

PRESSER

··

Jli

P29C

. -.

-

..

rC..&+IU

I

I

,.,. I \J

I

.

--

I

I

,..,.

I

I._....,..,_

I

I._....,..,...,

I

I

,,_,

p2417

------

..

--

-,....

.....-----:::.

_j

SPREADER LOOPER

•

•

H

~

-~

-

MH41E

MH41E MT01

·-

I

I

I

·-

I

IV

I MH41E I MT01 I UY128GAS#11

I

I

V

-

MH41E

-

-

MH41E

----_--J--

MT01 I UY128GAS#11

UY128GAS#11

I

UY128GAS#11

MT01

I

I

I MT01 I UY 128GAS#11

MT01

I

MT01

I

MT01

I

MT01

I

~~0~

UY128GAS#11

I

UY128GAS#11

I

UY128GAS#11

I

UY 128GAS#11

I

-

_I_

~

~

1

NEEDLE

I

I

I

I

I

~2~~~~~1-

~

Page 19

I

__._

01

I

0

MODEL

til

ZJW162-C1

ZJU162-C1

I

ZJW162

/UTP(UTR)-C1

1'!

~

I

SUB-CLASS

I ~

I

I

~

240 M5240

248

240

-~8

248

356

~

NEEDLE

I CLAMP

~

H

M5248

M5240

I

M5248

M5248

M5356

~

NEEDLE

PLATE

tti

lt

E3544

E3545

E3544

I

E3545

E3545

E3846

r

MAIN FEED

DOG

l:i.ti~<~

~--

D4206

D4206

I

D4206

04206

04206

J

DIFF.FEED

DOG FOOT

YJ:~J~tl~--

H4258 P0235

H4258

I

H4258 P0235

H4258 P0235

H4258

~

PRESSER

lli

58

59

Mil

P0226

P0227

P0234

P0226

_j

SPREADER

!I

H

MH41E

-

MH41E

/6

LOOPER

1'j

I

MT01A

MT01

MT01A

I

H I

I

1

NEEDLE

H

UY128GAS

#14-16

UY128GAS#1 1

I

UY128GAS

#14-16

"

'-I

I

ZJU162

I IUTQ(UTR)-C1

ZJW222

/CQ-C1

I ZJ U222/CQ-C 1

I_

- - - - - - - - - -

356

M5356

E4426P D3216

H3362

P2616

MH41E

MT01A

MT01

MT01A

UY128GAS

#14-16

UY 128GAS#11

UY128GAS#11 :

I

- - - - - - - - - J

Page 20

0

~

~~£J~_j

~

1

MODEL

ZJW222/CQAJ

CLA-Cl

ZJW322/CC-

I ZJU322/CC-C1 356 M5356 E2826P 02107L H3259

C1

I

SUB-CLASS

.lit

364 M5364 E4427P 03217 H3363 P2617 256

356

364 M5364 E2827P

NEEDLE NEEDLE MAINFEED DIFF.

I CLAMP

~

H

~L

M5356 E2326Q 02110 H2220Q P2906Q MH41E MT01 UY128GAS#11

M5356 E2826P 02107L H3259M P1406 I I

PLATE

H

.tJi

J:~*l~f X:

D2107L H3259M P1407

DOG

FEED

DOG

rJJ~*f!.f

......

cr

I ZJW322/CC/UPT I

(UTR)-C1

ICC/U:~~~)-Cll

ZJW322/CD-C1

ZJU3221CD-C1

ZJW322

I /

CO

/UTP(UTR)-Cl

---

--.

n•

I

---

---

364 M5364 E3627P

356

~~·

I ···---- I

.

·---.

I

..

•nn

I

...

____

··----

M5356 E3626P

··-~~·

I

I

-----·

------

----·

-----·

-----

~~~~-~

I

I

I -

· -

--.

--•••-

·-n

04207

04206

~·~~-

-·-

I .

I •·---••••1 •

I ...

---

_____

.

----·.

·--

.

H4159 P1607

H4158 P1406

'···-~

·

.•.

... I ..

--

PRESSER

FOOT SPREADER LOOPER NEEDLE

Hi

~

I '

.~........

•n

-.

·--

••n

I

..

--

---

~·

·--

!I

ft

MH41E MT01 UY128GAS#11

1

I - I

I I I UY128GAS#11

MH41E MT01

!')' H H

MT01

MT01

UY128GAS#11

I UY128GAS#11 I

I I MT01 I UY128GAS#11

I MH41E

- MT01 UY128GAS#11

MH41E MT01 UY128GAS#11

MT01

I UY128GAS#11

~~

:

/

CD/U~~(~~S)

ZJW322/CE-

I I

L

-~~3~~~-~~

-

Cll

C1

-

L-

n•

;~

356

_3?4_--""-

I :

:~~~~

~;;~

M5356 E2626P

~~~--

I

-

=~~~-:_

~~;;p

~_?~7£'

I -

-

---

I • n I

~;

107

D21

07 H3159 P1406 MT I

-

f22_1Q7

_ -

:_

•n

H;l;~

_lj~1~9--

Pl4~;

£>!4.9~-

I - I

MH41E MT01 I UY128GAS#11

-

--_-_ - -

MT01

--

-

_o~-

I UY128GAS#11

_l_u~~2-8~~~~,-

1

~

Page 21

~

.

z:-1'1-1...,.5f1!0.!F)

~

-~

. .

,· · ·-

l · ·.· ·

w . • • •

.•

.....

··""· ...

....

,. · · ....

!-......

, ~ · =

..

,.-~ :4

:.

-~

-:li~

......

:"'

........_

__

. . . . .

..

__.....,._

·

~

•Mr.M.*

··

a~;pr;

-.,.r-a.-....--

CONY

· ·

..

,

ww .....

..

-

•

-"'·-

.i,,

.

~

~;;;~

-----=-=

.

10N~u&.n-r

6

""'

,..-~.~t-;-.

.,

. :

.....

.

vnnn1

-.-

.,....~..-.....

- . . .

·

· . . ·

·.. . . ··

......

....

- -

.·

,...,.~

. . . _,,

·: ··.

....

,·_

....

~~-- --~~

-~

···~:-·

.l

• .

......

~

____::_:_

. '

~

!0

1 NEEDLE

1 MODEL

I

t~L

~~

I ZJW322/CEIUTP 356 M5356 E2626P D2107 H3159 P1406 I

I MH4, E

I (UTR)-C1 364 M5364 E2627P D2107 H3159 P1407 I

I ZJU322/CEIUTQ 356 M5356 E2626P D2107 H3159 P1606 I

: (UTS)-C1 364 M5364 E2627P D2107 H3159 P1607 - MT0

I ZJU322/CF-C1 248 M5348 E2625P D2106 H3158 P1605 -

:

I

......

-....!

I 240 M5240 E3524P 04206 H4258 P2914 I

I

I

I 356 M5356 E3826P 04206 H4258 P3216 MH41E

I

I 364 M5364 E3827P D4207 H4259 P3217 :

: ZJ

: (FFC)-C

I 364 M5364 E3827P D4207 H4259 P3717 I

I

: CRAICL-C1 364 M5364 E6427 D3222 H3268 P3117P

: ZJU522/FE(FFC)/ 356 M5356 E6426 D3222 H3268

I CRA/CL-

~

I ZJW522/FE(FFC)/ 356 M5356 E6426 D3222 H3268 P3116P I

: CRB/CL-C1 364 M5364 E6427 D3222 H3268 P3117P

I ZJU522/FE(FFC)/ 356 M5356 E6426 D3222 H3268 P3116P I

: CRB/

:

I /CURLP/CX-C1 364 M5364 E6427 D3222 H3268 P3817Q

L - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

2

ZJ~~

:S~~~TQ

ZJW512/FE I

(FFC)-C1

U512/FE I

1

ZJW522/FE(FFC)/ 356 M5356 E6426 D3222 H3268 P3116P I

--------

ZJW532CAAIUTP 356 M5356 E6426 D3222 H3268 P3817Q :

C1

---r-------+~----~--------r-------~--~~-r-------+--------+-------~--------

CL-C1

~

SUB-CLASS

~

m H

248 M5348 E2625P D2106 H3158 P1605 -

240 M5240 E3524P D4206 H4258 P3414 I

356 M5356 E3826P 04206 H4258 P3716 -

364 M5364 E6427 D3222 H3268 P3117P - MT0

364 M5364 E6427 D3222

te~f"

CLAMP

41.

NEEDLE

PLATE

H

ff1

MAINFEED

DOG DOG

u~H·.-r-J:~

J~_j

DIFF.

FEED

4J~tur

H~268

~

PRESSER

FOOT

11

;

P3116P :

P3117P - MT0

SPREADER LOOPER NEEDLE

ft4l

. 1

~ H

MH41E MT0

MH41E MT0

MH41E MT0

1'i

H H

MT01

1

MT01

MT01

MT01

MT01

1

1

1

1

1

UY 128GAS#11 I

UY12SGAS#

UY128GAS#11 I

UY128GAS#11 :

UY128GAS#11 I

UY128GAS#11 :

128

UY

128

UY

UY12BGAS#

12

UY

128

UY

1:

\~-

GAS#

GAS#

BGAS#

GAS#

1

I

11

:

11

:

11

I

----1

11

:

I

11

:

11

I

~

Page 22

·-

__......_.-._

~

.-----

·

--

...

~

-

--

-

--

-.

---

-----~--

-

- _,_,_ ;_ ;_ ; _

______

_ -

(

--

I

I

I

I

0 ~

I

I

I

MODEL

I

I

~l

' ZJU532CRNUTO

I

I

/CURLP/CX-C1

I ZJW532CRB/UTP

I

CURLP/CX-C1

I

: ZJU532CRB/UTO

I

CURLP/CX-C1

l

I

_,

I

CP

I

I

ZJW542CFC

I

(CFE)/CL-C1

I

I

I

I

I

I

ZJU542CFC

I

I

(CFE)/CL·C1

I

I

ZJU812CRL

I

I

/RL-C1

I

ZJU812CRL

j

I

/RL-C1

I

ZJW812CRL

I

/CHP/RL·C1

I

I

ZJU812CRL

I

I

.CHP/RL-C1 364 M5364

L - -

---

~~

-

-----

ll~i*fe

--

~

SUB-ClASS

.ll m

356 M5356

364 M5364

356

364 M5364 E6427 D3222

356 M5356

364

240

248

356

364 M5364 E2327P

240

248 M5248

356

364

356 M5356

364

356

364 M5364

356

364 M5364

356 M5356

- -

--

NEEDLE

CLAMP

~I

·

~

M5356

M5364 E6427

M5240

M5248 E2325P D2109

M5356 E2326P D2110

M5240

M5356

M5364

M5364

M5356

M5356

-

-1---

- -

--

- -

~

NEEDLE

PLATE

H

E6426 D3222

E6427

E6426 D3222 H3268

E6426 D3222 H3268

E2324P D2109

E2324P

E2325P

E2326P

E2327P D2110 H2220 P2907

E02260

E02270

E02260

E02270

E02260

E02270

E02260

E02270

-~-

·CONVERSION

fli

---

--

F

MAIN FEED

DOG

r= .

.iXt:

-1

D3222 H3268

03222

D2110 H2220 P2907

D2109

02109

D2110 H2220

D21010

D21010

D21010

D21010

D21010

D21010

021010

D21010

----

J

DIFF.FEED PRESSER

DOG

~

:

x~4J.iXnlf

H3268

H3268

H3268

H2219 P2904

H2219 P2905

H2220 P2906

H2219 P2904

H2219 P2905

H22030

H22030

H22030

H22030

H22030

H22030

H22030

H22030

~

- -

----

-

~

~~~

P38160

P38170

P38160

P38170

P38160

P38170

P2906

P2766

P2767

P0966

P0967

P2766

P2767

P0966

P0967

- - - -

CHART

--.-

_j

FOOT

SPREADER LOOPER

~

ttl

MH41E MT01

MH41E MT01

MH41E MT01 UY128GAS#11

MH41E MT01

--

- - - - - -

-l

~

1

NEEDLE

H

~'};

H H

- MT01 UY128GAS#11

UY128GAS#11

-

MT01

UY

UY128GAS#11

- MT01 UY128GAS#11

-

- MT01

MT01 UY128GAS#11

UY128GAS#11

UY128GAS#11

----

- - - -

l...

- - - - - - - - -

!}

128GAS#11

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

...1

Page 23

-

r-

-~---

1

I

·-

I

I

I

I

0

I

I

I

I

I

I ZJW812/CRUCHP

I

I

UTP/RL-C1

' ZJU812CRUCHP

I

UTQ/

I

: ZJW822/

I

CURL-C1

I ZJU822/CRUCY/

......

I

'

<0

I CURL-C1

'

ZJW822/CRUCY/

I

:

CUUPT

: ZJU822/CRUCY/ 356 M5356 E02

I

UTO/CURL-C1

I ZJU822/CRUCY/ 356

I

UTQ/CURL-C1

I

I

I

I I

I I

I I

I

I

I

I

I

I

L------ ---

MODEL

tiL

~~

RL-Cl

CRUCY

/CURL-C1

----

--- -- -- -- ----

-·

~

SUB-CLASS

~

/

-------

11~1*-

--

~

NEEDLE NEEDLE MAIN FEED DIFF.FEED PRESSER

CLAMP

H

~

~

356 M5356

364

356

364 M5364

356

364 M5364

356

364

356 M5356

364

364

364 M5364

--------1.....~---

t

M5364

M5356

M5356

M5356

M5364

M5364

M5364 E02

M5356

~

PlATE

;l

H

E0226Q

E02270

E02260

E02270

E02260

E02270

E02260

E02270

E02260

E02270

260

270

E02260

E02270

-

-

·CONVERSION CHART

-

--

~~~

_j

r

DOG DOG FOOT

i:~tr~

021010

D2101Q H2203Q P2767

D2101Q

D21010

021010

021010

021010

021010

021010

021010

021010

D21010

D21010

D21010

------

J

:

r.~

4J~'¥l~-f

H22

030

H22030

H2203Q P0967

H22030

H22030

H22030

H22030

H22030

H2203Q P27

H22030

H22030

H22030

H22030

---- --

~

SPREADER

II

i

~

P2766

P0966

P2766

P2767

P0966

P0967

P2766

67

P0966

P0967

P0966

P0967

- - - - - - L - - - - - - J - - - - - - -

nJI

MH41E MT01

MH41E MT01

MH41E MT01

-- --- - - ----- -.

~----

~

LOOPER

H

-

-

-

-

1'j

MT01

MT01 UY128GAS#11

MT01 UY128GAS#11

MT01

n

-....-....

-.----.---

--

NEEDLE

H

UY128GAS#11

UY128GAS#11

UY128GAS#11

UY128GAS#1 1

UY128GAS#11

'-

~--

------..J

1

II

"J

...

---~-

--

,

.-

'

1

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

-

Page 24

- T - - · - · - · - · - - - -

--.--

....

----·

--

- ·-·- --·-----

---·-·-·-------~-------~-----------------------

--

-

-~----·-·-·

-

- -------- · - · - ·- · - -·- ·--T -

1\)

0

PARTS

SM605

"'

o

I

I

/"

MF01·1

51.

1604·1

\

/

MF21·1

SM

600

/

·2

/ SM602

/

UST

'\

MF01-2 _

/

/

FOR MF GROUP

MFO

)~

SM1

39 ·--

//-

~

;

8

..

_

..

: /

/"

• \

~

MF

S

~

~t

?;:jJ[J

15

M61

2

.1

F

13

/

1,0

_

_,_

"

£o-3

PARTS

UST

KN43

FOR

MGQRCUt

KNt.4

MG58

KL15

"'·~

-,

M

G28

SM435

I

~

t)

·

~

.

..

~

'

~\

. -

I

St.l602

--

L

~-

'

()~

/

·3

~041

.

M026

-3

/ /

.

/

t

.1F

30

'\.

SWi01

I.IFJ.:E

l. - - - - - - -

~

M

G21

A134

- - - - - - - - - - - - - - - - -

I

~

Page 25

- - ,

I

I

I

t

--

---

--

-

-I

I

.J

-21-

Page 26

1\)

1\)

.;''

/

__,.......

//.:/

..,..,.,.,. I

_,..,..<:

,.

.......

.......

--....

;

.;_,. I ''

,(h

.,

::::

@_,./

1

;./·

/

- t

~

.....

I (J

','

I

©~

·

--J_..-~/

; / -'10

_,.::

/) : r-..~

_,.

',

',

<j//

I

I

~K.:o

VK~

'

I

'-

'.t_

C)

' '- '

I ©"'

I

,

I

.,..,.

//

.,...->t

/._,..;('

_,.~

'b.

CR

\

~

I .

,~~

\'

·,s~

I I <.B,\1

I I I .

I . J J

~

y ·

/r

_,.-'

"-..

~

;y'"

~

51.1432

MiG'

BH

VK~

I

S\W:;J

VK

CJ9.

Y(H)

(.0)

""'"'(!) t>J

··-

~

~

'

',.....

...

........

....

~-

.........

...

.........

J-~----

.....__

....

.......

-

____

---

- - -

/

I I

~·

I I

~·

I )

i

l

-~--1',,

:~:----

~

.......

...

WM800

WM810.:-I

NM811__=1

:'

/

,-

'"

,(

:

I

',

' ' ,

...........

.........

~'............

--

~

.......

....

..

......

...

..

...

......

)

,...,..,.

.. ''Y

..

----::

i::--'7"'

-

MY29

0

._/:?

c:.:.J-'

-::>

$

K39

1

"'Y,

r

~

!'

.,.

...

,..

...

'

.......

...

VK09-B(Ml

KGG4

KG()<

I

1...

- - - - - L

I

_______

...J

Page 27

I

1-----

/

i

- - - - - ,

r

,

.,

g

;:;

c.-

:<

.

"'

Ill

~"

(}J-tr

OP

()::::>

{)::J

I

§

I I 1

t'\.J

\ \ I

\ \ I

'f-

~J

I

I

I

'

I

'

I I I

I

I

~-

'

I

1 I

1 I

A

(-

-\

\

- '

/ / )

//0

_::\

I

I I

I I

1 I

I I

I I

I I

I I

I I

1 I

I I

I I

I I

\

\

\

\

\

I I

I I

I I

I I

'

\

\

\

\

\

\ \

\

I I

I I

1 I

I I

\

\

\

\

\

\

\ \

\

)-J

I I

I I

I I I I I

I I

----

N

(I)

0

X

¥

\

\

(I)

0

X

¥

0

s

X

¥

- - - - - - -

--<

I

_J

-23-

Page 28

~-

-

~--

-~~.-

-·-

---s-

-.----~.

---~

--~

-

·

--

--r-

I

1\:)

,::...

I

3Wns

UST

..

U...

PARTS

LBT

~

·,I.;J

POR

liS..,_.

I

~

I

L----------

l - - - - - - - - - -

\'$1(•

- - - - - -

~

- - -

~

Page 29

1\)

01

MS080

1.1506 r"\

MT16

S.,.502

I

I

\,......--~~;)

6

f':\

Th

~~--

~~

v

1"-,_.

n .

~~-<

l \

\

\.

\""""

C

.1

/ MT~

·-·

-

_)}

)!

·

P\1

. ' .....

'<;[ ·:......

:\

\Y.

~

,/

~~11

•m

)

110

~

$00

·

5....00

~

1

··

' ·

~m

o

f'

l.,,

' , MT32

~

~

MT30

$~

I

it

.

S'-'11

10

.

-

~21

St,II.U

L -

5

'11431

I

-

.J

Page 30

1\)

0>

.Ill

)

"-

MV09-1 I

""'

'

tr;l

-.

S~50

MV26

\ .

~1\

~

--

/

MVIO

I

r::

· ,

133

'

~

"

~/

i.

\

'-1~17·1

\

SM401

SM133

SM110~

~!"'~~

MV4D

~

'

Mv:?S

~

·

/

('-

v:· - S..W01

PM002>

' •

....._

..._

MVO$ SM603

- \

MV~

MV04

MV17D

'

' $1<576

. MV19

(j

M~

I

/~

SK25ot

MV18

MV43

W1<11

MV09·3

(240/248

MV09-4 SM

(356/

384Jij)

MV06

MV05 SM301 :

I

I

- \

PMIIO

SM135 I

SK555

:

~

-

-·

MVOI

',) _

MV03

DXXXX

~

/

MV22 1

, '"'...,

'

~M~l

>

W"~

/

SM435

~

MC60

SK576

SM~l

SM600

Q

EM164

'

.

HXXXX

MU12

I

/'

/

/

~

~?

\

MV27

I

Mv~s

~

/

MV32

~·!101

I

i "

~

;

(,'(), ·:.

J(;J

./

'IAV~l

~

·

" ,,

':

. • M\..01

•·

'IAV37H

;!/!)

,:

· ..

)./.

L----------

______

_

___

__

J

Page 31

I

""

I

'""'

MYOI

<?

-..r,.

~

iU

TPJC

.

--·--

IRIS)

I

KY04

IIZ

·=

-ir1

~,

~

I

I

"---

"---

27

~

,

KT14

MY

27

~

•

It

Ill

Ill

191

~

•

I UY12B

i1ii1

GI\S

SM886-A

--

-

~

L

---------

- - -

--------

SM886·4

e WM8 10•4

' SK391•S

------------------

Cl>

e!t

WM800•4

N\1811•4

I

I

I

l. - -

/

"-.

,

.

',

• /

"

"'-"/

/-""'--..

/

!l

lZJ

J.IZ23

SJR~

GOLD

EX

l-'11{

0 T

__

______

K

G

.J

Page 32

T--

- T

I

t\)

co

I

PARTS

LIST

KW05[H

SK4~~

lJJfKW22

i

FOR

MW

KW;l6f3

~

·~~

GROUP

,.

--

'''Sc

KW14F

:

K~9F:

NK2BD•5

SVvtl4•5

L

L

Loading...

Loading...