Page 1

HIGH-SPEED

ilJJ.Ii~B~~

LOCKSTITCH

SEWING

MACHINE

•

OPERATION MANUAL

PARTS

itt=

m

lil·mJI~illfliliRR~f~~~~~61

ZOJE

-¥

BOOK

SEWING

•

MACHINE

CO., L TO.

Page 2

~

$!i

~ ~]

tJL

1 .

±.

!}'jfi

/jt~~

2 .

~ ~]

tJL

1¥-1

Jll:z;t

J

3.

4 .

5.

6.

7.

8.

9.

10.

11.

12 .

1

3.

14.

15 .

16 .

17 .

:t~:fl·

~~a~

:1Jrt

~~

~~ffiS

m tt

~

tr~etr-J i

ffi

iii~

~~

-~*1J

~k~~ aqi~-;1"

~li~fF~Ii~

:fJL

!fi:

'iEb

••••••••••••••••• . ••. •......

nbki¥-J

nb

a9

!fi:

~L

\ (~~

~

.J3Ji1

)Jt4J

ffi

1J

l¥-1 ~ ~:1:1~

~

!lii~/1~···

tt

f•

11:.

Mtr

l't-J

'tl:

~

$

J9!

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 1

~

~

'

!};: ~ ...........................................................

~

1t

a

q~~

':l

···

...........................................................................

i~~

:li (nb~

':l/1 ~ · .... ·

~

n i*-· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 1 o

........

··· ··· ··· ···

··················································

aqi~~.ni*-

)

.. · ..

.........

...........•••••••••••.....•.••••••••••••••••••••.•...........

...

···

......... ···

...................................

.........

··· .................................... ···4

· · ·

······················6

.

.............

..........

...................................................

· .. · .. ·

.. · ..

· .. · .. ·

.. · ..

· .. · .. ·

.. · ..

· · .... ·

.. · ..

· .. · .. ·

.. · ..

..............................................................................

~

~

-;1"

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

..

.........................................................................

1¥-Ji~~

fli.

........................................................................ 14

••

••••••••••••••••••••••••••••

.!l! a9i~i1

)!l

a9

~ ~

..

................................................................

•••••••••••••••••

•••••••••••••••••••••••••

.................................................................. 16

..

................................................................ 1 1

••••••••••

2

2

···

4

5

···7

· · .. 9

1o

• 1 0

11

···12

···14

18

19.

20.

21.

22.

23 .

24 .

25.

26 .

27.

28 .

2

9.

30.

3

1.

.

1!;1

~ ~ ~i:J ~

~~

B-9

i~m

~*.&~

•

~~

mfi~

~

~

~~~E

~ ~~

~

ft¥~m~

~

fi

i"r=

m~t~~

n

JJ

J1~tl~···········································································2t

fl:·

························································

.1::§

1i~

tr-J

fiJf

~~J

1¥-Ji..ffllm

3if

l'fJ

i{fj

1¥-1

rPJ ~ ••••••••••••••••••••••••••••••••••••••••••••••••••

::)J!ffi

~:tl:7t

~

]tJLI¥-Jtf&~&

nb

~ ~

!::§1

~

:tJn

.. •

.. • .. • .. • .. • ..

·························

··········

m

JJ

·····

·

·······························

a'9

* ~ ··· ··· ··· ··· ···

.1::§

5I! ~ ..................................................................... 24

1¥-Jiiff

1@.1::§

£~

·

············

.........

............................................................. 25

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

~

Jj{

~

ft.m

*41l

...

............................................................ 2 7

......

··· ··· ··· ··· ··· ··· ··· .........

• .. • .. • .. • .. • .. • .. • • .. • .... • .. • .. • .. • • .... • 18

·

········

··· ......

··· ···

··· ··· ··· ··· ···

· · ·················

·

·································l9

·

········

··

·

·················

..........................

••••

•••••••••••••

•••

•••••••••••••••••••••••••

... ··· ··· ···

··· ··· ···

........................................................................... 30

1.&11:

7±

~$J9!

.......................................

............... 3 1

··········I9

2 2

....

....

..

23

26

28

··· 29

Page 3

Befo

_re operation····

CONTENTS

··································

·······

······························

···1

1. Specifications

2. l_nstallation ·

3. Adjusting the h

4. Insta lling the thread s

5. Lubricatio

6. Adjusting the amount

7. Adjusting the amount

8. Attaching the needle

9.

Sett

ing the bobbin

Adju sting the stitch length

10.

11.

Pre

sser foot press u

12. Threading the machine head

13. Winding

Th

read

14.

15.

Thr

16. Adjusting

17. Adjusting the needle stop position

ten

ead

take-up spring

··········

··

···

···

eig

n····

···········

the

bobbin thread

sio

n···················································

the

thread take-up stroke

·····

···

················

···

···

···

···

···

···

···

ht

of

the

knee

lifter-········

tand···········

···········

of

oil in th e hoo k

of

oil(

··························

int

o the bobbin

re·····

····

"· ..........

············

oil splashes) in the hook ······

..................

···

·····

........

......... .........

...............................................

······················

···

···

···

···

···

···

···

···

·······················

····

·······················

···

··············

·················

···

···············

case

"""

..............................

............

············

. ...

.....................

.....

...................................................

·········

...

.......................................

....

........

.....

····

. .........

·····

··············

···

···

···

···

···

·············

· ·· ·

······

···············

······

·······

····

···········

····

····················?

······················

................

··· ··· ·······

......

.........

·····

···· ·· ·

.....................

···

··········

···

······· ···6

........

......... 10

·····

...

·······

···

···

···

···

···

···5

···

······lO

......

·····

......

2

2

4

4

9

. 10

11

12

14

14

16

17

Oil cheak

18.

19. Adjusting

20. Pedal operat.ion

21. One-touc h reve rse stitching mechanism

22. W

23.

24

25. Change

26. Adjustment

27 . H

28.

29.

30 . Micro-lifting mechanism

31

ipe_t--

Needle-to-hook

. Change

eig

Adjusting

Thread tension r

. Caution when

and addition

of

the pedaJ

··· ··· ··· ··· ···

of

counter

of

counter

of

ht

and tilt

the

"'"'"'

...........................................................

··· ···

··· ··· ··· ·· · ···

··· ··· ··· ··· ··· ··· ···

relations

knife

knife and moving knife

trimming system

of

the feed dog ...

feed

timing·

elease

car

rying

..............................

hip····

.....

relea

or placing the sewing machine

·····

...

.....................

..................

........

sing

of

the presse

··· ··· ··· ··· ··· ··· ··· ···

···

··· ··· ··· ···

···

·····

...............

...

...

...

mechanism

........................ oo•18

··· ··· ··· ···

................................

···

···

··· ···

··················

.....

....

...............

···

.....

. ...

.......................................

........................

...........

r foot

"""

..............................

··· ··· ··· ··· ··· ···1 9

···

··· ··· ···

··············

........................

...............

........................

...

.............

.....................

..........

.

......

.......

......

··· ··· ···

·· ···

......

....

............

19

···

22

···2

24

... 25

26

27

. 28

....

29

30

..

31

21

3

Page 4

~•=~T~~m•~·-~~~·~·••~~~~~0

>•-~•~mme~~·~•~•(IT~)

>

-ttm

zHtri#-~t:tnatt

>••~m•~mzHtr.Mremena~~o

.P1Jnna

0

0

>••~m•~~~~~~·*•Mo

>

i~

-~

lt!.ffi

ii

~j!

~

iE

7iffJ

0

>

iFf

7iffri-A

It

iiJlHi

ik

:.l!

~

iE

7iffJ

:it

ft

o

>~m••~~"·

>••~~~~*~~~~n~~NIE•o

>•~wre•~m~mm.

•~~~-~m

~~~~~-~~#o

>*•~•~•w•*••~~fra~mft~~**·~~.~fta~mM,i#IE•

~~~•~me~~Mn*~m**

BEFORE OPERATION

Caution: To avoid malfunction and damage

};>

Remove air-vent cap (red color) attached to the sewing machine bed.

};>

Be sure to pour in the oil before using.

};>

Before you put the machine into operation for the first time

thoroughly.

};>

Remove all dust gathering during transportation and oil it well.

};>

Confirm that the voltage has been correctly set.

};>

Confirm that the power plug has been properly connected to the power supply.

};>

Never use the machine in the state where the voltage type is different from the designated

one.

};>

Confirm that the direction

};>

Do

not tilt the sewing machine head toward this side since oil leakage

occurs.

A safety switch is installed so

tilted. When operation the sewing machine, turn

on the table.

of

rotation

that

of

the machjne, confirm the following.

the sewing machine cannot

.

·

after

the set-up , clean it

of

the motor pulley is correct.

or

parts breakage

be

operated with the head

On the power switch after properly setting the head

- 1 -

Page 5

Jtl~

iWf4

J!):f

~

l&i'ili~:ii

f&::kttie

i!f~HJ

Ut

JJiJII;IljQj~

i~JH

~JL

»1:1

it

Jlf

Ft!

*JL

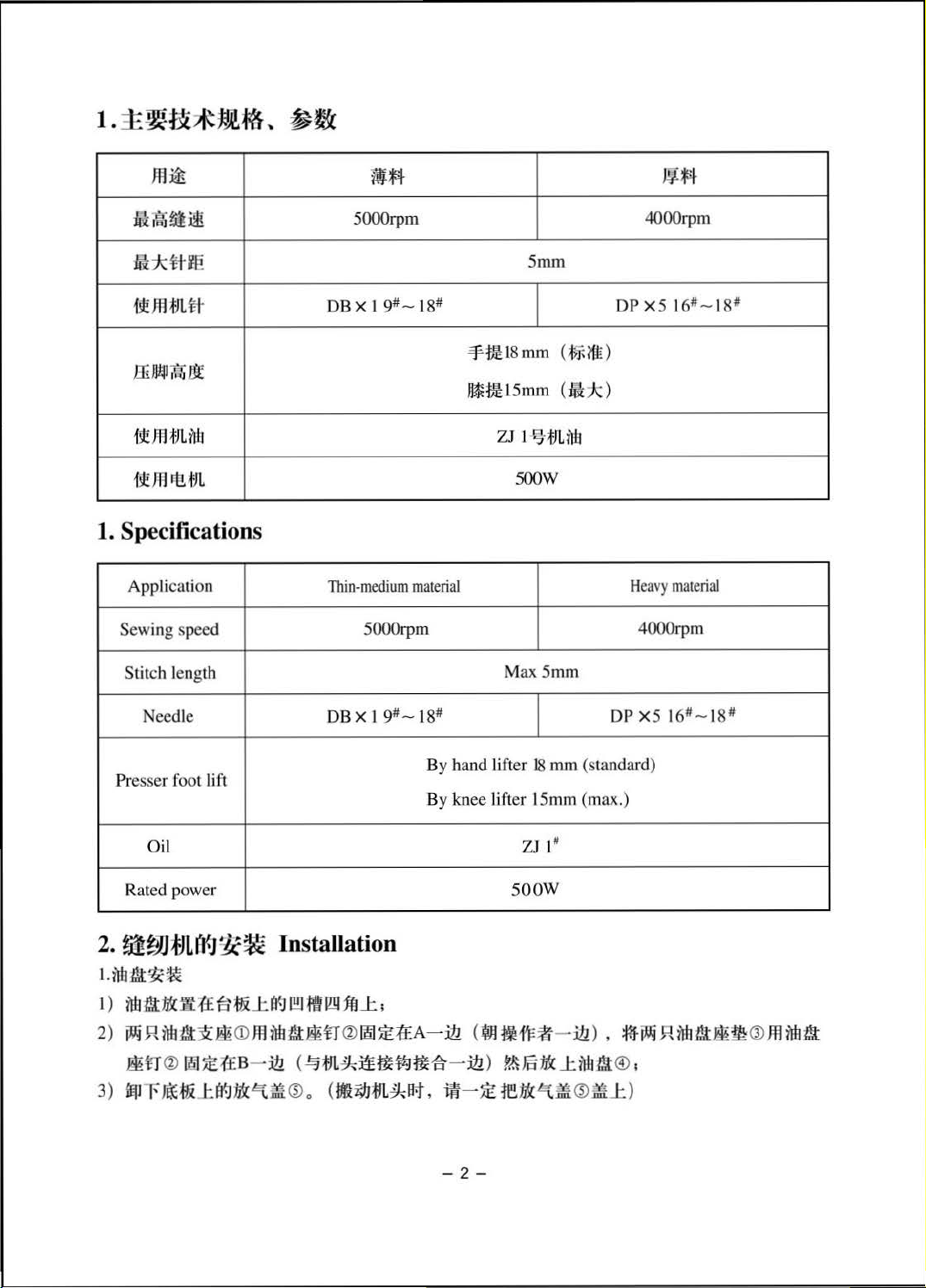

1. Specifications

Application

Sewing speed

length

Stitch

Needle DB X 1

5000rpm

DB X 1

Thin-medium

9#-18#

5000rpm

9#-18#

material

Smm

~tlt18mm

111tm:

15mm (-Ji);:)

z1

Ma

1

·

~-

m

500W

x5mm

(~(ft)

nn

4000rpm

DP

X5

H

eavy

4000rpm

DPX5

16#-18#

material

16#-18#

Pr

esser foot lift

Oil

Rated power

2.

~~Jmt¥J~~

Litl:l./lt~~

1 )

ntre.t

:It<

ft

1£

a

2)~R~~~~~Jtl~~~fl®~~~A-~(~~~~-~

~n®~~~B

3)

•~••J:~:It<

Installation

:t&

J:

atH!!l

.fltm

1ft

J: ,

- ~<~•~~~~~~

~~®o (m~m~H,a-~re:Jt<~m®~J:)

By hand lifter

By knee lifter 15mm (max.)

- ~)~Fo:tt<J:~a

- 2 -

18

ZJ IH

so

ow

mm

(standard)

),

~~R~~~~®m~~

®

,

Page 6

4)

:I~HJL

~

:itf

f&

fZ.J

®

:Jili

A

m;

tlHili

:fL

P-1

,

.!:§

€?

~

0

~m~:itf-~

till9

.R]M

~•:~-~~~-~-

~~~M itH

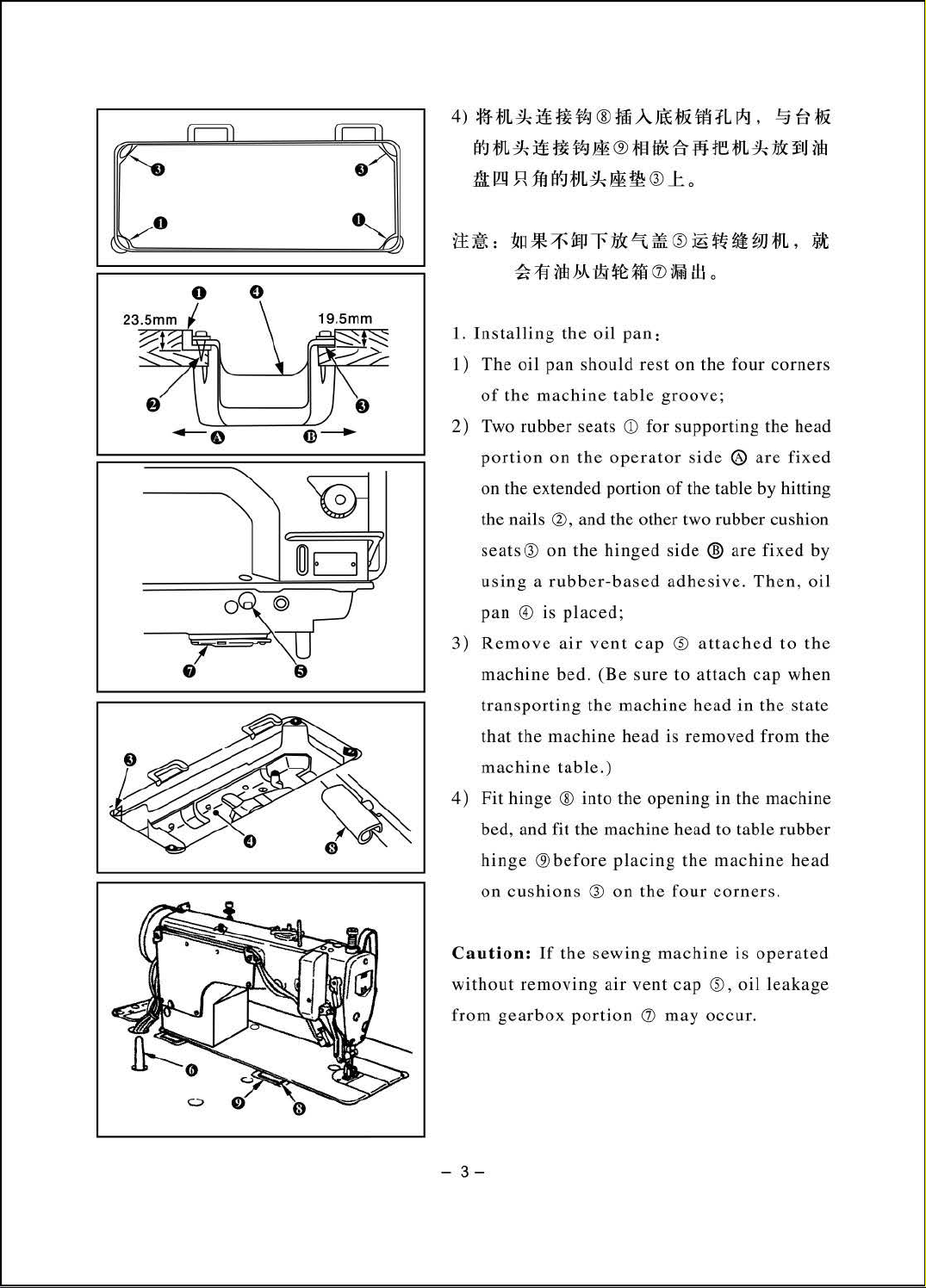

1. I

nstalling

1)

The oil pan s

of

the

mac

2)

Two rubber s

portion

extended portion

on the

the nails

seats

Q)

sing a rubber-based adhesive. Then,

u

pan

@)

3) Remove

&®a&

~tJL~&m

~~<D~tf.lo

the

oil

hould rest on the

hine table

eat

s

on

the

operator

Q), and the other two rubber cushion

on

the

hinged

is

placed;

air

vent

~wrem~•~~

Q)J:o

~~

ft•wm.a

pan:

groove;

CD

for

support

si

de ® are

of

the table by hitting

side ®

cap ~ attached to

four

corners

ing the head

fixe

are

fixed by

oil

the

d

mach

ine

bed. (

Be sure

transporting the

that

the

machine head is removed from the

machine

4)

Fit

bed, and fit the machine head to table rubber

hin

on

Cau

tion:

without

from

gearbox

-

3-

table.)

hinge ® into the openi ng in the machine

ge

®bef

cushion

If

the

removing air

machine head

ore

placing

s

Q)

on

sewing

port

ion

the

machine

vent

d)

to

attach

the

machine head

four

corners.

cap

~

may

occur.

in

is

.

oil

cap

when

the

state

operated

leaka

ge

Page 7

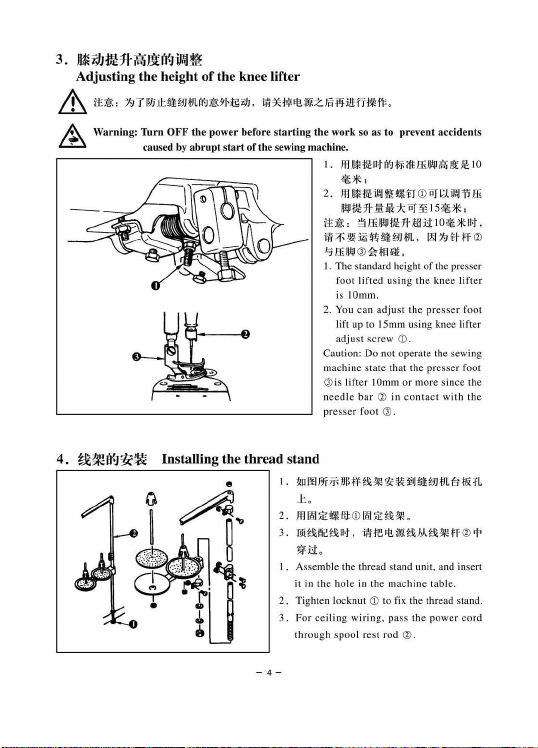

3.

JWi;JJi~Jl::ff-jl'~Ji:(J'1iJ.';J~

Adjusting the height

.&.

f£:lJ.

,

1>HJill:iJ!!

~

Warning:

~

4.

~?>f!IY-J"tif11&

Thrn

of

the knee lifter

J

JIJL(l'.J

:ll:~

r<i:

iii

OFF

the

power

abrupt

start

before

thread

caused

by

Installing the

J.

il11d>:iot!

ii!/.Z.JiiJ!iili'I

H\lfF.

starting

the

work

so as

to

of

the sewing machine.

I.

2.

lt.fr.,

ill'l;'l'iit~iJ!!JJ~

'lffi~

1. The standard height of the presser

foot

is IOmm.

2.

You can

lift

adjust screw

Caution: Do not opera te the sew ing

ma

chine s

@is

needle b

pr

esser

prevent

!I!I!H.lnt(l'.Jlii~

~*'

!I!I!Utii!J

l\'ll!!!trCD

~t:Hrliliil-*"'"'

~lli~!IHhllltll

())

~lillil!.

lift

ed usin

g the knee

adju

st th e presser foot

up

to 15mm usi ng knee lifter

CD.

tate

that

lifter

the

IOmrn or more si nce th e

ar

(1)

in

con

foot Q).

stand

I.

•oo•~·lf··~··iJ!!JJIJL8.R

J:

.

2.

!llllii1EI:!!JltCDiiii1EB!.I\!.

3.

••~•M.

~u.

I.

Assembl e the thread sta

it in

2.

Tighten locknut

3 .

For

throug h s

mre•••Ma•w

the hole in the mac

CD

ling

wiring,

pool rest rod

to fix the thread stand.

cei

nd

hine

pass the p

Q).

accidents

t

lli~i\l;IJ

U€

10

llJI;.(

ii!Ji'illi

1s**,

D/Glltllt

L.

IN1J\tlf0

lift

er

pre

sser

foot

tact

with

the

(l)

•

unit, and insert

tab

le.

ower cord

,

-4-

Page 8

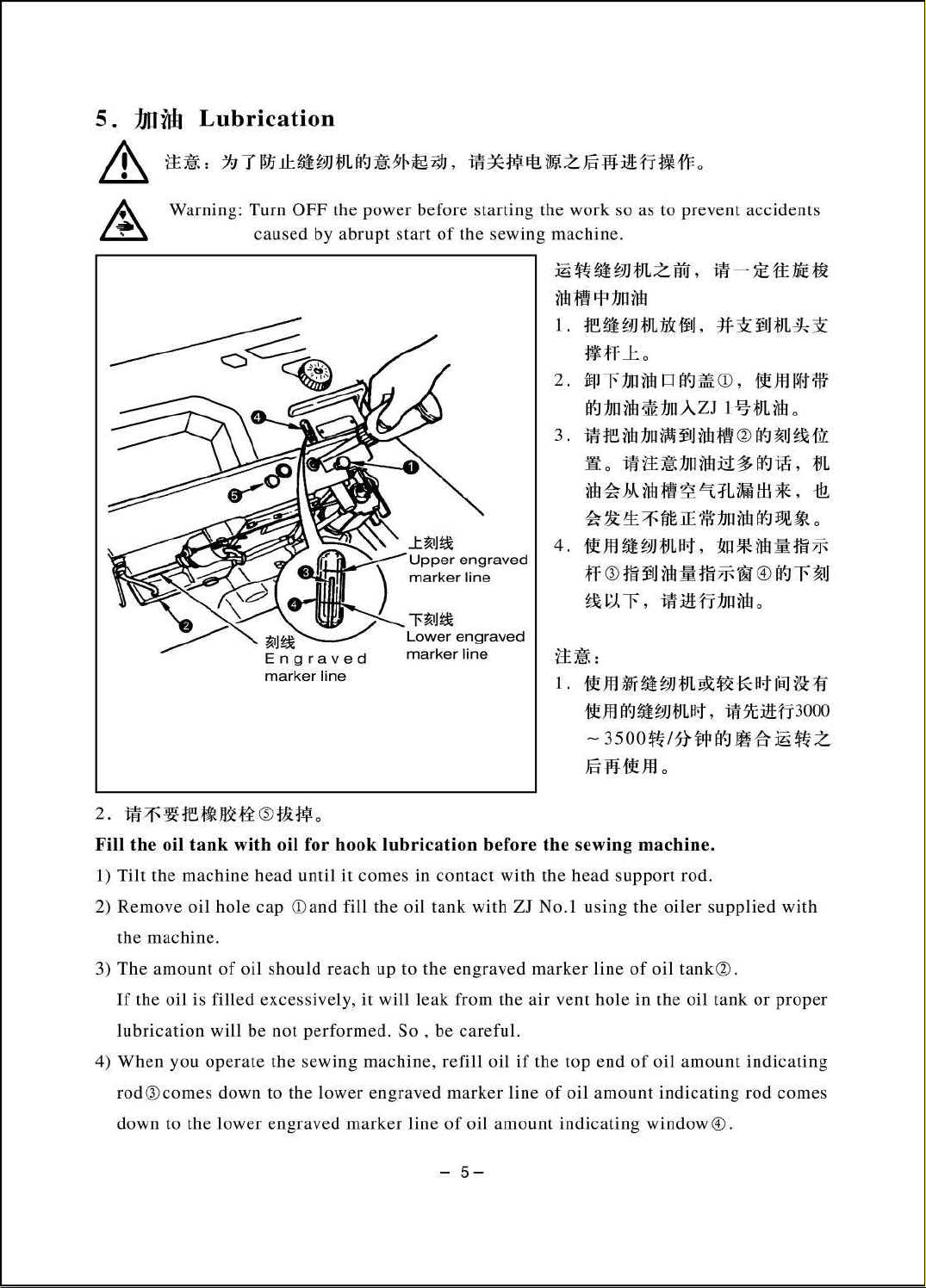

5.

:bnifll

Lubrication

&

t:t:

~

:

t:J

T

l!lLtl:

Warning: Turn

caused

~~]mat~

OFF

by

~)'~t9

the power before starting the wo rk

abrupt

~),

start

of

the sewing machine.

TR :¥dlji

It!

i1Jj{

zm

~~~~JH

nil

m

1.

2 .

3 .

4.

¥£~:

1 .

¥I*

rr

11

~

0

so

as to prevent

JLZ.M,

9='

1Ju

nil

t~J.iH3HJL1Vti~,

:};ff

J:

0

ffll

r

1Jn

nil

o

at~

f81Ju

nil

{i£

1Ju

A

i~He

nil1Jn m ¥lh1t

it

0

TR

11

!.lf.

1Ju

M~.JAilBM~-9.1L~

~

1st

~

~

1m

IE

~m~~JHJLar,

®

m¥1JM:IH~7Fm

ff

~l

LV-

r ,

iW

:tlHr

-tt

.m

Wr

~~31m

~m

a~~~JJ;j:JLBf,

-

3soo~t7titP

m¥I1~.m

0

accidents

ti\f-~tttifE~

#st¥IHJL*x

~

<D

,

1~

.m

llfHW

ZJ

1 -5

;j:JL

nil

o

:m

®

at~

~IJ

~

111:

nilli

~

at~

-m

,

:YL

lli*,

'ffi'

1JU

ilB

at~~~

:!ln.*M

®

nn

M 0

Wt~ -~at

-I1L

o

:!if~iF

at~r~u

1iiJ

¥5t

;;g

TR9CJH:rr3ooo

f8ll-€1

~~z.

Fill

the

oil

tank

with

oil

for

hook

lubric

ation

1)

Tilt the

2)

Remove

the

3)

The

If

lubrication will

4)

When

rod® comes down

down to the

machine bead until

oil hole

machin

amount

the

e.

oil

is filled excessively,

you

operate

cap <Dand

of

oil should

be

lower

it

com

es

in

contact

fill

the

oil

tank

reach up

not

performed. So

the

sewin

g machine, refill

to

the lower engraved marker

engraved

marker

it

to

the engraved

will

leak from

, be carefu l.

line of

-

before

with

oil

oil amount

5-

the

sewing

with

the

head

support

ZJ No.1 using the

marker

the

air

if

th e top end

line

line

vent

hole

of

oil amount

indicating

machine.

rod.

oiler supplied

of

oil

tank

in

the

oil

of

oil

amount

indicating

window®.

®.

tank

or

ind

rod

with

prop

er

icating

comes

Page 9

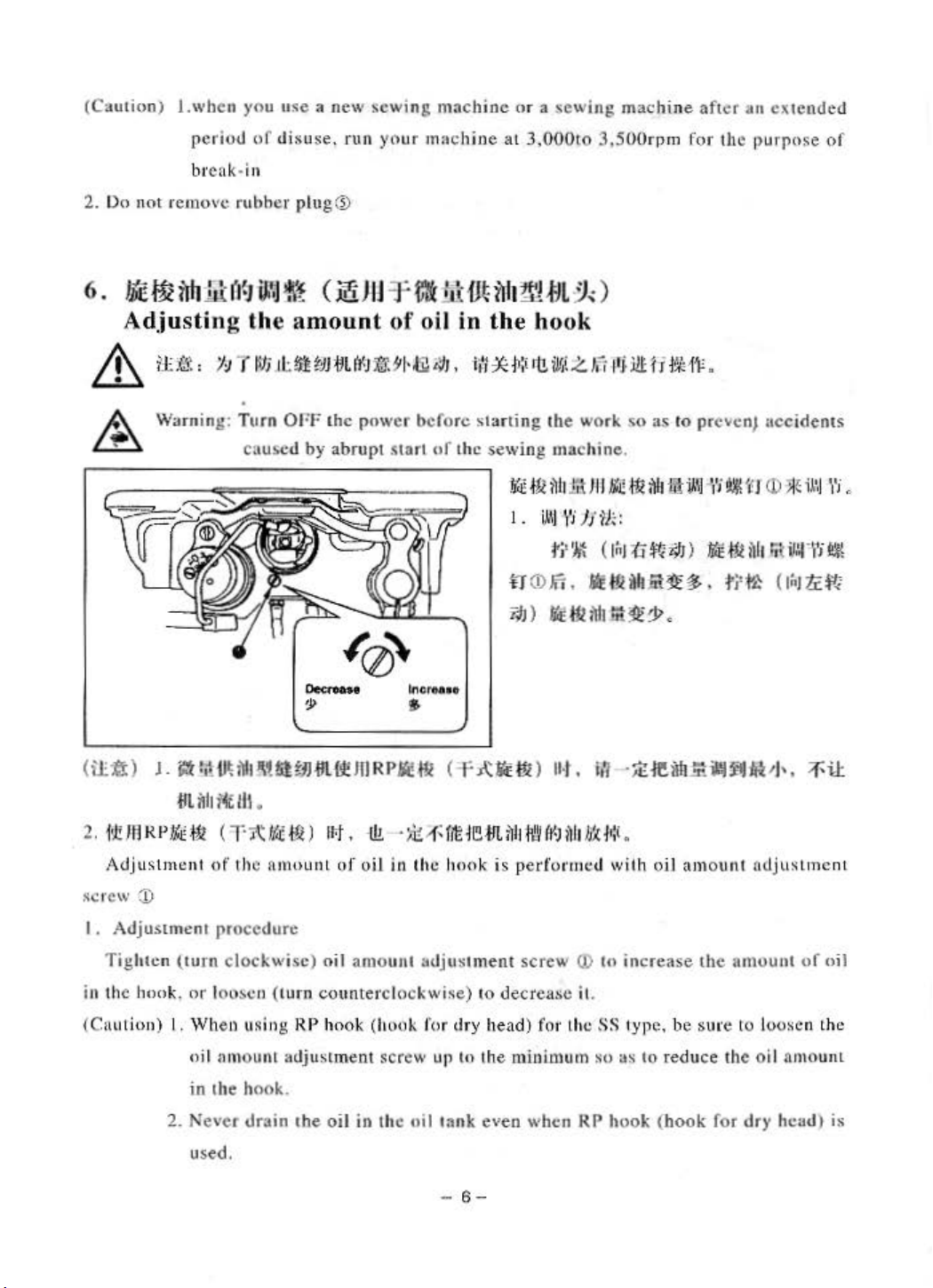

(Caution) J.when )tOu use a

new

sewing machine or a sewing machine

after

an extended

period

b

2. Do not remove rut>bcr plng(i)

6.

••Mhl~~•c•m~~~m

reak-in

uf

disuse . run

your

Adjustin g the amount

&

~

t±:Gl:,

hniJi.ll~H1J=l1

A Warning: Turn OFF t

caus

ed

by

l

t'tJ:Q:~

he

power

abrupt start

machine

of

oil in

I

·~

·~I.

before star

uf

at

J,OOO

M

~M~)

the

hook

iti*W

the

r

!J.~l

~Jti

ting

the work

sewi

ng mach

~

#Hhi,l/11

I .

~I

]

\'i

ti·~

uma.

l;IJ)

~~hh.r.tW1>.

to

3.5

00rp

rn

for tltc

t

t}:liH

:i

l

~ft

.

•o

as to

pr

evcn)

ine

.

&i!l'l1

;\It

ilk

i.I~-W!ll!{

fit}

;:

( '"'

:t

H~iJI)

•~•aw•.w•

h!E./11

purp<>Se

accidents

'H <D:il~il',J

iilt

Ji'(

of

•,•;.

ulfri~

<~

~•

(iU!)

2. 1

SCI'C

I . Adjusunenl

in the hook ,

(C

J.

~l;!iJ~

m.

\Cm

RP

I;dl1 ( T-1-:l

Adjustment

\\.' :I)

Tigh1cn (I

nulion)

I.

2.

ilh,.H

iHJJllla! lll

ilh

i't

Ill.

r.i

~)

of

the nmu

procedure

urn

cloc

or loo•c

When usi ng

Hi I am ount adjustment screw

in the hook.

Never

us

drain

ed.

kwise

n (

turn

unL

) o

counterc lockwis

RP

1he oil

RP

II!#I

111'. ·

l!!.

·

>k.-f;

of

oil

in the h

il

amo

unl

ho

ok

(hook fur dry head)

in

the oil

(

-f

A':JE

Ill

f,t

JB:flt

~lrh'Ht~

onk

is perf'ol'mc.d with

adjus

1ment sc•·ew (I) to i

e)

10

decrease il

up

to the minimum

lank

even when

-

6-

)

fo•·

ll·

t.

l1h

t

he

RP

lt1

·

It

IJH:i.

ncrease

.

SS

1ype, be sure to loo

so

as

to

hook (

fl!M~illfUi~'''.

oiJ

amount

the

reduce the oi l

hook

ncljusLmc.

amou

for dry hcad)

;r-iJ:

nl

uf

sen

the

amounL

nL

oil

is

Page 10

7.

Mf~t.iHrb

-§i ( ftb~)

Adjusting the amount

IY-Jim1~1Jl!

of

oil

(oil splashes) in the hook

Warning:

<D

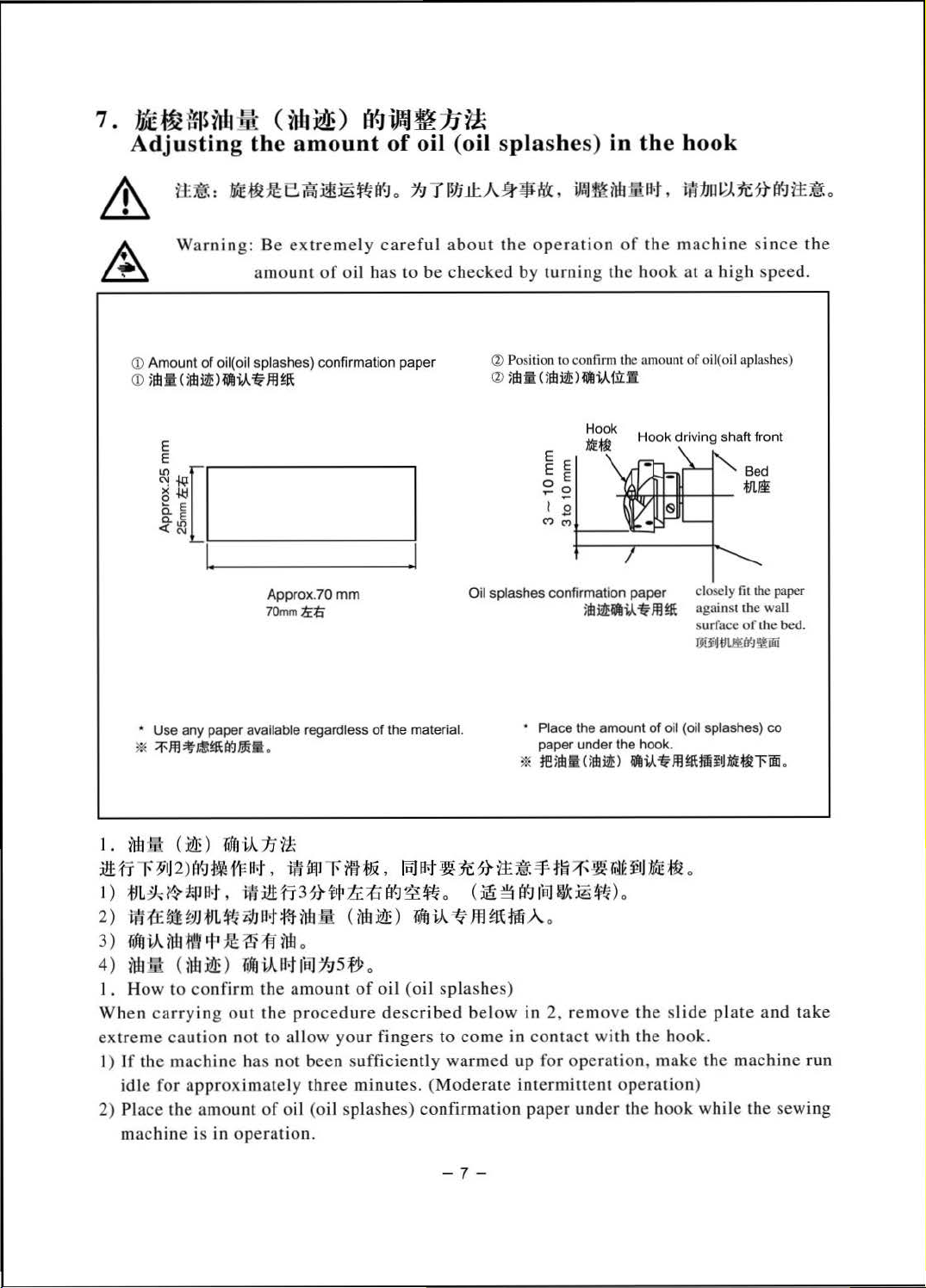

Amount

<D

of

i!IIA(iflli1t)~i-A1t.lfl~lt

E

E

U[

l I

11...-

• Use any paper available regardless

*

;r-m~.tt~tt-.Jm•

Be

extremely

am

ount

of

oil( oil splashes) confirmation paper

-------!

Approx. 70

70mmliti

.

careful about

oil has

mm

of

the material.

to

be

1

checked

Oil splashes confirmation paper cl

the

operation

by

turning

Q) Position to confirm

Q>

ilb:ll

Ulbi2E>

~i-Aitl

~:k

~!

1 2 ,

(')

(')

;drit!.i.A:1Hfl~

• Place the amount

paper under the hook.

* teidlil

U!Bil!l

of

the

th

.

I

the

machine

hook

at

e amount

J;

cr

.i.A.'lt

of

H

ook

driving shaft front

h~~

~

-

'---

against

surface of

TJiJIJM(J()!lliJii

of

oil (oil splashes)

Jll~fifiitJMEUll'im.

since

a hi

gh

oil( oil aplashes)

the

speed.

~e~

ose

ly

lit

the

paper

the

waU

the

bed.

co

1.

~

li1

( ~ )

Tiff

J

iA

15

'lt

:itHi

r

~r

j

2)

~1'-J

~~It-

t

,

iff

fiji

r

i1f

:f1i

,

1m

at~

1f.

?t

11:

~=f.

j~

=l~ * ~~

I )

;tiL~

It

~

I

P·

l',

~:itt

fj

3

?t

itjl

1C

;{J

tf.J

~

~

o (

~

~

tf.J

1

~11

ijX

:i6

~)

o

2)

~a~wm~~at•~•(M~)•~~m•MA

3 )

r~ffri-A

iw

f\'~

r

t•

:f€

~ ~ M o

4)

nil

iil

1. How

Wh

en

carry

extreme

1) If t

he

idle

2) Pl

ace

machine

U\:1! ~ )

to

caution

machine

for

approximate

the

Tdfri-A

confirm

ing

out

not

has

amo

unt

is in op

at

fij]

T:J

the

amount

the

procedure

to allow

not

been sufficiently

ly

three

of

oil (oil

erat

ion.

5 fy o

of

oil (oil splashe

described

your

fingers

minutes. (Mode

splashes)

confirmation

to

warmed

-7-

below

come

rate intermittent

s)

in 2, rem

in

contact

up

paper

o

ove

with

for

operation, make

operation)

under

the hook while

!l

j

ME~

the slid

the

hook.

o

e pl

the

ate

and

machine

the

sewing

take

run

Page 11

3) Confirm

that

4) Confirmation

of

time

with a

oil

exists in

of

the amount

watch.)

the

oil tank.

of

oil should be completed in five seconds. (Check the period

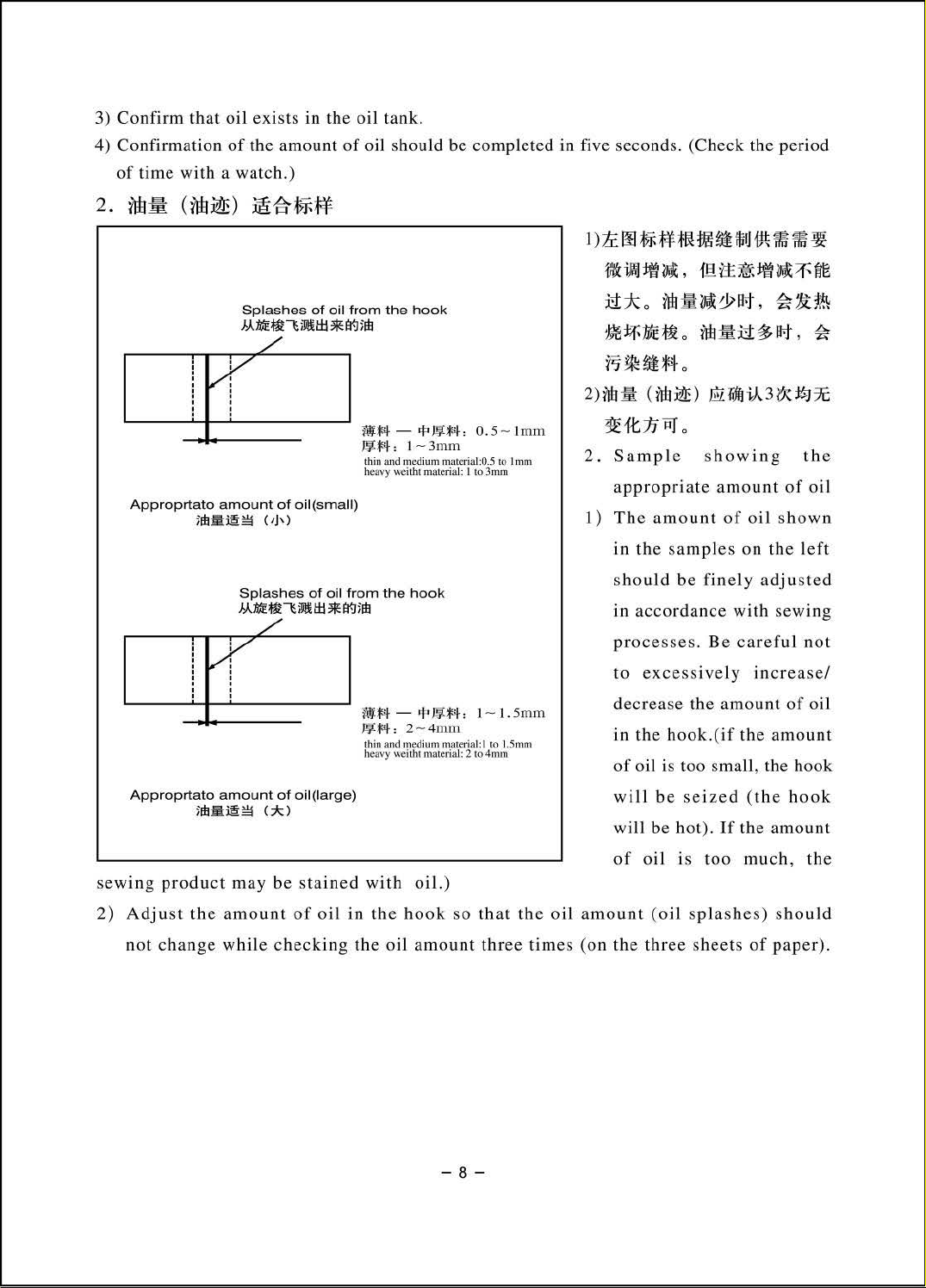

1

)tc

oo

t;-r-~m

:~m~

ifjfJ

-t~~

~ ~

!W

' '

: :

' '

' '

Approprtato

Approprtato

Splashes

J..A.:tE~~~tfj

of

/

)Jb

fi'i

amount

of

~~

Splashes

JAME~~~Iil

oil(small)

(Jj\)

of

/

~

:

'

'

amount

)Jbi!;~~

of

(;k)

oil(large)

oil

from

*Wlidl

oil

*Wlidl

the

~*il-

J!1*il-: 1 -

thin and

heavy weilht material: I

from

the

alf;t-•t•J!l!:f;t,

J~*il-:

thin and

heavy weit

hook

-

<j:o}!j(:jsj.

3mm

medium

hook

2-

4mrn

medium mat

htma

,

0.5

mat

erial:0.5 to I mm

to

1-

eria

l: I 10 I.Smm

terial:

2to

- l

3mm

l.Smm

4nun

mm

-VIt~~~'

U:koni:J

~

ff-

WE

fj

~~.Mo

2)

ilb

it

~1-t:IJRJ

2.

Sample

appropriate

1) The

in

the

s

hould

in

accor

proc

to

excessively

decrea

in

the

of

oil is too small, the hook

will

will

f

fl.tt~

.fl

~d>IJrt,~lt~

ttL

im

it

(

ilB ~ )

0

Ell

s

howing

amount

amount

samples

be

finely

dance

esses.

be

be hot).

Be

se the

hook.

amount

(if

seized (the

If

it~:::f'ffg

:i:t

~

1Ft

, ~

1iffriA

3

(X~

7C

the

of

oil

of

oil

shown

on

the

left

adjusted

with

sewing

careful

not

increase/

of

oil

the

amount

hook

the

amount

of

sewing

2)

Adju

not

product

st

the

change

may

amount

while

be

sta

ined

of

oil

checking

in

the

with

the

oil

oil.)

hook

amount

so

that the

three

oil

times

amount

(on

the

-8-

oil

is

too

(oil splashes

three sheets

much,

) s

hould

of

paper

the

).

Page 12

8.

lJL

*tf.J

~~Jj

r!

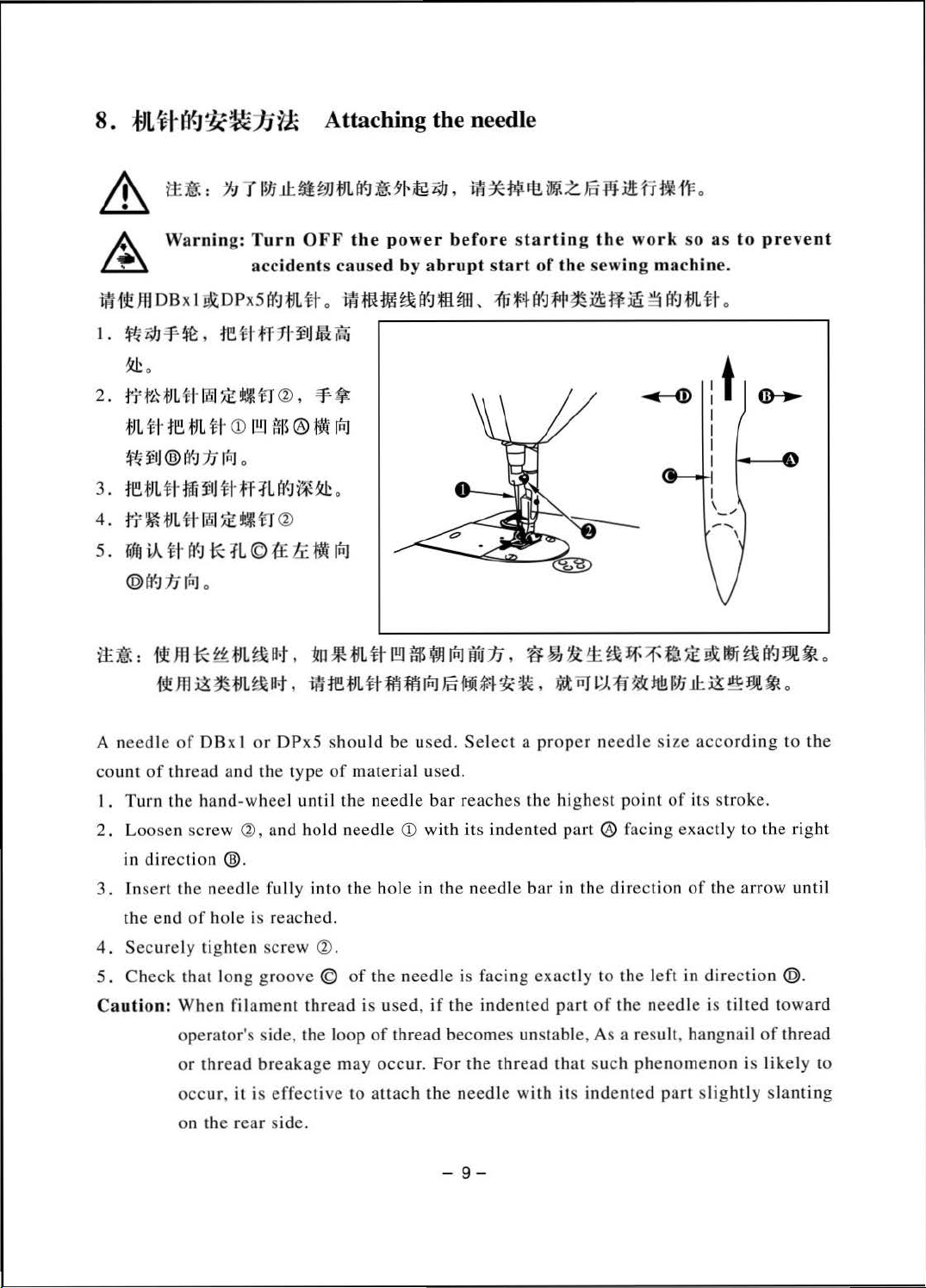

Attaching the needle

Warnin

i~i!l!JffDBx

1.

~i;JJ=f~, tEHff7!-~

2 .

:JY

t~

-tJL

tJL H tE

!ffl

flj

®

3.

retJLtf

·

4.

:fi'

~

fJL ~ lili

s .

rdfJ

iA

~

1·

@1¥]

:11

it~:

~

ffl

g:

Turn

acc

idents

I

!!X:DPxSJ'f.JtJUt

~t

IE

:iE

u~

n

<6J

tJ

L

~

I·

<D

1!!1

t5

B ®

I¥J

15

,.,

J 0

M~J~t·tr:fL(J'g1~~

l

:;E

Ul

t

.r

a:>

((~

*:

:fL

©

:££

lnJ

0

*:

i~

tJL~B·t,

Rm~•m~~.

OFF the

o

IJ:lti

•

=v-

*

~

rl:iJ

-

.li:

~

!RJ

"!ell

*t1LH

mremHMm!RJ~~~~•.

power

caused

i#;fllm~a~*JHHI,

r~

1!!1

before starting the

by

abrupt start

;{Jlfi.fl~~~~~ft~

$.f}I

!RJ

flu

15,

of the sewing mac

~ ~ ~ ~ ~~7f'fj~

-~~

work

«-

so as

hin

~

a'~tJLH

~M~~®••

to

prevent

e.

o

Wtlfi~

~m!~

·

o

A

needle of

count

of thread and the type

I . Turn

2.

Loosen screw (6), and hold needle Q) with its indented

in dir

3 . Inse rt the needle fully into

the end

Securely tighten screw

4 .

5. Check

C

aution:

DBxl

or 0Px5

the hand-whee

ect

ion

@.

of

hole is reached.

that

long gr

When filament

operator's side, the loop

or

thread

occur,

on the re

oove © of

breakage

it is

effective

ar

side.

sho

of

l until the n

(6)

.

thread

uld

be used.

material used.

eed

le

the

hole

in

the

needle

is used,

of

thread becomes unstable, As a result, hangnail

may

occur. For

to

attach

the needle with its

Sel

ect a proper

bar reaches

the

needle

is facing

if

the

ind

the thread

-9-

nee

dle

the highest point

part

® facing

bar

in the direction

exact

ly to the l

ented

part

of

th e needl e is tilted towa

that such phenomenon is

indented

size a

of

exact

eft

in

part

cco

rding

its stroke.

ly to the rig ht

of

the

arrow until

direction

slig

htl

y s

to

@.

of

thread

likely

lanting

the

rd

to

Page 13

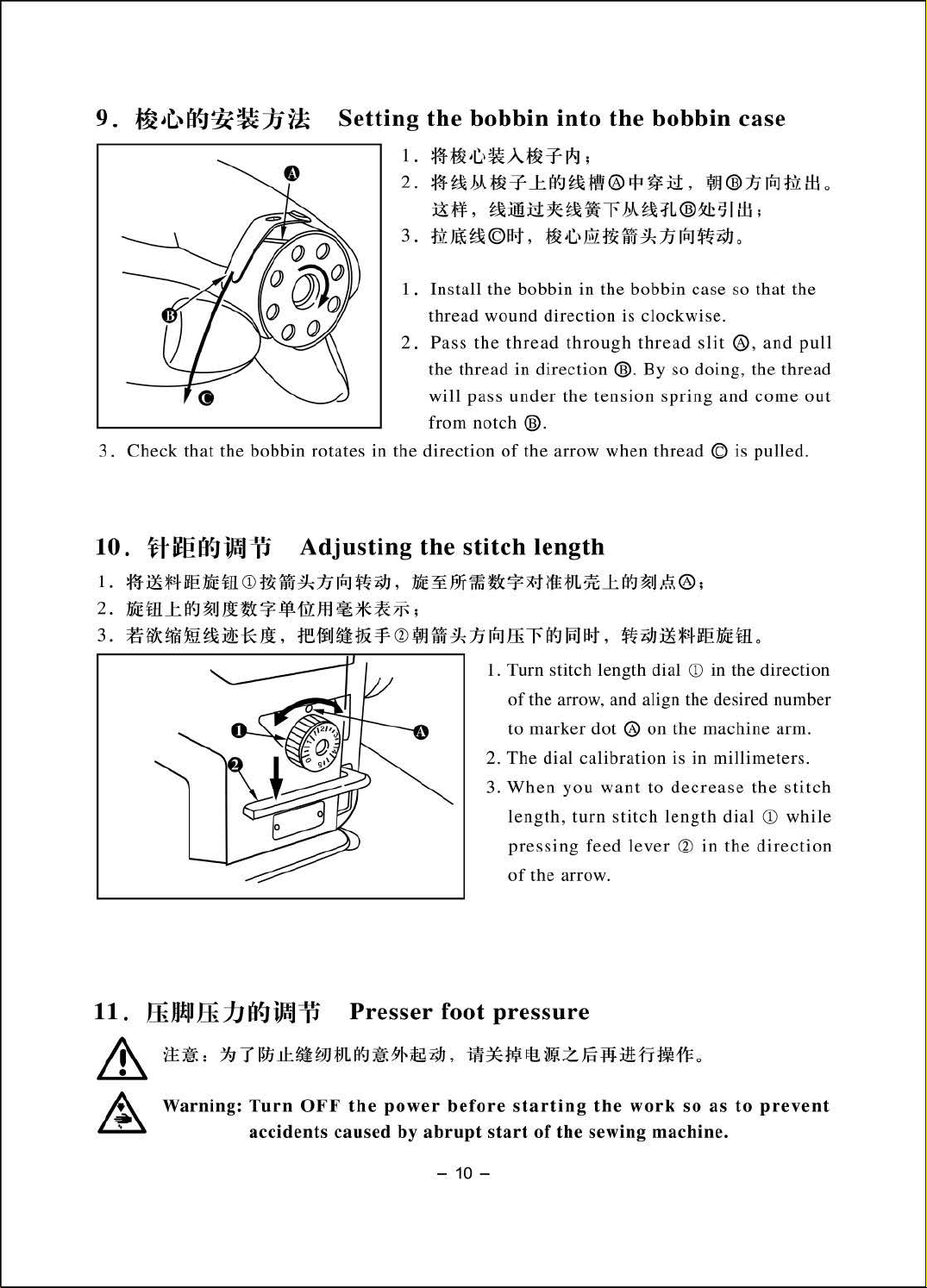

9.

~JL'ff.J:t(~JJ¥*

Setting

the

bobbin

1.

¥-t~·C.\~A.~JFF-1*1;

2.~~M~~~~~~®~~li.

:i!t-f,

3.m•~©"·•~m••~n~ft~o

~:ilii:i:1*~•-rM~1L®~sllli;

into

the

bobbin

~®n~~lli

case

o

3.

Check

10.

1.

•mMm•m

2.

•m~~~~•*•~m~*~~~

3.

~---~~*~·

that

the

bobbin rotates in the

li-~eEI9iPfP

ro

Adjusting

•n~n~ft~.•¥~••*~•m~~~~A®;

re••••®~•~n~ffir~~"·

1 . Insta

2. Pass

ll

thread wound

the thread in

will pass

from notch

direction

the

stitch

the

bobbin in the

direction

the

thread

under

of

through

direction

the

@.

the arrow when thread © is

bobbin

is

clockwise.

thread slit

®.

By

tension

length

ft~mMm•mo

1. Turn stitch length dial

of

the arrow, and align the desired number

to

2.

3.

marker

The

When

dial

calibration

you

dot

® on the

want

case

so

®,

so

doing

, the thread

spring

to

and

00

in the direction

machine

is in millimeters .

decrea

se

that the

and

pull

come

pulled.

arm.

the

stitch

out

l

ength, turn stitch length dial

11.

&

A

ffi

JJ!P

ffi.1J

1±

~ : ~ 7 ~

Warning: Turn

tl9ili'3il

J.l:.

;.]]

OFF

acciden

ts

Presser

fJL

~

~

the

power before starting

caused

foot

:9Ht~

i;IJ

,

by

abrupt

-

10-

pressing

of

pressure

ilt

*Wit

start

the

of

tuit

the

feed lever

arrow.

z m

~:itt

the

sew

ing

fJ

~

1'F

work

machine.

® in

o

so

the

as

ro

direction

to

prevent

while

Page 14

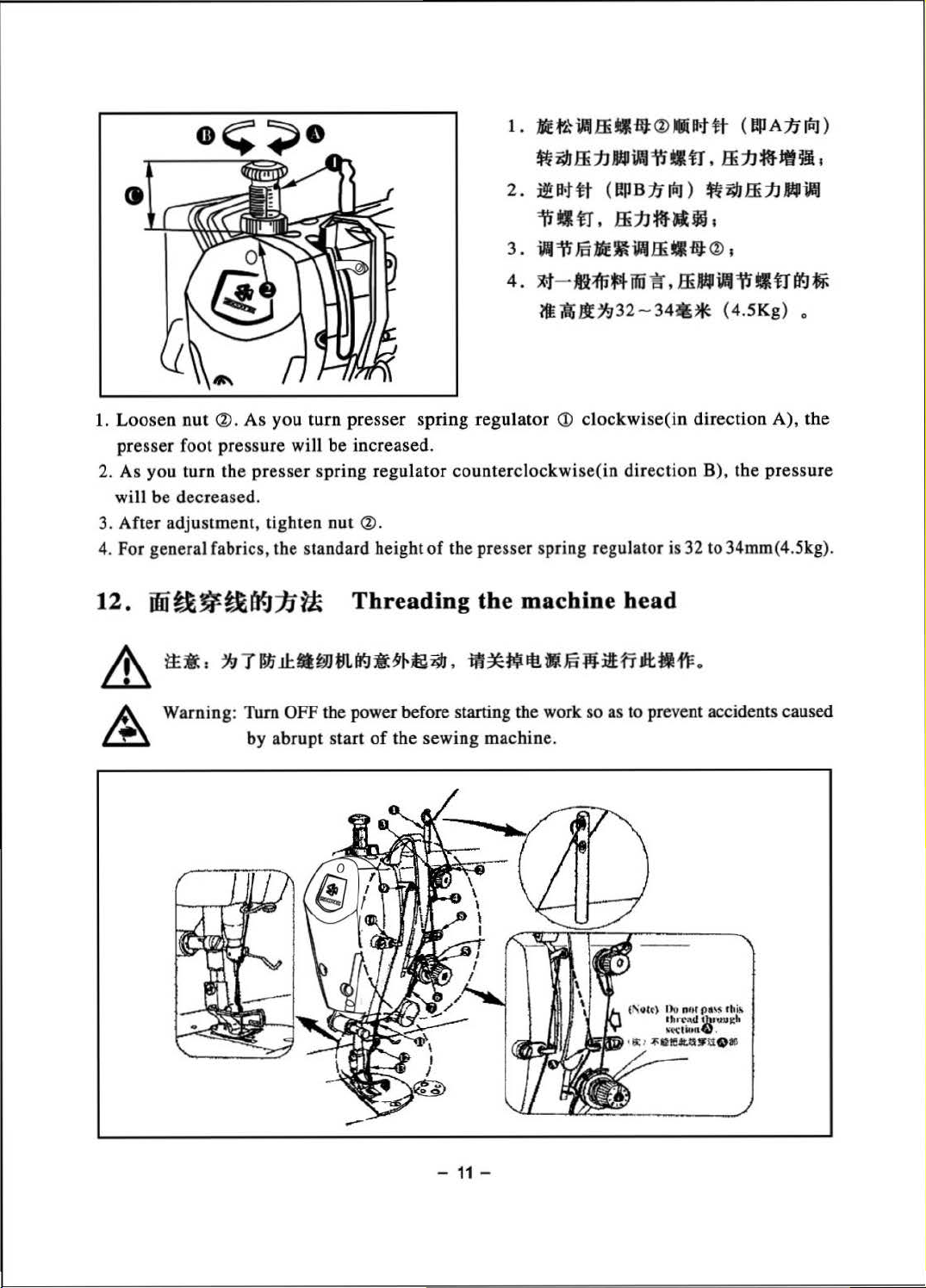

1.

ME

t'k~

.ffi

•

-at

® .lllflt

tt

(

ep

A:n

riiJ

>

$t~.ffijJ

2.~1flttt

"'WtJltJ

3.

W"'W

4.

~-tim*4ifii

$11Jlt~32-34•*

1.

Loosen

presser foot pressure will be increased.

2. As you turn the presser spring regulator counterclockwise(in direction B), the pressure

will be decreased.

3. After adjustment, tighten

4. For general fabrics, the standard height

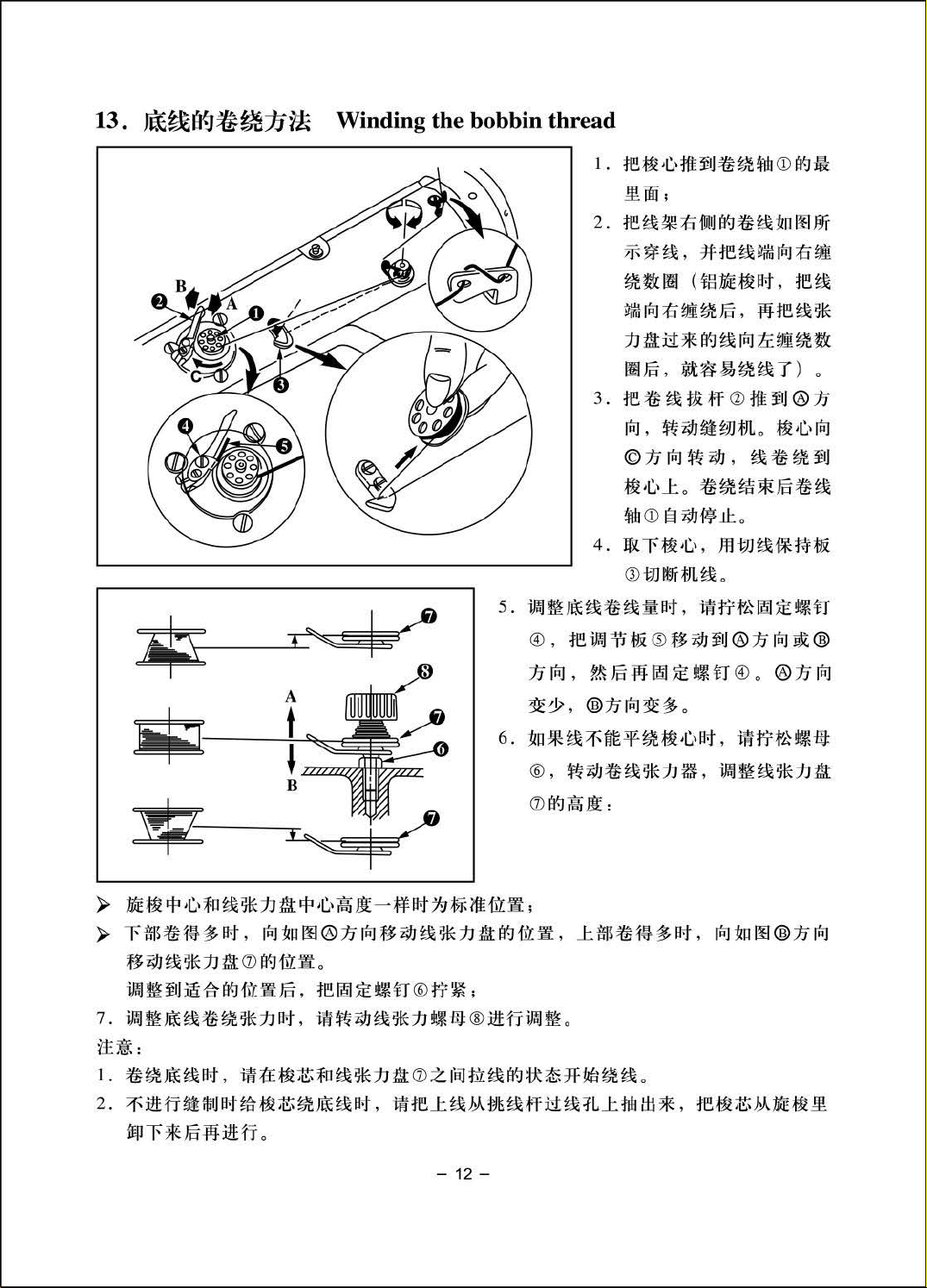

12.

nut

a>.

As

you

turn

presser

nut~.

ifiitl~tl~:1i~

Threading

spring regulator

<D

of

the presser spring regulator is 32 to 34mm( 4.5kg).

the

machine

-~"'WtJltJ

(~B~riiJ)

t

.ffijJ~Jljj

.1511E~i"f.ffiMtHi

"B". HiWiii"'Wt~tr~~

clockwise( in direction A),

t

.ffi1J~jft~

$t~ffi1JW.

I

®

I

(4.5Kg)

I

o

the

head

Warning:

Thm

OFF the power before starting the work so as to prevent accidents caused

by abrupt start

of

the sewing machine.

-

11

-

Page 15

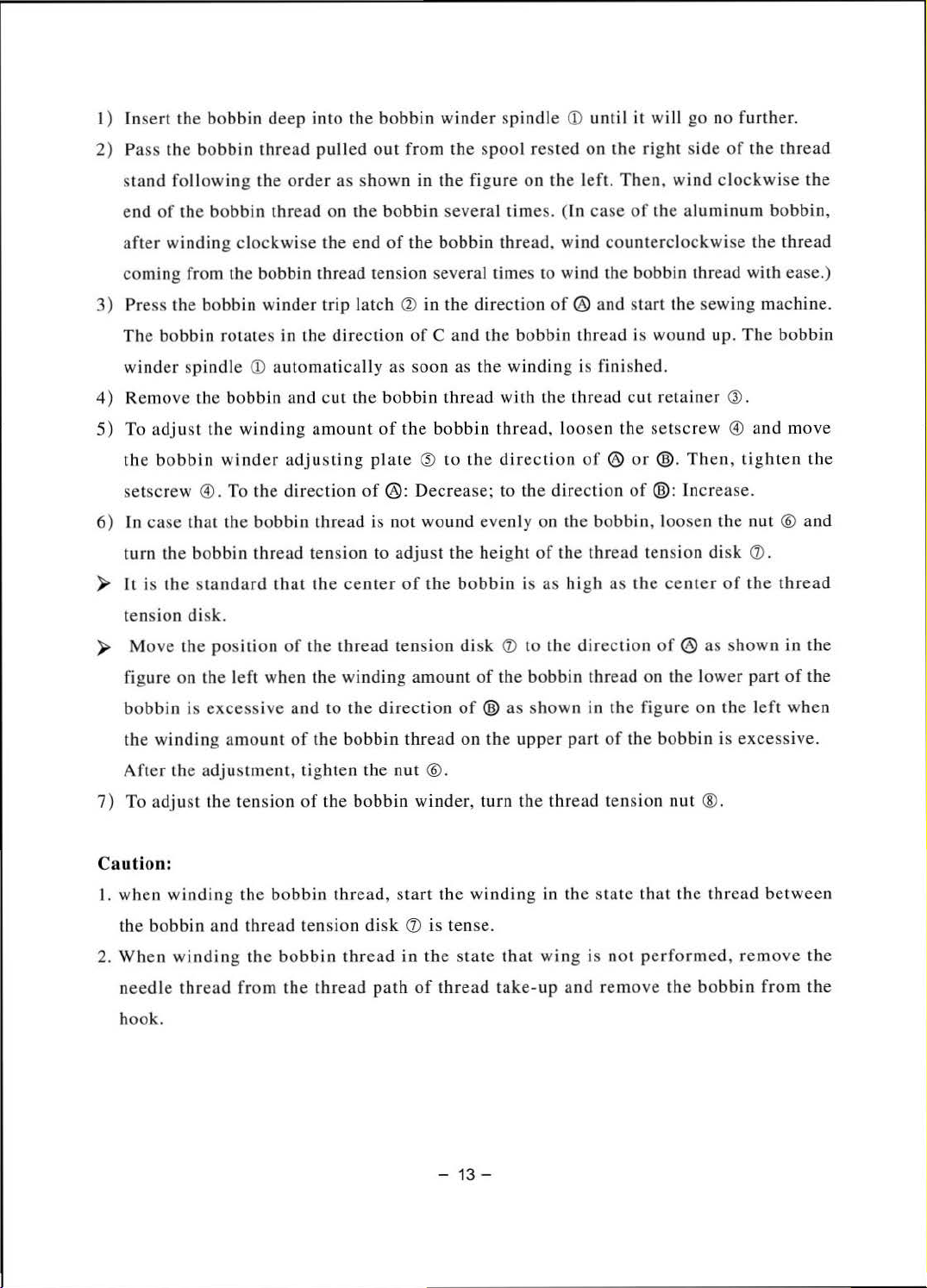

:n~,

A

~

:

)~S-----...-~~~

>

••~~~~*~•~~••-w"~fi•tt•;

~

t

~~

~

777777777?dtlr''77777"

B

W

~Y.

6.

~-~~••••~M.

®.~

Q)~·ll

r&JE.flJ~M~l;n®.

®~~~~

~·~*~~.

:

.

~·~*~·

®:ntn:~

•w~••

>~···~"·

8~~ij*~ft<V

••~-~~&•m.m~~•n®~•

7.

~·~~~~*~"·~~~~*~·~®*fi~··

11~

:

1.

•••~"·•a•~~~*~acvzoo~~~~~*~•~.

2.

~ana~"~-~~~~"'

~~*mf!J:il!:rr.

~~00®~~-~~*~-~tt•

~~ttll.

;

Mffl~~MM·ff~~R~~W*,

-

12-

.

~-··~~.

~~00®~~

re•~M··~

Page 16

1)

Insert

the

bobbin

deep

into

the

bobbin

winder

spindle

CD

until

it

will

go

no further.

2) Pass the

stand

following

end

of

the

after

winding

coming

3)

Pre

ss

the

The

bobb

win

der

4)

Rem

ove

5)

To

adjust

th e

bobbi

setsc

rew ®.To

6)

In

case

turn

the

);>

It

is

the standard

tension

);>

M

ove

the

bobbin

from the bobbin thread tension several times to wind

bobbin

in r

sp indl e

the

the

n win

that

bobbin

disk.

thread

the

order as

bobbin

posi ti

thread

clockwise

winde

otates

bobb

the

in

the

CD

au

tomatically

in

and

winding amount

der

adjusti

the

direc

bobbin

thr

ead

that

on

of

pulled

r trip

thread

tension

the

the

out

shown

on

the

the

end

latch

direction

cut

the

ng plate ~ to

tion

of®: Decre

is

to adj u

center of

thread

from

in

the

bobbin

of

as

bobbin thr

of

not

several

the

bobbin

Q)

in

the

of C and

soon

the

bobbin

wound

st

the

the

tension disk

the

spool

figure

dire

the

as

the

ead

th e

ase;

eve

height

bobbin

rested

on

the

left. Then,

times.

thread

ction

winding

with

thr

direction

to

nly

([)

(In

, wind

of@

bobbin

ead, loosen the

the

is

thread

is finis hed.

the

thread

of®

direction of@ : In c r

on

the

of

the thr

as hi

gh

to

the

direction

on

the

right side

wind

case

of

the

aluminum

counterclockwise

the

bobbin thread with

and s

tart

the

is

wound

cut

reta

iner

setscrew ® and

or

@. Then,

bobbin

ead

as

, l

oosen

tension

the

center

of®

of

the

clockwise

the

sewing

up.

The

Q)

.

tighten

ease.

the

nut® and

disk

([)

of

the

as shown

thread

the

bobbin,

thre

ad

ease.)

machine.

bobbin

move

th e

.

thread

in the

figure

bobbin

the

winding

After

7)

To

adjust

Caution:

1.

when

the

bobbin

2.

Wh

en

needle thr

hook.

on

the left

is

excessive

the

adjustment,

the

winding

and

winding

ead

when

amount

tension

the

bobbin threa

thread

the

from

the

windi

and

to

of

the bobbin thr

tighten

of

the

tension disk

bobbin

the

thr

thread

ead

the

direction

the

bobb

d,

path

ng

nut

in

start

([)

in

amou

nt of

ead

®.

winder,

the

is

tense.

th e

state

of

thread

-

the

of®

on

the

turn

winding

take-up

13-

as

upper

the

that

bobbin

shown

part

thread

in

the

wing

and

thread

in

the

of

tension

sta

te

is

not per

remove

on

figure

the

that

the lower

on

bobbin

nut

®.

the

thread

formed,

the

bobbin

part

the left

is

excess

between

remove

from

of t

he

when

ive.

the

the

Page 17

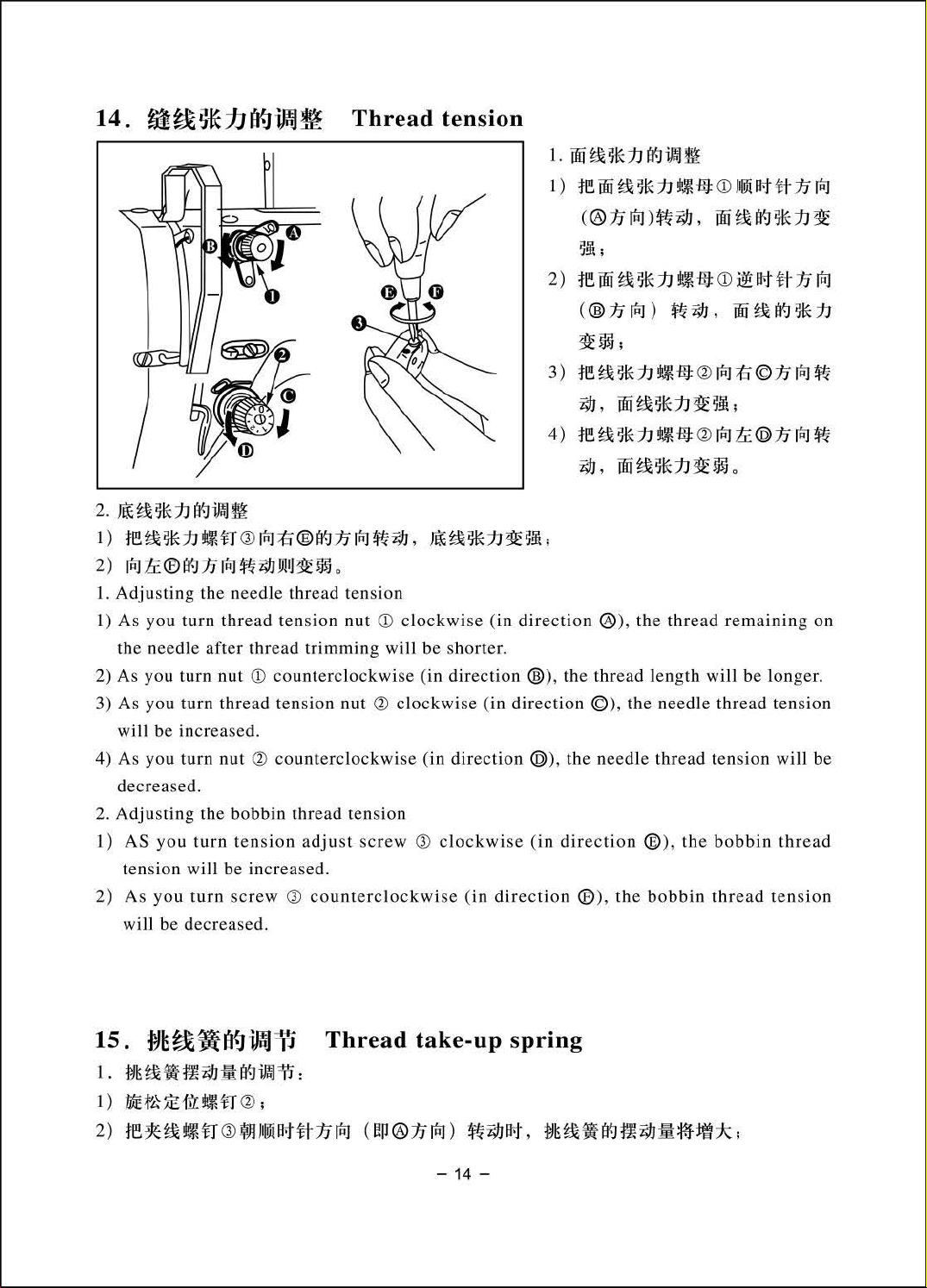

14.

~tt~*il

f.riPd

~

Thread tension

1.

ffii~5~1J

1)

fB!ii~*jJ~~HJ:CDJIID'i"#~~

frtl~~

2.

Ji\H.H~

l)ffl~*:1J~U®~~®~~~ft-.

2)

1.

Adjusting

1) As you turn

the

2) As you turn

3) As you turn thread

will be increased.

4)

As you turn

decreased

2.

Adjusting

1) AS

2)

:1J

U9

iJijJ

~

rf'iJ

tc ®

f8

:17

rf'iJ

R ~

9!IJ

~

mi

the

needle

thread

needle

tension will be increased.

As

you

will be decreased.

you

after

nut

nut

.

the

bobbin

turn

tension

turn

screw ® counterclockwise

thread

tension

thread

CD

Q)

trimming

counterclockwise

tension

counterclockwise

thread

adjust

-~*:1J~-;

o

tension

nut

CD

clockwise

will

be

shorter.

(in

direction

nut

Q)

clockwise

(in

direction

tension

screw ® clockwise

(in

(in

(in

direction

direction

<®:1JM)~i;JJ,

2)

fBffii~5~1J~~HJ:CD~at~i

(®nrRJ)

~j};

3)

fB~*JJ!t~HJ:<bl~~©~~ft

• '

4)

fB~*JJ!t~HJ:<bl~ti:©~~~

'i;IJ,

direction

@

),

the thread

@)

,

the

(in

direction@),

®).

ffii~fi9*1J~

-

~M

!ffl•.

ffii~5*1J~~!il;

ffii~S~1J~jjo

@),

the

thread

length

©),

the

needle

need

le thread

the

bobbin

oo~~*JJ

remaining

will be longer.

thread

tension

the

bobbin

thread

on

tension

will be

thread

tension

15.

~~

ttit

f.riPd

il

Thread take-up s

1.

~E~

..

fl!~ilfrtliJJil:

1 )

hiE

f'~

~

1fr

~ u

Q)

;

2)W~~~u®amM~:n~

(~®:n~)R•"·

-14-

pring

•~•frtl•~:~t•~*'

Page 18

(f!ll®!JriiJ)

4)

t~

~ ~

ij{

n

~~JA

·t,

<»

!:vJ

~

1!l~~

.

H~a~*:h~:ll:-.k

1t-t

H

11

lllJ

(

f!P

®

11

lllJ

;

)

~

J9

Jif1

3)

2.

I )

2)

3 )

,

1!l~

~ ~

re~~.u~-:n<»~~lf1#1511lJ

(

E!IJ

@

1J

[Rl

)

~

i;IJ

lf1

,

1!}~

~

Wfl'ttl~~ftthttps://manualmachine.com/j\0

1!J~~~~Il:1J

MEt~

1E

~

~

mt

.r~

~ m

~U

l!~j

t~ ~ ~JH~aT

(t1

ryll:

:1J

~~i'i:

1ft

tm

!fl

(ID

ftf:

) 1

~

n ® •

Q)

I

:m

-

~!X

<»

/J, o

a>

~

,

~

ti:PJ~

1=t

~

!®i

1t1

ft

7;tJ

11

~

~

lllJ

~~.m•~wrm.m~m~

71

'

IT:i

~

m

¥r

:ilHr

iflll

~

o

X

•

~~~I¥Ji71l::t.Ju~m,

i;IJ1'J:~tfl~M

• When the

midway, thread

tens

ion

of

thre

the

•~•i1oi~~~~~~11~:•~•~•~&1J~•Mm.

•~•s~•~a~m•~nm~®~••~i;IJ.••~•~•~ffi1J

1.

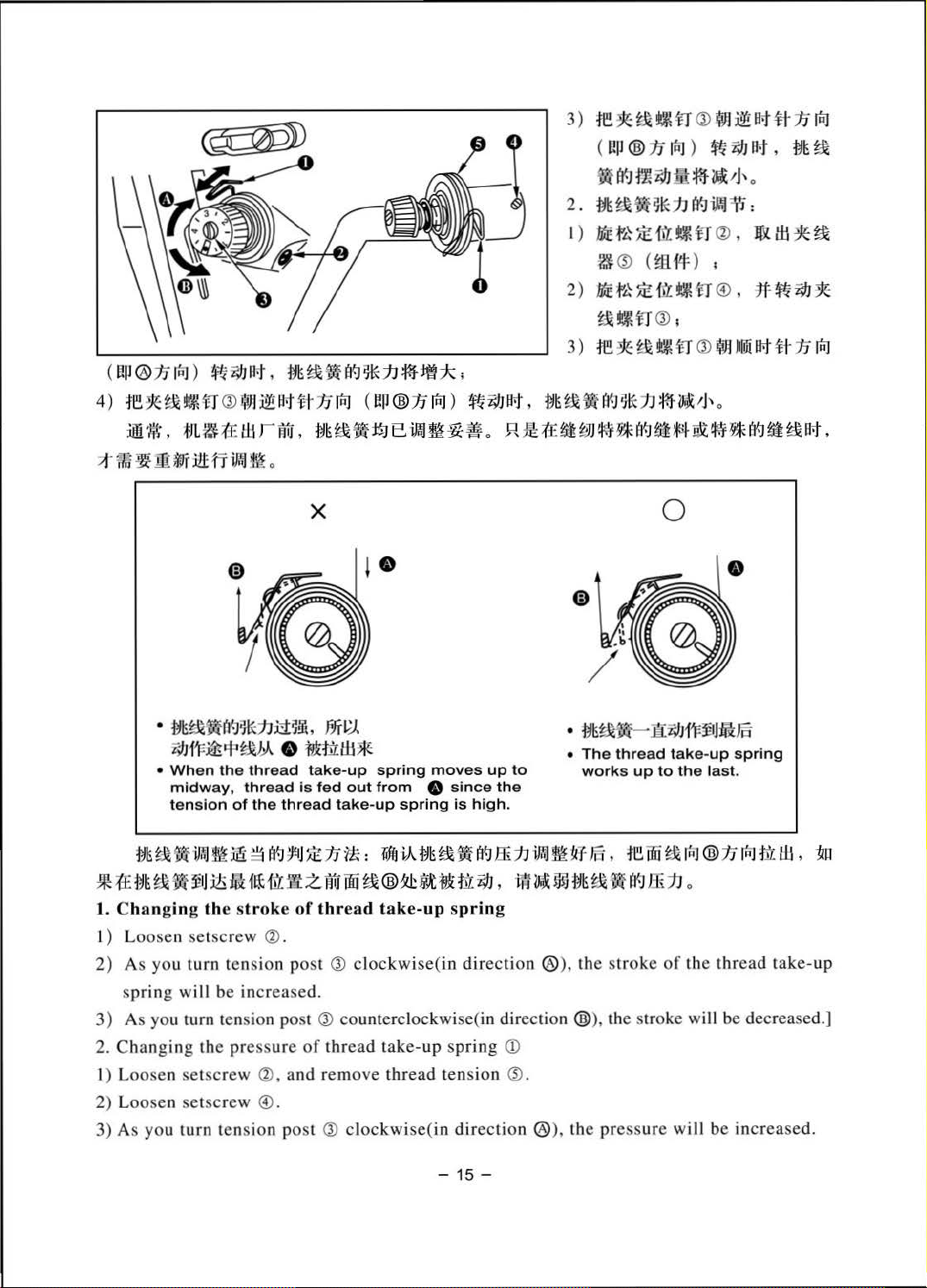

Changing

1)

Loosen setscrew

2)

As

you

spring will

3)

As you turn tension post

2.

Changing

1) L

oosen setscr

2) Loosen setscrew

3)

As

you

turn

the

turn

the s

ten

be

pressure

ew

ten

troke

a>

sion po

increased.

a>,

@)

sion post

r.JT~

8 titmlli*

ad

take-up

is

fed

thread

.

.

of

st

of

and

take-up spr

thread

Q)

Q)

counterclockwise(in direction @

thread

remove

Q)

s

w•~•o

out

spring

from

moves

8

ing

take-up

clockwise(in

take-up spring

thread

clockwise(in

R~a~~*•~aMdMa~a~~t.t.

up

to

since

the

is

high

.

spring

direction @),t

<D

tension

direction@), the

~

.

•

1!J~~

m-

• The

thread

works

he stroke

),

the stroke will

pressur

0

}[i;I

J1t=f!J/&.f§

take-up

up

to

the

mw~~®n~~w

of

e will

last

o

the

spring

.

thread

be

decreased.]

be

increased.

take

.

~

-up

-

15-

Page 19

4)

As

you

turn

ten s

ion

post

decreased.

ually, upon

Us

only

while

jud

s n

ot

ge

works

thread in

In

add

work

To

pring

s

needle

performed. When it do es not

spring.

doe

the

sew special

the work

up to

ition,

of

the

the

direction

the

properly.

machine

material

the thread

la st

stroke

For

Q)

counterclockwise(in

coming

thread, it

before

of

work

of

the

general fabrics

take

-up

needle

@after

up

to the

the

thread

out, all

need

spring,

the

the take-up spri

to

be

adju sted

confirm

thread

last,

is

pressure

decrease

take-up

, a

stroke

pull

of

spring

dir

ection @),

aga

whether or

ed

out

the

thread take-

the press ure

is

excess

of

10

to

the

pressure

ng ha s be

in.

from ® when

13

en

adjusted

not the thread

up spring

of

the thread

ively small,

mm is

proper

pu ll

the

will

take

ing

has

take

.

well

been

spri

be

,

-up

out

-up

ng

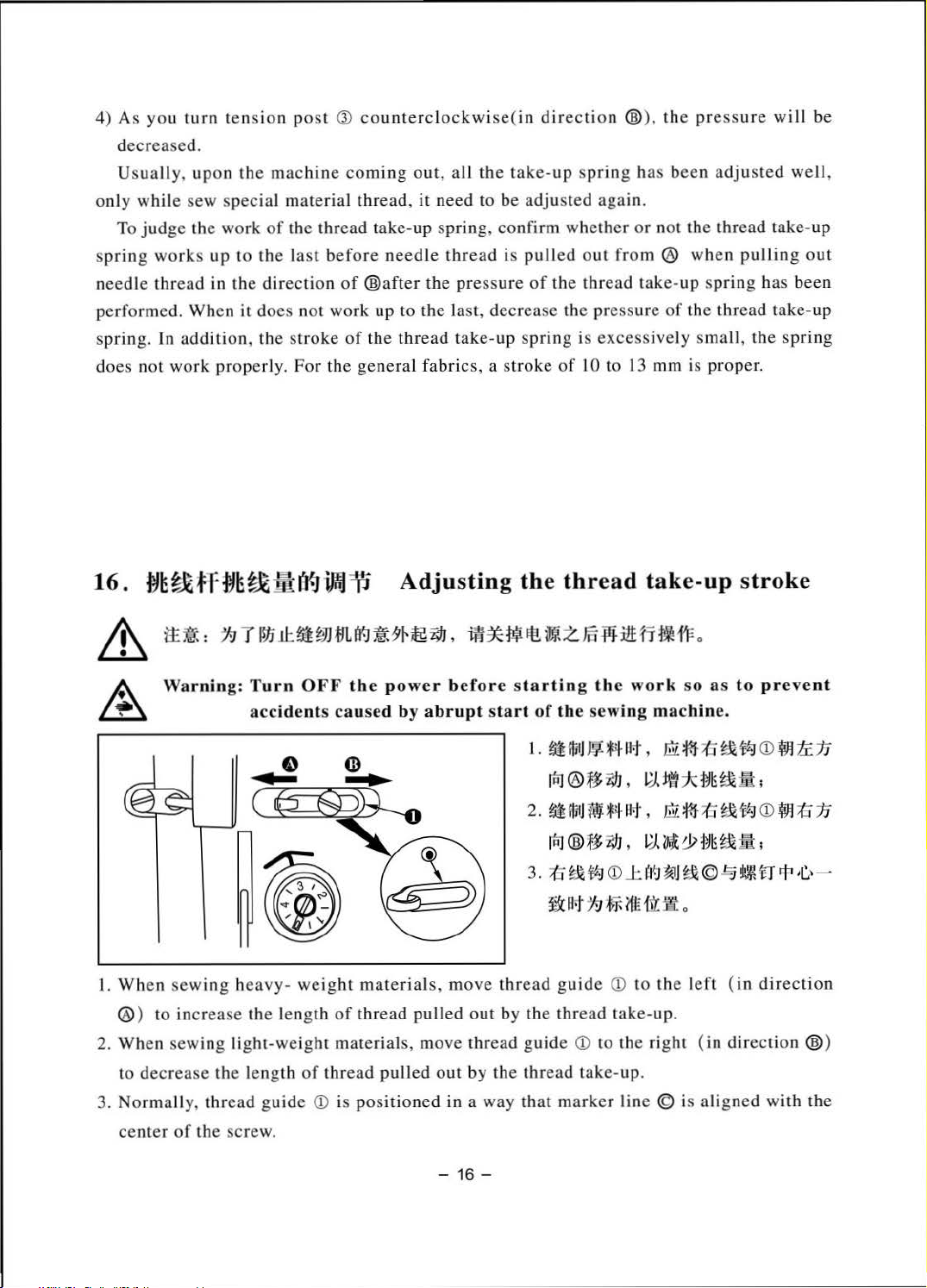

16.

~~tt~fj;J~

&

tt~

A Warning: Turn

. accidents ca used by abrupt

1. Wh

en sewing heavy-weig

@ ) to in

2.

When

to decrease

crease

sew ing light-we

tt:tl

:

19

Tltli

the

the length

a91JJil

Adjusting

.tUi;>JJ11Ut'~~;r~~f9J,

OFF

the

power

ht

materials, move

length

ight

of

thread

of

thread

materials,

pulled

pulled

move

the thread take-up stroke

m'*W~

befor

sta

out

thread

out

by

li:Z.m¥ll!tfi.f'F.

e s

tartin

rt

of

1.

2.

3. ;(:j

thread

by the thread take- up.

guide

the

thread

g the

the sewing machine.

~

111tJ

rRJ

®~f9J' L;l.it77c~~~fh

~

ffli

[l:ij

@*:t

~1#:1

~

IJ.t

guide

<D

wor

k so

as

to

W

~Ht.t

,

lliL

:m-

:fl

~

lf:J

J

tW

Mi

lt , lliL

qJ

,

<D

J:

JJ

:l>T-

liE

<D

to

the right (in di rection @ )

take-up.

:m-

L;/.

~9>~~

(t~ ~~ ~l

{1~

S!t

0

to the

:fl

~iiI

©~

left

~

(in

lf:J

~u

pre

vent

<D

~

tc

1J

<D

~

::S

.1J

4'

,c_,

-

direction

3. Normally,

center

thread

of

the screw.

guide

<D

is

positioned

in a way

-

16-

that

marke

r line © is

aligned

with

the

Page 20

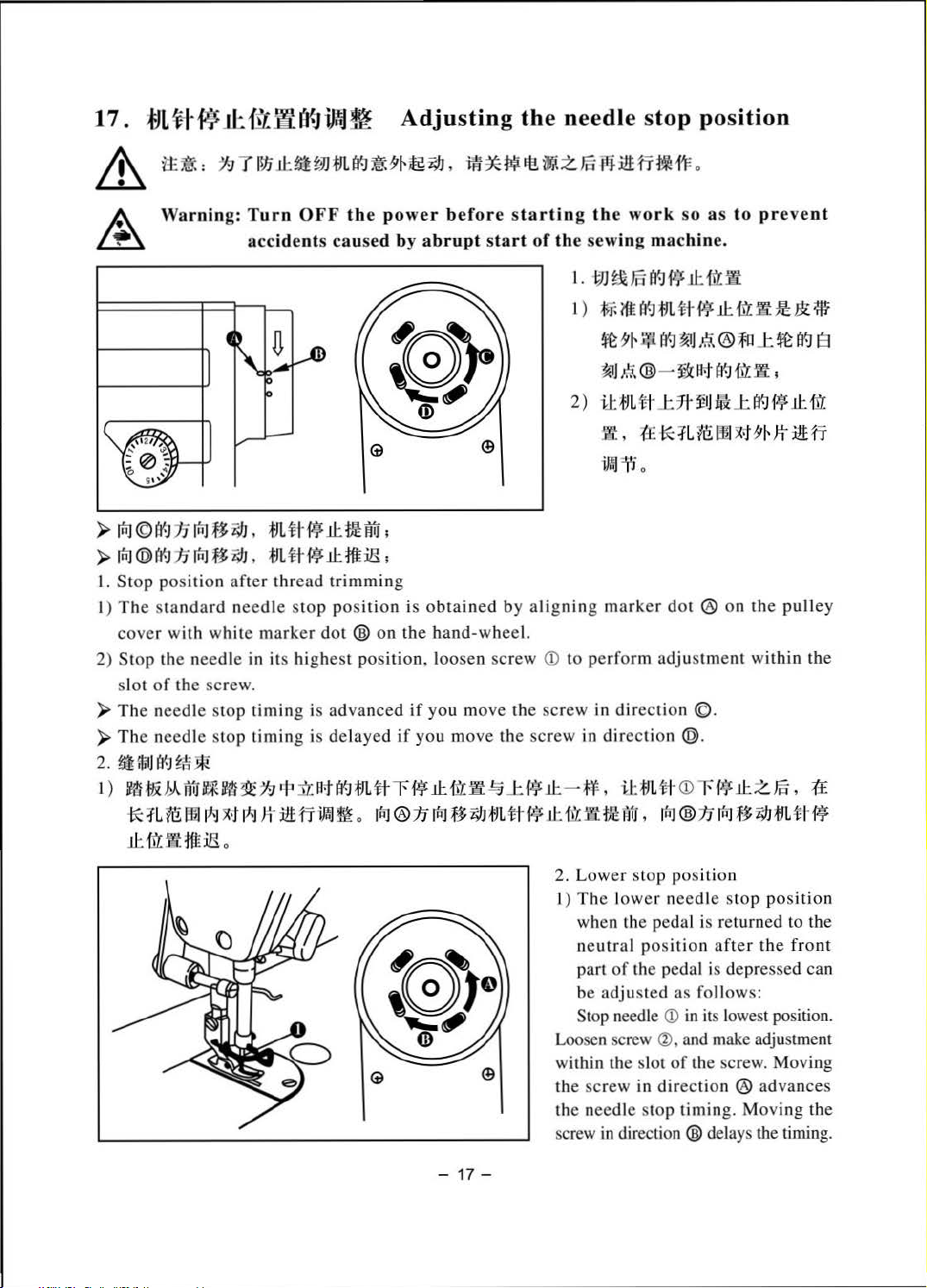

17.

*JL!fi·W

11:

1'

$t:lt

i¥JifnJm

Adjusting

the

needle

stop position

&

~

)>

)>

1.

I)

2) Stop the needle in its highest pos

)>The needle stop

)>T

2.

l)MfiMMaM

tt

tJ:

:

:'19

Tllti

11:

~

~JJ

m

(f)~

Warn

in

g:

~:~:e~~:at:

M ©

IY'.!

17

rfiJ

.n

~

J. m ~

riT.J@t~

St

The

cove

sl

~;fjlj(f.J

:n

rR:J

.nl;f

J. mtt~ll:tt:ilS;

op position

standa

r with w

ot

of

the screw.

he ne

edle

~fi

*nM~~m~~illfi~M

11:

-tto! m :ilS

aft

rd nee

hit

stop

*

~ ~~~

o

H¥

11:

er

thread

dl e stop pos

e marker dot

timin

timin

trimming

g is

advanced

g is de

M~mtt~~li:~W~~

tf!

ition

®o

lay

o ~®

5

ffii

5'

1-

18}

~

,

i1f

*

f!li

El!

tiff-

Z.

Fo

r'l

:i

t.H'T

1~d'F

o

::~;::::;:::a

:

~a

~t::

:

0

1.

1)

2)

s

~~

i~~o:~

WJ

~ ml'l~

~lll'f.JfJL#

~5'1-J!li'J'.J

~J

t.\

i

J:

fJ

11.

,

~ii

® -

L 'it J:

.ft

~

o

cs

h~na:

i'f

.u:

m

~

.ll:tt~:ll&:*

~~

F.i.

®lll~~

~'3c

lt-tfJ<){\t

7~ ~

IJ

Mi

:t

Ut1t:mx--

;

is

obtain

n the ha

ition

, loos

if

ed

if

you move

:n~n~mtt-Wkm~m~

ed by

nd-wheel.

en scr

ew

you

mo ve th e screw in

the

Wll:

alignin

scre

g marker do

CD

to perfo rm adj ustme

dir

ect

w in directio

- ~.~mttCD~

t®

ion ©.

n@

.

Wll:z~.~

.

~®:n~n~mttw

to

prev

JYt

~

;

J:

I'J'.J

i • .ll:

J

5'

1-

~:ill:

on

the pulley

nt wit

hin

e

nt

I'!{]

B

1ft

fi

the

2.

Lower stop posi

1)

The

lower needle st

wh

en the pedal is returned to the

ne

utr

al position

part

of

be a

dju

Stop needle

Loosen screw ® , a

withjn the slot

the scr

the needle stop timing. Moving

screw

- 17 -

ew

in

directio

tio

n

op pos

after

the

the pedal is depresse

sted as fo

in

direction

llow

s:

CD

in its lowest position.

nd

make adjustment

of

the screw. Moving

® advances

n®

delays the timing.

ition

front

d can

the

Page 21

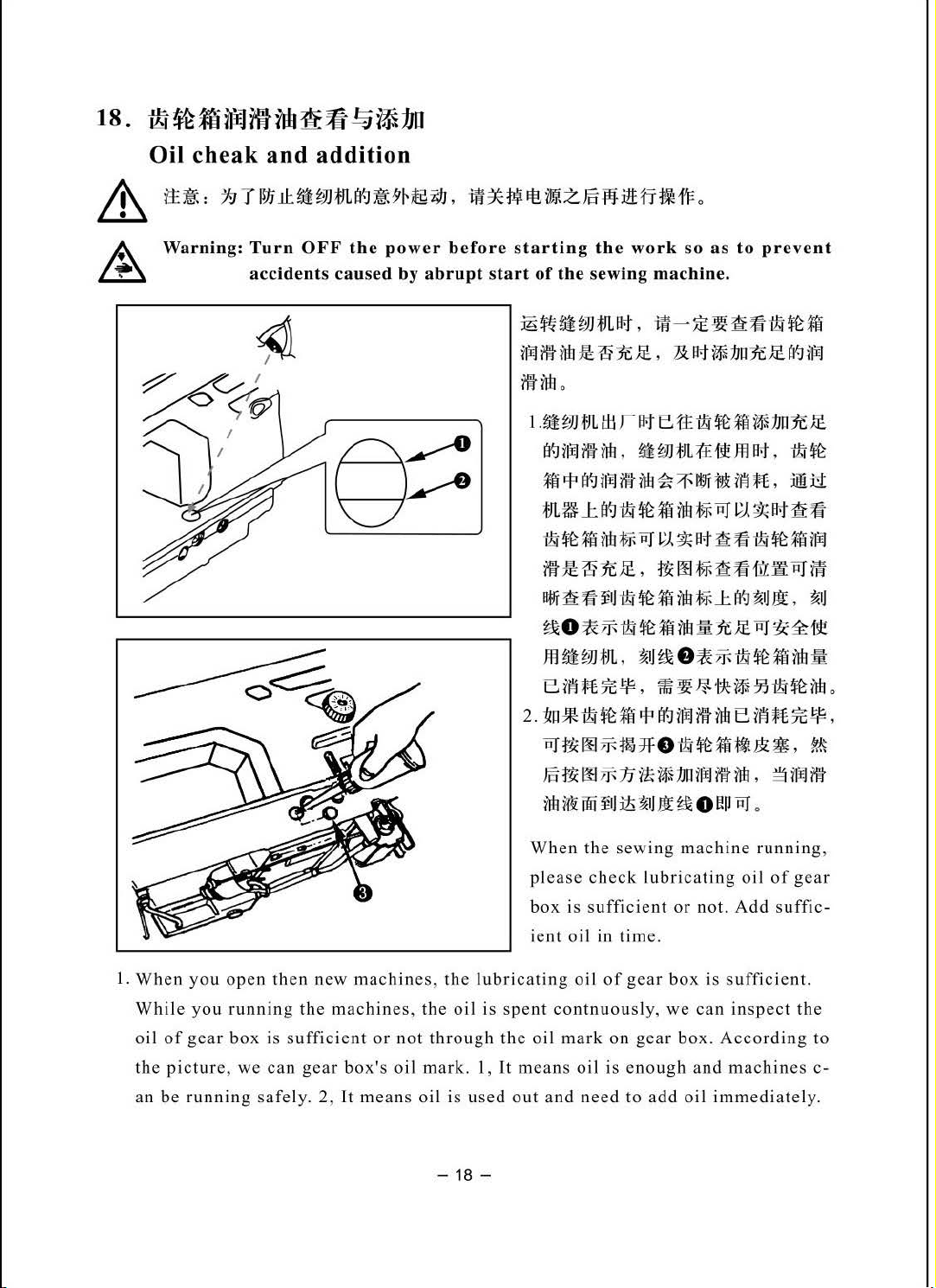

18.

®~*iWJifnbifli

Oil

cheak

and

addition

~~1JO

&

A

.

r:t:

~

:

79

Warning:

T

l!1i

1l:Jil

Turn

accidents

~J

1JL

OFF

the

caused

~

~

jf-

pow

~

i#J

,

er

before

by

abrupt start

i1f

*~Itt

W1.

z

J5

¥J

:ilHT

starting

of

~~~~!J.J1!Lat,

iii!

m-

m-

ilb

1

J.iH~HJL

;t:JU~

2 .

:!Ill*

the

work

the

sewing

im

i'l

~

n:,@

0

1:1:\

ratE

~

rlil

it

1iti

, ~

~

9='

af.J

iii!

M

J::

af.J

IN~

'®~~M~RJ

it:Ji!:~YE,@,

!ti!T~;ffiJ1&~%ii!H~J::~~IjJ.l'

~

0

7lf

7f-

iJH~

JfJ

~~!J.J;j:JL'

E

r~K;tc$,

IN~

~

iVdt

o

so

as

to prev

machine.

i1f-~!N~;t

,

litat

~

;JJu

n:,@

t:t

liH~ ~ ~

~31

;J:JL

1:£

1t

JfJ

ilH

~ ~ ~

%li

~,'fkattE*

tt<OO;tT-

~

~lj~ 87lf7f;l!i~~1itl

~!N~·~~!fh'&~ilil

"P

af.J

l1Jc

i~

:¥€

ilb

;tT-

RJ

~

1k

-

1!f~1ftitRJlW

ilH

:ii:

1t:,@

rf'EJ

ilit

ilH

E

ent

-i;!H~%i

af.J

rf'EI

;JJn

YE,@

Bt

,

IN

~

,

:iii

ii

a~t

~ ~

~~%iiJ'EJ

~lj

'ilf

~

~

1!J!

]l

o

t~

f=€

7t

1~

,

1.

When

While

oil

of

the

pictur

an

be

you

open

you

running

gear

box

e,

we

running

then

the

is

sufficient

can

safely.

new

machines, the

machines,

gear

box's

2,

It

or

not

oil

means

the

oil

through

mark.

oil

is

-18-

When

please

box

ient

lubricating

is

spent

the

oil

1,

It

means

used

out

PJf!.i:007f-mJF

J5

~

oo

7f-

nn

rr!'i

oo

fiJ

the

check

is s

ufficient

oil

in

oil

of

contnuously,

mark

oil

and

need

o·~~%i~&:~,

:n

tt

~

11u

rf'EJ

ilit

:iis

~IJ

It~

o

erJ

sewing

time.

gear

on

is

enough

to

machine

lubricating

or

not.

box

we

can

gear

box.

and

add

oil

is

sufficient.

According

immediately.

ilH

,

~

RJ

o

running

oil

of

Add

inspect

machines

r&

rf¥1

ilit

gear

suffic-

the

,

to

c-

Page 22

2. If

then

the

oil

add

is

lub

used

ica

out,

ting

please

oil, it

uncover

is

ok

when

the

the

rubber

oil

is

plug I of

up to

the

gear

box(note

scale 1 of

oil

the

mark.

picture

),

19.

&

~

2)

Loosen

if:titf..JiJJ~

~i":

:

:79TWJli::~;.JJtJ1ff.Jliit.5'~jfgi;IJ,

Warning: Turn O

accidents caused by abrupt start

adjust

screw@),

Adjustment

FF

the

power

and

adjust

the

of

the pedal

iW*tlii~mzm¥J:l£t1'ti~o

before

length

starting

of

of

connecting

the

work

the sewing machine.

1.

a*

I)

fRJ

~::k

CD

,

H<6l

2.

m~ff.J1ftlt

1)

iJWi'J:itf~Ha<:l*It

~~~ff.JJfJJto

2)

rrr~i!n111~~n

H

<6l

1. Installing the connecting rod

1) Move

left as illustrated by the arrows

so

that

and

straightened.

2. Adjusting the pedal angle

1)

The

adjusted by changing the length

of

the conn

rod

so

l-r

ff.J

~ ~

ti

1

P:J

~i;IJm~i!n111~

iJ:

fb

:it

t£

nlt-

1l~o

:ilHJ'

iJWi'J

pedal

Q)

motor

connecting

pedal

tilt

ecting rod.

Q).

as

to

prevent

fliiJ

H

CD

fll

Ji

e

P~

® ,

~i;IJ:i!*

o

to

the

right

contro

l lever

rod

Q)

can

be

freely

~

~J

r&

or

CD

are

-

19-

Page 23

20. •:Hi

lift

Pedal operation

~----

~

I @ 0

I

I

I

I--

• I

I

-k!$

::

I I

~

0

1.

~

tlii

.fl4

~.&

W!

~

I)

rt"J

HIJ4£~/ll·tlli~f~ia!~W@;

2)

.flj.~~ttiVJ!ll~:t&~~:i!~~JJ

®;

(

@.:fl'

*~€,

i§t~ 7 ~

ff~~~*z.m~~:i!

~iill~

~

*Rffia~~-mftR~M.

•m~~~©n•••••~m~~~.

~

:!Ia

ft!

(f.J

~

I

i5/J

f~rj

ft!

9='

,

t~

~

M

iWi

:iY!

~ ~JJ

Ii

.X:

f~

i~Hll

~JJ

~

rtt

~JJ

m ·

oo

;l

tJ:t

t~

~t. • J~&

~

~;.)]:tiL?-?

1. The pedal is

I)

The machine

pe

dal@.

2)

The

pedal

high

3) The

* If

you mac

1!:

machine

@. (If

speed

after

machine

{JL

~ -

operate

runs at

runs at

the

automatic

it

trims thr

hine

is

r-

Itt

?it~

d in the followi

low

high sewing

completes

eads

provided

a~~~WM~OO~~--*~·

M fill&

1ft

liD

@I

rtJ

€ m

9='

iz:

{lL

Z.

J§

,

sewing

reverse

reverse

when

with

9='

iz:

{lL

1:1

• M

~

m m

:flo

:lit!~

ng four

spee

speed

feed

feed stit

you

fully

the

Auto-lifter, an

-

i!t

.!i!IJ

;t:&

rt!

~

1TH~

7H~

d wh

en

when

stitching

depress

~m&&•M•.

~

~HJL

ffrJ

ft! tfi

>K

€

f

~

J.l:.

~JJ

:tJL:t~~fiiJ-~J

re

~

:tiL

tH·t ,

steps:

you

you

ching.)

~

•

m

jC

0

ttl

tt

Iff

Ill

lightly

further depress

has

the

depre

been

back

addition

preset,

part

step

-~ M

ss

of

:t&

the

front

the

front

the

machine

the

pedal

is

given between

o

part

part

@.

~ff

of

the

of

the

runs at

the

machine

the

is

~

If

at

~

The machine

the pedal

~

The ma

neutral pos

~

When

depre

sto

p and

back part

actuated.

you

res

seam start, the

the

ss

of

et

the

will

immediately

chine

will

ition

machine stops with its

the

back part

thread-trimming

the

peda

l ©,

and

pedal

to

its

neutral

machine stops after

perform

completely

immediately

normal

following

of

the

pedal

perform

after the

step.

The

if

you

further

position

it

completes

thread

high

needle

once.

trimming

or

low

thread

machine started

down, and

-

20-

pre

sser

foot

depre

during the

speed

trimming

goes

ss

the back part,

automatic

the

rever

even

if

sew

ing.

even

thread

if

you

up

se

you

if

trimming

want

when you lightly

the

thread

reverse

feed s

depre

you reset

to

bring

titchin

ss

the

the pedal

act

feed s

g;

back

ion.

the

depress

trimmer

titching

part

of

to

its

needle up,

Page 24

21.

ltiffim

One-touch

~mff

Util

type

reverse

feed

stitching

mechanism

1.1t.mn¥*

t)~~***ffro.•wm~~••~

2)

1£

#(

~

1¥-J

at

tal

i!H1'

f!tl ~ ,

3)

-=F-:f~*~R

P

~79IE

rliJ

.;JJ

o

3)

The

machine

2.

**A'·ljfijJj(

&

A

1)

2)•re**ID~Uz:Kfll

1)

2)

it~

Warning:

**CDfi~f=iUl:!filJ

Switch

In addition, when you desire to lower the position

in

the

back

ill

resumes

Height

:

19

can

of

of

T 1

!15

.Jl.

Turn

accidents

be

used in two

the

machine

norma

l feed

stitching

the

switch

~JHJL

ft9

~

5'Ht9

OFF

the

power

caused

~1:4!#1

~

~M.

head

by

1

-~~•wmww~~~•n~.

positions

and

191

, l#

before starting

abrupt

by turning it.

lower

1. How

1)

2) The mac hine performs reverse feed

switch

to

operate

The

moment

machine

as

long as the switch lever is held depressed.

the

moment

;Yd¥

It!.

start

of

of

base

switch

performs

the switch lever is rel

tmt

z

!a

the

sewing ma

switch

®.

lever

reverse

fll

:ill:

fi

the

work

CD,

loosen setscrew ~ located

CD

is

pressed,

fee

d stitching.

~

1

1"

o

so

as

to

chine.

~~**•®o

st

itching

eased

.

prevent

the

-

21-

Page 25

22.

f£ttff

Wiper

&

A

1±

~

: h T

Warning:

WLLI:-Jl

Turn

accidents

;.]

OFF the

fJUI~

~

)'Ht9

i9J , i13C

power

caused

by

before

abrupt

P-i!

It

imt

Z.

Ji5

.pj:

:itt

starting

start

of

l.

r

o

2)

3)

1.

according to the thickness

the

the

sewing

1£

~

;ff

(f.]

ttH.l

ff

JIJ

17

¥R

:itt

rn:JIE·~

~J

1.(

CD

JIH£

~

~~~~~tyQ),

$

*'J

;fJUt

~-ftJflt!{~;ffat,

**

Positioning

Adjust

the

fi

ti

1'F

o

work

at~

fi

1J

X1

so

as

to

prevent

machine.

1tr

~

-m:

:m

m w ;{fi

iftl

11

rn:J~i9J~~.

ifUJL%

tr.J

~IJ

*4

at~

JJ

il:~~s

.~

a>

o

;ff $ ® ffU!H.l ;ff , M

1~~5~ff(f.J.ifJ!!

r.p

,c,,

at~~~

1iJ

t~

~~

1iJ

ii3CP-i!t£~;ff

the

wiper

position

of

the

of

the material

wiper

It

Ji5

1

mm

~

tT

;

-22-

sewn.

The

adjustment

follows

1) Turn the

2)

3)

:

hand-whe

direction

marker

with marker

arm.

Adjust

flat

of

the needle to 1 mm. Tighten wiper

adjust

pre

@).

When the wiper is unnecessary, turn

wiper

of

dot

the

part

of

the

screw

ssed and

switch

rotation

CD

dot

distance

Q)

fixed

procedure

el in the

on

the

Q)

on

wiper

so

that

by

@ OFF.

normal

to

align

hand-wheel

the

machine

between

and the

the

wiper

wiper

is

as

white

the

center

is

collar

Page 26

23.

tJLtJ-

!:§~f£®=*~

Needle-to-hook relationship

Warning:

1.

~~~~.~#ff~~-~~.

2.

1iftJ~ti·ff~

l)~mDB#~,

~

{ft~~tr

2)~mDA#~,

~

1iL

~;

tr

3.

1iftl~-~{ftft

l)~mDB#H, -~~

Turn

OFF

accidents

It:

~#ff~~~~M®~$#ff~MW

00

;

~#ff~~~~M©~$#ff~M

CD

o

:

---~{ft-tr,

the

caused

pow

er

before

by

abrupt

Mfitr~#ff~•tt•~•uoo;

starting the

start

of

the

®

W®~

#~~~~.

work

sewing

~~-.

~-.

~#ff~~~~~~~~~®

5C1/t#ff~··® ~~~ffil;

2) 1

4.

machine.

MfiW.#ff~•tt

MfiW.#ff~•tt

tmDAttll>t,

-~{ftt,~tr,

1~

t-1

· tr

M@~lt#ff~MW®~

~~;

t£~~~:1\~~,

1;J

~ ~ ~

•C.\

, #

o.o4 ~ 0.1 L:kf.l)

so

~

t£

5C1?l

1=3

as

to

prevent

Wt~.=UW

:tf:~~~~'

~~

~ ~ ~ ~u

~--A~

:J:JL~H

~)

~

I=J=t

W •

~ lalfl-~

19

~*,

•~w••~•~•tr

~~

1.

~

~li:~l~t:7.c*,

2.

••tm~~£~.

;m[i'iJ~!W-'%o

l.

Turn

the

loosen

2.

Adjusting

1)

While using

bushing

hand-wheel

setscrew

the

needle

DB

®,

then

to

bright

CD

.

bar

hei

ght

needle

tighten setscrew

, al

ign

the

needle

:

marker line®

00

bar

.

-23-

down

with

to

the

the

lowe

bottom

st

:

!'13

1

~jjt:;J.c;J

..

' ~

1!1b'l·~;

~51~W~#;

fl!f

point

of its

stroke,

end

of

needle

bar

lower

o

1:i!!m

and

Page 27

2)

Whil

e using

bus

hin

3. L

ocate

1)

Whil

e us

mark

er

bu

shing

2)

Whi

le using

marker

bushing

4.

After

making

with

the

between

Caution:

1.

If

the clearanc

value, the bl

will

resu

2. Use a ho

DA nee

g Q), then

the hook

ing

lin

Q)

lin

Q)

center

the need

lt.

ok

tighten setscrew

position:

DB

needle

e ®

on

.

DA

needle, loosen

e @

on asce

.

th e

adjustments mentioned

of

nee

le

e between the blade

ade

point

of

the same

dle, align

, l

oosen

ascending

nding

dle

® .

and

the

hook,

of

hook

part

marker

the

needle

the

needle

Provide a clearance

will

No.

line © with the

CD

.

three hook set screw,

bar 2 with

three hook set

bar 2 with

in

the

then

securely

point

of

hook

be

damaged.

when

replacing your

bottom

turn

the

bott

screw,

the

bottom end

above

of 0.04

tight

and

If the cl

step

mm to 0.1

en

setscrew

the needle is smaller than the spec ified

earance

hook

end

the ha

om e

nd

of need

turn

the hand-wheel,

of

s,

align h

Omm(reference valu

s in the

is larger, stitch s

with

a n

of nee

dle

nd-wheel,

le

needle

ook

blade

hook.

ew

one.

bar

and align

bar lower

bar

lower

and

align

lower

point

kip-ping

<2)

e)

24.

~ntr.JJ!Jflfj~J!~

Change

&,

A

tt

~

Warning: Turn

E)

Moving kni

E)

374JJJ

of

:

1:1 7 ll1i

accidents cau

counter

11:

fe

C.if

fll

r3J

m

~W

OFF

the

G)Cen

e mtt.P·t'

JJ)

knife

~

:Yr

~

power before

sed

by

ter

of

need

(Parallel

i;IJ

, m

*~It

abrupt start

0

~

le

knife)

i1ff.

z

.15

w.

starting the

of

the

sewin g machine.

iJJ J J ~

F,Jr

~

Wf

~~:fit

l)

te!.fim

ZUf.J

Jllt~lf£t'I~UoJ'

2)

ttli:®:tJ

1±

~ : m m

-nrt.

o

.i1Hr

rlHI:

o

work

Jlf

0

~

so

as

to

prevent

'I:

R B·j,

·

rtf~

lf. 'till

00

©

~

~

JJ

CD

,

?~

.15

IE

TdfJ

A9

JJ

fttJ~~ifr~tt*~ltti:

;fi

@

:1J

lt.:J

n

i;IJ

,

iiJ

~

*

~;

~t.:~n~.

ll!if

~ n

-w~~~

n·t

i't!f

1±

~

1iJf

.

•

-

24-

Page 28

When the knife sharpness has

in ©

.a

nd

properly

If

the mountin g position

1)

mounting position, the thread length

2)

If

the

mou nting position

accordingly.

Caution: When re-s

hand ling

reinstall it.

harpening

of

the knife.

of the

is moved in

the kni

deteriorated,

counter

knife

after

direction @,the

fe blade,

re-sharpen

is moved in

thread trimming will be increased accordingly.

extra

counter

direction

thread length

special care

knife

CD

@ from the

will be

must

be

taken

as illustra ted

standa

rd

decreased

on

the

2s .

J£

Change

&

11

A Wa

25.1

25.2

!M)i::JJ

?JJJJ

n

f;O

~J n rl'~

of

~

:

19

T

~Ji

rnin

g:

Turn

ac

JiJf

If!

counter

11:

~

~JJ

;tiL atJ

OFF

cidents

caus

~

J!~

knife

~

~~

the

power

ed

oren)

and

moving

~

i;IJ

,

iii*

tt.i

before

by

abrupt start

1.

2.

3.

*

~~nfE

~~JJff.JrvJ-!1/Jt~

~JJA~•

1.

2 .

3 .

4.

5.

6.

7.

starting the work

:iDe

fiiJ

m

~

~~~n

f'~~~fi

lfR

r:t:JU-1-

J=IHfl

ffi

n~

r~

tJii

t'«

n

•i;IJ=t-~

:iDe

JIJ;tJ

L

~

~~~~~n~m~~~~~~m®~¥~

f!J

~fi0tf.Ji!Lfl

f'~~~fi

knife

It

Wit

z

Jfi

of the sewin g machin

0

®.

mr~~~~~®o

®,

~Iii

ttftft:ffiU

.

~oo~nM~®~•~~~JJ0o

0

1

tli

=f.

ttl

CDr

21-l.

• •

#ff~*¥Q~ff.J~~o

o

0[2

1-1.

(Rotation

:jiJ

:ilHHNd'l=

IOI~JJ0o

:

ffiil'f<J~Il&~~:ill:fi

i8Hli

Jl~

~~

~!.{

J§

0

ti.{J§~:±I~JJJ®o

o

so as

~

o

J&

ill

~-

knife)

to

prevent

e.

o

:

:ffi

0 0

*

~~

n'lt-

i#~Jm~

-

25-

iiii

P9.fl;l&.

~!it:i!Hr

o

Page 29

26.

!)Y~~IHf.J~~

Adjustment

Oren)

of

trimming

system

(Rotation

knife)

Warning:

Turn

accidents

OFF

the

power