Page 1

1.01

1.02

I .

03

~~..........................................................................................

~-~~~~··············································································

I

fj:;cp(tg~l'!li!±;Jll.:!Jl::0[

fltlli:E'i'i!i-

· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 2

...

...... ......

...

...

......

...

...

...

...

......

...

......

... ...

...... I

I

I

I

~

'

i

.J

,,

1,'

1

'

:I

. '

I

!

II

. '

''

:i

i I

'I

,,

''I

!;

:<,-1

!

:I

'

'

!,;

·I

11

,,

I

,,

II

,

:I

:

I

'

'

:I

''I

I.

'II

:.!1

,:

I

I

''I

''!I

!

2

3

3.01

3.02

3.03

4

5

5.01

5.02

5.03

5.04

5.05

5.06

5.07

6

6.01

6.01.01

6.02

6.02.02

6.02.03

6.02.04

6.02.05

6.02.06

6.02.07

6.02.08

6.03

6.04

6.05

6.06

7

7.01

7.02

7.03

7.04

~m•~

tlioil:~t\S

ZJ9625,

#fo~

~mmll'9m~&~m~·······························································

Ifl=OO~

J%!

ft

:7C

ff1:'kt~l!i!(f3(ffl"f~'it:fl-D3il'9:1JLl*)

orrtxi1EH~J}Jflgll9:~t~.c.,~J5!iM<*

~t&

&i~ffiiJ!jljji

il*Ji%ff

~i1E·I-':li:i9;'i!i't:!CI!I!

m~J±IJ!jl~oJPH;7l!J

~'itfollt$

'ti:'it .......................................................................................

~&ali:ll9oo•········································································

~~~~

~~llfJ:'iHi'<ll&

'ti:~mat?\11.

'ti:~1ll'"*~il'9fl'!.7l!J:fMH:I;t&J:

'ti:~1ll'"*~il'9fl'!.7i!J:IJL¥U:IJL<*J:

'ti:~t!;J:*lt*fooo•&:**fl

*~*"*~fl'!.7i!J:IJL!l9&:1ll'll0JP-'Ii

it~'ti:~:Jf~

"\Jt$

ll:ll#lil9x**

~t&Mill1lf.il:.R.

'ti:~~fli

mai1Ei\1r

1±ZJ9625fOZJ9610:IJL~J:'it:IJL#

1±ZJ9620:IJL!I'IJ:!\t:fMt ... ... ... ... ... ......... ... ...... ... ... ......... ... ... ... .........

~#lb~,

Jf!tl±l/~.A.:ft''Jt

················································································

...

...... ......

ZJ9620, ZJ9610 ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...... 5

....................................................................................

...

...

...

...... ......... ...... ...

... ...

...

... ... ...

.........

... ...

4

5

5

6

... ... ... ............... ... ... ..................... ......... .................. 6

f'f

.. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . ..

. 7

...... ... ...... ... ... ...... ... ... ... ... ... ... 7

...

...

...

... ...

...

... ... ... ...

...

...

...

...

...

...

...

1

....................................................................................... 8

'¥

.. . ...

.. . .. . .. . .. . .. . .. . ...

.. . .. . ...

.. . .. . ...

.. . .. . ...

.. . .. . .. . .. . ... ... ...

8

.................................................................................... 8

...

...

...... ......

...

...

...... ......

..............................................................................

.................................................................................

... ...

... ... ...

...

...........................................................................

... ... ... ...

··············································································

.....................

...

...

......

....................................................................................

OO"'J#Ib~il9fJJMI*fl

c

..........

...

...

...

... ...

-t

................................ ·

...

...

...

......

... ... ...

...

...

...

...

... ...

...

... ...

...

... ...

...... ......

...

...

... ...

......

...

...

... ......

... ... ...

... ...

... ...

... ......

... ......

... ...

... ...

... ...

...

......... ......

... ...

......

... ... ...

...

...

...

.........................................................

.. · ..

· ..... · .............. · ........... ·

...

...

...

......

... ...

...

... ...

·..........................................................

...

...

...

... ...

...

...

......

...

......

... ...

...

... ...

...

...

... ...

...

......

... ...

...

... ...

... ... ... ......... ... ... ...... ... ... ...... ... .........

... ...

... ...

... ... ...... ...

... ...

... ...

...

... ...

...

... ...

...

...

..

· ..... ·

......

...

......

... ...

.........

...

... ... ...

............

... ...

...

... ... ... ... ...

......

...

...

... ...

...

... ... ...

... ...

...

... ... ...

...

... ...

......

...

..

·..

.... 13

... ... ...

...

...

...

...

...

...

9

9

to

10

10

11

II

12

12

13

14

14

15

15

16

16

11

17

18

19

20

I

! "'

Page 2

I I

:!

I

i

' '

I

···I

''

'

i I

''

'i

; I

7.05

I

7.06

7.07

7.08

8

8.01

8.02

8.03

8.04

8.05

8.06

8.07

9

9.01

9.02

9.03

9.03.01

9.03.02

9.03.03

9.03.04

9.03.05

9.03.06

9.03.07

9.03.08

9.03.09

9.03.10

9.03.11

9.03.12

9.03.13

9.03.14

9.03.15

9.03.16

9.03.17

9.03.18

9.03.19

9.03.20

9.03.21

9.03.22

9.03.23

9.03.24

9.03.25

9.03.26

~'J!E'!if

;ff:ZJ9625]il:ZJ9610tll.i!X!I...t.!fi't~:lt!ffil1Jiil

;f£ZJ9620;flli!X'J._t5f~HHFiJiill11ft~

i;!:j[!£:12l'-h':&

#itif'

fit1:!l'

~$'2:4:/J!tli!il-m/ililii't~i¥J:i:tlfc\li'<J

~it···.......................................................................................

ff'intf~!JU

ntf~WJ

ff'i~ililii't*~i¥1"11!!][iJOilll·

~ii"~i&4101!tliJ"ili1't···......

if.J'M··· ... ... ... ... ...

xtif.J>MifF1'19:l!i'o:if-········································································

IJ!t..

iJlilllt¥liill;fil~············

tEZJ9625;fllZJ96IO;flli!X'J._t,)!JJ!m:!JitJ_tt[;fll~ti¥Jffl:j[··················

tEZJ9620Vl.ll!/..t.h!.~i'3.J::IJ

1m

tEZJ9625Vl.ll!/_t

tEZJ9620;flli!X'J._t

tEZJ9610;flli!X'J.I.fti¥JI.3t,

::{:£ZJ9625t!Li!X'J.I.h!.@

::{:£ZJ962omm..t.».¥1ir~~!JJ::I1itJtrmtti¥1ffl:'i':

::{:£ZJ9610t!Li!X'J._t})!.;jjj;

Tf~~i¥J~J'!(;fl11l'T"il

:tE

::{:£ZJ9620t!Lil!!I.:i£ff'i410~JJ!'I'I(]if.jli![

::{:£

~;l2l'f(;JJ!'~illtl

~Jm>f(;JJ!'ttl)'!(:lll.:if.Jli!!:

ff:J:it

ff

~&

1&410ffilli!Ji)lijli![

J'i(~Jm'

.410J±Ili!J;fll:i£ff'i4101'19~&7if.J······················································

ffit-J.ff( {Jl.ZJ9620t!Lil!/;t:ff)· · ·

MHJ!ff

!ft~t't:~if.Jli![

t:it

t:Jt~~if.J-(ZJ9620tfLil!/)

iilV

if.Jl113HA:~

. . . . . . . . .

~ill~

/VilJ11'2:"1;J±J'J ·· · · · · · · · · · · ··· · · · · · · ·· · ·· · · · · · · · ···

Zf7iJlil'flHti¥J

z;

9625tJL m _t

Z J

96IOtJLIJ!!

ill!

:tit

!lli

410

1±

~~if.J.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

il!i

· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

i1'tilll

][

· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

:!iHJil;f11~1:':1i!JJlill'~i':4···

r~JJ'!(

_t

l'l(]i@j,c,,J'!(l,lljm:

ffl¥1J

:i£fff4106(]

ffl¥U

I&

410

lli!I

;fl1

J£

ff'i

... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...

f(;Il!'

trJ

JJ!':Ill.:

·········

···

. . . . . . . . . .. .

(ZJ9625;fll

1¥1

~IUJ

· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

..

. . . . . . . . . . . . . . . .

.. . . . .

..

. ... ... ... ...

· ·

··

· · · ·

..

. . . . . . .

......

'*1:1

..

···

··

.. . .. . ..

... ... ...

~j(f.jJ

···

..

. . . . . . . . . .

· · · ·

··

. ... ... . . .

...

··

· · · · · · ·

. ... . . . . . .

......

···

·········

· · · · · · · · · ·

.. . ..

···

. ...

..

··

· · · · ··· · · · · · ·

..

. . . . . . . . . .

·· · ··

· · · ·

···

..

. . . .

..

... ... ... ... ...

··· ··· ··· ··· ··· ···

· · · · · ·

··

. . . . ...

..

··

.. . .. . ...

··

· · · ·

··

. ... .

..

. . . . . .

......

· · · ·

. . . . ... . . . . . .

· · · · ··· · · · ··· · · ·

.. . ...

· · · · ·

... ... ...

··· ··· ··· ······ ··· ·'···· ··· ··· ··· ··· ··· ········· ··· ··· ···

...............

li>T!Hil/f"!·l'l(]{fl:'ill':

· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

fti¥JI.:Jt,

lfti¥J

J£

fff

:i£

ff'i

1±

lli!J

410

z.rEil

1'19

············

ntf~3i!JHI'i9

I.3t

,

ntf~¥1J

ntf~¥1Jtti¥Jl'Elill,

1i

'fi!ilWJ::IJ

1[

'f~t-)]::11

... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...

410

"'"

!l'

410

i"'J

JJ!'

i¥J

. . .

..

. .. . . . . . . . . . .

ftz;tJiJliJm:

1'19

1t

z;tJ

if.J

1'19

liE

Jill

t~

~{![

if.J

···

..

. . . . . . .

ZJ9610t!Li!X'J.)

·· · ··

···················································

· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

liE

Jill,

i!ti¥J~

lfti¥1

l'Elill,

1ft

fti¥J~J'!(;flltplftff·

ft)

tf;fll

tt

1¥1

ft)

tit!Ltt

1'19

VilJ

li!!:

if.]

li!!:

...

..

. . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

li!!:

· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 4 9

i¥1

ffl::ll· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 3

··· ··· ··· ··· ··· ··· ··· ··· ··· ··· ··· ··· ··· ··· ··· ···

· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 4 5

..

. .. . ...

..

.. . ..

. . . . . . .

J'!(;fll!Pft~·

i¥1

,<0

J'!(;fll!Ptt~

{:\l:l!t

· · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

... ... ... ... ... ... ... ... ... ...

. . . . .

.. ..

. . . . . . . .. .

..

. ...

..

. . . . ... . . . . . . .. .

· · · · · · · · · · · · · ·

· · · · · · · · · · · · · · · 3 5

· ·

..

. . . .

· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · . . . . . . . . . . . . . . . . .

1/i!fii~lm'

··

·····················

· · · · · · · · · · · · · ··· ··· ···

f(;ll{ · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

· ··· · · · ··· · · ·

..

. . . . . . . . . . .

··

· ··· · · · ··· · · · ··· · · · ··· · · · ··· · · · ··· · · ·

···

·················· ···············

..

... . . .

.. . ..

. . . .

..

. .. . . . . . . .

· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

·· · ··

· ···

·· · ··

· ··· ·· · ··· ··· ··· ···

·· · ··

· · · ·

. . . . . .

·· · ·· · ··

.. . ..

. ...

......

··· ··· ··· 30

·· · ··

· ··· ···

.. . ..

. . . . ...

..

. . . . .. .

.. . 47

..

. ...

·· · 54

..

. . . .

..

. . . .

20

21

···

22

..

. 23

24

24

..

.

25

25

26

27

·

27

.. . 28

29

29

29

30

31

32

33

37

39

40

41

42

44

46

48

5o

51

52

53

55

56

57

58

Page 3

.

''I

i

,,

':'1

''"l

,(

''··''

I

I'.·,

h

I :

: i

l,;J

il''l

I

I i

I

''I

I,

''

',

]1

'

i '

9.03.27

9.03.28

9.03.29

9.03.30

9.04

9.04.01

9.04.02

9.04.03

9.04.04

9.04.05

9.04.06

9.04.07

9.04.08

9.04.09

9.05

9.05.01

9.05.02

9.05.03

9.05.04

9.05.05

i

9.05.06

•••···················································································· w

m~ffJl!1Ja{]ffniJlll~

i~i'Jit"""

*~a•••~········································································

·--~~-~···························································

rn-Ttti'F~iit

···-~~:i'i)ll!~·······························································

···~*&~~~·····························································

···~·jj,lj~·····································································

mn~•~mnffn

•.

'f-4!1

~••r~•

~:k4!Ji'ftfii.J~(llCZJ9620tJl'Jll:fj')

i),lJ~1l!tl~f!L;jtJ-D3

f!L#tEWfL'i"~~'ii

rn~ff-~4!1&'ii~•••oo•················································

j1!j(t~~~4!J&li~4:"&~

4:"&~liiUfBllf~jj,lj~(tEZJ9625~ZJ9620fJL"!l'J:)

nHfr~~~4!J&li~4:"&~00·(tEZJ961DtJl"!l'J:)

4:-&~Jiil]fii]

... ...

Ga~M··

~

Mb.tfl£;

.. . ... ... ...

ll:~:i'/riili'J

......

llJJijj,lj.(t£ZJ9610tiL~J::)

... ... ...

.. . ...

......

... ... ... ... ... ...

""~~1£

...

... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...

......

... ... ...

rliJ

~~too~

......

..

· ..... · ..... ·

...

......

.. · ..

... ... ...

·.........

·······························································

................................... : ................................

.. · .. · .. · ..

· ..... ·

.. · ..

· ........ · ..... · ..... ·

..................

... ... ... ... ... ... ... ... ... ... ...

(lJC)(;j''fZJ9625'fQZJ9610fJL'Jll)

............

... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...

(tEZJ9625'fQZJ9620fJL'Jll.l:)

........................

... ...... ... ... ... ... ... ... ... ... ... ......

..

· ..... ·

.. · ..

· ..... ·

......

...

..

. ... ... ... ... ... ... ... ... ... ...

.....................

..................... · 75

... ... ... ...

.........

... ... ... ... ... ... ... ...

... ... ...

61

...

62

~

...... M

64

M

M

~

68

®

..

· ...

70

......

11

72

73

73

~

76

77

78

I "'!

I .

II'

! I

I

I

j

'i

I: , I'

I

:1.

! '

I • I I

I

·,

''

I

.

'!!-:I

ll

I

1

''

't·

i

I

I

I

!I

11

'

!

i

I

Page 4

,,,

j:

'"

i

,,

i

'i

1

1.01

1.02

1.03

2

3

3.01

3.02

3.D3

4

5

5.01

5.02

5.03

5.04

5.05

5.06

5.07

Safety

......................................................................................

Safety symbols

Important points for the user

D,anger

...............................................................

Proper use

Specifications

ZJ9625, ZJ9620, ZJ9610

Needles and threads

Possible models and subclasses

Explanation

Controls

Keys

on

the machine head (only for machines with -D3 )

Bobbin thread monitoring with stitch counting

Pedal

......................................................................................

Lever for lifting roller presser

Knee lever

Key for setting stitch length

Swing out roller presser

..........................................................................

...........................................................

.............................................................................

..........................................................................

....................................................................

....................................................................

.....................................................

of

symbols

........................

..............................................................

·'

................... , ..................................

...................................

........................................................

................................................................................

...........................................................

..............................................................

····················2

.....................

..

J

J

J

4

5

5

5

6

6

'I

':/

'I

8

8

8

9

9

6

6.01

6.01.01

6.02

6.02.02

6.02.03

6.02.04

6.02.05

6.02.06

'i

!

,!'i

6.02.07

6.02.08

6.03

6.04

6.05

6.06

7

7.01

7.02

7.03

7.04

Installation and commissioning

Installation

Adusting the table height

Fitting the reel stand

Fitting the tilt lock

Fitting

...............................................................................

.....................................

..............................

.......................................................................

th.e

machine cover

Mounting the flange motor to the bearing plate

Mounting the flange motor to the machine

Mounting the toothed belt and adjusting the tension

Mounting the belt guard

of

Connecting the safety switch

Commissioning

Tilted

work

Table top cutout

Mounting the table top

Preparation

......

...................................................................

base

......................................................................

.........................................................................

................................................................

...........................................................................

Inserting needle on model ZJ9625 and ZJ9610

Inserting the needle

on

model

.................................................

'

........................

,

.....................................

.............................................................

..................................

............................................

................................

the flange motor

........................................

..........................................................

......................................

ZJ9620

.............................................

Winding the bobbin thread; adjusting the primary thread tension

Removing/Inserting the bobbin case

................................................

................

-10

·10

·10

lJ

lJ

-l2

·12

lJ

lJ

-14

-14

·15

·15

-16

-16

··17

17

··18

-19

··20

'i

Page 5

I

I

I

I

I'

I

I

I

,.

"

i'

I

I:

I,

jl

I

I

I

I

I

I

I

I

'

I

1

i;

I

I,

I,

I

I

'

I

I

I

I'

jl

j

:

I

I

I

I

I

I

:I

'i

.i

I

i

i

!

'il

:':i

:·I!

•I;

i

i

I

I I

iII

':''

,I

,I

.I

'I'

i

I

'

:!.I

I[

' ~ I ' I

'1

1'·:

':;J

1''·,

1:

!

~

,,

::.1

I

..

I,

,,

,;ll

H

Contexts

7.05

7.06

7.07

7.08

8

8.01

8.02

8.03

8.04

8.05

8.06

8.07

9

9.01

9.02

9.03

9.03.01

9.03.02

9.03.03

9.03.04

9.03.05

9.03.06

9.03.07

9.03.08

9.03.09

9.03.10

9.03.11

9.03.12

9.03.13

9.03.14

9.03.15

9.03.16

9.03.17

9.03.18

9.03.19

9.03.20

9.03.21

9.03.22

9.03.23

9.03.24

9.03.25

9.03.26

Threading the bobbin case/ Adjusting the bobbin thread tension

Threading the needle thread and regulating its tension on model ZJ9625 and

ZJ9610

Threading the needle thread and regulating its tension

Setting the stitch length ..

Care

Checking f-\,ljusting the air pressure

Cleaning the air filter

Cleaning.. . ..

Oiling the

Oil bowl for hook

Filling the oil reservoir

Lubricating the bevel gears.. .

Adjustment

Notes on

Tools, gauges and other

Adjusting the basic

Needle position in sewing direction

Needle position in sewing direction on the

Preliminary adjustment

Needle rise, hook clearance, needle height and needle guard on the

Needle rise, hook clearance, needle height and needle guard on the

Needle rise, hook clearance, needle height and needle guard on the

Needle position crosswise

Needle position crosswise to sewing direction on the

Needle position crosswise to sewing direction on the

Height and stroke

Height

Height

Height

Stitch length control eccentric ..

Stitch length scale disk ..

Shaft crank to feed wheel drive

Shaft crank to roller presser

Clearnce between roller presser and

Roller presser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stitch length on stitch length scale

Synchronization

Retainer( only on ZJ9620)...

Knee lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Needle thread tension release . . . . . . .. .. . . . .. . . .. . .. . . .. . . . ..

Thread check spring (ZJ9625 and ZJ9610)

Thread check springs (ZJ9620)

..

..

..

..

.......................................................................................

on

model

ZJ9620.........

.. ..

..

.. ..

.. ..

.. ..

..

..

..

.. .. .. .. .. ..

and

•naintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

......

... ...

...

of

the

air-filter/lubricator....................................

.. .. ..

..

.. .. . .. . .. . ..

hook

..

..

..

.. .. .. ..

lubrication..................

of

..

. .. . ..

..

.. ..

adjustment.........

machine......

of

of

the bobbin case opener

of

the feed wheel

of

the feed wheel on the ZJ9620 .. ..

of

the feed wheel

of

roller presser

. .. . ..

..

.. .. .. .. .. . .. . ..

..

..

.. .. .. .. ..

the thread lubrication

.. . ..

. ..

..

.. .. . ..

..

..

.. .. .

accessories................................................

the needle height

to

sewing direction

on

the

ZJ9625......

on

the ZJ9610

..

..

..

....

..

.. ..

drive......................................................

and

...... ......

.. ..

..

. .. .

.. . ..

..

. .. . .. .

..

.. . .. . .. . .. . ..

..

..

..

.. . ..

on

the

..

......

..

..

..

..

..

......

..

....

.. ..

..

..

feed

wheel ..

..

.. ..

.. .. .. ..

feed wheel

......

..

.. ..

..

..

..

. ..

..

..

..

..

..

.. . ..

. .. .

..

. .. . .. .

ZJ9625

ZJ9620..............................

..

..

.. ..

on

the ZJ9625.. .. . . . . . . . . . . . . . . . . . . . . 39

.. ..

.. ..

....

.. .. ..

..

.. ..

.. .. .. .. ..

..

....

.. .. .. .. ..

.. ..

..

.. .. ..

..

.. .. .. ..

......

....

..

..

.. ..

..

..

.. ..

.. ..

.. ..

..

.. .. ..

...

...

... ...

......

... ...

. .. .

.. . .. . ..

. .. . .. .

.. . ..

.. . .. . ..

..

.. ..

..

..

..

..

.. ..

..

..

..

..

..

..

..

..

.. .. .. .. .. ..

unit..............................

..

.. ..

. .. .

.. . ..

..

..

.. . ..

. .. .

..

..

..

.. .

..

. .. .

..

..

. ..

..

.. ..

. .. . .. . .. .

.. . ..

..

..

..

and

ZJ961 0 .. . ..

..

.. ..

..

ZJ9620.....................

ZJ9610........................

..

..

.. ..

..

....

.. ..

..

.. ..

..

....

..

....

..

.. .. .. ..

....

.. ..

....

..

.. ..

..

..

.. .. .. .. .. ..

..

.. ..

..

.. ..

.. ..

..

.. .. ..

..

...

..

..

....

...

......

...

..

. . . . . . . . . . . .. .. .. .. . . .. . . . .

....

.. ..

..

..

..

..

.. ..

..

.. .. ..

.. . ..

. .. . .. . ..

.. ..

.. .. .. .. ..

....

..

..

..

. .. . .. .

..

..

..

..

..

..

ZJ9625......

ZJ9620 . . . . . . 35

ZJ9610 .. .. .. 37

..

..

..

....

..

............

.. .. .. ..

.. ..

.. .. .. ..

....

..

..

.. ..

..

..

..

....

..

..

..

.. ..

..

.. ..

.. .. .. .. .. .. .. .. .. .. 52

...

. . ..

...... ......

....

......

..

..

.. .. .. .. .. ..

..

..

.........

.. ..

..

.. .. .. ..

.. ..

. ..

..

..

..

.. . .. . ..

....

..

..

..

..

..

.. ..

......

..

..

..

..

.. .. ..

..

.. .. ..

... . ...

...

.... ....

. ..

.. ..

..

..

.. .. ..

.. ..

.. . ..

..

..

.. .. .. 42

..

.. ..

......

..

.. ..

.. . 26

.. . 27

..

..

. 29

. 30

..

.. 30

..

. 32

.. .. 44

.. .. 45

.. . 46

..

..

..

..

.. 53

..

..

..

. 58

20

21

22

23

24

24

25

25

27

28

29

29

31

33

40

41

43

47

48

49

50

51

54

56

57

Page 6

i

I.

9.03.27

9.03.28

9.03.29

9.03.30

9.04

9.04.01

9.04.02

9.04.03

9.04.04

9.04.05

9.04.06

9.04.07

9.04.08

9.04.09

9.05

9.05.01

9.05.02

9.05.03

9.05.04

9.05.05

9.0SM•

Bobbin winder

Pressure

Lubrication

Re-engage safety coupling

Adjusting the thread

Resting position

Position

Distance between thread catcher and need!e plate

Position

Knife position and knife pressure

Bobbin thread retaining spring

Manual cutting test

Releasing the tension

Linkage rod (only for ZJ9620)

Adjustinent backtacking mechanism-03

Needle

Coupling for roller presser drive

.............................................................................

of

roller presser

.................................................................

................................................................................

..............................................................

trimmer-0

of

the roller lever/radial position

of

the thread catcher holder

of

the thread catcher

........................................................

of

the control cam

...............................................

...................................

..................................................

.....................................................

.......................................................

....................................................................

............................................................

........................................................

...............................................

in

needle hole( only for ZJ9625 and ZJ9610)

...............................

........................................................

Bever gears for feed wheel drive (on the ZJ9625 and ZJ9620)

Bevel gear play( on the ZJ9625 and ZJ9620)

Bevel gears for feed wheel drive (on the ZJ9610)

Bevel gear play( on the ZJ9610)

..........................................................

.........................................

..................................

........

,

,

.......

....................

.....

. 60,

61

.

. 62

. 63

.

64

.

64

. 65

.

65

.

67

. 68

.. 69

. 70

.

71

.

72

.

73

..

73

. 74

.

75

. 76

..

77

.

78

'

,,

Page 7

J

II

,,

'

I'

d

'i

i

~

1.

't7:1t

Safety

~1t

Safety

I

I

I

I:

'

i

I

I

i

::

'

~

: i

'I

1i:

;

~

il

'I

i

!I

j

~

I

I

'

'

II

!

II

:I

1,!!

:i;l

,

'I

! '

'I

;

'·

:!!

,,

'

:1

I

~

"I

j '

~

I

, I

I

~ ' ~

'I

:l

!

'

,!!

,I

'

'

!

1.01

1.

02

¥=t~'t7:1t00~

Safety symbols.

A fe;llfr{;L'i"[! Danger!

~

I

1'1"

'F

ff.J

*fJ?!<¥=1::

Important points

e 1!ffl

•

e

e

•

e

tll,

aJJ

4>

i'E

tll'IJ\1-J.\$

'16~~Jil.M!l¥!1t

tiL~

ff<J

flffl

i'JL

1m

il'-J

1:leffl1lf

t!L

~

il''l

1!ffl1lf

iilHJ:I:JJii

for

the

user

Jill

-f-tJlA/5-,'f~:Jl-.

i/ffJ

~JJ:z

lltr.

'16,

A

9'!

A

-'7

!il'AJJU!t1fl'f::X:tJL

~1'1

P,

1±1!iH!EtJL

'16,

;m

+IHJE

:rv'F

'16,

50

ii

it,

Xl)i

I)IJ

*i:tl:

~

JUt

it11H1t\C

12'1

Jitl*1t

v11tffl

fHnr

ill,

IE

'Ill'

I¥J

1<'-i:':\iltlll'l!IG

8'J

A.W

fl}j

R~

7G

e This Instruction Manual is a component

the operating personnel at all times.

e The Instruction Manual must be read before operating the machine

time.

e The operating and specialist personnel must to be instructed in the safeguards

the machine and safe work methods.

e It is the duty

e It is the obligation

removed or deactivated.

e It

is

the obligation

work on the machine.

of

the

user

to operate the machine

of

the

user

to ensure that none

·•

of

the user to ensure that only authorized persons operate and

'1\f:llUi'l:~.l':lo

xt!l\idt A

Danger

specialist personnel!

Do not operate without finger guard

and safety devices.

Before threading, changing bobbin

and

needle, cleaning etcs witch off

main switch.

'16~~Jil

!illHt"f

Points to be observed

filA

1<

!il'A

9Hf

~131

of

injury

for

operating and

~llii.ffl

o

ts 0

Ef.J

IIIJJ'?'t!El!i'A3C:'i'.I1t"1JOO

1'01~~i:k

A

of

i&i

TiE

11'

o

itt:

1fl

'X);:!I:

o

9'!

i±t!Ll*

the machine and must be available to

...ti1t

in

perfect running order.

of

o

the safety mechanisms are

Ef.J:I'ifiJII

for

the first

ie;

o

llfr !

of

1

Page 8

1.03

Safety

I

I

I

I

I

I

I

I

I

I

'

'

I

I

!

'1:·1

::1

'

'I

'

!I

:·:i

'I

)

:

•:I

i

'

'

I

:'

i

'I

'

I

'

I

I

: !

' i

'

~

,J

i I

:,:

!.

1

J

~

I

!.

ij

tJLn@i'i1~'i1

!i:\Mfa•J±J!!.,

A working area

the machine

:tE£i~JM~'il'P.

Never reach into the sewing area while sewing! Danger of injury by the

needle!

iJlilli!~::Cfti1~'P,

fi~!

ctr;)}!(IJYTi5L

Never leave objects on the table while adjusting the machine settings!

Objects can become trapped

::fi:'f:ffz;/J~'A3!i:iM4

)§Ill

il'~

Do not operate the machine without support

sewing head! Machine can

'P,

~·~iili'E:ffll*ft'Jlltr

::f'lt~ll.J.J!!.~:i.t!:tfLi!~o

of

1 meter

in

operation so that the machine

::fiif1:E£ii'Jlti!R~xill\l{!(

is

::fiif:tEI ftil'

'i.894t!l~fjji'i;:8{]fit~il!

1

8{]tJ1Am!

89

fit

llfr

!

2

IB

~{!¥;

l1ii

1 m

fi<J

§ EI3I fi'm

to

be

kept free both

f:EfoJE<illi!

J:$:fff"J4t!J~~!

or

be

slung away! Danger of injury!

lt'Jf,):ffl*~~·ij\":!!l:.

tip

over backwards when tilted!

in

is

always easily accessible.

1HEi~HLfE89fitllfr!

4t!lo"off;)}!(-Fft:Dt;)}!(:f!i'JE(J{_JO]"

31nJJ§f~*411t.

1!

Danger due to topheavy

l'lll,

front of and behind

~

i'f:ilEA

tJLlmfl"lnJ

.,

'i

,,

,,

I

i

'

'

'

i!

2

Page 9

t<~

1:Ert.JJ§fijjj;J<4HL~~iJIJ:Jtf.dl,@Tf:A!

'fHltrt!LilUi!:>'Hi!lil'!lfJJi9Ji'i81~1l&!

Switch the machine off before tilting it backwards!

Danger

of

injury if the machine is started accidentally!

Safety

71'i'r7f?,}]~

11r&ti~~Mf1Y~?,}]itfnilia<Httll&!

Do not operate the machine without its take-up lever guard 2!

Danger

'Iff

fi

t~

'll=*

On machines with thread lubricator, only operate the machine with the eye

guard 3

from the thread lubrication!

7Gi!f7fr}J~tr

W1BiEkt?'

Do not operate the machine without belt guard 4!

Danger

.'fit7f41J

B'

:tEtJL

Do not operate the machine without tilt lock 5!

Danger

'!lt!E~#JP

of

injury due to the motion

niJ

ll'H*

81

f)

El

~il'iJtetEJ'>Jii!IV'iJ[t!i.iJJi'f

lowered! The eye guard 3 protects the eyes from oil particles

!±

wlliHP~4(J{JtJLllt'!

81

~!Zi;JJ

&Jll'f%

of

injury by rotating drive belt!

~IFF!

li'MtiJl?

:\l;~uttrlkz

of

crushing between sewing head and table top!

'i::L281f!L<l~

L@

71'

i'f-i±

1!.'

(J{J~

!Jtl5

81

tiL~

l'fiJ

'IMJ\'iJJ

!

of

the take-up lever!

HIR~E'

0

I!&

Ei<J

58;

!

!

I!&

3

!

t!CFlltr

Tf?,}]

!

1?

H&

~:1!3-f*JP

H&lll1i

:!ll

. '

; ;

, I

I

I

I

•

I

3

Page 10

i

-;,;1

: I

~

I

'I

I

~

I I

"

!l

MJIHJ\!~

2

ii\ZJ'fHli\JE

Proper use

Proper use

ZJ9625

ZJ9620

ZJ9610

J!

!t~tJl~

The machines are used for sewing lockstitch seams in the leather and upholste-

ry

industries.

Mlf'-#,

,f}l

Is a single needle, high-speed post bed sewing machine (post to

the

and synchronized

:li!:Xltit, iflil£,

Is a double-needle, high-speed post bed sewing machine with driven

feed

M.>¥'-~1,

tJL

c

Is a single needle, high-speed post bed sewing machine (post to the

right

chronized

Rlr

Slif

r~J!l.

'ffi'1HJ!i$J:iS*'I-1t,

m1tJJ'Il!ill'fP

IEJZJ'ifi·ErtJttJ't!i(l';:flii~i'JJ

(ttj'\;/i(l';:fliii'E#Li:Jll) 0

left

of

the needle) with driven feed wheel and roller presser

needle.

11Hl:fi!U;IJJ2<t41t,

wheel and roller presser.

;%)

tJul~~tm

Specifications

3

3.01

15Uf~~W.

Specifications

ZJ9625, ZJ9620, ZJ9610&

&l<iiE:!IJ!*

t£1-#$tffi/l!ill'iB!:i::tii:il.t Clearacne under roller presser .. · .. ·

'£fa]

"i':fBlii'iiJt

.f±:>\;!l'!::~ii'ii

fJi&JltJUfl/k.R.

-K:l.lt

:00:/t

?.1IJ

/t(

Jlttlit.R./t

~ii'ii:iai!t

ZJ9625, ZJ9620, ZJ9610

ZJ9620,

Nli&l<~li.S

I

f'F

JIJt**EJfJJJJ¥ Max.power consumption

fliH"r

Stitch

type···

.. ·

........ · ........

:lt.!lt

Clearance width

Clearance height

JJt

Post height

>t

Sewing head dimensions

Length .. · .. · .. ·

Width · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · :;ld"J/approx. 240

........ · .... · ............

...........................

...... · .... · .............. · ........

............ · .............

E'tlit:LI:) Height (above table) .. · .. ·

Bedplatc

Max.speed

ZJ961 0 C:!IJ!/Modcl .. · .. · .. · .. · .. · .. · .. · .. · .. · .. · ·

Connection data

~ffi

Operating voltage

H Fuse protection .. · .. · .. · .. · .. · .. ·

dimensions"

A+

Bi\~!/Model

.... · ............ · .............. · ........

.... · ..........

· .. · .. · .. · .. · .. · .. · .. · .. · .. · 30 I

..............

· .. · .. · .. ·

· .. · .. · .. · .. · .. · .. · .. · .. · .. ·

..............

· ·

....

· .. ·

...... · .........................

.............. · .............. · ..................

........

· .. · .. · .. ·

.............. ; ............

···

.................................

· .. · .. ·

· .. · ·

....

.............. · ........

....

· .. ·

...... · ........

(%1*&1<~/lockstitch)

....................

)d"Jiapprox.

· .. ·

*t"J/approx.

· 3000

........

· 2000

· 230 V ± 1 0%, 50/60 Hz

1 x

· .. · .. · .. · .. · 7

· 518 x 177 mm

&\i;~/5}/spm+

https://manualmachine.com/7}/spm•

16

A,

245

115 mm

· 180 mm

615

500 mm

1.2 kVA

pg

J;Uinsert

mm

mm

mm

mm

II

i

I I I

II

i

I '

3.02

tJLil'J

A

B

c

Model

A

B

c

Needles

f<!Hffit/!-"""

:®:*:•

A.:iili:HtiE!ili\

Thread thickness

(Nm) max.

Synthetics

60/3

40/3

15/3

60/3

40/3

15/3

(N

m)

and

threads

q~Jll*lt

t(i.{iL 1/1 OOmrn

70

90

120

"""Needle

thickness

1/100mm

70

90

120

ZJ9625

tfltl

~!:IE

134

134

ZJ9625

Needle system

134

134

ZJ9620

t!WI~Ut

134-35

134-35

ZJ9620

Needle system

134-35

134-35

ZJ9610

t!ltt~!:IE

134

134

134

ZJ9610

Needle system

134

134

134

5

Page 12

tt71tficfm

.A.

.A.

Specifications

.t!lG

ftffl

or

similar strengths

itllJI: A

Jl.'lf

IPl

:W5ii\JJ't

ll¥1'4

't'i$*4 B Medium-weight materials

B

C

W:¥4

(lfJ

:Jt

'to

f'i'"R

IY-1

~x

of

other types

Note: A lightweight materials

•

of

thread

C Medium-heavy materials

3.03

4 I

"TfJ!ifft~tJLM&7tVLM

ZJ9625, ZJ9610

A

11'1

··

· ··· ·

··

· · ·

·· · ··

· · · · · · · · · ·

ModelA····························································For

ZJ9625, ZJ961 0

B M

..............................

Model

B··

· · · · ·· · ·· · · · · ·· · ·· ·

ZJ9620, ZJ9610

c

11'1

································· ··· ··· ········· ··· ··· ··· ··· ··· ··· ··· ·········

Model C · · · ·· · ·· · · · · · ·· · · · · · · ·· · · · · · ·· · · · · · · ·· · · · · · · · · · · · · · ·· · For sewing medium-heavy materials

flitiJQi!it

71-

Subclass-D·· · · ·· · · · · · · ·· · · · · · · · · · · · · · · · · ·· · · · · · · · ·· · ·· · ·· · · · · · · · · · · · ········Automatic edge trimmer

~Additional

t!l11'!

-D · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . §

equipment

?1-mmm····································§ZlJ:JM!'X'\!1•.

Subclass-D3

-ft.~~

~*1tffl*~~op.

J!!f1~ffl

In

this Instruction Manual, work to be carried out

is accentuated by symbols which have the following meanings:

······Automatic

Explanation

m~mfi(lfJI~~-~MA$~~~(1fJE5-~.

(lfJ

E

t.ii'~WT:ftl1l';8::

Possible models and subclasses

·· · ··

· · · · ·

··

··

· · · ·

·· · ·· · ·· · ··

··· ............... ··· ..................

···

· · · · · · ·· · · · · ·· · ·· · · · · · · · · · · · · · For sewing medium-weight materials

edge trimmer, automatic presser foot lifter, backtacking device.

of

symbols

· · · ·

·· · ··

· ·

··

· · · · ·

·mffl

sewing lightweight materials

mffl+§JUJJ'i''1!iWI'l!t.t1'4

§~~ffi••~·•~••

or

important information

+~~JJ~lifl:11'!;f.H.il

mfflr;~iiJJJ'H.tt4

Z9J

!Jj

!3t

'1!11:

[I]

~

flt;ij:;.

mii!i.

rit?.

Maintenance, repairs, adjustment, service work (only to be carried

out by technical staff)

-r;:r

.m

1~~

1t:*.l'l!.

i.!ll~.

Note, information

Cleaning, care

Lubrication

r1i'1t:*

c.Rilb!J1f\[Jc.A.V'\%Ji'Z(IfJI1tl

6

Page 13

1*1'Fnflf

Controls

5

5.01

5.02

Controls

tJldld'li:i'M!

(

-&Jfl

-T~~

'8

-D3i'J(J1'JL~)

Keys on the machine head (only for machines

;lm

~-

=~-.

I

(\)

~-

:

\

•

:tt~l'JJu1'1l'P.

7fli'iJ,Sf}tJX~o

•

jg<mam*i&:jf.~g&i¥J,

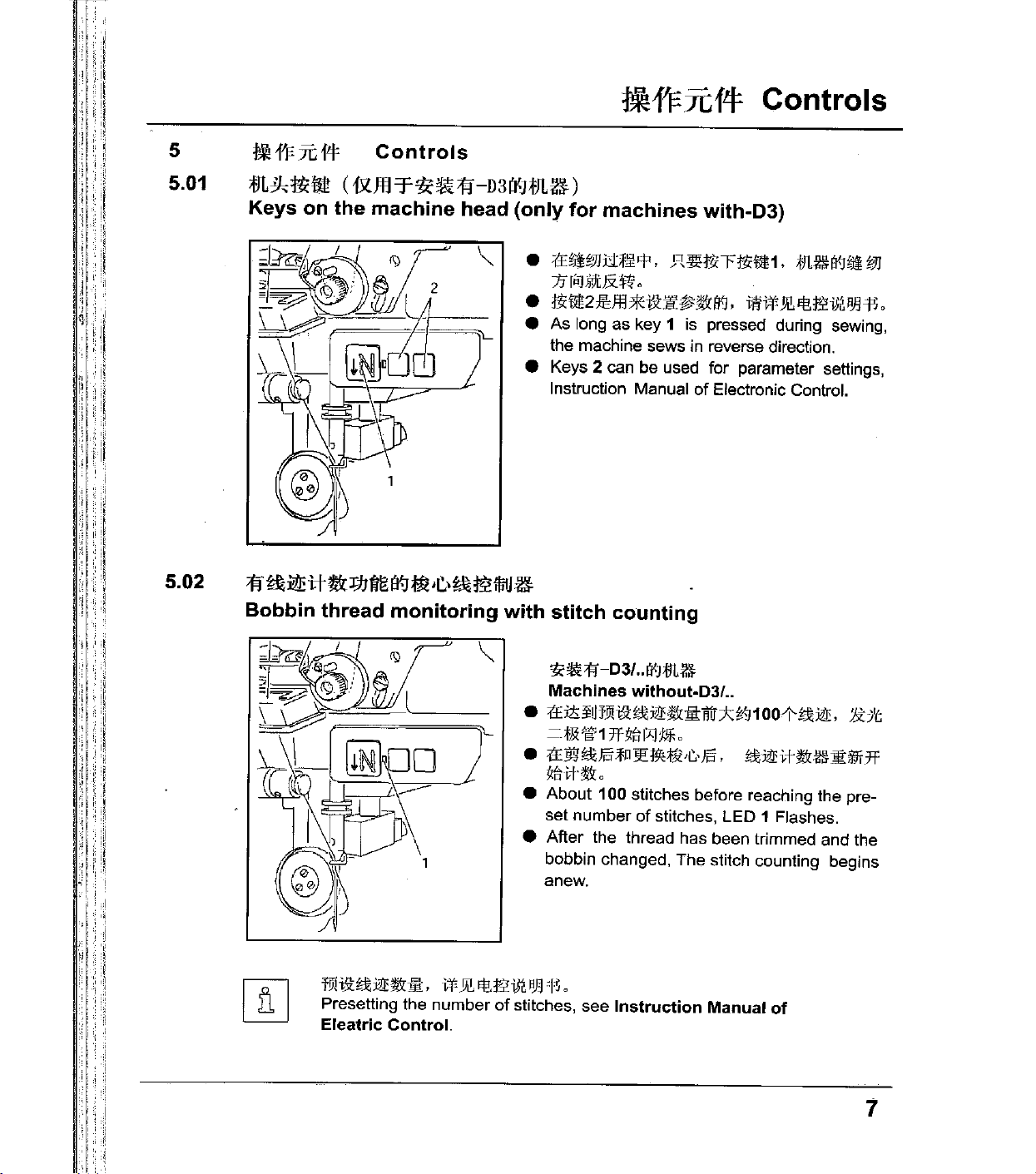

e As long as key 1

the machine sews in reverse direction.

e Keys 2 can be used for parameter settings,

L

Instruction Manual

JUl~ti.rrjg;'m1.

is

I

1f

~:i!mi.H&

Bobbin thread monitoring with stitch counting

J1Jfil3

1'8

~

•C.•

~

t5!

lliiJ

~

with-03)

m~i¥J;ii

iWWJI\Efi.t£iJIJlJlflo

pressed during sewing,

of

Electronic Control.

i'JJ

:'

,,

i', i

; , I

·•I!

'!'

i

; i

\

'ti:~:fl-03/

Machines

e

:tfiis:jUJ'N

=-

;j,!Z',§l'

e

tE~~J§'lP'l'i:J~;j)H,•J§',

~ilrl

g&o

..

[){Jt!L~

without-03/

i&:

iiJbi'£

1

7f

ftili:Y

..

g&:i:frr:k~'-1

t'l<

0

1

oo-t-~JiE,

~J1Eitg&llli]!l:ili1f7f

:&7't

e About 100 stitches before reaching the pre-

set

number

of

stitches, LED 1 Flashes.

e After the thread has been trimmed and the

bobbin changed, The stitch counting begins

anew.

I

fmi&:~J1Eg&~'

Presetting the number

Eleatric Control.

'i

w

Jl\

Efi.t£iJI.IlJlll

0

of

stitches, see Instruction Manual

of

7

Page 14

"'

'

'['

,,

~1'Fnft!:

5.03

'

'

Controls

ll;!il&

Pedal

/

-:;:--' ~ -

,,

=

0=

ilttll:{iL:li

=

!Jii?JJ

1

2=

tilililiff~tlliH!IJ

Raiser

3=

~~-

Trim sewing

Neutral position

Sewing

C{:[ji:~i'f

roller presser( on

({:E'JO<~i'f-D

..

Il{];l)li!i'iJ:)

threads

-D3

machines

(on

machines

..

1¥JVl<tLU

with-03

with-D

!:;zG,~,:p;,o,-;;!}

2 3 .

..

)

..

)

'

5.04 Lever for lifting roller presser

•

OJ

(!..(Jmjj:~i9.JJJR¥

e

The

roller

presser

turning

lever

1

J"ili!fl!:R$&Jli)jj;jJ

can

be raised

1.

0

by

' '

·

•. · ·.

:

~

' i

1

5.05

8

JJ;fJHf

~~~

Knee

~Y,

lever

I

~~

f--"1/

~

-

J

I

e

PJ

(!..(

JillJ::tloJ

:li<:J"ilii9!:R$&

e

The

roller

pressing the knee lever 1 in the direction

of

the

presser

arrow.

ll1i

~J!Jf7k1:f

lliH!IJ

0

can

loJ

fiHtJm'j;'jl,;ff1,

be raised

by

Page 15

!fd'J:::JC14

Controls

5.06

5.07

~~*11ri5tll~i@

Key

for

setting stitch length

-

)

'\

i

e

I--

~

I=

~~

lliJl!l!

Swing

/

rliJ

out

7H~

z;JJ

roller

presser

~~

=::>

e JmiiitCFtl<m 1 #

IJf.

(

1$

}Jil.~7.08~

e

The

stitch length is set

and turning the balance wheel (see

Chapter 7.08 Setting the stitch length).

PJE~-'l'-!i!i*11!:JI[~J11¥:.

"\!!:JI~~*!Jf''

by

pressing key 1

) 0

e

~

fi

e

When

.

can

downwards.

~

't::

be

!iii

Jli

,

f~

the

swung

HtiJ

1il

Jt

lnJ

roller

/t9

,If, ,

7H1ll

presser

out

PJ

$1

by

[;.(

JHi

o

is

pulling

li

lnJ

raised,

it

lightly

T

~

it

9

Page 16

~~;fiJiA$

Installation and commissioning

6

6.01

-.t:

~

;to

iA

:$

Installation

Rfei'f~~f!\8(]AJJ:ixtiJL4l~Jtt1r'ii:':\i!itn\Jct$!

13:!1'!.

Lh

'.t:

The machine must only be installed and commissioned by qualified

personnel!

All relevant safety regulations must be strictly adhered to!

·

!zp

!iiHiit~Jl

~:fJL#'fP

~~~~fi~B(]J§l~~~~~$~W~~JEo

If the machine is delivered without a table, be sure to use a otand and

table top that can hold the weight

It is very important to ensure that the stand of the machine

steady, also during sewing.

~

Installation

~i'Jl.#'ll:~Ji!Jr.\1:,

~:tn.M'll:&Ji!Jr.\1:,

The site where the machine is installed must be provided with suitable

connections for electric current.

It must be ensured that the standing surface

firm and horizontal. and that sufficient lighting is provided for.

&:,

and

{il!

commissioning

:ilt

'if

PIT

1f

l'l

:X:

R'JJ

tJVf 'lll'ifi'

>t\tJl.

fJj(

#tilt •

B(];ll!jl:

o

&;'§l)j~

~-~~-.-~B(]Ji!JOO,

!

3l:

.!£

~Jll

JE

!

mn

1'P

a1

J'JI

ffl

a<J

tJl.~lll

of

the machine with its motor.

~tJl.#t§:(q:B(]

>t\i1Jii:J3:!

a

Q 0

~&~*B(]R~.

of

the machine site is

f.lj(&;,~91

1!lHIU~i!t

is

firm and

ffi

··'i

.•.

:1

' '

:::;'j

: I 'I

'

:'

'

~

6'

0 1 . 0 1

~~~-lll~-8(]-~.

For packing and transportation reasons the table top is in the lowered

position. The table height

€1'

1:&

m;

13£

Adjusting

LJ)

·--

1¥1

iffill!I1E

the

table

u

,--,--J--J

I

'')-,

height

I

J§lf.lj(f~.

is

adjusted as described below.

e tc7t'i!l'HHn2.

Jl_

!,...-'

•

e

e Loosen screws 1 and 2 and set the

J§lf.lj(

]WB(]i@JJJ[

:ltr~H1$1'1ij±i!!fi'~.

i%-Jil'l\f.lj(.'i'f!TlmB(]NJC.

H2tT~.

table height as required.

e Firmly tighten screw 1.

I

I

L_)

.•.

.,_,

10

'

:''

e Set the required pedal position and

'

tighten screw

••

0

B(]

••

~TPIT~o

:Ji'~41§lf.lj(•m£PJT

:lf.A.i%-t~

2.

Page 17

~~:flli:tt$

Installation and commissioning

'

,·

I,

'

I

:

I

I

'

,

:·:i

:i_

l

;

'

'

'','(

"I

:I

'"

1

lj

:j

'I

,;'!

1

.1

!

6.02

6.02.02

$:~~~

Fitting the reel stand

•

e

e Fit the reel stand as shown in Fig.

e Afterwards insert the stand

'ti:~llill$1d%1l&

Fitting the tilt lock

~

l!n

OOJ'JT71'1<~!%~

i'!.\

JB

:11fi%~1ill

A

~

o

;j;i

EfHL

'I' ;!i

ffl

JlJ1i

1lJ

1¥1

t'lUIJ:

Ji'Ht!!fliJJEo

in

the hole

table top and secure it with the nuts provided.

e

a

ffl~ii2[]I;IiEliJJH'1Jtl~'V:l

::nt3fz;JJi:~t'fJ'llllH'1%~1fi<J;fJL~!

:Y-:

;fU

Jfl;j;il:

fBJ

1JliF'f{t

<

00flft141.!Uii

8<J

:r.;

Pif

!

of

the

l o

l'fi'±f!l.

l'iJ

a Switch

;i

'l_li

:

: 1

~

I

'I

;1:

i

Danger

is the started accidentally!

e Screw on the

in accessories, using screw 2.

a Do not operate the machine without

~

tilt lock 1.Danger

sewing head and table top!

of

the machine!

of

injury if the machine

tilt

lock 1 provided

of

crushing between

11

Page 18

,,

i '

' '

I,

::

'i'l

l

l! ( ,.

!

~~~iJ\$

Installation and commissioning

I··~~~

I

I

I'

:1'1

I

i;

I,,

I<

,:

I I

!•

,f.

'I

i

:_·I

6.02.03

6.02.04

~'IU1L~1P"'ii-

Fitting the machine

4

~~m'¥*-"-1¥1

Mounting the flange motor to the bearing plate

cover

•

:tEt~n2

J:),

4

J£,

• m

2

e Slide the slots

cover 1 behind the heads

attach with screws

2 through the

&g

*l1~

sl!li

<t~

H2rw5ttr:tE

:ltrt?

~1;'{}

Tll1Jff(Jfi!!fll'f

~Fn:ii!iJi:ii!iJLrr~!I!!H2o

~~

n

41l\l

J£;t;:.ti

J!ll

ll!l

?J-t?

of

the lower section

3,

then tighten screws

holes.

e Attach right and left cover sections with

screws 4.

Ff:!.7i!JfJL~IJ'm:fil:

e

J!nOOJ'JT7J',

;fJ[2_.L

e

}y\

ltlziMJUill4_t;f$1;1$111to

•

ffJt~;li6[ll!J

e

"Jt~·:ffti!

H

I¥J

~$

• ¥J-!I!!#srr

FH~fi3¥l'-:t/':W11IT!J.€3i~EI'.4J

JE:iiJ

.±J'll:5o

&g

&:

'<ll':'ft?f~

'll'

IE

1>'!:

A3i~~Wl

'f

El'.i9J

El'.i9J

Wiillli''l l"l

"P,

{!

L3'C

AJH!l~H31IT!

~ 0

of

the

of

screws 2 and

t!L'il!IH. ,

fi!!f

t;

'P o

'

e Attach bearing plate 1 to

motor2

with

screws3

e Remove the wedge from motor shaft 4.

e Attach angle bracket 5 with screws 6.

e Fit toothed belt wheel 7 to the motor shaft 4,

located in the the groove

e Screw threaded stud 8 into the bearing plate

12

of

motor shaft.

as shown in Fig.

so

that the point

1.

of

the screw

is

Page 19

I

I;

I

·.

I 1

11

•.

I .

I

·.

''l

i'

!·!i

i'

.!:

1

·:•:11

.

I

I

!

i

i '

rljl

I I i

j:i.

i,!,

.

1

1

1

..

;I

I,

:i

I!

:1

il

~

.,

~~.flliJt$.

.

6.02.05

~

~

'111¥* , ,_

Mounting

iY-J

the

/

2

Installation and commissioning

~

#rf'JLf!J

flange

fJLff:

J::

motor

to

the

machine

:fR

111'!1

J.E!EU

:ffl#9Hi':.l. c

'l!tt~t±3)

Attach bearing Plate 1

to the machine case with screws 3.

(Onely tighten screws 3 lightly

0

.R

of

:li!o:l£1ii.Htlrti'

motor 2

).

lr

I!·

I'

i

I

I

I

j,

I'

I,

I

'

I'

],,

1::

I'

,

'·

1:

]!:

i''

i

I

I

::

..

'

·t

;j

~

11

irj

::1

:

. I

. I

(I!

'

,.g

:111

• I

!

:1

i:l

; '

'··l

'·i

,I

i

~

I

!)

'j

•I

. '

! '

''I

I'

..

6.

02.06

~~itO~

E!e:W

Mounting

;fo

the

iffil i!llf

Et

{fHIUJ

toothed

belt

and

adjusting

•

:tti3:1'lli.lll'1<~tllmltw1

•

mi9J

lt'liL

•

1'Ei3:

the

tension

El'.i9J m li'1

1't'L

lll'JT

0

~.NJii2,

'l!t~~3

iiH!i:

0

'lit

ilim

e In this position fit toothed belt 1.

e Swing the bearing plate 2

e

In

this position tighten screws

i I

I .

~

~

'',,)

'.1

of

the motor,so that the toothed belt is tensioned.

3.

13

Page 20

~~::fllit\:$

'

'.

'

6.02.07

'ti:~**u.

Mounting the belt guard

Installation and commissioning

ftl.~:f!Lff.Jlli:'lffi!Jit?~

of

the flange motor

e

F!l~H2li13[1!JJEE'l'lil'il1JJP"ll

1o

e Attach belt guard 1 with screws 2 and '3.

~i!!H3JVlfJL.'k

m~M\ilJ,

When the sewing head is tilted back, the safety switch prevents the

machine starting when the main switch is

!OJJ§'i~~4at,

:ff,fJL~,ffi,lf~t'll'Jl!HJiJ·tl'flJI.

14

'

:l

:j

on.

r,

~:i:lf~;J{r-llif

11:

Page 21

, I

i I

...

,1

'i

il

• i:l

il

'

.,

. I

I

: I

~

·

.. · .1··.:1

II

::

. : I

~

I

'.';I

. I

' i '

~

l

6.03

~~flliJ\$

"jj\'f

e

•

•

Commissioning

#11'ttJL1ltifiloi'i:t!1fflW,

WJrn<~i'litJL@,

rn

~

\[]t_J\

F-r

til:

±l!J:ffti§ii£:;1[.!!!.

Installation and commissioning

!f!fJlrJfilo

~rn~irtJE;)(;:JJQirtl

il: o

tJL

1*

=it~

o

1'Ef±foJ:tJ

'~SJ!i~:t!7Gtffli;F

<

iw*

i¥l

>jj.41J

rJL.12

i'i

ft

:±l

Ai¥J't¥i

illU\"1

+'f

JtJ

B 'If

i5G

T,

o

nl

"£MI'~'f*~"

i¥J

Ft\

i1!t

t!c:cf

i!f:FF$ o

>tllli

\!13:

ii!J

)

,

e Check the machine, particularly the electrical wiring for any damage.

e Clean the machine thoroughly and then

and maintenance).

e Have a mechanic check whether the motor

available power supply, and that the motor

the

tion box. If there are any discrepancies.

under

any

circumstances.

oil

it

or

fill oil

of

the machine can be operated with

is

the

machine

in

(see Chapter

correctly connected

must

not

>tliilrtfl.;ll[:i'f

in

be operated

IE

11

Care

the junc-

liffl

'·

. I

1.:;

. '

i

'.'JI

:I

~ : ~

i!

II

!I

''l

6.04

~

~

•

e

e When the machine

tJL~.RftiifWtEWJ~±l!l~I¥J.Jill)'ji;..t!

The machine only be connected to an earthed socket!

tJ1AllilE1rllt,

X>Jw:ft

;!;]

4.41J~]l[i¥JtJL~,

6 bar o

If it does not, the motor connection must be changed by a mechanic.

¥~t-G,;911<iJ1*fFJ\9.\::-?I<DiiJE~

-G,;iJ!~tJL~tl<..tlliml~4;

Jrp

:ll<:tffi~,

urmt

m:itt1TiWJ'li11(

is

running, the balance wheel must turn towards the operator.

o

Jrn.ll1)f'X>J,

t~*

Jlii.Ul"

83~\[]t_J\!J.\~fti.>i!rtfl.'Wctli!o

t-U<BZ*ii!E

s.o1

o

1>

"1\\'zi!l'/~l>~"\ffin"

1li.7J~BZ~ilfr7.J'J±.7J

) ,

e Machines with pneumatic equipment must be connected to the compressed air

of

supply. The pressure gauge should indicate a pressure

8.01

adjust to the correct setting (see Chapter

ssure).

ftm~H8x~~

Tilted

"

work

"

113

base

3±0

1

340-5.2

339.6±0

3

Checking

F

"'

~

6 bar. If necessary,

Adjusting

the

air

pre-

A

'i

II

r.

i''

:1

Ill

[)!

··'

~

..I

,..._

"

"'

~

~

@:·

15

Page 22

,

:.I

'II

il

'

I.

J,

J,

, .

:'

I'

' I

!

·

....

11.1

'I

''I

'I'

';I

[!

';

''

i i

ri

'

ii

lj

.

il

!I

~~~1-A$

6.05

E?t!.Hf;ft!lffMfi:R

Tilted

work

Installation

-t

base

and

commissioning

I•

1:

~

I;

;

•.

' ' f !

, I

lj

'

!I'

"

1

,

I

,

'I

l:!j

1,1

'·:1'

iJ

6.06

~~€rttit

Mounting

~

the

table

top

~

""

--"'

-1

__

¥

i

i

i

J-':<1

l.4

~J

3-fl135

~

..

·-·

~

i

I

I

'

~

·~

'

ej

170

'""'

'

II

16

:j

I

II

Page 23

I

I,

,,

i

':

I

'

,i

I

I

I

ii!

}I

·,·I

I!

7

fJL~(f£~

Preparation

'.IZ,cl!Ji:iJ:'il"

!1\J!JliJ

All instructions and regulations in this lnstrution Manual must be

observed.

Special attention must be paid to all safety regulations!

:<$:i.lliJil""'

%Hi:;\!!;

FIT

'I"

PJT

11·

Ef1~!\!Jt:.fnm7J'"

1J

81

~:'E:~.m'iE

!

rJL~fliT

Preparation

~

I

,I

t•.l

J'Mf1Jl*lif!E.Ji'r

:f:EM

irA'~

1ill); '

All setting-up work must only be carried out by personnel with the

;

I

7.01

,f:EZJ9625

disconnected from its power supply by turning off the on/off switch,

1;).

appropriate training. For

removing the plug from the electric power socket.

;fll

ZJ961

I

fe

Jl. ft.

i'F

El3

'll:uffiJ!IZJ\'fiJII

m

*!ill£

.Ji'r

I

it

at.

16·

~m:illiu~

~

i'JlAlli

Iff

<11

0

all setting-up work the machine must be

O,j:JLlli!J:~fJL'ft

81 A !JlJ'G!iJZ

10JJ

.~.

:JT~!l't1!r

o

JA

<11

iJJ:tili

mLt

tltl'lji

or

Inserting needle on model ZJ9625 and ZJ9610

&

~ffit!l*li<fliJJ!

Switch the machine off! Danger

accidentally!

~*B<rfl*li£7HI!!jlj)z;IJ1JJ'lll'Ef1:f0;1t\Z!

of

injury if the machine is started

.R

~ffl134~mB1:mtt

Only use needles

•

Jil'jlj)~!fj);Jlijjlijl

e

t£H*fr2;)!'~

1

;)l'~;l't

"fli~i**l!!:tiliA:f!L#

xtZJ9625:1Jl'tl'i,

xt'fZJ961

e

tf~*H2;1l'~~~tllii!Jii!~@!~Uffii:i\rji'o

Otflll'i,

o

of

system 134

luJ

7'H1lz;/Jo

*

#;fl!!i

*#;fl!!i

o

'.IZ·~Nl!illul

'.IZ·~j)jl!i]luJ

:ti:iil,

Li:::iilo

e Raise the roller presser 1 and swing it out.

e Loosen screw 2 and insert the needles as far

as possible. The long groove must face to

the right on model ZJ9625 and to left on

ZJ9610.

(-:_

model

111111111~

e Tighten screw 2 and swing roller presser 1

back to position.

I

:.

1

,;

I

; t lo

!

Iii

II

'II

'·'i

: i

'

tJL#Ef]Jlliffll[l(

~"

)

The Choice

thread and material used (see

t!<'f:IJl*!iEfJ't\'1

of

needle depends on the model of the machine and the

~,

i::li.fOJ'Jrg)f§g]Ef]M'if4

Chapter 3.02 Needles and threads).

C *

!Jii.~3.02'P

"~Ho

17

Page 24

,

IJ

:1

;t;JL~ft-il-

'

!l---------------------------------

Preparation

1

!I

!J

!

IJ

:I

i'

i

7.02

:B:ZJ9620;t]L~J:~;t]L#

Inserting

/.::...

~

the

needle

~PfltJL1*El'l.ilill'

Switch the machine off! Danger

accidentally!

on

model

ZJ9620

~tBLtn1*~7rrl!!iti:\MiJJ'ill'A'Jfi1~ft'

of

injury

if

the machine is started

:I

'

il

I

il

,,

il

:J

9.1tJFJ

Only use needles of system 134-35.

134-35-*iiitl't-:rlll

e

Jiliti:\~$&£&1!!11

e

;f',{Jf~H2f\'jjlj.AtfWI>

e

rr'lltt~H2:Jt:m~$&llii!!1J~@l~rJ!liiffl:lli'o

1

:Jf:mJt.:

# o

l'il

YH~M

o

f~E::illtiL#i¥J-jj;;#:ft\llli'i

l'il

;t;:lll,

e Raise the roller presser 1 and swing it out.

e Loosen screws 2 and insert the needles so that the long groove of the left needle

is

!I

facing right, and that of the right needle

e Tighten screws 2 and swing roller presser 1 back into position.

is

facing left.

'i

!!

'l

;I

I

I;!

,,

l

l

''

'!1

'

I:

,•

18

,j

:I

'I

;fJL#

I¥Jil!1fll

~" )

The Choice

ad and material used (see

l{JU:k:rtfL

of

li*I¥J

needle depends on the model

1\'J

'%,

Chapter

~.fO

?Ji~tJJ

3.02 Needles and threads).

;t':lll;fJL#I¥J

-jj;;#:ft\lilii

l¥ltt:f4 C $ !A'.m3.021'

of

the machine and the thre-

l'iJ

E::ill o

"lH~

Page 25

' '

'

ill

:i

..

I!.

'

:,!

~.·

·.:

...

11

~

' I j

•.

i ! .

•.i!l

" ,'1

. '

.i

':I

,,

Ill

,,

,·'1

r

'i

I

i'

'I

i

!:

'i!

!:

!i!

t:

) I

·:

;II

II·,!

I i

'I

II

11

7.03

~.r,,~;

lJili-'P~·L.,~f8MIJil'J~1J

;tJL~<l~

Preparation

Winding the bobbin thread; adjusting the primary thread tension

e i'J-1-2i¥Jt.!N.•1

e

j!Q

00Wi?J'9-03~i'3N<"~l'

•

"3

~

1!1lli

r

'k'lUumt\!~1l!i2_L

tl!, ;lf#ft\!JI[i)ii!1#1J

m~:l!*!i1lli25fllt_[ff3,

!il

Z)l)~tl!*li

loJ

:tE~·C.·

0

J:mJL

1m

o

e Place an empty bobbin 1 into bobbin winder spindle 2.

e Thread the bobbin as shown in Fig. And wind it clockwise around

bobbin

e Switch on the bobbin winder while pressing bobbin winder spindle

2 and lever

:tE~t'JHif11'i",

The bobbin is filled up during sewing.

•

:tE~

•

~~·C.·~iii!it\!J§f,

e The thread tension

e The bobbin winder stops automatically when bobbin 1 is full.

.!In

If the thread is wound unevenly:.

1 a few times

,c,,

1

J::

5!HJI:

!1Vf

3.

~-C.·t~~

i¥J

tl!

l'l<fr'oJ

t~t\!~HJZ)I)f-$rl::,

of

:ISJ

?J

,

0

~ m i!'l::ll:J•~

bobbin 1 can be adjusted

tt

4J£1riJiiJ

'lli:

o

by

knurled screw 4.

ill

i

1:

i.'l'

,,

I·

,.

!:

' I

i;

·i

I!

I

I'

ill'

!:

:I

li

' I

" '

,I

!,,

i

• t::JH.!\

e

;ffifS\Ztlll±i!!~Z)I).\'J't\!{R6o

•

:JT'l!U~U5,

I

El5o

Loosen nut

Turn thread guide 6 accordingly.

Tighten nut

5.

5.

·j!

19

Page 26

;ffl~£~

Preparation

'

'

i(

''

:',.1

'I

I

\!

:1

I

,I

'I

i::

:1

,_,

I

,-It

,I

:l

irrJ

1

11

;,i

lj

I'

'

,,

'I

'

!f

ji

lr·,

I

7.04

lliU±!

/~A.t!t

~

Removing/Inserting the bobbin case

/J;.

L.l:!l.

~I'll

t!lo$

EE\iJ;~

!

iHJ.IltJLllli

Switch the machine off! Danger

accidentally!

tt

5Hill/8lz;JJ

J{)(

til

Removing the bobbin case:

•

tr:Jf:l±:i~Jti:j;R~\jl

•

1i't/E9:!&

of

injury

:!&

:]\\

1'11"'1 1 Jl'l!lC

e Open the post cap.

e Raise latch 1 and remove bobbin case 2.

•

e

e Insert bobbin case 2.

e Close the latch and close the post

X1ZJ9620i'!l1l'!li"JW1fi:'Jm

ZJ9620 is shown in Fig.

~

1'7f71'

511lA:!&

Inserting bobbin case:

~Af&%2o

~I'll:!&

e

•

•

•

e Insert the bobbin into the bobbin case 1.

J'L'

I'J

o

:#1-:l&•l):li<A:!&%1

iifrx'!l"rt5'll~2TiiiiJ*t!'l'l'

:f4f

tx

"J'

imii~Z9l~'iJ3iJ!J'll:l&>C.,~i)k.1J

e Pass the thread through the slot under

spring 2.

e Pass the thread through the notch.

e Adjust the thread tension by turning

screw

fJJ

*'

fi<J

fii;

llfr

!

if

the machine is started

'

0

tll:!&%2 0

j'=J

::If

llHn

il\Lt.f:l'J'\:Jl\'Oj;R

'Po

rt

L"J

o

l1L

3.

~ o

o

0

:::1

i-!

,,

'

I!

,;

I

~

i

Iii

I

"

'

I

·I

I

I

:!

.,

'

'

:i

20

~~~M.

When the thread is pulled, the bobbin must rotate in the direction

arrow.

~~~---~~~-~0

il

II

of

,.

the

Page 27

rJL~at-11i

Preparation

7.06 ZJ9625,&ZJ961

Threading the needle thread and regulating its tension on

model ZJ9625 and ZJ961

:k

PJ:i

til ili\ It\

f!f:Mitn.

Switch the machine off!

Danger

e

rt:J.L;f~z;!JJI'§IR"!l.J

•

izp

e 1'EZJ9625W1U:..

#~M/Atcr~J:tl'!¥

e

Jl!ii:t~i9J~1tt!l\fi2iiW'iHH2lHi<J~lt:iJ

e Tilt up the eye guard 1.

e Thread the needle thread as shown

e On model

left, and on model

e Adjust the needle thread tension by turning milled screw 2.

O:!'JLlli'J::l"iftt~:.ff:

im!

iHt~91UJ

0.

iUlt

!

l!li

:&

5'Ht!l~r)J1JJ

of

injury

l'!l

Jifr

71'

v

1t

ZJ9625

§

il'~

m;

I!&

!

if

the machine is started accidentally!

o

~

0

'ft~Jl!,hl,:brt:Jli:V,

0

the needle is threaded from the right to the

ZJ961 0 from left to the right.

ililtEZJ9610tfl.gli_t,

o

in

Fig.