Page 1

ZJ900

SUPER HIGH-SPEED OVERLOCK SEWING MACHINE

ZOJE SEWING MACHINE CO., LTD.

:

ADD: DAMAIYU ZONE,YUHUAN,ZHEJIANG, 317604 CHINA

: TEL: 800-857-6715

OPERATION MANUAL

PARTS BOOK

ZOJE SEWING MACHINE CO., LTD.

ZJ900

SUPER HIGH-SPEED OVERLOCK SEWING MACHINE

ZOJE SEWING MACHINE CO., LTD.

:

ADD: DAMAIYU ZONE,YUHUAN,ZHEJIANG, 317604 CHINA

: TEL: 800-857-6715

OPERATION MANUAL

PARTS BOOK

ZOJE SEWING MACHINE CO., LTD.

Page 2

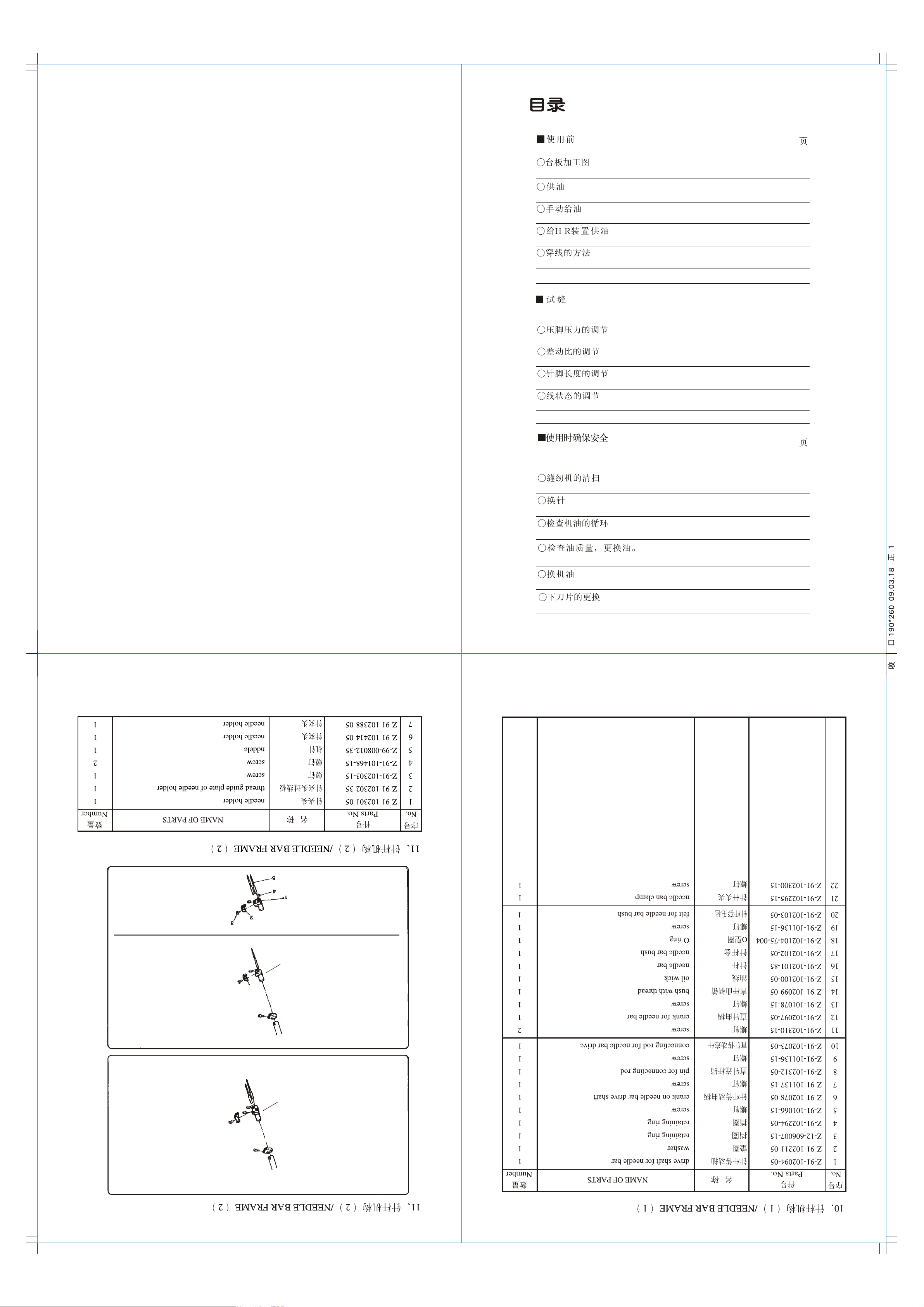

CONTENTS

BEFORE OPERATING

Schematic diagram of the machine table

Lubrication

Manual lubrication

Filling the HR device with silicon oil

Threading

TEST SEWING

Presser foot pressure

Diff.feed ratio

PAGE

1

2

3

4

5

6

7

Stitch length

Thread tension

MAINTENANCE DURING

USE

Cleaning the machine

Replacing the needle

Checking the oil circulation

Checking and replacing the oil filter

Checking the oil

Replacing the lower knife

8

9

PAGE

10

11

12

13

14

15

-31--30-

6

7

Page 3

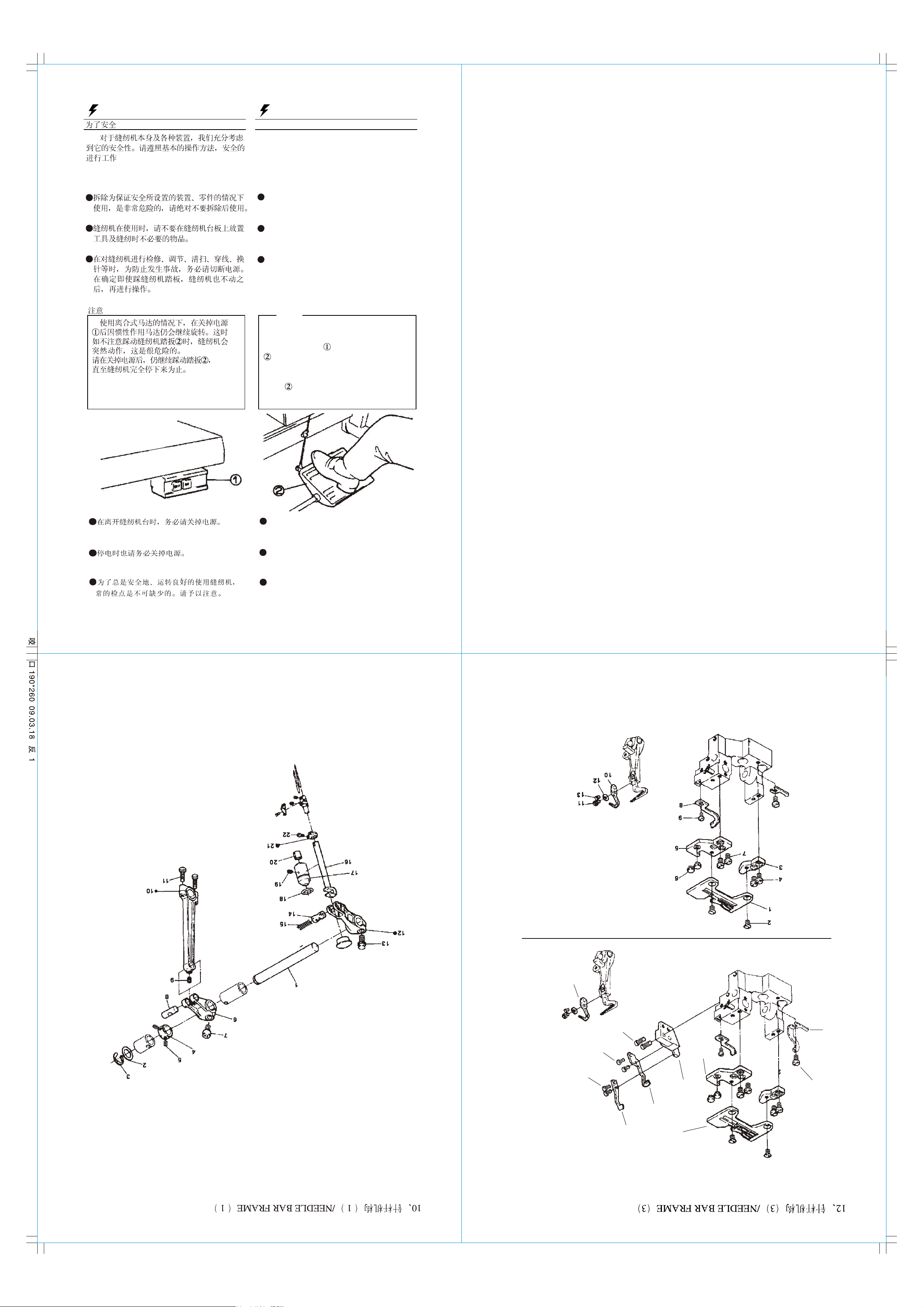

CAUTION

OBSERVE THESE SAFETY PRECAUTIONS

Though Pegasus takes the utmost care to

produce safe sewing machines and devices,

operstors should follow these basic safety

rules.

To prevent accidents,do not remove safety

devices or parts while operating the

machine.

Do not leave tools or other unnecessary

objects on the machine table while

operating the machine.

Before maintenance,adjusting,cleaning,

threading or replacing the needle,and to

prevent accidents,be sure the power is

turned off.Check that the machine will not

operate when the pedal is pressed.

Note

lncase a clutch type motor is used,it will

keep on rotating by inertia after turning

off power supply. lf the machine pedal

is stepped on inadvertently,it is

dangerous because the machine will move

unexpectedly.keep on stepping on the

pedal until the machine comes to a stop

after tuming off power supply.

Tum the power off before leaving the

machine table.

In the event of a power failure,be sure to

tum the machine off.

H

Check that the machine is securely

grounded.

-29-

-32-

24

23

22

21

20

19

16

18

14

17

15

Page 4

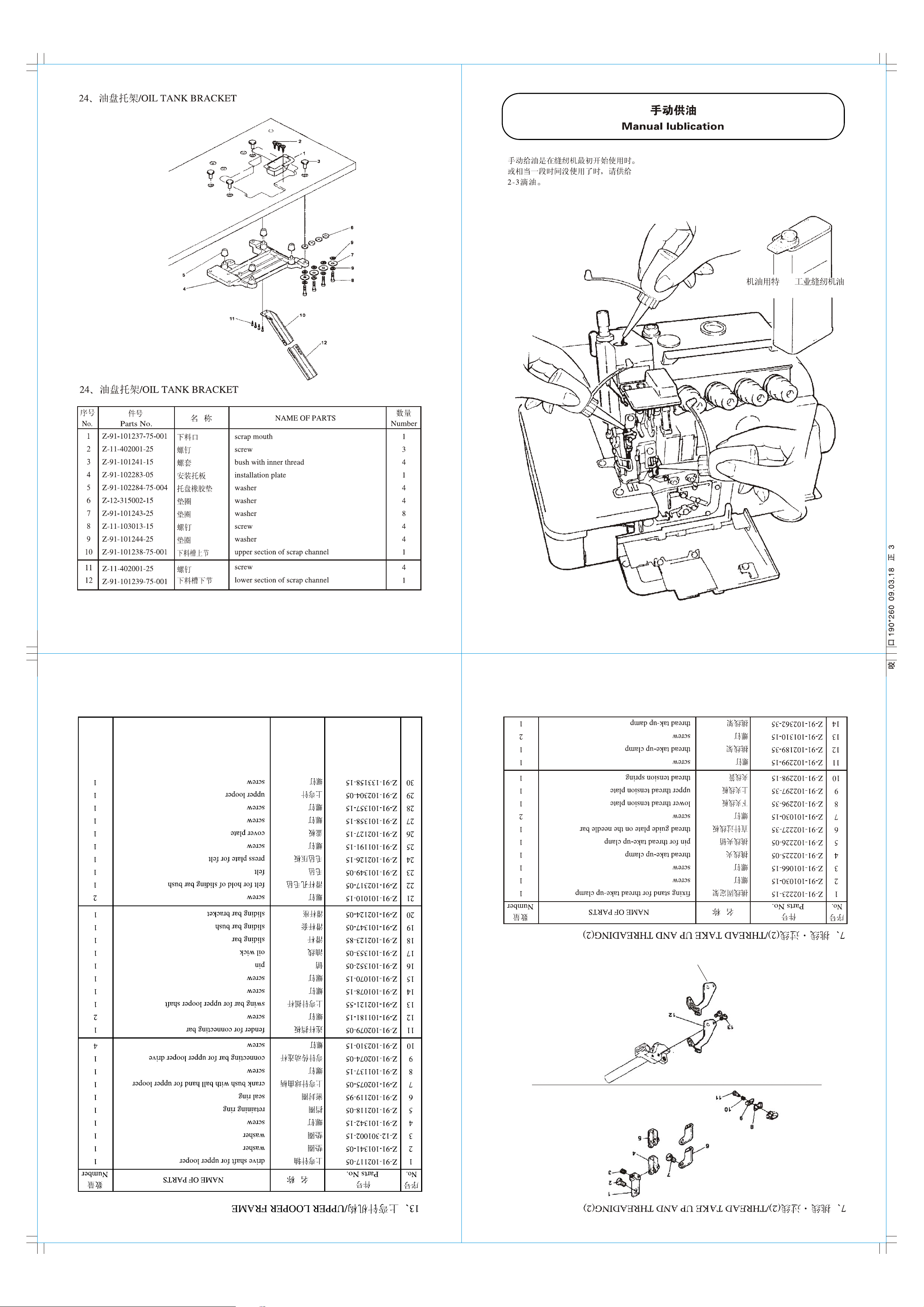

932 GAUGE PARTS LIST

Cut the table refeming to the diagram.

932 GAUGE PARTS LIST

55

70

80

86.3

115

Standard dimention

...........................................306mm

EFKA QUICK .......................334mm

Notes

Dimension for motors in Jopan....................................306mm

Dimension for EFK motor.............................................334mm

-60-

-33--28-

-1-

Page 5

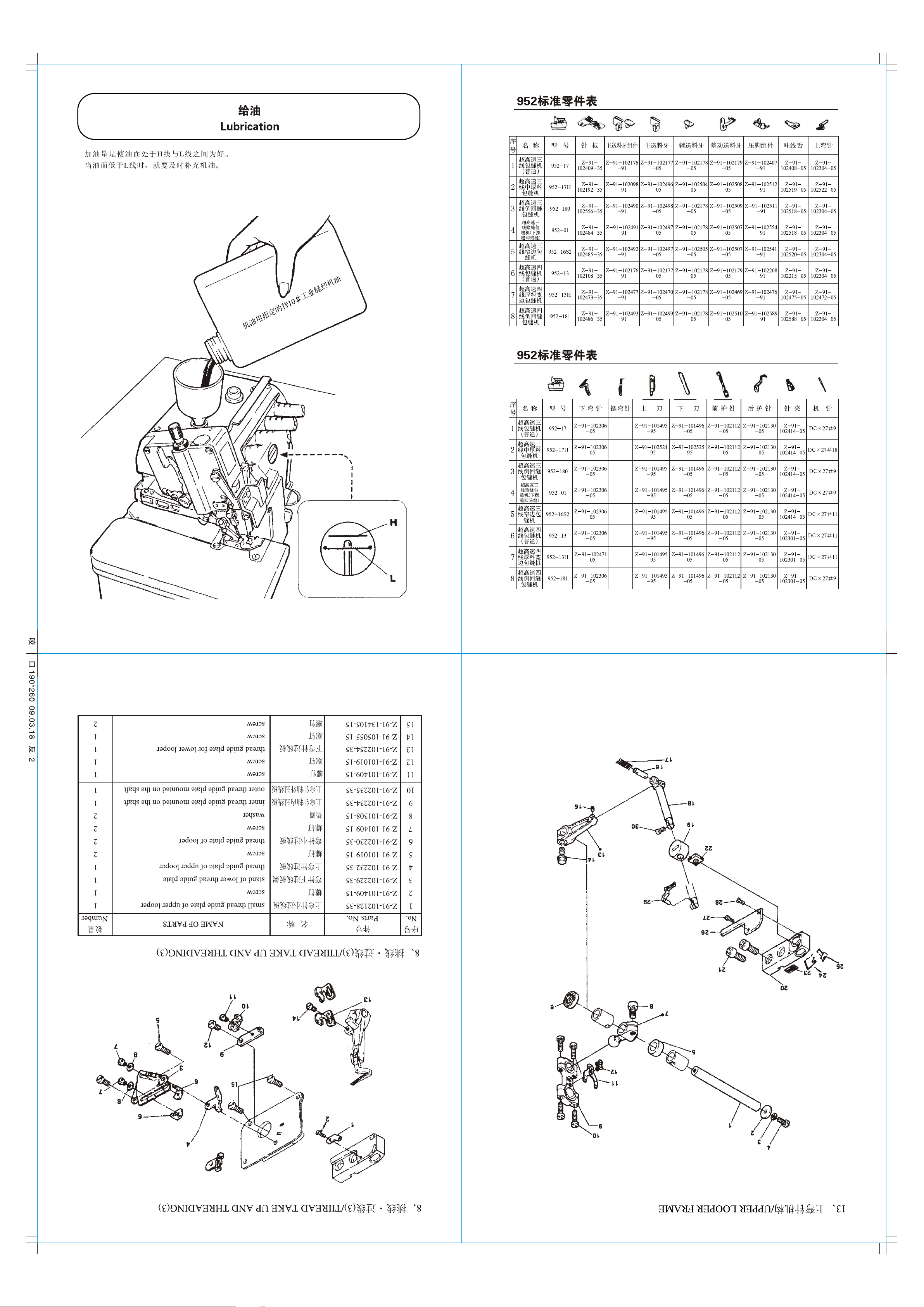

After filling the oil pan ,the top of the indicator

should lie between (H)and(L) lines.

Add oil, when the oil level indicator reaches or

goes below(L).

ocite oil NO.18

Mobil vel

932 ±ê×¼Áã¼þ±í

952 GAUGE PARTS LIST

952 GAUGE PARTS LIST

-2-

-59-

-34- -27-

Page 6

Apply 2 or 3 drops of oil by hand when the

machine is used for the first time or has been

left unused for some time.

18 #

Mobil velocite oil No.18

-58-

-3-

-26- -35-

14

Page 7

Fill the HR device with oil before it is too low in

order to prevent needle thread breakage and

fabric damage.

Note:Use Pegasus recommended silicon oil.

UNION CARBIDE CORPORATION

UCC L-45(10)

-4-

-57-

-25--36-

18

Page 8

Needle thread

Trim the knots off neatly

before passing through

the eye of the needle to

rethread.

Open three covers.

Sewing the presser foot aside.

Knot the preset thread and the

thread being used together to

thread the machine.

Looper thread

Trim the knots off neatly

after passing through the

eye of the looper

-5--56-

Make sure the machine is

threaded correctly by referring

to the threading diagram.

Threadlng diagram

-37-

-24-

Page 9

Light

Loosen sdjusting nut and turn adjusting nut

to adjust the presser foot pressure. Is should

be as light as possible.yet be sufficient to

obtain the proper stitch formation.

Heavy

18

18

-6-

-23--38-

-55-

Page 10

Loosen the adjusting nut and tum the

adjusting nut to adjust the dlfferentlal

feed ratio.

-54-

To shrink

To stretch

-7-

-39--22-

31

33

32

34

Page 11

While pressing the push button , turn the hang-

wheel to seek the position at which the push

button goes further into the depth.

Then, keeping the push button pressed,

turn the handwheel and set the desired

scale to the aligning mark.

Ailgning Mark

Coarse

Note: Stitch length adjustment must only be

made after the differential feed ratio

has been changed.

Push Button

Flne

Handwheel

-8-

-53-

-21--40-

Page 12

Make tension adjustments with the needle

thread knob the upper looper knob

and the lower looper knob .

To tighten

To loosen

-52-

-9-

-20- -41-

Page 13

Mainly the slots of the needle plate and the

feed rows should be cleaned.

-10-

-51-

-19--42-

Page 14

* Check the needle carefully to see that the

scarf is turded to the rear of the machine.

* Insert the needle to the proper depth,and

fasten securely.

Standard needle:Organ DC 27

E3200H 5200Hseries:Organ Dc 27

Scarf

-50-

-11-

-18- -43-

Page 15

Operating

-12-

-17--44-

-49-

Page 16

Check and replace the oil filter every six

months.

-13--48-

-16- -45-

Page 17

Replacing the oil one month after the firstuse

and every six months thereafter.(See p 2.)

Lower knife

plate

of the needleA

Top surface

-14- -47-

-15--46-

Chek cutting action of knife

Level of A Level of B

the lower knife B

Cuttung edge of

(See the right figure.)

Insert the lower knife

Tighten the screw.

holder slide to the right.

makes the lower knife

Loosening the screw

Tighten the screw.

Upper knife

drawing on the right figure.

Thin the hand wheel as the

To replace the lower knife

knife holder to the left.

after sliding the lower

Temporarily screw

Remove the lower k

Loosen the screw.

Loosen the screw.

the lower knife

Correct angles to resharpen

To remove the lower knife

Loading...

Loading...