Page 1

Z..JBBOOA

HIGH-SPEED

OPERATION

LOCKSTITCH

SEWING

MANUAL

MACHINE

llllil·

ZOJE

PARTS

m

Jl

~il

SEWING

BOOK

~!11

mn

n~

fH

MACHINE

~

ae

CO.

~

, L

TO.

61

Page 2

INSTRUCTION MANUAL

To

get the most out of the many functions of this machine and operate it in safety, it is necessary

to use this machine correctly.

Please read this Instruction Manual carefully before use.

your machine for a long time.

Please remember to keep this manual in a safe place.

1.

Observe the basic safety measures, including, but not limited to the following ones, whenever

you use the mach ine .

2.

Read all the instructions, including, but

u

se

the machine, In

anytime when necessary.

3. Use the mach ine after it has been ascertai

valid

in

your country.

4.

All safety devices must be in position when the machine is ready for work

The operation without the specified safety devices is not allowed.

5. This machine shall be operated by appropriately-trained operators.

6. For your personal protection, we recommend that you wear safety glasses.

7. For the following, turn off the power switch

the receptacle.

7-1

For threading needle (s) and replacing bobbin.

7-2 For replacing part (s)

7-3 For repair work,

7-4 When leaving the working place of when

8.

If

you should allow oil, grease, etc. used with the machine and

with

your

eyes

contacted areas and consult a medical doctor.

or

add

skin

ition,

keep

of

needle, presser foot, throat plate, feed dog, cloth guide etc.

or

swallow

this

any

not

limited to this Instruction Manual before you

Instruction

ned

that it conforms with safety rules/standards

of

disconnect the power plug

the

working place is unattended.

of

such liquid by mistake, immediately wash

We

hope you will enjoy the use of

Manual

so

that you may read

or

of

the machine from

dev

ices to come in contact

in operation.

it

the

at

9. Tampering with the live parts and

is prohibited.

10. Repairing, remodeling and adjustment works must only be done

technicians or specially skilled personnel.

11

. General maintenance and inspection works have to

12. Repair and maintenance works of electrical components shall be conducted by qualified

electric technicians

Whenever your find a failure

Periodically clean

13.

or

under the audit and gu dance

thE

! machine throughout the period

of

dev

ices. regardless

any

of

electrical components, immediately stop the machine.

of

whether the machine is powered ,

be

done by appropriately trai

of

specially skill

of use

- 12 -

by

appropriately trained

ned

personnel.

ed

personnel.

.

Page 3

14. Ground ing the machine is always necessary fot the normal operation

machine has to be operated in an enviorment that is free from strong noise sources such

as high

15. An appropriate power plug has to be attached to the machine by electric technicians, Power

plug has to be connected to a grounded

-f

requency welder.

receptacle.

of

the machine. The

16. The machine is only

17. Remodel or modify

all the effective

remodeling

18. Warning hints are marked with the two shown symbols.

or

~

~

&

Clllowed

t11e

machine in accordance with the safety rules/standards while taking

safely

modification

measures. We assumes no responsibility for

Danger

l~ems

to

be

used for the purpose intended. Other used are not allowed.

of

the machine.

of

injury to operator or service staff

requiring special attention

damage

caused

by

-

13

-

Page 4

FOR SAFE OPERATION

~

&

I

I

1. To avoid electrical shock hazards, neither open the cover

for

the motor nor touch the components mounted inside the electrical box.

1. To avoid personal injury, never operate the machine with any

cover, finger guard

To

prevent possible personal injuries caused by being caught in the machine.

2.

your

keep

the motor

them.

3.

To avoid personal injury, never put your hand under the needle when you

turn

To

avoid personal injury, never put your fingers into the thread take-up cover

4.

while the machine is in operation.

5.

The hook rotates at a high speed while the machine is in operation.

possible injury to hands, be sure to keep your hands away from the vicinity

of

the

the machine when replacing the bobbin.

6.

To avoid possible personal injuries, be careful not to allow

the

To

avoid possible accidents because

7.

OFF

the

8.

If

your machine is equipped with a serve-motor, the motor does not produce

noise

start

To

avoid electrical shock hazards, never operate the sewing machine with

9.

the ground wire

0.

To

prevent possible accidents because

1

component (s

of

on

fingers, head and clothes away from the handwheel, V belt and

while the machine

"ON" the power switch or operate the machine.

hook

during operation. In addition, be sure to turn OFF the power to

machine

the

power

belt cover and the V be

while the machine is

of

the machine, be sure to turn OFF the power to the machine.

the power plug.

of

safety davices removed.

is

in operation. In addition, place nothing around

whe

n tiling/raising the

to the machine when tilting the machine head

lt.

at

rest.

for

the power supply removed.

),

tum

OFF

the power switch

mac

hine head.

of

abrupt start

To

avoid poss ible accidents

of

electric shock or damaged electrical

in

prior to

of

the electrical box

of

To

your

fingers in

of

the machine, turn

or

removing

due

to abrupt

the

connectrion/disconnecti

the

belt

prevent

-

14-

Page 5

CONTENTS

BEFORE

l.

INSTALLATION··············· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·16

2.

LUBRICTION · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·17

3. ADJUSTING

4.

ATTAClfiNG

5.

SETTING THE

6.

THREADING THE

7.

ADJUSTING THE STITCH

8.

TIIR.EADTENSION······························

9.

TliREA

10.

11.

12.

13.

OPERATION·················································································

THE

AMOUNT OF OIL (OIL SPLASHES)

THE

NEEDLE·······································································

BOBB£N

INTO THE BOBBIN

MACHIN'E

HEAD····························································

CASE·······································

IN

THE

HOOK·················

LENGTH·················································

TAKE-UP

HAND

LIF"TER···

PRESSER FOOT

SPRING····································

····

··

··· ··· ···

PRESSURE····································································

ADJUSTING THE FEED

HEIGHT OF

THE

FOOT

·············

···

··· ··· ··· ···

...

··· ··· ···

TIMING····························································

DOG··································································

....

·····································21

..

·························

······

··· ··· ···

······

··· ··· ···

·· ···

..

·········

···

··· ···

······20

···16

·17

·19

···19

20

·21

···22

·22

···22

···23

14.

NEEDLE-TO-HOOK

15.

ADJUSTING THE HEIGHT OF THE PRESSER

16.

ADJUSTING

17.

INSTALLING THE

18.

ADJUSTING THE HEIGHT OF

19.

WINDING THE

20.

SPECIFICATIONS····················································································26

THE

RELATIONSHIP·························································

THREAD TAKE-UP

BELT

COVER··········································

THE

KNEE

FOOT

STROKE············································

LIFTER·········································

...

············

...

··················

· · · · · · · · · · · · · · · .. · · · ·

BOBBIN···········································································26

-

15-

···23

···24

·24

24

·25

Page 6

I Attention

required

before

operation

Attention:

To

avoid machine damaging

1.before using the machine for the first time,please clean it thoroughly, get rid

the dust and make sufficient lubrication.

2.make sure that

connected.

3.if the voltage in your country is different from the voltage

do not use

4

..

make sure the running direction

S.during the first month when using this machine,you should run it in the normal

speed or lower speed.

the voltage is right,and that plug and power source are correctly

it.

--------

or

some accident, please do remember:

of

this machine,please

of

the motor wheel is right.

----

----

------------

------

----~

of

all

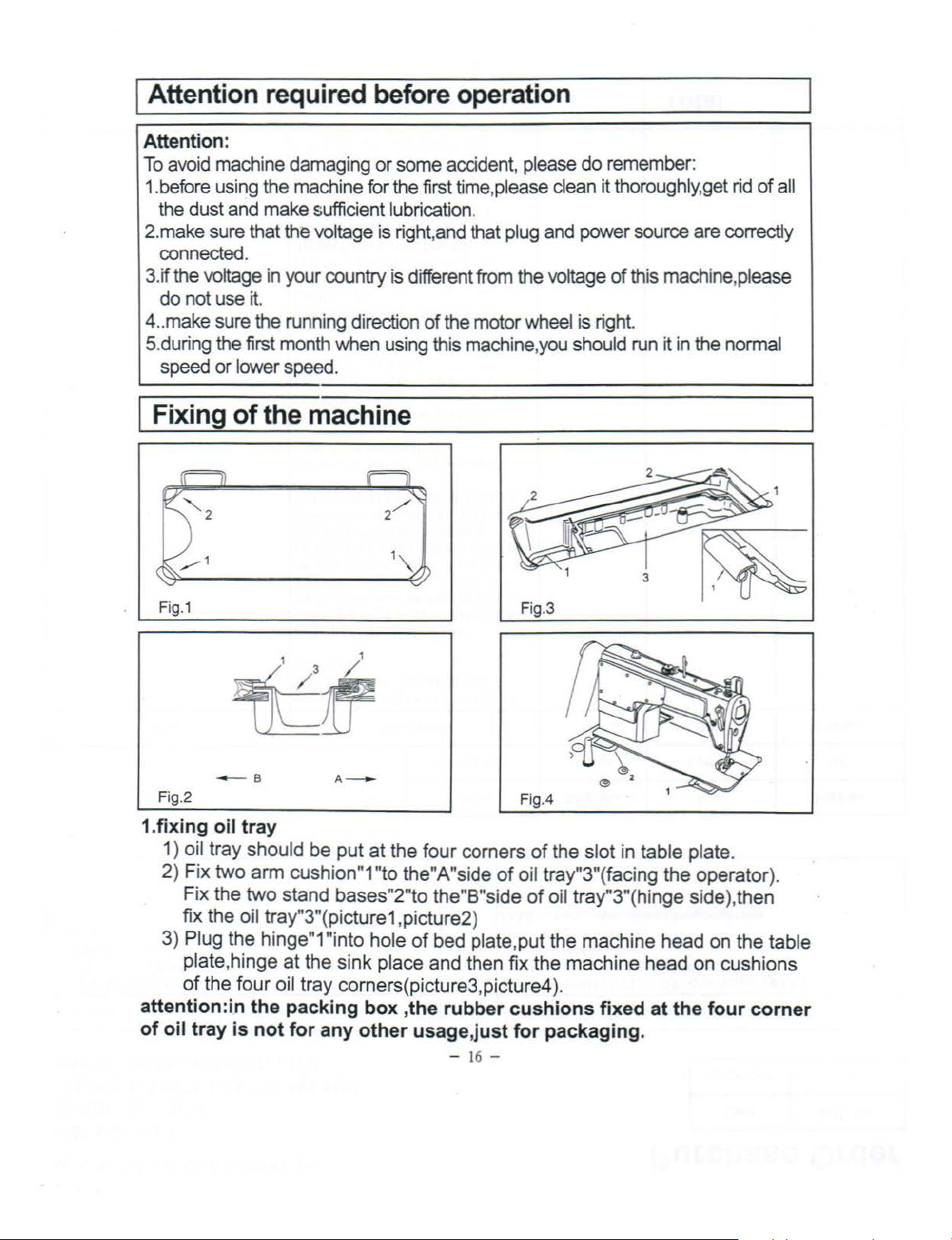

Fixing

F

ig.1

Fig.2 Fig.4

1.fixing oil tray

1)

2)

fix

3) Plug the hinge"1"into

plate,hinge at the

of

attention :

of

oil tray is not for any other usage,just for packaging.

of

the

machine

---

B A -

oil tray should be put

Fix two

Fix the

arm

cushion"1 "to the"A"side

two

stand

the oil tray"3"(picture1,picture2)

the

four

oil tray corners(picture3,picture4

i.n

the packing box ,the rubber cushions fixed at the four corner

at

the

bases

sink

"2"

hole

place and then

four

to

of

~~

corners

of

the"B"side

bed plate, put the machine head on the table

- 16 -

--------------

of

the slot in table plate.

oil tray"3"(facing

of

oil tray"3"(hinge side),

fix

the machine head

).

the

operator).

on

------~

then

cushions

Page 7

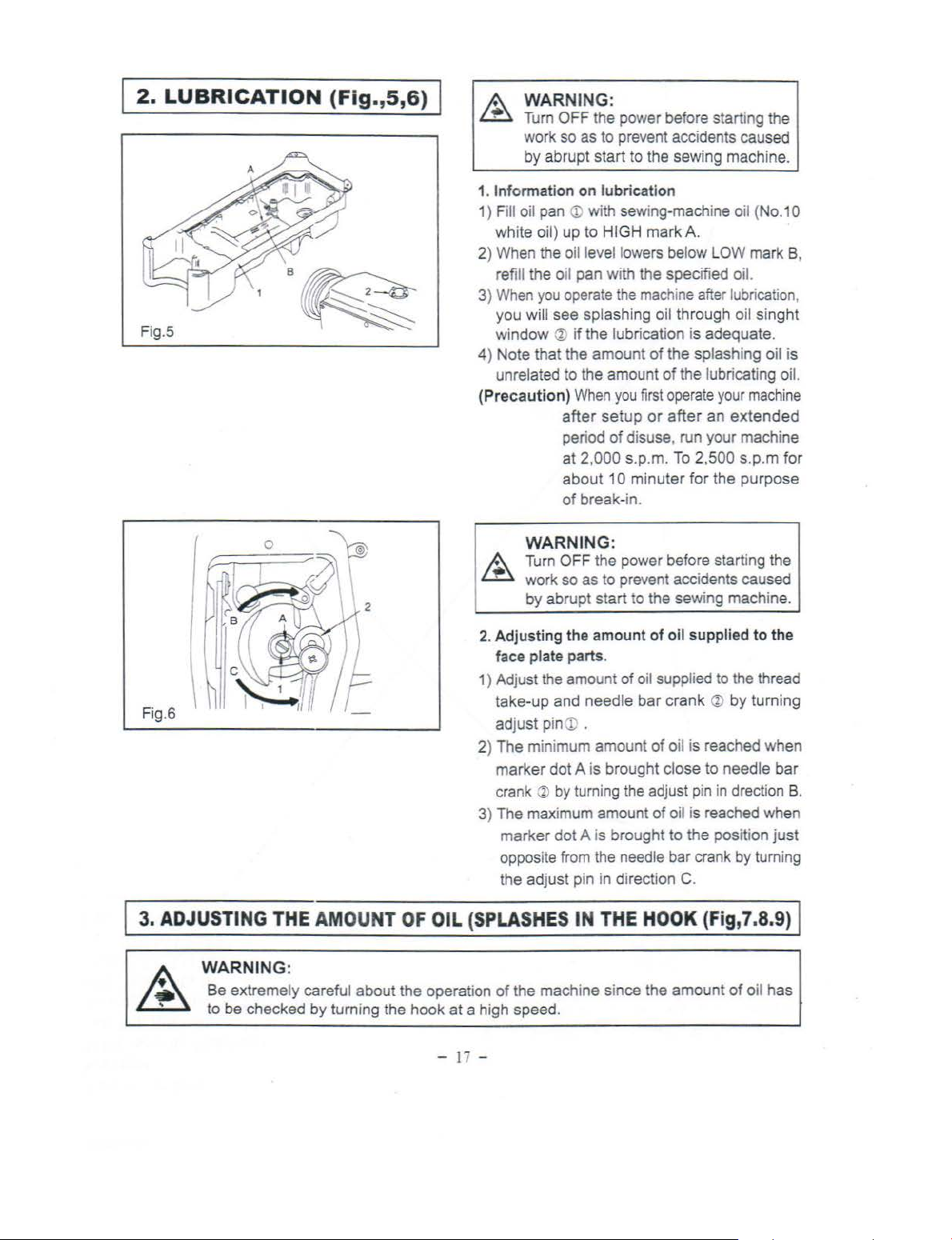

2.

LUBRICATION

(Fig.,5,6)

WARNING:

Turn

OFF

the power before starting the

work so as

by

abrupt start to the sewing machine.

Inf

ormation

1.

Fill oil pan

1)

white oil) up

2) When the

refi

ll

the oil

3) When

4) Note

(Precautio

you

you

will

window

that

unrelated to the amount

to

on l

ubricat

<D

with sewing-machine oil (No.1 0

to

HIGH

o

il

level lowers bel

pan

with the specified oil.

operate

see

splashing oil through oil

<»

if

the lubrication is adequate.

the

amount

n)

When

after

setup

per

iod

of

at

2,0

00

about

1 0

of

break-in.

WARNING:

Turn OFF the power before starting the

work

so

as

to

by

abrupt

start

prevent accidents caused

ion

mark

A.

ow

LOW mark B,

the

machine after lubrication,

singht

of

the splashing oil is

of

the lubricating oil.

you

first operate

or

after

disuse, run your machine

s.p.m.

minuter

prevent accidents caused

to the sewing

your

an

To 2,500

for

the

machine

extended

s.p.m

purpose

mach

ine.

for

Fi

g.6

I

3.

ADJUSTING

THE AMOU

NT

OF

OIL (SPLASHES

WARNING:

Be extremely careful about the operation

to

be

checked by turning the

hook

-

at

a high speed.

17

2. Ad

justing

face

1) Adjust the amount

take

adjust

2)

The

marker

crank ~ by turning the adjust pin in drection

3) The maximum amount

mark

opposite from the needle bar crank by turni

the adjust pin in direction C.

of

the machine since the amount

-

the

amount

plate parts.

of

-up and

minimum amount

er

needle

pin

eD

.

dot

A is brought close to needle

dot

A is brought

IN

THE

of

oil supplied

oil suppli

bar

HOOK

ed

to

crank ~ by

of

oil is reached when

of

oil is reached when

to

the

position

(Fig,7

of

the thread

to

the

turning

bar

B.

just

ng

.8.9) I

oil has

Page 8

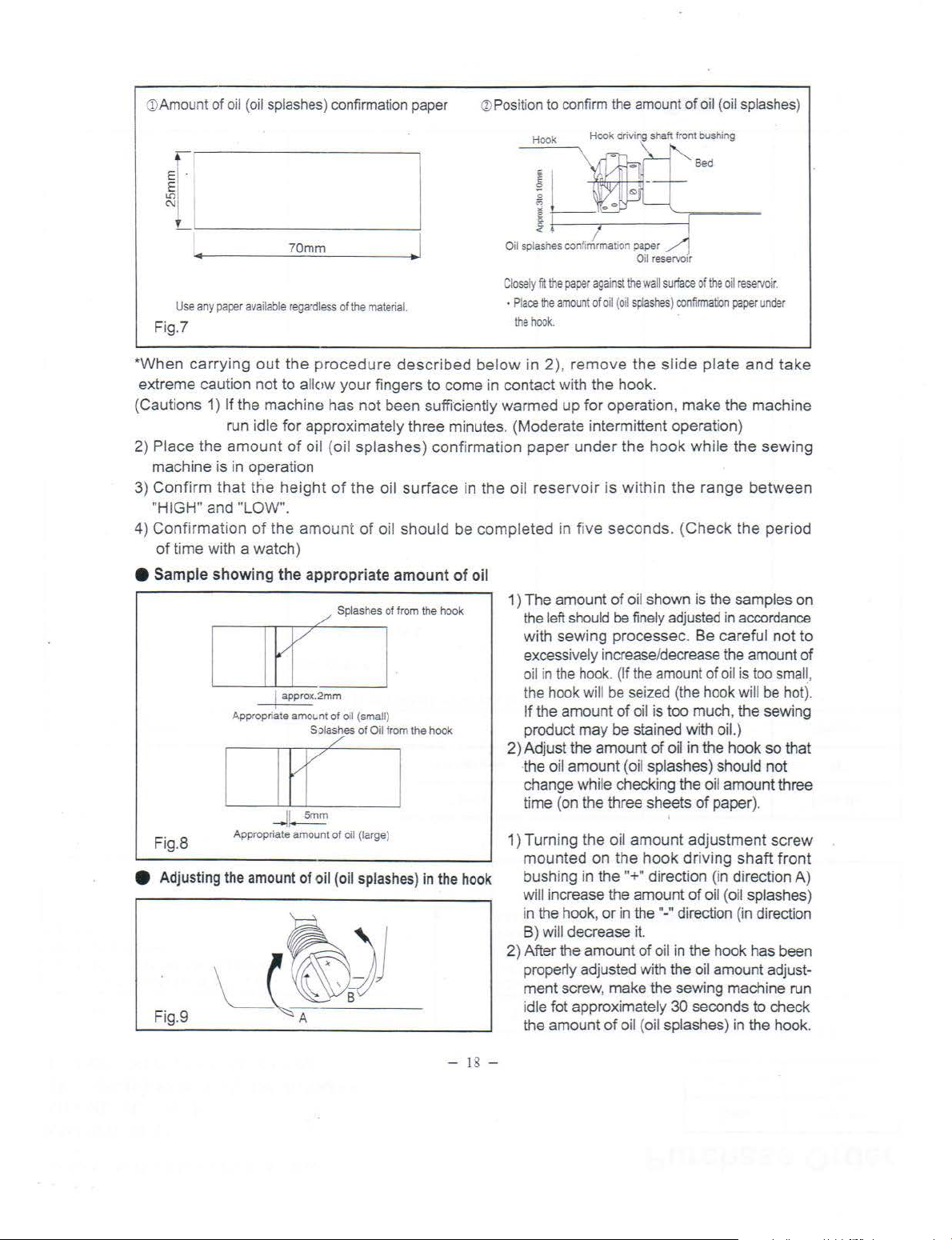

(!)

Amount

of

oil (oil

splashes) confi

rmation paper

~

Positio

n

to confi

rm the amount

of

oil (oil splashes)

~

r

~

~-

1

..

Use

any

paper

availab

le

Fig.?

*

When

extreme

(

Cautions

2)

3)

4)

e Sa

carrying

caution not

1) If the

Place

the

machine

Confirm that the hei

"HIGH" and "LO

Con

firm

of tim

e with a

mple showing

out

the

to

mac

run i

dle for

amount of oil (oil sp

is in

operation

W".

ation

of the amo

watch

the

[

1 1

1 approx.2mm

Appropriate

I I

--1

Ap

Fig

.8

propriate amount

e Adjusting the amount

Fig.9

~

70mm

regardless

of

the

procedu

all

ow

your fi

hine h

as not b

approximately

ght

of the

unt

of oil

)

appropriate

/s··~T~~hook

amo~on

t

of

oil (smal

S Jlashes of Oil from the hook

[L

1

Smm

of

on (large)

of

oil (oil splashes) in the hook

.,

1

Close

ly

· Pl

materia

l.

re

described bel

nge

rs to

come

een suffid

three

lashes) confirmation pap

oil

surface

sho

amount

l)

I

ently war

minutes. (Moderate intermittent

in

uld

be compl

of

oil

ace

the hook.

ow

in

in

contact

med

the

oil

eted

1)

The

the left should be finely adjusted in accordance

with

excessively increase/decrease the amount

oil in the hook. (If the amount

the hook will be seized (the hook will be hot).

If the

product

2)

Adjust

t

he

change while

ti

1) Turn

moun

bush

will increase the

in the hook,

B)

2) After the

properly

ment

i

dle

the

Hook Hook driving shan front bus

Sed

lit

the pape

r a

gainst

th

e w

all

surface

of

the

amount of

o

il (oil

splashes) confirmation

2), re

mo

ve

the slide plate

with

the

hook

.

up for

operation, make

opera

er under

reservoir is within t

in

amount

sewing

amo

the

oil

amount

me (on

ing

ted

ing in

wi

ll

decrease it.

screw, make

fat

approxima

amount

the hook whi

he

five

seconds

of oil

processec. Be

unt of oil is too

may be

amount

checking

the three sheets

the oil

on the

the

or

in the"-" direction (in direction

amoun

ad

justed with the oil amount adjust-

of

oil {oil splashes) in the

. (Check

shown

stain

(oil spl

amou

hook

"+" direction

amount

t of oil in the hook has been

tely

is the

much, the

ed

with oil.)

of

oil in

ashes

the oil

of

.

nt

adjustme

driving

of

the sewing machine run

30

seconds

hin

g

the

oil reservo

ir.

paper und

er

and

take

the

machine

tion)

le

the

sewing

range

between

the

period

samples

careful

of oil

the

) should

amount

paper

(in directi

oil (oil splashes)

not

is too small,

sewing

hook

so

not

three

).

nt scr

shaft

front

on

to

check

hook

that

ew

on

to

of

A)

.

-

18

-

Page 9

I

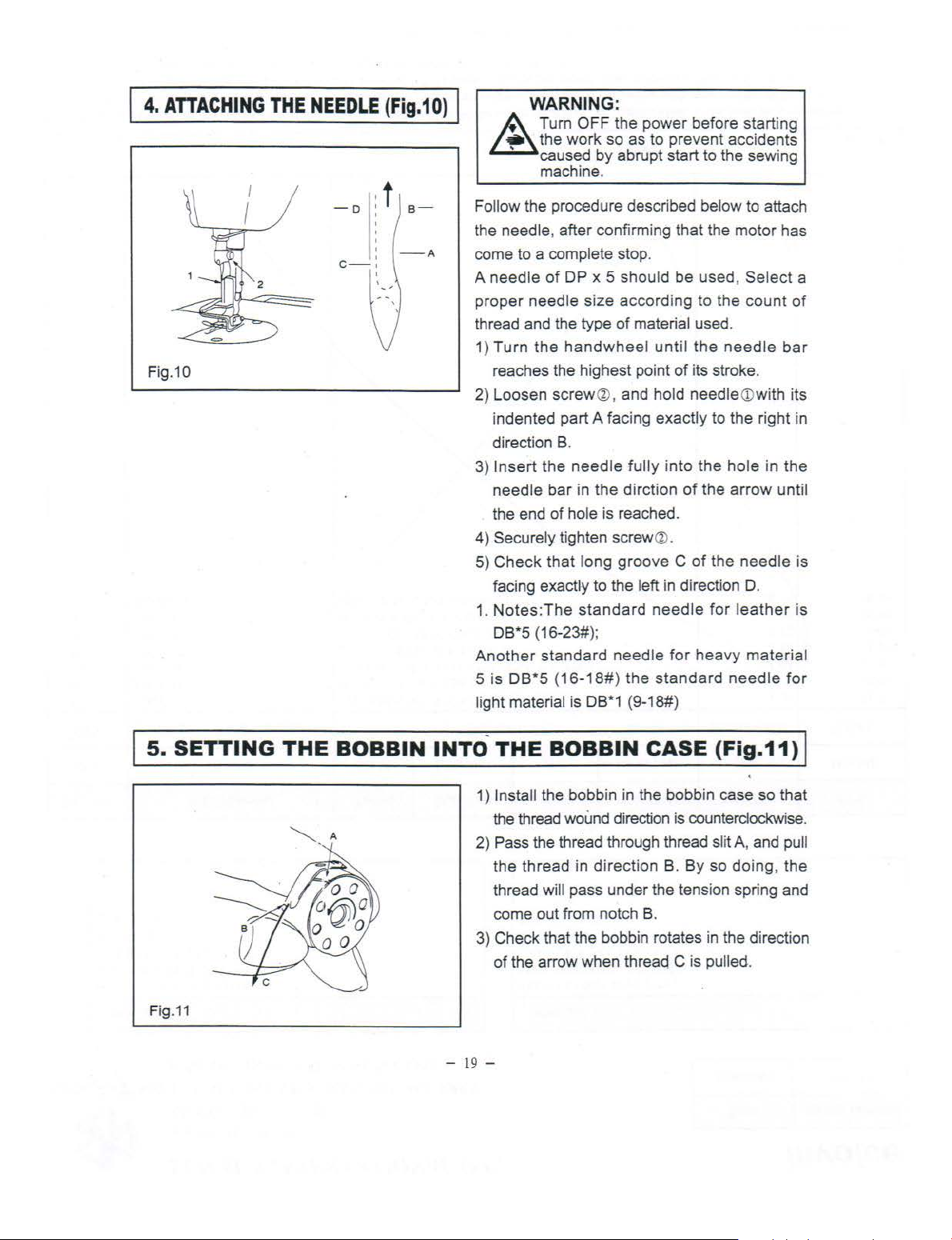

4.

ATTACHING

THE

NEEDLE

(Fig.10)

I

L.:1!::::::.

WARNING:

A Turn

the

' caused

machine.

OFF

work

the

power

so as

by

abrupt start to the sewing

before starting

to

prevent

accidents

Fig.10

-o

c-

Follow the procedure described below to attach

the needle,

I

,

I

I

come to a complete stop.

needle

A

proper

thread and the type

Turn

1)

reaches the highest point

2)

Loosen

indented part A facing

direction

3)

Insert

needle

the end

4)

Securely tighten screw

5)

Check

facing exactly

1.

Notes:The

DB*S {16-23#);

Another

5

is

DB*5

light material is DB*1 (9-18#)

after

of

DP

x 5

needle

the

size

handwheel

screw

B.

the

needle

bar

in

of

hole is reached.

that

long

to

standard

standard

{16-18#)

confirming that the

should

according

of

@,

and hold

fully

the

dirction

groove C of

the left in direction D.

needle

the

be used, Sel

to the

material used.

until

the

of

its stroke .

needle<Dwith its

exactly

®.

needle

standard

into

of

for

the

the

heavy

to the right in

the

for

motor

count

needle

hole

in

arrow

needle

leather

material

needle

has

ect

bar

the

until

a

of

is

is

for

I

5.

SETTING

Fig.

11

THE

~-

BOBBIN

A

INTO-THE

1) Install the bobbin in the bobbin case

the thread wound direction is counterclockwise.

2) Pass the thread through thread

the

thread

come

3) Check that the bobbin rotates in the direction

of

- 1

9-

BOBBIN

thread

the arrow when thread C is pulled.

in

direction

will pass under the tension spring and

out

from notch

CASE

B.

By

B.

(Fig.11)

sl

so

so

it

A, and pull

doing

, the

I

that

Page 10

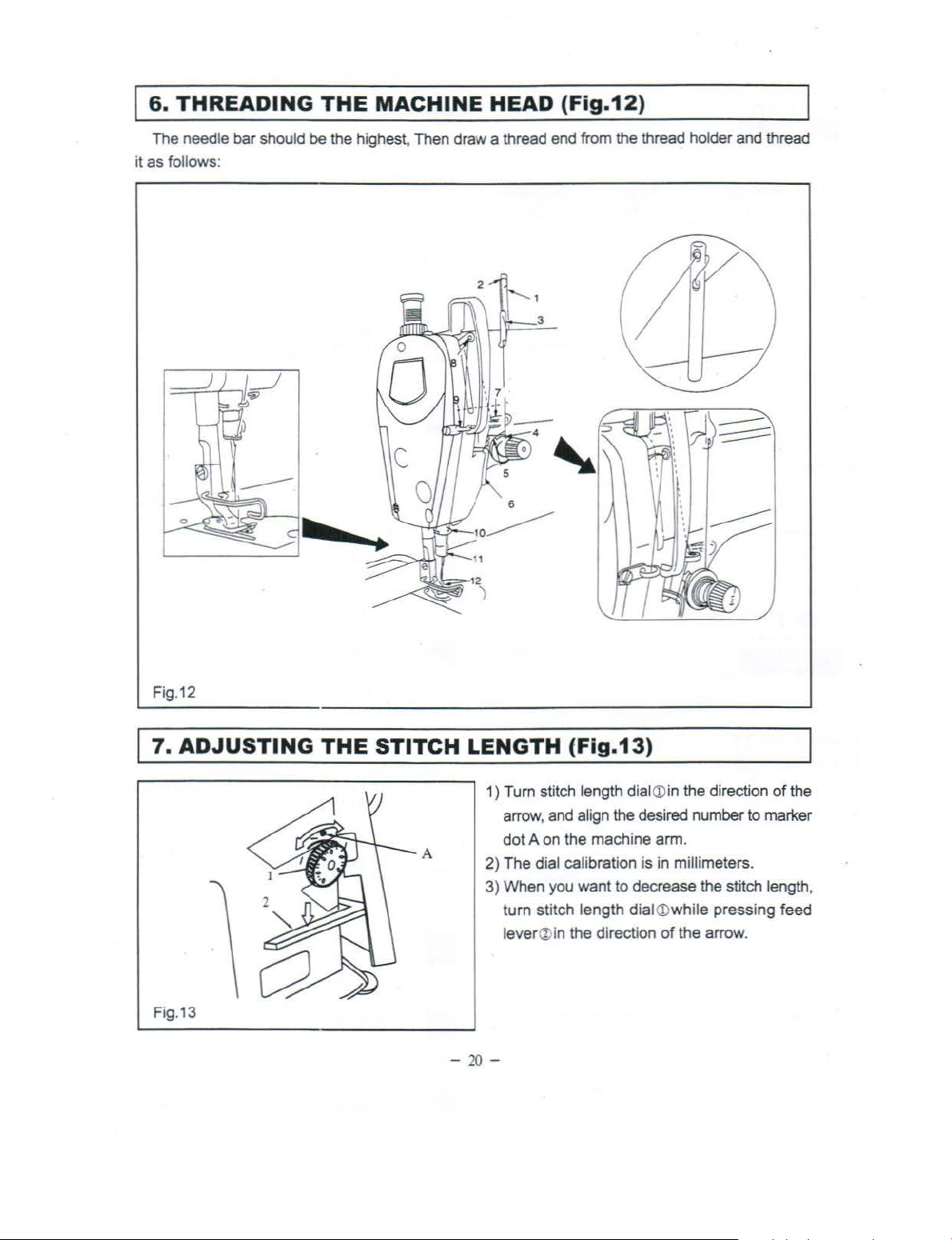

6.

THREADING

The needle bar should be the highest, Then draw a thread end from the thread holder and thread

follows:

it as

THE

MACHINE

HEAD

(Fig.12)

Fig.12

7.

ADJUSTING

Fig.13

THE

STITCH

A

LENGTH

1) Turn stitch length

arrow, and

dot

A on the machine arm.

2)

The dial calibration is in millimeters.

3)

When you want to decrease the stitch length,

turn stitch length

lever

a>i

-

20

-

(Fig.13)

dial <Din the direction

align the desired number to marker

diai<Dwhile

n the direction

of

pressing feed

the arrow.

of

the

Page 11

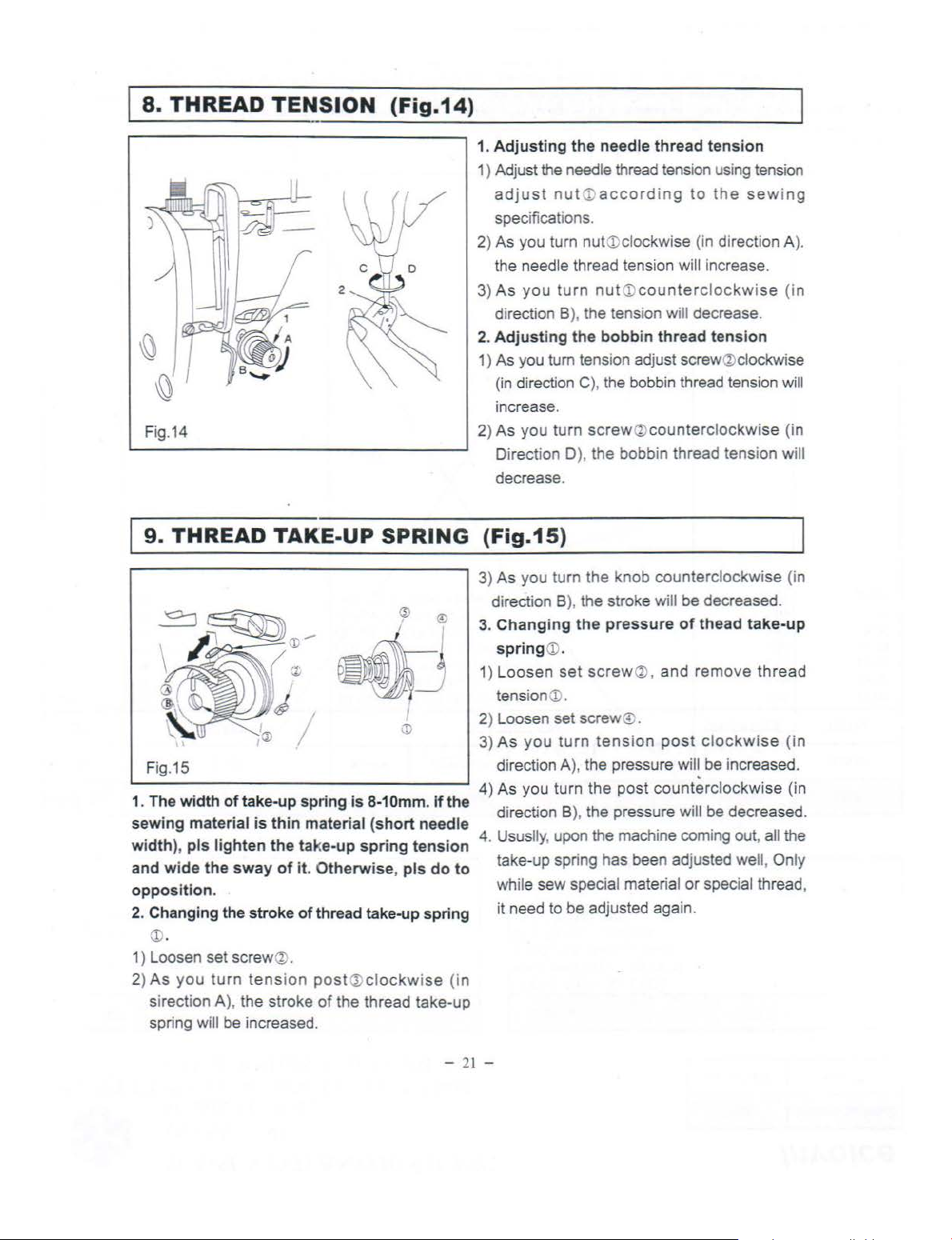

8.

THREAD

)

Fig.

14

TENSION

L------------------1

9.

THREAD

TAKE-UP

(Fig.14)

SPRING

1.

Adjusting

1) Adjust

adjust

specifications.

2) As you turn

the needle thread tension will increase.

As

you

3)

direction B

Adjust

2.

1) As you turn tension adjust screw

(in

direction C

increase.

2) As you turn screw

Direction 0), the bobbin thread tension will

decrease.

the needle thread tens

the

needle

nut<Daccording

turn

ing the bo

thread

tension usi

to

nutCDclockwise (in direction A

nut<Dcounterclockwise (in

), the tension will decrease.

bbin

thread tension

),

the bobbin thread tension will

(bl

counterclockwise (in

ion

ng

the

sew

(%)

clockwise

tensi

(Fig.15)

on

ing

).

3) As you tu

directi

Changing

3.

spring CD.

1) Loosen

tensioneD.

2) Loosen set screw® .

3)

As

Fig.

15

of

1. The width

· t ·

sewmg ma

'

dth

) 1 I'

WI , p s

wide

and

oppos

ition. while sew special material

2. Changing the stroke

<D

.

1) Loosen set screwQ).

2)

As

you

sirection A

ng

spri

take-up spring is

·

1

ena

IS

ht

19

en e a e-up

the

sway

turn

tension post

),

the stroke

will

be

increased.

th

· t .

m ma

th

t k . t . 4. Ususlly, u

of

it. Otherwise,

of

thread take-up spring it need

of

8-1

Omm. If

( h direction B

1

ena s ort

spnng

(]) cl

ockw

the thread take-up

the . . .

needle

ens1on . .

pis

do

ise (in

direction A

4) As you turn the post counterclockwise (in

to

take-up spnng has been adjusted well, Only

rn

on

B), the stroke will be decreased.

the

set

you

turn

),

),

pon

to

be adjusted again.

the knob counterclockwise (in

pressure

screw

tens

the pressure

the pressure

the machi

of

thead

Q),

and remove thread

ion

post clockwise

wil~

be

increased.

Will

be decreased.

ne

comi

ng

out, all

or

special thread,

take-up

(in

the

- 2

1-

Page 12

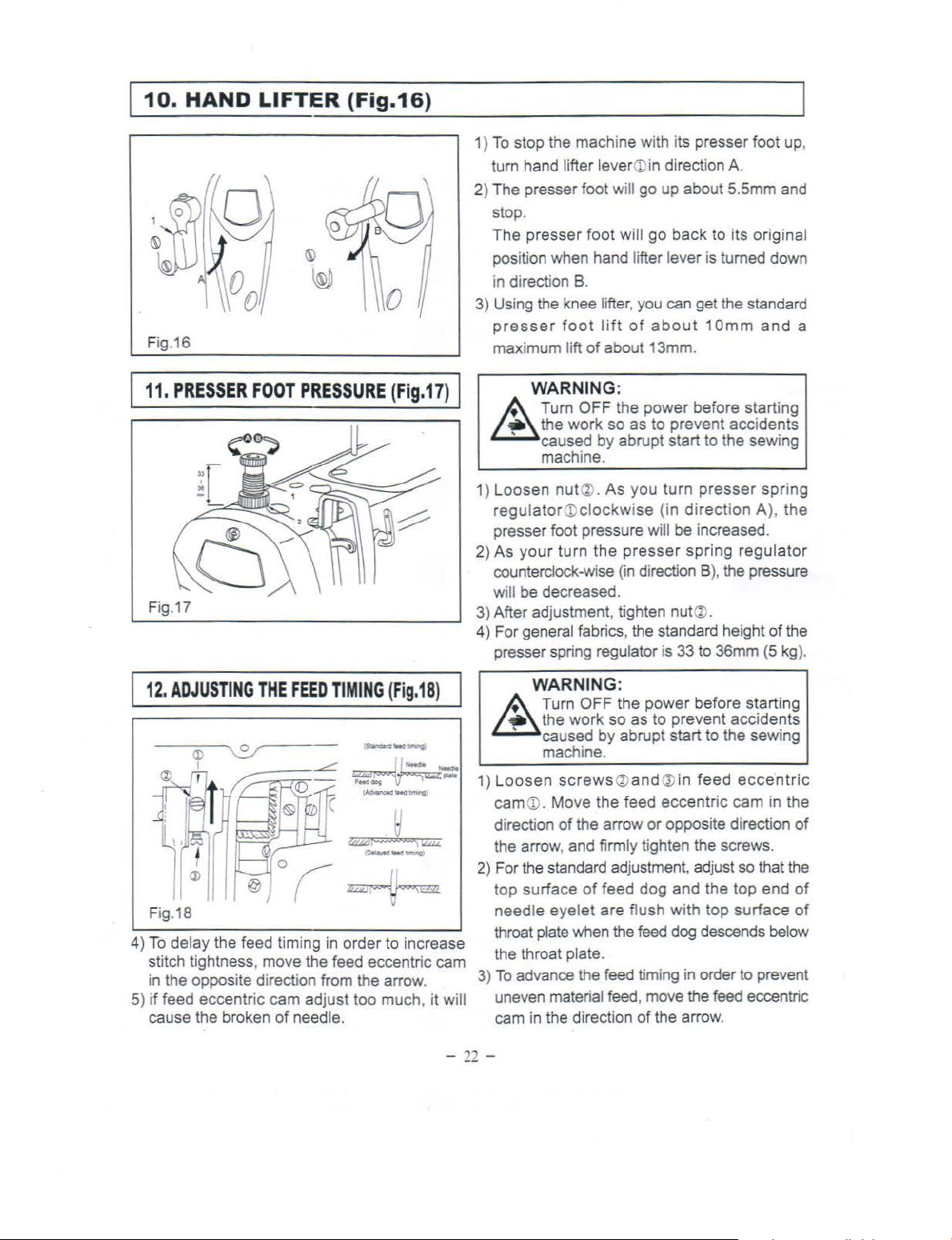

10.

Fig.16

HAND

LIFTER

(Fig.16)

1)

To

stop the machine with its presser foot up,

turn hand

2) The presser foot will

stop.

The presser foot

position when hand lifter lever

in

direction

3) Using the knee lifter,

presser

maximum

lifter lever<Din direction

go

up about 5.5mm and

will

go

back to its original

is

B.

you

can get the standard

foot

lift

of

lift

of

about 13mm.

about

1 Omm

A.

turned down

and

a

1

11.

PRESSER

Fig.17

12.

ADJUSTING

Fig.18

To

delay the feed timing

4)

stitch tightness, move the feed eccentric cam

in the opposite direction from the arrow.

if

feed eccentric cam adjust too much, it will

5)

cause the broken

FOOT

PRESSURE

THE

FEED

of

needle.

(Fig.17)

TIMING

in

(Fi

g.18

order to increase

I

WARNING:

A Turn OFF the power before starting

~

1)

2)

3) After adjustment, tighten

4) For general fabrics, the standard height

)

~

1)

2)

3)

the

work

so

as to prevent accidents

caused by abrupt start to the sewing

machine.

Loosen

regulator<Dclockwise

presser foot pressure will

As

counterclock-wise

will be decreased.

presser spring regulator

nutQ).

you r turn the

As

you turn

(in

presser

(in

direction B

is

nut@.

WARNING :

A Turn OFF the power before starting

the

work so as to prevent accidents

caused

machine.

Loosen

cam<D. Move the feed eccentric cam in the

direction

the arrow, and firmly tighten the screws.

For the standard adjustment, adjust so that the

top surface

needle eyelet are flush

throat plate when the feed dog descends below

the throat plate.

To

advance the feed timing in order to prevent

uneven material feed, move the feed eccentric

in

cam

the direction of the arrow.

by

abrupt start to the sewing

screwsa>andO)in

of

the arrow or opposite direction

of

feed dog and the top end

with

presser

direction A),

be

increased.

spring regul a

),

33 to 36mm (5 kg).

feed

top surface

spring

the

tor

the pressure

of

the

eccentric

of

of

of

-

22-

Page 13

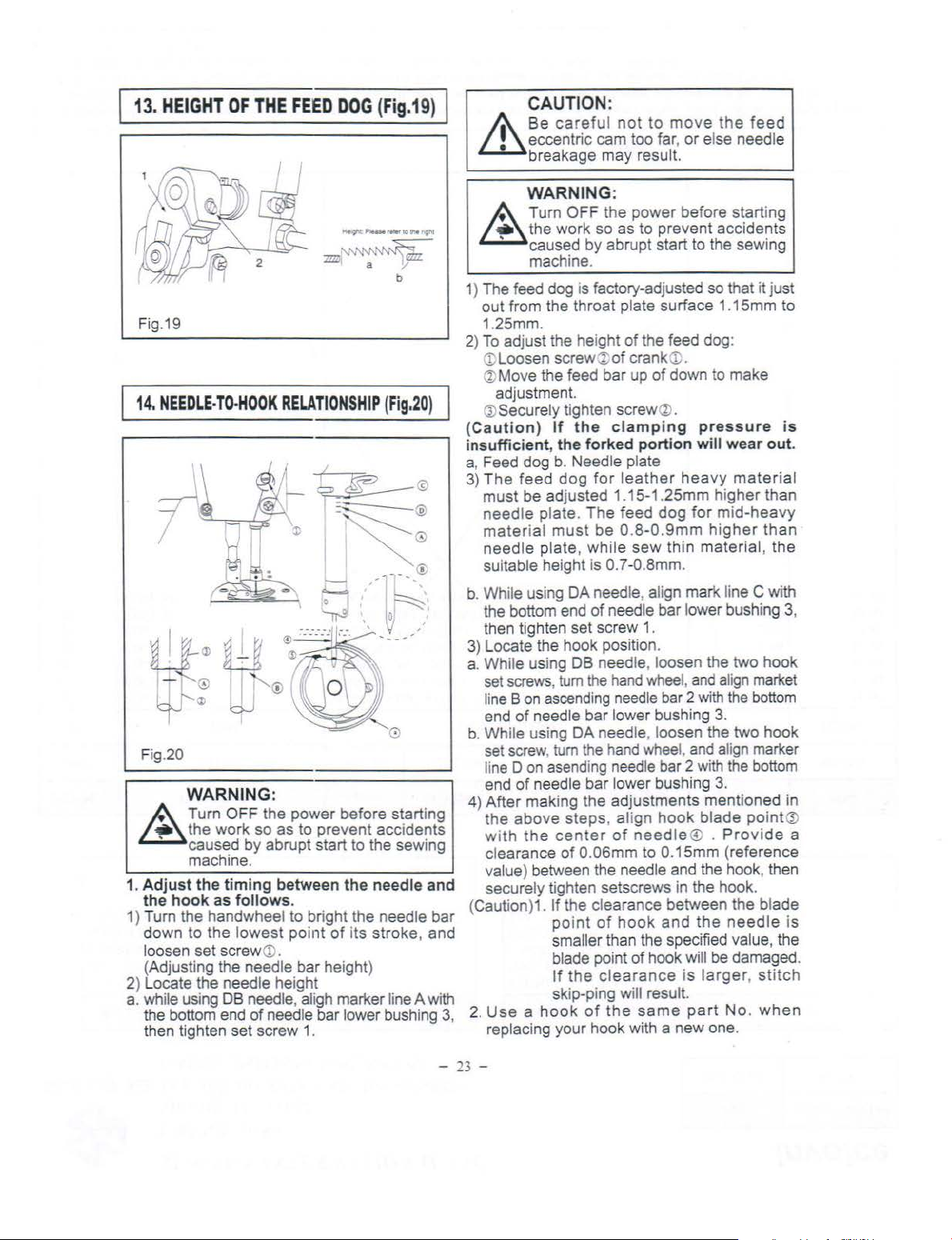

13. HEIGHT

Fig.19

14. NEEDLE-TO-HOOK

Fig.20

OF

THE

FEED

DOG (Fig.

RELATIONSHIP

I

~

=s_---

-

"""

I I

....__.

~

·.·.-_-_

-_.

t.·. ' ; ,

(

Fig.20

~

-- - ®

, I -.

,'

~

:

~

0 I

' '

...

-

..

-

19)

)

@

'D'

.;>

G

'.

:

WARNING:

A Turn OFF the power before starting

~

1.

1) Tum the handwheel to bright the needle bar

2) Locate the needle

a. whi

the

work

so

caused by abrupt start to the sewing

machine.

Adjust

the

down

loosen set screw

(Adjusting the needle bar height)

the bottom end of needle bar lower bushing 3,

then tighten set screw

the

timing

hook

as

to

the lowest point

le

using DB needle, ahgh

as to prevent accidents

follows

CD

heigh~

between

.

.

the

of

its stroke , and

marl<er

1.

needle and

. .

hne A w1th

CAUTION:

& Be

careful not

eccentric cam too far,

breakage may result.

to

move the

or

else needle

feed

WARNING:

~

1) The feed dog is factory-adjusted so that it just

2)

(C

nsufficient, the

i

a Feed dog

3)

b. Wh

3)

a. While using DB needle, loosen the two hook

b. Wh

4) After making the adjustments mentioned

(Cauti

2.

Turn

OFF the power before starting

the work so as to prevent accidents

caused by abrupt start to the sewing

machine.

out from the throat plate surface 1 .15mm to

1.25mm.

To

adjust the height

CD

Loosen screw@

®Move

~

autio

The

must be adjusted

needle plate .

mater

needle

suitable height is

the bottom end

then tighten set screw 1 .

Locate the hook position.

set

li

ne B on

end

set

li

ne D on

end

the above

with

clearance

value) between the needle and the hook, then

securely tighten setscrews in the hook .

Use a hook

replacing your hook with a new one.

the feed bar up

adjustment.

Securely

il

e usi

screws, tum

of

il

screw,

on)1.

tighten screw

n)

If

the

b.

Needle plate

feed dog

ial

must

plate ,

ng

DA needle. align

ascending

needle bar lower bushing 3.

e using DA needle, loosen the two hook

tum

asending

of

needle bar lower bushing

steps

the

center

of

If the clearance between the

point

smaller than the specified value, the

blade point of hook will

If

the

skip-ping will result.

of

the feed dog:

of

crankeD.

of

down to make

(%)

.

clamping

forked

The

while

of

the

the hand

0.06mm to 0.15mm (reference

of

portio

for leather

1.

15-1.25mm h1gher than

feed dog

be

0.8-0.

sew

0.

7 -0.8mm.

needle bar lower bushing 3,

hand

whee

needle

whee

needle bar 2

, align

of

need

of

hook

clearance

the

same

pressure

n

will

wear

heav~

9mm

thin material,

l,

bar 2 with

l,

hook

le® .

and

is larger, stitch

material

for mid-heavy

higher

marl<

line C with

and ali

gn

the

and ali

gn

with

the

3.

blade point@

Provide

the

needle

be

damaged.

part

No.

is

out

than

the

market

bottom

marker

bottom

bla~e

when

in

a

IS

-

23

-

Page 14

15.

ADJUSTING

THE

HEIGHT

OF

T.HE

PRESSER FOOT (Fig.21)

WARNING :

A Turn OFF the power before starting

~

the

' caused by abrupt start

work so as to prevent accidents

machine.

to

the sewing

Fig.21

16.

ADJUSTING

Fig.22

THE

1) Loosen setscrew

foot height and the angle

2) After

(1).

ad

justment, securely

X;

. And adjust the presser

of

the

presser foot.

tighten

the

THREAD TAKE-UP STROKE (Fig.22)

WARNING :

A Turn O

~

1) When sewi

thread

increase the length

the thread take-up.

2) When sewing light-weight materials, move

thread

to

the thread take-up.

3)

way

center of the screw.

the

' caused by abrupt start

machi

decrease the length

Normally, thread guide<Dis positioned in a

that marker line C is al igned with the

FF

the power before starting

work so as to prevent accidents

ne.

ng

heavy-weight materials, move

gu ideCDto the le ft in direct ion A to

of

guide<Dto the

of

to

thread pulled out by

right

in

thread pulled out

set screw

the sewing

direction

B

by

17.

INSTALLING

Fig.23

THE

BELT COVER (Fig.23,

1.

Installation procedure

Drill four guiding holes A and B for wooden

1)

2)

fi

I

3)

I

liT

4)

5) Fix belt cover

-

24

-

screws

Install

hole

Pass the handwheel through the hole

cover A

arm. At this time , you can smoothly

th

han

illustrated

Place

and B.

®,

screw®with

in

the table.

belt

in

arm.

Q),

e handwheel diagonally

dwhee

in the figure.

belt

(i)and

washer

24,

25)

cover

then set the handwheel on the

l by tiltin g be

cover BQ;

supportCDin the

from

the rear

lt

cover AQ)

on guiding

AQ)on the arm using screws

@,

At

this time, tighten

a t i

ghtening

taped

in

install

holes

torque

of

belt

the

as

A

of

Page 15

Fig.24

Fig.25

1

18.

ADJUSTING

THE

HEIGHT

of

30

kgf

/cm

and

torque

screws, the securing state

not change.

6)

Warnings:1)

OF

of

25 kgf/cm. If you tighten further these

Move

belt

cover Ba:>

rubber section

contact with belt cover A

move the

by

0.5 to 1 mm. Now,

in

position using wooden screw and washer.

7)

Fit cat

THE

belt cover B in the same direction

For

safty's

should be installed.

(!)

to

the belt cover

KNEE LIFTER (Fig.26,

screw~with

of

backward E until the

of

belt

cover

fix

needs,

a

the belt cover will

B~comes

(l). Then, further

the

belt

A.

tightening

cover

belt

cover

27)

in

B

I

Fig.26

WARNING:

A Turn OFF the power before starting

~

1. The standard height of the presser foot

2) You can

3)

the

work so as to prevent accidents

' caused by abrupt start to the sewing

machine.

using the knee lifter

adjust

13mm using knee lifter adjust

When

you

have adjusted the presser foot lift

to over 1

of

not hit presser

Fig.27

Omm

needle bar a; in its

is 1 Omm.

the

presser

, be sure that the bottom end

lowest

footQ).

foot

lift

screw

<D

position does

lift

up to

..

ed

-

25

-

Page 16

19.

Winding

20.

SPECIFICATIONS

the

------

bobbin

----

----------------

Thread

bobbin thread onto the bobbin

in t

he

figu

the

re 28.

bobb

in

----

winder

--------~

and

wind

the

as

illustrated

Application

Max Sewing

Speed

Max Stitch

Length

Lifting

height Lifter

of

presser

r fool

Hand

Knee

Lifter

Needle

L

Lubrication oil

Motor power

1.

While Sewing Light materials, the machine

dog and do some adjustment.

2.

Machine with "R" added is using roller presser foot.

For Light mediumheavy materials

5500 RPM

mm

5

6mm (MAX.) 6mm (MAX.) 8mm (MAX.)

13mm (MAX.) 13mm (MAX.)

9#-18#

DBX1

.

need

For heavy materials I

I

3000 RPM

8mm

DPX5

16#-18#

White oil No.1

370W

to

change the presser foot, needle bar and feed

0

For Leather

materials

3000 RPM

8mm

13mm (MAX.)

DPX5 20#- 23#

-

26-

Page 17

To

order

or

further information , please contact:

* Please

when necessary.

* The description covered in this instruction manual is subject to change for impr?vement

the commodity without

do

not hesitate to contact

not

ice.

our

distributors

or

agents in your areas for further information

-

27

-

of

Page 18

•itt::J.M

PARTS BOOK

The machine with "R" added

Please confirm the relative applications Ref.No,

When buying the

parts

.

is

using roller presser foot.

part

no.

-

28-

Page 19

CONTENTS

1.

ffl~5J'ffi.i

2.

3:.~J1.:}jt~ff5J-ffi.f4:

4:

Machine Frame & Miscellaneous Cover Components·· ................... 30

Main

Shaft & Thread Take-up Lever Components .... ........... 33

Driving Shaft Components ... ......... .......... .............. ................................ .......

4.

ffiM415J-ffi.f4:

5.

~*451-ffi.i4:

6.

fji]~5J-~14:

7.

~filft5J-ffi.f4:

8.

&:iW~~i1~~51-~fH4:

9.

~~R~~ffiM411fJ.1H4:

10.

~f4:

Presser Foot Components ....... .......

Feed

Mechanism Components ..............

0il

Lubrication

0il

Reserv

Accessories

........................... ................................... ...........

Co111ponents ...........

oir

Components ............... .........

Belt

Cover & Thread Stand Components .................... .... 47

Modei"R

"

Presser Rollar Special Accessory .....................

..................................

...

.....

.............

..........

........

········· ........ .......

......

..... ....

..................

.. ..

.........

.........

.... ..... .

.......

35

39

40

.

43

45

49

51

-

29

-

Page 20

1,

m767t!L-flf

Machine frame & miscellaneous cover components

8

35

f

3e r

--

-------2Y

I •

I

0

l3s:5LC) l

I I

I

39

I

140

---

L

__________

•>

b-._

~

- I

,,

I

I

I

J

-

30-

74

Page 21

1

~

m~

Ff~

REF.

~p.

{4:

PART

2.10GR101

I

240GOIOI

2

GS159-8

3

GR679n

4

'

GR585-8

5

()

GR584-8

GS300-8

7

8 240GRI02

9

24000102

10

GR586-8

GR587-8

11

12

GR611·8

GRS00-8

GR602-8

13

14

GQ200-8

15

GS310.8

16

GS310.8

17

GR603-8

18

GS313-8

19

.!0

GL23~-8

21

GR609·8

G\

22

GW202-8

23

GW608-8

24

GR607-8

GS314-8

25

GW183-8

26

27

GR606-8

28

GS315·8

29

GS316-8

30 GX200-8

31

G~1166-8

G.MI73-8

32 GS338-8

33

GS604-8

34

GS313-8

35

GR583·8

36 GS300-8

37 GM167/4-8

38 GM!68-8

39 GWI90-8

7tm

1lf

~

~o.

-s

\-'

184-8

Machine frame & miscellaneous cover components

fi:Q

li

.t

DESCRIPTION

iiitfi Face plate

iiH!H~

llJj~tfitltJ

jjj;flj!lJiTtlltti1ftH!f:

titl~fflft.,1l

ttfflll!

.15\UHitr

€m';f1i

J<iS~.H~

~~~~

r~li1L

i:t~~

i:ttiltE Needle thread guide pin

=.mt&tE

tl:ltl!f!iff-AA!

it~ff!)!l_;f;~

=:.!tlf&~tlfT

:b~~

~~~ilfT

~tiittfl-14'

~HH.Illl.

~til$1Ji;I.J

~~-

~~1fTen~ion

~~ttl

~~Ui

~tltlfr

~~-

tf5tUh'lli'il!li

;t~jJtJ'~iUltJ

~tUUinJ

f'~~U

tttti

:-\eedle

tt~

:\eedle

fttljtltf

tr:t&tl:l

tr:~~iltT

iii~~"lit!R*

iiii!itltT 3/16" x 28

tli!i$-14' Bed slide ASM. I

tt~

Slide

tttti•

AS~

.

Face plate gasket

S~ll/8

"

X44

ARM oil

. Rubber plug

li'i~1L*

SJ;.ring

Rubber plug

SM3/16" X

Side plate

Gasket

if~L*

Rubber plug

* Rubber plug

.t'eedle thread guide pin

Three-hole thread eyelet

Earthing indication

5~!3/16

'

SM3/16

" X

Arm

thread

guide-Ring

SMII/64"X40L=6

Thread

tension AS:M.

Tension

i!i

Tension

Ter

Tension Disc

Screw

Take-up

Thread

11/64

AR.\1

nut

Tension

Spring

Spring

.sion Disc

spring

Tesion

S~19

Screw

release

plate

plate

"

X4

0W.5

thread

ll/64"X40L=6

Rubber

L--9

plate

of

slide plate I

L=4

Sere"

sh.ie

ld ASM.

281...--9

Sere.,.

X

28

L=6

28

L=6

Screw

Screw

Disc

stopper

stopper

post

socket

64

''

pin

Screw

guide-left

Screw

plug

Screw3/

~

1/8

" X44

3/16"X!8

plate

Saew

3/16"X28

3/16

" X

II/

164"X40L=6

Screw

9

64

11/64" x4()

ll/64"X40L=6

16"x28

L=4

28

"

W.5

L=9

QTY

1...--9

L=6

L=6

medium-heavy

1

I

I

I

2

I

8

I

I

1

I

1

I

I

1

I

I

I

I

1

I

I

I

I

I

2

I

I

I

I

I

I

I

I

2

I

I

2

3

I

,

*"~

For

Light

materials

*

* *

* *

*

*

*

*

*

*

*

*

*

*

*

* *

*

* *

* * *

* *

*

*

*

* *

*

* *

* *

* *

*

* *

*

*

* *

*

*

*

* *

*

* * *

*

.1Jt4

For

heavy

materials

*

*

*

*

*

*

*

* *

*

* *

*

*

*

*

* *

* *

*

*

* *

* *

* *

*

*

*

*

.!t¥1'4

For

leather

materials

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

-

31

-

Page 22

1..

ff1%7tm.

.*%

REF.

Np.

i4:

PART No.

GS339·8

40

41 GS299-8

GS724-8

42

GS373·8

43

24008102

44

GK153-5

45

GK162-8

GQI%-8

46

47

GR1428-8

48

GS705-8

49

SOIGB107

50

SS-4080440

51

501BJI03

50181104

52

SOIGBI14

53

501GWI04

54

501GL103

55

56

501GL104

57

501BJI01

58

501GB113

59

501GK104

501GW103

60

61

501BJ102

62

501GB

63 501GB I 10

501GBI12

64

65

501GFI18

SOIGWIOI

66

67

50JGW102

68

501GK102

69

SO!GK!03

70

501GKI05

71

SOIGFIIO

72

50!GS109

73

GQ139-8

74

GX186-8

flt:

Machine

%

tl~i

UT

3132" X

~~~

lt

Bed screw stud

RHil~Jl

m1!!:~Jltur

!r!~~

tlUUfJIJi~~

itf:UfJIJi~~

~~tli;;f-~

0~1!!!

~Ill

~lll

~tl~JJII~tln

~ill~~-

.Pi:tlllii!:llfll:

:'.IE~~

:'R:t&Jt

1!-*f~tlt.liU:

~f&t.liU:

~f&B

~i;f.J~

ri~

~;t;~·

~{.·fii~f*!:li

III

~~~1!1:~

fii~~M

li!$ll~

It~~

~1!!:*~•

~tiH!BIItJf

fii~-~

~~5tli;!Jt!i-fflle

~f&ittltl8~-~l!!

fii~-0~111

~U

;!IL~~

;!IL~~WtJ

Ruler plate

Model plate

Rubber ring

it~

1!1

tnr

~JJ

1bread

Thread tension disk

1bread

Kut

Bobbin winder

Bobbin winder shaft COMPL.

Jl

Wahser 2

Latch spring

Bobbin lever

Adjusting plate

Rubber ring

Cushing I

Screw

Number plate

frame & mi

~

DESCRIPTION

56

L=l.9

Screw3/32"

Ruler plate screw

1bread

take-up lever cover

1bread take-up

Safety-indicanng plate

Screw

cutter

Screw

Bobbin

thread

Bobbin thread tension rod

tension spring

Tbread tension nut

ASM

Bobbin fitting bas'.s

fll:

Bobbin winder regulator I

Long spring

Short spring

Retaining riLg

E-ring

0-ring

Pole

scellaneous cover components

fit\

x56

lever

co,·er

tension ASM.

ASM

. 1

COMPL

flit

QTY

L=1.9 2

. I

. I

rt,

medium-heavy

4

1

2

1

I

I

l

I

3

1

2

I

2

1

I

I

I

I

1

1

I

I

1

1

1

I

1

1

1

'FJJ:tsl-

For

Light

materials

*

*

JJ:tsl-

Forheav:y

materials

* *

*

* *

*

*

*

* *

*

*

*

*

*

* *

*

*

*

* *

*

*

* *

* *

*

*

*

* *

*

* *

*

*

* *

* * *

*

*

*

*

*

*

* * *

* *

* *

*

*

*

*

*

*

* *

* *

* *

* *

* *

* *

*

*

*

Jt1j[f4

For

leather

materials

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

-

32

-

Page 23

2

~ ±$11l&~E~ff7t!l.

1It:

Main shaft & thread take-

up

lever components

6------13

~14

27

-

33

-

Page 24

2,

±

~lk~~ff~m

'flf

Main shaft & thread take-up lever com

pon

ents

14

1¥-+5

REF.

:t\o.

I

2

3

4

5

6

7

8

9

10

II

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30 GR590-8

31

32 GR591-8

33 GS311-8

34

35

-i5

PART No. DESCRIPTION

GX199-8

GR59612-8

GS308-8

GR595-8

GH2l2-8

GH212-8

GH21<W4-8

GH35<W4--8

G0265-8

GH20812-8

GH35212-8

GH213-8

GS309-8

GS30--8

GH349-8

GH207-8

GRI6i

GR592-8

GS371-8

GTI56-8

GTI59-8

GS332

G0256-8

GR588-8

GR650-8

GR589-8

GS305-8

G0259-8

GXI98-8

G0258-8

GS306-8

GR638-8

GR808-8

240GP101

GS3Q.1-8

GZ229-8

G0261-8

GP172-8

GS709-8

tltliUfti'Hlll~

tttliUfmlltl~

tl~i:Uflitlfrl5

t~UUfi!E!lli

tfe~li:ff

tlt&itff

tltli!ff~~

fl~ilff~~~

~f&ffiatt~~

tlf&lll!tili$f/f Needle bar crank

!t~lll!fililfll'f!F

tt:ffit:ff

fl~lll!ti'iti'.llUUJ

ttff

ttff

ttffllllti'i

-8

!tf&lll!f1li~fittltT

~-tfr*ltTO~I!!i

ttfflll!ti'i~{t!t:UT

)lifl(Q.C.

ili*HiiH.

-8

iliflU11.C.•$01fJ

£~.Ia~~

J::~l'lbf;t

ff;

.lf

J::

~t\1

J:$1!t\ll!!llfJ l/40X40L=6 Screw

J::~nl~·

S!Wil'lb•i.ll~~

l:~lf>~·

.H!rlf>~gtltJ

ili-~fa·C.·~MVi

~*'1-fa.C.

_t~

J:~tltr

_t$!!!

!la1i'il'IBARUi!JfS

111!1i'il'lllfili.ll'i'HIH~

lll!filiii!J•ilfiH¥10~1!1

Uli·C·~

~f&±#J~

~f&±~~~~tUJ

~Oil

l11read

Thread take-up bar

Needle bar

Ill!

ti'i¥

I!'Uitr

Ill!

1i'i

Counter weight

Counter weight

·

~

·~

Oil

i!:ff~

JJl

!I!

Thrust coller

•~i'll

Hand

wheel

Screw

Main

shaft

tt

~

-

tltr

1!5

Thread take-up crank

Thread take-up crank

/

64X28L=IOS

resie!allt

take-up bar

~Thread

Thread take-up lever

Needle bar crank

Needle

bar

crank

9/64x40L=4.8

9/32 X

I/40 X

Rubber ring

9/32x28L=18

Feed

drive eccentric cam

Feed

dri,·e eccentric cam

I/40 X40L=Il

Mo.in

shaft rear bushing

seal

t\11!1

Snap ring

Main

shaft front bushing

Oil

amount

Intermediate bushing I

Screw

Thrust coller

Vi

Thrust coller 1

Roller felt I

Sleeve of oil

0-ring I

9/64 x

40L--6

Bobbin

winder

Screw

Screw IS/64x28L=IOS

cover

take-up lever

crank

rod

End

28L=

40L=6

Screw

16

Screw I/40X40L=6

Screw

_Screw

1140X40L=6

adjusong

amount

Screw

driving w1eel

f$

shaft

shaft

ASM

ASM

screw

left

9/64X40L=48

9/32 X 28L= I 6 I

9/32X28L=18

l/40X40L=Il

lin

adjusting

9/64 x 40L=6

pin

1\J,.P.IJ*4

fiil

mediwn-heavy

QTY

I

I

I

I

1

I

I

I

2

I

I

I

I

I

I

2

I

I

I

I

2

I

I

I

I

2

I

I

2

1

I

I

I

I

2

1

2

J!J*4

For Light

For heavy

materials materials

R

lt

*'

lt

* *

*

lt

*

*

* *

*

* *

* *

*

* *

* *

*

* * *

*

*

*

*

*

* * *

* *

*

* *

*

*

* *

* *

* *

*

*

* *

* * *

*

* *

* *

* *

*

lt

*

*

* *

lt lt

*

* *

* *

*

*

*

*

*

* *

*

~~*4

For

leather

materials

*

*

*

*

*

*

*

*

*

lt

*

lt

*

*

*

*

*

*

*

*

*

lt

*

- 34 -

Page 25

3,

*ff,

l$11i&i~l~$11ij)-!

'{It

~

eedle

bar

, u

prig

ht sh

aft & hook

driving shaft

components

~13

~"

2

~

1~

13~

15

..

'r

17

19

1'

20

21

~

~----"

®---13

32

22

30

23

18

34

3s

p!;j

~

!

31

-

29

28

35-

Page 26

3,

Wff,

l~.&i~ltJJ~7HI114

Needle b

ar,

upright

shaft & hook

driving shaft

components

~%

REF.

14=

PART

Np.

GR599-8

1

240G0104

2

GZ230-8

3

GZ251-8

GR598-8

4

GS311-8

5

GU152-8

6

7 GR600-8

GR801-8

00267-8

8

00289-8

GS312-8

9

10

GR601-8

· GR802-8

GV132-8

11

GV134-8

12 GC157-8

GS319-8

13

14

GC156-8

15

GCISS-8

16

GC15~8

17

GZ23~8

GZ255·8

18

G;-.1139-8

GN566-8

19

00272

20

GS403-8

21

00271-8

22

00270-8

23

GNL37-8

24

GR636-8

25

GS331-8

26

GR631-8

GR818·8

27

GS328-8

00269-8

28

00291-8

29 GS316-8

GS414-8

30

GR634-8

31

GS330-8

~

No.

ti':ff

...t~fHL*

ftff

..1:~~

ft:ff

!'\eedle bar 1

:->c-edle

ti':ff

ftffi!~tt

ftffiill!tlfJ

tt:ffit~tti1t~

ti':ff'"F~¥~~

tr:ffr~¥~~

tt:ffr~t;

tt:ffrfif;

1itrt.ur

ttff~1f:l

ti'ff~

~tt

(DB X 1) Needle DB X I

~tt

(DB X 5) Needle DB X 5

..1:~*1&~

"~tltr

~~_t1jt1!}~

~~r1it~~

r~*t!l~

~~

l

~$11!

l

~·C•

Bobbin

~·I)

Bobbin

-8

~$11!..1:~¥

~tB..I:fifUifJ

~$lkr$11!¥

rtestelf

1$f~

Hook

1tf1!!

Hook

r~~ll!

rt9~1!UifT

1tE

~~

Ji.tl~ftr~

tlEl!1~fir~tlfT

rteftil~¥

r$.liii~~lf

r$lllftiifi~t.UT

l'$iftiltal'lftltrScrew

rti~illll!!!

'f"'~lll!llilt'J

~

DESCRIPTION

Needle

bar

Needle bar connecung-rod

9/64 X 40L=6 Screw 9/64 X 40L=6

Slide black

Needle bar lower bushing

Needle bar lower bushing

l/8x44L=4.5

:"eedle

li.i

Needle bar lower bushing

( * ) Gear

1.

4X

(.1•) Gear ofupnght shaft

(

*)

( 1]\)

plight

shaft

plight

shaft

Upper

3

Upright

Rear

Thrust collar I

II

64X40L=U

-!i'!tfJ

Positioning

Positioning

II/64X40L=9.5

Front bushing

Front bushing

Screw

Thrust

II

.

f,j\

Cap

bar

upper bushing

l'eedle

bar

thread guide

Needle bar thread guide

Screw I/8X44L=4.5

bar

lower bushtng

of

main shaft (big)

401.=8 Screw 1/4X40L=8

(s

Gearofuprightshaft (big)

Gear

of hook driving shaft (small) 1

bushing

16X28~-9

bushing

collar

64401..=3.5

Screw3/16X28~-9

shalt

lower

bushing l

Screwll/64X40~.8

finger

finger

Screw

ll/64X40L--9.5

Crew

11164X40L=3.5

fl:il

QTY

mall) I

1W.

medium-heaYy

1

1

l

1

I

I

1

1

I

1

1

I

I

I

I

I

8

I

1

1

1

I

1

1

I

I

I

2

I

I

I

1

I

I

I

I

2

tJ:I.IJ*4

For

Light F

materials

ili*4

F

or

hea•: leather

materials

* * *

*

*

*

* *

*

*

* * *

* * *

*

* *

*

*

*

*

*

* *

*

* *

*

*

*

*

* *

*

*

*

* * *

*

*

*

* *

*

*

*

*

*

*

*

*

* *

* *

*

*

*

* *

* *

*

*

*

*

* *

* *

&:lfif:lt

or

material~

*

*

*

*

*

*

*

*

*

*

*

*

*

-t!

*

*

*

*

*

*

-

36-

Page 27

3,

~Hf.

f*UI:&i:!?lOOiJJWI7Hiiilf

Needle bar,

upright

shaft & hook

driving

shaft

components

.Ff%

REF.

Np.

32

33

3-1

35

36

%

it

PART No.

GR233-8

GR252-8

G:-:138-8

GR633-8

G$329-8

G$402-8

~

DESCRIPTION

r$Jl Hook driving

r!lll

Hook drhi.ng

tt7C

Bobbu case

t!l1C

Bobbin case

r$\li~illl~

r$\lill!lilli!.UT

r-~$!

Oi

l wick

Screw

~tlf

T

3/

16 X 2SL=12

shaft

shaft

""

Screw

3/16X28L=I2

f£:11:

QTY

I

I

I

I

1

I

I

r:fl.IJ~

~-

For Light

medium-heavy

materials materials

For hea\')

*

*

*

* *

*

JJ~

Jt1fi~

materials

*

*

* *

*

For

leather

*

*

*

*

-

37

-

Page 28

4

..

EliJ1f41

7t!i

itf:

Presser foot components

I

)

15

11

21

.

~

l)~

l

~~

19

-

38

-

Page 29

4,

Bi.IJ!P7tm

1tf:

Presser foot components

11'=%

RE

~p.

f4

F.

PART No.

I

GR619-8

~

GS32:!-8

GR621·8

4 GR620n-8

5

GR62313-8

6 GR625·8

GS323-8

G:\11~·5-8

GR803/5-8

GR625-8

10

GR6~~-S

II

GR626-8

12

GS326-8

13

GS325-8

14

GR629-8

IS

GR630-8

16

GR628-8

17

GR625-8

18

GW189-8

GW185-8

19

G)QOJ-8

20

GR62.,-8

21

:!2

GR32-H

23

GS318-8

24

GLI68-8

25

GRI494

26

GW253

GW20J-8

27

GR61

GZ231-8

28

29

GR615-8

GS319-8

30

31

GS320-8

G0268-8

3:!

G0290-8

GS321-8

33

%

ffi~~~

ffi~~~!JrT

~l!!Pu~$i!lo!N!I!!

ffi~f&~8~$K:

fflffi.3!liAtrti~a!ll!f

tiiff:1fD~!I!I

liiittiftltl:fli

f.SIH~$K:

i!

lli~$14'

t'«tl:Ul:1f

ffi~*!:.tt!i

71-~~ii~:1fo

ffl.I:H~t!fftUr

FctUftl!ltii!Jtr

¥ci

lliP.!ll.Fcfl:ff

ffl

ffi~Eiiff

ltffi~tHI

!ltl:m:1fC

I'~

t&

Eii

t~ii~tTSttl~

t~t&llitJ

~iiEiit!i

~ii]jltfi!Jti£~

i}:J

ffitltJ

\J.llffi!f.H}

~ffi~ff

o!'4ffiit

\llilffiiif Presser spring

-H

ffi 1f ~ ~

ffi

ff

!:11ili.L1!iHi!

ffi~~~t1!fJ

t£~lii~~I!Jtf9i6lX~L=8.5

ffiff~~

ffi*T~'Ili

m/!J!ii!ltf

~

DESCRIPTION

!-land

hfter

SCREW

Rubber

Hand

Hand

Snapring

Lmk

~haft

Presser

foot

Prc~scr

foot

0

~R!l

Snap ring

Llfung le' er

~!!i.i

Lifting lever ring

Hinge

H1nge

Lifting level link

Connecting

Lifung le\

~Ill!

Snap ring

tli !Hi!

Pi

Tension release return

Tension release

Tension

release supponing

Tension release plate

Tension release shaft

Pressenpring regulation

Nut

Pre~ser

gu1de

Presser

~pnng

Pre>>er

bar

guide

Presser bar

Presser bar thread guide

140X40L=8

Presser bar

Presser bar

9/64

lower

lower

X40L=l0.5

nng

lifter cam

lifter link

AS~

AS:\1

s..."re\\

sere'>'

rod

vemcal

el

connecung

bar

bracket

busrung

bushing

Screw

~

pin

spnng

Sere'>'

Sere'>'

9/~XJOL-=10.5

rod

S?ring

pin

li-'XJOL=S

9.64x40L=85

fdt

QTY

I

I

I

I

I

I

2

I

I

3

I

I

I

I

I

1

1

~

I

I

I

I

I

I

1

1

1

1

1

1

I

I

2

I

1

I

c:fJJ:M

~'

For Light

medium-heavy

materials materials

,:r

For

IJ*'l

hea\)'

*

*

*

,:r

*

*

*

*

,:r

*

*

,:r

* *

*

* *

* *

* *

* *

* *

*

* *

*

*

*

*

* *

* *

*

* *

* * *

* * *

*

,:r

*

* *

*

*

*

*

*

*

*

*

* *

*

*

*

*

*

*

*

*

&:¥*'1

For

leather

materials

*

* 3

*

*

*

* 7

* 8

* 9

*

,:r

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

-

39

-

Page 30

5

~

*~--1-:frm

14

Feed mechanism components

21

20 3

10

53

31

~

I

55

33~

~37

40

58

61

- 40 -

Page 31

5

~ *~

-l-

7.tm

1-*

Feed mechanism components

~%

J

REf

.\'p.

I

:!

14

16

18

19

20

21

~2

23

24 GR641/2-8

25

26

27

28

29 GR643-8

30 GM165-8

31

32

f4:

l • I

PART

G~2-8

GH355-8

G)GI:!-8

GX123-8

GR654-8.

3

GR814-S

.)

G027+8

GS343-8 i!Millli1tlti Sere"

5

GWI91-8

6

GX211

7

GR652

8

GR813-8

GS

9

GH21+8

10

GH353-8

GX104-S

II

12

GS333-8

GH218

13

GR653-8 iti#ifill

G\\'192-8

15

GW204-8

GR625

17

GH344

GH35i

GS346-8

GS407-8

GR625-8

GS3ll-8

GX205

GR639-8 ittt·HH!i'#Jt!i

GR

GR81112

GX207

GS-48

GS333-8

GX222-8

GM17+8

GS337-8

GR648

GR810

~

.\

o.

m:JB":ao

~ili:tsl-~ff

lititi~:i!ff~

~ia*'H!ffflll

iti~illllie

±S*l~i1~

~~illn'H:Hs~

i!flile-~Jf

-8

ittfl-~!Hll!~tl'i

-8 ittt:HtHtffi Feed

i!

M~llm

342-8

640-8

itt*lie.llEtll.~ltJ

i2S

1'-li!ff C onneeting

ittfl-:liff

ia

*'1-:li

ff

~*4i'Hftl!ii1UJ9

tfi

-8

-S

-8

-8

3fa:f'f

i'i~tiO~I!I

ii4

i2S

fl-

tlt.

m~Mttt:Jf

ii4~Mifff~!r!l

iill3MIIbWHilli4=

{iiJ~:f!fiiiiW!$1*

fi4~*411!riPitUT

till~fl-llbfjij'!tJ

ii4.iaflitffr.il!!

it:f'fftHUT9/64x

~f!f#J~ittltl'i

~M~n!i'#Jt&

~~*4-D!ZdJf.i~~ff

-8

~:iaflf!i;l)f&~illiff

:ia~H!id.l1l:.!\t!

ti::QllitltJIS/64 X 28L=7

it:f'ftfU.UJ9/64

3f~ll1

~*4$.UaJIH~I!!

:iatl-Jf

jbfl3f

:ia~Jffltfi

3f~tllll*

3f~mlftl:

~

~

DESCRIFTION

l:f

Feed

adju~t

rod

Feed

adJUSl

ro( I

Feed regulator

Feed

Feed

regulator

Feed regulator

Feed regulator bushmg

Spring I

Pin

d1al

Feed dial

Screw I

C onneeting

Wi

Pin

/

64X40L=6

Conneeung rod

spring

Spring I

Snap nng

Reverse

Re.,erse

Screw I

Sere" 1

Snap

40.1...=6

Pin

Linl:

Link (short) 2

ti::OM

X 40L=6 Screw

Feed

bar shaft

Retairung

Feed

dog

Feed

dog

/

8X44.1...=6

Feed bar

ASM

Feed bar

AS~!

pm

regulator

pm

rod

rod

Screw

9/64X40L=6 l

Rubber ring I

feed

ann

ASM

feed

ann

ASM

ring

Sere" 9/64x40L=6 2

(long)

Feed adjusting

Feed adjusting AS\1

Adjusting link shaft

Screw 15/64"X

ring

Sere" l/8X44L=6

9/64"

ASM

281...=7

X40L=6

fr

ill

QTY

1

I

1

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

2

2

I

I

2

2

I

I

I

I

1

2

I

I

lf!W:f-1-

~-

For Light

medium-hea1·.'

marerials

*

*

~f-1-

/ For

heal}

macerials I materials

...::-

"<:!

*

*

...::-

*

* *

* *

* *

*

*

*

*

*

*

*

* *

*

* *

*

*

*

* * *

* * *

* *

*

*

*

* *

*

*

*

*

*

*

* *

* *

* *

t:

*

*

* *

*

*

*

*

*

*

* *

*

*

*

*

&:ifif-1-

For

leather

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

-

41-

Page 32

5,

* f

-1-7}!1

{lf Feed mechanism components

~~

REF.

Np.

flj:

PART

GR657-8

33

GR816-8

GZ235-8

34

GX208-8

35

GS333-8

36

37

Gll

GH215-8

38

GH354-8

GS334-8

39

GH2l7

40

41

GS334-8

G$341-8

~2

43 GZ236-8

'GR589-8

44

GSI67

45

G0273-8

46

47

GS344-8

GS051

48

GS336-8

49

GR634

GR807-8

50

51

GSI42

GR658

52

GH216-8

53

GS340-8

54

G0273

55

GR589-8

56

57

GSI6i

GR424-8

58

GZ237-8

59

GZ253-8

G0275

60

61

GR656-8

62 GS319-8

63 GS319-8

GZl5.L8

64

GW193-8

65

GW205-8

G$408-8

66

67

GR817-8

GR815-8

68

GS347

69

%

:\o.

ttX

!lil

t'!JUl$r1fi Feed spring hook I

~~*i

~:lS!-Il!IWill!i

!lil"!¥ili'I~U9

·.\2-8

ff;lfi!ff$l!J{lrtJlij:

iafl!-ll!llili Feed rocker

iafll-ll!l lili Feed rocker

i5*41!lim*I*T

-8 ¥.ilf.€!1l!lili Lifting rocker

ff;

5f

Fall

1fi.aii!tf$!Bf:IO.UJ

ff>Bi$111

iatHi~l!!!

ia~$"i~!lliltT

~f4$"ifoJ$l!J~

~~\II.JilllU

ff(~~Hllt~!IU

.lf~itlfltJ

ffilli$"i~JIH~R!l

.lf

~Ill

~~~tUJ'/16X28L=I.i

ttm~

tfi

BiJOf~

ff!Bi):~ll!!!iUUTI

-8

ff>Bi$l!Jin$11ilt

tfHiifi~!l

~ffifis~ll'lUJtTI

ii4~f:+!1!10lt!

fif~f:+~

fif*,*4-~

-8

fif~fll.~~~

li4ia~Pi~

:i4~1<~!'i

fi4~~!1i~/Ei[;,'J:fJJ

~Milllfi~*'l!

m~ri!HIHl{l'rfll

l!~tliP.lU!{lrif

ia:lS!-YIIi1a$l!JtUr

iaM~~8$11i~!m

fftia ...

~fU:t&t3tT

.t

DESCRIPTIO:\

~

!1i

Feed spnng book

F~edrockersh~~

Pin

/

40X40L=6

3/16x28L=I5.5 Sere"

!!

*I~

3/

16

x 28L=15.5

Feed

drhing

Thrust coll

I/

4X40L=6

Feed rocker shaft bushing

!b

~~n

Screw 3/16" X 28L=7

11

/64 X 40L=7 Screv. 3

Retaining riog I

Feed bar dri

Washer 1

lllllt1l

Lifting fork

li

64X.!QL=l0

Feed rocker shaft bushing I

Thrust collar I

I4X

Rubber ring

Reverse feed shaft I

Reverse feed shaft

Bushing

Reverse feed cootrolle,er

-

HltT114X.WL=8

Feed adjusting

Reverse feed spnng

Reverse feed spring

$111~~11!!

Washer

Screw

~

fl:.!i't

QTY

Screv. 9/

64x40L=6

9:32X~2S

Sere"

~!:aft

,;ng

/

4X.!{)L=8

Screw I

Washer

i'ut

3/16"

X28L=l

Screv. 3/1

6x28L=15.5 I

ar

Screw I/

4X40L=6

Screw l l/6-f' X40L=7

/16

X 28L=7

crank

Scr~w

3/!6"

X28L=:4

.5

Screw

I

1 !

54"X~L=I0.5

.WL=6

Se

re"

1,4·x~L=6

Screw 1'4 X40L=8

Sere" t 4"x40L=8

~haft

5.5

9"JJ:t4

~.

For

Light

medium-heavy

materials materials

I

I

1

I

I

I

1

I

I

-tl

-tl

*'

*

*

*

*

*

I

I

I

2

I

I

I

I

I

I

I

I

:2

I

I

I

I

I

I

I

I

1

I

I

:!

*

* * *

'!:!

*

* * *

*

*

*

* * *

*

* *

*

* *

*

,:r

~

* *

*

*

*

*

*

*

*

*

)J:~

For

heavy

*

*

*

* *

*

*

*

*

*

*

*

*

*

* *

* *

*

*

* *

*

* *

*

* *

* *

*

*

* *

*

* *

* *

It~

~

For

leather

matenals

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

~

~

*

- 42 -

Page 33

6,

jlf]

iff7tm i

lf

Oil lubrication components

- 43 -

Page 34

6~

hflift~m

.ffr~

REF

.

:'\p.

I

2 GR6"'3-8

3

-l

5

6

7 GR678-8

8

Q

10

II

12 GR671-8

13

14

15

16 GR659119-8

1-

18

19 GR662-8

20

21

22

23 GR664-8

24 GR666-8

25

26 GS350..8

2i

28

29 GR668-8

%

ftF

PART

:'\o. DESCRlPTIOX

GR6~2-8

GR669-8

GS351-8

GS353-8

GS310-8

GR675-8

GR644-8

GR670-8

GS353-8

GW195-8

GS32-8

GS660-8

GS348-8

GR663-8

GS349-8

GR665-8

GW194-8

GR667-8

GS328-8

-flf

Oil lubrication components

t

iil!tir Oil sight window I

ill!

NO~!!

J:.fi!lfitil!!~

iil!~ii~i.'i\tl:

l'iUU.1\tl15/64 X28L=9 Screwi5

!IDilllW~!UT/16X28L=6

liD

idlla~

!IDilbWW.{Il:

!IDilllfi~

**+~ilk!'&

lilEJRUtilhu Oil

ME~Utiiltv

BSt!itlfrtS/64 X 401.=9.5 Screw 15/6-iX 40L=9.5 I

li:Et!lilllitill!i'ijl

8lH!lill!:!:~i'i!!;tT

iil!~${1!:

i'IB~~~t!i

ii!J*~~tJtJ

iil!~l*

l'l!l~pt~

illliltHitUT

l'I!!Jtill

l'IB1!lPf~ff:t!i

!IDl'l!ltl:

f.UHf Plunger spring

tt~t.ltr

rttil~it!lf.i

tltt:iU~tUT1

Utl'l!lif~:!J,;

Rubber ring

.\1am

shan

Oil pump

Oil felt presser

Oil rerum rube ASM

Holder I ~

Oil wick

rube

ffi1fi

Tube holder lower

Spring

Oil adjusting

OilpumpASM

Oil pump installing base I

.\13X8 Sere"' .\13X8

Oil pump I

Oil pump impeller I

&reu

Oil

pumpco,er

Oil pump impeller cover I

* Plunger I

Plunger screw

Hook driving shaft oil

l/64x40L=9.5 Screw! 1/6-lx40L=9.5 I

Oil rube joi

¥i\

oil rube

suppon

164

X28L--9 I

Scre"'3/16X28L=6 I

sere"

rube

nt

\W,

fl:.S:

medium-hea\}

QTY

I

I

I

1

I

I

I ~

1

I

I

I

3

3

I

1

I

I

I

!:f!J¥:1'4

For

Light F

materials

~

~

~

~

*

*

*

~*""

For

bea,·y

materials

~

~

* *

~

*

* *

*

* * *

~

* *

*

*

* * *

~

* *

* *

* *

*

*

* *

* *

* * *

* *

*

*

*

*

* * *

* *

* * *

*

*

* *